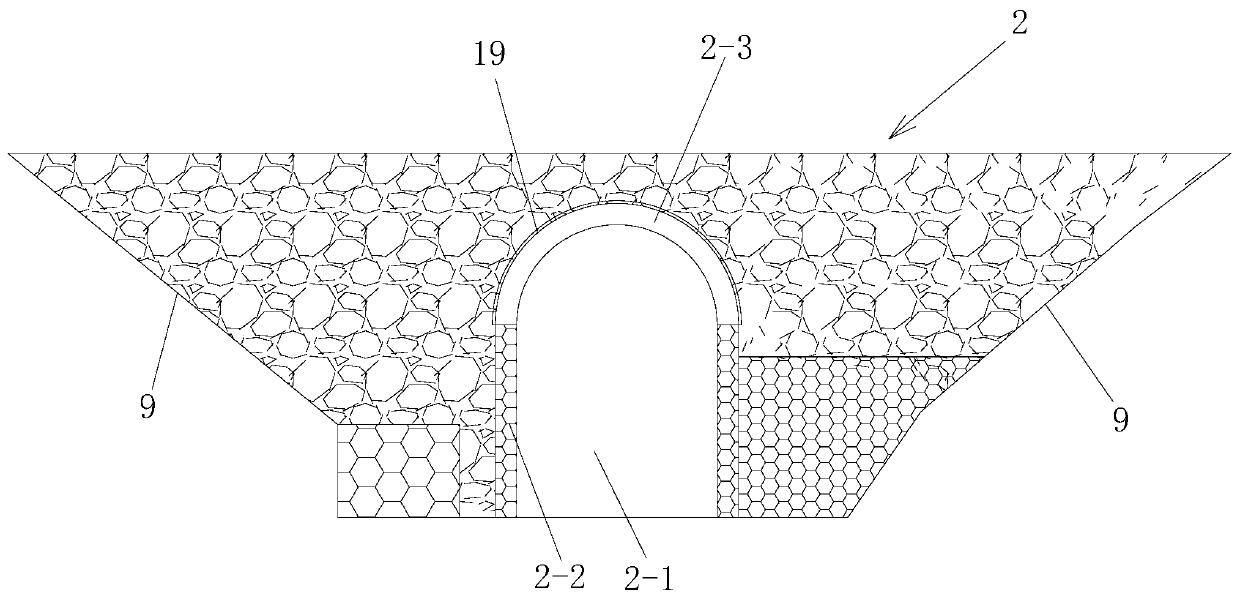

However, when the highway arch bridge (that is, the public-span iron arch bridge) built in the early 1970s over the existing

railway line was demolished, due to the special structure of the demolished arch bridge and the lack of steel materials at that time, the arch bridge was demolished. The use of an open-hole structure consisting of plain concrete arch rings and masonry

rubble pavement structures to meet the traffic needs of highways crossing railway overpasses was the mainstream and product of the times to solve the problem of crossing railway overpasses on national and

