Patents

Literature

182results about How to "Monitor pressure in real time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

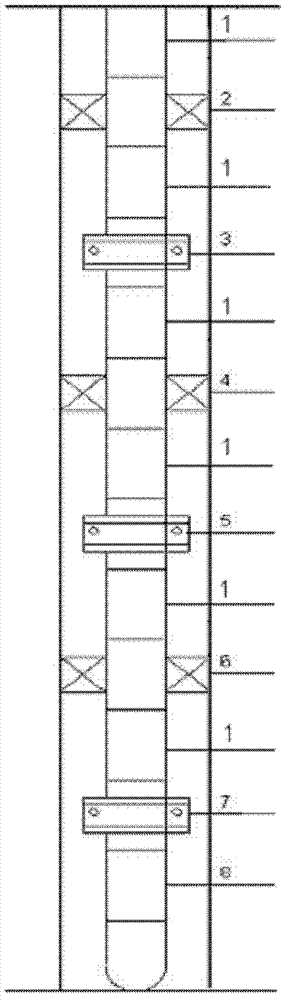

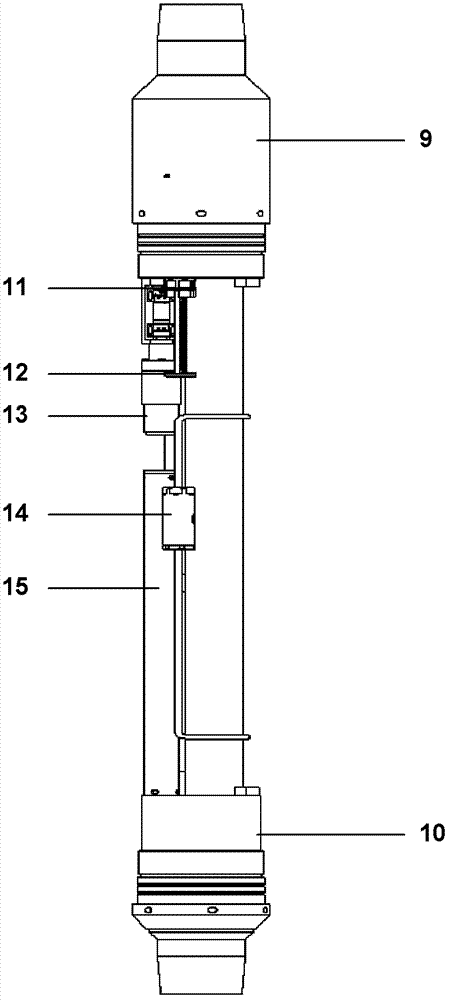

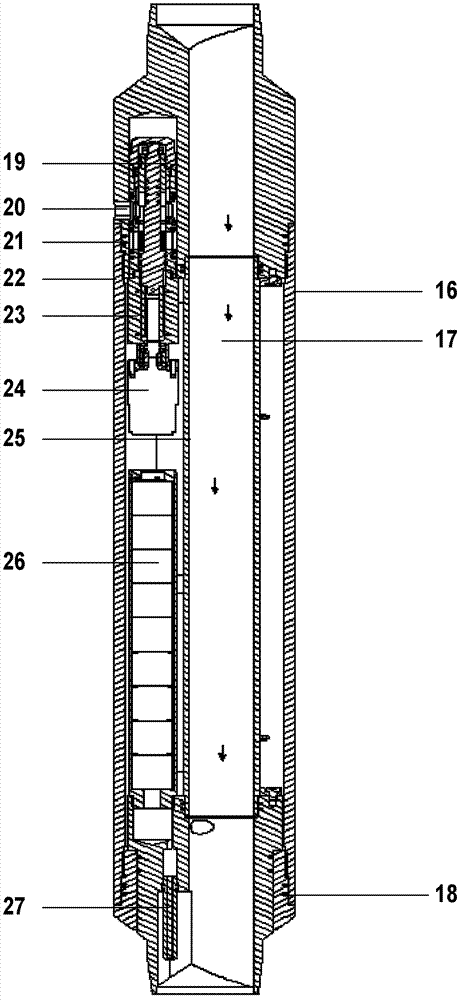

Digital underground layering water injection testing and adjusting process pipe column and operation method thereof

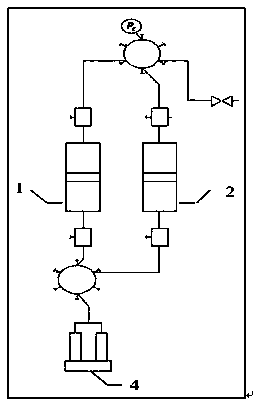

The invention discloses a digital underground layering water injection testing and adjusting process pipe column and an operation method thereof. According to the purpose, the instantaneous flow rate and the accumulative total injection rate of a single reservoir stratum can be monitored and recorded in real time underground, pressure of the reservoir stratum is monitored in real time, underground well shut-in layering pressure drop is tested, and bi-directional transmission of data and orders between a down-hole and the ground is carried out in a wireless mode. The process pipe column is formed by connecting a multistage digital water distributor and an Y344 water injection packer through an oil pipe, and eliminates steps of testing and allocating steel wires of the flow rate compared with an existing water distributor and a packer used for layering water injection. Meanwhile, the instantaneous flow rate and the accumulative total injection rate of the single reservoir stratum can be monitored and recorded in real time underground, the pressure of the reservoir stratum is monitored in real time, and the underground well shut-in layering pressure drop is tested. The pipe column can greatly reduce workloads of matching tests and pressure-drop tests of an oil field layering water injection well, provides the true and reliable accumulative total injection rate of the single stratum, and provides reliable evidence for policy adjustment of the oil field development technology.

Owner:PETROCHINA CO LTD

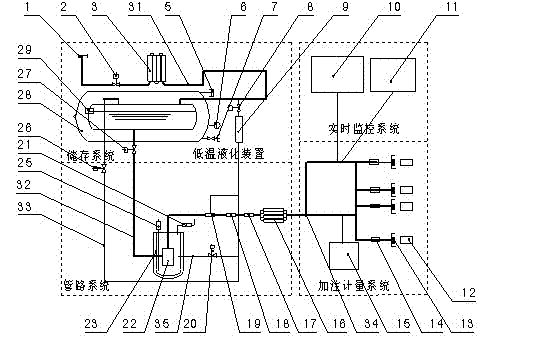

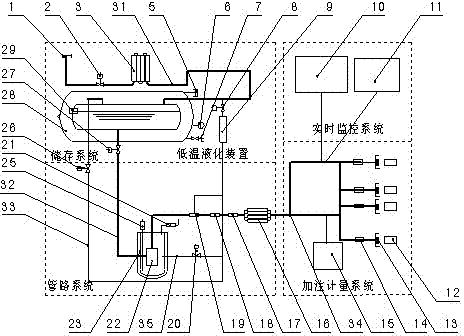

Liquefied natural gas (LNG) filling station and gas filling method of LNG

ActiveCN102200220AReduce environmental pollutionSave resourcesPipeline systemsLiquefied natural gasProcess engineering

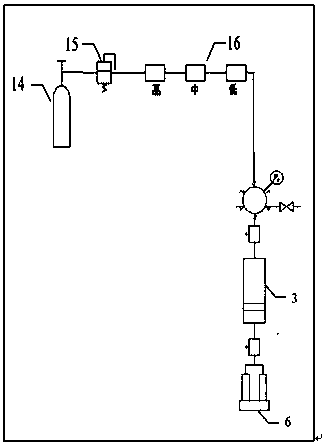

The invention discloses a gas filling method of a liquefied natural gas (LNG). The method can be used for filling for various vehicles at normal pressure or lower pressure, reducing environment pollution and saving resources. In the method, gas-liquid separation is performed on a gas-state natural gas mixed in the LNG during delivery of the LNG in a storage system to a filling metering device; the purified LNG is delivered to the filling metering device; the separated gas-state natural gas is transformed to a liquid-state natural gas through liquefaction; and the liquid-state natural gas is returned to the storage system. The invention also discloses an LNG filling station built based on the filling method. The LNG filling station has the advantages of low emission loss, short pre-cooling time of initial starting, high gas filling precision and efficiency, long lossless storage time and the like, thereby promoting the promotion and the application of an LNG automobile.

Owner:ZHANGJIAGANG FURUI SPECIAL EQUIP CO LTD

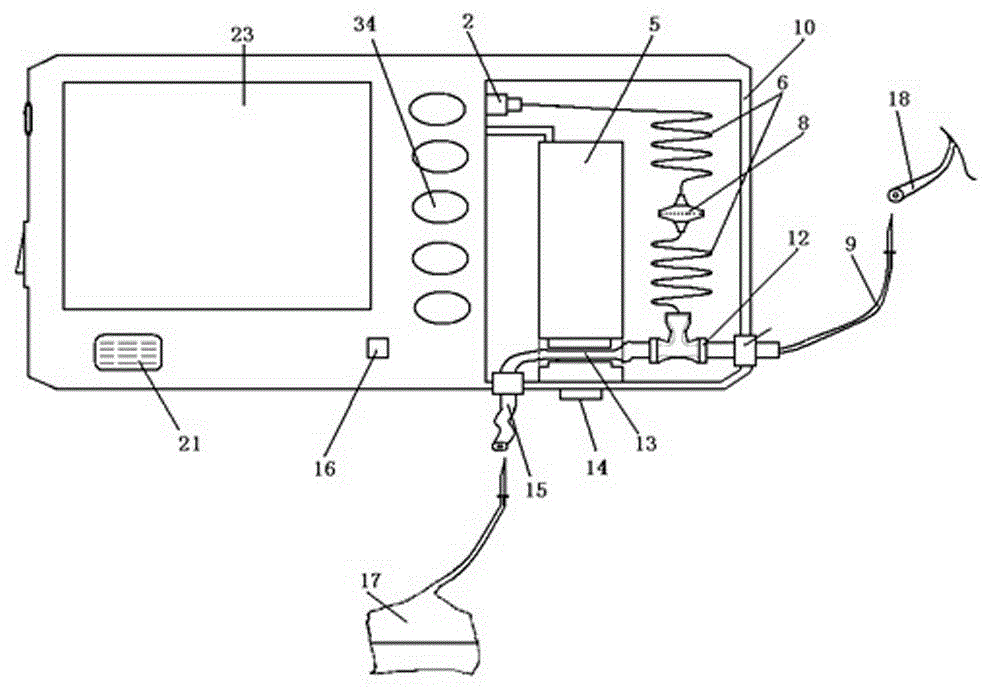

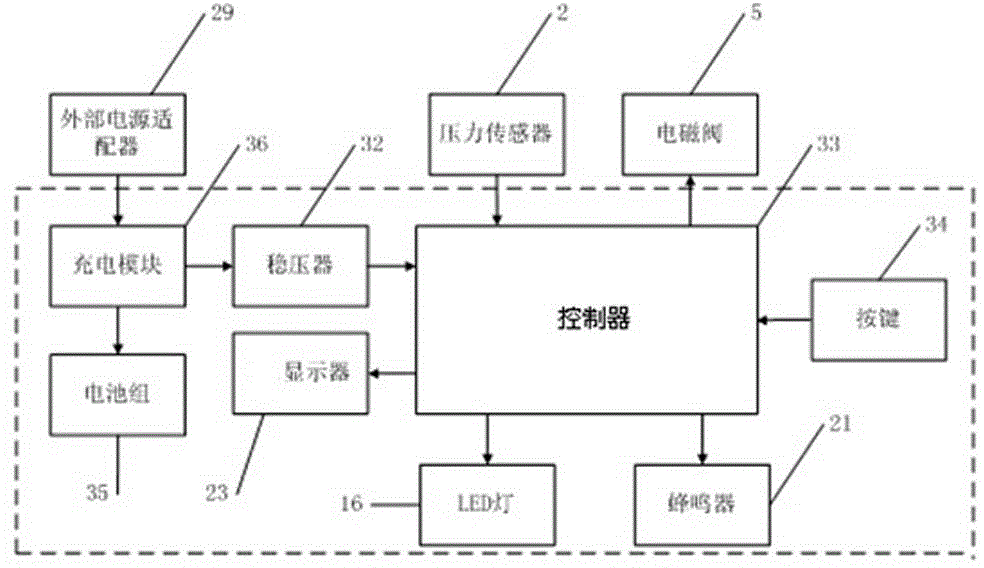

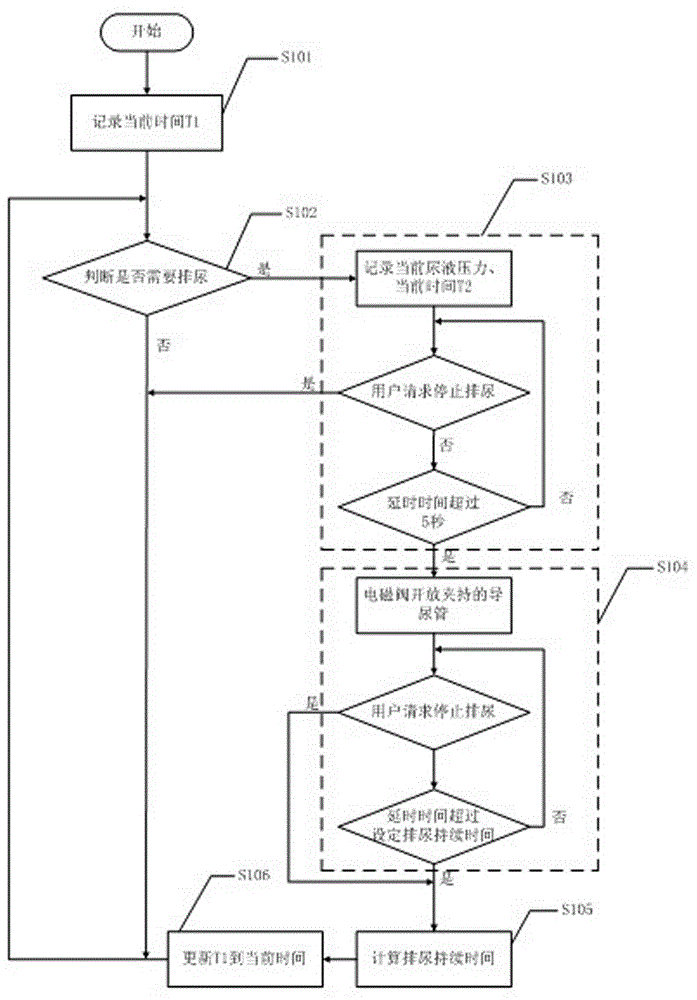

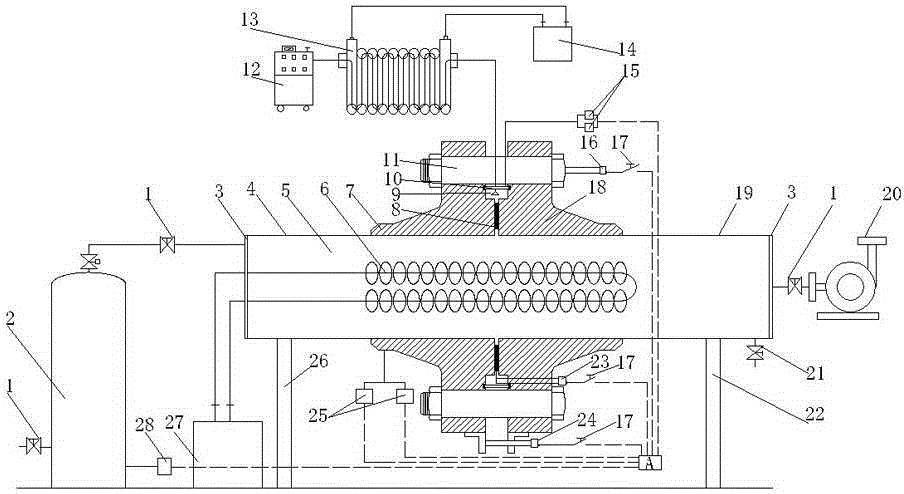

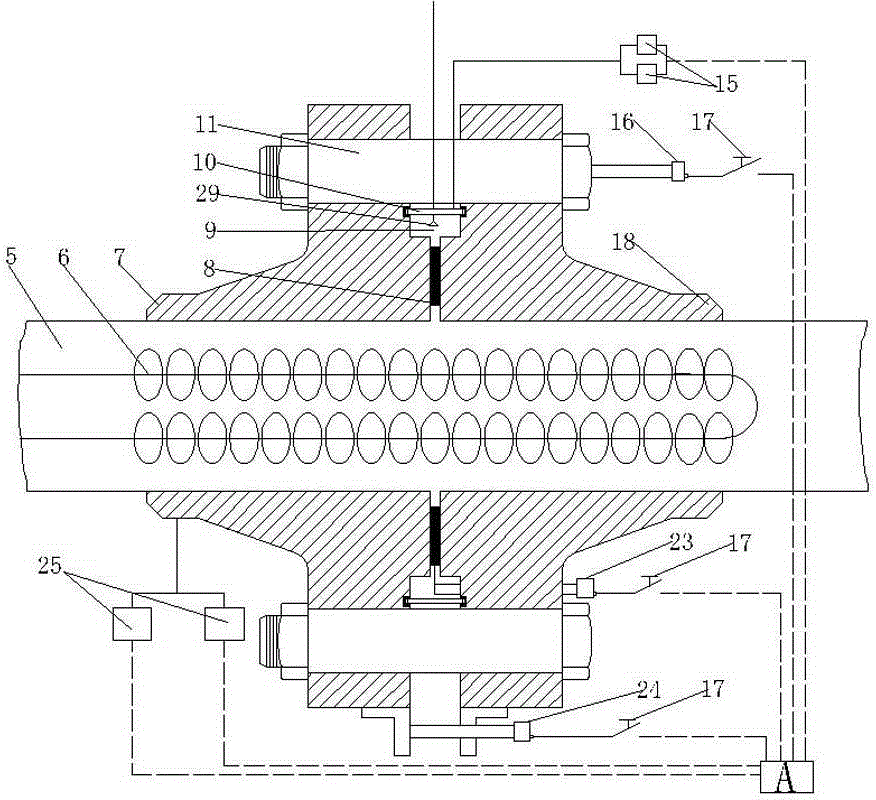

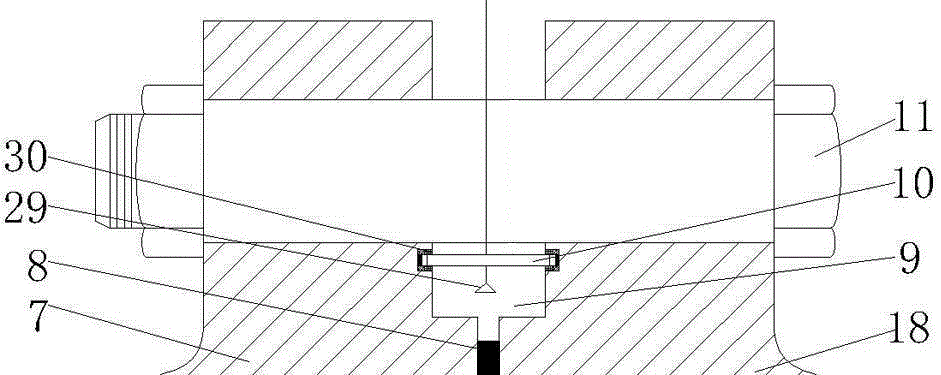

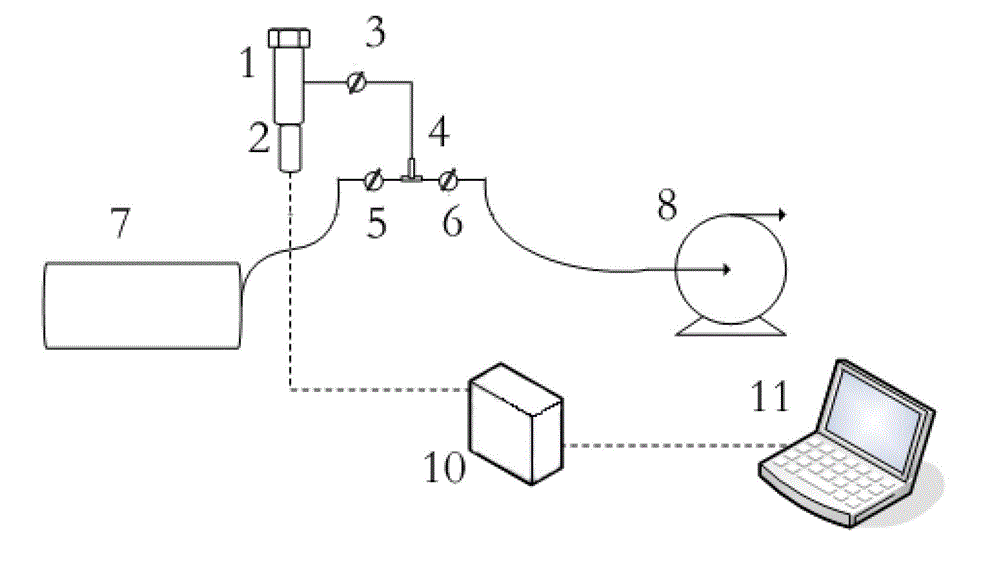

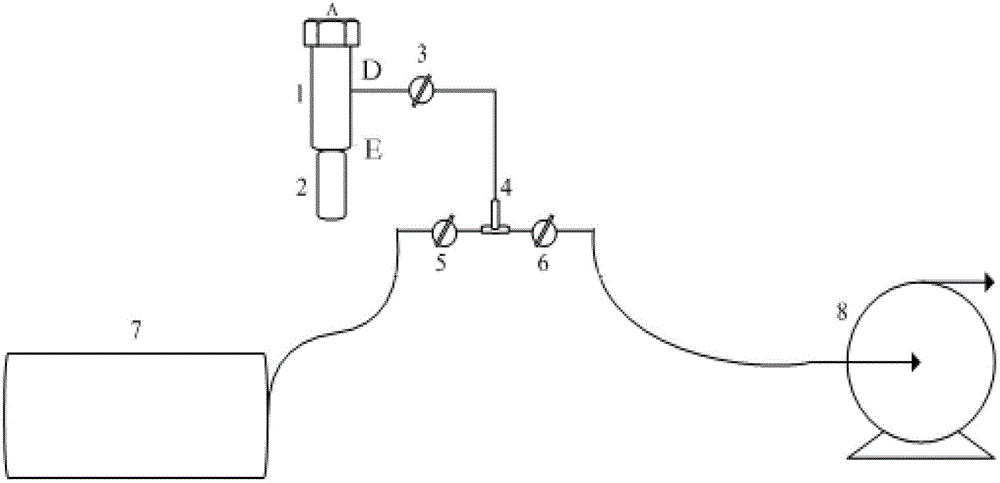

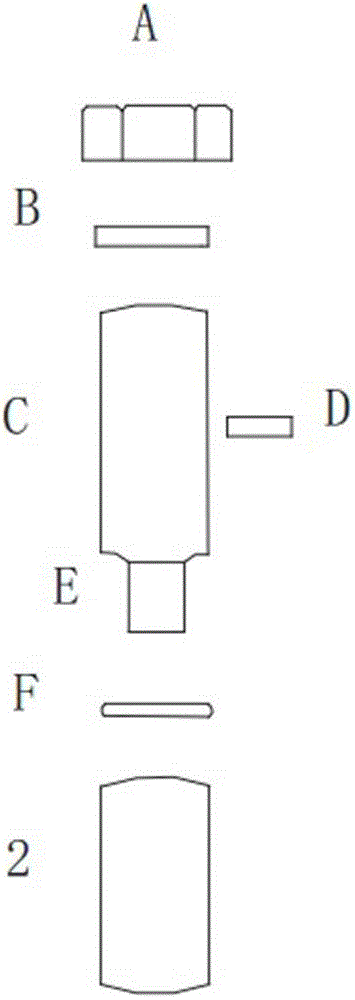

Intelligent urinary bladder micturition rehabilitation device and micturition monitoring method thereof

