Novel processing method for green tea capable of being stored and having abundant inclusions

A processing method and technology of inclusions, which are applied in the field of new green tea processing, can solve the problems of deterioration, dull aroma, dark yellow color of dry tea, etc., and achieve the effects of avoiding damage, improving drying effect and high tea integrity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A novel green tea processing method capable of storing rich content, said method comprising the following steps:

[0051] 1) Picking of fresh leaves: pick the fresh leaves of local one-bud and two-three-leaf tea as raw materials, and require the fresh tea leaves to have a certain degree of tenderness, uniform size, and uniform length;

[0052] 2) Greening of fresh leaves: the picked fresh leaves are spread on the greening tank in time, the temperature of greening is 19-20°C, the time of greening is 10-20 hours, when the moisture content of fresh leaves is 71%-75% Finish;

[0053] 3) Cleaning of fresh leaves: After step 2), the fresh leaves after spreading green are cleaned by fresh leaf cleaning equipment, firstly in the washing tank, then sprayed and washed by spray conveyor belt, and then dehydrated by slope conveyor and conveyed by conveyor belt. Dehydration by strong wind in flat transportation, when 70-80% of the washed leaves surface is dry, the fresh leaves are ...

Embodiment 2

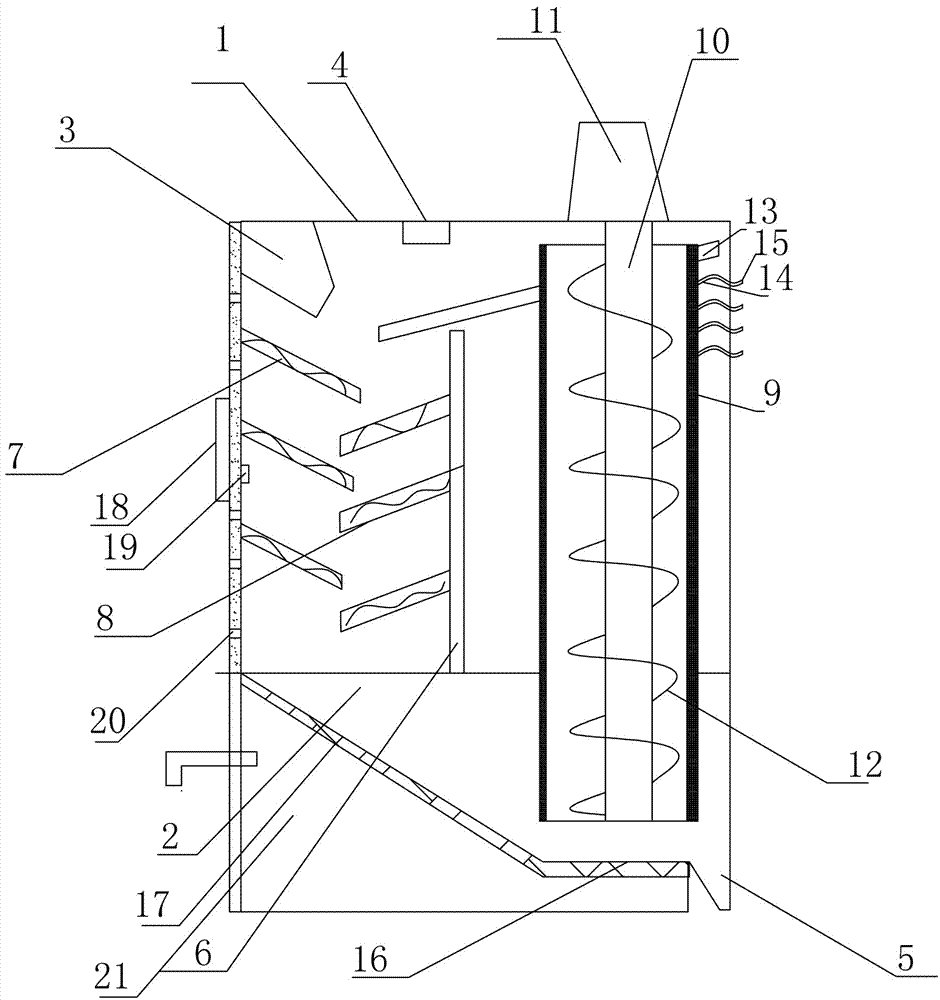

[0071] The dryer used in step 7) and step 9) of the method described in Example 1 includes a rectangular casing 1, and a casing cover is fixed on the top of the casing 1. There is a feed hopper 3 on the left side of the upper end of the casing 1, which is characterized in that: the lower end of the casing 1 is fixedly connected to the conical cylinder 2, the conical cylinder 2 is welded and communicated with the casing 1, and the left side of the conical cylinder 2 is conical. The right side is a vertical surface, the lower end of the conical cylinder 2 has a discharge port 5, the shell 1 is welded with a partition 6 that divides the shell 1 into a left chamber and a right chamber, and the outlet of the feed hopper 3 Located above the left chamber, the discharge port 5 is located below the right chamber. The left chamber inner wall is provided with some first inclined plates 7 whose free ends are inclined downwards, and the left side wall of the dividing plate 6 is also welded...

Embodiment 3

[0081] Others are the same as in Example 1, step 6) in the method. The preferred scheme of steam deenzyming can also be deenzymed by vacuum microwave. The deenzyming conditions are 100-150° C. of deenzyming temperature, negative pressure of 0.02-0.08MPa, and microwave power of 0.5-1.5w / g. The killing time is 0.5-1 minute. Microwave negative pressure is used to complete greening, and the high-speed transformation of tea raw material molecules realizes "rapid self-heating as a whole". The energy transfer of tea raw materials is not affected under the negative pressure microwave state, and its molecules are transformed at a high speed. Fast speed, short finishing cycle, uniform finishing quality, high thermal efficiency and good finishing quality, and low production cost, no thermal inertia in the production environment, can improve economic benefits, and because of microwave heating, water molecules evaporate due to self-heating, no There will be a ripe smell. At the same time,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com