Charging pasting machine

A plastering machine and rechargeable technology, applied in construction, building construction, etc., can solve problems such as potential safety hazards, high energy consumption, and machine inoperability, and achieve volume and weight reduction, high energy conversion efficiency, and energy saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

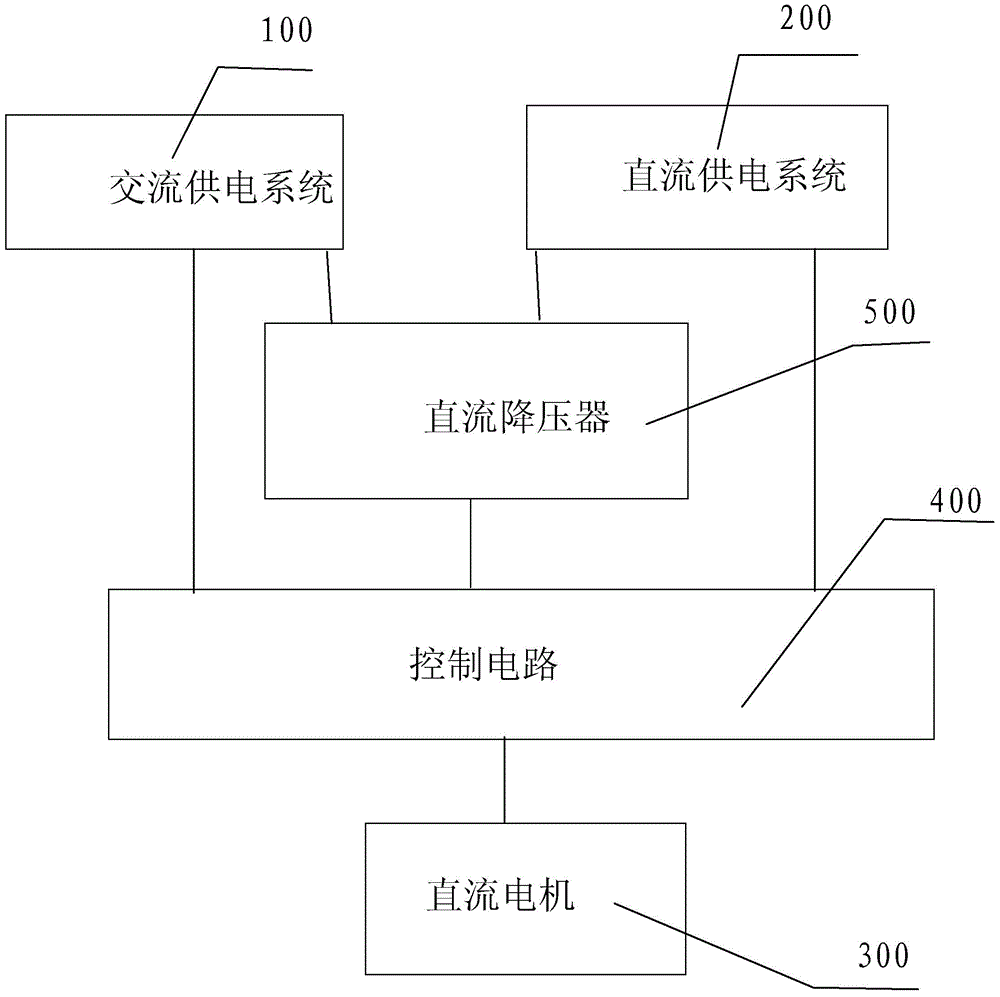

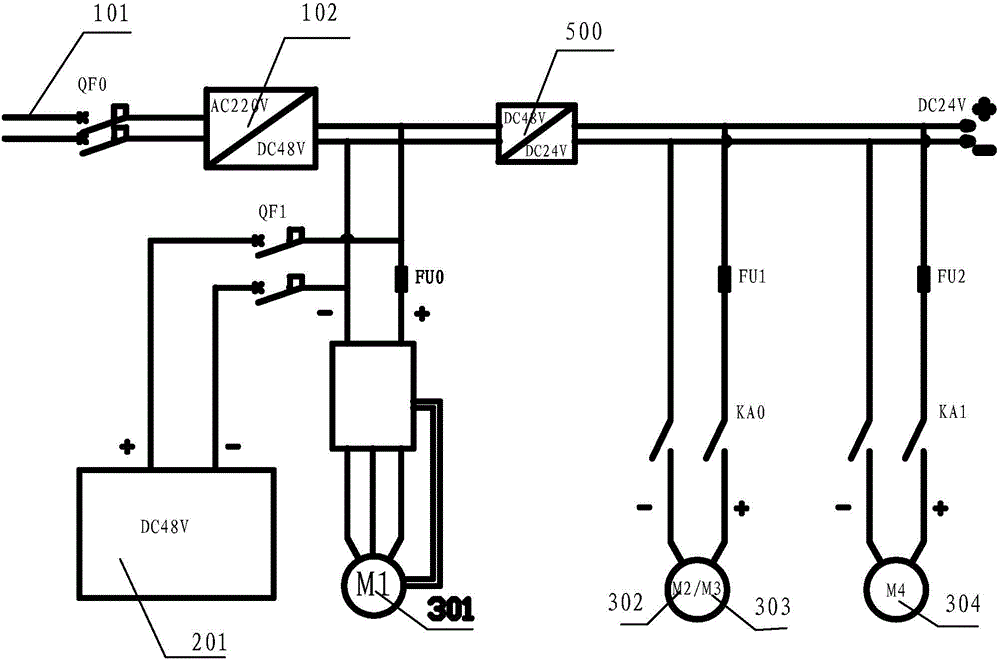

[0017] figure 1 with figure 2 constitute specific embodiments of the invention.

[0018] refer to figure 1 with figure 2 In this embodiment, an invention of a rechargeable plastering machine includes an AC power supply system 100, a DC power supply system 200, a DC motor 300, a control circuit 400, and a DC voltage reducer 500. The AC power supply system 100 includes an AC power supply 101 and an AC power supply system. The DC conversion switching power supply 102, the AC power supply 101 is converted into a DC power supply by the AC-DC conversion switching power supply 102 and then electrically connected to the DC motor 300, the DC power supply system 200 includes a storage battery 201, and the storage battery 201 is electrically connected to the DC motor 300, and the control circuit 400 enables only one of the AC power supply system and the DC power supply system to supply power to the DC motor 300 at the same time.

[0019] The AC power supply 101 is rectified and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com