Patents

Literature

136results about How to "Avoid crash situations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

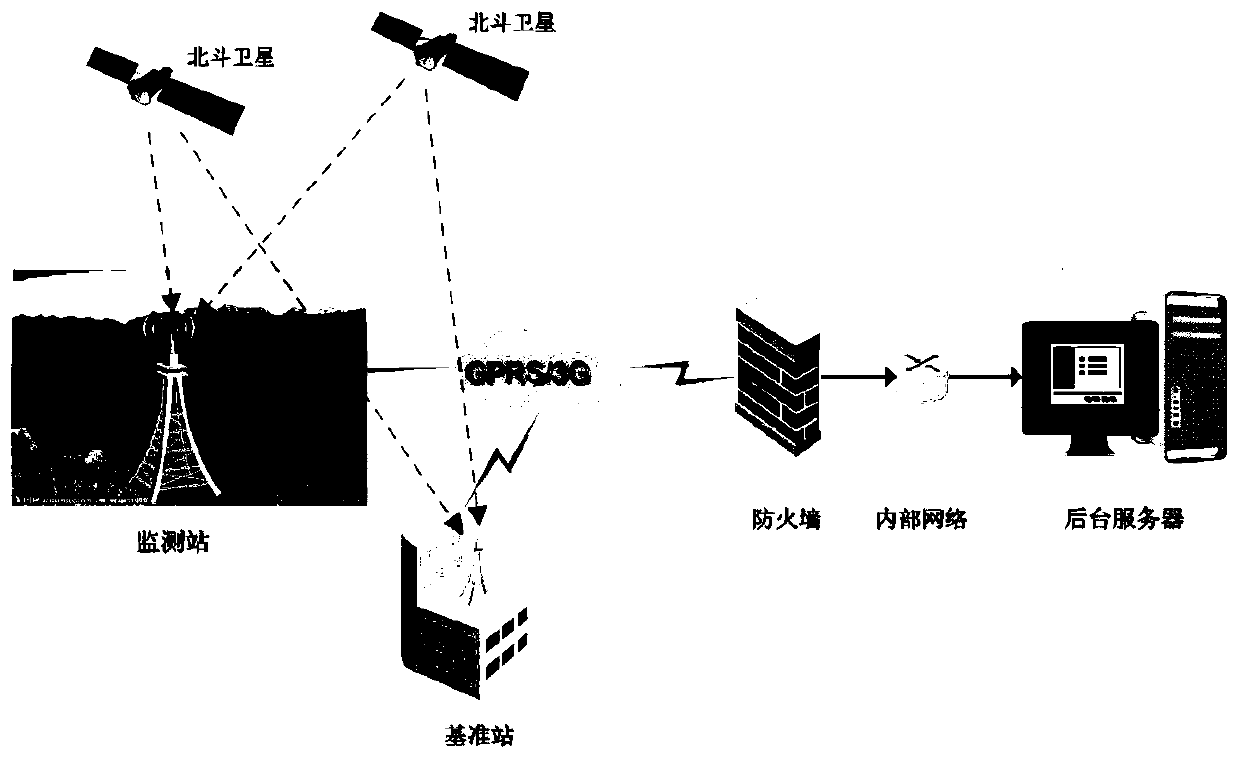

Method and system for monitoring multi-dimensional deformations of electric transmission lines in real time on basis of differential positioning

InactiveCN110068849AImprove settlement accuracySimple structureElectrical/magnetic solid deformation measurementSatellite radio beaconingLongitudeEngineering

The invention discloses a method for system for monitoring multi-dimensional deformations of electric transmission lines in real time on the basis of differential positioning. According to the methodand system, a base station is electrified to carry out measurement or increase measurement frequency, longitude and latitude information of the base station is updated in real time by utilizing a known base station coordinate, and a measured carrier phase observed value, a measured pseudo-range observed value and the base station coordinate are transmitted to a background server through a 4G network in an RTCM format or a self-defined format; a monitoring station uploads acquired field state data and a command for processing a client to the background through the 4G network in the RTCM formator the self-defined format; the background server receives the information sent by the base station and the monitoring station and carries out single-system and multi-system combined calculation; andthe background server converts the three-dimensional position of the base station into a longitude, a latitude and an altitude so as to obtain the position information, relative to the base station, of the monitoring station to complete the real-time monitoring. The method and system can be used for monitoring the multi-dimensional postures of electric transmission line towers on complicated geologies so as to ensure the safe operation of the electric transmission lines.

Owner:DONGYING POWER SUPPLY COMPANY STATE GRID SHANDONG ELECTRIC POWER

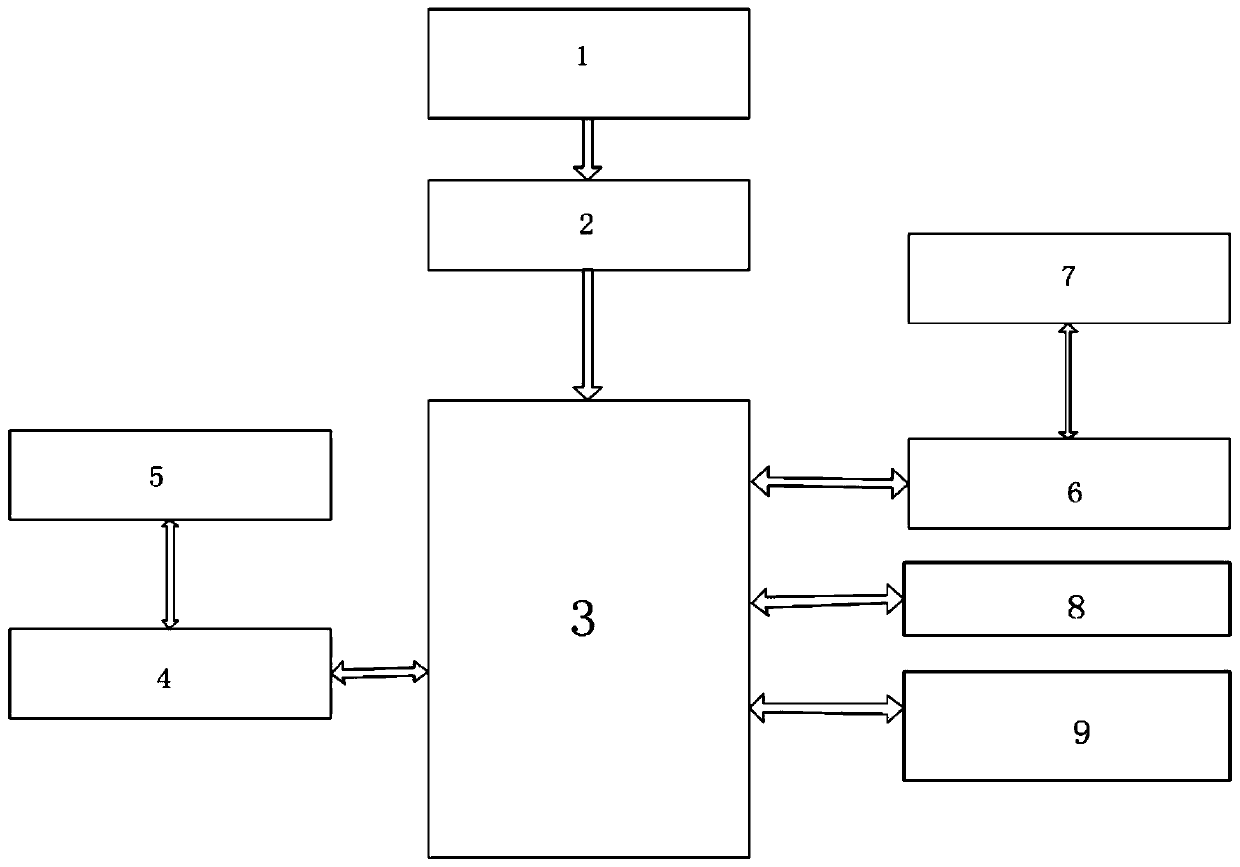

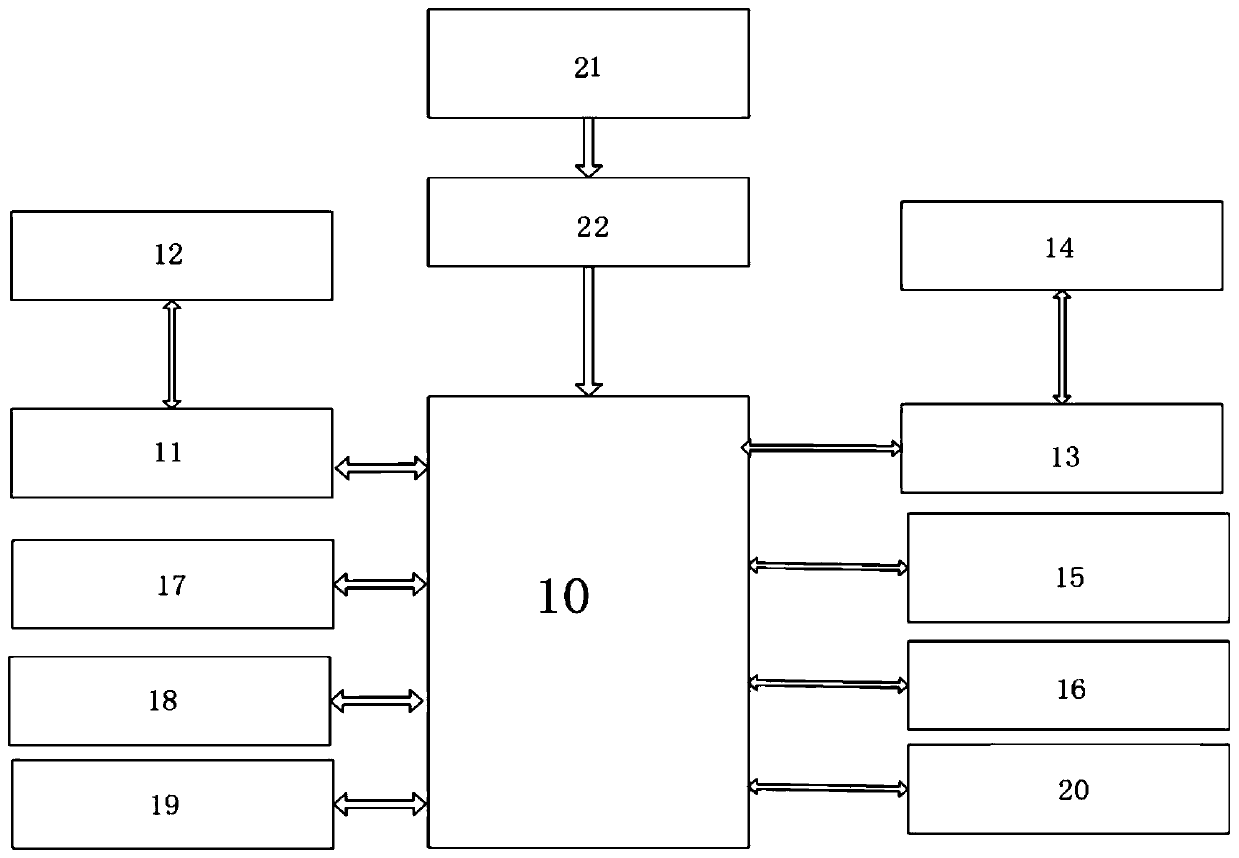

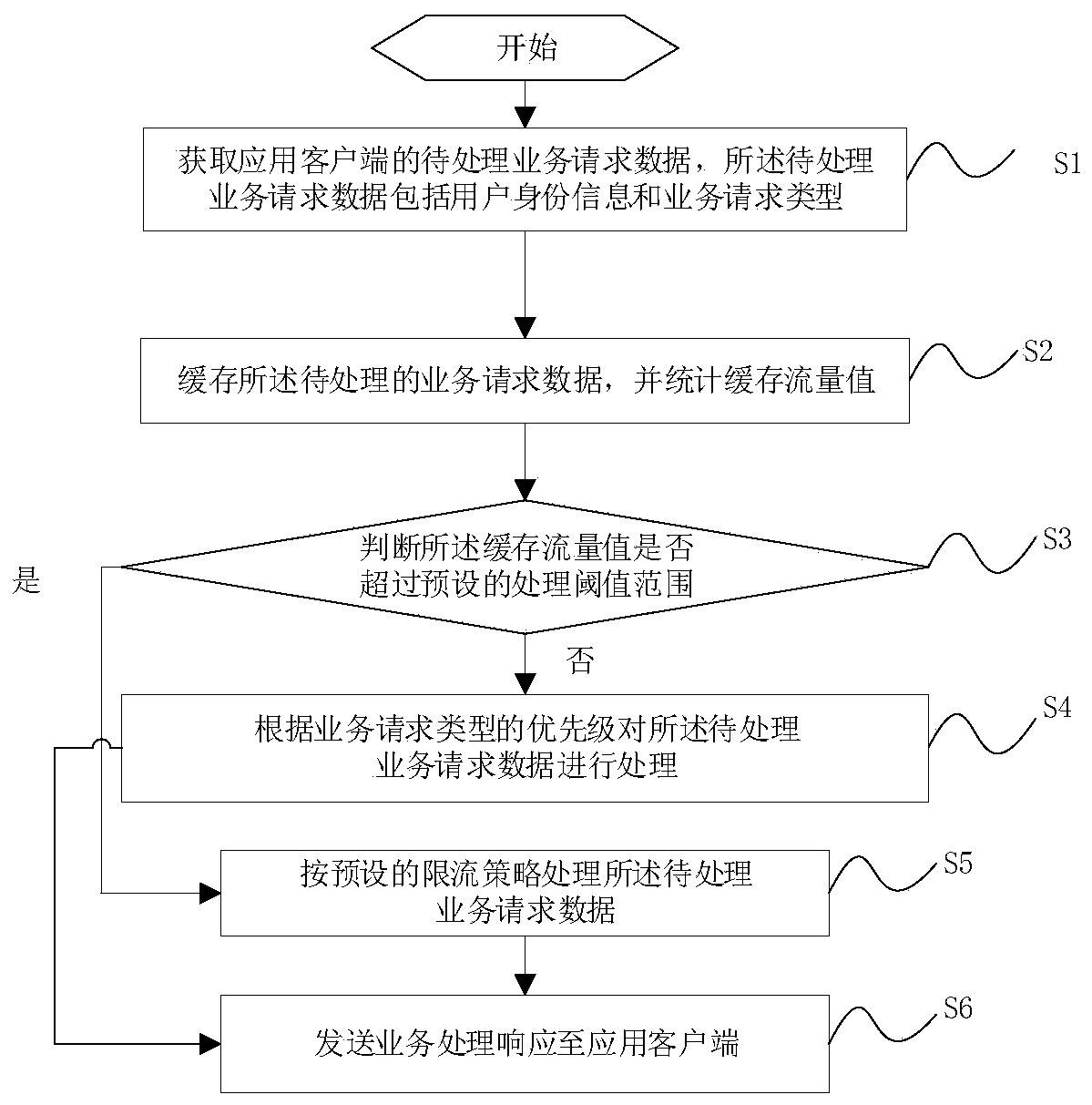

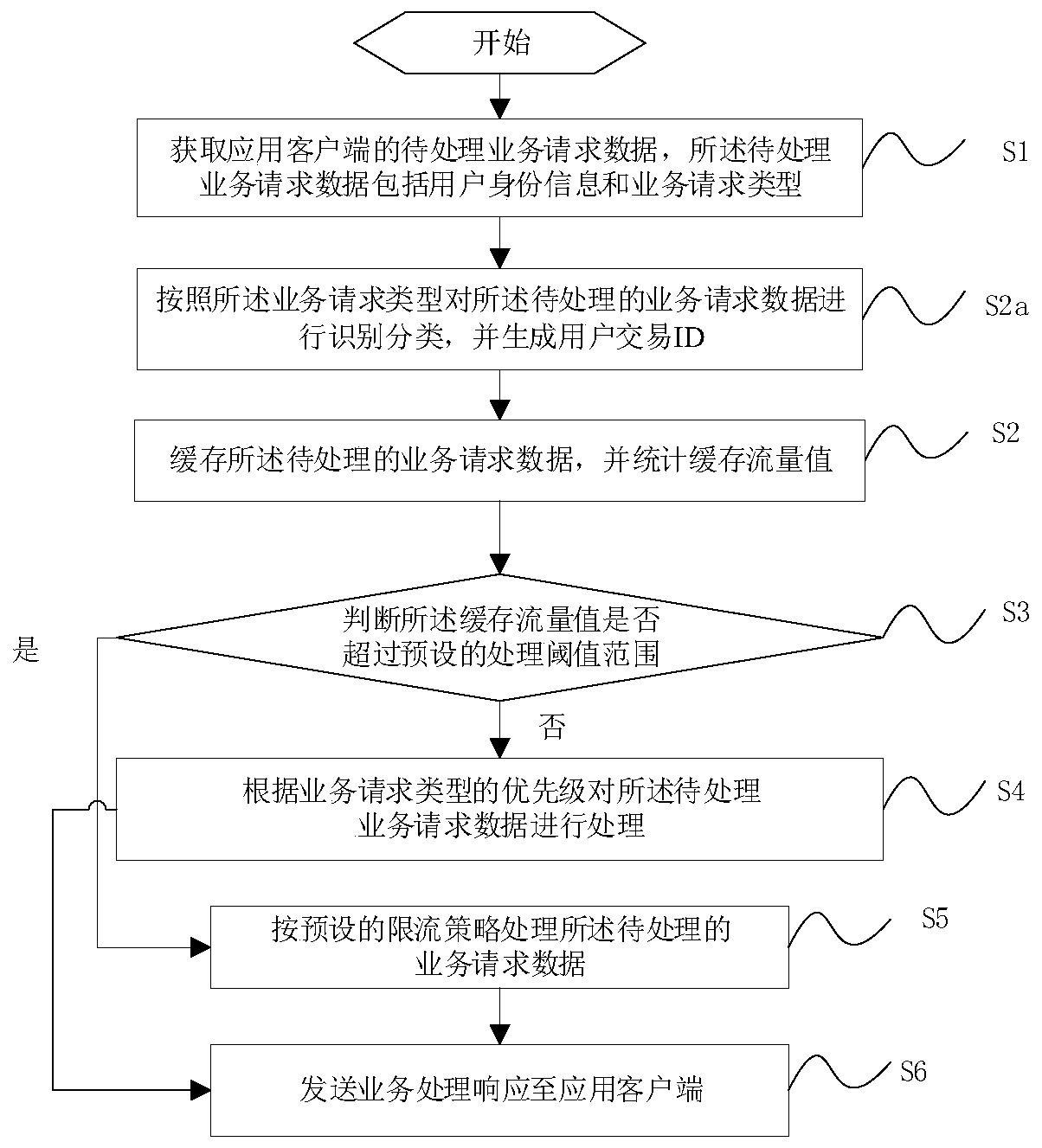

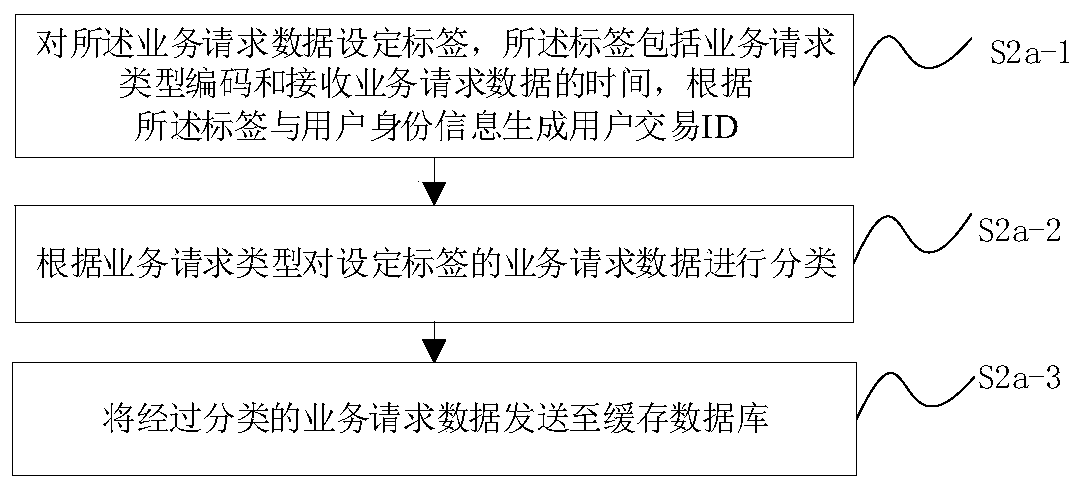

Data processing method, electronic device, computer device and storage medium

PendingCN109885399AAvoid wastingAvoid system crashResource allocationDatabase management systemsClient-sideTraffic volume

The invention relates to a data processing method and device, a computer device and a storage medium, and the method comprises the steps of obtaining the to-be-processed service request data of an application client, the to-be-processed service request data comprising user identity information and a service request type; caching the service request data to be processed, and counting a cache flow value; Judging whether the cache flow value exceeds a preset processing threshold range or not; if not, processing the to-be-processed service request data according to the priority of the service request type; if yes, processing the to-be-processed service request data according to a preset current limiting strategy; and sending a service processing response to the application client. By adoptingthe method, the pressure of an application system interface or service under the condition that the transaction data volume is sharply increased can be effectively relieved, and the activity effect isensured while the client experience is ensured.

Owner:PINGAN PUHUI ENTERPRISE MANAGEMENT CO LTD

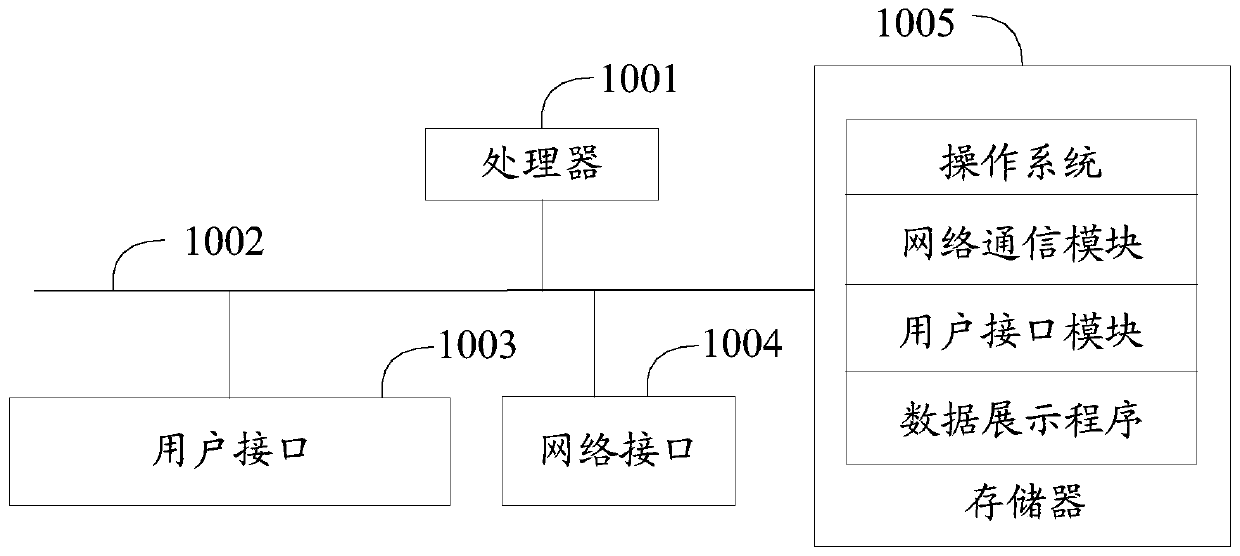

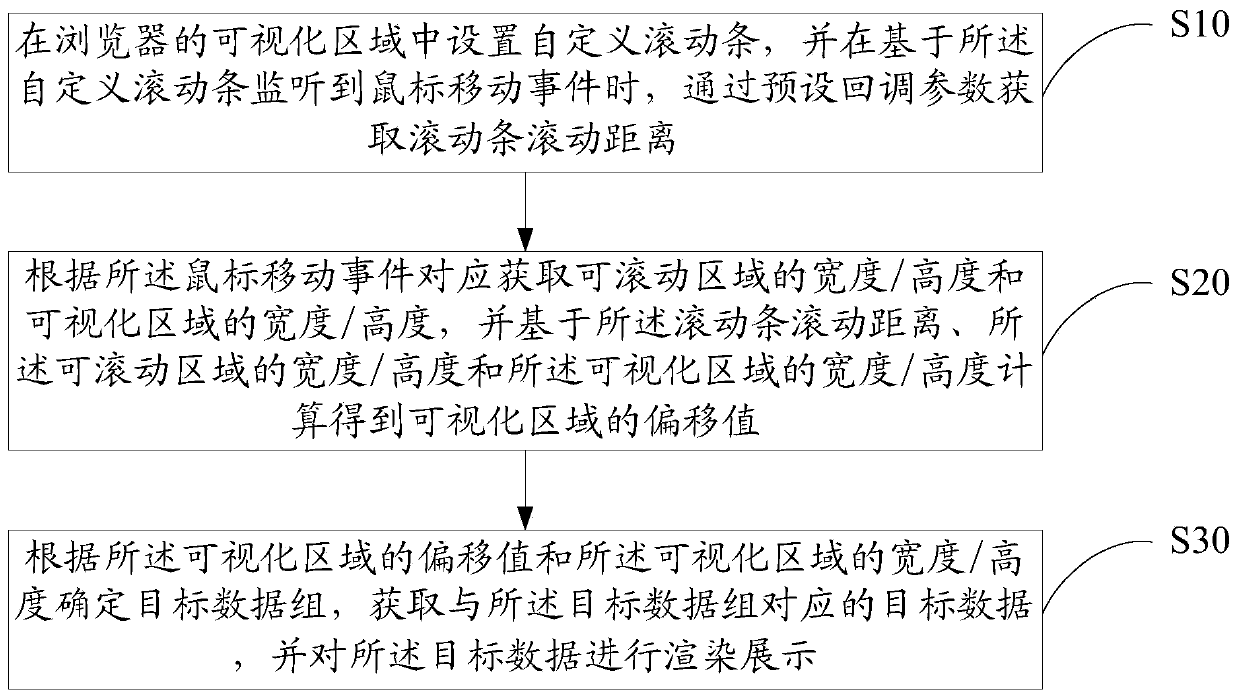

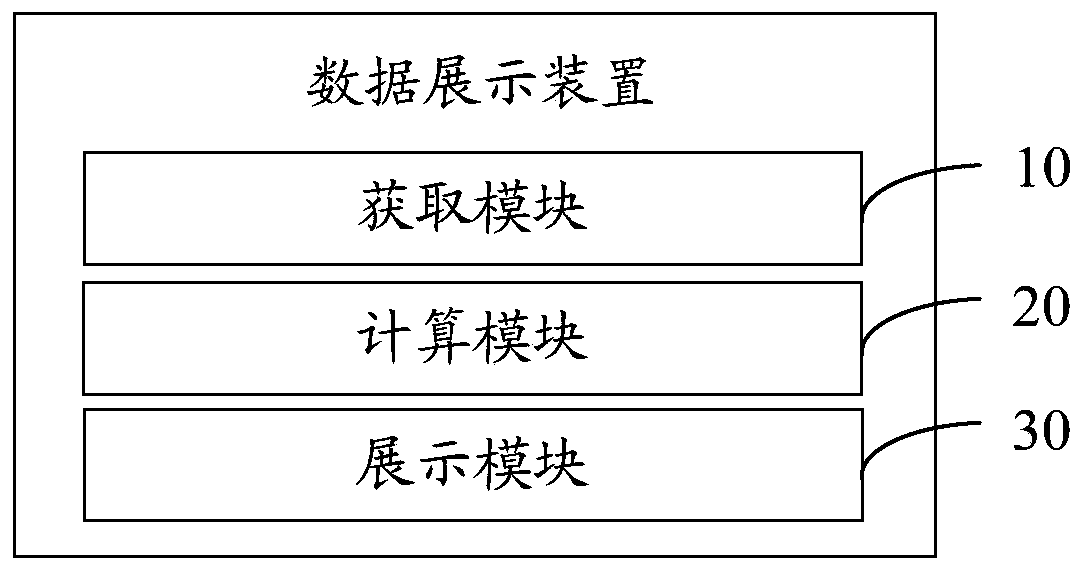

Data display method, device and apparatus and computer readable storage medium

PendingCN110134308ARelieve pressureAvoid crash situationsSpecial data processing applicationsInput/output processes for data processingData displayData set

The invention discloses a data display method, device and apparatus and a computer readable storage medium. The method comprises the following steps: setting a custom scroll bar in a visual area of abrowser, and when a mouse movement event is monitored based on the custom scroll bar, obtaining a scroll bar rolling distance through a preset callback parameter; correspondingly acquiring the width / height of the scrollable area and the width / height of the visual area according to the mouse movement event, and calculating to obtain an offset value of the visual area based on the scrolling distanceof the scrolling strip, the width / height of the scrollable area and the width / height of the visual area; and determining a target data set according to the offset value of the visual area and the width / height of the visual area, obtaining target data corresponding to the target data set, and performing rendering display on the target data. According to the method and the device, the problems of javascript script blockage, page lagging and even browser crash caused by too large data volume during data display in the prior art can be solved.