ActiveCN104623745AMonitor pressure in real timeAvoid cross infectionMedical devicesIntravenous devicesAir filterFoley catheter

An intelligent urinary bladder micturition rehabilitation device is installed between an indwelling catheter and a urine bag and comprises a three-way connector, an extrusion type electromagnetic valve, a pressure sensor and a controller, the three-way connector is provided with an inner chamber, an inlet end, an outlet end and a detection end, the inlet end, the outlet end and the detection end are communicated with the inner chamber, the inlet end is communicated with the indwelling catheter through a catheter, the detection end is communicated with the pressure sensor through a capillary tube, and the outlet end is communicated with the urine bag through an evacuating catheter; an air filter element beneficial to isolating urine from air is further arranged in the middle of the capillary tube, the extrusion type electromagnetic valve is provided with a mechanical switch capable of controlling the evacuating catheter to be opened, and the controller can control opening or closing of the extrusion type electromagnetic valve according to urine pressure output by the pressure sensor. According to a micturition monitoring method used through the intelligent urinary bladder micturition rehabilitation device, pressure of the urinary bladder is measured through urine in the catheter, opening and closing of the catheter are further controlled, the automatic micturition control function is achieved, and the advantages of convenience, sanitation, asepsis, non-pollution and no-cleaning are achieved.

Owner:KUNSHAN SHUANGQIAO SENSOR MEASUREMENT CONTROLLING

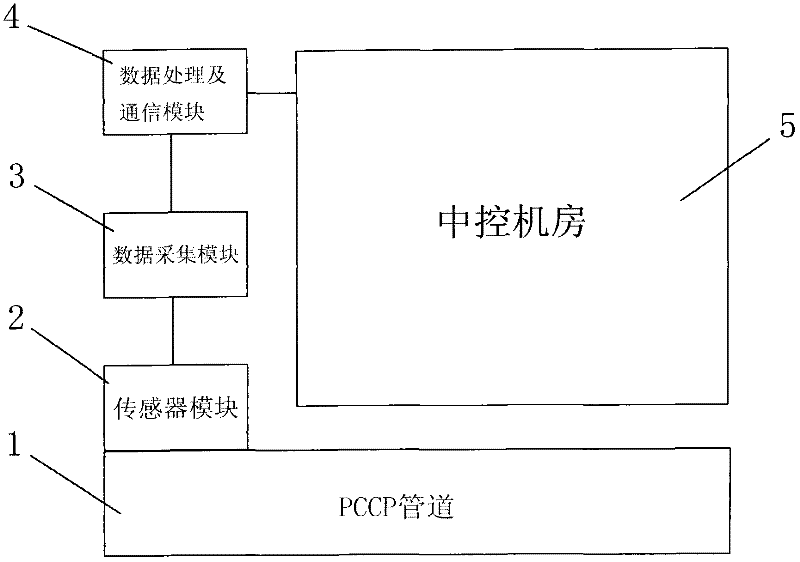

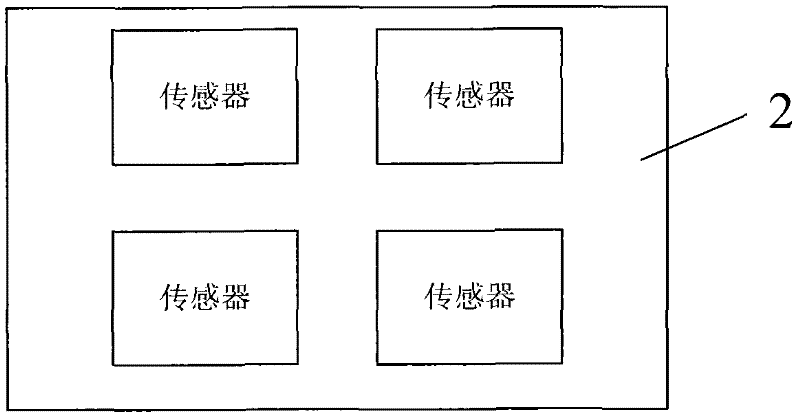

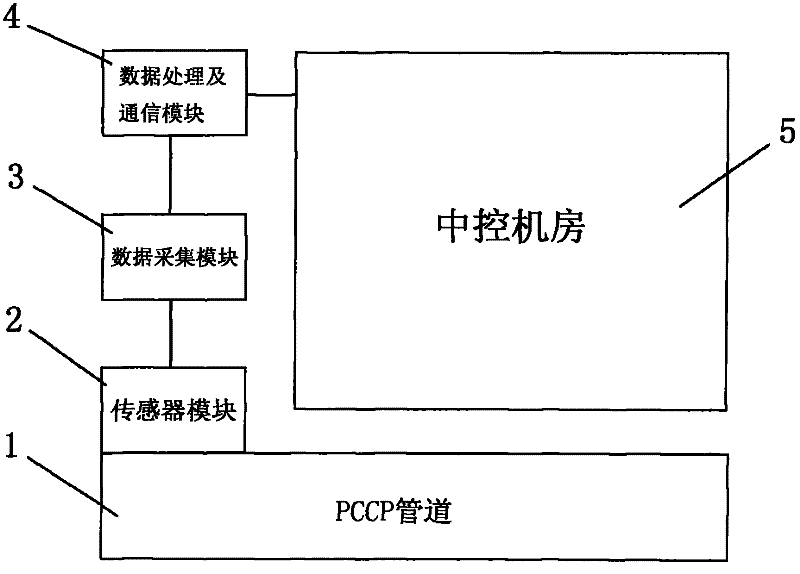

Online real-time monitoring system for an embedded delivery pipeline

InactiveCN102635786AImprove the level of informatizationReduce maintenance costsPipeline systemsTraffic volumeWater delivery

The invention discloses an online real-time monitoring system for an embedded delivery pipeline, which is characterized by comprising a PCCP (prestressed concrete cylinder pipeline), a sensor module, a data processing module, a communication module and a center control machine room. The sensor module is attached onto the PCCP, and is connected with the data processing module on earth surface or embedded shallowly through a cable, the data processing module is then connected with the communication module, and the communication module is connected with the center control machine room. Compared with the prior art, the online real-time monitoring system for the embedded delivery pipeline has the advantages that statues of pressure, flow rate, vibration, sedimentation and the like of the delivery pipeline can be monitored in real time, detail operation and safety states of the full delivery pipeline can be controlled in real time, history monitoring data can be accumulated, an emergency monitoring warning mechanism can be established, informatization level of engineering running can be increased, and safety of water delivery engineering can be guaranteed while operation maintenance cost can be lowered.

Owner:深圳市合益自动化科技发展有限公司 +3

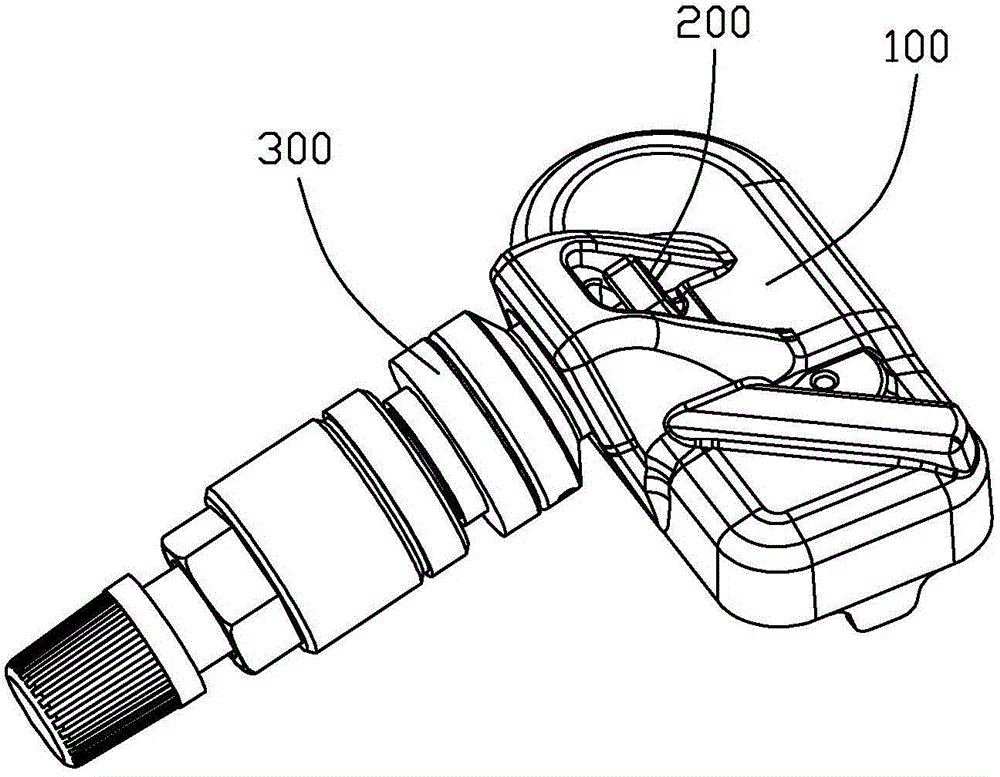

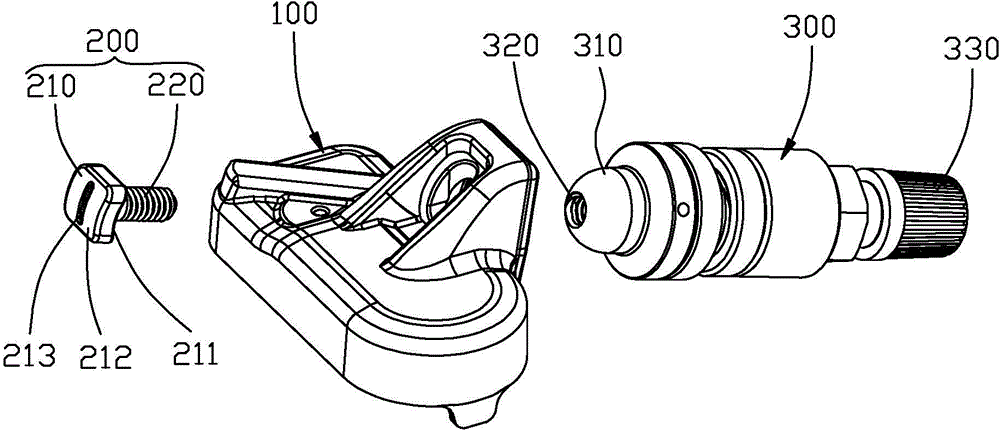

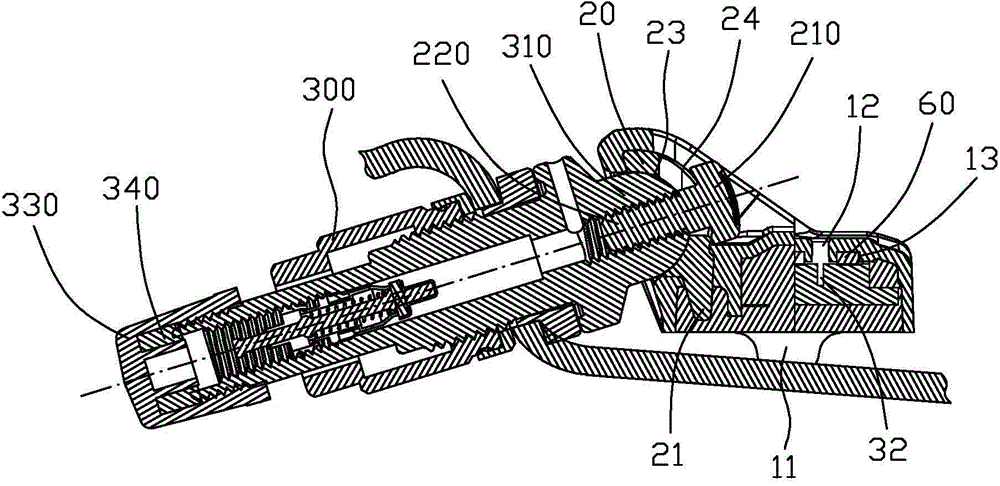

Built-in tire pressure sensor

ActiveCN104626892AMonitor temperature in real timeMonitor pressure in real timeTyre measurementsPressure sensorTire pressure

The invention relates to a built-in tire pressure sensor which is mounted in an automobile tire and used for detecting the pressure and temperature inside the automobile tire. The built-in tire pressure sensor comprises a shell, a circuit board accommodated in the shell, a battery connected with the circuit board and a sensor body, wherein a locating component is arranged on the shell and is fixedly connected with the shell into a whole, a hole through which a fixing component penetrates to be connected with an inflating valve is formed in the locating component, and the inner wall surface, facing the inflating valve, of the locating component is a concave curved surface. When the tire pressure sensor is assembled, the inflating valve and the inner wall surface of the locating component are in tight fit, the fixing component penetrates through the hole in the locating component to be fixedly connected to the inflating valve; since the inner wall surface, acting on the inflating valve, of the locating component is a spherical surface, the tire pressure sensor can rotate relative to the inflating valve and is still in tight fit with the inflating valve; therefore, by adjusting the angle of the tire pressure sensor, the tire pressure sensor can come into tight fit with assembly interfaces of different tires without swinging or rotating so as to monitor temperature, pressure and the like in the tires in real time.

Owner:SHENZHEN LONGHORN AUTOMOTIVE ELECTRONICS EQUIPCO

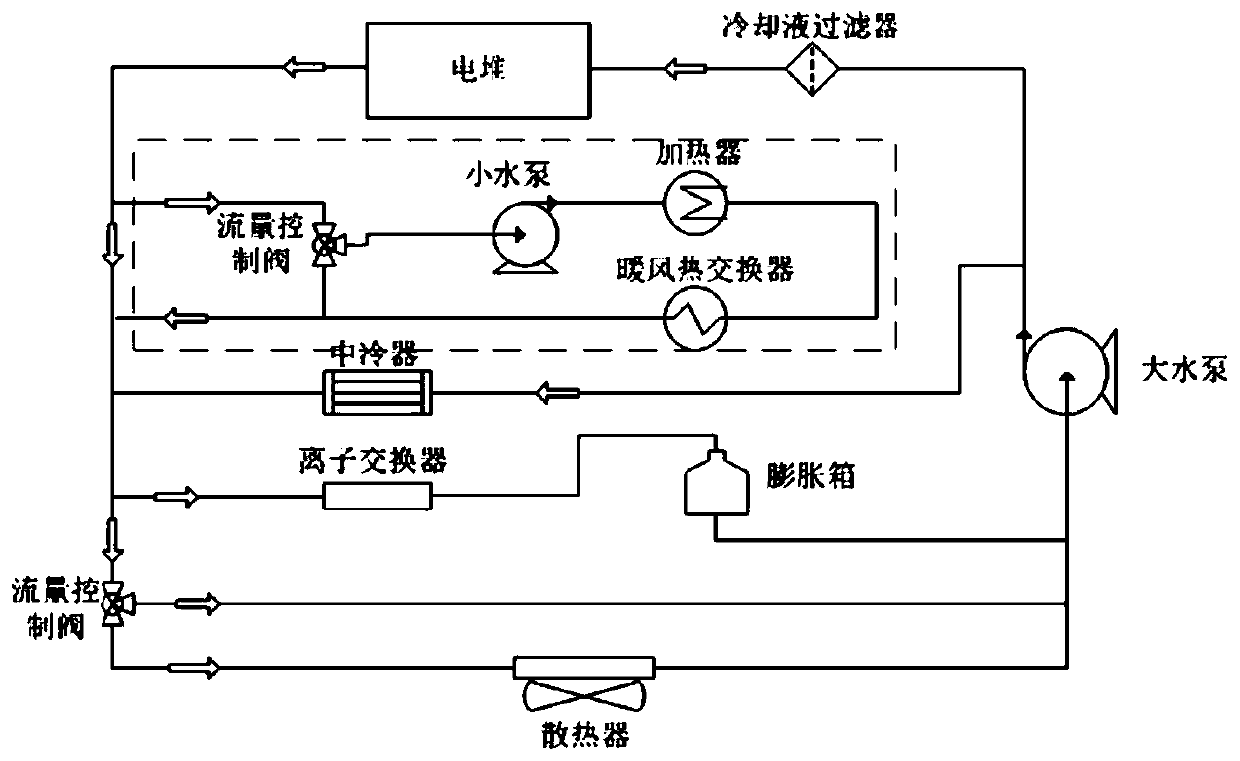

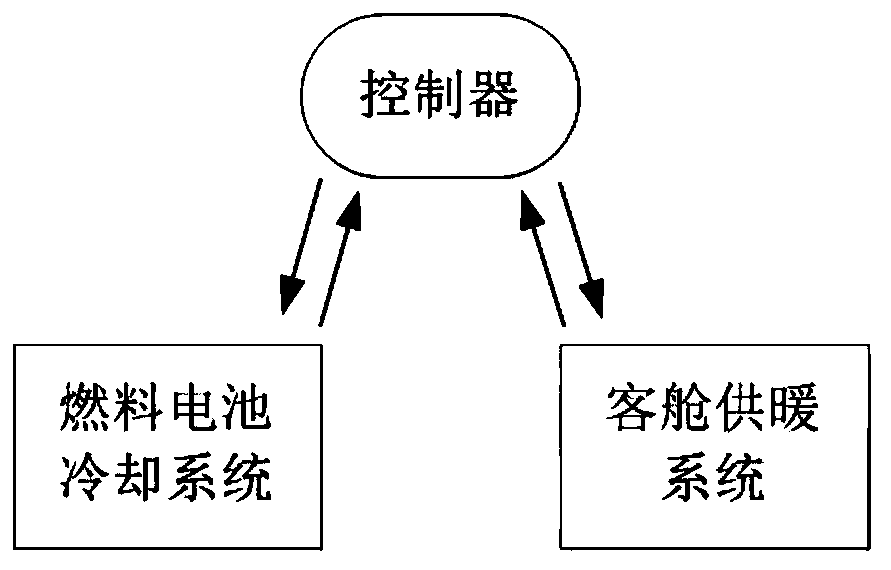

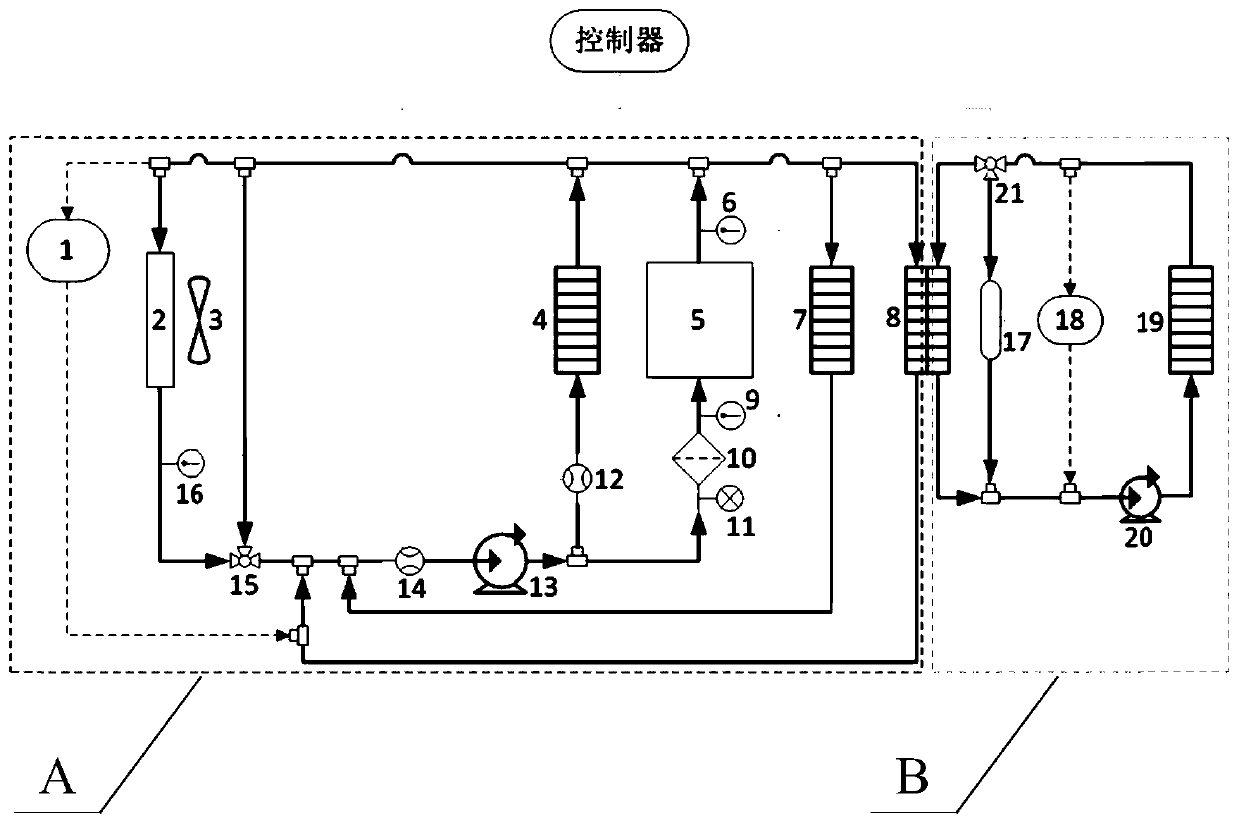

Thermal cycle management system for vehicle fuel cell

PendingCN111129541AExtended replacement cycleReduce raiseAir-treating devicesVehicle heating/cooling devicesFuel cellsCooling fluid

A thermal cycle management system for a vehicle fuel cell includes a stack cooling circuit, a cabin heating circuit, and a controller; the stack cooling circuit includes a first water pump, a deionization and filter assembly, a stack, and a cabin heat exchanger. The first water pump is arranged on a main loop of the stack cooling loop and used for providing circulating power for the galvanic pilecooling loop; the deionization and filter assembly is connected in series behind the first water pump and is used for removing ions and impurities in the cooling liquid; the stack is connected in series behind the deionization and filter assembly and is used for generating electric energy; the cabin heat exchanger is connected in series behind the stack and used for exchanging a part of heat generated by the stack to the cabin heating loop. According to the thermal cycle management system of the vehicle fuel cell, an integrated scheme of integrating the ion exchanger and the cooling liquid filter is adopted, the system performance is guaranteed, and the number of parts is reduced.