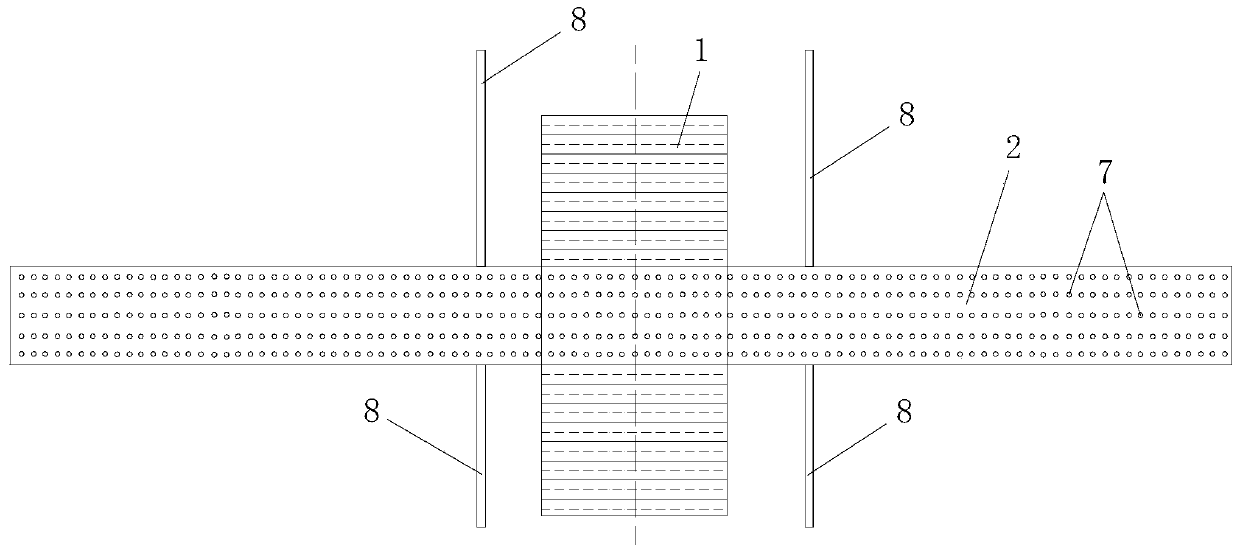

rural roads at that time, but it was not possible. The overall hoisting and dismantling is very difficult, especially when the demolished arch bridge is located in a mountainous area or in a river valley, the construction site is narrow, and the overall dismantling is more difficult and basically impossible

However, when the in-situ demolition method based on the construction of temporary convenience lines is used for demolition, temporary convenience lines need to be constructed, and after the temporary convenience lines are opened, the existing railway traffic needs to be interrupted, and then the upper span bridges should be dismantled in situ. Due to constraints such as the difficulty of demolition of villager settlements along the line and the difficulty of demolition, the implementation conditions for in-situ demolition of temporary convenience lines are not available, and when the in-situ demolition of temporary convenience lines is adopted, the investment in rerouting is large

[0004] The in-situ demolition of the existing line arch bridge with upper span is very difficult, mainly in the following four aspects: First, the concrete arch ring has no reinforcement after

radar monitoring, the arch ring is plain concrete arch ring, and the construction site site It is too narrow to support large-

tonnage lifting equipment. The

catenary catenary cables and wires are located in the arc of the arch ring. There are many existing equipment such as

catenary pillars and optical cables on both sides of the arch bridge and the lower part of the arch bridge. The overall hoisting plain concrete arch ring is broken and damaged Most of the equipment has caused serious accident consequences, so it does not have the conditions for overall hoisting and dismantling. The blasting method is used, and the existing operating equipment is dense, and it is impossible to achieve foolproof and absolutely reliable safety protection. It is easy to cause accidents, and the conditions are not available, so it is difficult to implement; 2. The demolished masonry

rubble is easy to fall into the existing railway limits, damaging the catenary and other driving equipment, and endangering the safety of traffic; because the demolished arch bridge was built in a special age, the construction personnel have a strong sense of quality, and the arch bridge The masonry structure is strong and man-made With the low demolition rate of small machinery, it cannot meet the needs of the construction period; moreover, blasting is strictly prohibited above the business line, and blasting may cause

instability of other structures such as arch rings. If the demolition method is improper and biased, it is easy to cause the arch bridge to collapse and interrupt the existing railway traffic. Caused a major accident; third, the existing line crossed by the demolished arch bridge was an important transportation channel and the traffic density was high, so it was difficult to apply for the demolition construction to grow the "

skylight point", and the construction could only be carried out at the "

skylight point" with a

maximum duration of 120 minutes. Demolition construction is a destructive behavior. In-site demolition construction must not only achieve the goal of demolishing structures, but also ensure the safety, stability and integrity of the reserved parts, and ensure the safety of driving after the site is completed; Fourth, the demolition of the arch ring The difficulty is high, because the arch ring of the demolished arch bridge is a plain concrete arch ring, and the width of the arch ring is the same as the transverse width of the demolished arch bridge. The weight of the demolition of the arch ring is quite large, and a crane of more than 300t is required. However, due to the limited construction site, large-

tonnage cranes cannot enter the construction site, and because the demolished arch ring is a plain concrete arch ring, the demolition of the demolished arch ring should be carried out as a whole. During hoisting, the arch ring is prone to breakage and fall, which will damage the catenary, line rails, other underground optical cables and other driving equipment under the removed bridge and cause major accidents. Therefore, the overall removal and hoisting of the arch ring is subject to the construction site , the structural characteristics of the plain concrete arch ring itself, and other factors, it cannot be implemented; however, when the demolished arch ring is demolished by blasting method, the construction is difficult, the risk is high, and the interference to the existing

railway line is very large.

Login to View More

Login to View More