Owner:WEBANK (CHINA)

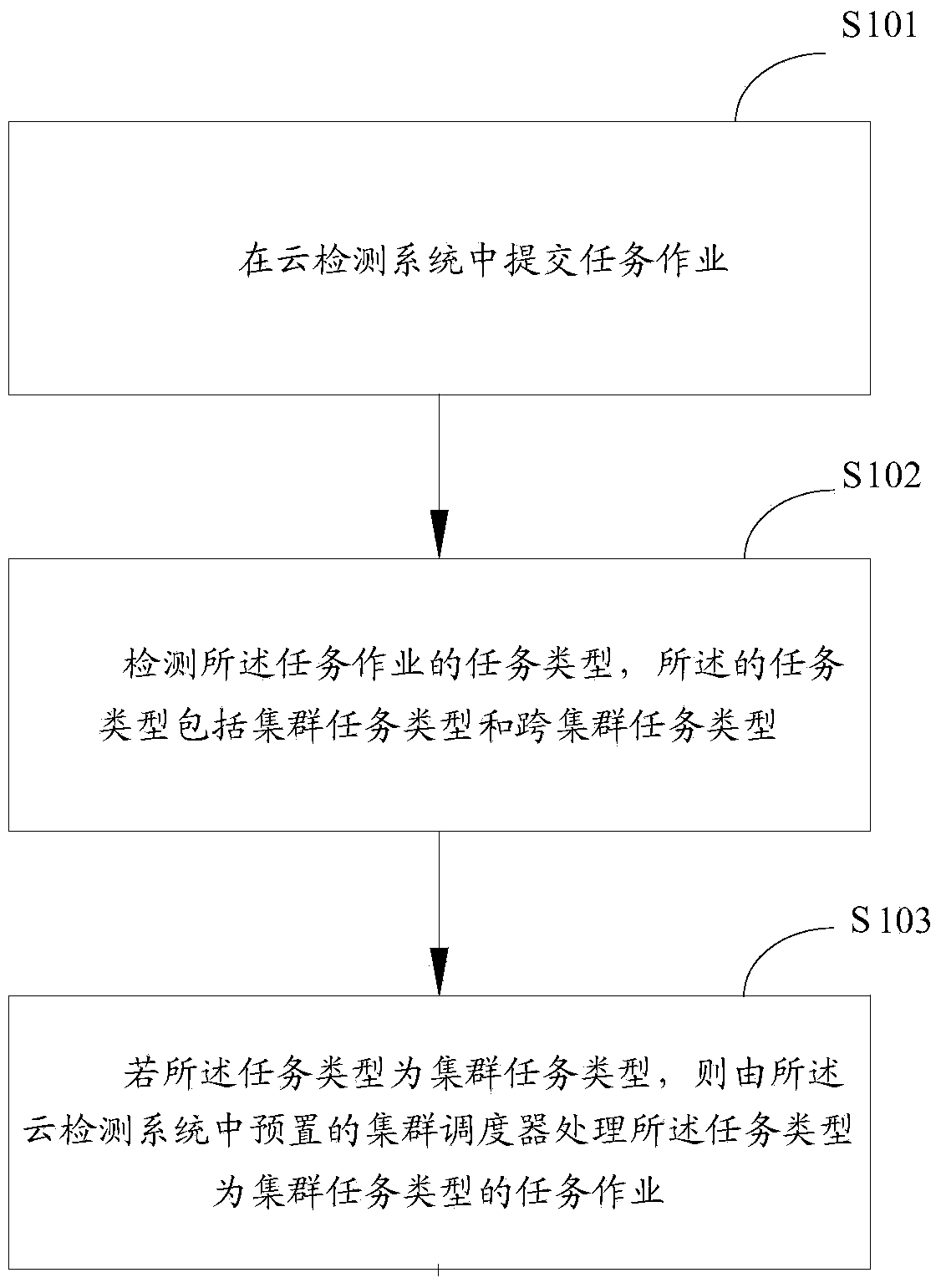

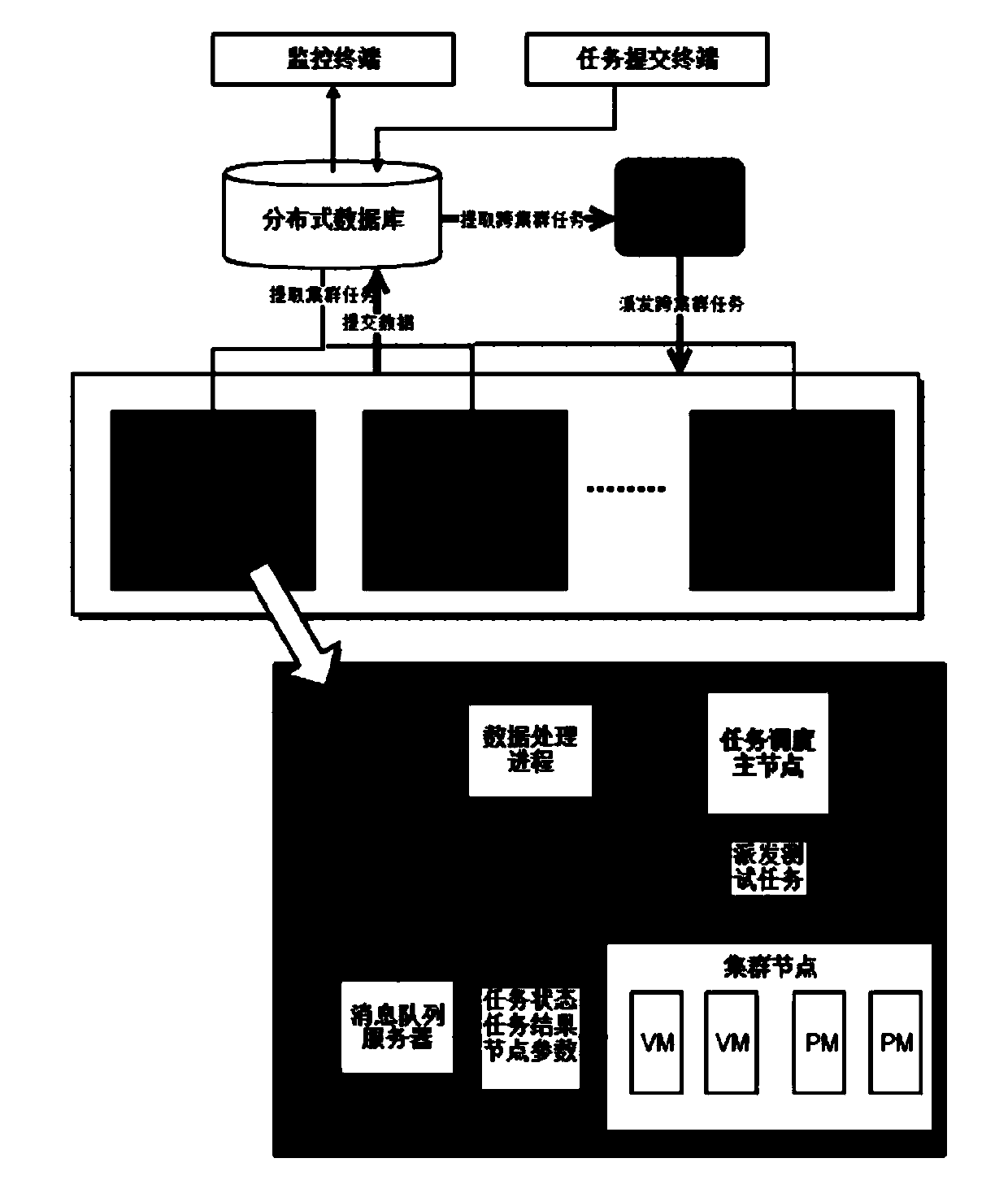

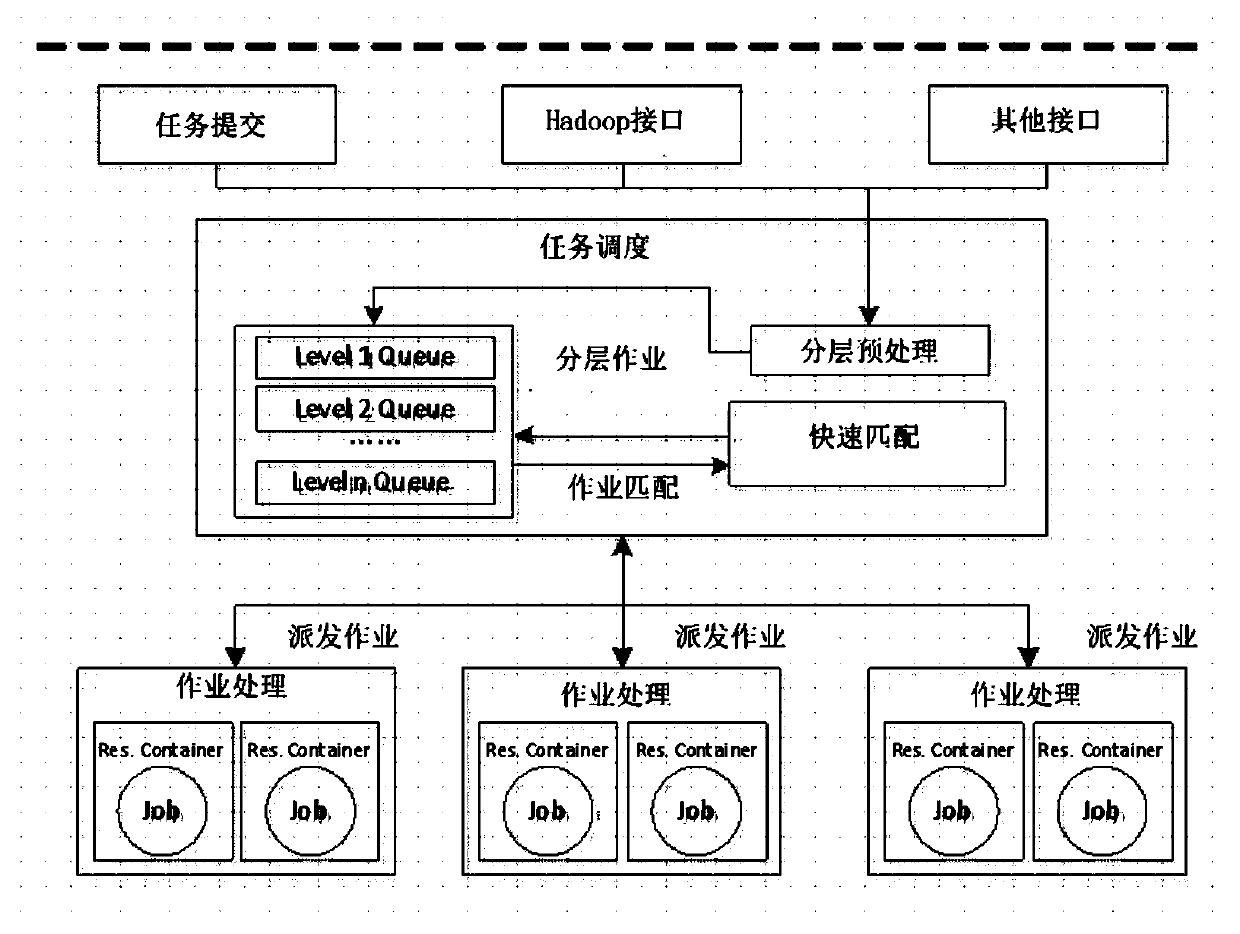

Method, device and system for task operation processing

ActiveCN103744734AAvoid crash situationsImprove efficiencyResource allocationSoftware simulation/interpretation/emulationCloud detectionSystem stability

The invention is suitable for the technical field of cloud detection and provides a method, device and system for task operation processing. The method comprises the steps of submitting task operation in a cloud detection system; detecting task types of task operation, and enabling the task types to comprise a cluster task type and a trans-cluster task type; if the task type is the cluster task type, utilizing a preset cluster scheduler in the cloud detection system to process the task operation with the task type being the cluster task type; and if the task type is the trans-cluster task type, utilizing a preset trans-cluster scheduler in the cloud detection system to process the task operation with the task type being the trans-cluster task type. The cluster task type is a type of utilizing one cluster to process the task operation, and the trans-cluster task type is a type of utilizing at least two clusters to process the task operation. The conditions that the system collapses easily are avoided, and system stability and task processing efficiency are improved.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

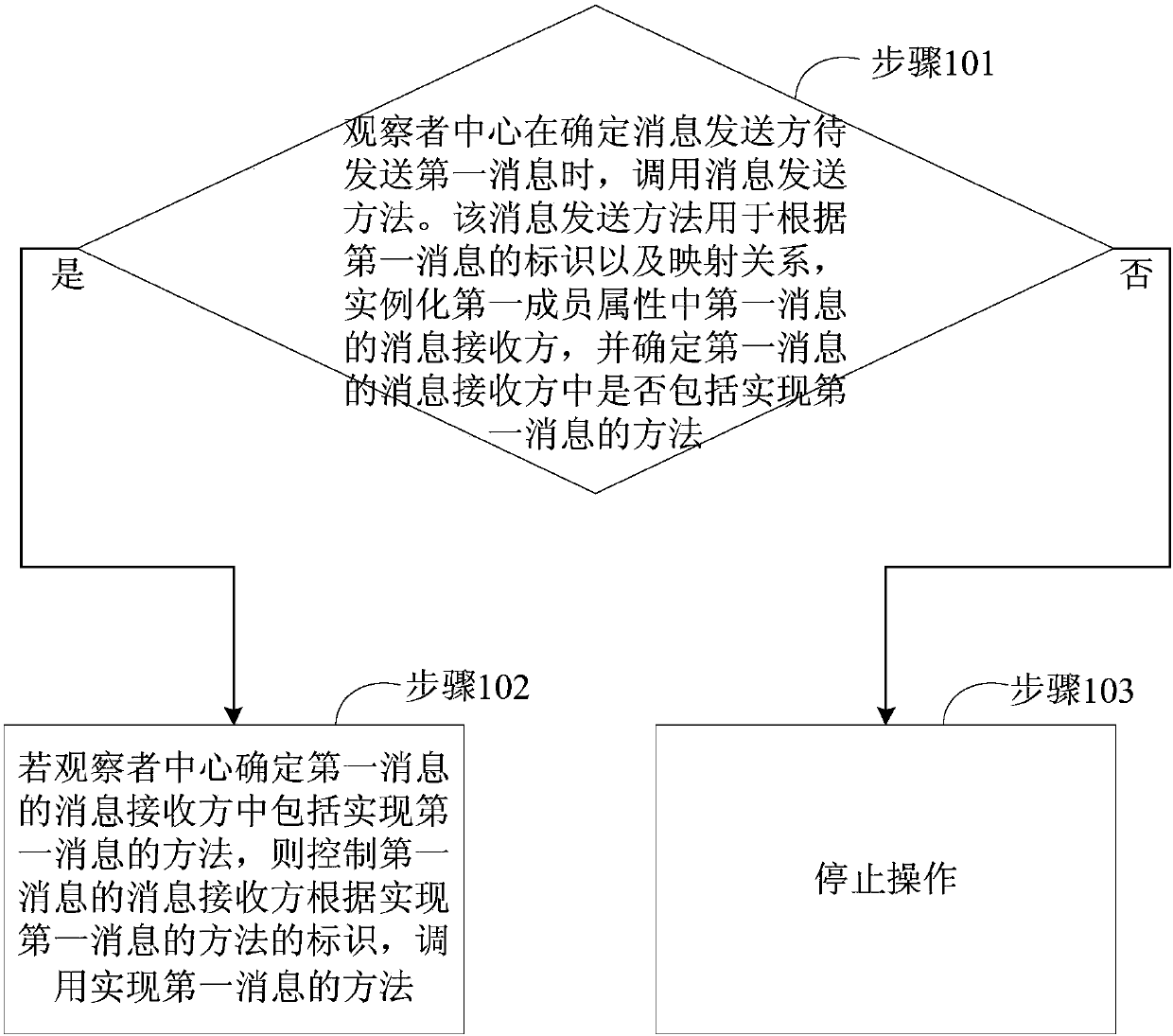

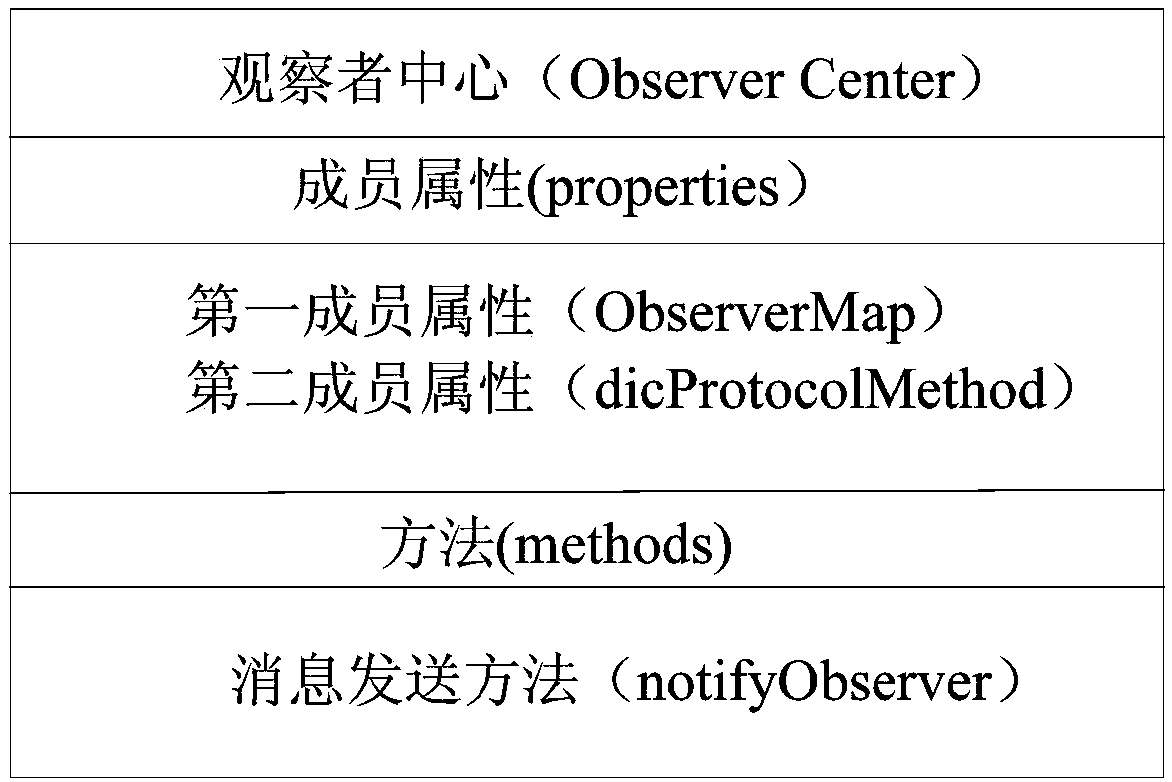

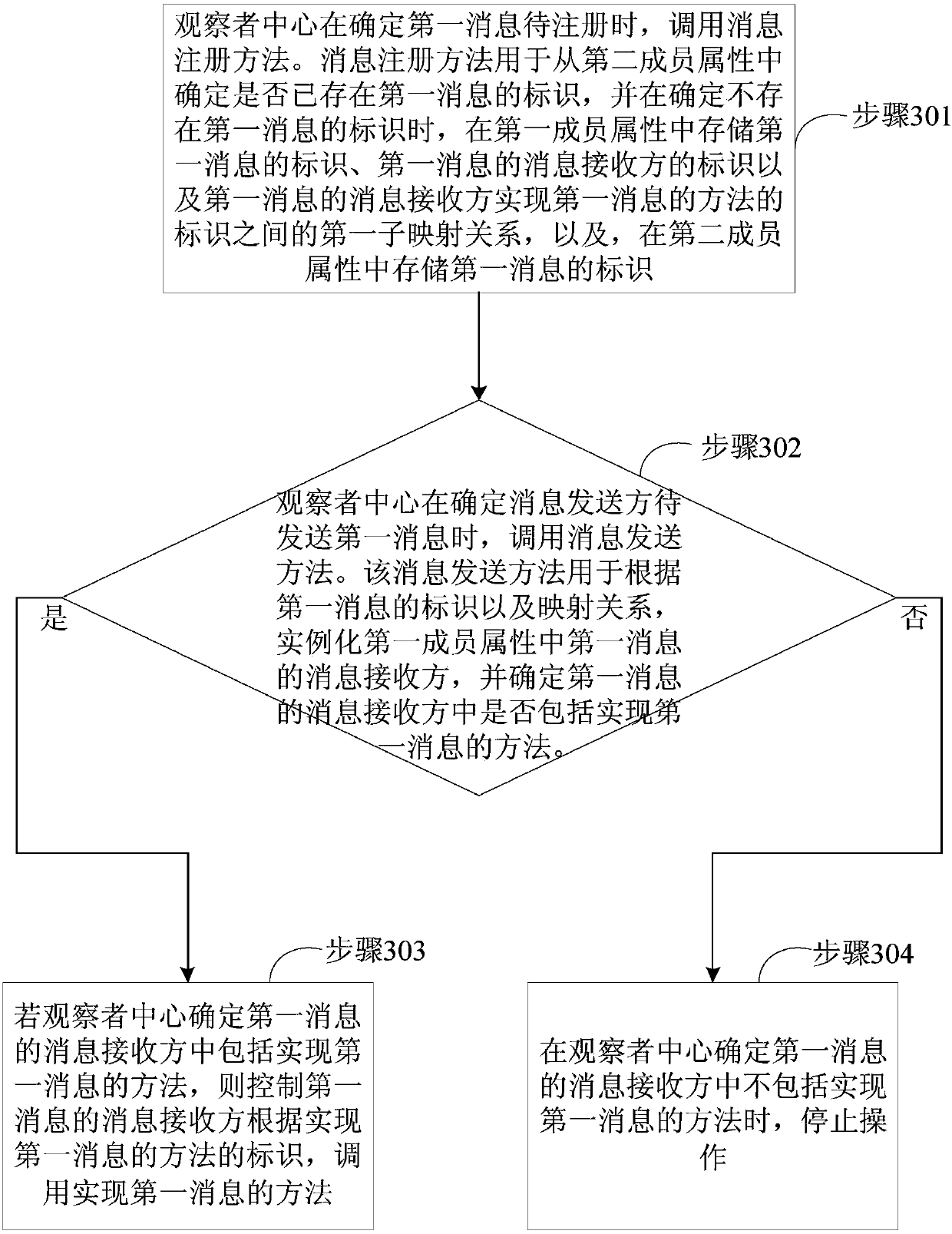

Message distribution method and apparatus in application program

ActiveCN108023808ASolve the messFix crashData switching networksComputer hardwareDistribution method

The invention discloses a message distribution method and apparatus in an application program. The method comprises the following steps: when an observer center determines that a message sender is about to send a first message, calling a message sending method, wherein the message sending method is used for instantiating a message receiver of a first message in a first member attribute according to an identifier of the first message and a mapping relationship, and determining whether the message receiver of the first message comprises a method for implementing the first message, wherein the first message is contained in a defined message, the first message comprises the identifier of the first message, if the observer center determines that the message receiver of the first message comprises the method for implementing the first message, controlling the message receiver of the first message to call the method for implementing the first message according to the identifier of the methodfor implementing the first message. The problem of code confusion of the current APP and the problem of crash of the APP in a running process are solved.

Owner:SHENZHEN LEXIN SOFTWARE TECH CO LTD

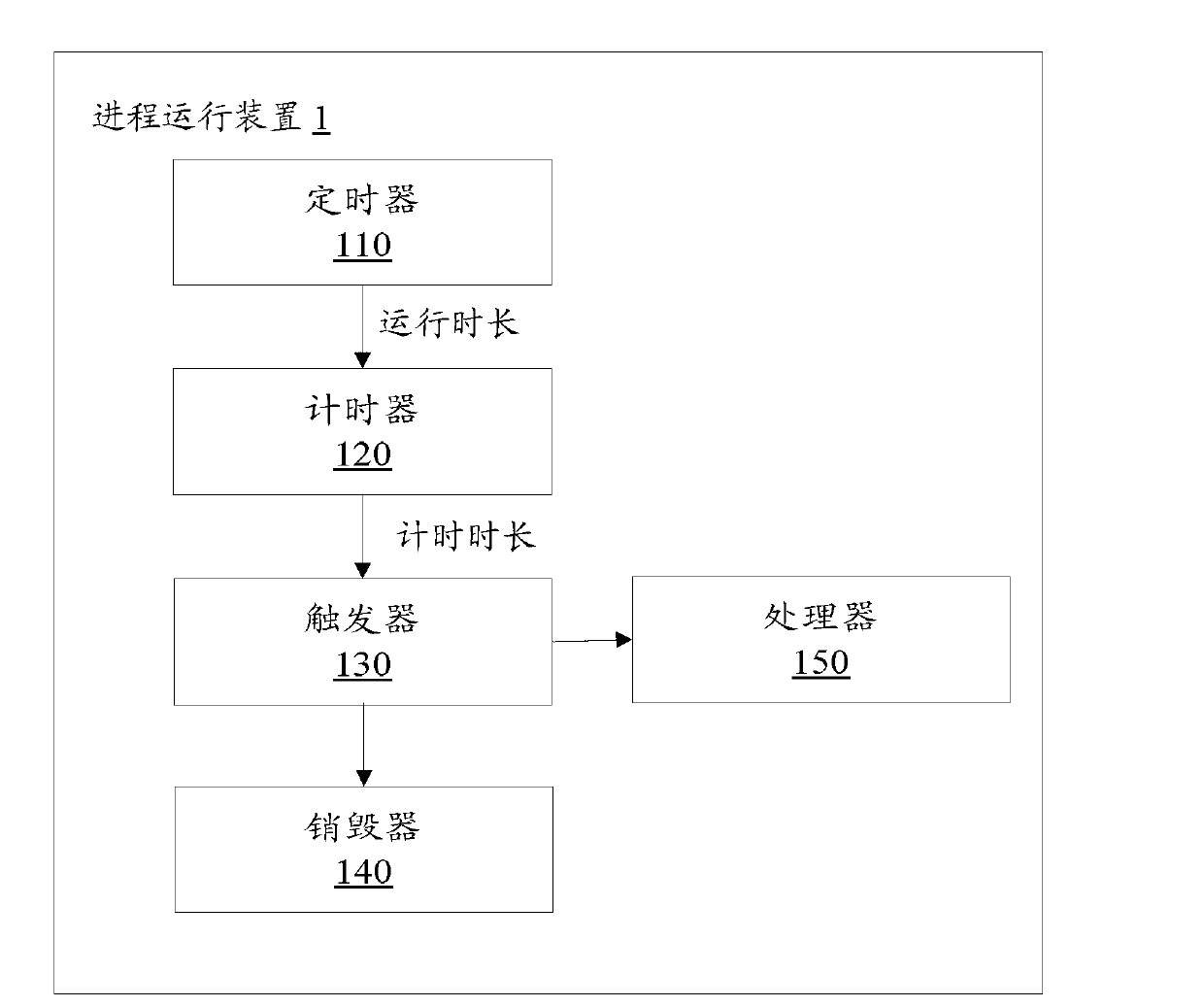

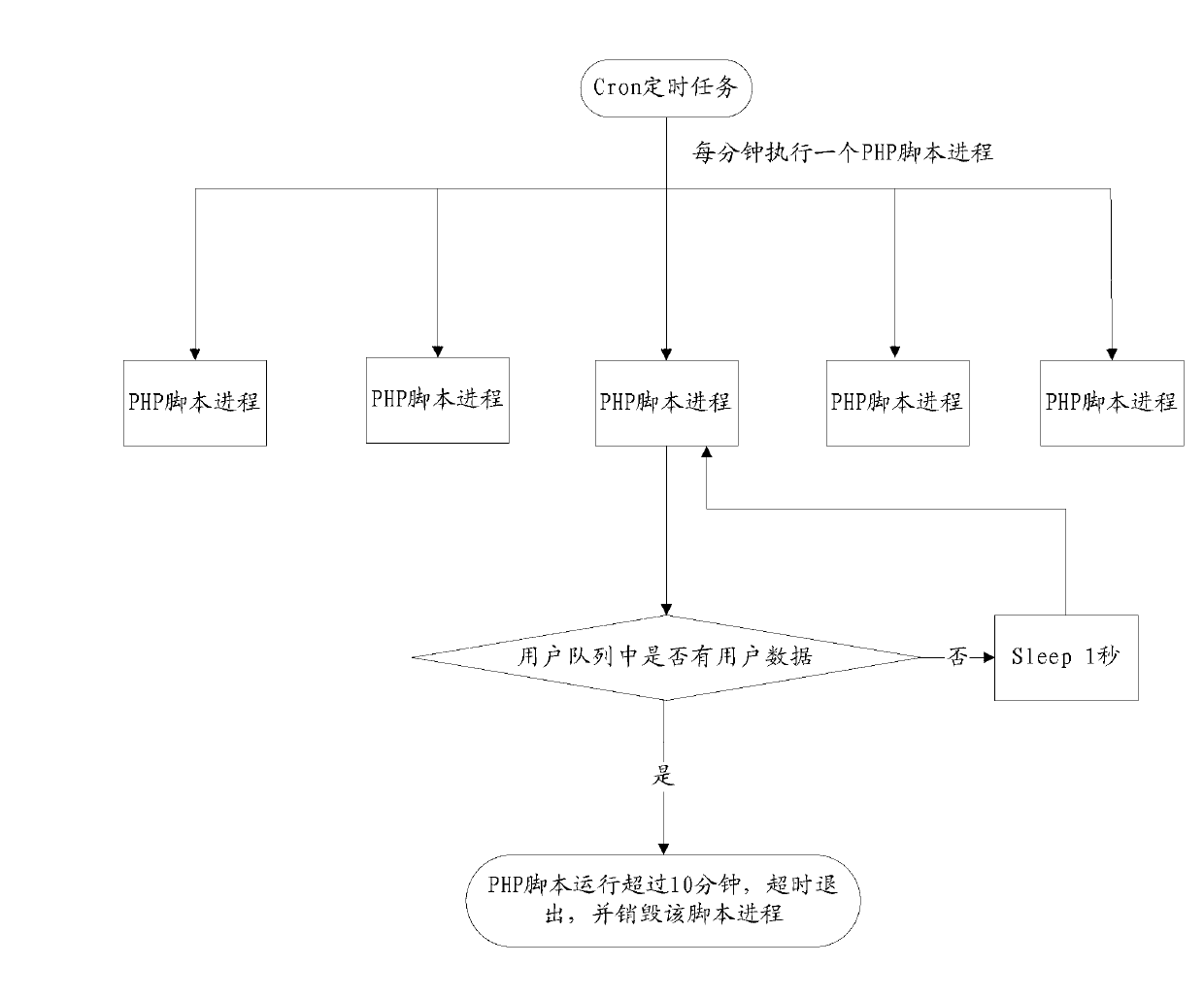

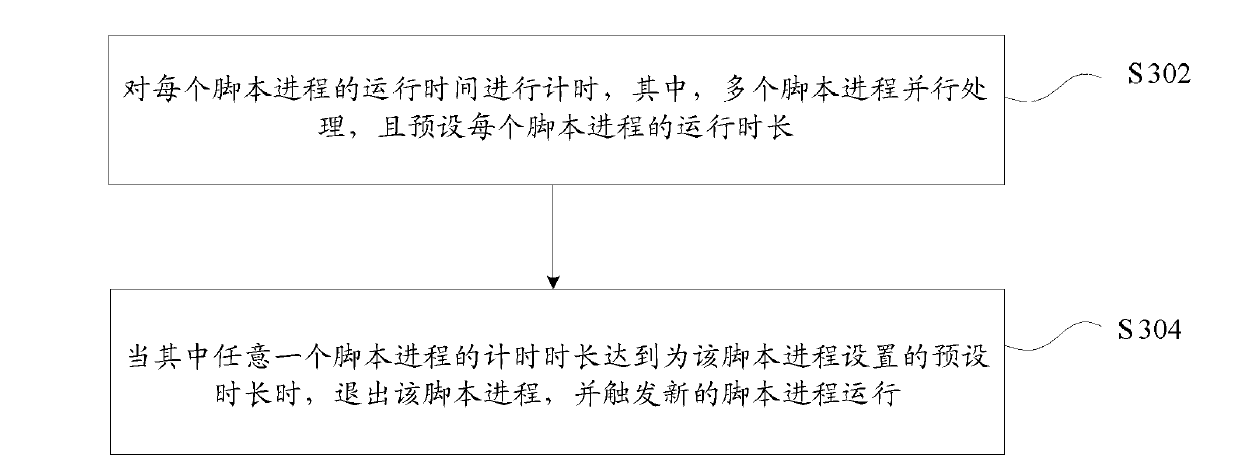

Process running device and method

ActiveCN102999387AImprove experienceSpeed up application processingProgram initiation/switchingOperational systemRunning time

The invention discloses a process running device. The device comprises a time customizer, a timer and a trigger, wherein the time customizer is configured to customize running durations of a plurality of script processes, and a plurality of script processes are processed in parallel; the timer is configured to time the running time of each script process; and the trigger is configured to quit the script process corresponding to the timer when the running duration of the time customizer reaches the running duration of the script process regarding an arbitrary script process, and trigger new script process to run. The invention discloses a corresponding process running method. By adopting the process control device and method, the technical problem of network application service interruption caused by an operation system or daemon process interruption can be solved.