Owner:GUANGXI YUCHAI MASCH CO LTD

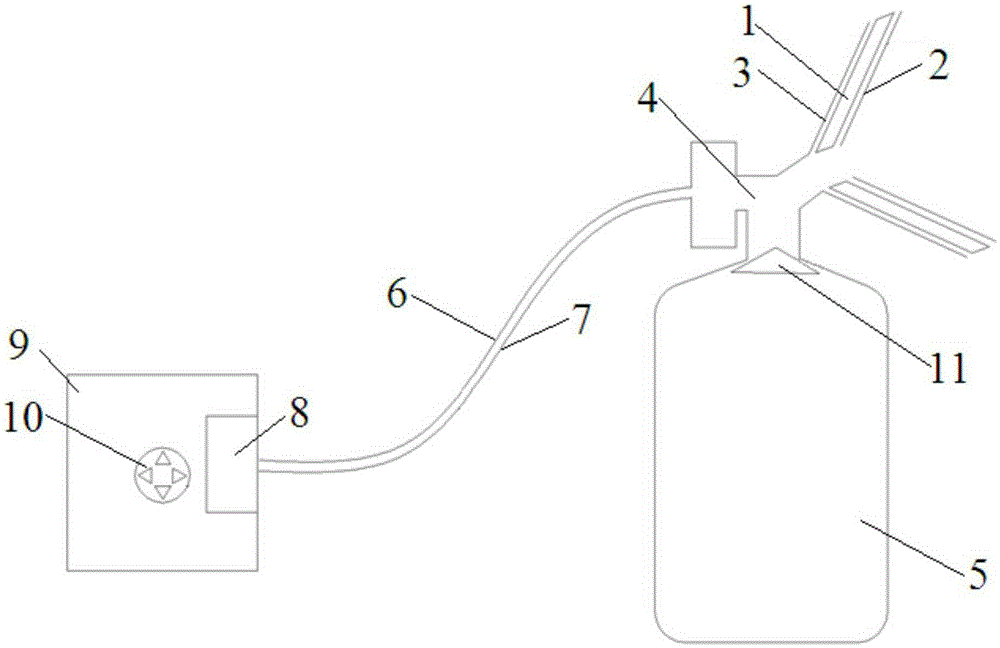

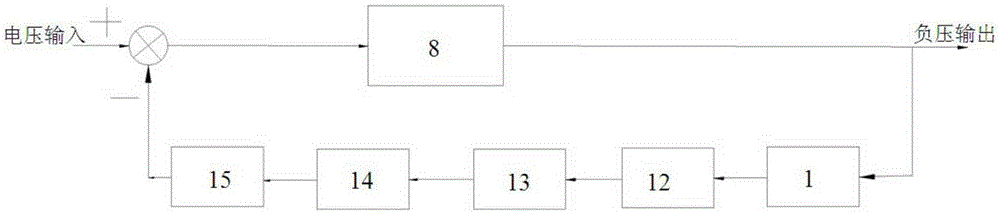

Electric breast pump for pressure feedback control based on flexible pressure sensor

The invention relates to an electric breast pump for pressure feedback control based on a flexible pressure sensor. The electric breast pump comprises a breast pump shield, a main body, an air suction tube, a vacuum pump and a control host, and further comprises a piezoelectric film sensor and a feedback unit, wherein the breast pump shield is connected to the main body; the main body is connected to the vacuum pump by virtue of the air suction tube; the vacuum pump is arranged inside the control host; a receiving container is connected to the lower end of the main body; the piezoelectric film sensor is arranged on the inner side of the breast pump shield; the feedback unit is arranged inside the control host; the piezoelectric film sensor is connected to the feedback unit; the piezoelectric film sensor is used for detecting negative pressure born by surface tissues of breasts and for transmitting the negative pressure to the feedback unit; and the feedback unit is used for controlling suction force of the vacuum pump according to feedback information. Compared with the prior art, the electric breast pump disclosed by the invention can monitor pressure on the breasts of a breast pump user in real time and can dynamically regulate the vacuum suction force of the breast pump, so as to avoid breast injury caused by the excessive vacuum suction force and to protect the healthy breasts of the user.

Owner:SHANGHAI NORMAL UNIVERSITY

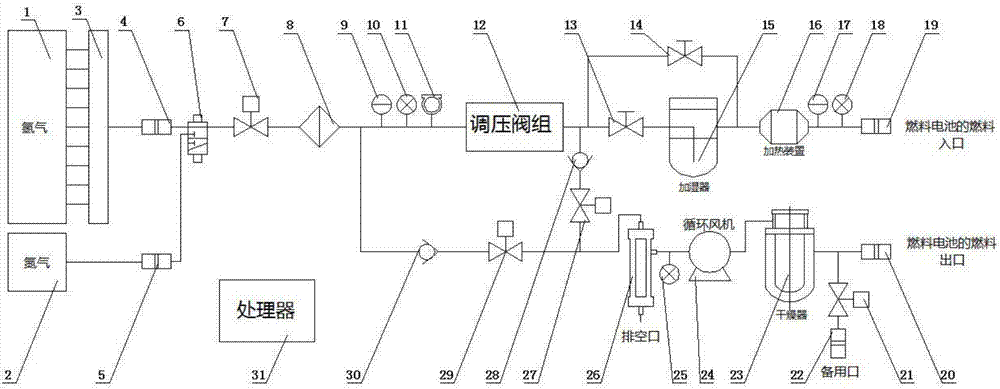

Fuel real-time monitoring and recycle device of fuel cell vehicle

PendingCN107017421AMonitor temperature in real timeMonitor pressure in real timeFuel cell controlVehicular energy storageProcess engineeringHydrogen supply

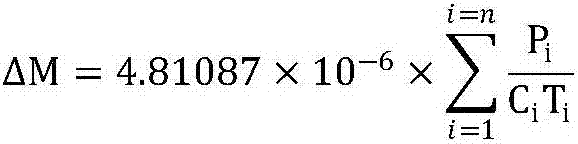

The invention provides a fuel real-time monitoring and recycle device of a fuel cell vehicle. The fuel real-time monitoring and recycle device comprises a main hydrogen supply pipeline and a hydrogen recycle pipeline, wherein the main hydrogen supply pipeline is used for adjusting pressure, temperature and humidity of hydrogen at an air outlet of the device by devices such as a temperature sensor, a heating device, a pressure regulation valve group and a pressure sensor, monitoring state quantity of the hydrogen in real time and calculating mass of the consumed hydrogen by an algorithm, and the hydrogen recycle pipeline is used for separating moisture and air from the hydrogen discharged out of the air outlet of the device, pressurizing the remaining hydrogen and then combining the remaining hydrogen to the main hydrogen supply pipeline. The main hydrogen supply in the device provided by the invention can be used for monitoring the temperature, the pressure and the flowing quantity of the hydrogen in real time and calculating the consumed hydrogen quantity by the algorithm, the pressure and the flowing quantity of the hydrogen at an inlet can be adjusted by the pressure regulation valve group, the temperature of the hydrogen at the inlet can be adjusted by the heating device, so that the optimal working condition of a fuel cell is reached.

Owner:BEIJING JIAOTONG UNIV

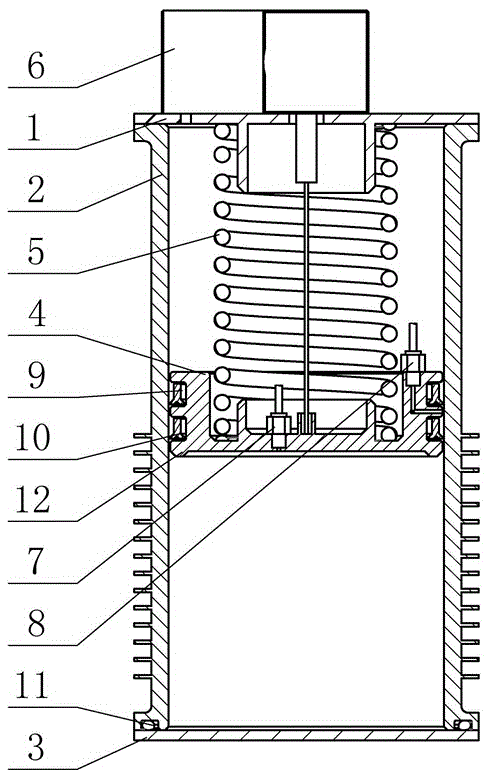

Porous medium penetration slip-casting multi-parameter monitoring device and test method thereof

InactiveCN105136195AMonitor pressure in real timeReal-time density monitoringMaterial analysisBoundary effectsPorous medium

The invention discloses a porous medium penetration slip-casting multi-parameter monitoring device and a test method thereof. The monitoring device comprises a slip-casting apparatus, which his connected to an inlet cabin. The inlet cabin is connected to one end of a connection steel pipe through connecting pieces, and the other end of the steel pipe is connected to an outlet cabin through connecting pieces. A joint position of the inlet cabin and the steel pipe and a joint position of the outlet cabin and the steel pipe are both provided with filter plates. The steel pipe is provided with a press measuring device. Slurry discharge pipes are connected at the bottom of the steel pipe, and a volume measuring apparatus is disposed below each slurry discharge pipe and positioned above a weighing apparatus. The filter plate of the outlet cabin is connected with a screw, and the screw is provided with a lower packing box. The outlet cabin is equipped with a flow measuring apparatus. The monitoring device helps to solve the problem of monitoring key parameters during porous medium penetration slip-casting. Compared with conventional research, the monitoring device has the advantages that various parameters can be monitored, the monitoring precision is high, the boundary effect of the device can be eliminated, and the device is adjustable in dimension and simple to operate.

Owner:SHANDONG UNIV

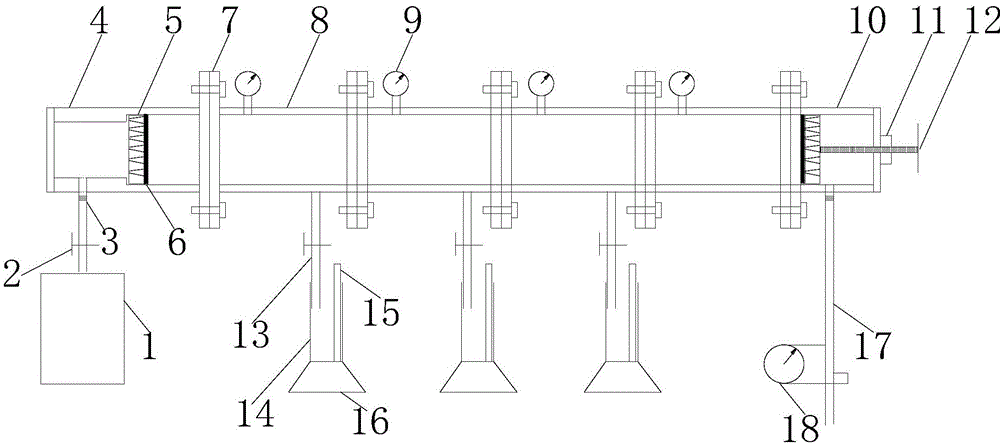

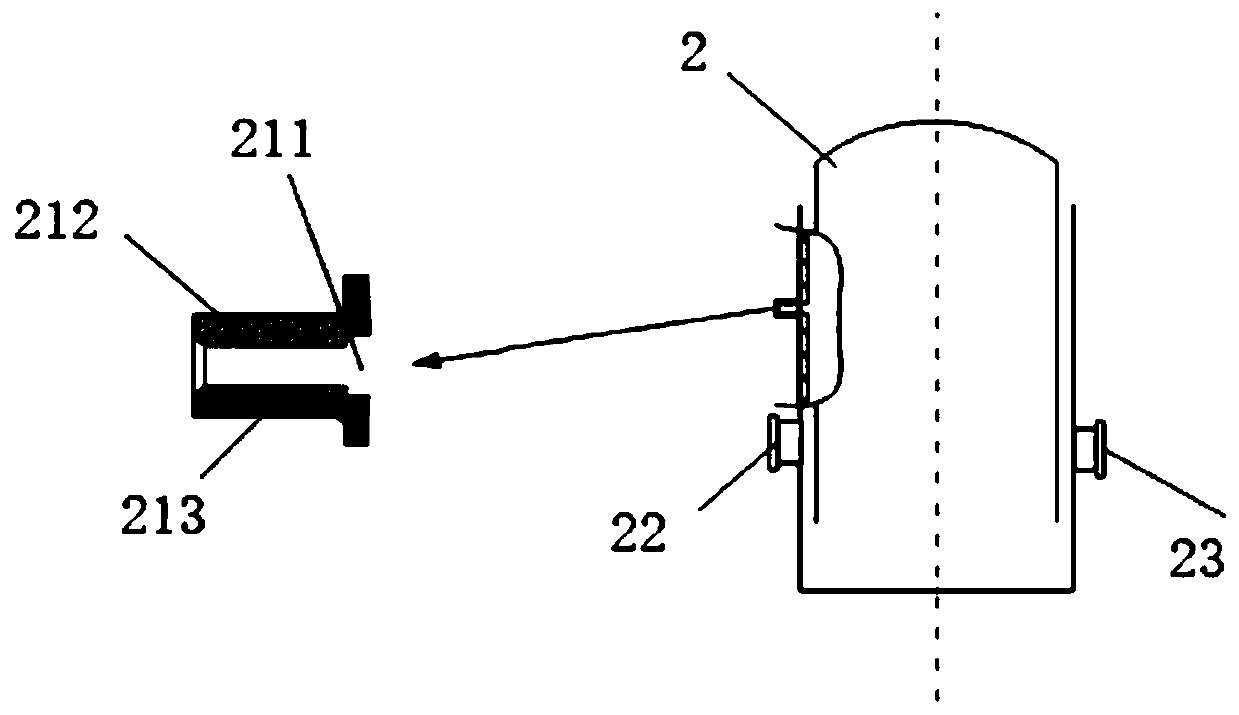

Spring pressurization closed type hydraulic oil tank with volume, pressure and leakage detecting function

ActiveCN104863909ACompact structureSmall footprintFluid-pressure actuator testingAccumulator installationsVolume variationEngineering

The invention discloses a spring pressurization closed type hydraulic oil tank with the volume, pressure and leakage detecting function. The spring pressurization closed type hydraulic oil tank comprises a stay wire sensor, a first mini-type pressure sensor, a second mini-type pressure sensor, a first piston seal ring, a second piston seal ring and base plate static seal rings, wherein annular radial radiating fins are arranged on the outer side surface of the oil tank barrel; annular sealing grooves are formed in the end surface of the bottom end of the oil tank barrel; each base plate static seal ring is mounted inside the corresponding annular sealing groove; the stay wire sensor is mounted on the top surface of an upper plate; the first mini-type pressure sensor and the second mini-type pressure sensor both connected with an accommodating chamber are mounted on a piston; two through holes respectively serving as an oil inlet and an oil outlet of the oil tank are machined in a base plate; the oil tank is connected with an external valve block by taking the bottom surface of the base plate as a mounting surface and by adopting a plate-type mounting manner. According to the invention, the hydraulic oil tank is compact in structure, small in occupied space, and isolated from air, can be used for pressurizing accommodated hydraulic media, and can adapt to the volume variation of the accommodated hydraulic media; the sensors of the oil tank can be used for monitoring the volume and pressure of the hydraulic media in the oil tank in a real-time manner, and can be used for monitoring whether the oil tank leaks or not, so that powerful data support can be provided for healthy management of the hydraulic system provided with the oil tank.

Owner:ZHEJIANG UNIV

Gas burning system and igniting method thereof

InactiveCN104421959AAvoid enteringImprove securityFuel supply regulationCombustion systemCombustion chamber

The invention discloses a gas burning system. The gas burning system comprises a burning chamber, a gas main pipeline, a gas branch pipeline, an air main pipeline and a central control unit, wherein the gas main pipeline and the air main pipeline are respectively connected with the burning chamber, the gas main pipeline is sequentially provided with a first gas pressure sensor, a first cutting valve, a second cutting valve and a second gas pressure sensor along the flowing direction of gas, the gas main pipeline between the first cutting valve and the second cutting valve is communicated with one end of the gas branch pipeline, the other end of the gas branch pipeline is connected with the burning chamber, the gas branch pipeline is provided with a third cutting valve and a fourth cutting valve, and an igniting device and a fire detecting device are arranged inside the burning chamber. The burning system ignites in a fire-leading mode and can control the process before and during fire-leading and during working and burning. Accidents caused by the deflagration phenomenon and the gas leakage are prevented.

Owner:BEIJING NEW BUILDING MATERIALS PLC

On-line monitoring system of substation low-oil equipment

InactiveCN108051032AEasy to collectComprehensive collectionMeasurement devicesTransformerMonitoring system

The invention discloses an on-line monitoring system of substation low-oil equipment. The on-line monitoring system can monitor the oil hydraulic force, the temperature and the hydrogen content of theoil-less equipment such as a voltage transformer, a low-oil circuit breaker and a (insulation) sleeve in real time, to timely discover defects, and the monitoring effect is reliable and comprehensive. The structure of the original equipment body does not need to be damaged, and a very convenient oil sample collection structure is also provided. The device comprises a tee joint installed on an oildischarge port; and one inlet of the tee joint is connected with the oil discharge port, and the two outlets of the tee joint are respectively provided with a monitoring sensor and a leading-down sampling tube. A threaded mounting head used for being assembled on one outlet of the tee joint is arranged in the center of the bottom cover of the monitoring sensor. A pressure transmitter mounting block fixedly arranged on the bottom cover and a hydrogen sensor fixing on the pressure transmitter mounting block are arranged in sequence from bottom to top in a shell. A pressure transmitter is arranged on the pressure transmitter mounting block.

Owner:STATE GRID XINJIANG ELECTRIC POWER CORP +2

Device for measuring resistance of powder material

InactiveCN106324350AConstant volumeMonitor pressure in real timeResistance/reactance/impedenceElectrical resistance and conductanceMeasuring instrument

The invention relates to a device for measuring the resistance of a powder material, and the device is characterized in that the device comprises a pedestal support, wherein the interior of the pedestal support is provided with a pressure maintaining mechanism, a pressure sensor, and a powder container; the pressure maintaining mechanism, wherein the upper end of the pressure maintaining mechanism is provided with a pressurizer, and the lower end of the pressure maintaining mechanism is connected with the pressure sensor; the pressure sensor which is connected with a pressure measuring device; the powder container which contains a temperature sensor, wherein the upper and lower ends of the powder container are respectively provided with an upper electrode and a lower electrode, which can move; a resistance measuring instrument which is movably connected with the upper electrode and the lower electrode through wires; and insulating layers which are disposed at two ends of the powder container. Because a mechanism for adjusting the pressure and maintaining the pressure stability in a measurement process is set and the pressure sensor, the pressure measuring instrument and a temperature sensor are also set, the device can enable the powder in the powder container to be kept under the specified requirements, also can monitor the pressure and temperature of powder in real time, and enables the resistance measurement data to be more accurate.

