Filling gun capable of achieving safe filling

A filling gun, safe technology, applied in the field of low temperature medium transportation, can solve the problems of excessive loss of instruments, prone to malfunction, complicated power supply methods for feeding and withdrawing guns, etc., to ensure stability, easy control, and continuous improvement. The effect of the ability to raise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing, the present invention is described in detail.

[0034] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0035] In this embodiment, the data used is the preferred solution, but is not intended to limit the present invention;

[0036] The present invention can realize the safe filling action of the filling gun through various power action modes. In this embodiment, low-temperature gas is used as the transmission power source to illustrate this embodiment. In this embodiment, the pressure of the driving gas source is 0.3MPa-0.8 MPa.

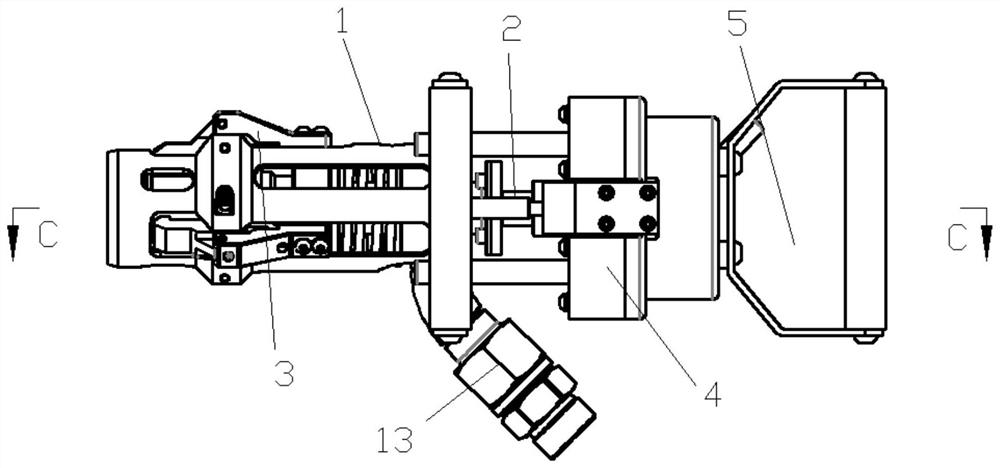

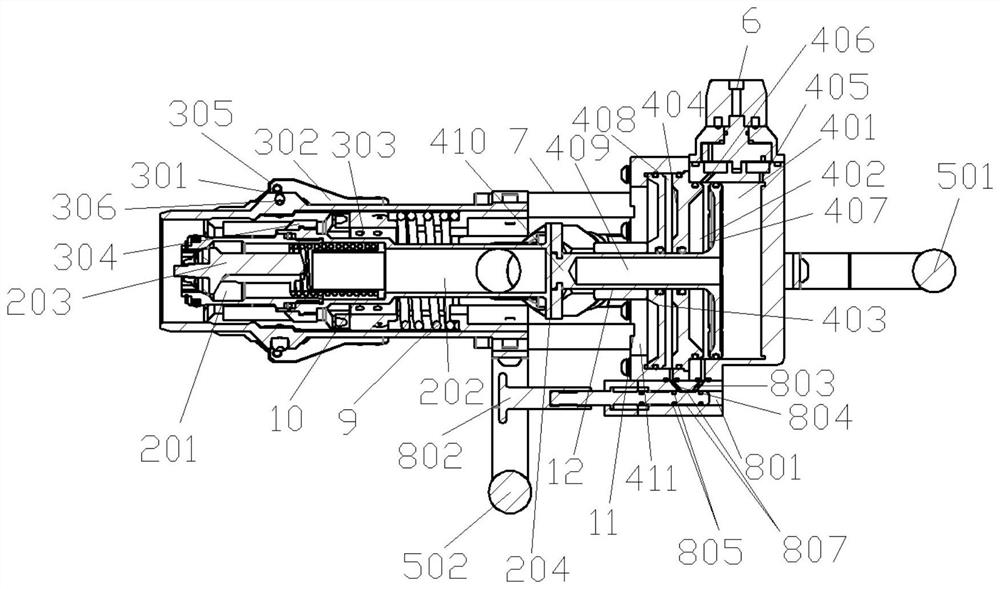

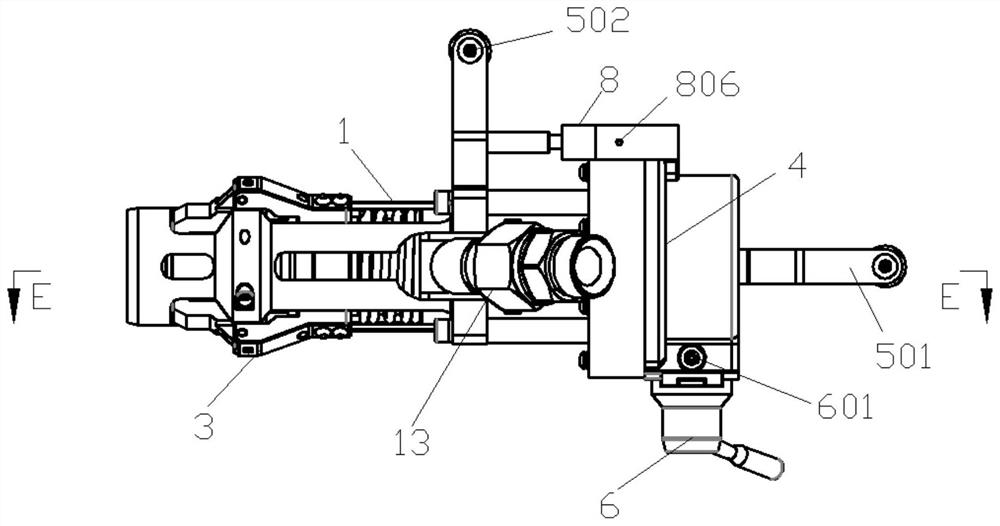

[0037] Such as Figure 1-5 As shown, this embodiment provides a filling gun for safe filling, including an inner gun barrel, an outer gun barrel, a clamping mechanism, a power chamber and a handle mechanism, the inner g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com