Owner:BEIJING QIHOO TECH CO LTD

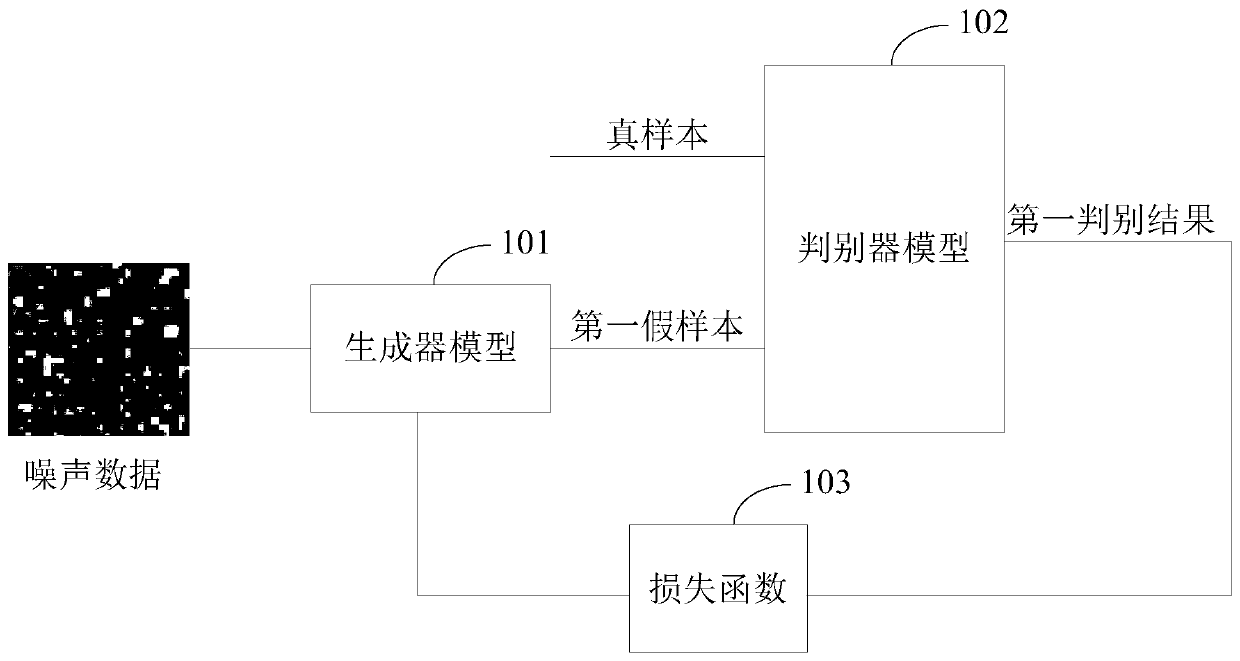

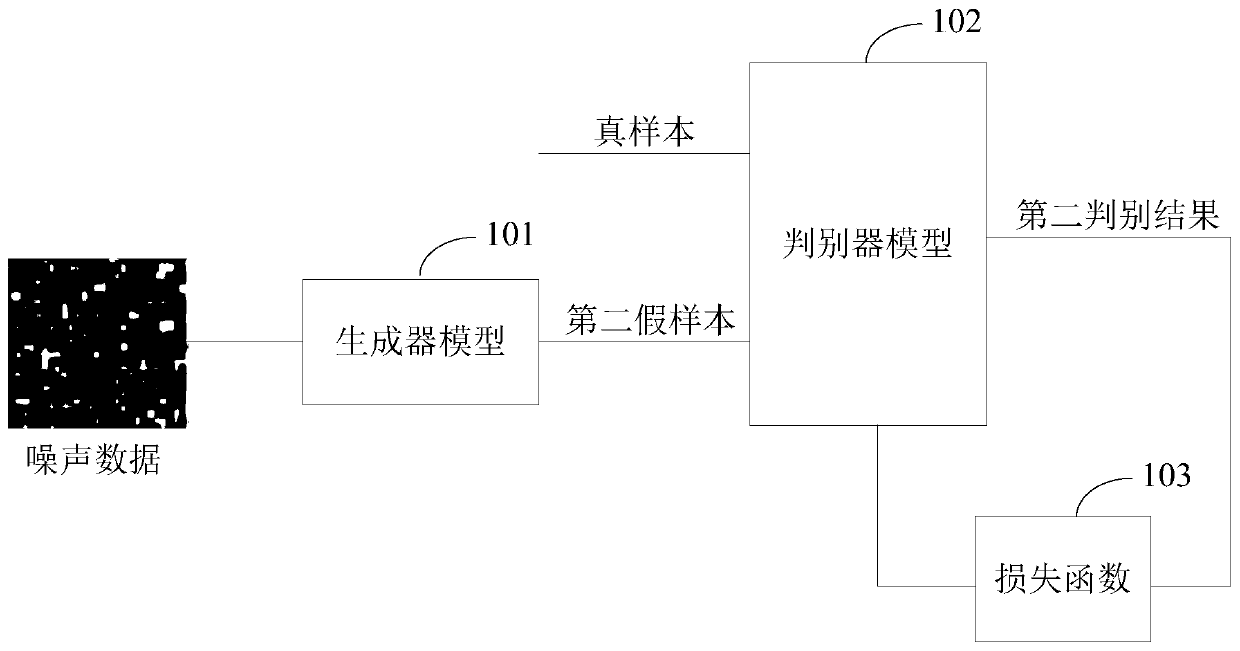

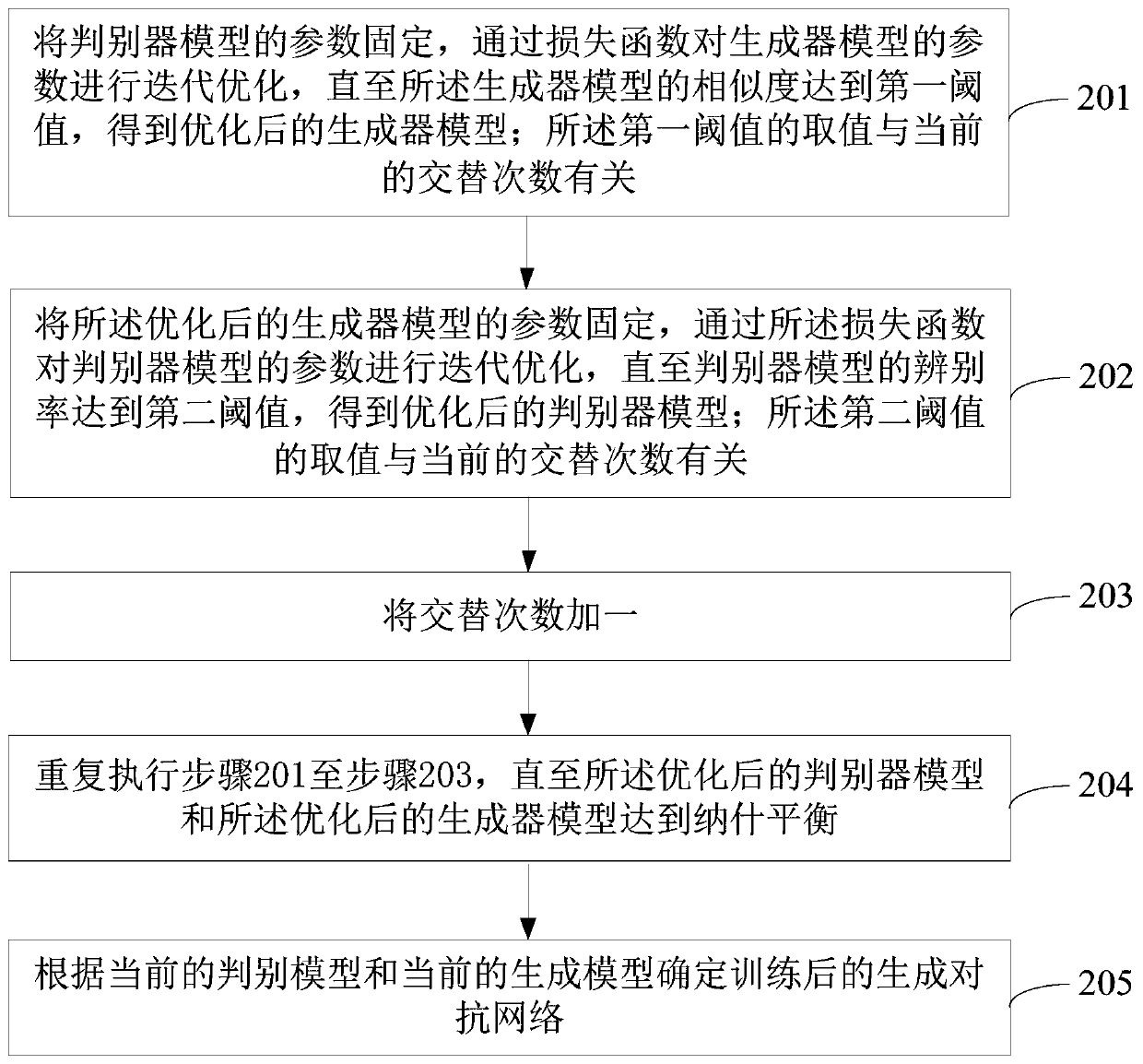

Generative adversarial network training method and device

PendingCN110796253AImprove training efficiencyAvoid crash situationsNeural learning methodsDiscriminatorSimulation

The embodiment of the invention provides a generative adversarial network training method and device, and the method comprises the steps: fixing parameters of a discriminator model, and carrying out iterative optimization of the parameters of a generator model through a loss function till the similarity of the generator model reaches a first threshold value; fixing the parameters of the generatormodel, and iteratively optimizing the parameters of the discriminator model through a loss function until the discrimination rate of the discriminator model reaches a second threshold; wherein the value of the first threshold value and the value of the second threshold value are both related to the current alternating frequency; adding 1 to the alternating times; repeating the above steps until the discriminator model and the generator model reach Nash equilibrium; and determining the trained generative adversarial network according to the current discrimination model and the current generation model. According to the embodiment of the invention, the iteration time of the generator model and the discriminator model can be controlled, the training efficiency of the generative adversarial model can be improved, and the situation of model crash is avoided.

Owner:CHINA UNITED NETWORK COMM GRP CO LTD +1

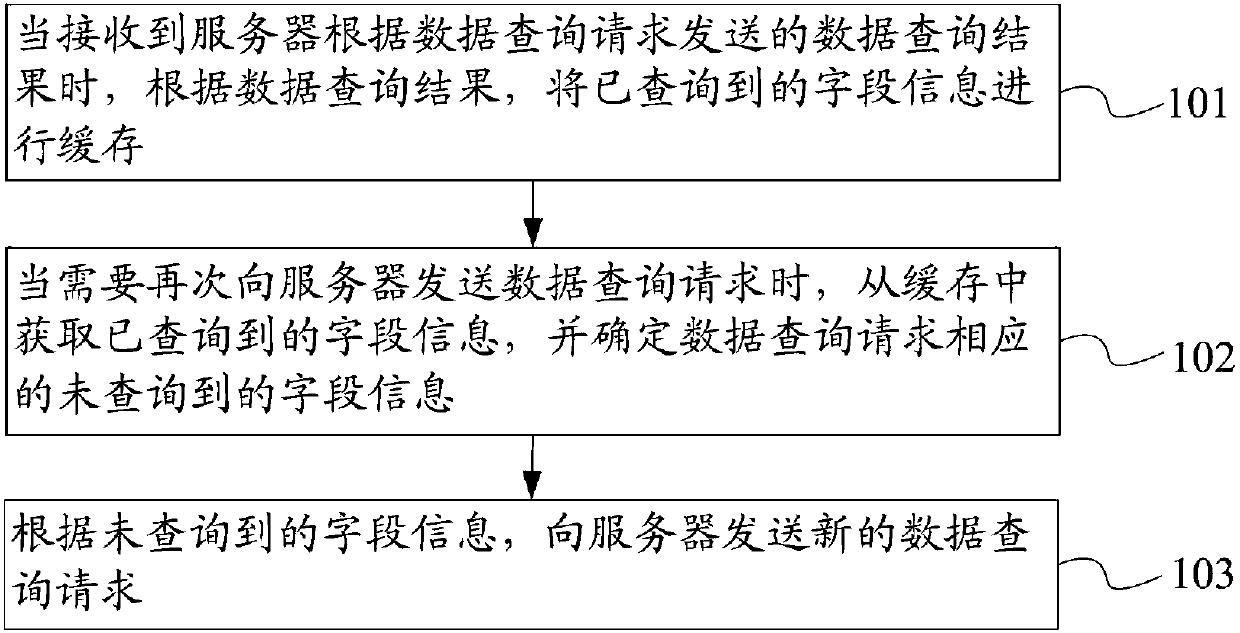

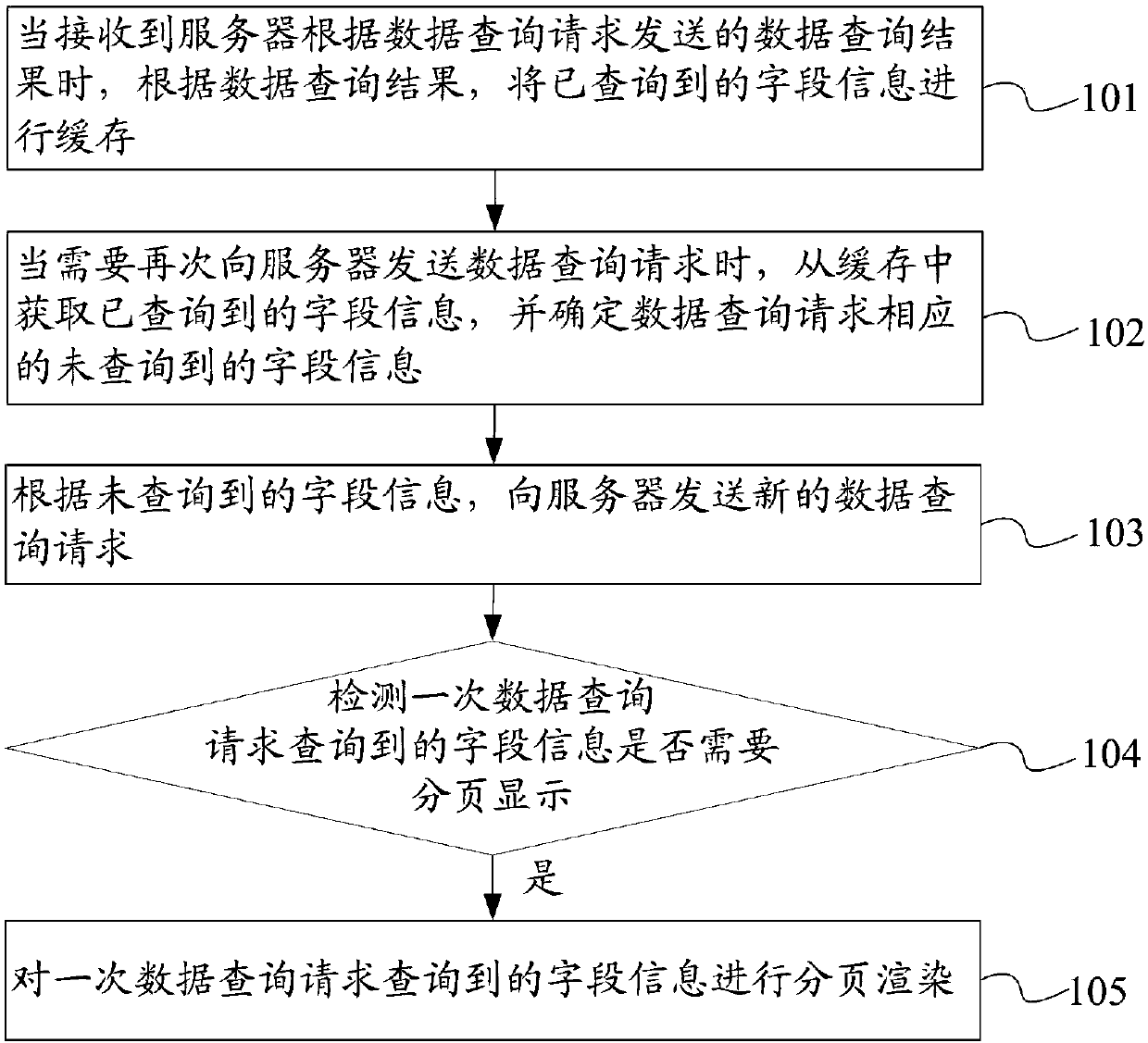

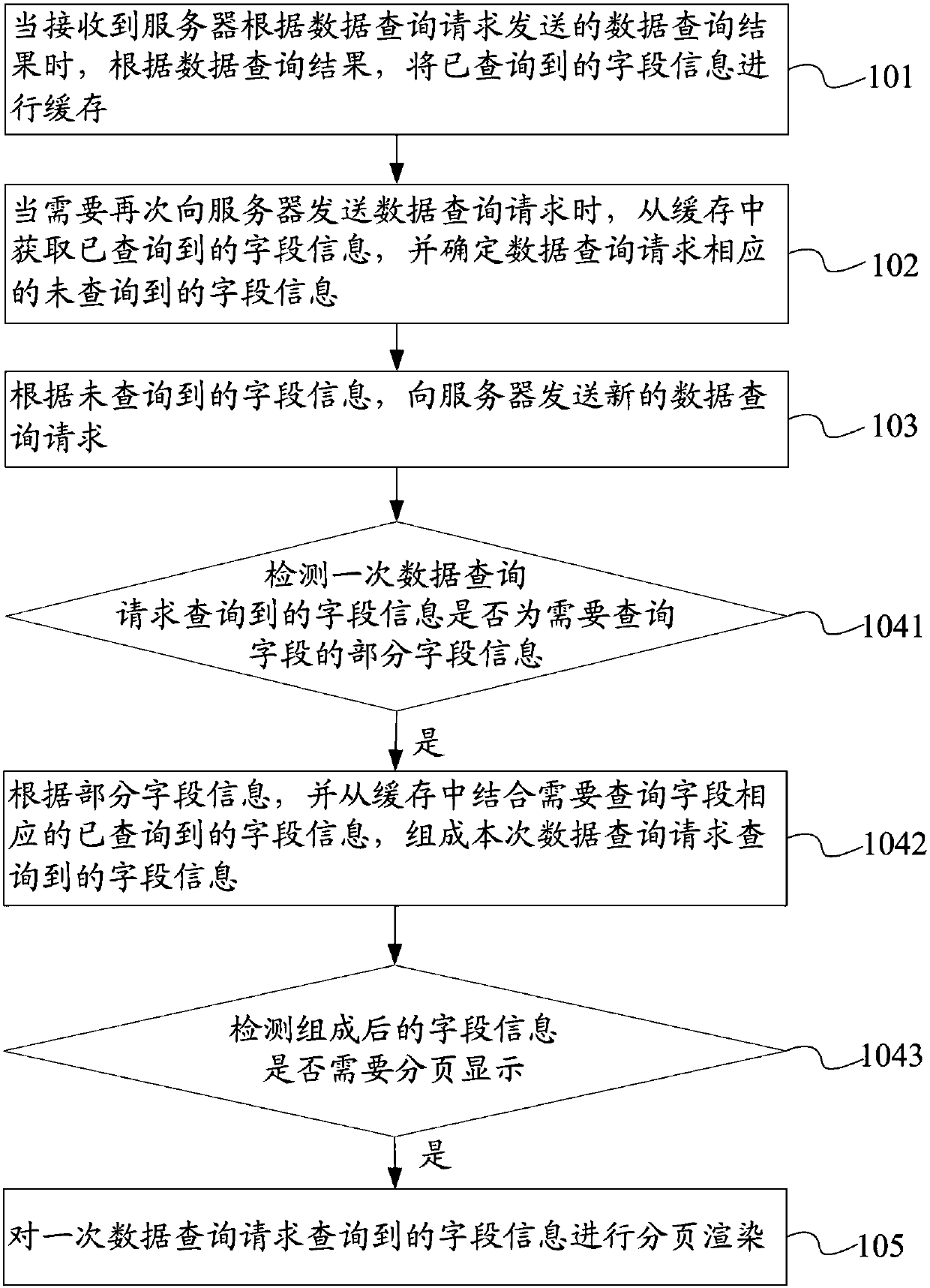

Data query method and device

ActiveCN107590275AReduce query volumeAvoid server crashesSpecial data processing applicationsData query

The invention discloses a data query method and device. The data query method comprises the steps of when receiving a data query result sent by a server according to the data query request and cachinginquired field information according to the data query result; when the data query result needs to be sent to the server again, obtaining the inquired field information from the cache and determiningthe field information which is not inquired corresponding to the data query request; sending a new data query request to the server according to the field information which is not inquired to make the server return a data query result corresponding to the field information which is not inquired. According to the technical scheme, the query amount of the server is reduced, and the situation that the server breaks down since the query amount is too large is effectively avoided.

Owner:北京时之砂科技有限公司

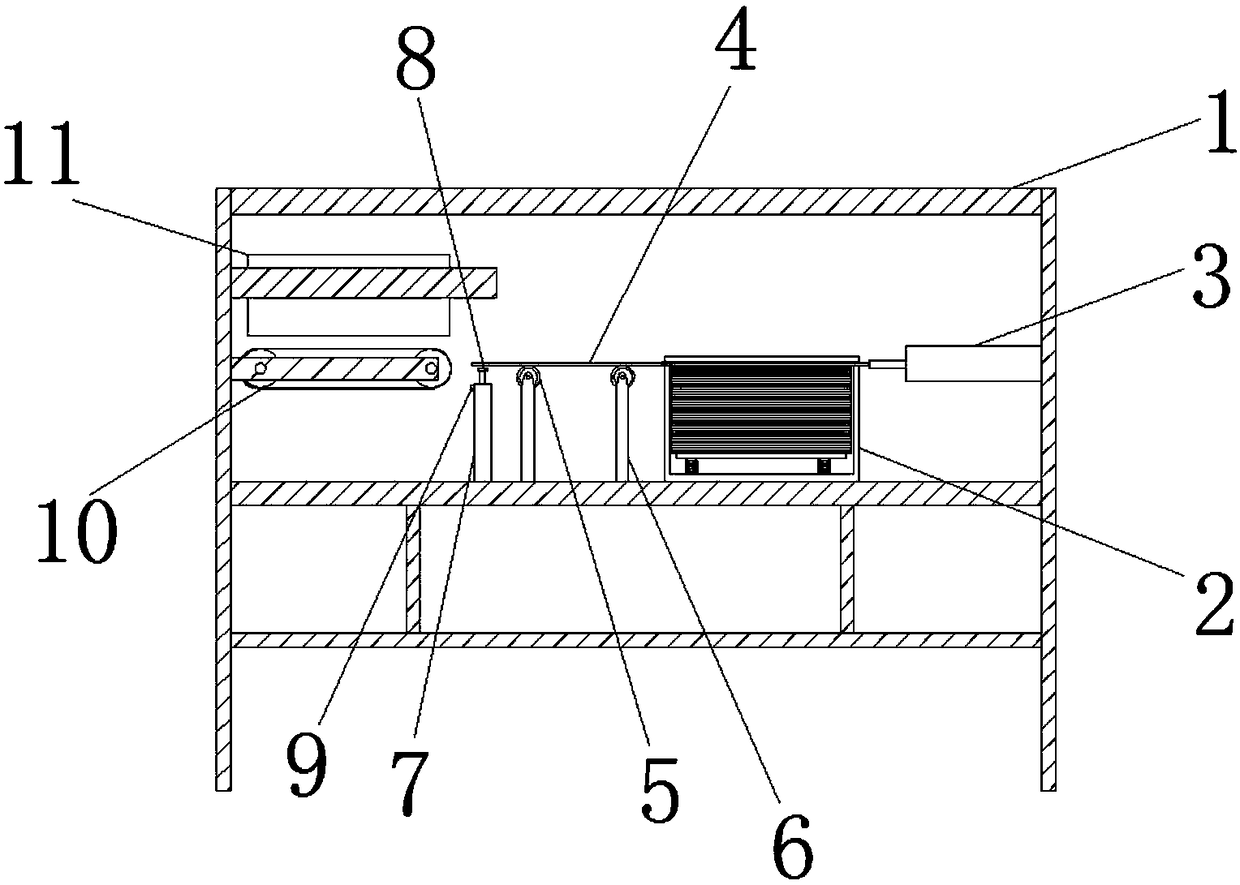

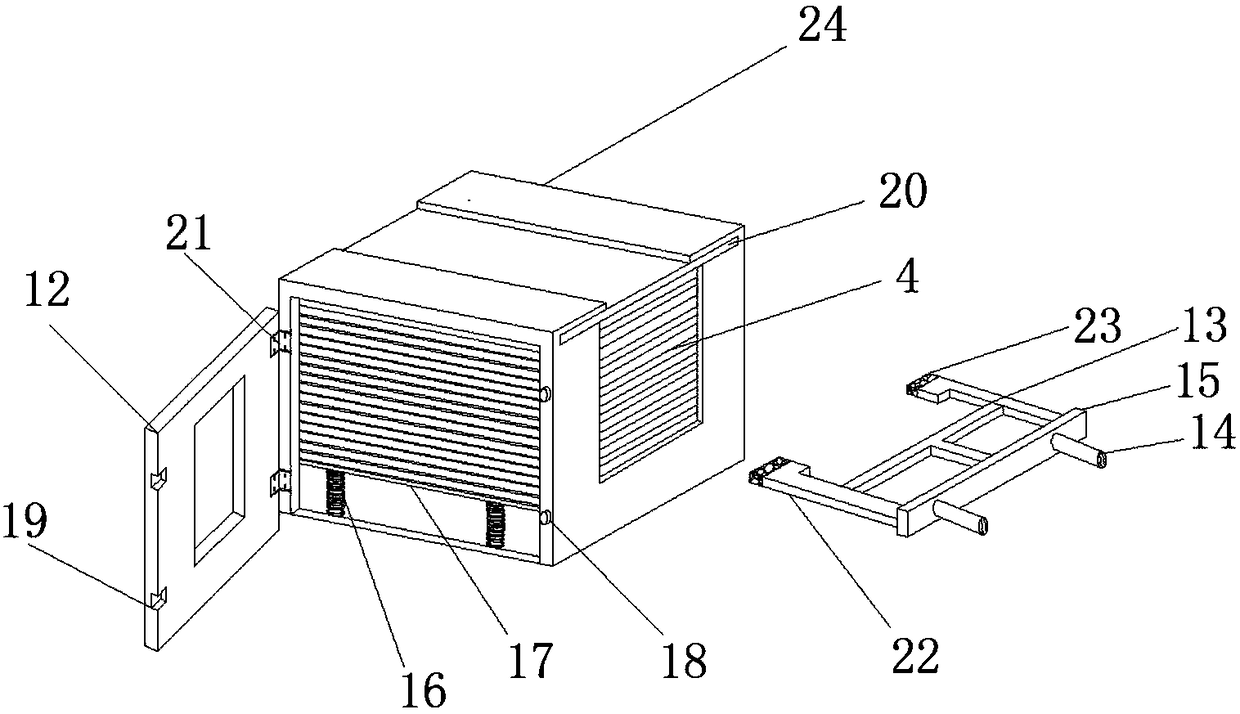

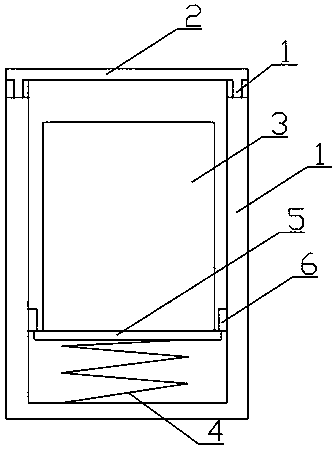

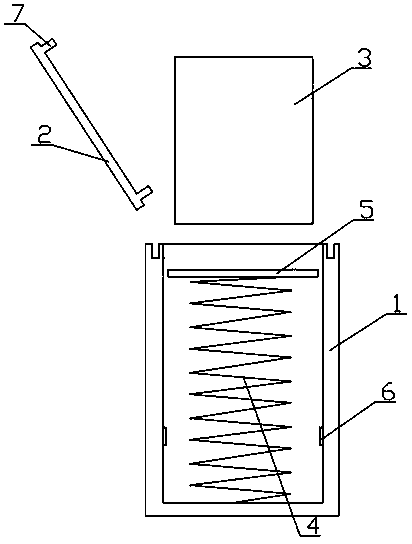

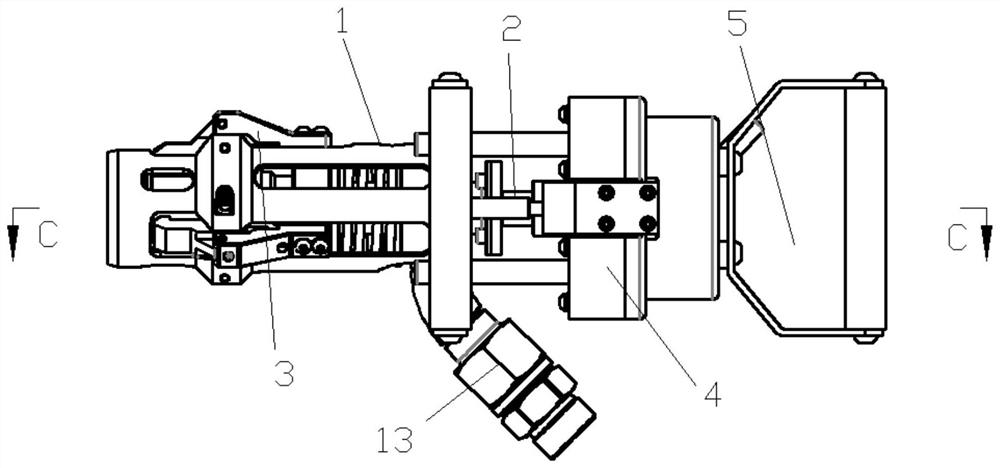

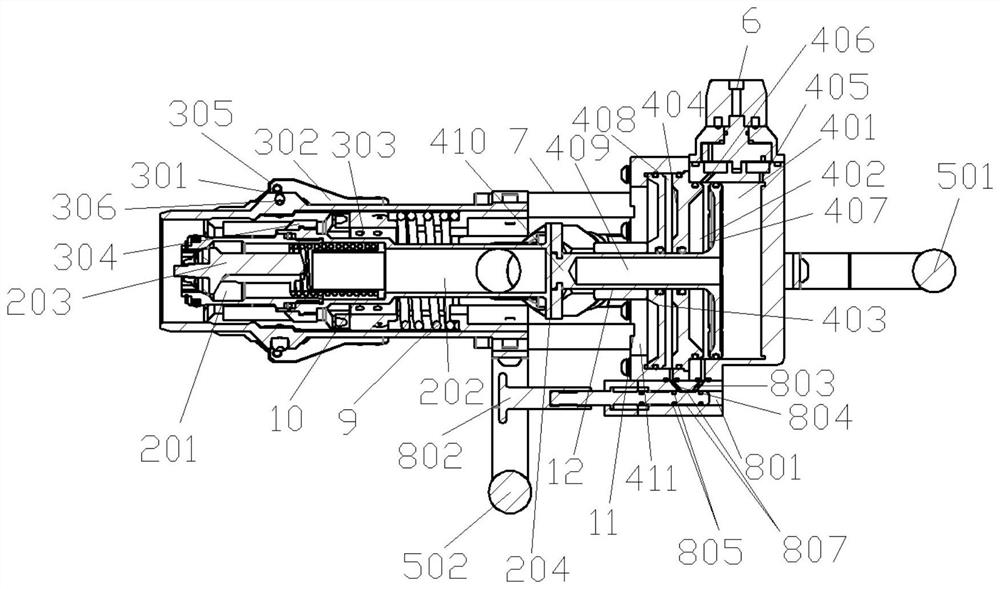

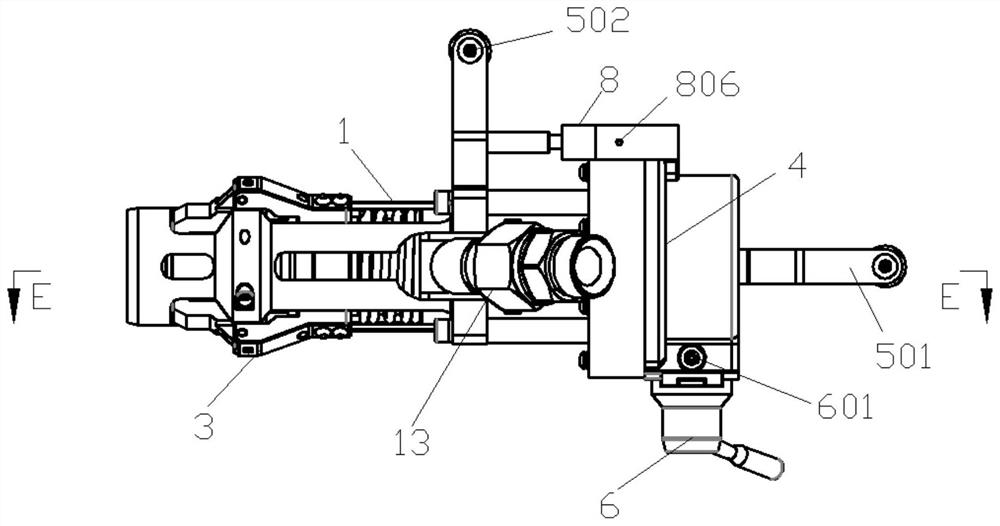

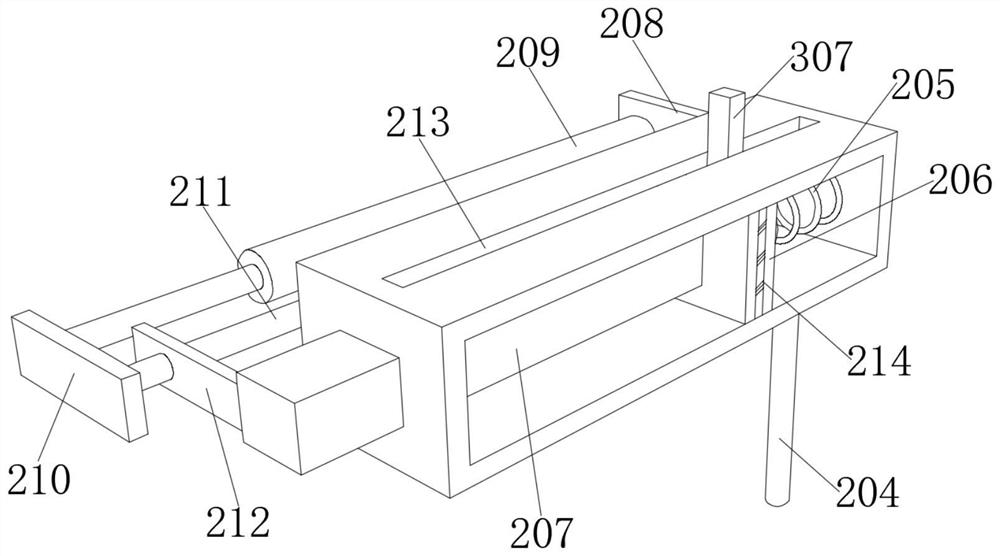

Material taking device for aluminum gusset plate thermal transfer printing machine