Owner:GUANGDONG POLYTECHNIC NORMAL UNIV

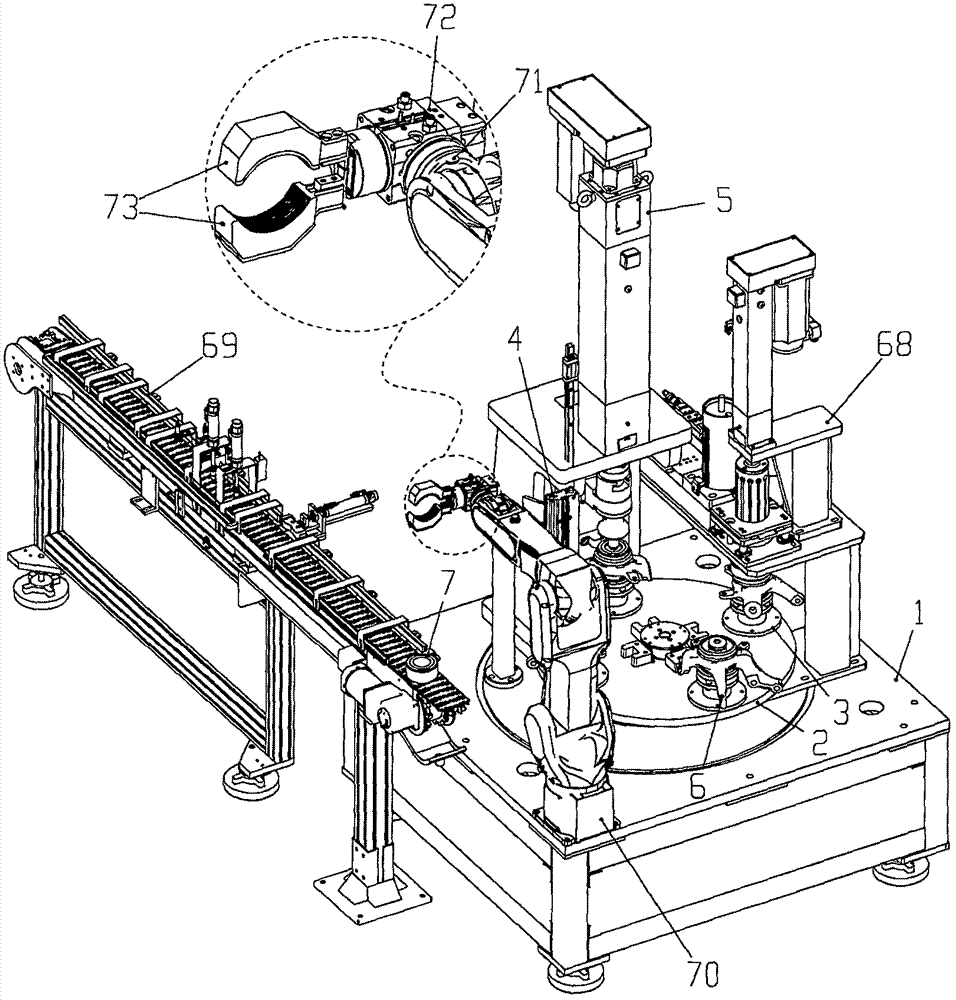

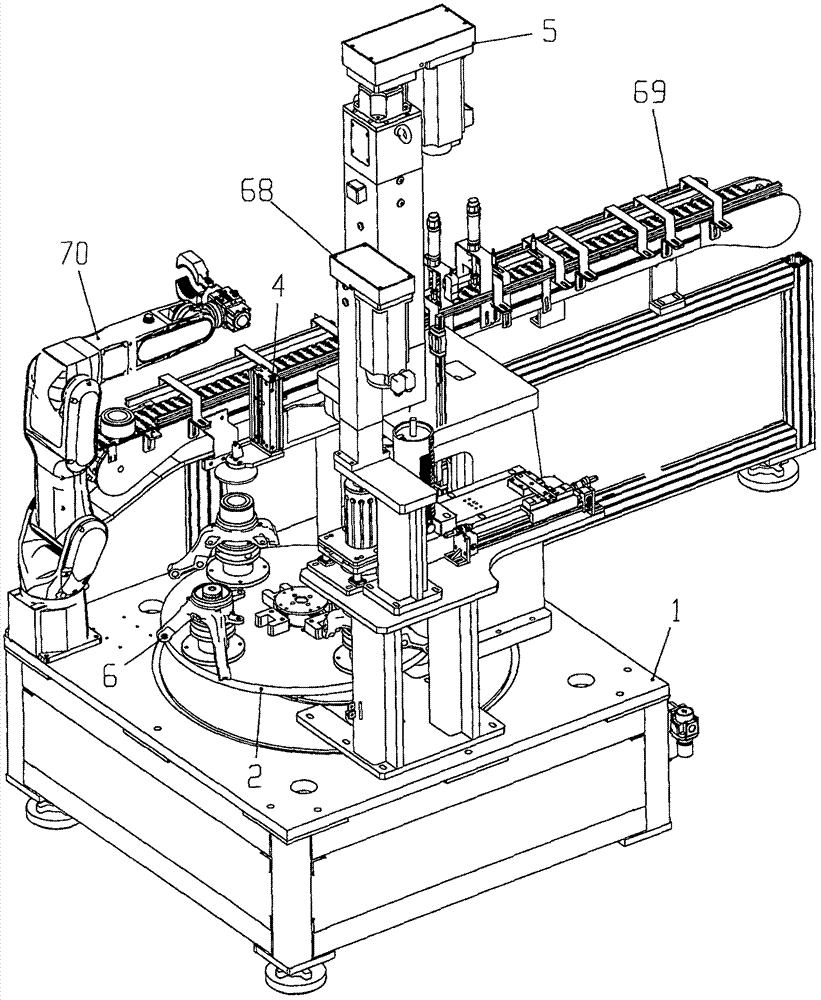

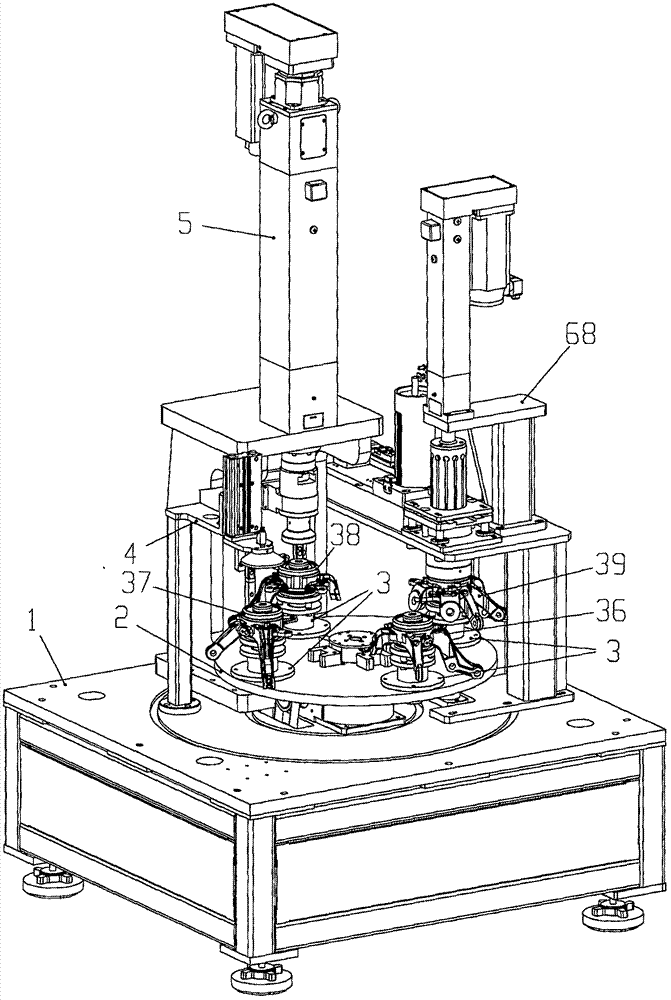

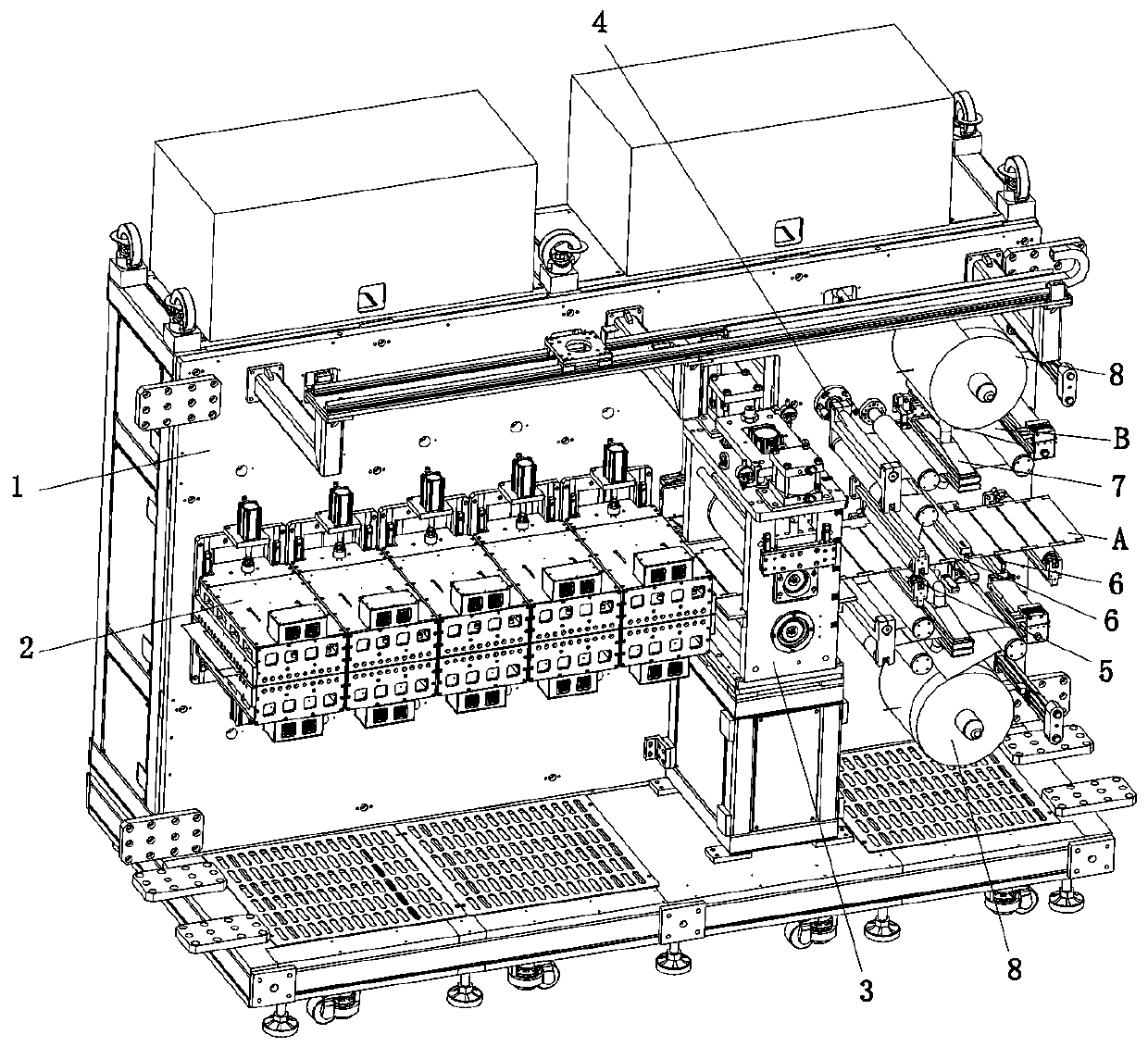

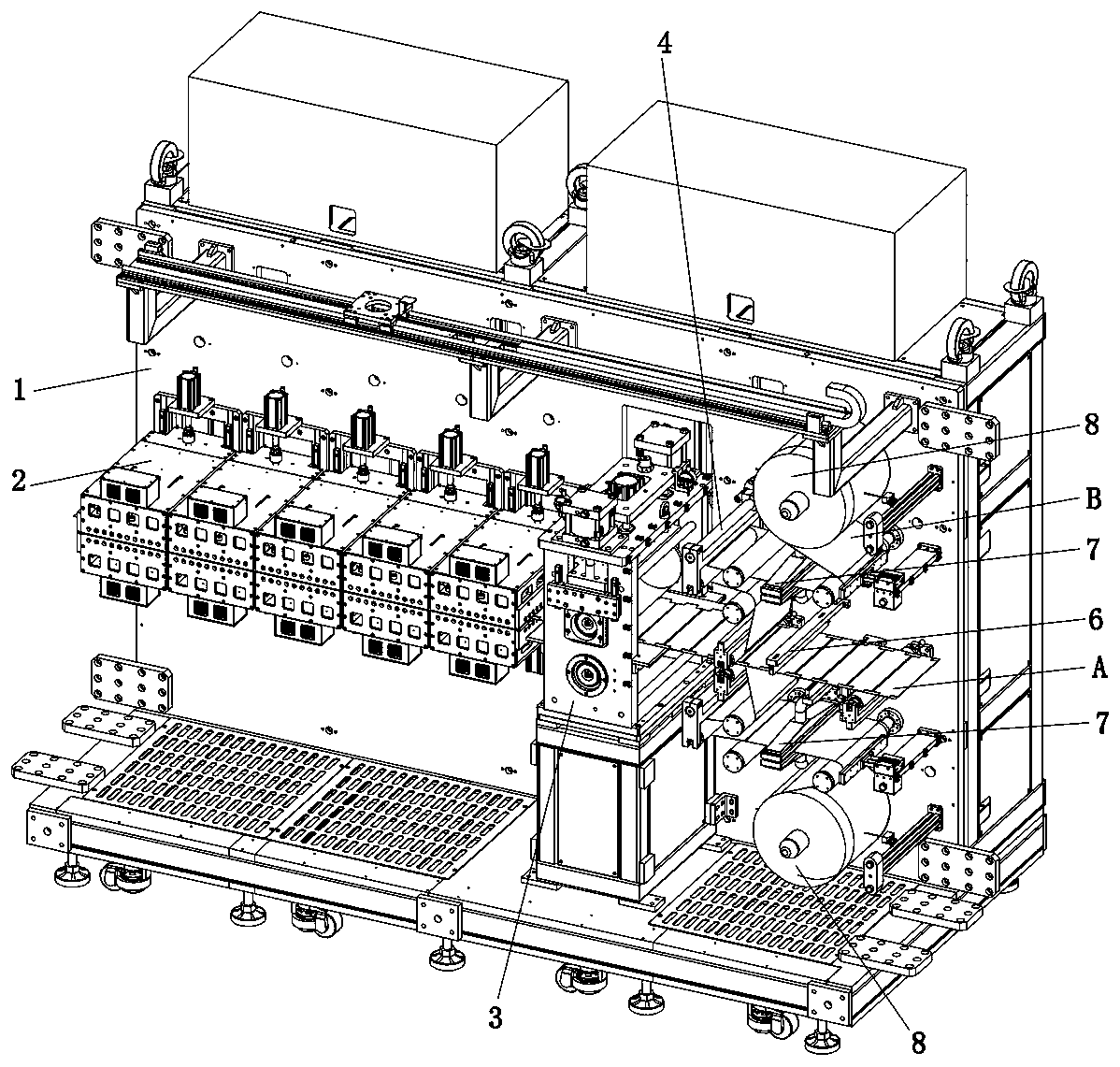

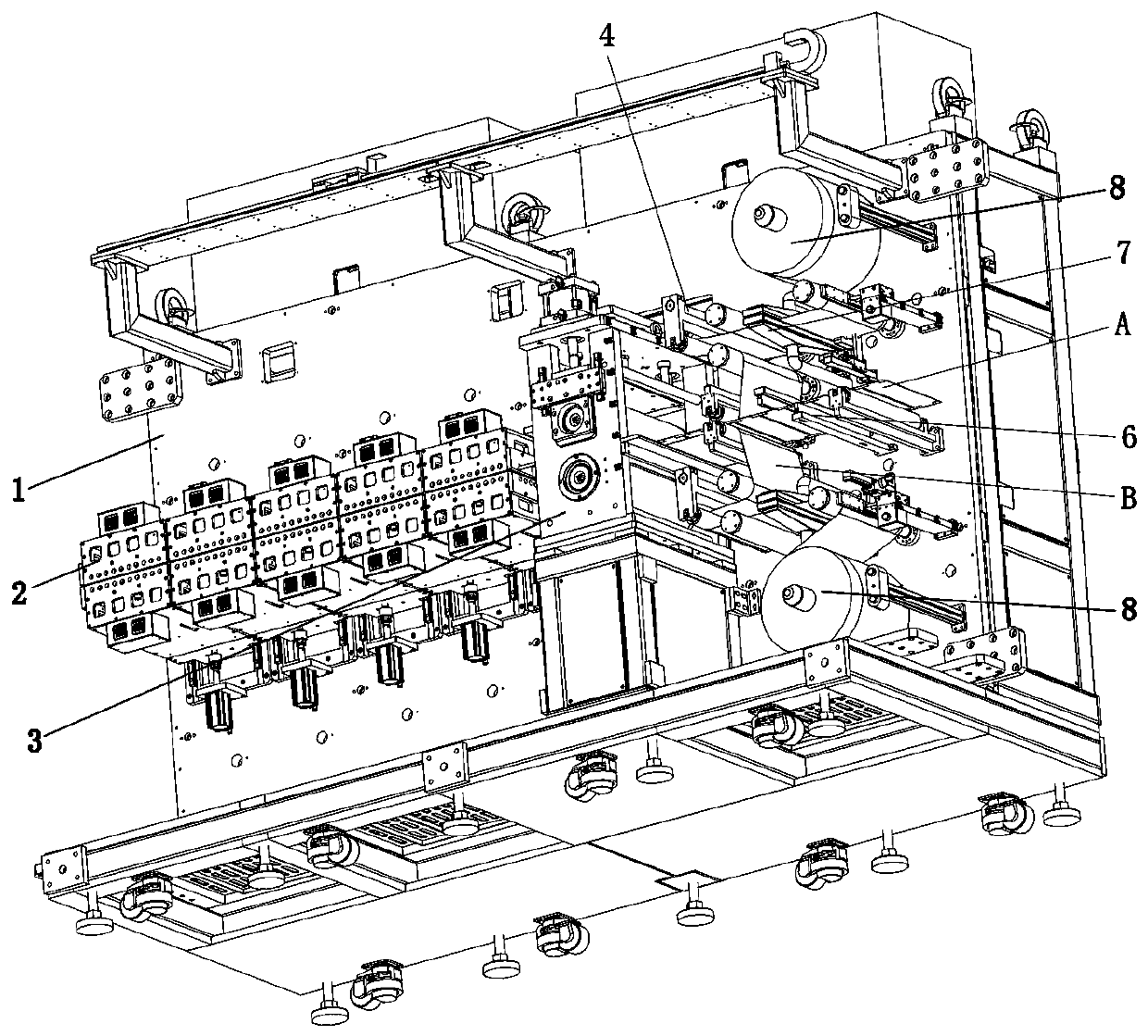

Industrial robot assisted intelligent flexible manufacturing production line

InactiveCN106956133AReduce frictional resistanceFirmly connectedAssembly machinesProduction lineAssembly line

The invention relates to an industrial automatic equipment assembly line, in particular to an automatic assembly line used for manufacturing automotive components. An industrial robot assisted intelligent flexible manufacturing production line comprises a conveying chain used for conveying a bearing, a robot mechanism used for grabbing the bearing, a machine base, a clamp used for loading and unloading of a steering knuckle, a rotating disc mechanism used for driving the clamp to carry out station conversion, a lubricating system used for lubricating a bearing hole of the steering knuckle, an extruding mechanism used for extruding the bearing so as to enable the bearing to enter the bearing hole, and a clamping spring assembling mechanism used for assembling an inner clamping spring into the steering knuckle. According to the industrial robot assisted intelligent flexible manufacturing production line, automatic precise assembling of the bearing, the inner clamping spring and the steering knuckle can be achieved, and smooth and controllable assembling process is ensured.

