Spiral shield cable sheath extrusion device and anti-broken method

A technology for shielding cables and extrusion devices, which is used in cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of complex manufacturing process, high cost, and the lack of sheath material for the outer shielding spiral groove of the cable. , to solve the effect of cable breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] A preferred embodiment of the present invention will be briefly described below in conjunction with the accompanying drawings.

[0025] Such as Figures 1 to 4 Shown:

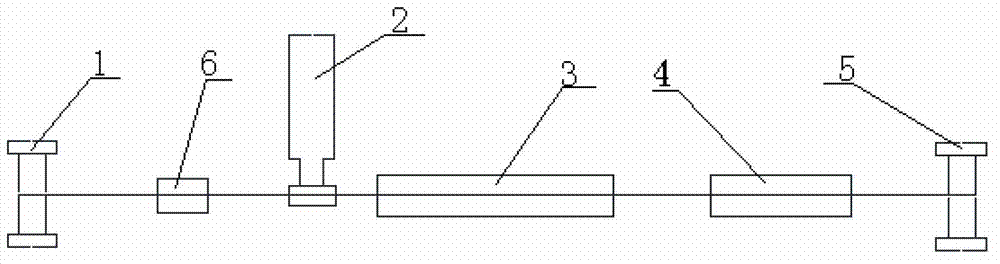

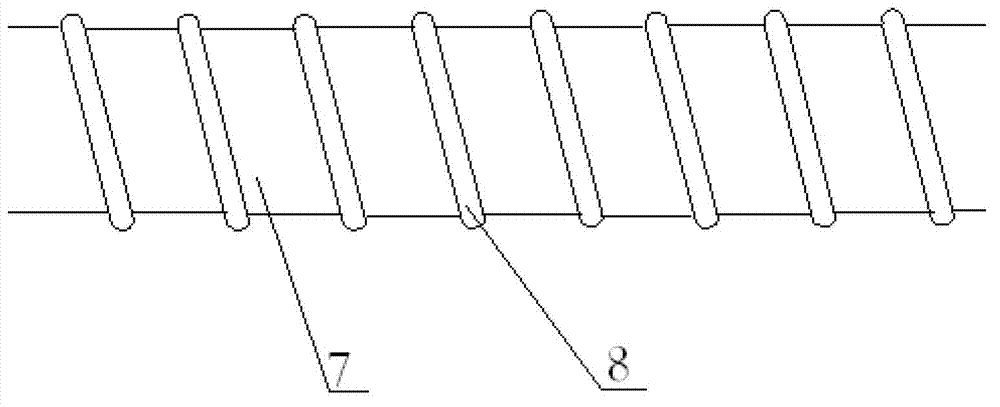

[0026] A method for preventing the overall breakage of the spiral shielded cable. The conductor core is released from the pay-off frame 1 and transported to the extruder 2 for extruding the cable sheath. The conductor core is heated before entering the extruder 2;

[0027] Extruder 2 uses semi-extruded tube extrusion technology to extrude the cable sheath;

[0028] After the extruder 2 comes out, the cable is cooled through the cooling water tank 3 .

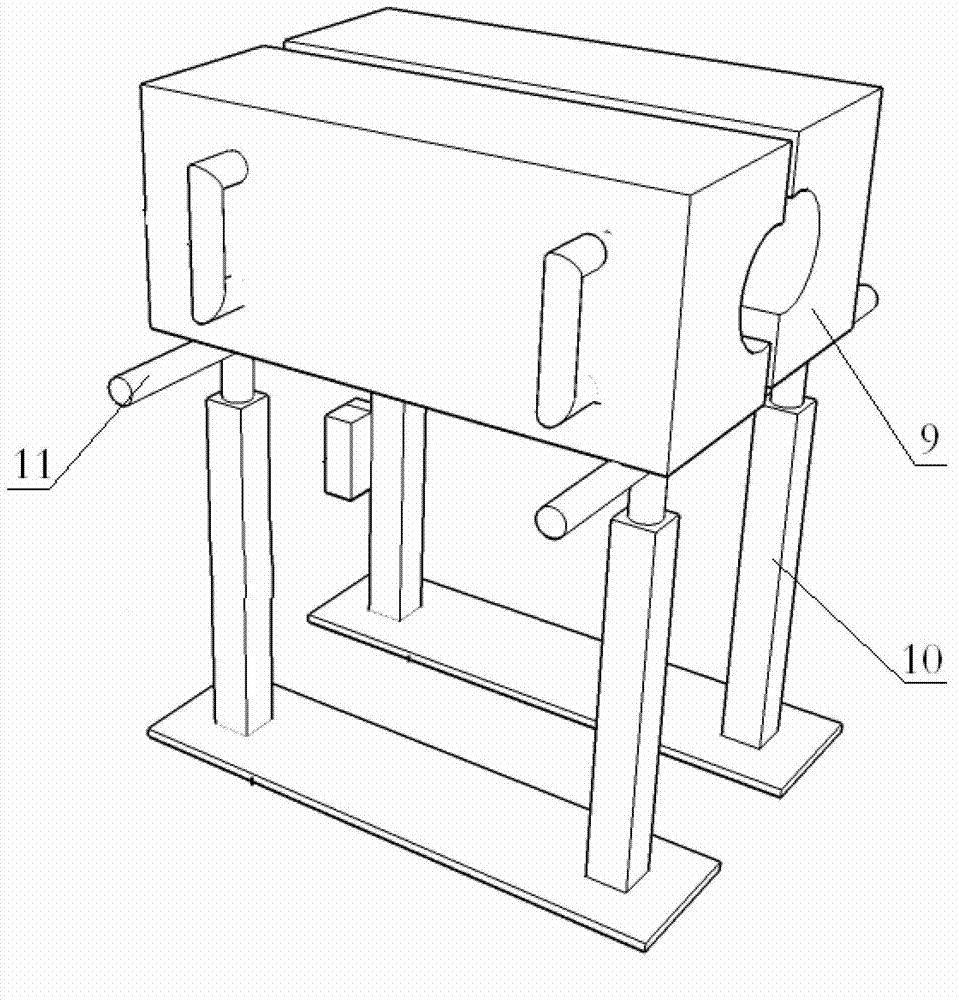

[0029] A spiral shielded cable sheath extruding device, comprising a pay-off frame 1, an extruder 2, a cooling water tank 3, a tractor 4 and a take-up frame 5 arranged in series, and the extruder 2 includes a frame 1. The extruding screw rod in the frame and the extruding mold of the machine head part, an incoming line heating device 6 is added between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com