InactiveCN108313704ANo adhesionAvoid Crash SituationsControl devices for conveyorsDe-stacking articlesGusset platePush out

The invention discloses a material taking device for an aluminum gusset plate thermal transfer printing machine. The material taking device comprises a frame, the thermal transfer printing device anda material taking device body. The thermal transfer printing device and the material taking device body are correspondingly arranged at the two ends of the frame. A conveying device is arranged underthe thermal transfer printing device. A guide rolling wheel and an ascending rod are sequentially arranged on the portion, from the material taking end to the conveying end and between the conveying device and the material taking device body, of the frame. According to the material taking device for the thermal transfer printing machine, elastic plates in a material pressing frame are used for orderly pressing raw material aluminum plates in the material pressing frame, and then a pushing cylinder is used for pushing a material pushing frame to advance, so that the automatic material taking isrealized, and at the same time, it is guaranteed that the raw material aluminum plates can be completely separated without adhesion; and the raw material aluminum plates pushed out of the material pressing frame are guided and transferred by the guide rolling wheel and then fall on the conveying device to be conveyed to the thermal transfer printing device for thermal transfer printing, and the situation that the raw material aluminum plates and the conveying device are improperly connected and the whole machine crashes can be avoided effectively.

Owner:嘉兴洁阳电子科技有限公司

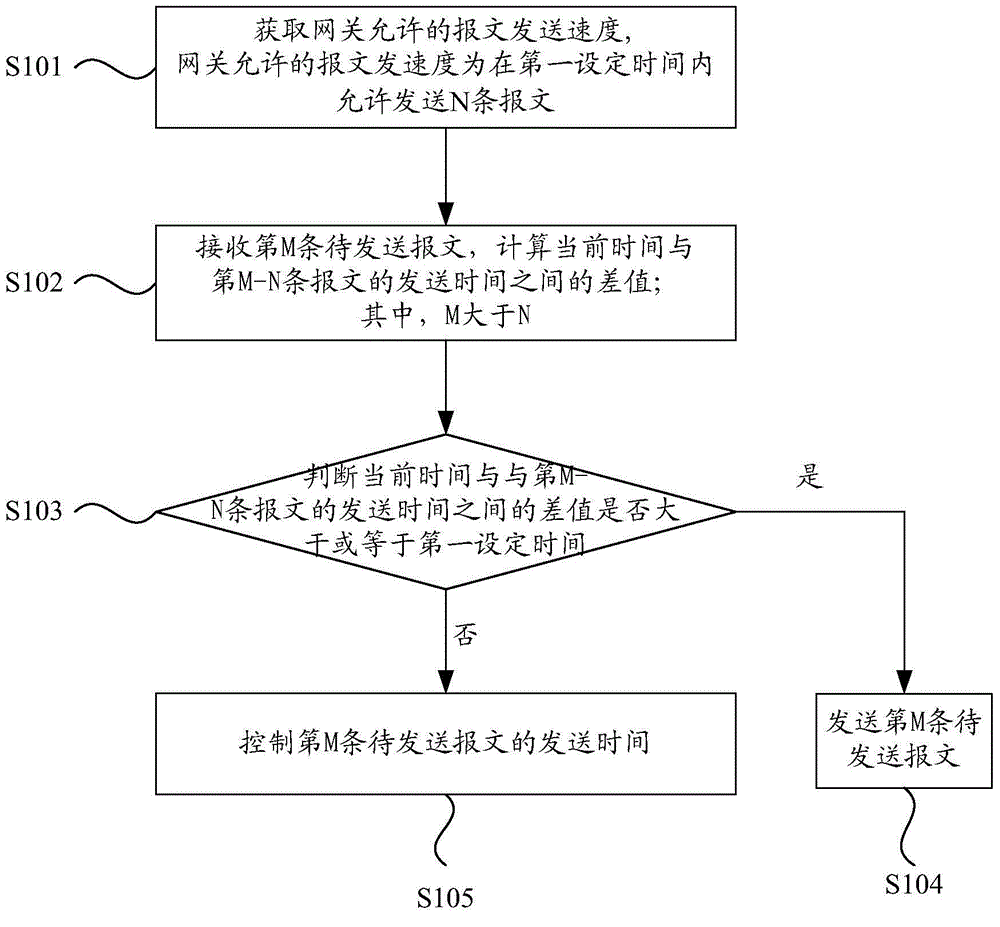

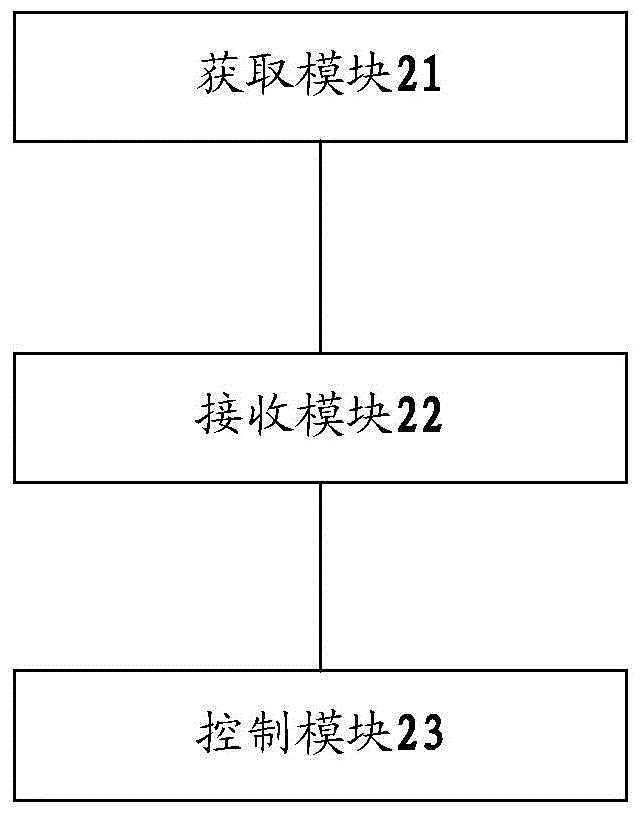

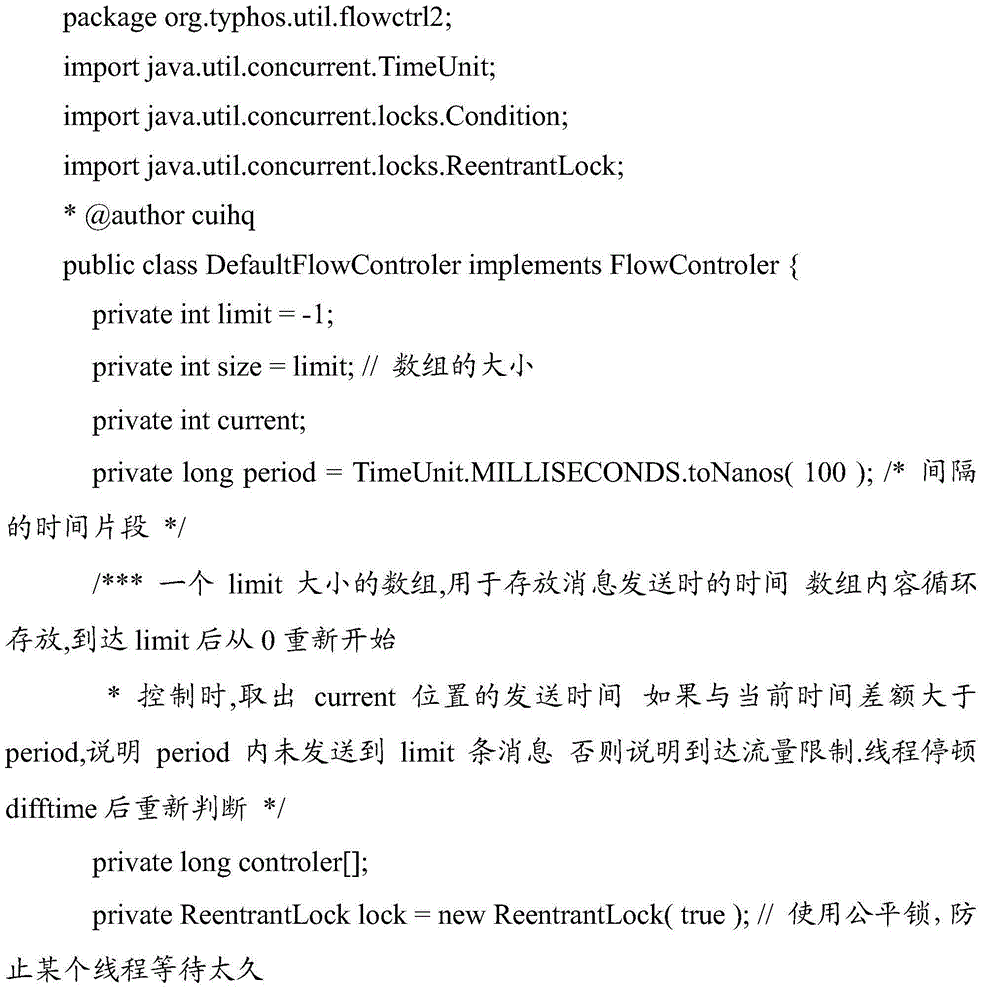

Method for controlling message sending and device for controlling message sending

InactiveCN104917690AControl sending speedSending speed is not overspeedData switching networksMessage passingCurrent time

The invention discloses a method for controlling message sending and a device for controlling the message sending. The method comprises obtaining a message sending speed which is allowed by a gateway and which is N messages allowed to be sent in first set time, receiving an Mth to-be-sent message, calculating a difference value between current time and sending time of an (M-N)th message, and, if the difference value between the current time and the sending time of the (M-N)th message is less than the first set time, controlling sending time of the Mth to-be-sent message. As can be seen, when the difference value is less than the first set time, the sending time of the Mth message is controlled, and then the message sending speed in any time period can be guaranteed to be not overspeed, so, through control of the sending time of the Mth message, the message sending speed in any time period can be controlled to be not overspeed to relieve a pressure of the gateway, and then conditions that a gateway response speed slows down, the message sending fails and the gateway collapses are prevented from occurrence.

Owner:UNION MOBILE PAY

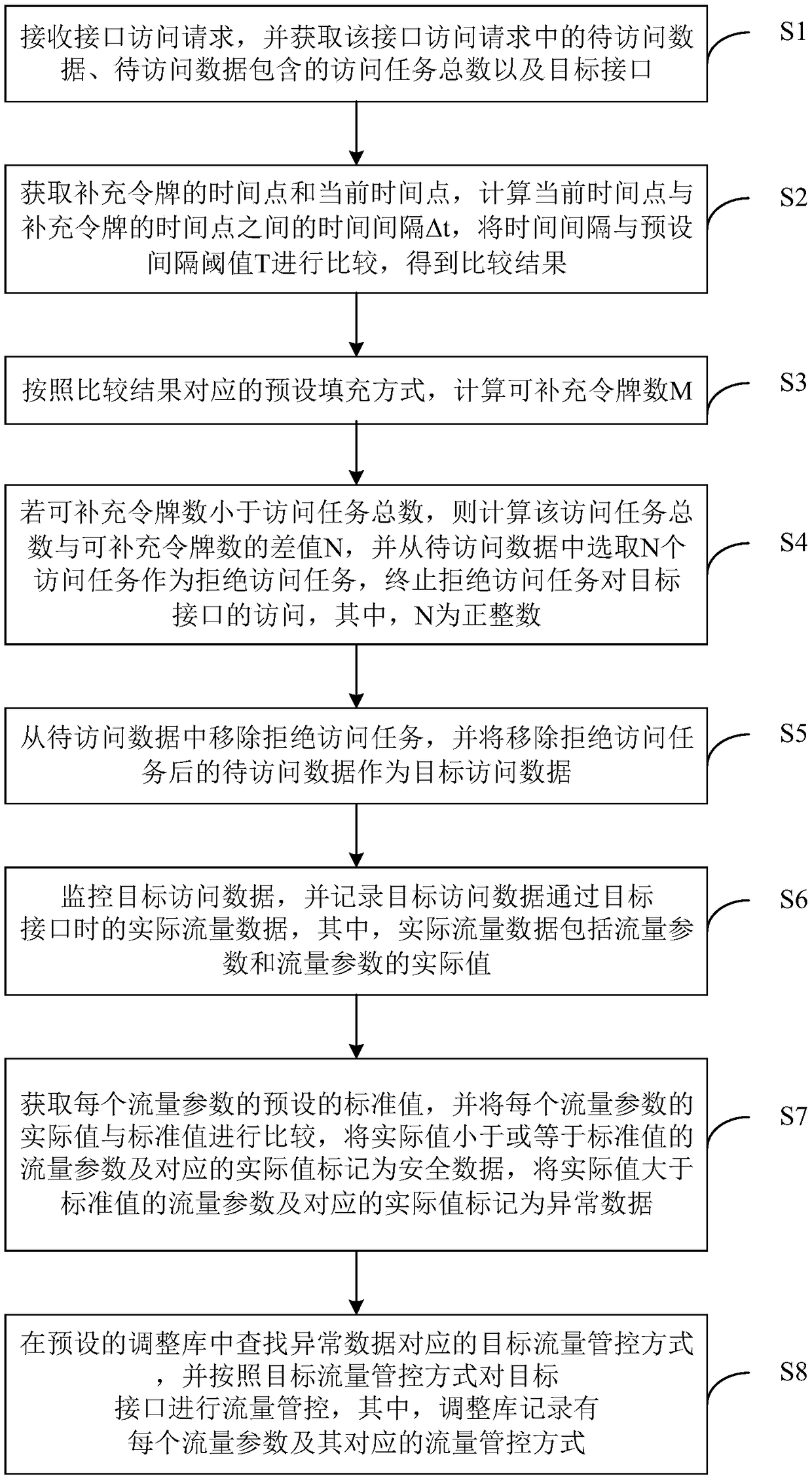

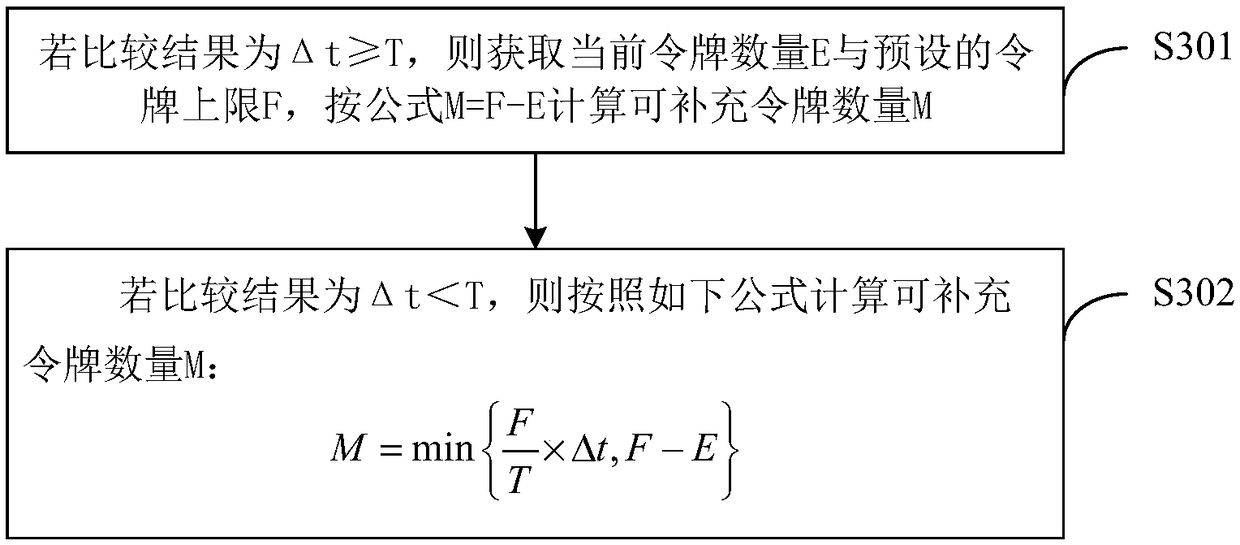

Traffic flow control method, device and equipment, and storage medium

ActiveCN109246026ARelieve stressImprove efficiencyData switching networksMaintainabilityTraffic flow control

The invention relates to the technical field of computers, and provides a traffic flow control method, device and equipment and a storage medium. The method includes the steps: calculating the numberof replenishable tokens through obtaining the to-be-accessed data in an interface access request, the total number of access tasks included in the to-be-accessed data and the target Interface, calculating target access data, monitoring the target access data, and recording the actual traffic data when the target access data passes through the target interface, obtaining a preset standard value ofeach traffic parameter, comparing the actual value of each flow parameter with a standard value, and marking the flow parameter with the actual value being greater than the standard value and the corresponding actual value as abnormal data; searching a target flow control mode corresponding to the abnormal data in a preset adjustment library, and performing the traffic flow control of the target interface in the target flow control mode. The method achieves an improvement in the use efficiency and maintainability of the target interface.

