Full-biobased epoxy resin composition and condensate

A technology based on epoxy resin and rosin-based epoxy resin, applied in the field of bio-based thermosetting resin, can solve the problems of high brittleness and poor comprehensive performance, and achieve good mechanical properties, excellent UV resistance and strong operability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

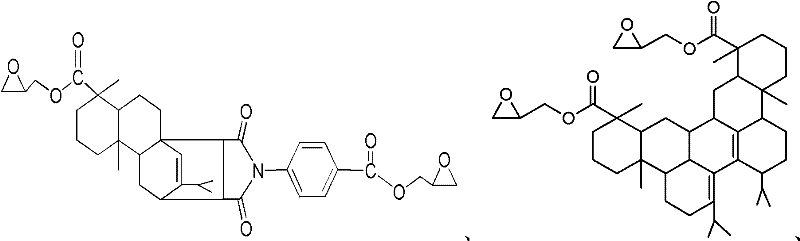

[0042] (1) Mix 400 grams of maleopimaric anhydride, 300 grams of epichlorohydrin, and 18 grams of water, add 8 grams of tetramethylammonium bromide, react at 80 ° C for 1 hour, and recover the remaining rings from the reaction by distillation under reduced pressure. Oxychloropropane, then add 50 milliliters of toluene, and add a total of 170 grams of potassium hydroxide in 4 equal amounts at 100 ° C, maintain the reaction for 2 hours, filter and wash until neutral, and recycle the solvent by distillation under reduced pressure to obtain the formula Light yellow transparent rosin-based epoxy resin monomer with I structure;

[0043]

[0044] Rosin-based epoxy resin monomer of formula I structure

[0045] (2) 100 grams of rosin-based epoxy resin monomers and 50 grams of tung oil anhydride (purchased from Henan Linmei Technology Co., Ltd., wherein the weight percentage of the anhydride is 14%; the viscosity at 25° C. 4000mPa s) and catalyzer 1-methyl-2-ethylimidazole 3 grams a...

Embodiment 2

[0049] (1) Dissolve 100 grams of maleopimaric anhydride in 150 milliliters of N,N-dimethylformamide, add 46 grams of p-aminobenzoic acid, stir at room temperature for 3 hours, then heat up to 150°C and stir for 4 hours, then cool to At room temperature, it becomes a yellow-brown solid. Add 150 grams of distilled water and stir, and a yellow precipitate occurs. Filtrate, wash, vacuum dry at 60°C for 3 hours, recrystallize repeatedly with DMF and water, the final product becomes a white powdery solid, put it in a vacuum drying oven at 90°C for 10 hours, and obtain maleopimaric acid imide binary Acid, yield 86%. Under the protection of nitrogen, the obtained maleopimaric acid imide dibasic acid and 40 grams of epoxybromopropane were added into a three-necked flask with mechanical stirring, heated and dissolved into a homogeneous phase, and cetyl trimethyl bromide was added React 3 grams of ammonium at 90°C for 5 hours, cool to 65°C, add 5 grams of sodium hydroxide each time, a t...

Embodiment 3

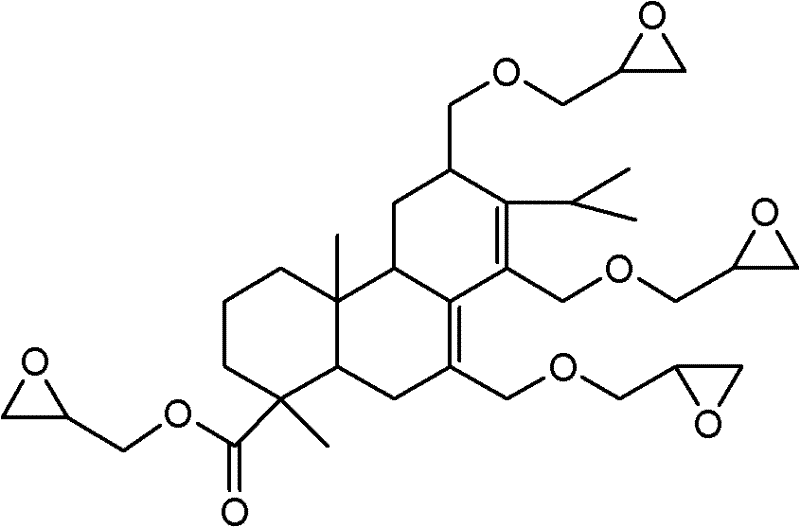

[0056] (1) Add 100 grams of formaldehyde-modified rosin and 480 grams of epichlorohydrin into a four-necked flask with a thermometer, a stirrer and a condenser tube and mix evenly. After the temperature is raised to 85° C., 0.45 grams of tetramethylammonium chloride are added. React for 5 hours, add 75 grams of benzene and 29 grams of sodium hydroxide after cooling, control the temperature at 70 ° C, and then react for 3.5 hours. Filtrate, wash with water until there is no halogen ion, remove the solvent under reduced pressure, and dry in vacuum at 60° C. for 6 hours to obtain a rosin-based epoxy resin monomer with the structure of formula V;

[0057]

[0058] Rosin-based epoxy resin monomer of formula V structure

[0059] (2) 100 grams of rosin-based epoxy resin monomer of the above-mentioned formula V structure, 300 grams of tung oil anhydride (purchased from Henan Linmei Technology Co., Ltd., wherein, the weight percentage of anhydride is 13.1%; the viscosity at 25 ° C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com