Owner:WENZHOU POLYTECHNIC

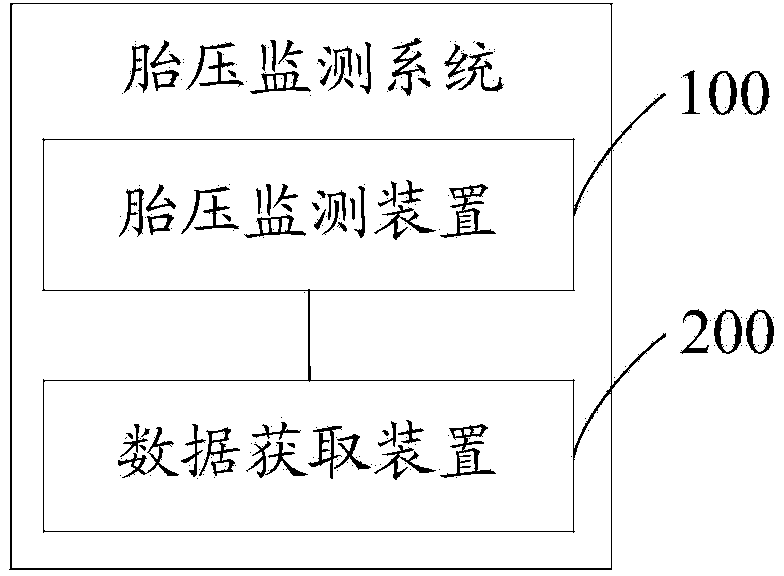

Tire pressure monitoring system and device

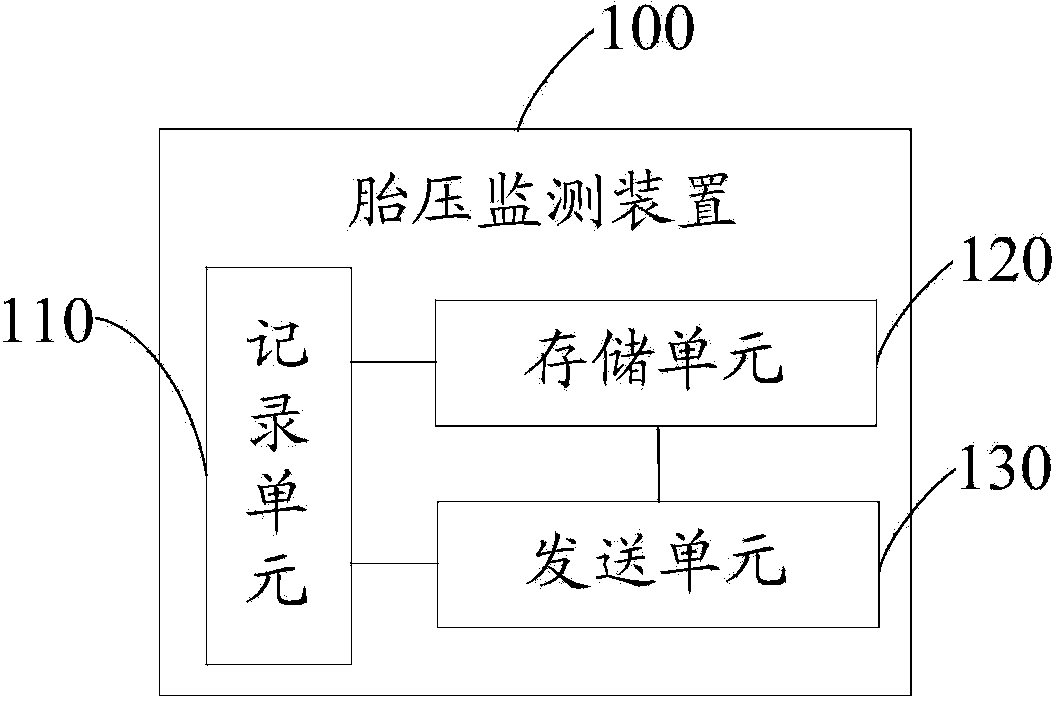

ActiveCN103832224AMonitor pressure in real timeImplementation track recordTyre measurementsInternal memoryTire-pressure monitoring system

The invention discloses a tire pressure monitoring system and a tire pressure monitoring device. The tire pressure monitoring system comprises the tire pressure monitoring device and a data acquiring device, wherein the tire pressure monitoring device is used for monitoring a tire parameter in real time, recording primary state data into an internal memory of the tire pressure monitoring device and sending the state data to the data acquiring device when the tire parameter reaches the preset value; the data acquiring device is used for acquiring the state data including recording time and tire parameters. According to the tire pressure monitoring system and the tire pressure monitoring device, the tire parameters including the pressure and the like can be monitored in real time, thus achieving real-time monitoring and pre-warning purposes; a driving state of an automobile in a certain time and the situation changes of the parameters including the pressure, the temperature, the accelerated speed and the like can be recorded, so that the track record to the driving state of the automobile is realized, and the stability and the reliability are improved; meanwhile, the system and the device can further play helping roles in the driving state analysis, troubleshooting and the like of the automobile after an event and even play certain reference roles in the accident cause affirmation of vehicles.

Owner:AUTEL INTELLIGENT TECHNOLOGY CORP LTD

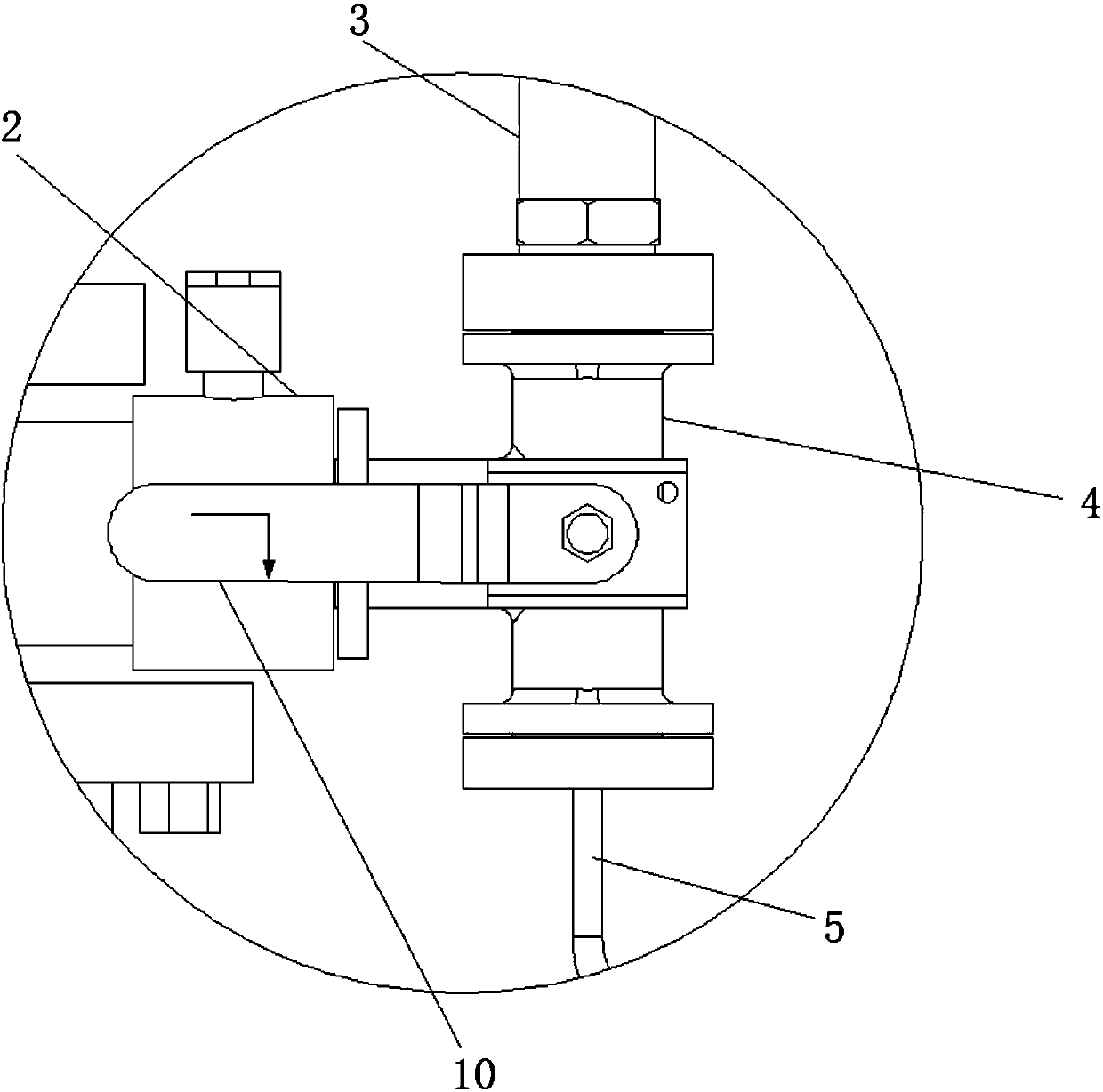

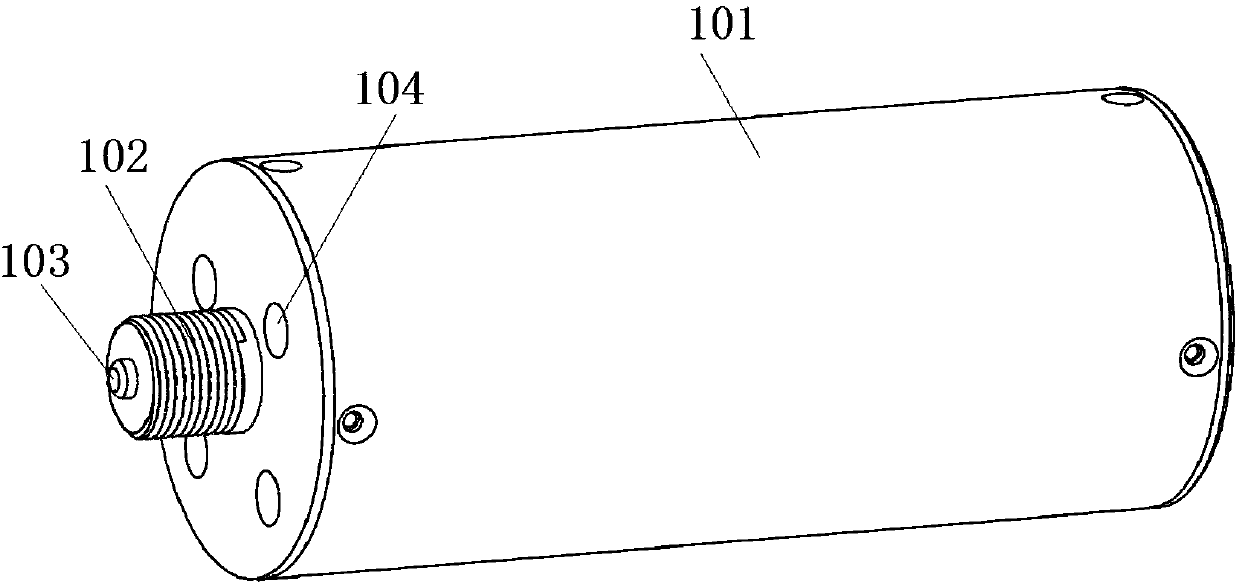

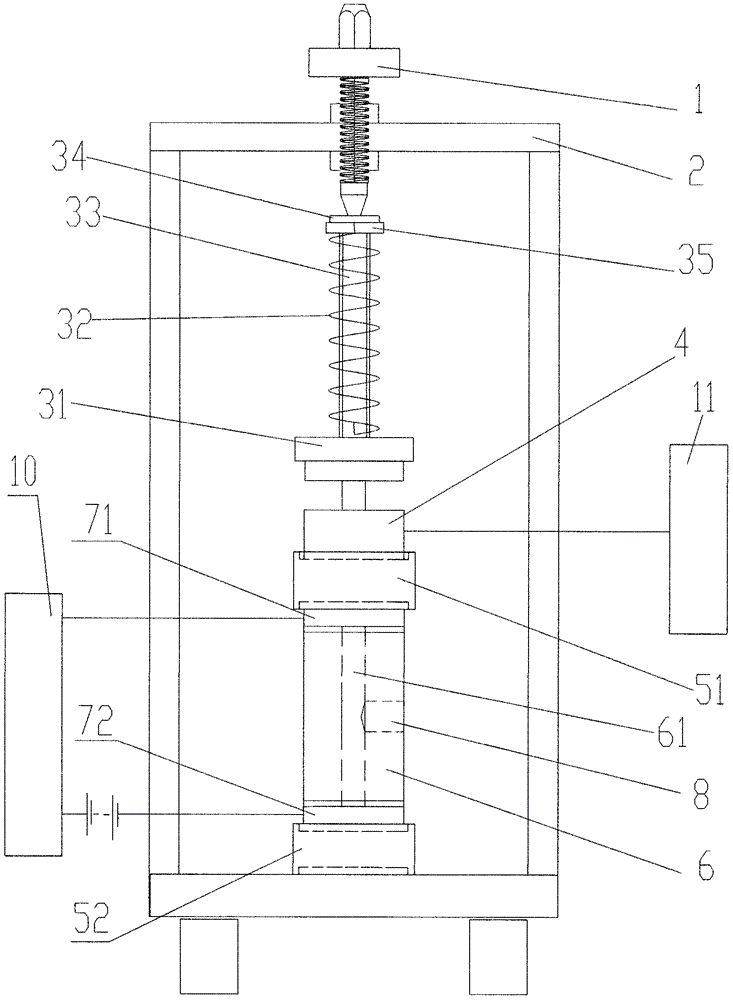

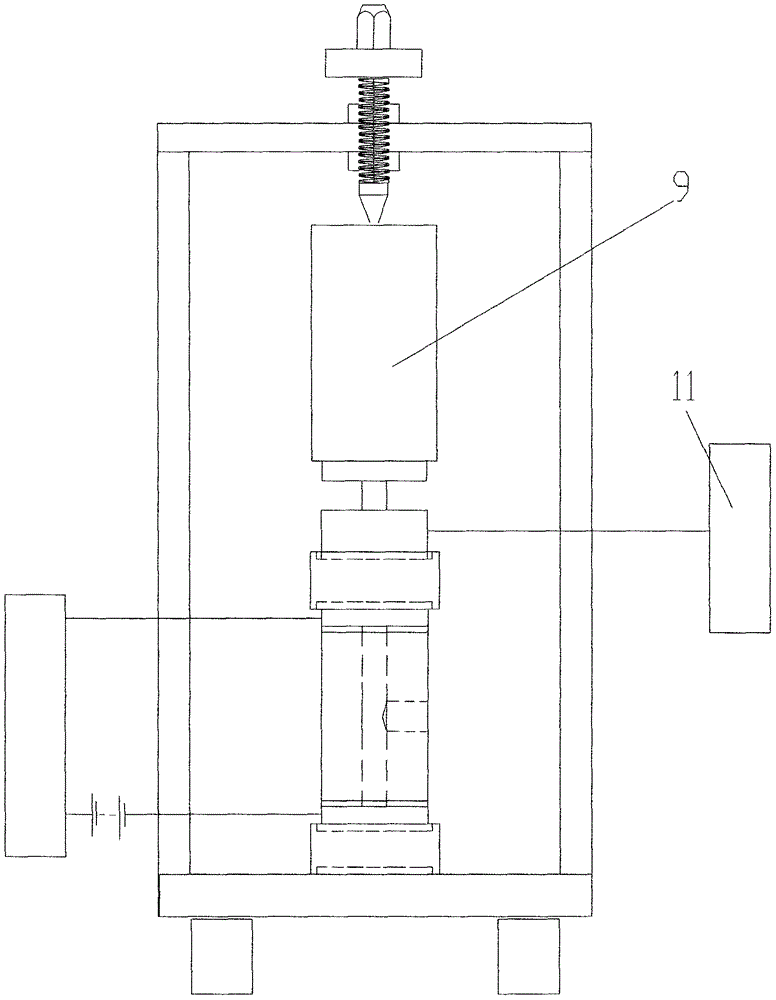

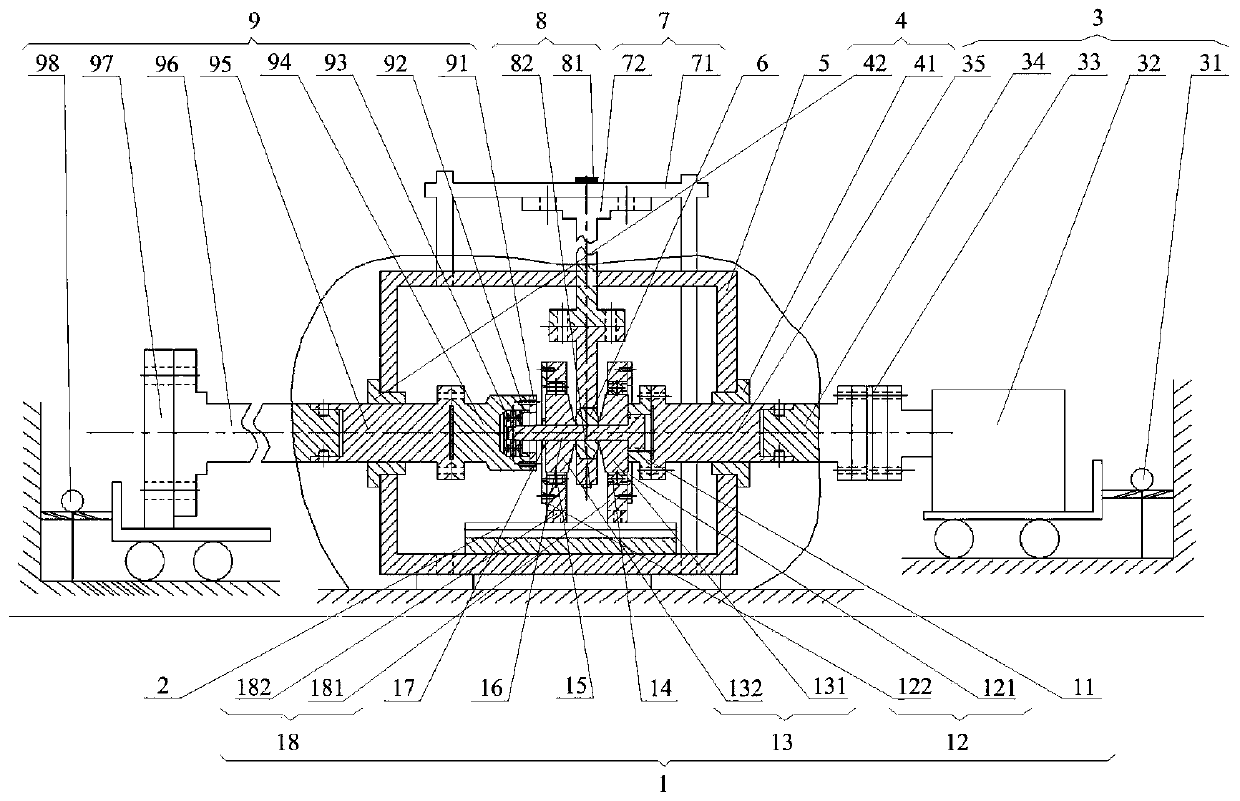

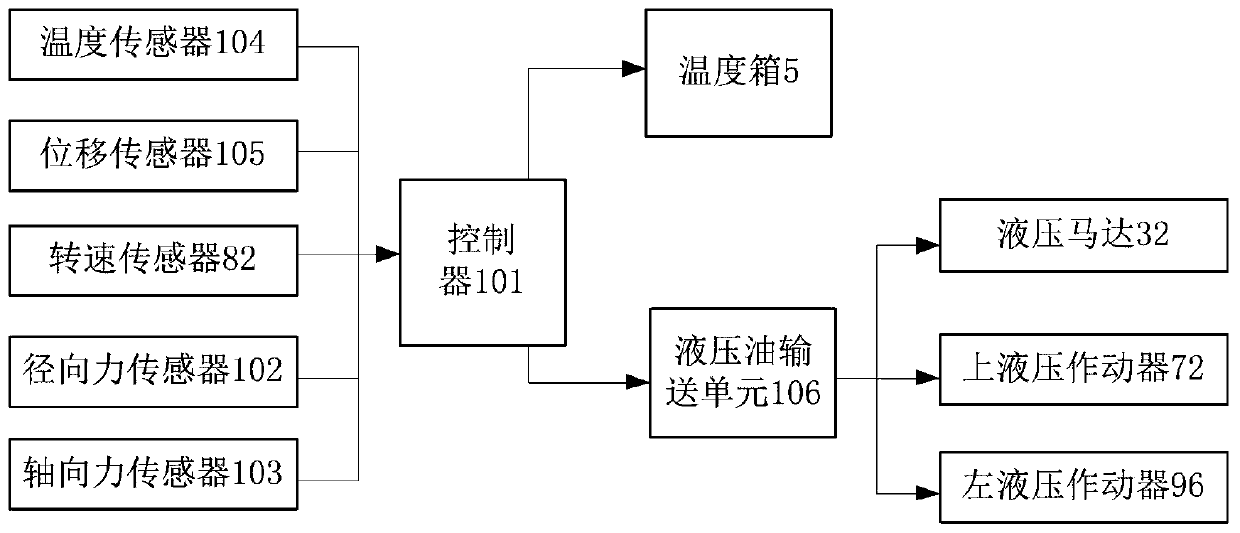

Clamp system for joint bearing life test

ActiveCN111189636AQuick installationQuick releaseMachine bearings testingControl systemClassical mechanics

The invention provides a clamp system for a joint bearing life test. The clamp system comprises a joint bearing clamping subsystem, a base, a rotation applying subsystem, a box penetrating shaft sleeve, a temperature box, a tested joint bearing, a radial load applying subsystem, an axial load applying subsystem, and an acquisition and control system. The clamp can apply an axial load to the testedjoint bearing through the axial load applying subsystem, and apply a radial load to the tested joint bearing through the radial load applying subsystem. The clamp has strong universality, clamping oflife tests of joint bearings of different width series can be achieved by replacing and adjusting bushings, clamping of life tests of joint bearings of different diameters can be achieved by replacing a core shaft, an ejector block and a loading plate, and the test clamp is high in utilization rate and good in universality.

Owner:CHINA AERO POLYTECH ESTAB

Conveying pipeline pressure detection device

PendingCN109253394AMonitor pressure in real timeSave operating timeFluid pressure measurementPipeline systemsInternal pressureEngineering

The invention relates to the technical field of pressure detection devices and discloses a conveying pipeline pressure detection device. The conveying pipeline pressure detection device comprises a pipe body, the top end of the pipe body is provided with a first opening, a transmission rod is slidably mounted in the first opening, a pressure testing plate is welded to the bottom end of the transmission rod and positioned in the pipe body, and first sliders are fixedly mounted on two sides of the pressure testing plate. Two limiting supporting frames are welded to the top inner wall of the pipebody and positioned on two sides of the pressure testing plate respectively. A slide device is mounted at the top end of the pipe body and comprises a driven plate welded to the top end of the transmission rod, the driven plate is positioned in a fixing supporting frame which is welded to the top end of the pipe, and a scale rod is welded to the center of the top end of the driven plate. The conveying pipeline pressure detection device is simple in structure and convenient to use, the pipeline internal pressure can be observed in real time, easiness in operation is achieved, operating time ofoperating personnel is shortened, and operating efficiency is greatly improved.