Owner:CHINA PING AN LIFE INSURANCE CO LTD

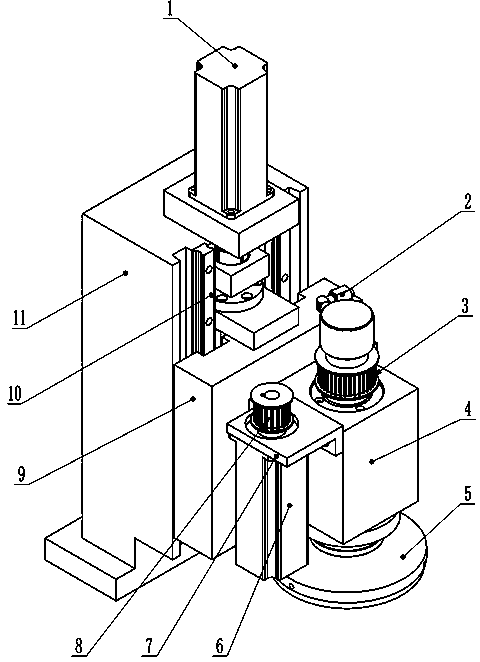

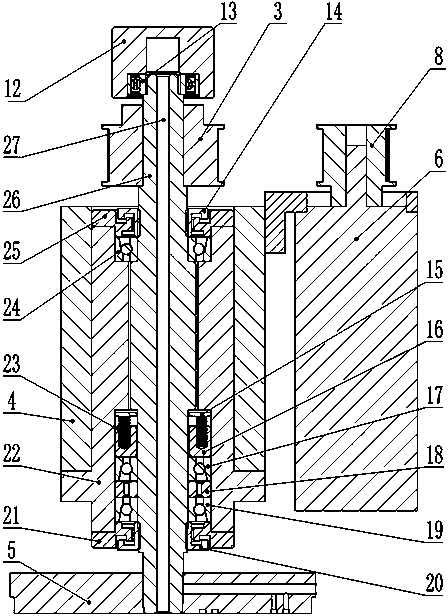

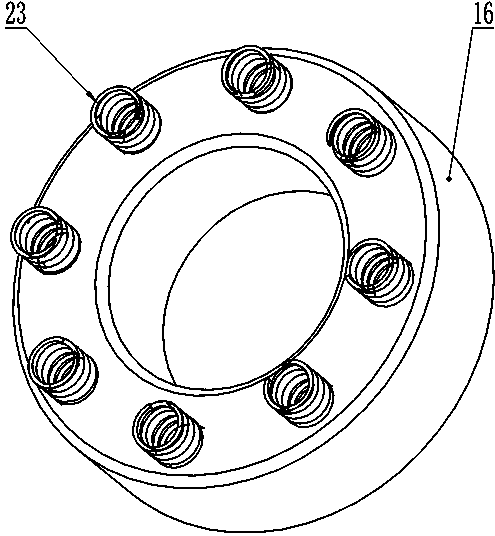

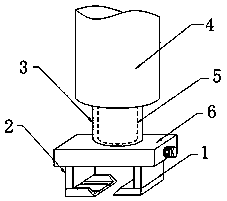

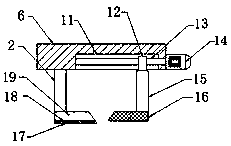

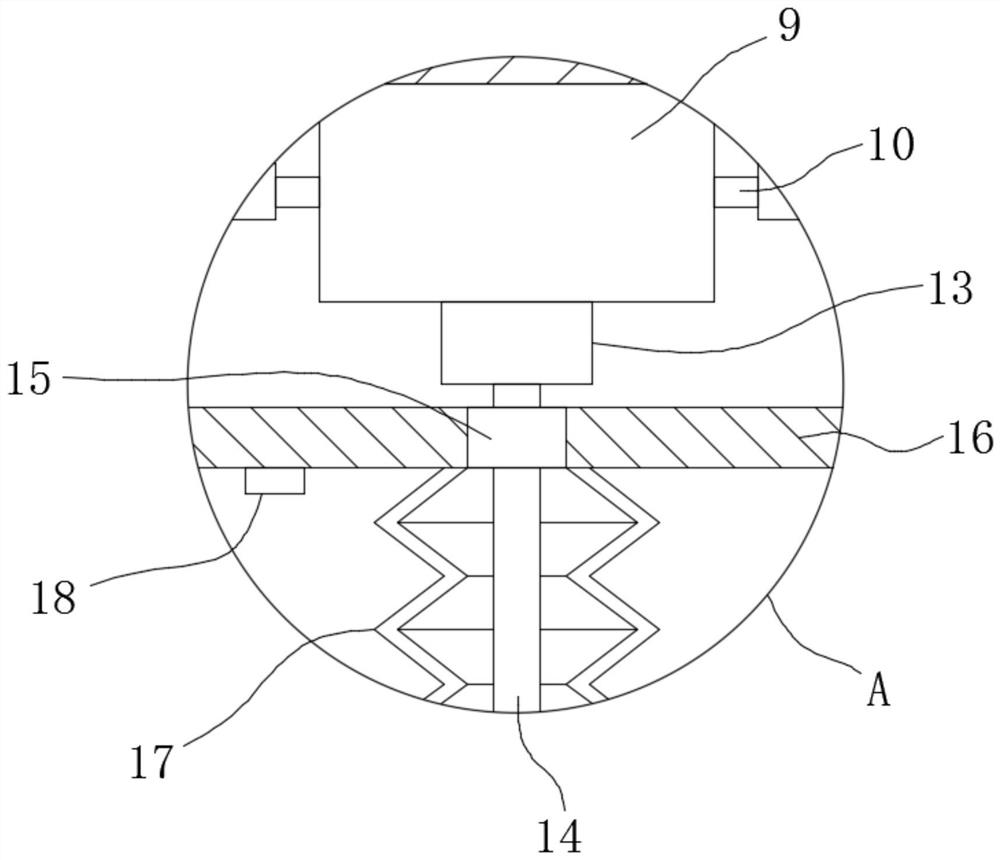

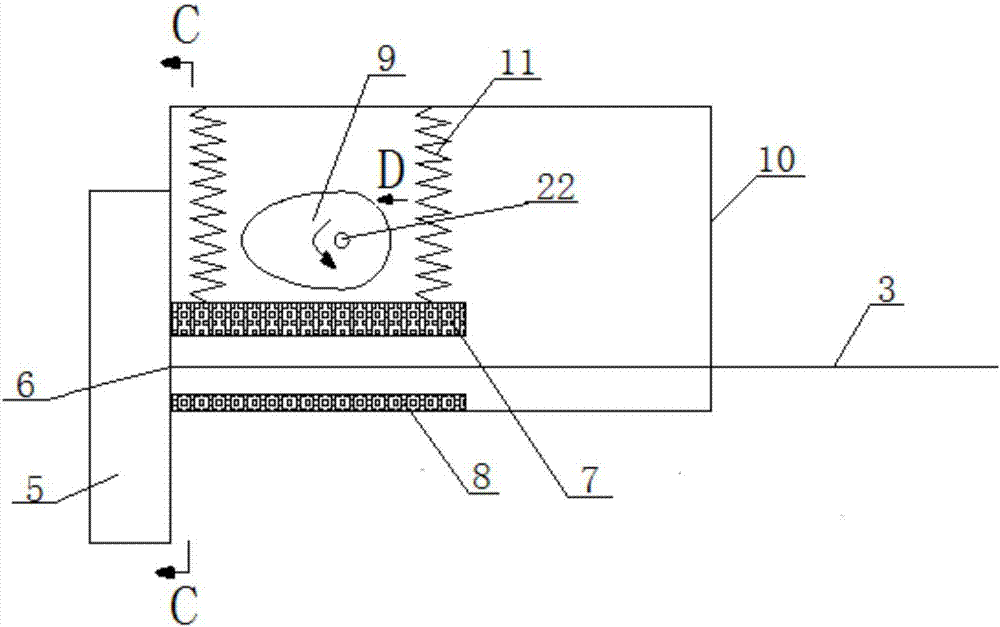

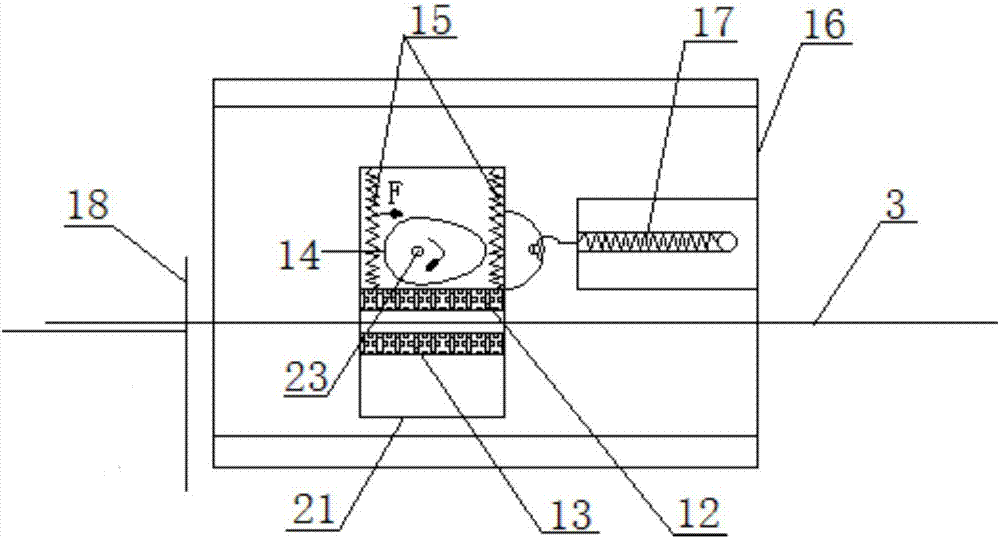

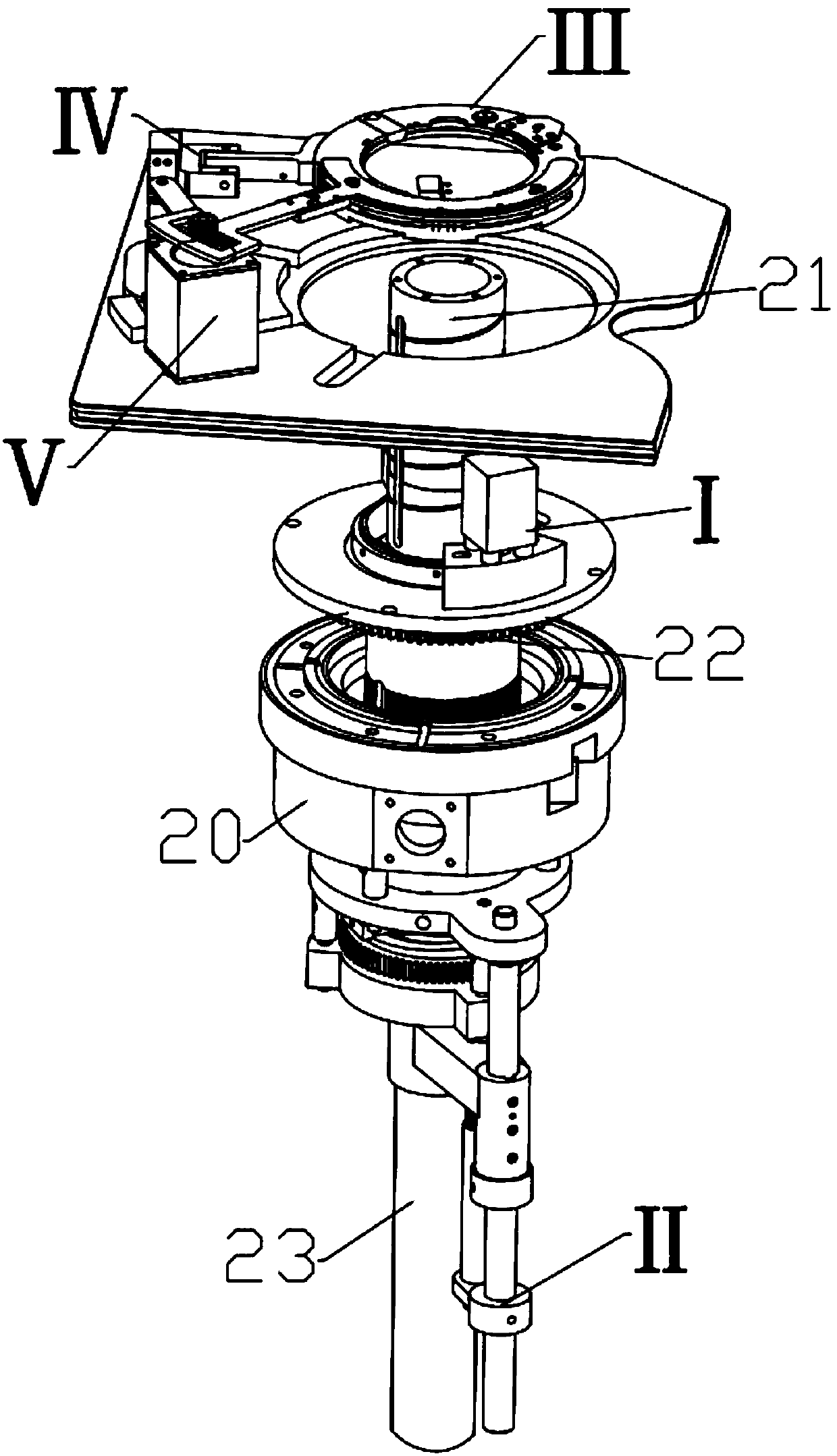

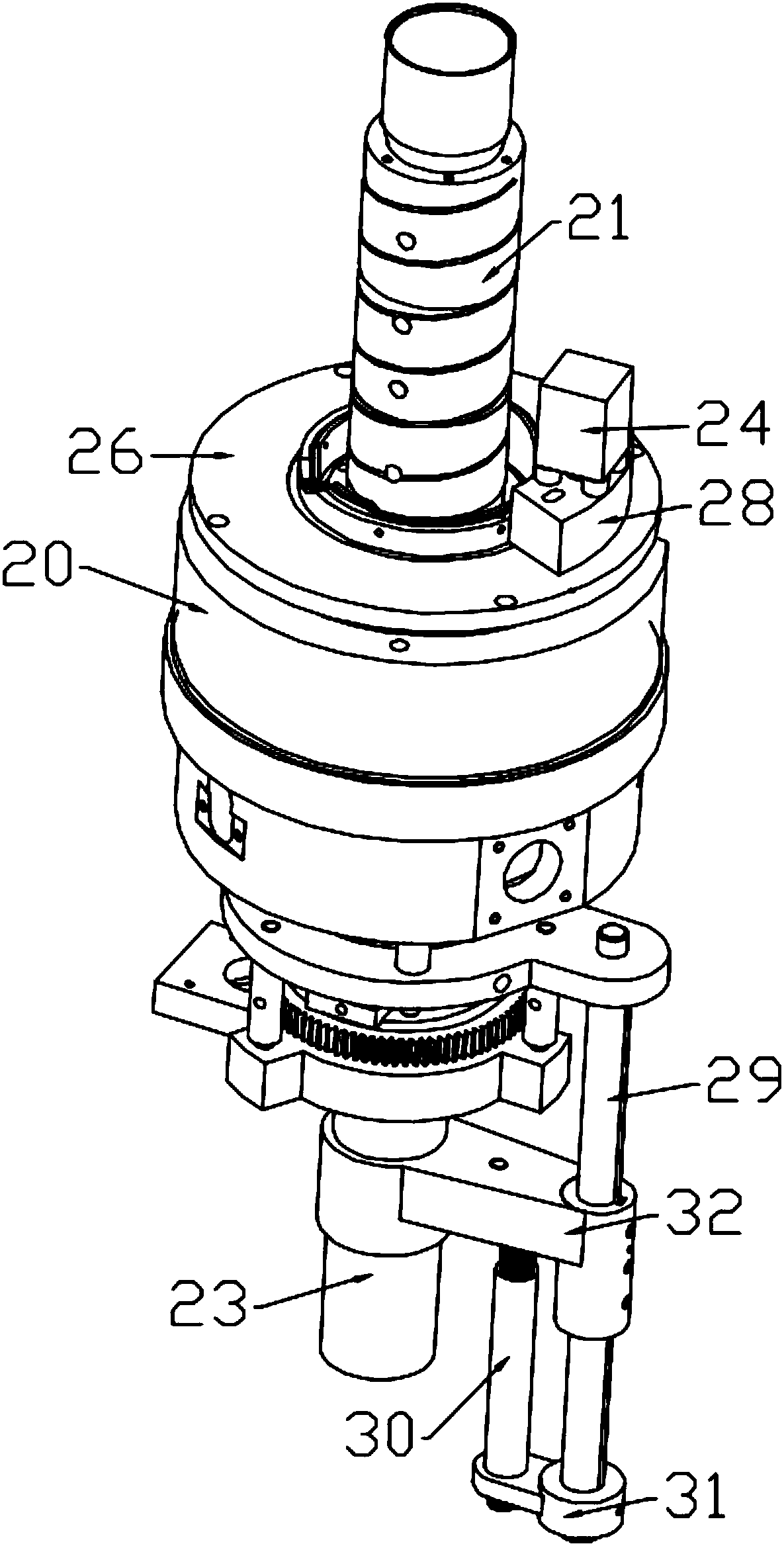

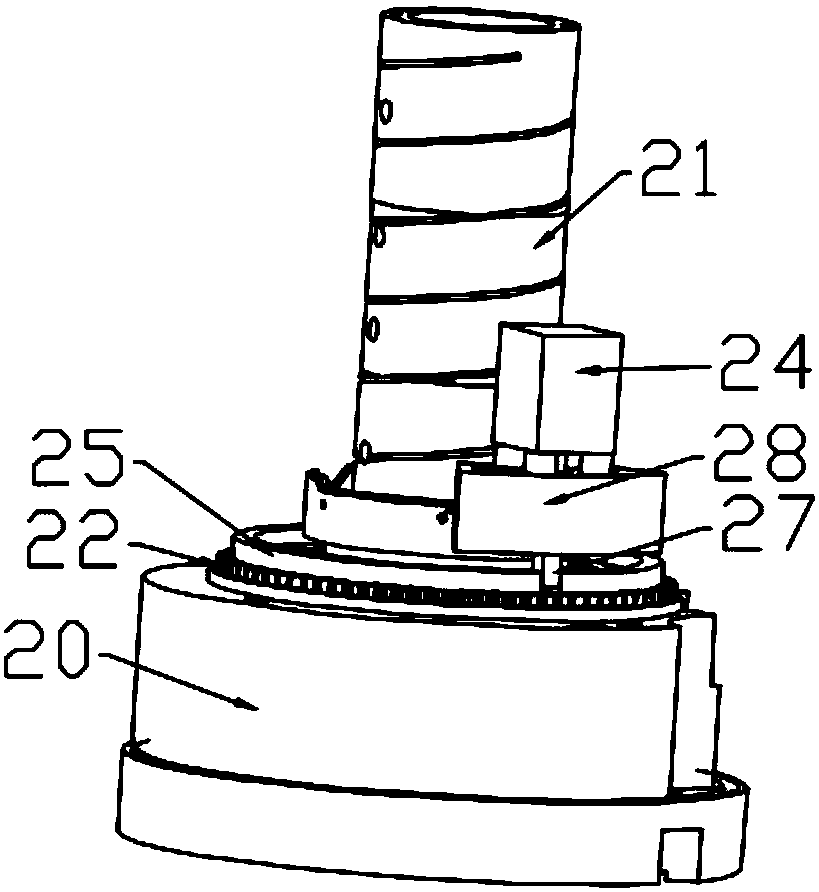

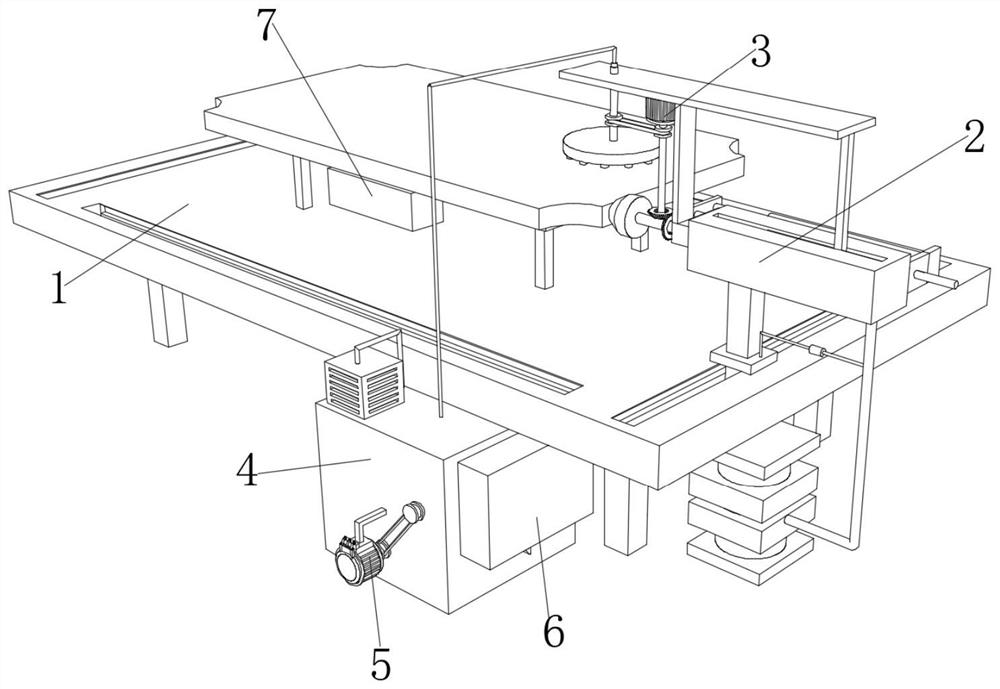

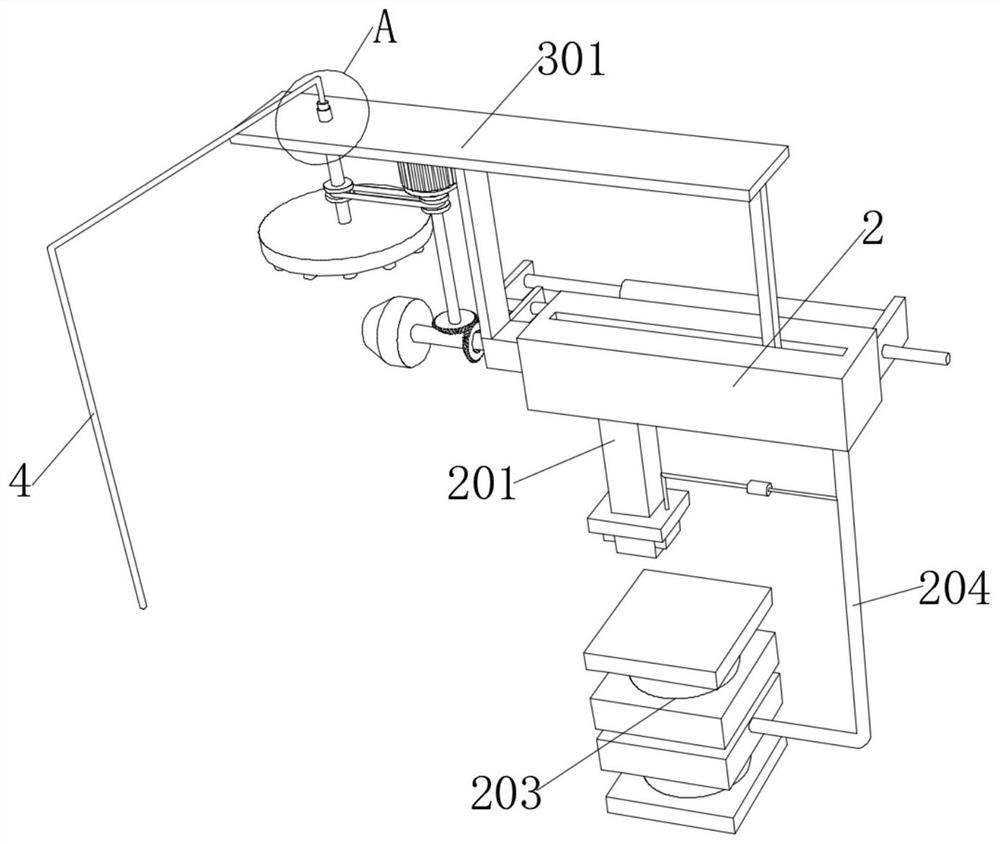

Upper disc structure of high-precision single-sided grinding machine

The invention discloses an upper disc structure of a high-precision single-sided grinding machine. The upper disc structure comprises a framework, a movable platform and a driving device. The movable platform is mounted on the framework, the driving device is mounted on the movable platform, guide rails are mounted on the framework, the movable platform is mounted on the guide rails, is connected with the driving device, moves to drive an upper disc to move and presses a workpiece, a rotation movement driving motor for driving the upper disc to rotate is fixed onto a base, the base is mounted on the movable platform, a driving belt pulley which is mounted on an output shaft of the rotation movement driving motor is connected with a driven belt pulley by a synchronous belt, the driven belt pulley is mounted on a spindle, the upper disc is mounted at an end of the spindle, the rotation movement driving motor drives the upper disc to rotate via a belt transmission mechanism, sucker structures which are used for fixing the workpiece are arranged on the lower end surface of the upper disc and are connected with a vacuum generator by a vacuum channel arranged on the spindle, and a rotary encoder which controls the rotational speed of the upper disc is arranged on the spindle. The upper disc structure has the advantages of stability in pressing, zero pollution to grinding environments and convenience in workpiece replacement.

Owner:GUANGDONG UNIV OF TECH

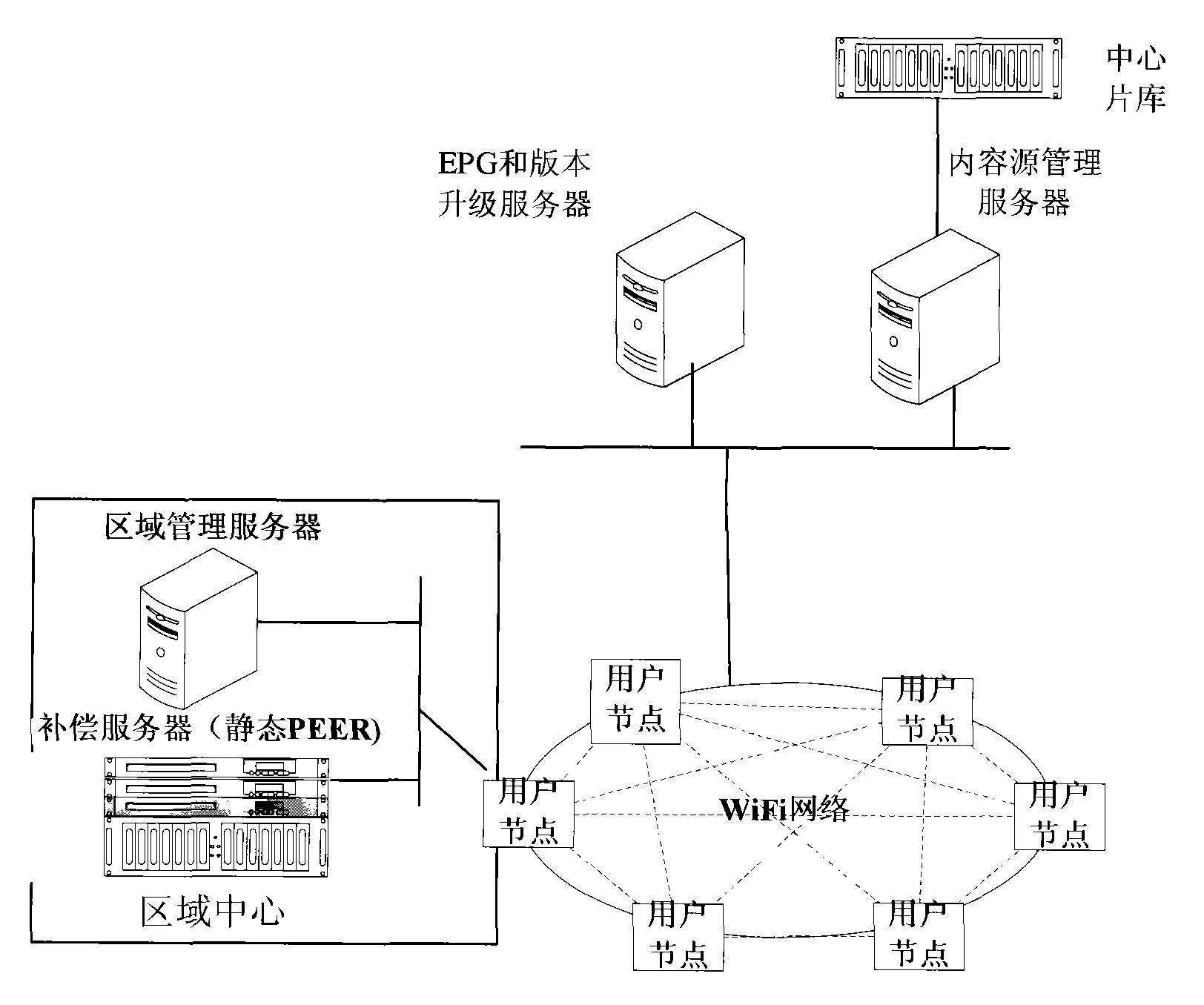

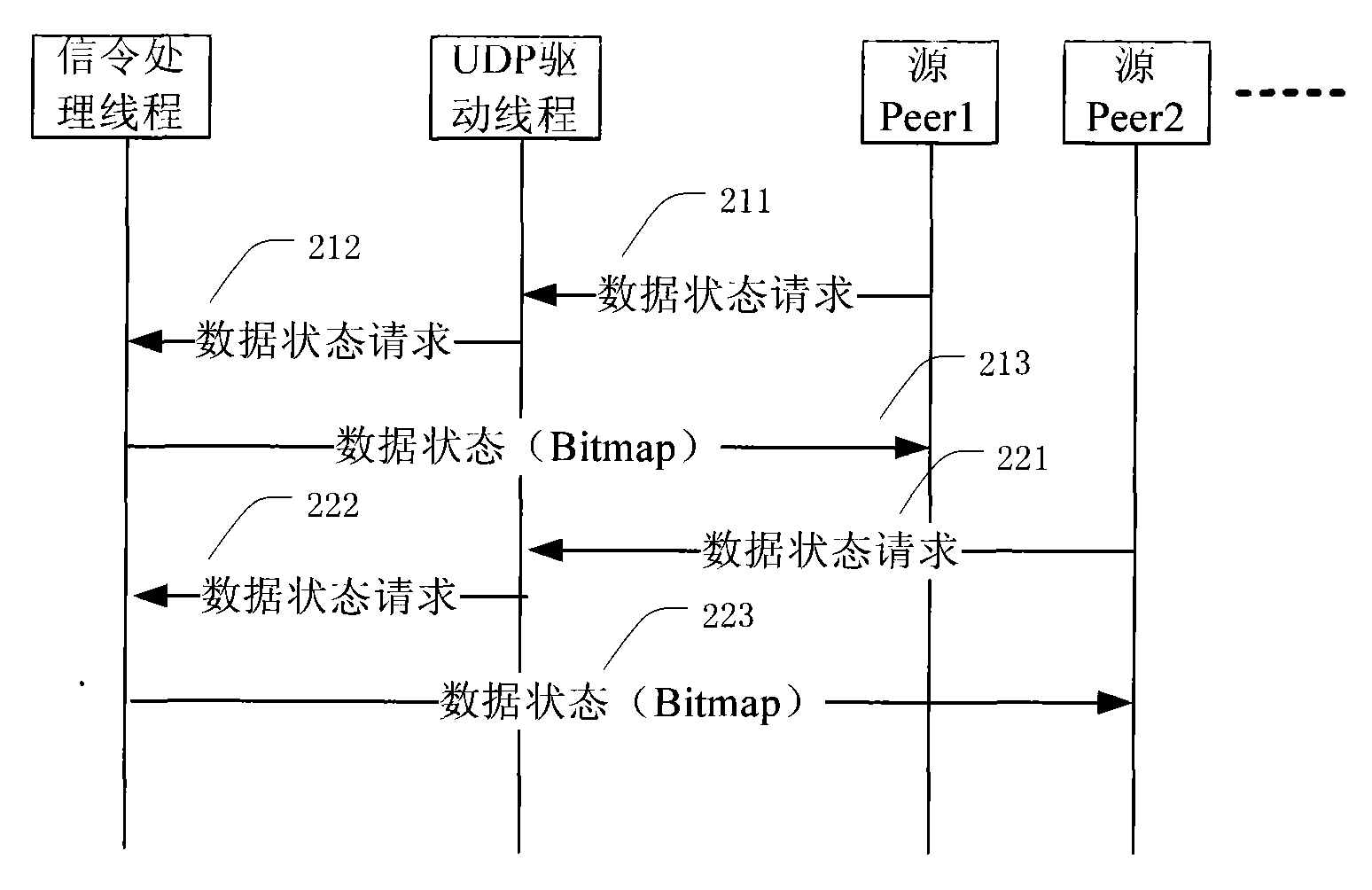

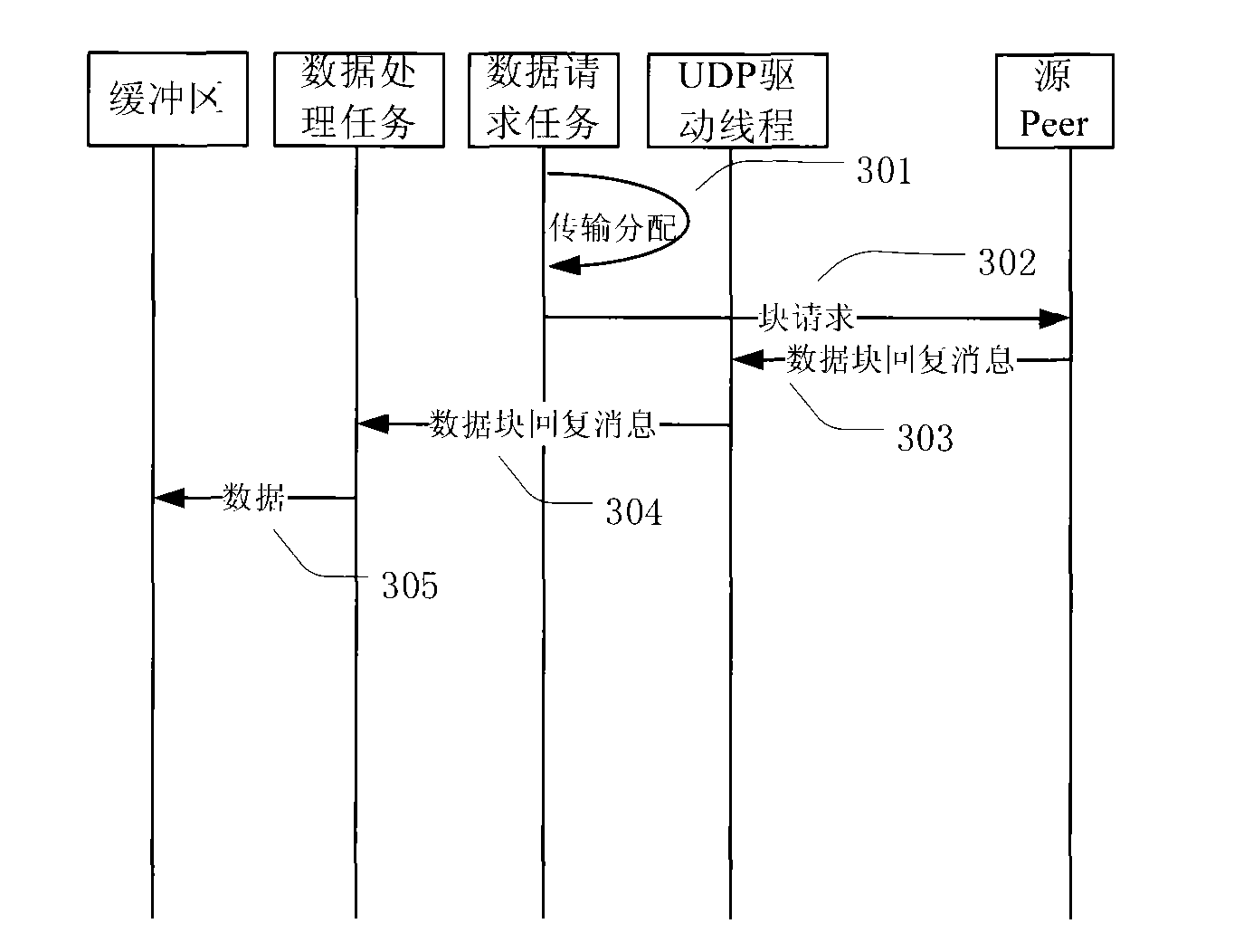

Transmission method and player for point-to-point mobile streaming media

InactiveCN101562530ASolve congestionSolving Interaction ProblemsSpecial service provision for substationReliable transmissionNetwork conditions

The invention relates to a transmission method and a player for a point-to-point mobile streaming media, which support a streaming media player to share and dispense the contents organized by an operator in a mobile communication network and comprise the following steps of: sending a fragment request periodically according to the requirement of playing the streaming media information, recording the time emitted by the fragment request and adding the time to a request list, receiving the response of the fragment request, deleting the fragment request that receives response from the request list, judging whether the fragment requests in the request list is overtime according to the time emitted by every fragment request periodically by an arranged timer; if not, turning to the step (1) and if so, deleting the overtime fragment request from the request list and re-dispensing a request and turning the step (2). The invention realizes the reliable transmission of the UDP by the improved upper layer application, and overcomes the defects that the UDP of the existing P2P transmits a large amount of residual messages and corresponding adjustment can not be carried out according to the fluctuation of the network condition.

Owner:聂明辉 +4

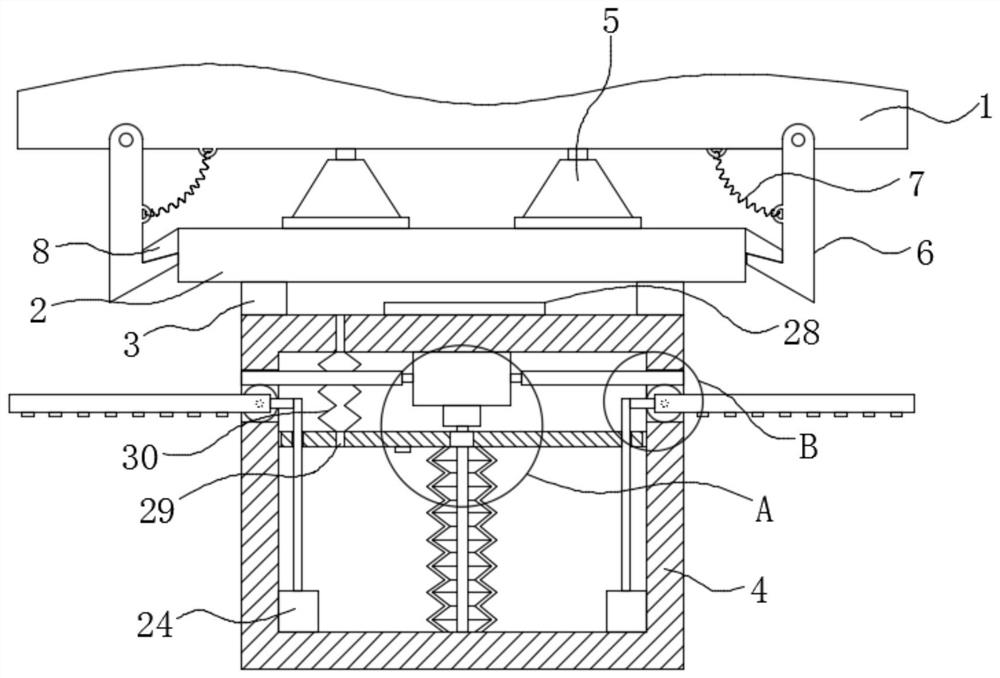

Rotatable simple industrial mechanical hand

InactiveCN107696057ARealize the function of anti-fallAvoid crash situationsGripping headsBall screwEngineering

The invention provides a rotatable simple industrial mechanical hand which comprises a ball screw, a moving clamping plate, a supporting block, an auxiliary bearing table, a guiding groove, a guide-incavity, a transparent protection sleeve, a guide wheel and an annular sliding groove. The ball screw is assembled to the middle position of the interior of the groove. The moving clamping plate is installed on the lower end face of a nut seat. The supporting block is fixed to the lower end face of the moving clamping plate. The auxiliary bearing table is installed on the lower end face of a fixedclamping plate. The guiding groove is formed in the lower end face of the interior of the guide-in cavity. The guide-in cavity is formed in the middle position of the auxiliary bearing table. By means of the design, the anti-falling function of goods clamping is achieved, the transparent protection sleeve is arranged on the annular side face of a rotating shaft in a sleeving manner, the guide wheel is installed on the upper end face of the transparent protection sleeve, and the annular sliding groove is formed in the lower end of a mechanical arm. By means of the design, the protection function of the rotating shaft is achieved, the service life of the rotating shaft is prolonged, and the rotatable simple industrial mechanical hand is reasonable in structure, good in protection performance, long in service life, good in stability and high in reliability.

