Safe filling device of filling gun

A technology for filling devices and filling guns, which is applied to equipment loaded into pressure vessels, gas treatment applications, and container discharge methods, etc., and can solve complex power supply methods for gun entry and withdrawal, potential safety hazards, and human intervention control The opening and closing of the three-headed claws and other problems achieve the effect of improving continuous filling ability and easy manipulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below with reference to the accompanying drawings.

[0031] In order to make the objectives, technical solutions and advantages of the present invention, the present invention will be described in further detail below with reference to the accompanying drawings and examples.

[0032] In this embodiment, the data employed is a preferred embodiment, but is not intended to limit the invention;

[0033] The present invention can achieve a safety filling operation of a spray gun by a plurality of dynamic operations, in this embodiment, the use of low temperature gas is used as the conveying power source.

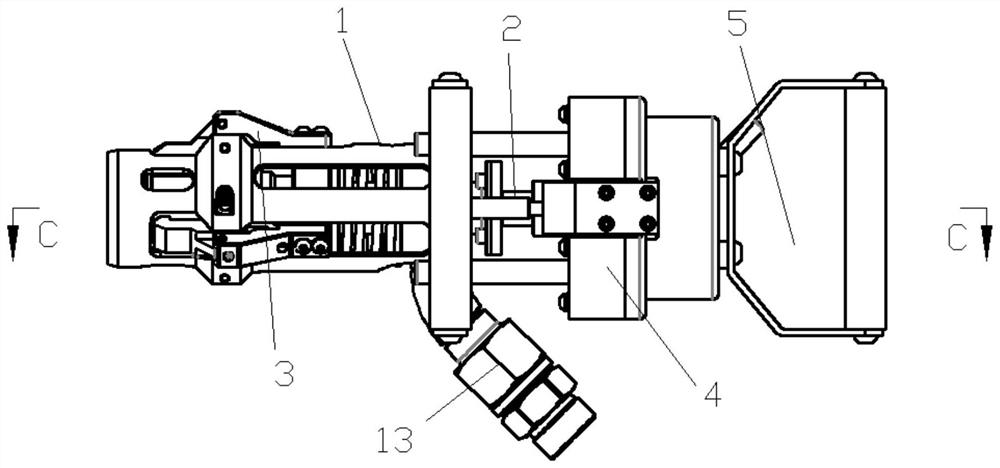

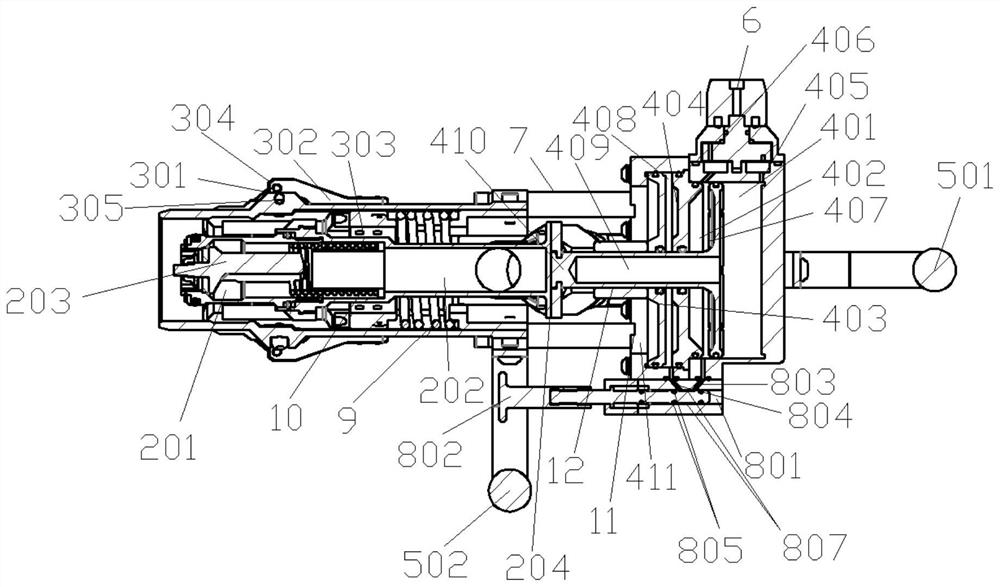

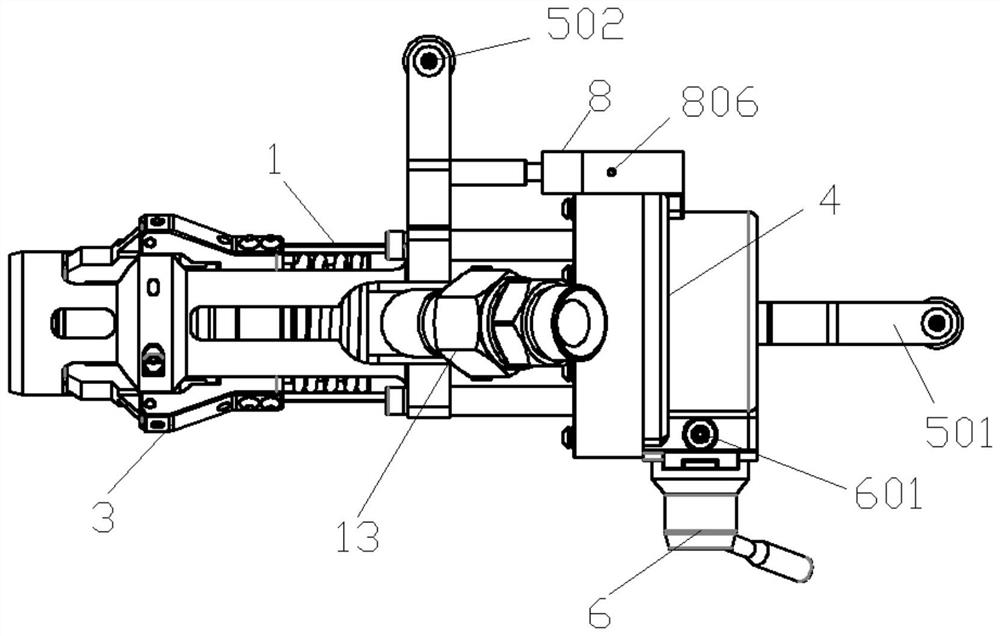

[0034] like Figure 1-4 As shown, this embodiment provides a filling gun safe and raised moving chamber, including inner barrels, outer tubes, clip mechanisms, and handle mechanisms, and the inner barrel is disposed within the outer tube, through the first The compression spring telescopus is relatively slid in the outer gun tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com