Uvioresistant impact resistant composite type flexible freight bag film

An impact-resistant, composite technology, applied in sacks, synthetic resin layered products, containers, etc., can solve the problems of easy creases or breaks, poor impact resistance, insufficient toughness, etc., to achieve high sealing and high barrier properties, Good impact resistance, good anti-ultraviolet effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

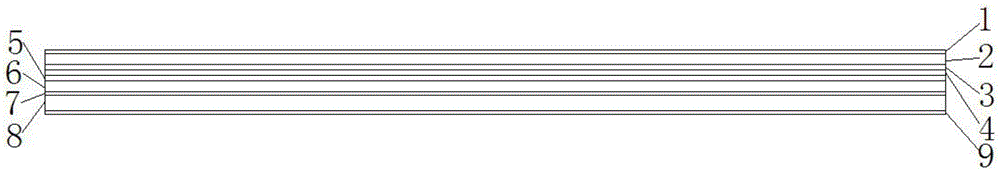

[0012] Such as figure 1 As shown, the anti-ultraviolet and impact-resistant composite container bag film of the present invention includes a PET outer film layer 1, a first adhesive layer 2, a first connecting film layer 3, an ultraviolet absorbing film layer 4, a second connecting film layer The film layer 5, the second adhesive layer 6, the PET inner film layer 7, the aluminum-coated layer 8 and the PE film layer 9 are sequentially connected, and the aluminum-coated layer 8 is plated on one side of the PET inner film layer 7, and the PET Outer film layer 1, first adhesive layer 2, first connecting film layer 3, ultraviolet absorbing film layer 4, second connecting film layer 5, second adhesive layer 6, PET inner film layer 7, aluminum plating layer 8 and The thickness of the PE film layer 9 is 1.2 μm, 6 μm, 1.5 μm, 1.8 μm, 1.5 μm, 6 μm, 1.2 μm, 9 μm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com