Work piece transport system

A technology for conveying systems and workpieces, which is applied to the field of workpiece conveying systems for conveying in the workpiece storage unit, which can solve problems such as operating restrictions, increased product costs, and time-consuming recovery, and achieves reduced product costs, high speed, and simple separate supply Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

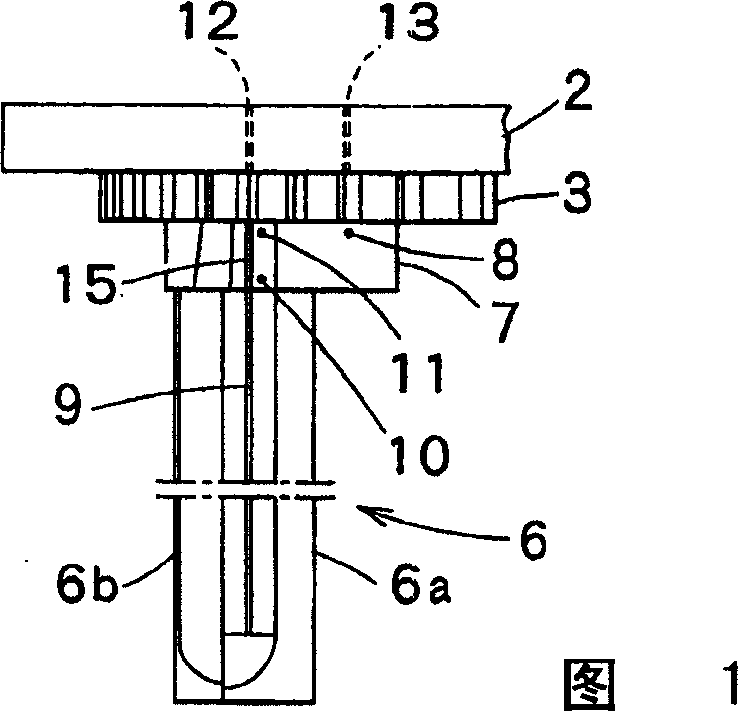

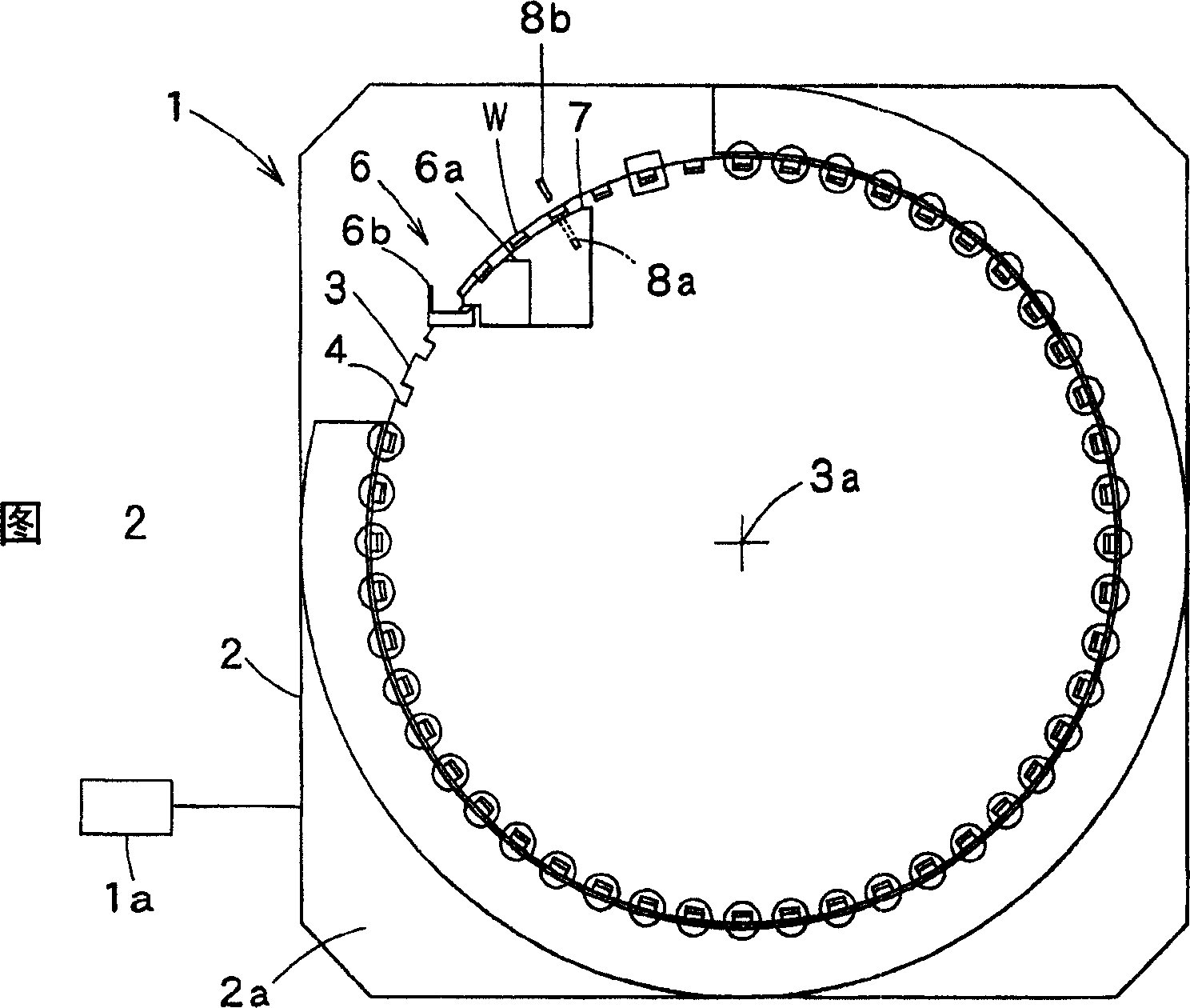

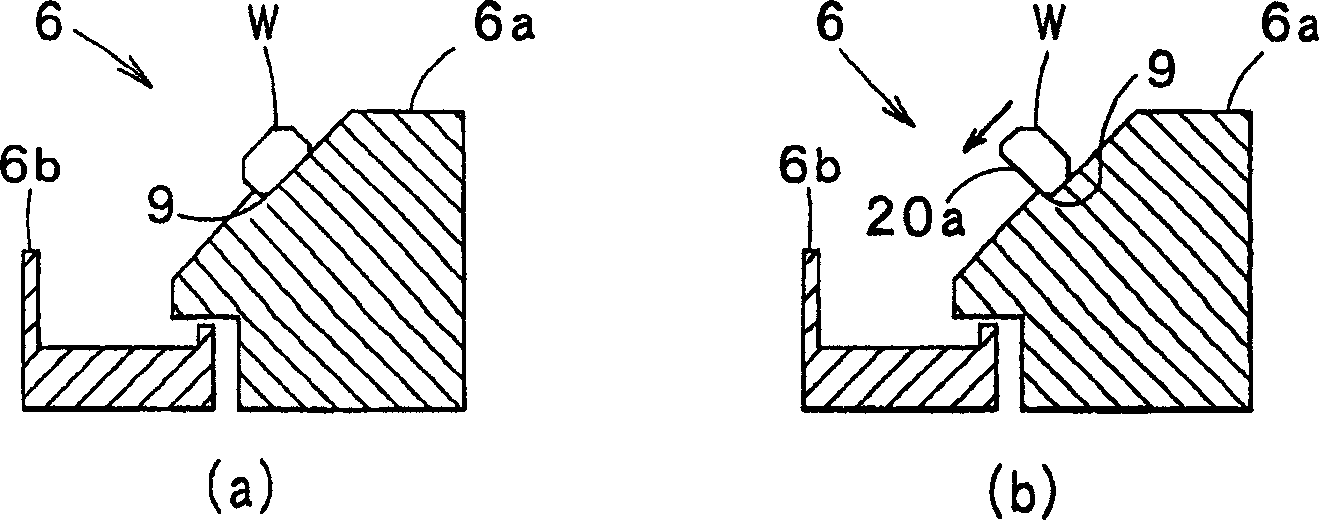

[0033] FIG. 1 is a plan view showing an embodiment of the workpiece conveying system of the present invention, and FIG. 2 is a front view showing the workpiece conveying system, image 3 (a) is an enlarged cross-sectional view of a linear feeder in a normal conveying state, image 3 (b) is an enlarged cross-sectional view of the linear feeder in an abnormal conveying state, and Fig. 4(a) to Fig. 4(c) are explanatory views of the supply feeder, Figure 5 6 is a front view showing the separation chute, FIG. 6 is a side view showing the workpiece loading hole, and FIG. 7 is a side view showing the workpiece discharge hole.

[0034] In Fig. 1 and Fig. 2, the workpiece conveying system 1 includes: a vertically arranged workbench base 2; arranged on the vertical surface 2a of the workbench base 2, arranged around the horizontal rotation axis 3a to rotate freely intermittently,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com