Owner:NANJING JIAYE INSPECTION ENG

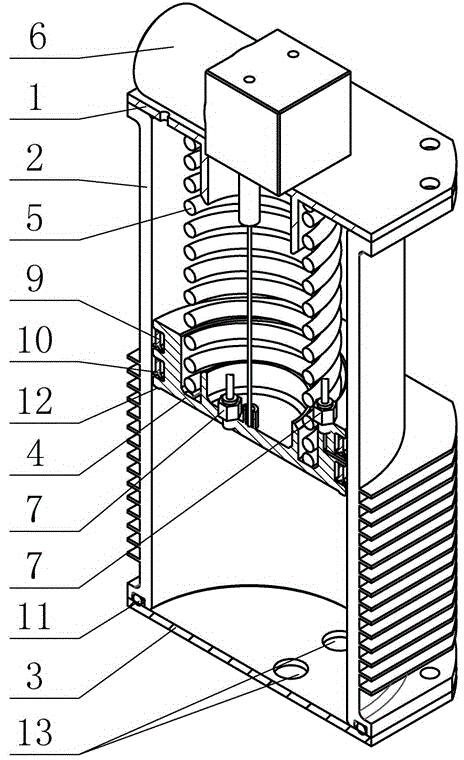

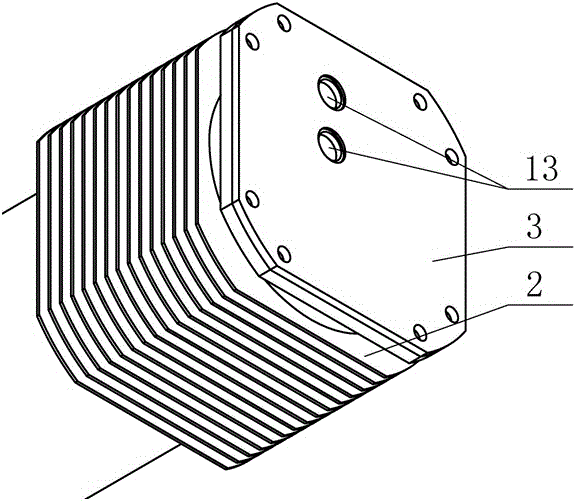

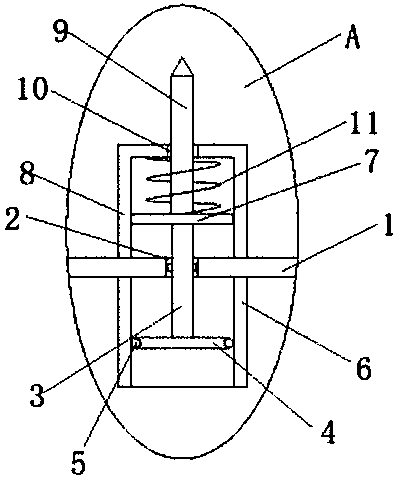

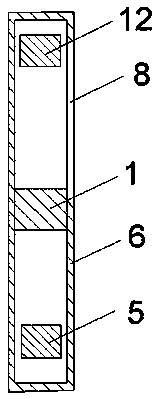

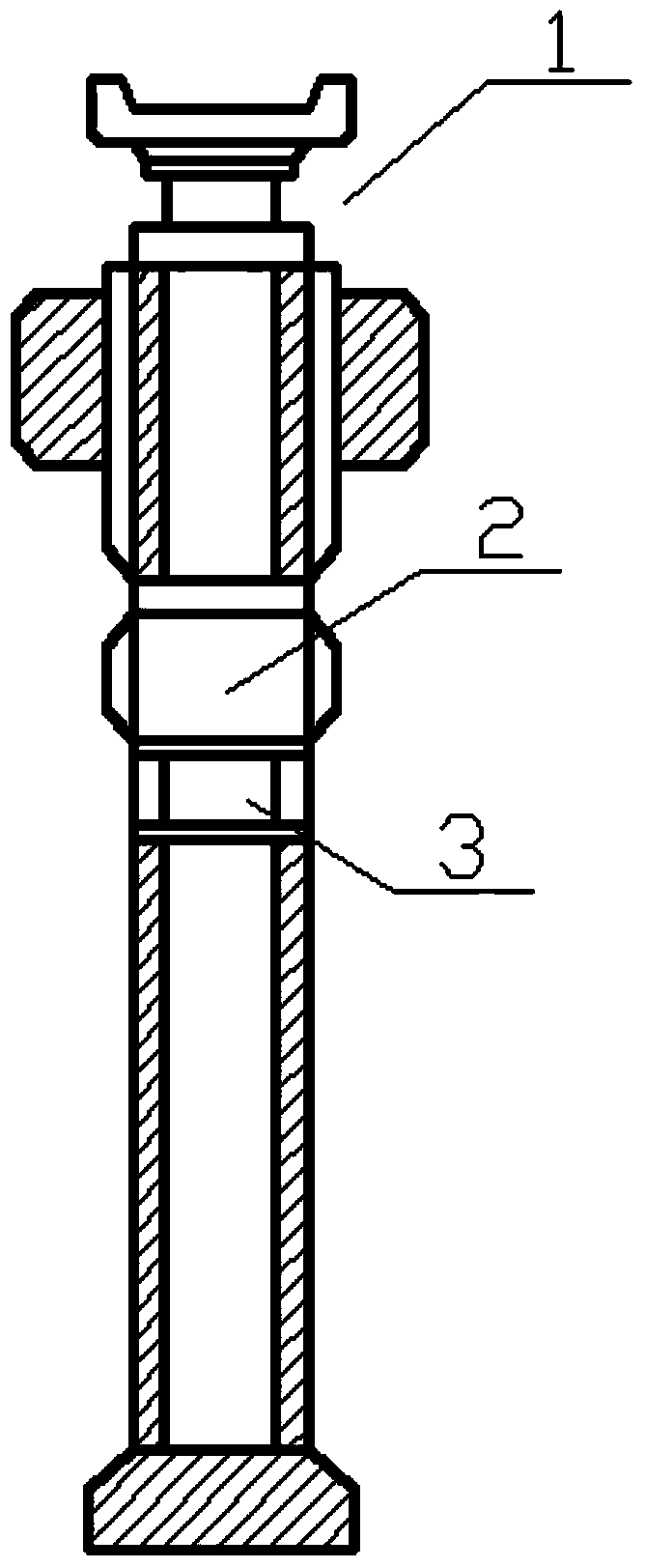

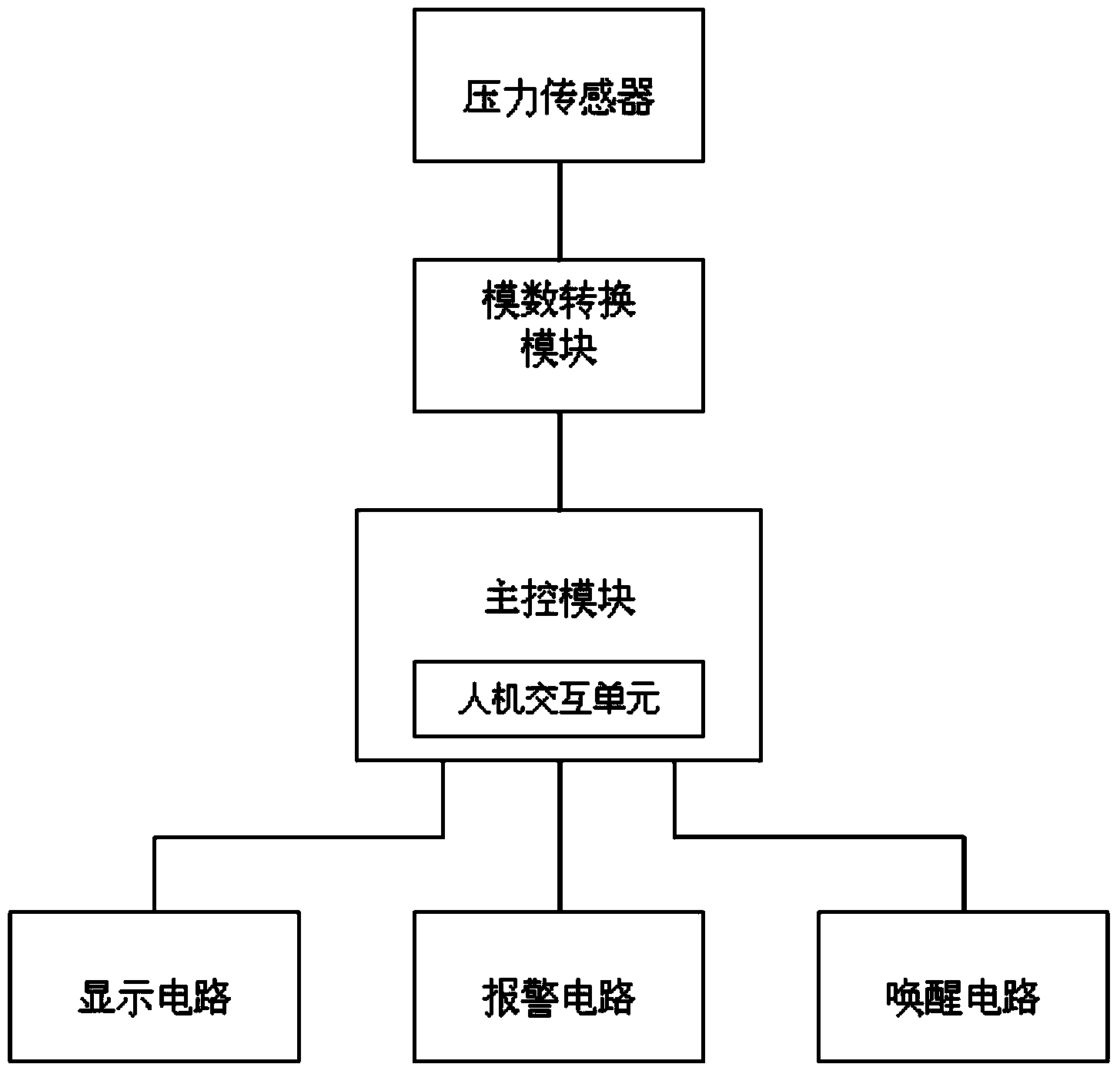

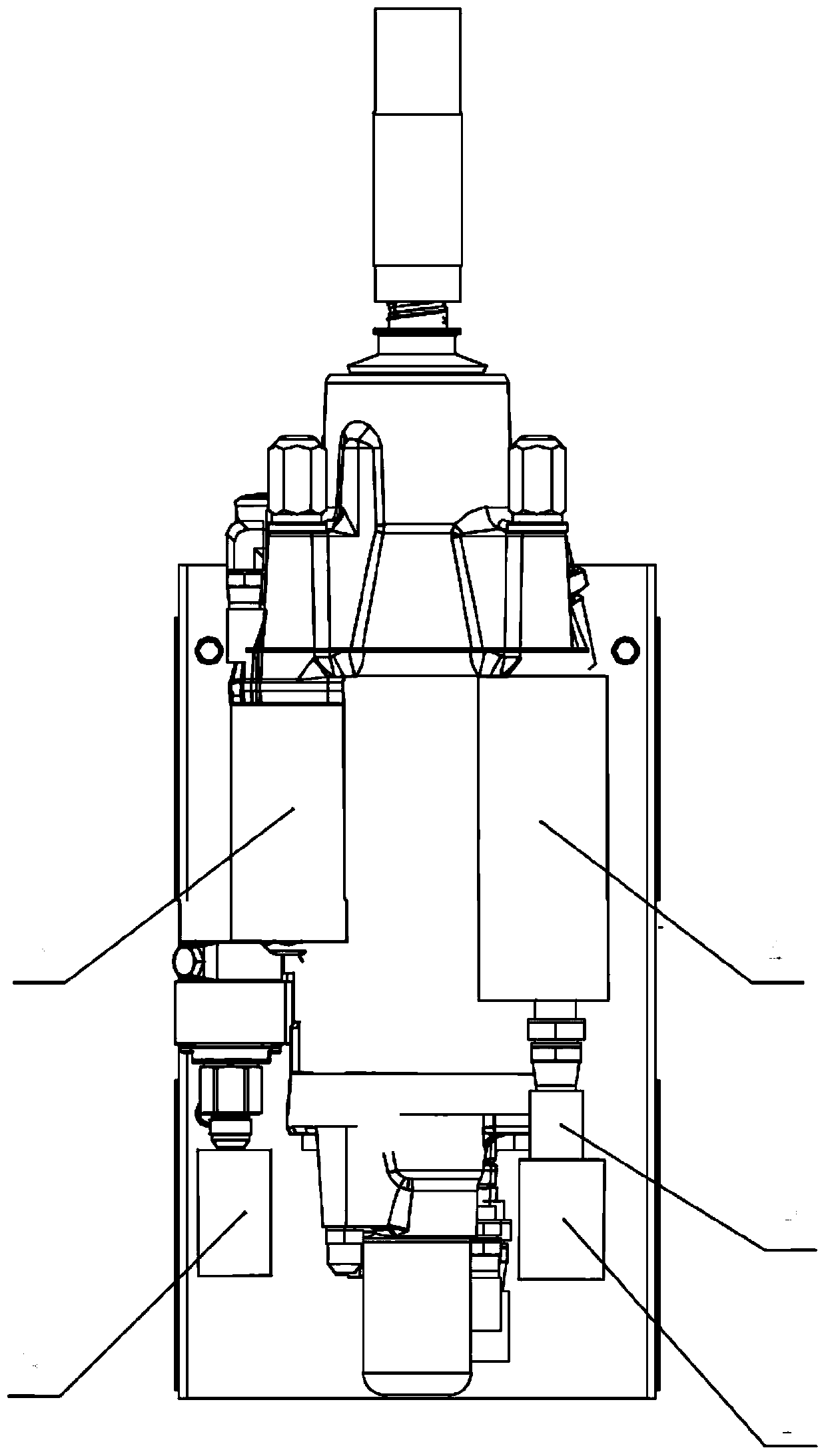

Intelligent single-body hydraulic prop

InactiveCN104074532AReal-time monitoring of pressure valuesMonitor pressure in real timeProps/chocksComputer moduleEngineering

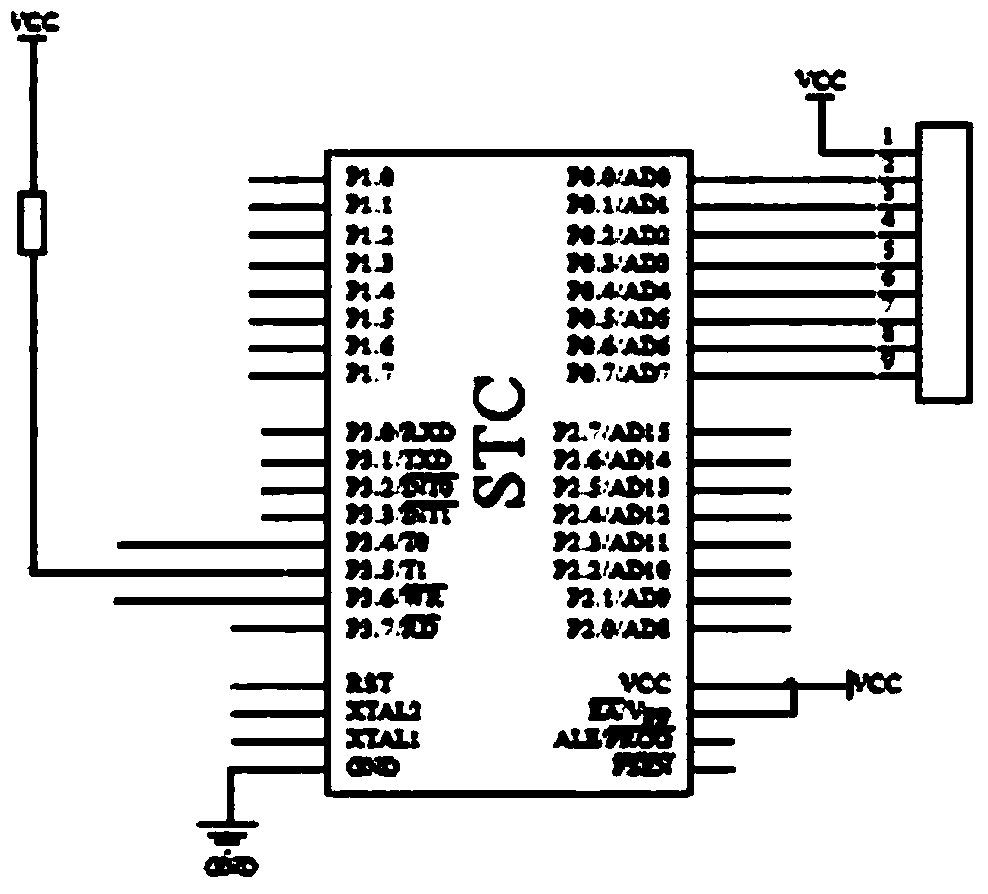

The invention discloses an intelligent single-body hydraulic prop, which belongs to the technical field of support equipment. A man-machine interaction unit (2) and a main control module (3) are arranged on a prop main body (1); the main control module (3) controls the man-machine interaction unit (2); the main control module (3) monitors signals of a pressure sensor through an analog-to-digital module; and the main control module (3) controls a display circuit, a warning circuit and a wake-up circuit. The intelligent single-body hydraulic prop has the advantages that the pressure condition of the single-body hydraulic prop can be effectively monitored, potential safety hazards can be discovered in advance, and the safety performance is enhanced; and meanwhile, the man-machine interaction function of the single-body hydraulic prop is realized, so the use of the single-body hydraulic prop is more intelligent and humanized.

Owner:XUZHOU ZHONAN SCI & TECH CO LTD

Device for testing leakage rate of bolted flange connection system

ActiveCN105181267AMonitor temperature in real timeMonitor pressure in real timeDetection of fluid at leakage pointEngineeringVacuum pump

The invention relates to a device for testing the leakage rate of a bolted flange connection system. The device includes a left pipeline, a right pipeline, a left flange, a right flange, a bolt, a gasket, a gas storage tank, a vacuum pump, a heating mechanism and a mass-spectrometer leak detector; non-connecting ends of the left pipeline and the right pipeline are both closed; a sealed cavity is formed in the left pipeline and the right pipeline; a cylinder is arranged at the radial outer side of the gasket and is located between the left pipeline and the right pipeline; the cylinder, the left flange, the right flange and the gasket enclose a leak detection cavity; the gas storage tank and the vacuum pump are communicated with the sealed cavity through pipelines; the heating mechanism is arranged in the sealed cavity; and the mass-spectrometer leak detector is communicated with the leak detection cavity through a pipeline. The device has the advantages of simple structure and convenient operation. With the device adopted, whether a leakage phenomenon exists on the bolted flange connection system can be detected, and leakage rates under different pressure and temperature conditions can be accurately calculated. The device is of reference significance for tightness research of the bolted flange connection system.