Owner:董杰

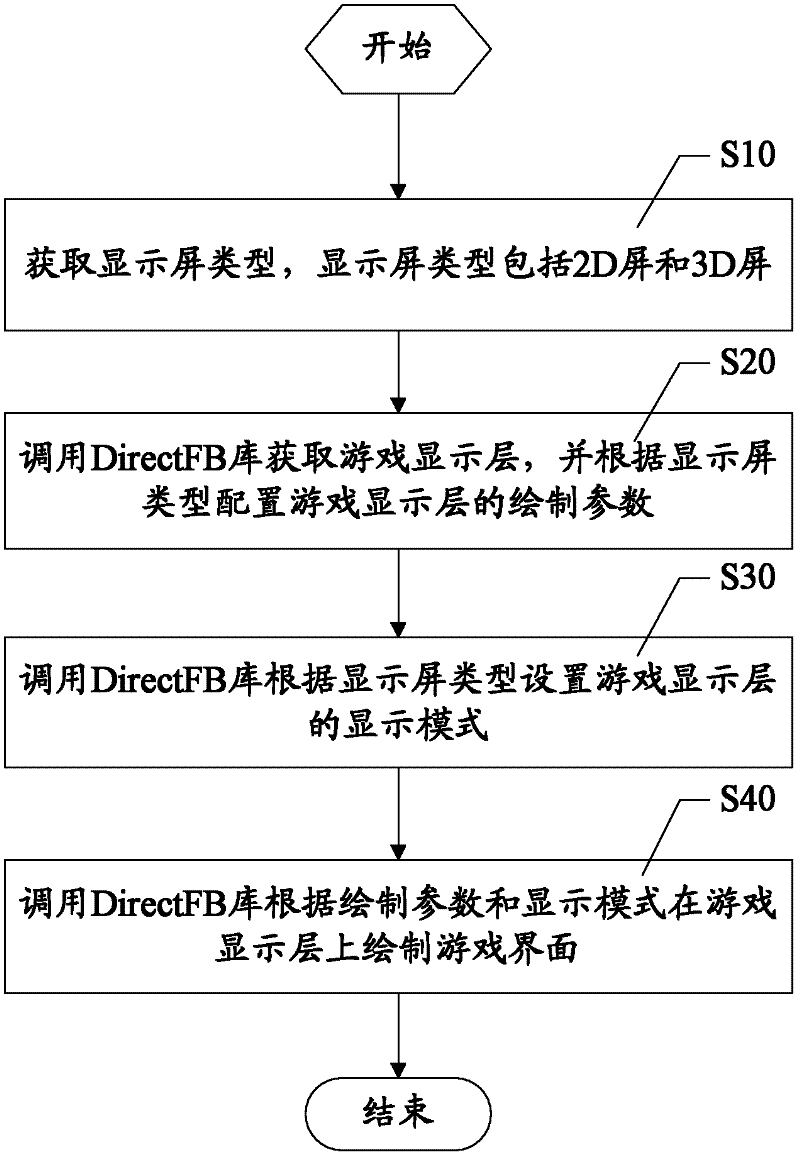

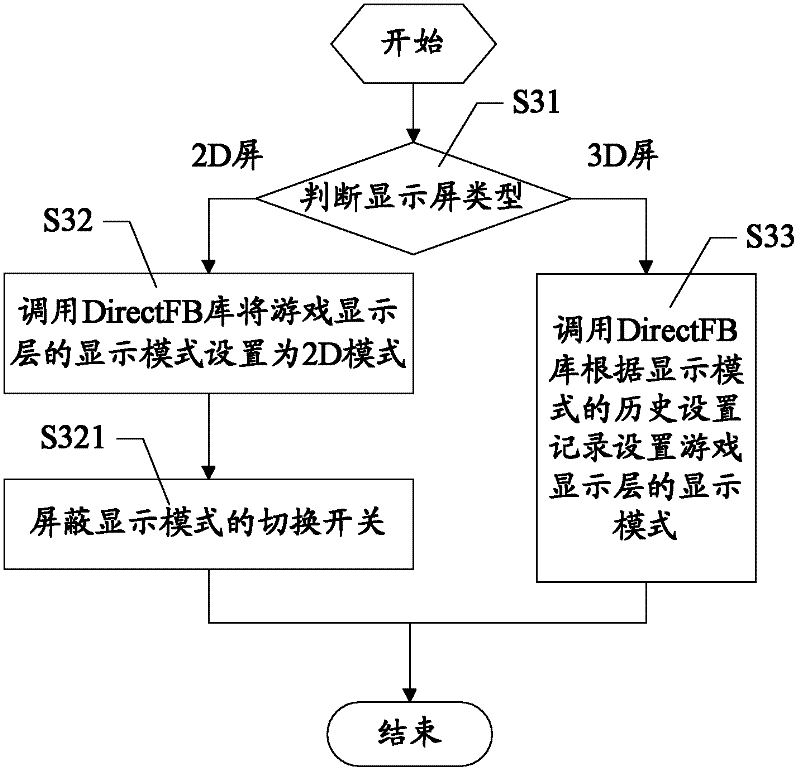

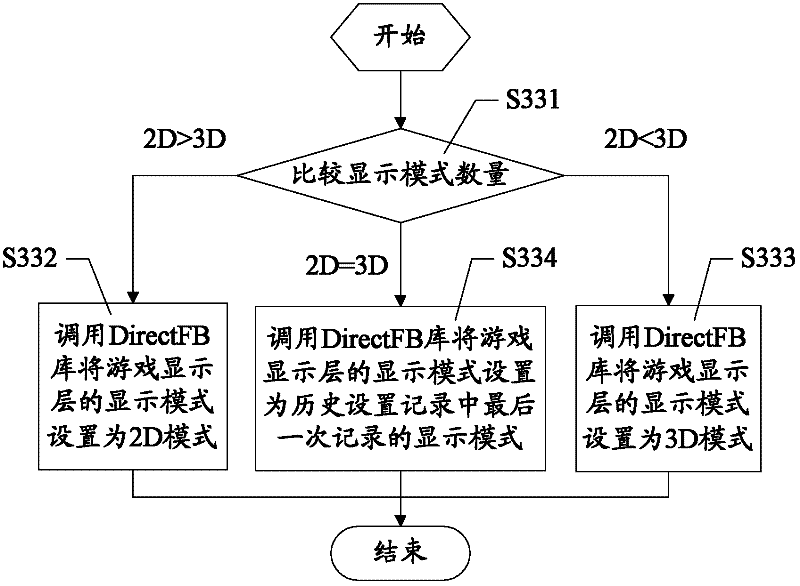

Method and device for adaptively switching game display modes

ActiveCN102611902AAvoid game not working or TV system crashingImprove user experienceVideo gamesSteroscopic systemsSelf adaptiveAdaptive switching

The invention discloses a method and a device for adaptively switching game display modes. The method comprises the steps of: obtaining a display screen type, wherein the display screen type includes 2D (2-Dimensional) screen and 3D (3-Dimensional) screen; invoking DirectFB library to obtain a game display layer, and configuring the drawing parameters of the game display layer according to the display screen type; invoking the DirectFB library and setting the display mode of the game display layer according to the display screen type; and invoking the DirectFB library and then drawing a game interface on the game display layer according to the drawing parameters and the display mode. The method comprises automatically setting the display mode of the display layer according to the display screen type, thereby avoiding the case that the game cannot be run or the television system crashes because the 2D screen does not supports the 3D game; and the display mode is set according to the use habits of users to meet the habits and hobby requirements of different users; therefore, the experiences of the users are enhanced.

Owner:SHENZHEN COOCAA NETWORK TECH CO LTD

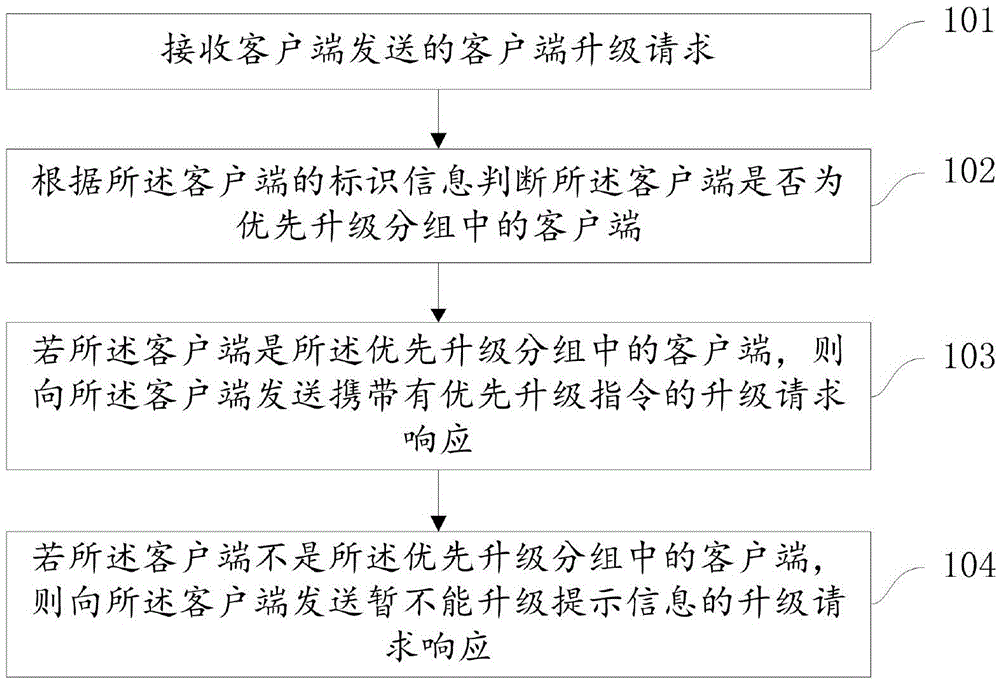

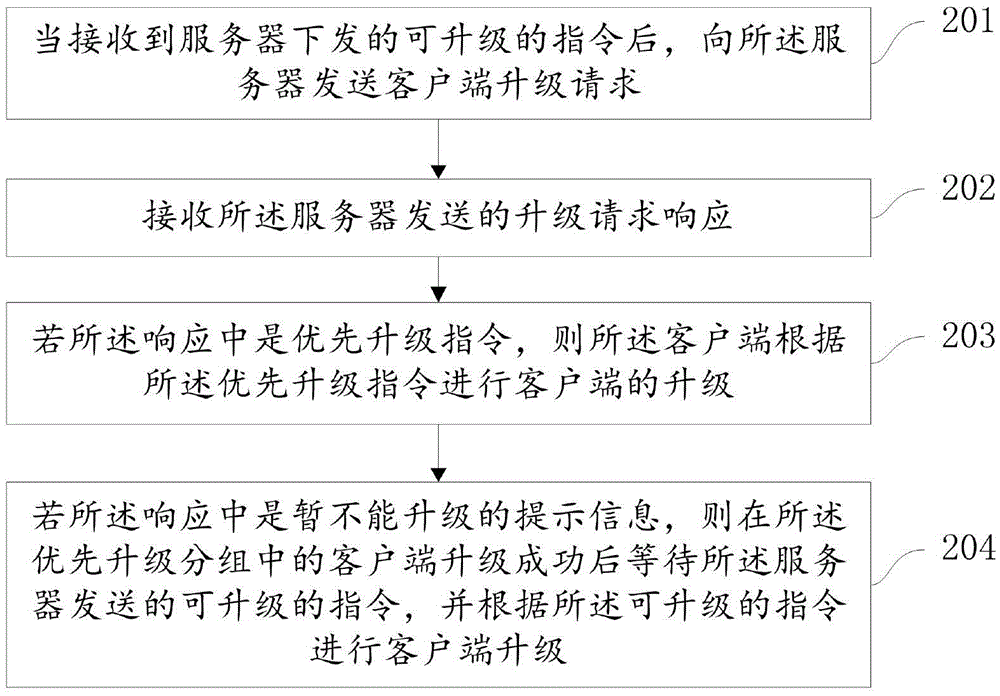

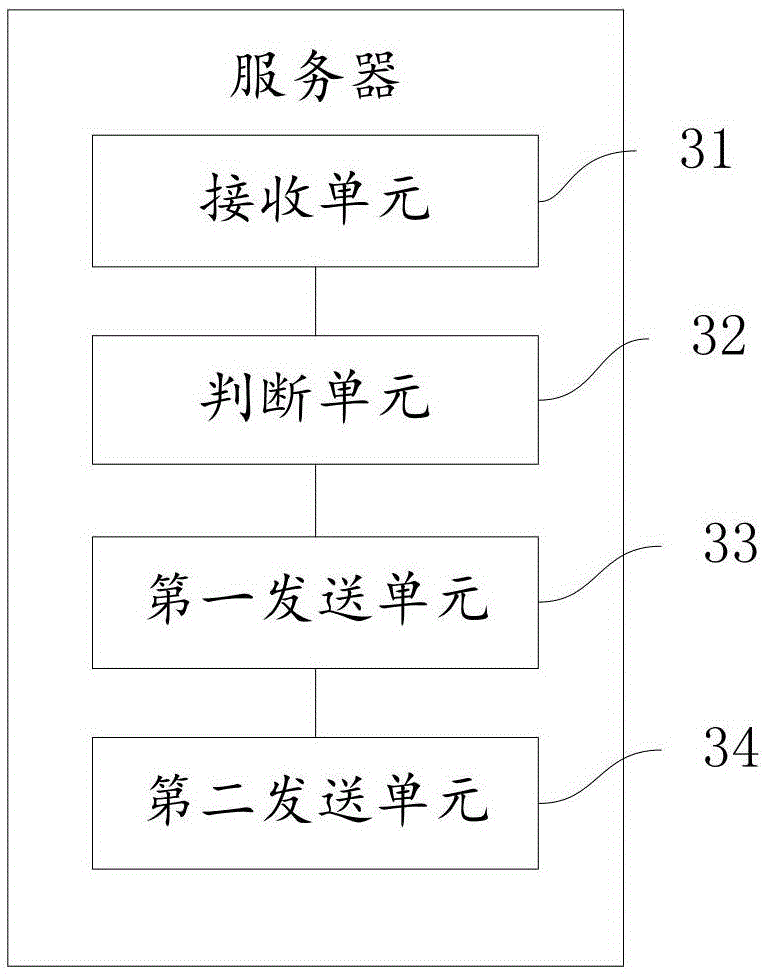

Software upgrade method, device and system

InactiveCN105653318AImprove reliabilityImprove stabilityProgram loading/initiatingDependabilityClient-side

The invention discloses a software upgrade method, device and system, relates to the technical field of computers, can solve the problem that client side software is not compatible after software is upgraded, and improves software upgrade reliability and stability. The method comprises the following steps: receiving a client side upgrade request sent from a client side, wherein the client side upgrade request carries the identification information of the client side; according to the identification information of the client side, judging whether the client side is the client side in a priority upgrade group or not; if the client side is the client side in the priority upgrade group, sending upgrade request response which carries a priority upgrade instruction to the client side; and if the client side is not the client side in the priority upgrade group, sending the upgrade request response that prompt information can not be upgraded temporarily to the client side, and sending an instruction that upgrade can be carried out to the client side after the client side in the priority upgrade group succeeds in being upgraded. The method is mainly used for software upgrade.

Owner:BEIJING QIHOO TECH CO LTD +1

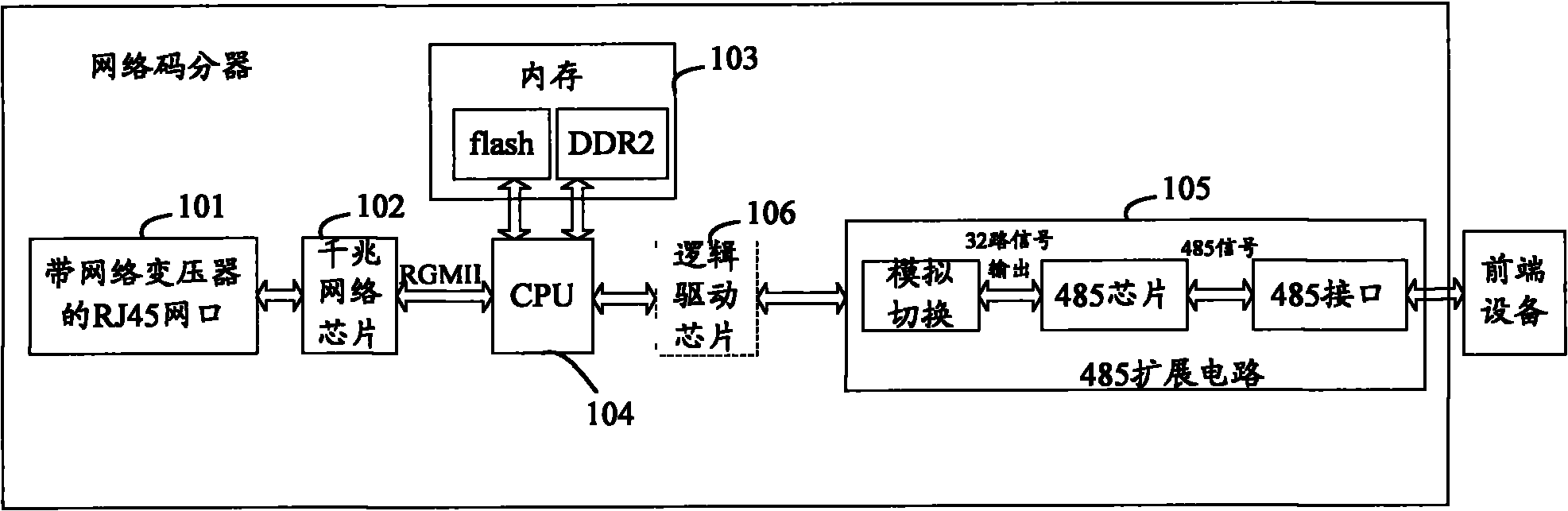

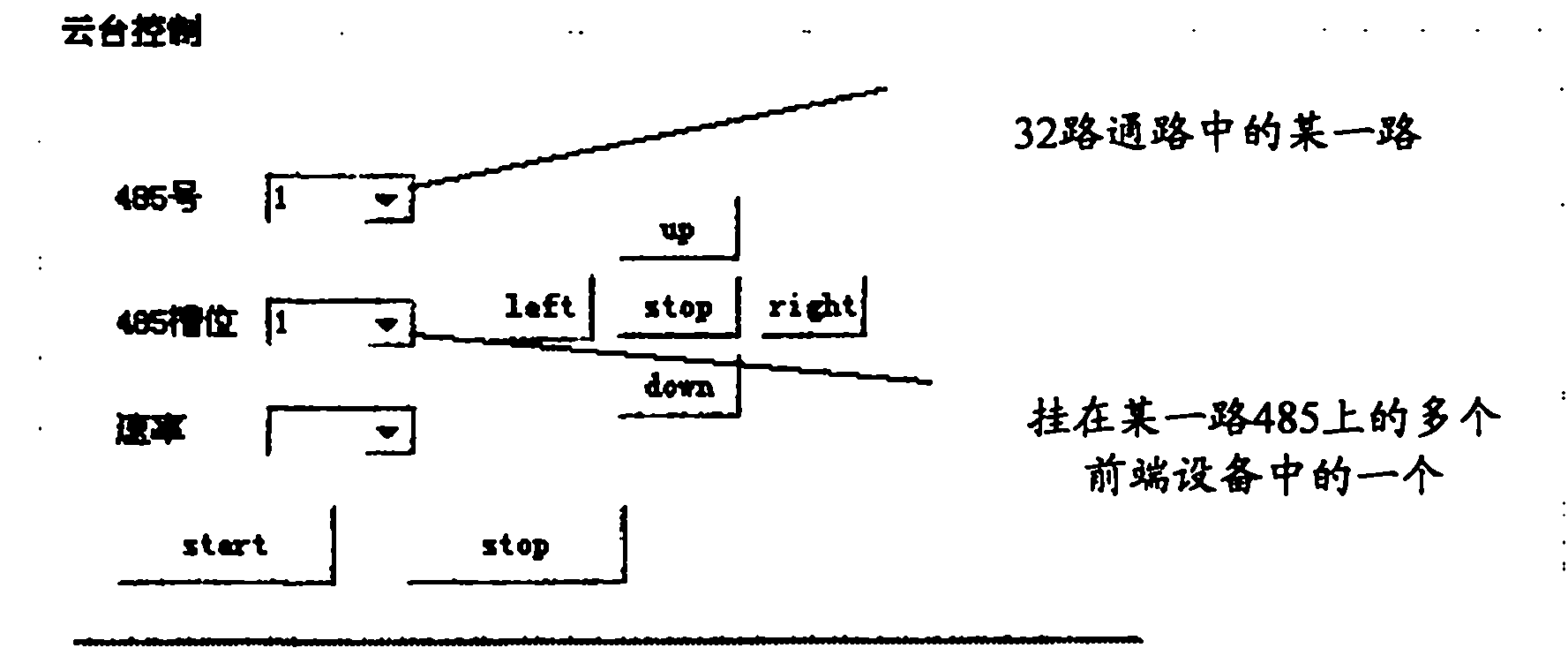

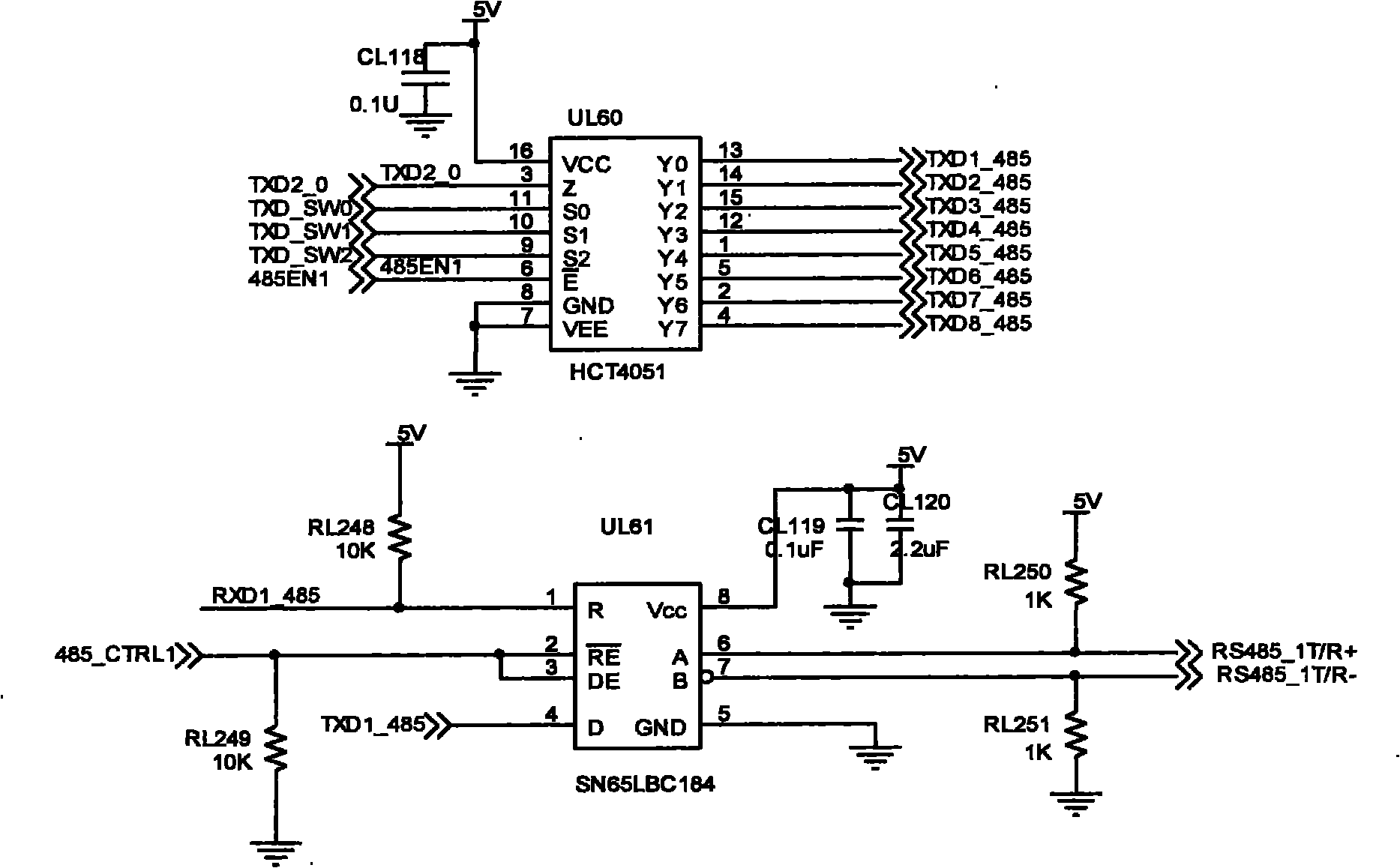

Network code divider and method for controlling front-end equipment

ActiveCN101873242ARealize unified managementAvoid crash situationsClosed circuit television systemsBus networksPower-on resetNetwork code

The invention discloses a network code divider and a method for controlling front-end equipment. The network code divider comprises a network port, a network chip, a memory unit, a CPU and a 485 expander circuit, wherein the network port is used for connecting a monitoring center through a network cable and receiving a control command from the monitoring center; the network chip is used for converting the received network signals into second-type signals; the memory unit is used for storing applications and buffer data; the CPU is used for loading the applications from the memory when the network code divider is in power on reset so as to complete initialization operation, receiving the converted second-type signals, extracting control object information from the second-type signals and operating information indicated by the control command, and transmitting the control object information and the operating information to the 485 expander circuit; and the 485 expander circuit is used for controlling the front-end equipment corresponding to the control object information to execute the operation indicated by the control command. Through the network code divider, the monitoring center can perform data communication with the code divider through the network, and the centralized control of a plurality of pieces of front-end equipment is realized.

Owner:HANGZHOU HIKVISION DIGITAL TECH

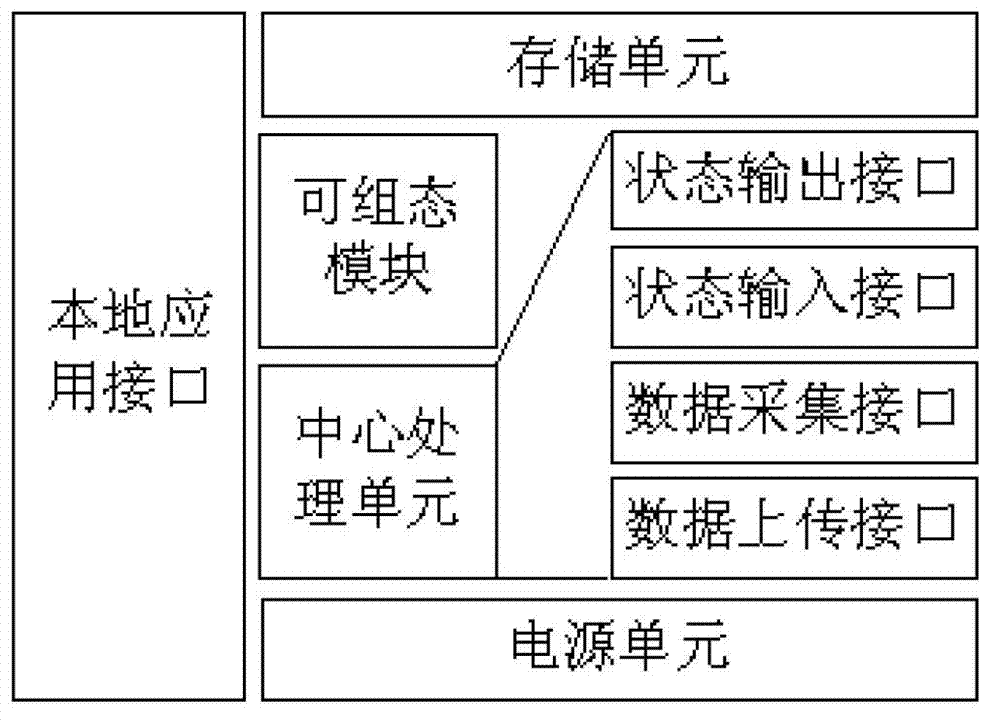

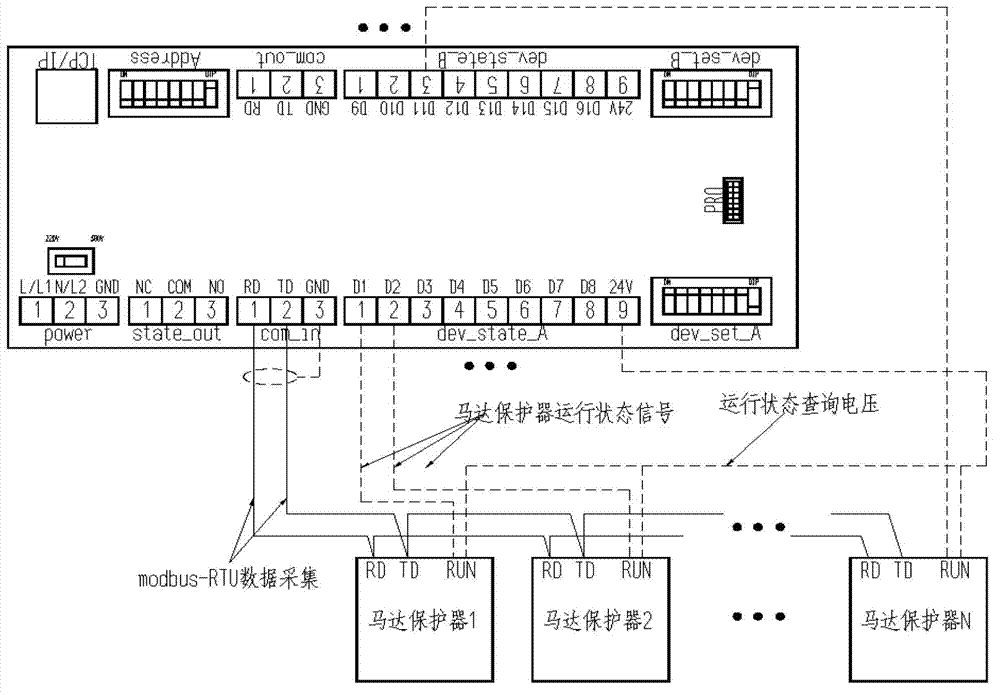

Data communication module of motor protector

ActiveCN102968103ANo need to waste communication timeAvoid data collectionTotal factory controlProgramme total factory controlData acquisitionComputer module

The invention discloses a data communication module of a motor protector. The data communication module comprises a central processing unit, a storage unit, a power supply unit, a configurable module, a local application interface, field control interfaces and a connector assembly, wherein the field control interfaces comprise a status input interface, a status output interface, a data acquisition module and a data uploading interface; the connector assembly is used for signal connection; the data acquisition interface of the field control interfaces is arranged on the communication module for acquiring current, voltage, startup time, operation and fault data of a motor; the data uploading interface is arranged on the communication module for packing the acquired data according to the requirements set by the user and then uploading the packed data to an upper communication device for an upper acquisition system. The data communication module of the motor protector disclosed by the invention is used for judging whether data acquisition is carried out to the motor protector or not by monitoring the operation status of an MCC (Motor Control Center) switch cabinet motor protector, so that system does not waste redundant communication time.

Owner:NANJING CEC AUTOMATION

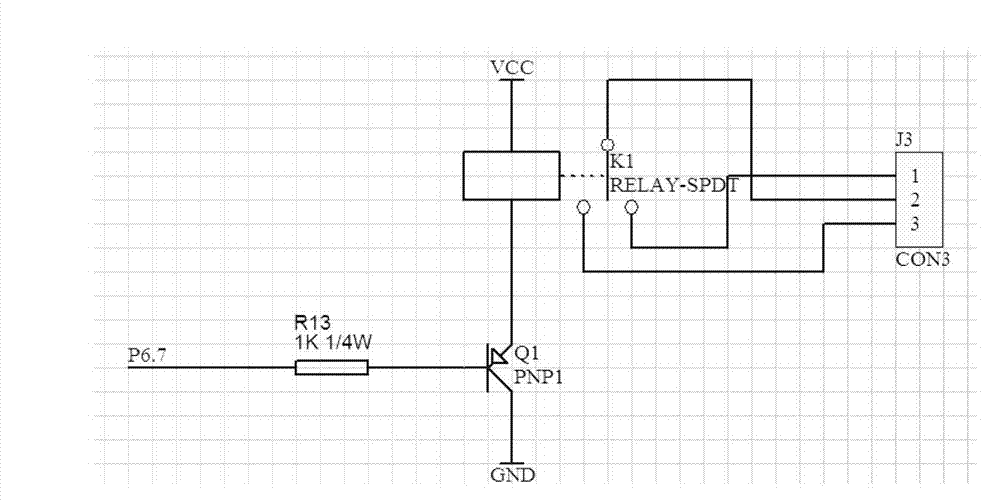

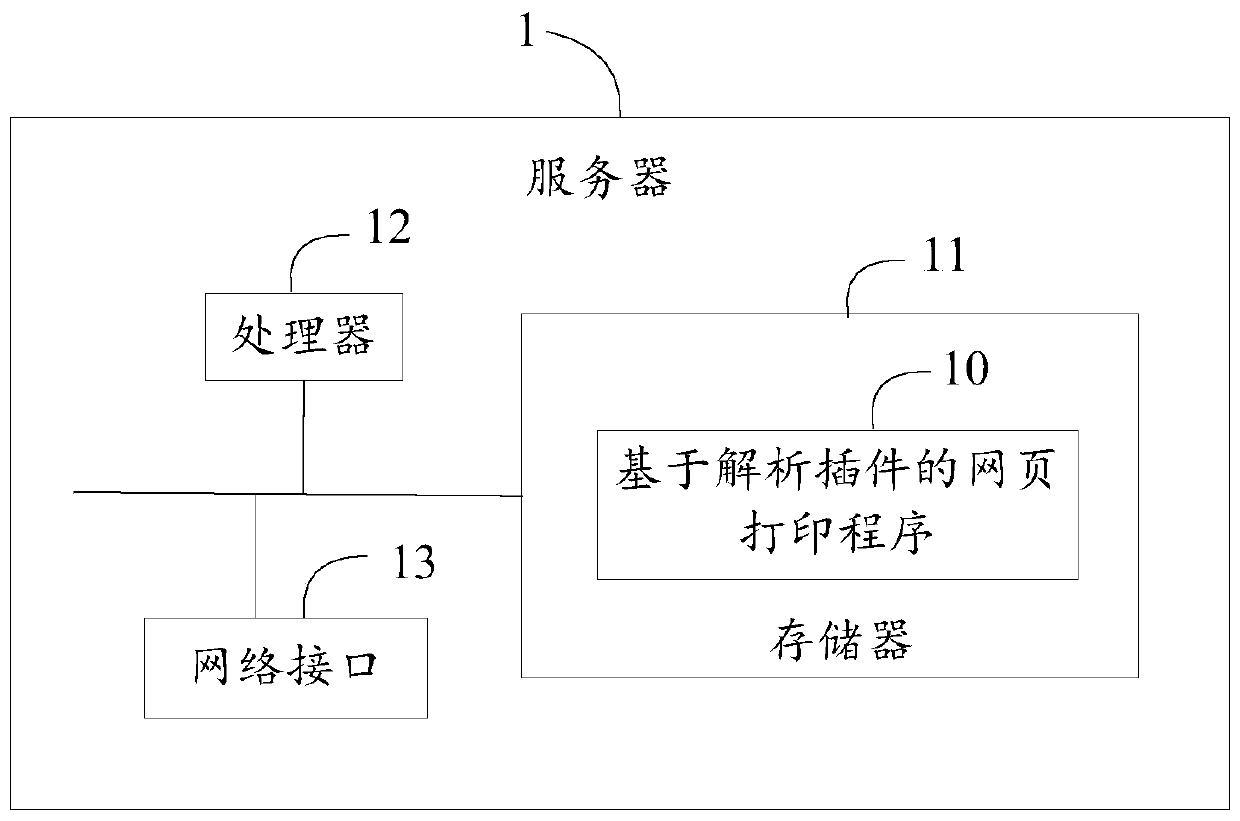

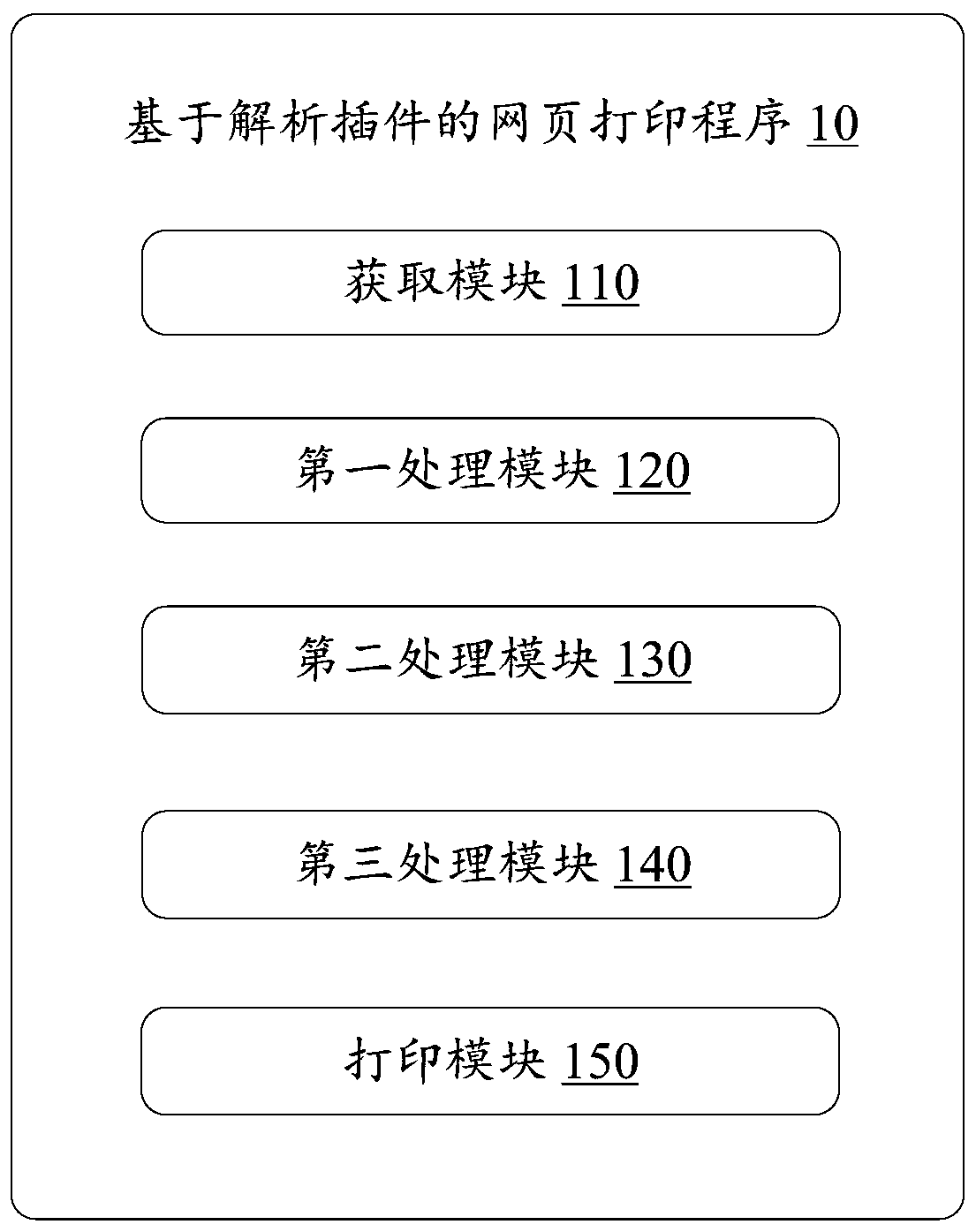

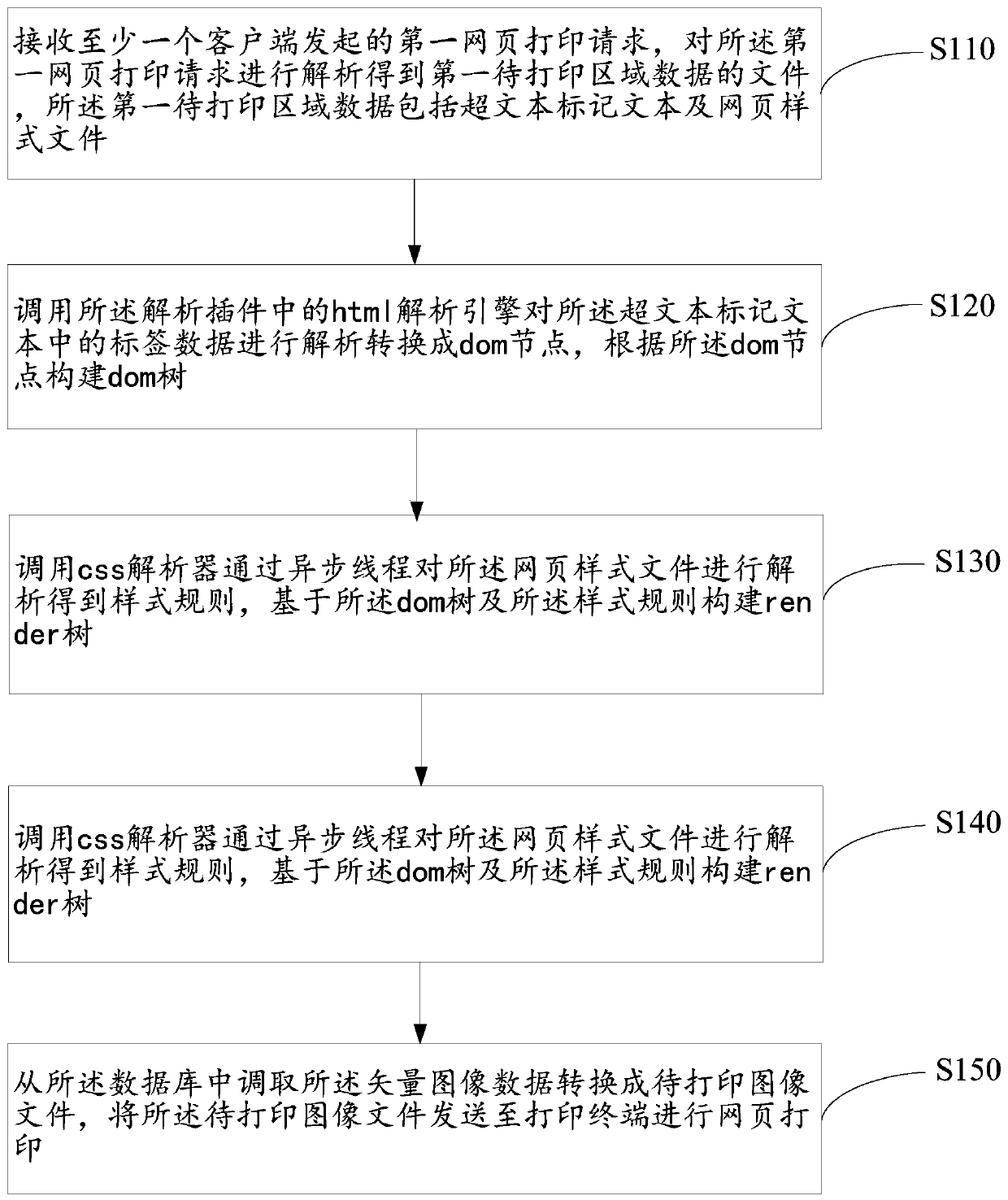

Webpage printing method based on analysis plug-in, server and storage medium

PendingCN110837347AAvoid crash situationsDigital output to print unitsInformation retrievalHypertext

The invention discloses a webpage printing method based on an analysis plug-in. The method is applied to a server. The method comprises the steps of receiving first to-be-printed area data including ahypertext marking text and a webpage style file, calling an html parsing engine in the parsing plug-in to parse and convert the label data in the hypertext markup text into dom nodes; constructing adom tree according to the dom nodes; calling a css parser to parse the webpage style file to obtain a style rule; and constructing a render tree based on the dom tree and the style rule, constructinga virtual drawing context based on the constructed render tree, generating vector image data from the virtual drawing context, converting the vector image data into a to-be-printed image file, and sending the to-be-printed image file to a printing terminal for webpage printing. According to the method, the compatibility problem caused by non-uniform kernel or internal version of the browser of theuser is avoided, and the situation that the browser crashes due to the fact that the maximum bearing capacity of the browser is exceeded when a large amount of webpage data needs to be printed at thesame time can also be avoided.

Owner:王前

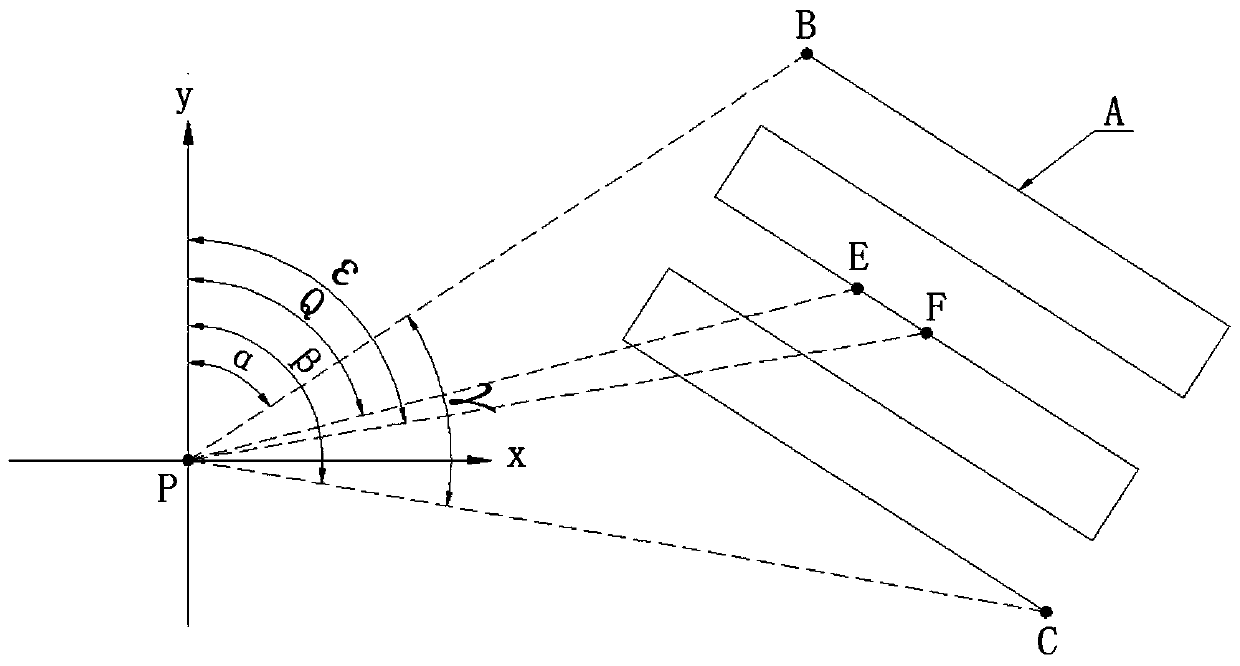

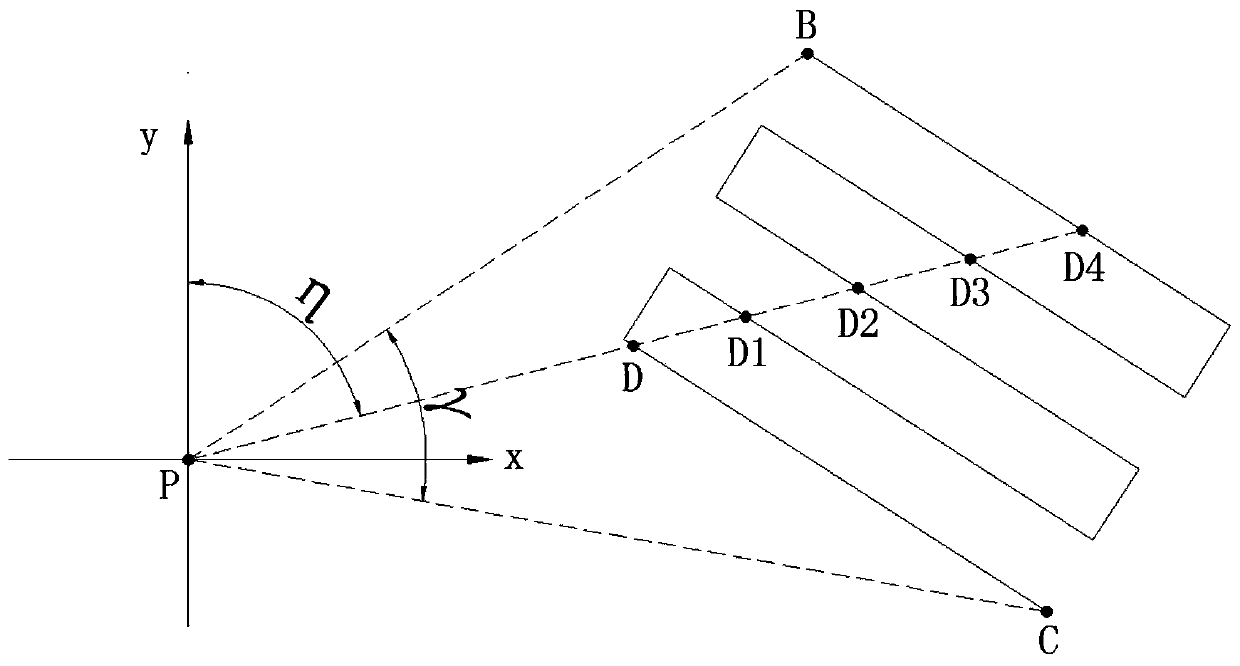

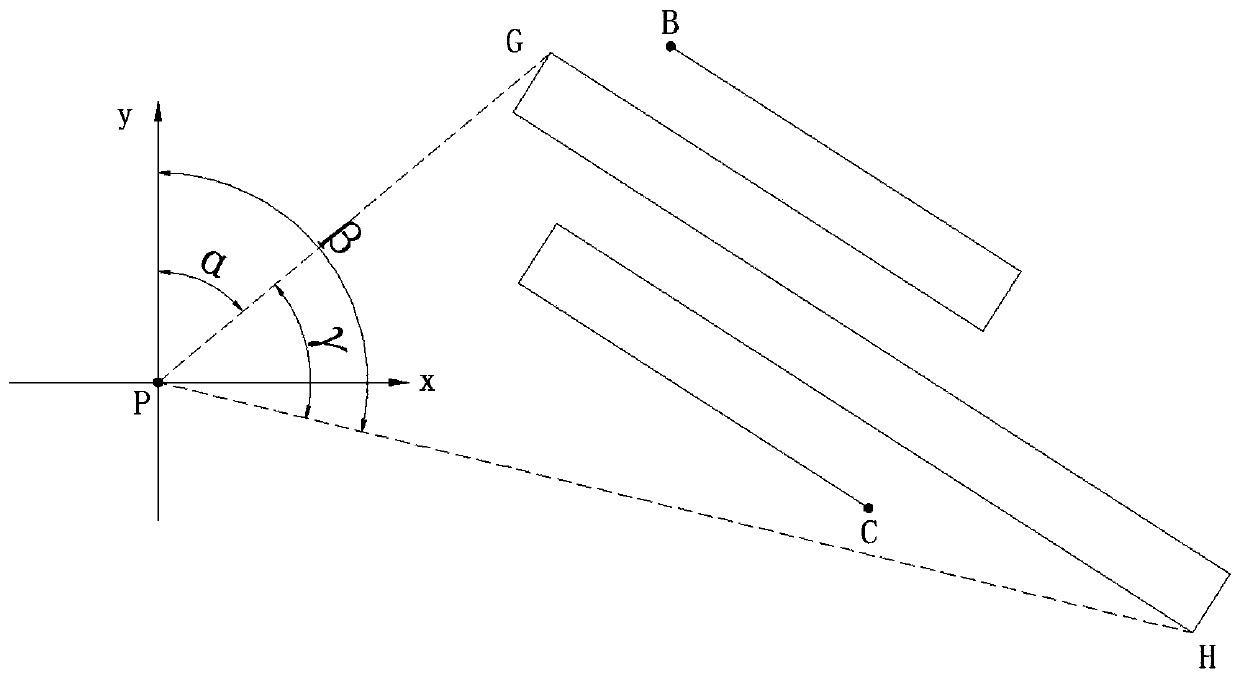

Safe return route planning method for unmanned aerial vehicle

PendingCN110864682AAvoiding the risk of a crashSolve the problem of crashingNavigation instrumentsInternal combustion piston enginesAutomotive engineeringRoute planning

The invention discloses a safe return route planning method for an unmanned aerial vehicle. The method comprises the following steps of establishing a rectangular coordinate system, determining a course azimuth angle, searching an elevation digital map in an azimuth angle range, storing marks and corresponding angle values by the unmanned aerial vehicle, and automatically planning a safety path bya lost unmanned aerial vehicle. The invention discloses a safe return route planning method for the unmanned aerial vehicle. Before the unmanned aerial vehicle takes off, an elevation lookup table ismade through a ground PC end according to corresponding parameters and transmitted to the unmanned aerial vehicle to be stored, a safe path can be selected as a return route through calculation afterthe unmanned aerial vehicle is out of contact, and the problem that the unmanned aerial vehicle crashes due to the fact that the ground elevation cannot be determined by the unmanned aerial vehicle is solved; meanwhile, the problem that the unmanned aerial vehicle cannot store a large-area elevation digital map is also solved.

Owner:CHENGDU JOUAV AUTOMATION TECH

Intelligent agricultural unmanned aerial vehicle pesticide spraying device

PendingCN112825838AAchieve initial fixationEasy to fixAircraft componentsInsect catchers and killersAgricultural engineeringGravity center

The invention discloses an intelligent agricultural unmanned aerial vehicle pesticide spraying device. The intelligent agricultural unmanned aerial vehicle pesticide spraying device comprises an unmanned aerial vehicle body, two vacuum suction cups are symmetrically installed at the lower end of the unmanned aerial vehicle body, hook plates are symmetrically hinged to the lower end of the unmanned aerial vehicle body, the two hook plates are located on the two sides of the vacuum suction cups, the sides, close to the vacuum suction cups, of the hook plates and the lower end of the unmanned aerial vehicle body are jointly and fixedly connected with an arc-shaped tension spring, the two vacuum suction cups are jointly provided with a flat plate in an adsorbing mode, the two sides of the flat plate are both fixedly connected with clamping plates connected with the hook plates in a clamped mode, the lower end of the flat plate is symmetrically and fixedly connected with two supporting columns, the lower ends of the two supporting columns are jointly and fixedly connected with a pesticide box, and a double-shaft motor is fixedly installed on the inner top wall of the pesticide box. The intelligent agricultural unmanned aerial vehicle pesticide spraying device has the advantages that the intelligent agricultural unmanned aerial vehicle pesticide spraying device is convenient to disassemble and assemble, the gravity center balance is maintained, the situation of air crash caused by imbalance due to inertia are avoided, in addition, the spraying range can be adjusted, and the situation of waste caused by direct spraying on the ground is avoided.

Owner:郭桂田

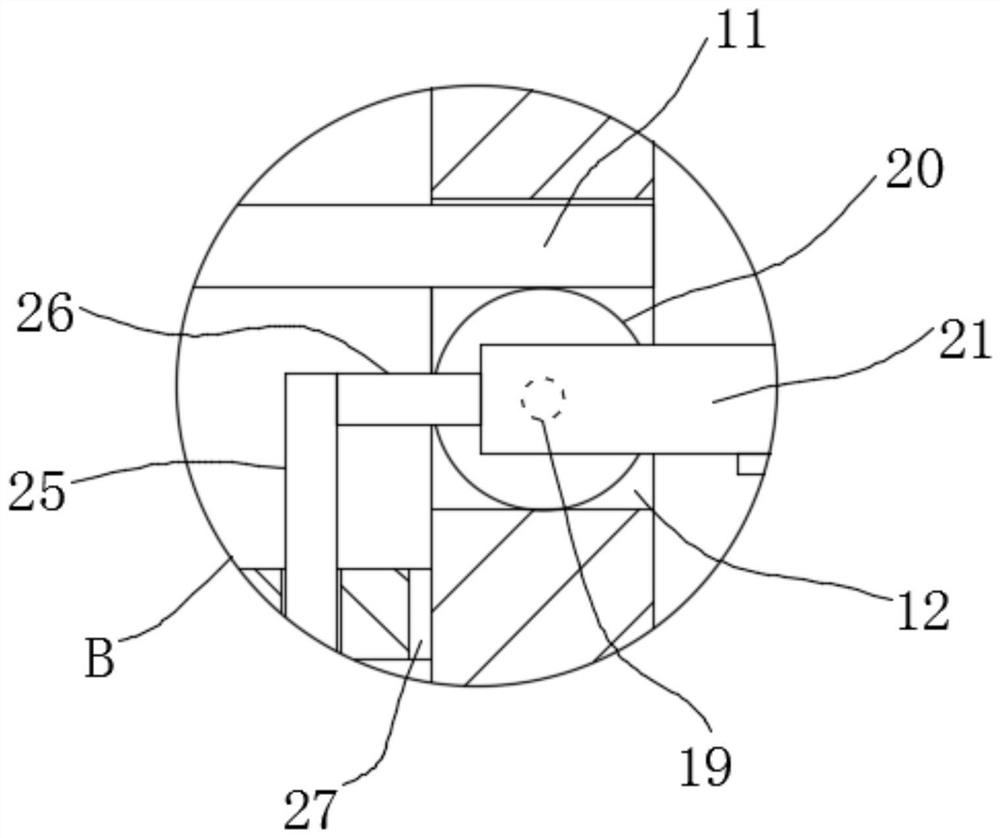

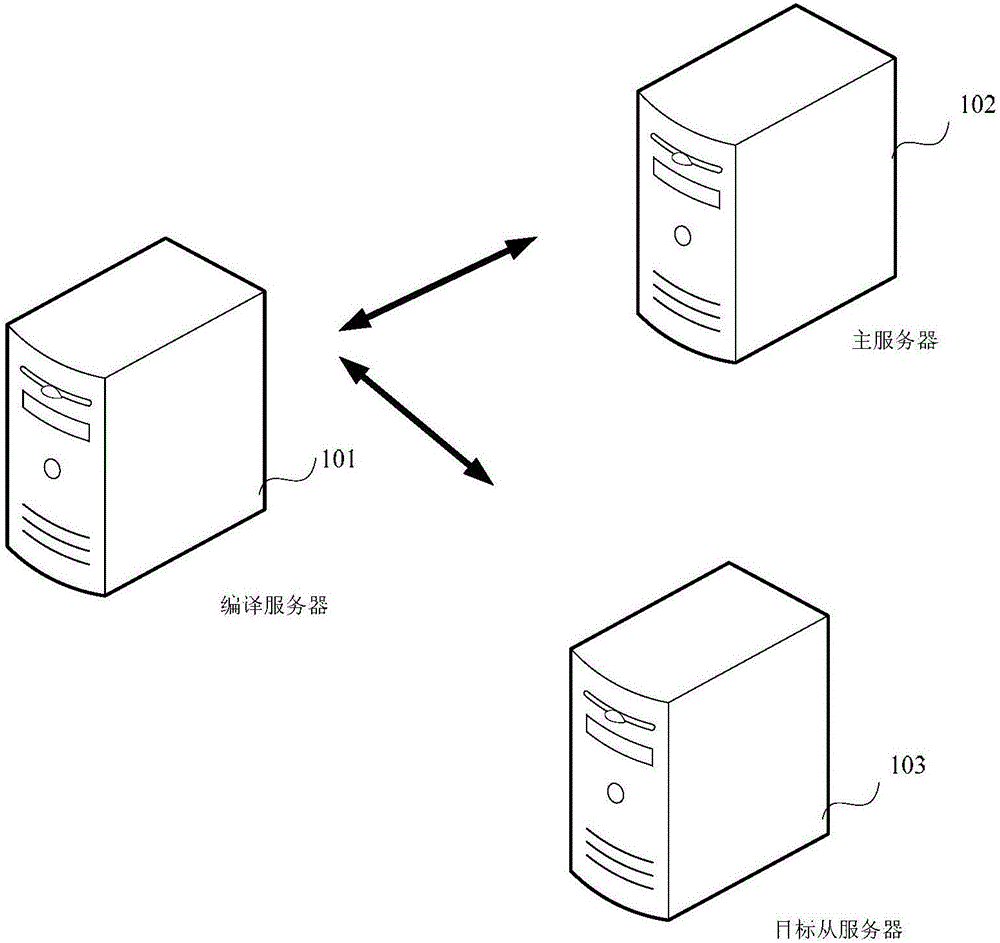

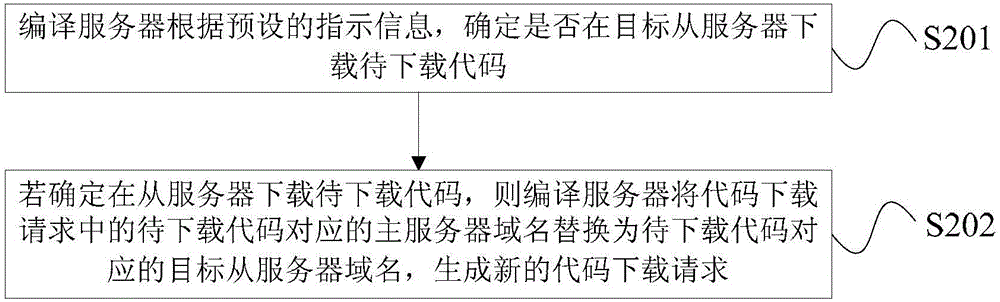

Code downloading method and compiling server

InactiveCN106325958AReduce downloadsReduce overheadProgram loading/initiatingMemory systemsDomain nameComputer network

The invention relates to a code downloading method and a compiling server, comprising the following steps: a) the compiling server gets the code downloading request which comprises the domain name of the master server of the code to be downloaded. b) the domain name of the master server of the code to be downloaded is replaced by the compiling server to the domain name of the targeted slave server of the code to be downloaded. c) the compiling server downloads the code from the targeted slave server according to the targeted slave server of the code to be downloaded. When the server room of the compiling server is provided with the slave server, the domain name for the slave server which is located in the same server room with the compiling server, can be used as the domain name for the targeted slave server to replace the domain name for the master server in the code downloading request through the code downloading method and the compiling server provided by the invention, which can enable the compiling server to download the code from the target slave server, can reduce the downloads of the master server, decrease the cost of the master server, and improve the reliability of the master server.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