Owner:WUHAN INSTITUTE OF TECHNOLOGY +1

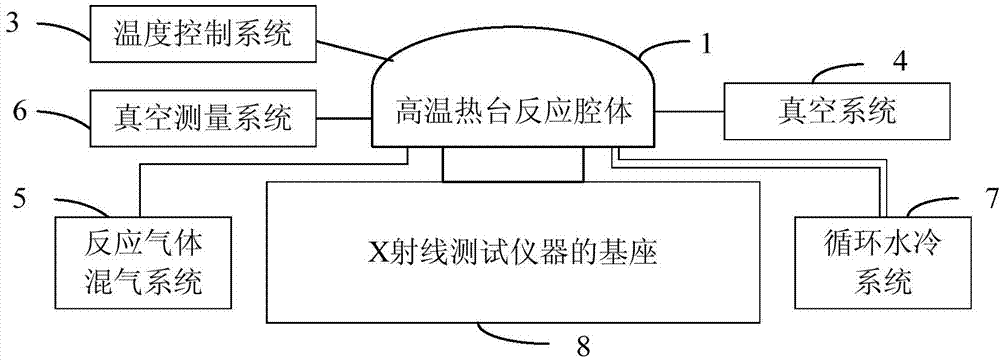

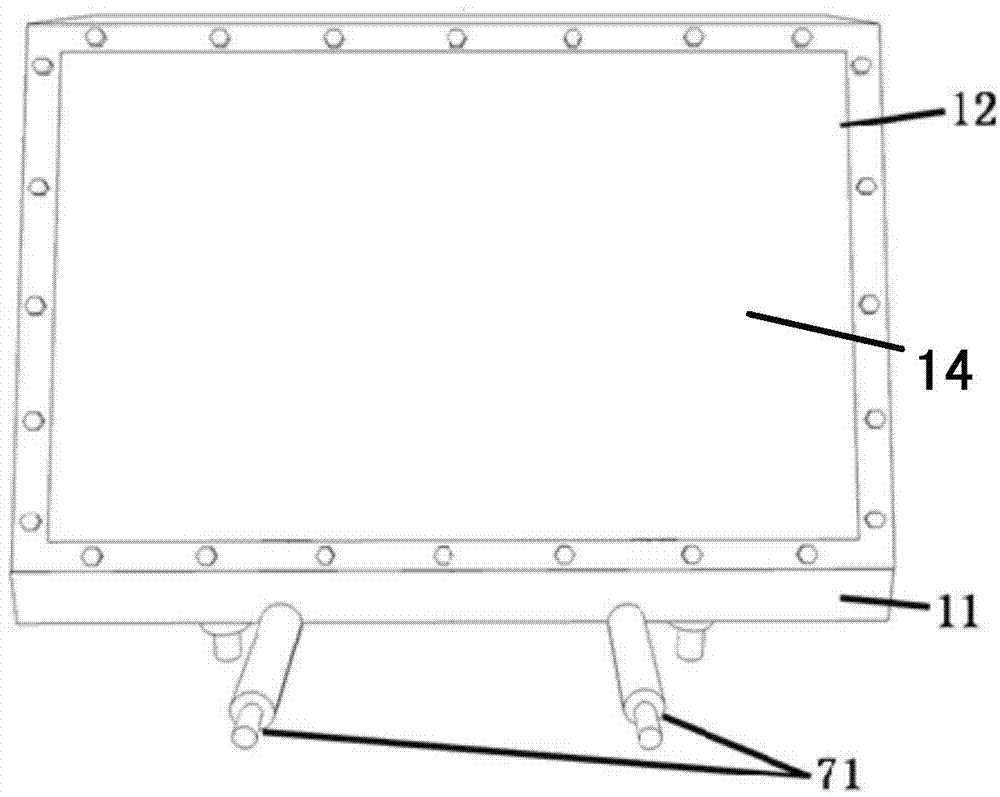

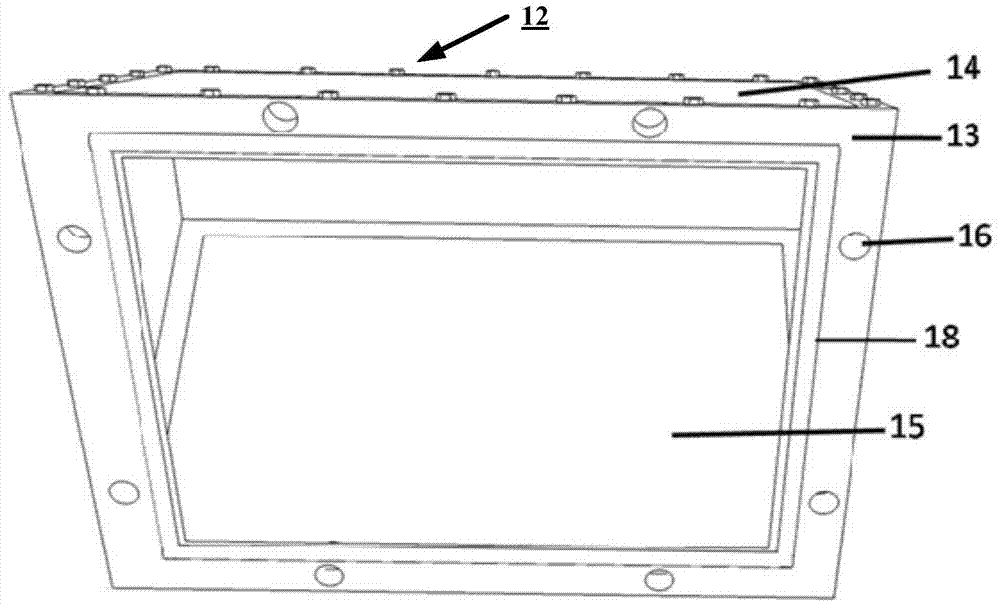

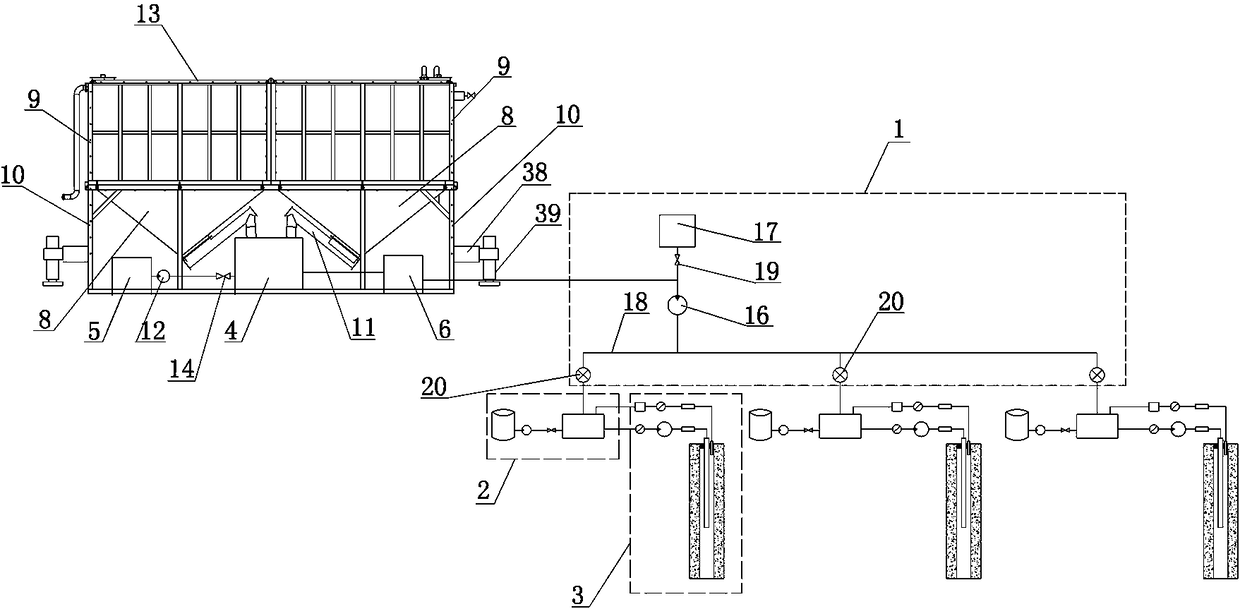

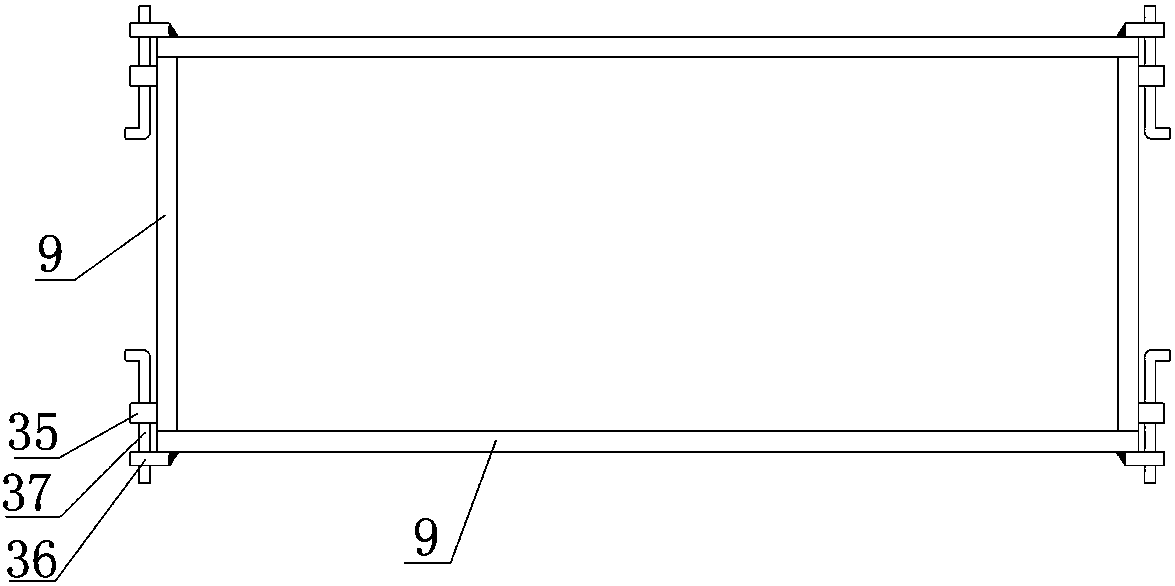

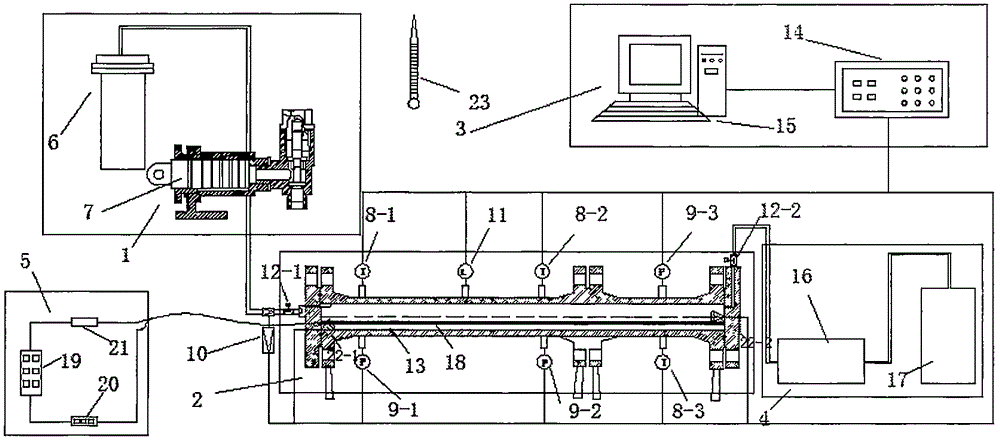

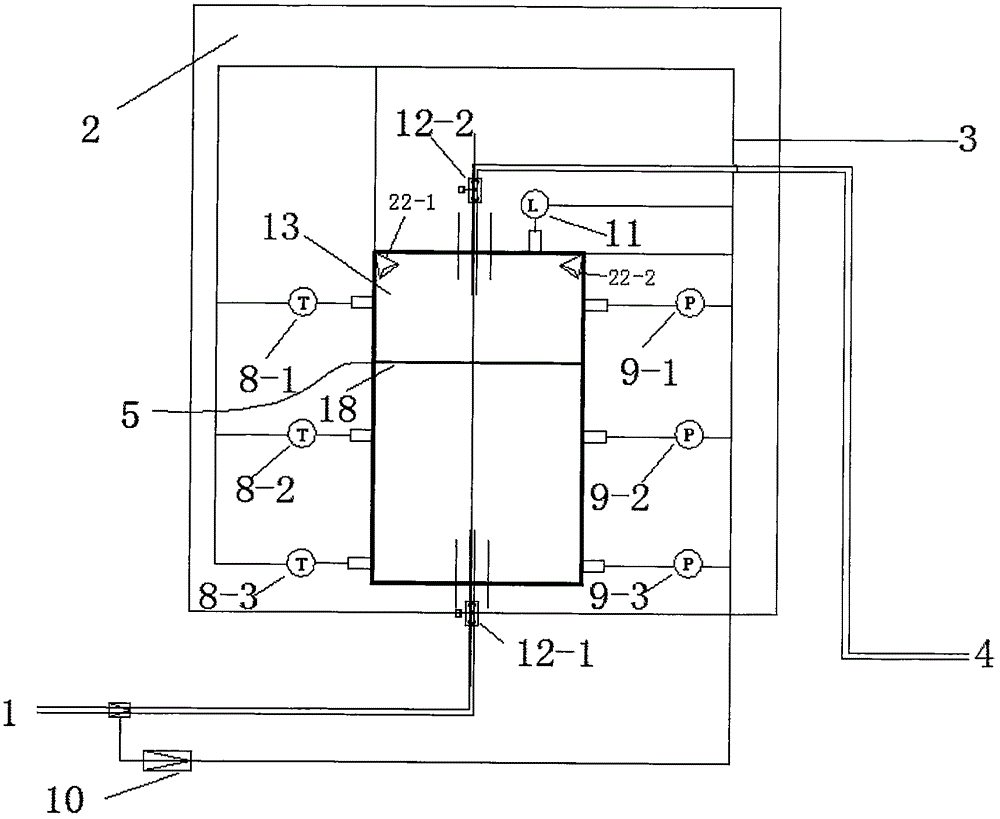

In-situ testing platform for thermal chemical vapor deposition

InactiveCN104502367AAdjustable temperatureMonitor pressure in real timeMaterial analysis using wave/particle radiationTemperature controlGas phase

The invention provides an in-situ testing platform for thermal chemical vapor deposition. The in-situ testing platform comprises a high-temperature hot platform reaction cavity, a ceramic heating platform, a temperature controlling system, a vacuum system, a reaction gas mixing system and a vacuum measuring system, wherein the high-temperature hot platform reaction cavity consists of a hot platform base and a vacuum outer cover, the vacuum outer cover consists of a frame main body, an incident window plate and an exit window plate, the incident window plate and the exit window plate are tightly installed on the frame main body; the ceramic heating platform is installed on the hot platform base to be used for bearing a sample; the temperature controlling system is used for regulating the temperature of the ceramic heating platform in real time; the vacuum system is used for vacuumizing the interior of the high-temperature hot platform reaction cavity; the reaction gas mixing system is used for providing a gas source needed by the thermal chemical vapor deposition for the interior of the high-temperature hot platform reaction cavity; the vacuum measuring system is used for monitoring the gas pressure intensity in the high-temperature hot platform reaction cavity in real time. The in-situ testing platform is capable of penetrating through x ray and also capable of online regulating the reaction conditions including the temperature, the pressure and an air flow, so that real-time in-situ characterization and study of the processes including growth and phase variation of a material in the thermal chemical vapor deposition process can be realized online.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

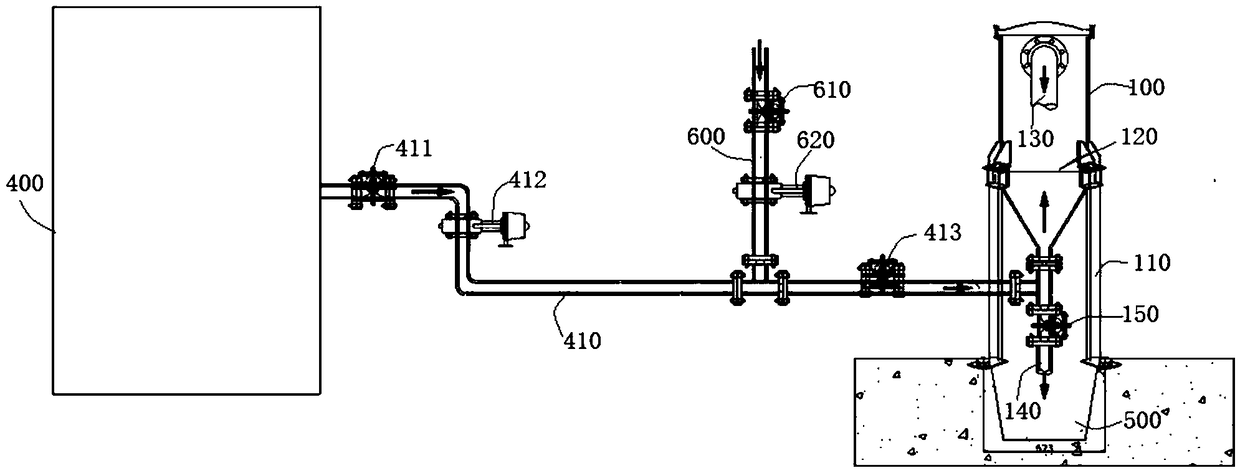

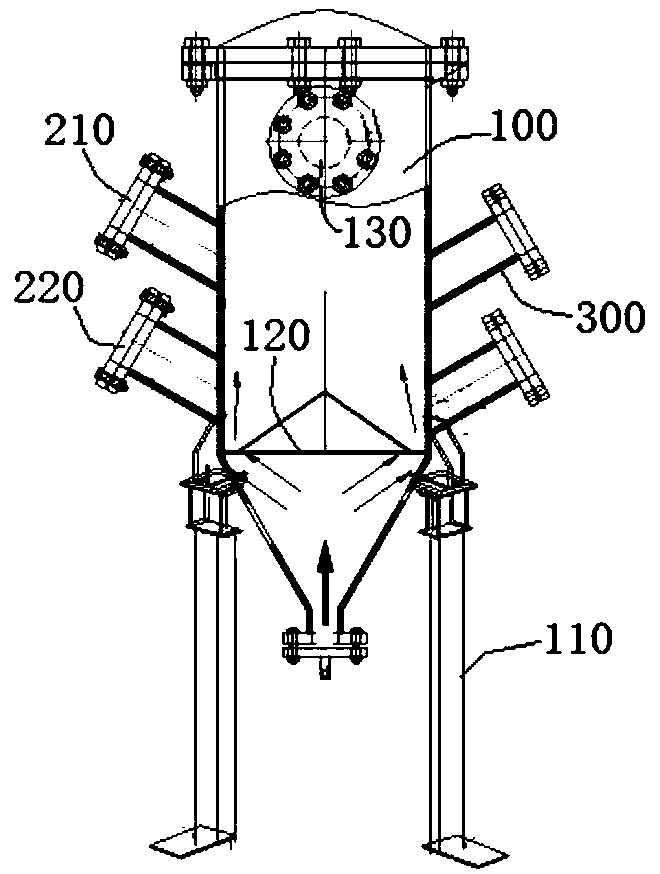

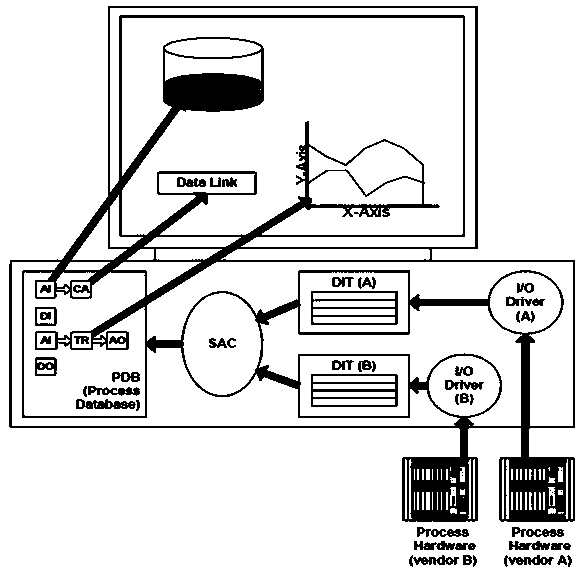

Automatic grouting production system

InactiveCN108705678ARealize continuous preparationEasy to controlMixing operation control apparatusFoundation engineeringControl systemMonitoring system

The invention discloses an automatic grouting production system. The automatic grouting production system comprises a control system, a grout making station, a grout conveying system, grout proportionstations and grouting monitoring systems. The automatic grouting production system has the advantages that the automation degree is high, the labor cost is saved, the operation is simple, the unmanned production or the flexible manpower line is realized, the proportion precision is improved, and the labor intensity is reduced.