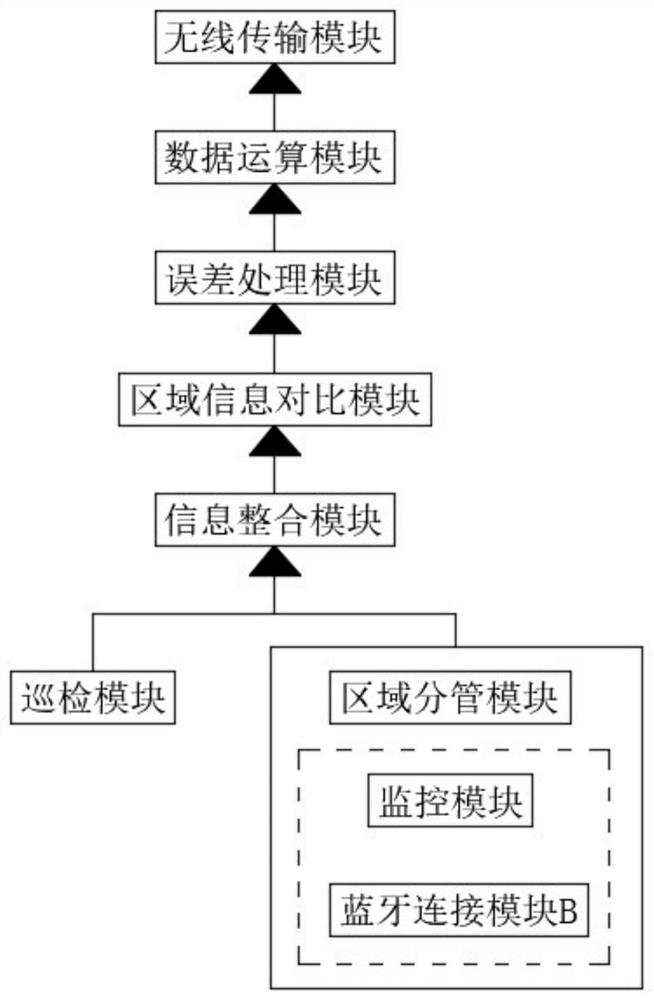

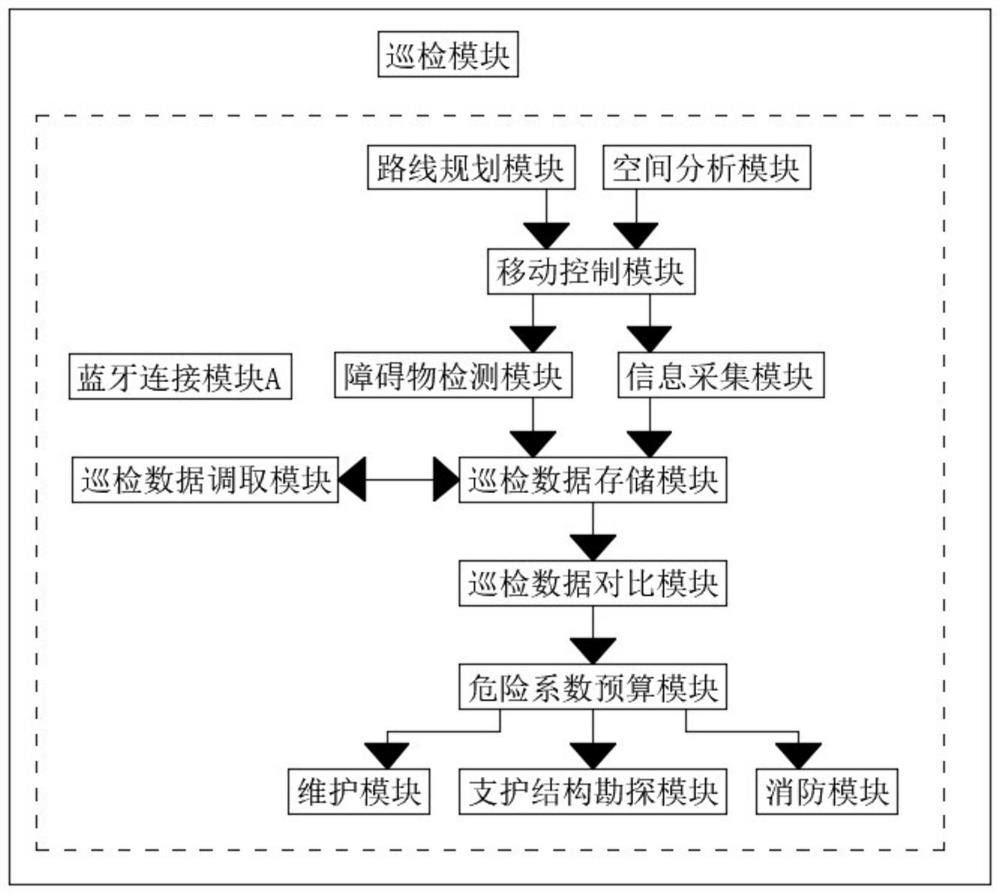

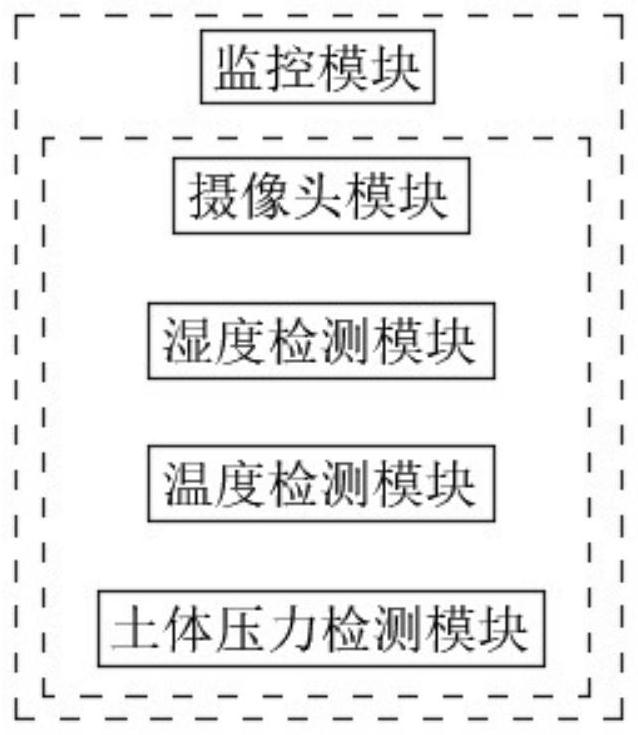

Underground pipe gallery model monitoring and early warning system applied to smart city

InactiveCN112684744AComprehensive and accurate monitoringMonitor pressure in real timeProgramme controlChecking time patrolsEarly warning systemAccident avoidance

The invention discloses an underground pipe gallery model monitoring and early warning system applied to smart city, which belongs to the technical field of underground pipe galleries. The system comprises an inspection module, regional branch pipe modules and an information integration module, the output end of the information integration module is electrically connected with the input end of a regional information comparison module, and the output end of the regional information comparison module is electrically connected with the input end of a data operation module. According to the invention, the multiple regional branch pipe modules are arranged and arranged in different regional sections in the underground pipe gallery correspondingly, so that the underground pipe gallery can be comprehensively and accurately monitored, a soil body pressure detection module can be arranged in a soil layer around the underground pipe gallery, and the pressure borne by the interior of the soil layer is monitored in real time; the situation that a supporting structure on the periphery of the underground pipe gallery cannot bear large pressure and collapses is avoided, pressure is monitored in time, countermeasures can be taken in advance, accidents are avoided, and the danger coefficient during the accidents is reduced.

Owner:鼎嘉(杭州)智能科技有限责任公司

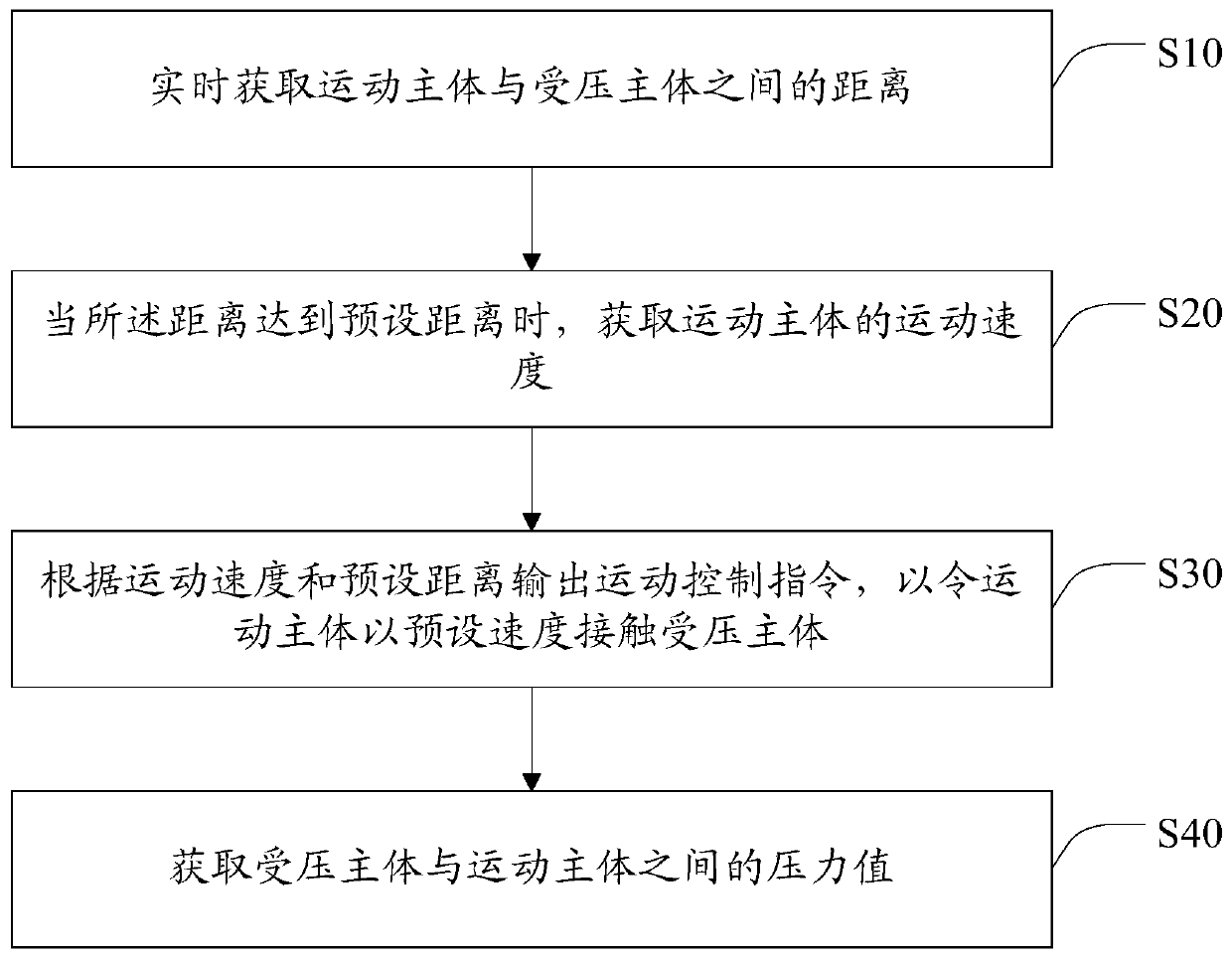

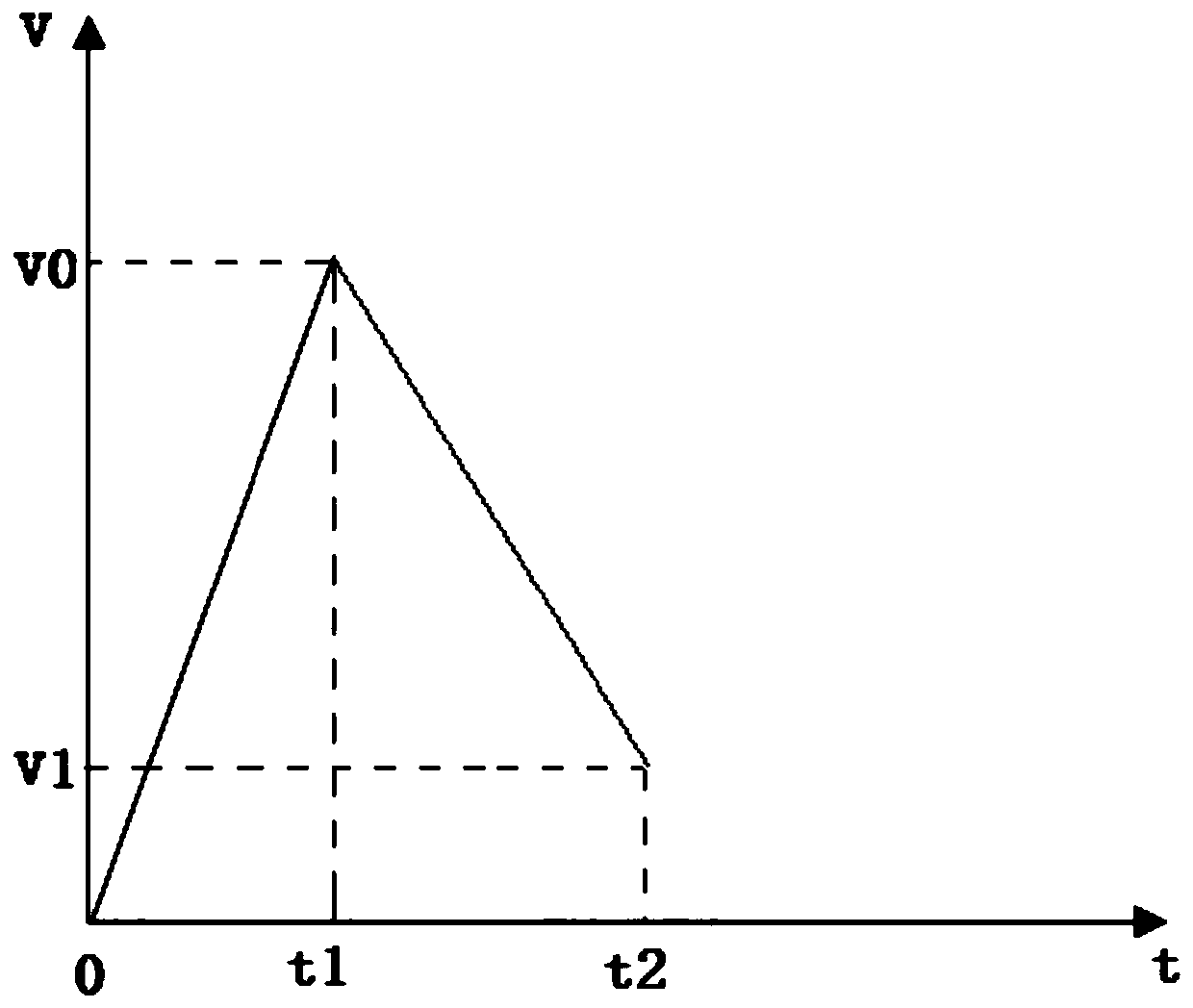

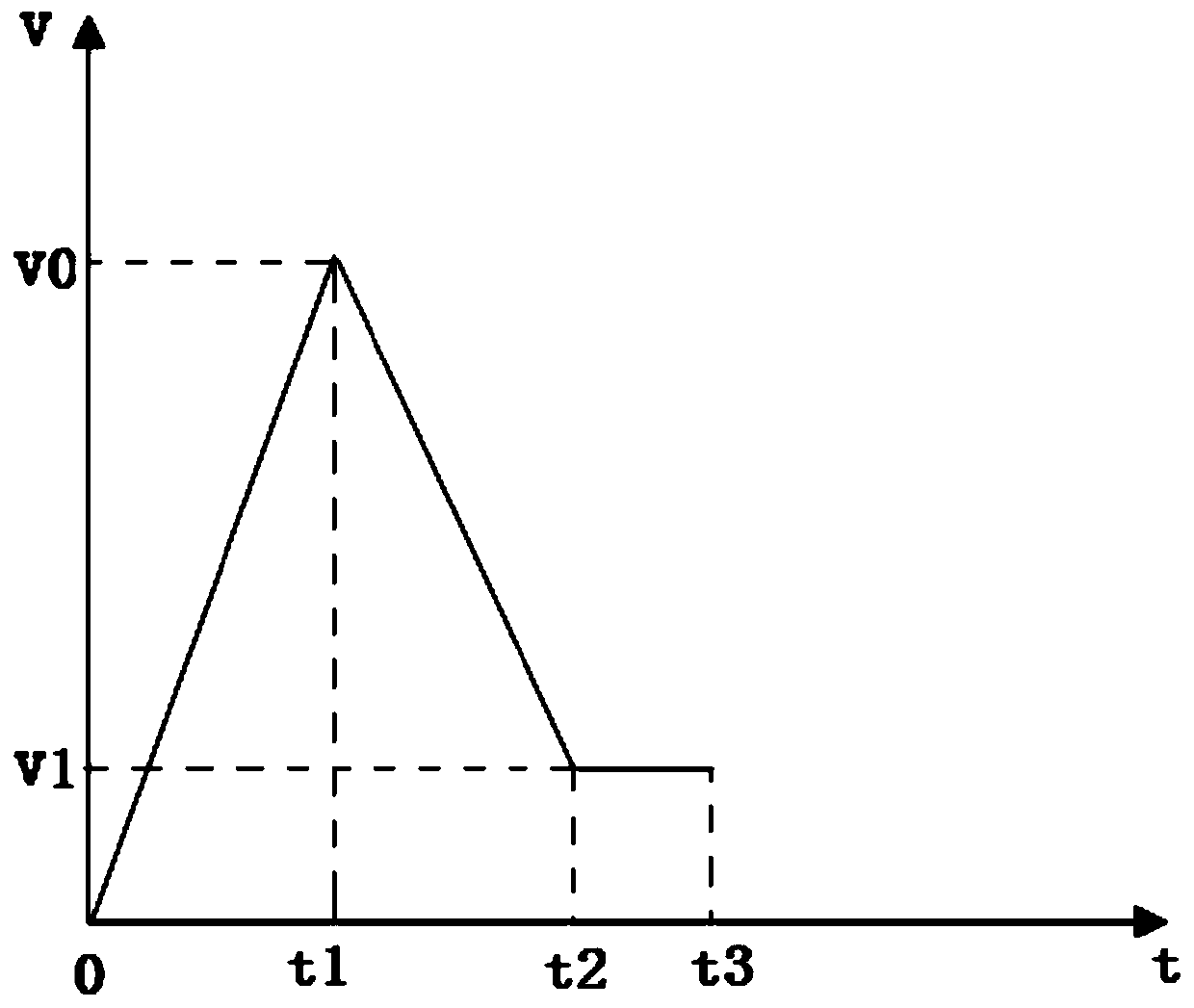

Pressure detection method and pressure detection device with distance measurement protection

PendingCN110082028AAvoid crash situationsForce measurement by measuring frquency variationsForce measurement by measuring magnetic property varationBody contactComputer science

The invention discloses a pressure detection method with distance measurement protection. The method comprises the following steps: obtaining the distance between a moving main body and a pressed mainbody in real time; when the distance reaches preset distance, obtaining moving speed of the moving main body; outputting a motion control instruction according to the moving speed and the preset distance to make the moving main body contact the pressed main body at a preset speed; and obtaining the pressure value between the pressed main body and the moving main body. Impulsive force generated when the moving main body strikes the pressed main body is adjusted by controlling the movement process of the moving main body to prevent the case that excessive impulsive force damages a pressure sensor on the pressed main body.

Owner:深圳市卓航自动化设备有限公司

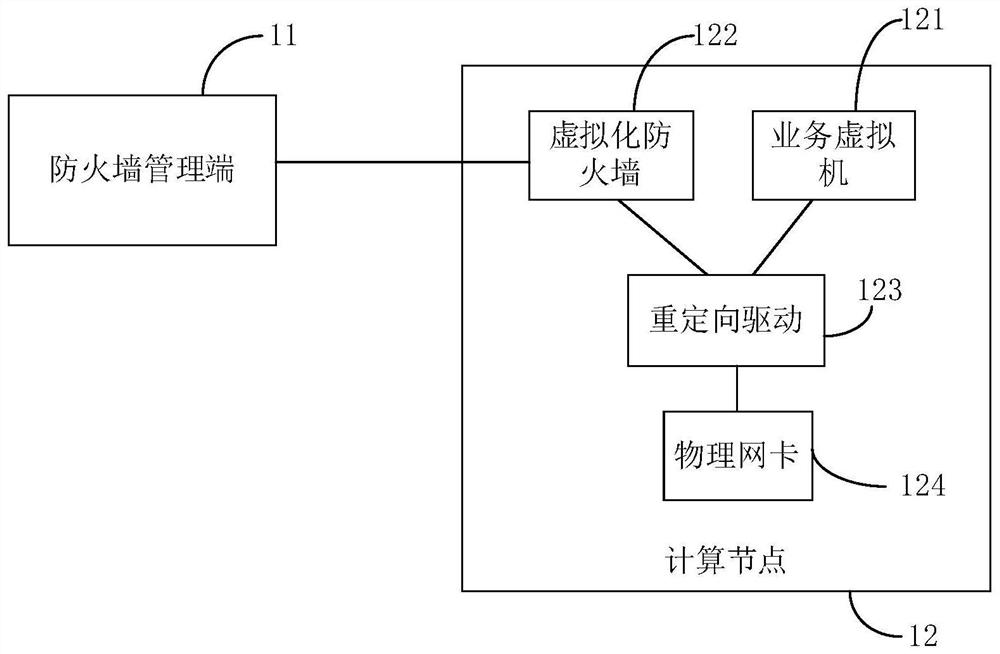

Flow protection method, electronic equipment and storage medium

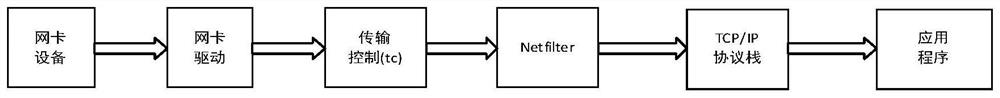

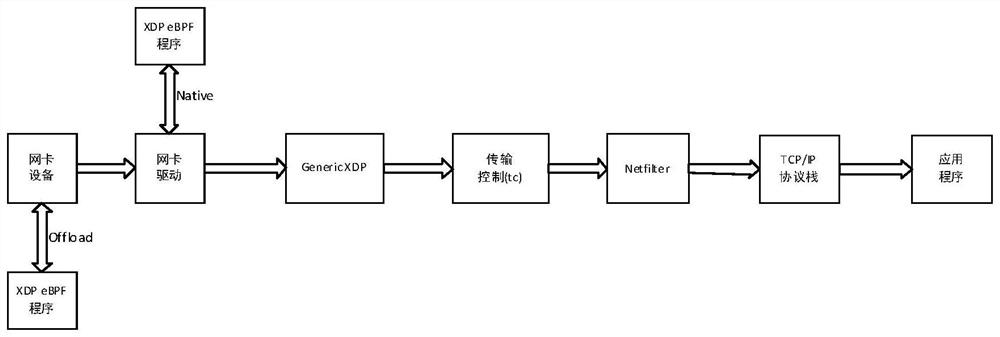

PendingCN114039789AAvoid crash situationsAvoid overheadSoftware simulation/interpretation/emulationSecuring communicationVirtualizationSoftware engineering

The invention provides a flow protection method, electronic equipment and a storage medium, the method is applied to a host machine, the host machine is deployed with a virtualization firewall and a service virtual machine, and the method comprises the following steps: issuing an eBPF program on an XDP network hook of a network card driving program; through the eBPF program, redirecting the traffic sent out by the service virtual machine to the virtualized firewall; and sending the flow which is detected, confirmed and released by the virtualization firewall to a target virtual machine or a target physical network card through the eBPF program. According to the method, the eBPF program is adopted, the situation that the host machine crashes and the like cannot be caused even if the BUG exists, and different Linux kernel versions can be adapted.

Owner:BEIJING TOPSEC NETWORK SECURITY TECH +2

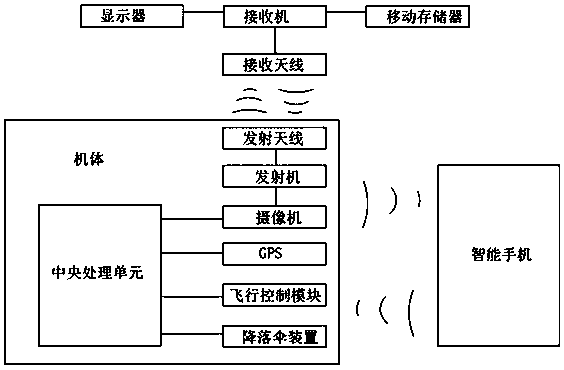

Drone camera shooting system

InactiveCN107628254AGuaranteed integrityPrevent crashTelevision system detailsParachutesUncrewed vehicleSTI Outpatient

The invention discloses a drone camera shooting system. The system comprises a drone body, a flight control module, a camera, a transmitter, a transmitting antenna, a GPS, a parachute device, a central processing unit, a ground receiver and a smart phone. A double control mode is adopted by the system, and protection measures are additionally arranged for a drone used for camera shooting in the air, so that drone crash accidents are effectively avoided, it can be guaranteed that the drone body and the camera are intact in emergency circumstances, equipment recycle is convenient, and the safetyis high.

Owner:廖珏婷

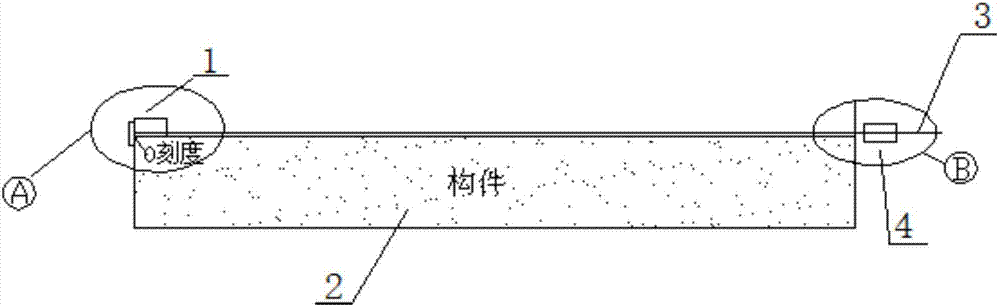

Steel measuring tape measurement apparatus based on clamping apparatus and measurement method thereof

The invention discloses a steel measuring tape measurement apparatus based on a clamping apparatus and a measurement method thereof. The apparatus comprises a steel measuring tape, a clamping seat and a tensioning force measurement apparatus. The clamping seat is arranged on an initial end of the steel measuring tape. The tensioning force measurement apparatus is arranged on a tensioning end of the steel measuring tape. The tensioning force measurement apparatus comprises a second shell, a clamping device and a spring balance, wherein the clamping device and the spring balance are arranged in the second shell. The clamping device is connected to one end of the spring balance. The other end of the spring balance is connected to the second shell. The steel measuring tape passes through the clamping device. Measurement accuracy and measurement precision are increased. An error is reduced. The structure of the apparatus is simple, the size is small, weight is light and operation is simple. The apparatus is especially suitable for measurement of a medium-length component. Only one person can operate the apparatus so that manpower cost is saved.

Owner:WUHAN YIYE STEEL STRUCTURE

Filling gun capable of achieving safe filling

PendingCN113483257AImprove continuous filling abilityEliminate hidden dangers of safety accidentsGas handling applicationsContainer discharging methodsReciprocating motionControl valves

The invention discloses a filling gun capable of achieving safe filling. The filling gun adopts a piston power operation mechanism with double power cylinders and three cavities to drive an inner gun barrel and an outer gun barrel to do relative reciprocating motion, gun feeding and gun withdrawing operation of the filling gun is executed in a most reasonable pneumatic action mode, and further, a clamping mechanism and an air pressure adjusting hole are arranged in a matched mode, a power source pressure intensity adjusting control valve and the locking structure of the clamping mechanism enable clamping jaws of the clamping structure and an inner gun barrel gun head to be stably locked in the gun feeding action process of the filling gun, it is guaranteed that the safety accident of gun collapse does not occur in the gun feeding and withdrawing processes of the filling gun, and the continuous filling capacity of the power cylinders is improved.

Owner:CHENGDU ANDERSON MEASUREMENT +1

Hosiery body locating and ejecting device with movable sinker cover for integrated hosiery knitting machine

ActiveCN107805875AAccurate stop positionAvoid Seam FailureTextile/flexible product manufactureCircular knitting machinesEngineeringMechanical engineering

The invention discloses a hosiery body locating and ejecting device with a movable sinker cover for an integrated knitting machine. The precision requirement for the displacement of a cover piece is high, and the thickness requirements of different parts of hosiery are different. When existing hosiery knitting and end sewing integrated machines are used for transferring the hosiery, the problem that kitting needles are inaccurately aligned with transfer sheets easily occurs. The device comprises a rack, a needle cylinder core, a gear, a hosiery containing cylinder, a locating mechanism, a lifting mechanism, a support plate, the sinker cover, a connecting rod, a cover piece adjusting mechanism and a mechanism for adjusting a left eyebrow-shaped piece and a right eyebrow-shaped piece; the locating mechanism comprises a locating air cylinder, a locating ring, a fixing disc and a limiting block; the lifting mechanism includes an optical axis, a lifting air cylinder, an air cylinder supportbase and a lifting sliding block. By means of the device, the situation that end sewing fails since a needle head is misaligned in the process of transferring the hosiery by the hosiery knitting andend sewing integrated machine can be avoided, the displacement angle of the sinker cover can be controlled, the tightness degrees of the different parts of the hosiery can be controlled, and the quality of the hosiery is improved.

Owner:浙江专博纺织机械有限公司

Billiard table stone plate corner polishing device with automatic adjustment function

PendingCN114536143AReduce risk of damageImprove sanding effectEdge grinding machinesGrinding drivesPolishingBilliard ball

The invention relates to the technical field of billiard accessory machining equipment, in particular to a billiard table stone plate corner grinding device with an automatic adjustment function. The self-adaptive assembly is slidably arranged at the top end of the workbench; the polishing assembly used for polishing the corners of the stone plate is arranged on one side below the self-adaptive assembly; the dust treatment assembly is used for eliminating dust generated in the grinding process and is arranged on the grinding assembly; according to the device, the self-adaption assembly can limit the final grinding position, meanwhile, when the stone plate corners are irregular and the grinding angle is large, the grinding assembly can automatically contract, a certain protection effect is achieved on the grinding assembly, the risk of damage to the grinding assembly is reduced, meanwhile, the stone plate corners can be ground step by step, and the grinding efficiency is improved. Therefore, the polishing effect is improved, and the situation that the corners of the stone plate are broken is avoided.

Owner:JIUJIANG JINYING TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com