Owner:XIYI AUTOMATION SYST ENG CHENGDU +1

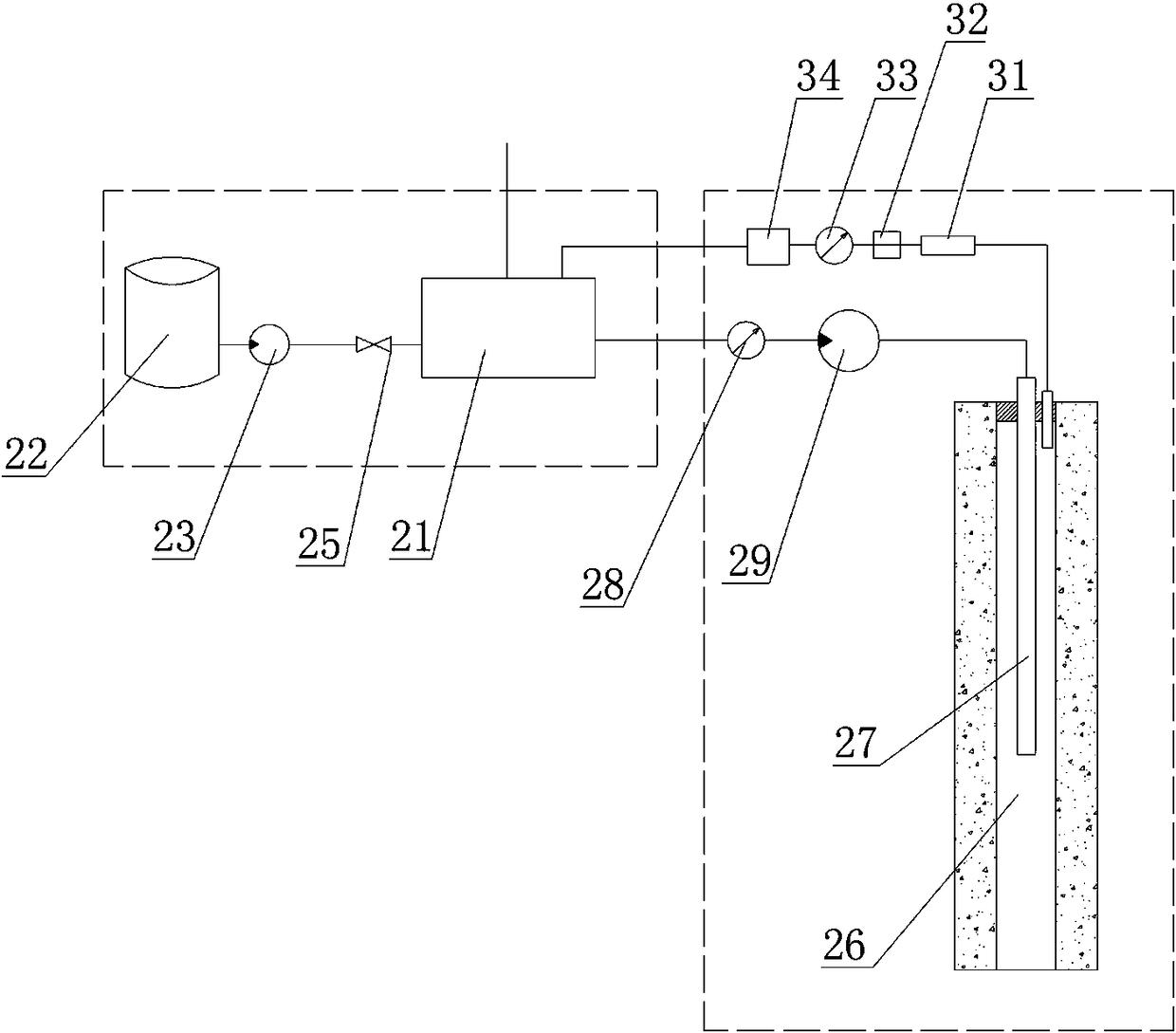

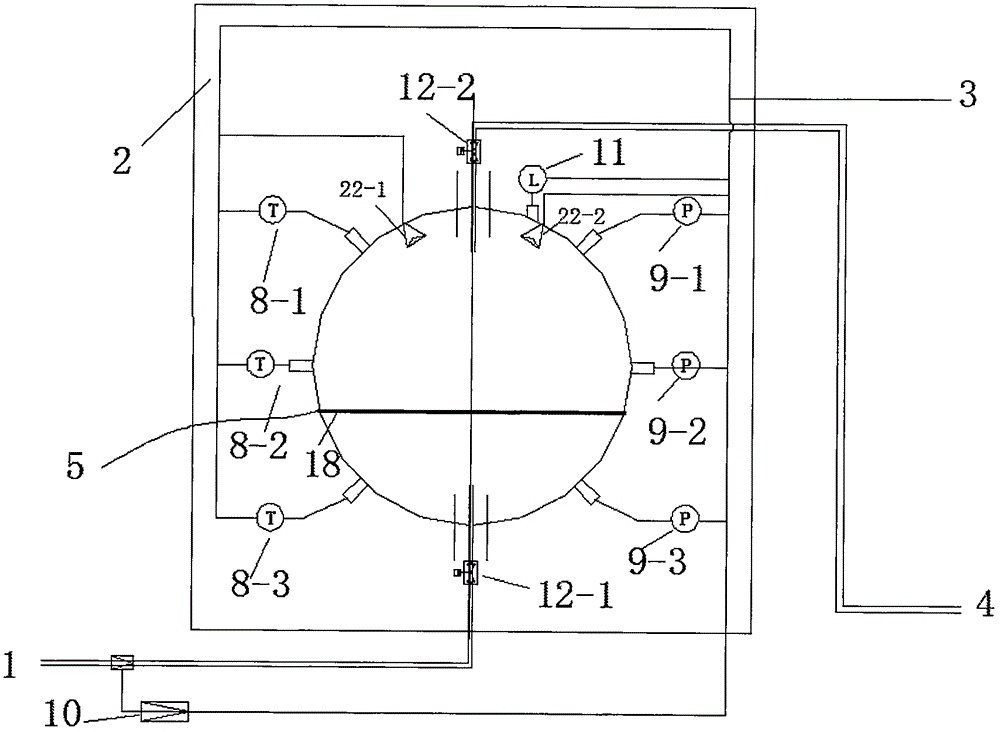

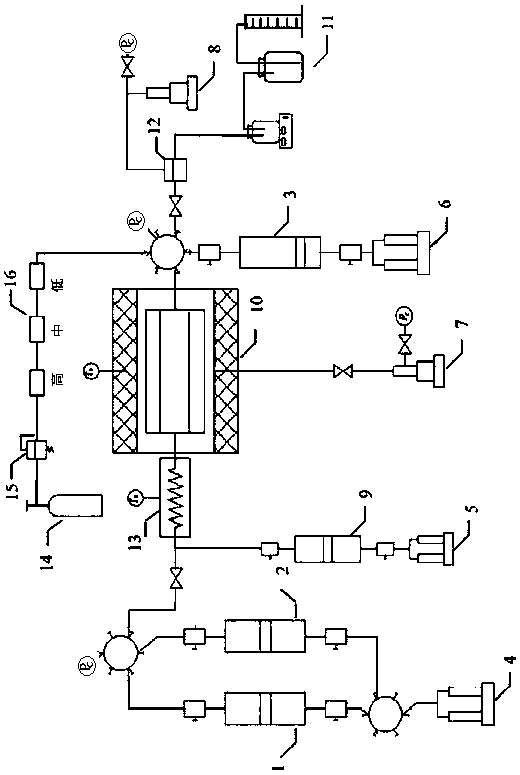

Simulated testing system of liquid-state CO2 phase change process

InactiveCN106645269ARealize phase state judgmentMonitor pressure in real timeInvestigating phase/state changeData acquisitionHigh pressure

The invention discloses a simulated testing system of a liquid-state CO2 phase change process. The simulated testing system comprises five parts including a liquid-state CO2 pump pressure injection system, a sealed high-pressure-resisting container system, a data acquisition and storage system, a waste gas and waste liquid recycling and cyclic utilization system and a manual heating system, wherein the liquid-state CO2 pump pressure injection system comprises a Dewar flask mounted beside sealed high-pressure-resisting containers and a manual variable piston pump; the sealed high-pressure-resisting container system comprises three sealed high-pressure-resisting containers with different types, including a pipeline type low-temperature-resisting and high-pressure-resisting container, a spherical type low-temperature-resisting and high-pressure-resisting container and a storage tank type low-temperature-resisting and high-pressure-resisting container; the data acquisition and storage system comprises a temperature sensor, a pressure sensor, a liquid level sensor and an infrared thermal imager which are mounted in each sealed high-pressure-resisting container. The simulated testing system disclosed by the invention can be used for monitoring changes of parameters including temperature, pressure, liquid levels and the like of liquid-state CO2 in the sealed high-pressure-resisting containers in real time; a phase state attributed graph of the CO2 is combined and phase state judgment of the CO2 in the system is realized.

Owner:XIAN UNIV OF SCI & TECH +1

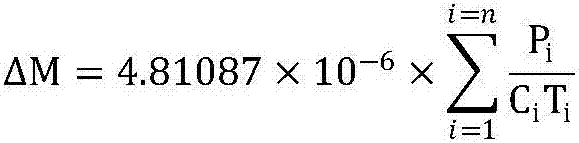

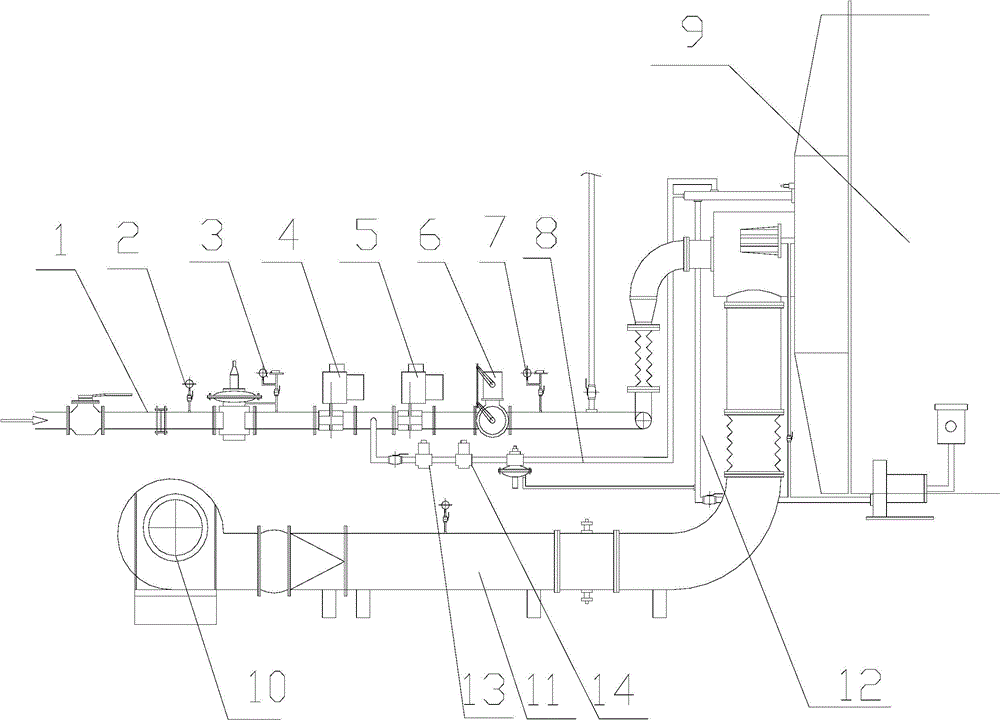

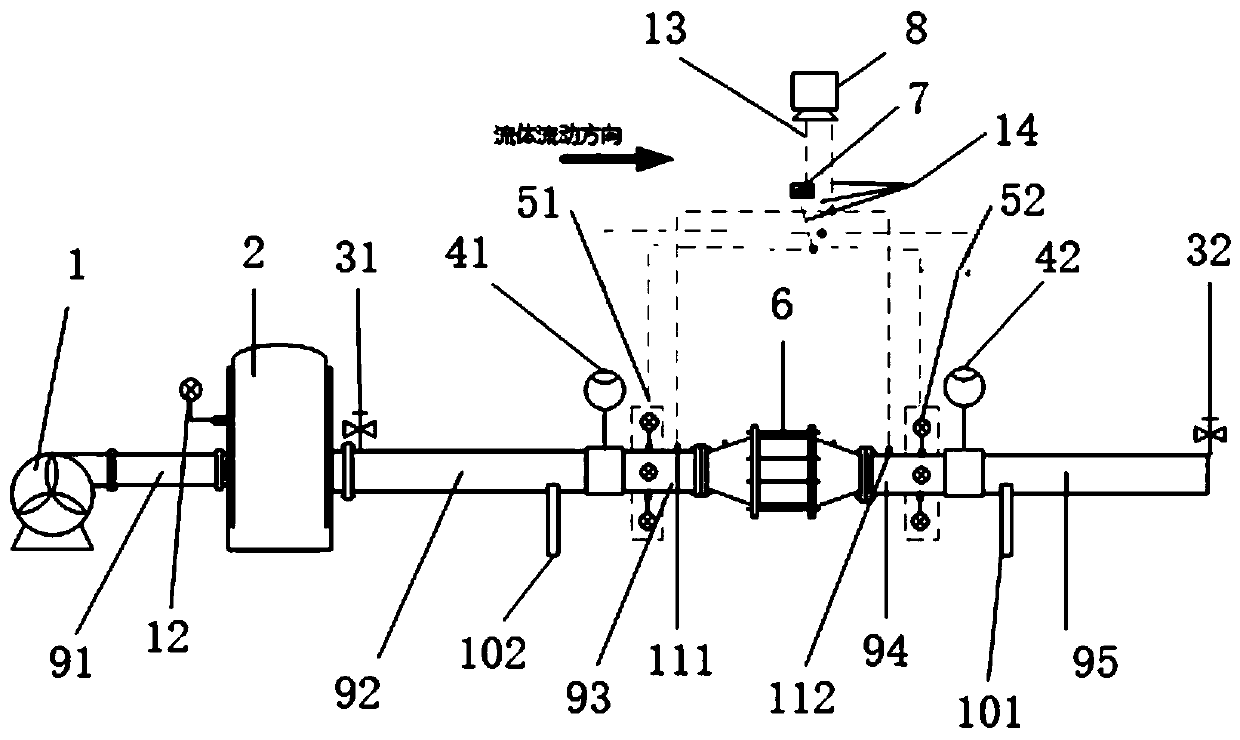

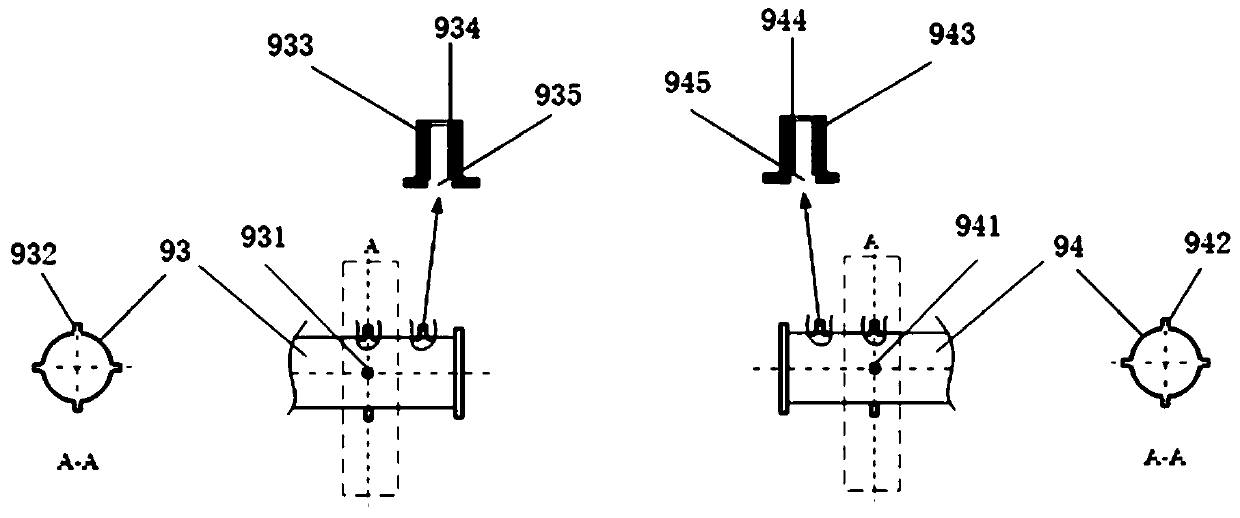

System and method for testing local resistance loss coefficient of flame arrester

InactiveCN111157228AImprove performanceSimple structureMachine part testingFlame arresterThermodynamics

The invention discloses a system and a method for testing a local resistance loss coefficient of a flame arrester. The invention belongs to the technical field of flame spreading blocking in the petrochemical industry, and particularly relates to a monitoring and testing device for realizing changes of pressure, temperature and flow of experimental gas in pipelines at the front end and the rear end of a flame arrester and a calculation method of a local resistance loss coefficient comprehensively considering the pressure, the temperature and the flow in a flowing process of compressible gas ina test pipeline. The device comprises a mechanical structure unit and an electric control data acquisition unit, can correctly measure local resistance loss data caused by the flame arrester, and ishelpful for improving the reliability of the flame arrester in the using process and perfecting a corresponding theoretical system and technical specifications in flame arrester testing to a certain extent.

Owner:CHINA UNIV OF MINING & TECH +1

Automatic sampling detection device for pH meters of desulfurizing absorption towers in thermal power plants

ActiveCN109142646AReal-time adjustment of slurry supply volumeQuality improvementWithdrawing sample devicesBuffer tankSlurry

The invention discloses an automatic sampling detection device for pH meters of desulfurizing absorption towers in thermal power plants, and belongs to the field of desulfurizing absorption towers. The automatic sampling detection device comprises a buffer tank and a breather pipe, wherein the buffer tank is communicated with an absorption tower through a slurry inlet pipe; a first pH meter, a second pH meter and a pressure difference transmitter, which are obliquely inserted into the tank is arranged on the side wall of the buffer tank; a filter unit is arranged at the inner lower part of thebuffer tank; an overflow pipe is arranged on the upper side wall of the buffer tank; the breather pipe is arranged on one side of the slurry inlet pipe and communicated with the slurry inlet pipe; and a manually operated valve and an electrically operated valve are arranged on the breather pipe. According to the automatic sampling detection device, pH meters of desulfurizing absorption towers aretransformed, so that the measurement precision of the pH meters is improved, the measurement correctness is improved, the desulfurization efficiency is improved, environment-friendly data exceeding is prevented, the maintenance vigor of personnel is saved, abrasion of the pH meters is decreased, and the service life of the pH meters is prolonged.

Owner:DATANG BINZHOU POWER GENERATION CO LTD

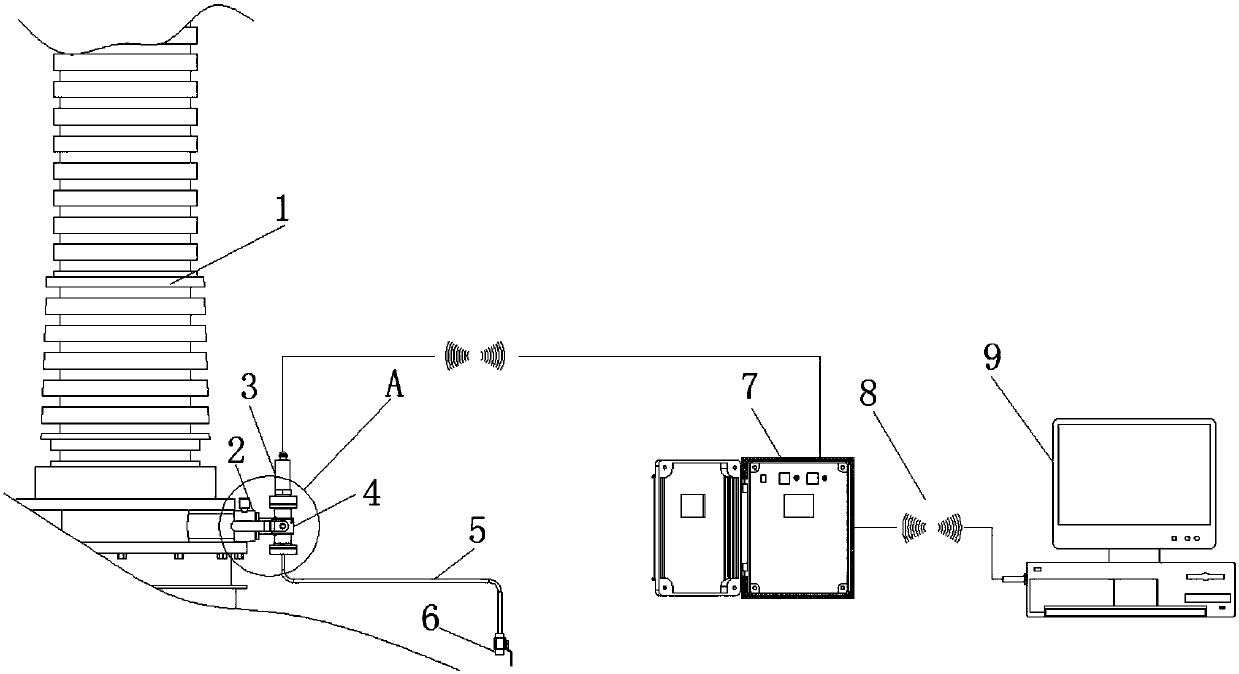

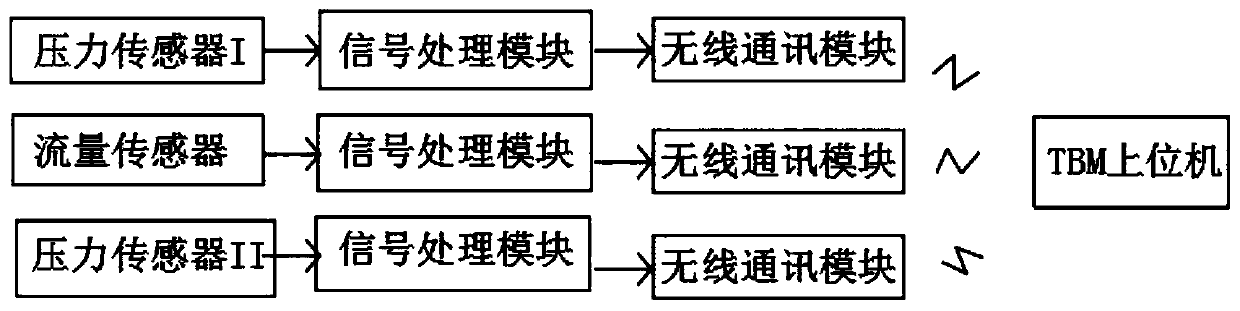

TBM anchor drilling rig real-time online monitoring system based on hydraulic system and monitoring method

ActiveCN110107274AReal-time monitoring of propulsion speedReal-time monitoring distanceTotal factory controlMeasurement devices for drillingMonitoring systemRock bolt

The invention discloses a TBM anchor drilling rig real-time online monitoring system based on a hydraulic system and a monitoring method. The TBM anchor drilling rig real-time online monitoring systemcomprises a signal acquisition module, wireless communication modules and a TBM upper computer; and the signal acquisition module comprises a pressure sensor I, a pressure sensor II and a flow sensor, wherein the pressure sensor I detects the oil pressure of a hydraulic pipe of a propulsion cylinder, the flow sensor detects the oil flow rate of the hydraulic pipe of the propulsion cylinder, the pressure sensor II detects the oil pressure in a hydraulic pipe of an impact cylinder, and the oil pressure and oil flow rate of the hydraulic pipe of the propulsion cylinder and the oil pressure in the hydraulic pipe of the impact cylinder are processed by signal processing modules and uploaded to the TBM upper computer through the wireless communication modules. The TBM anchor drilling rig real-time online monitoring system monitors the propulsion speeds and distance of the propulsion cylinder as well as the drilling speeds and pressure of a TBM anchor drilling rig in real time, real-time monitoring of a plurality of indicators can reduce the errors, and data communication with the TBM upper computer ensures the working state of the anchor drilling rig and surrounding rock related information in the TBM excavation process, and the problem that monitoring data in the prior art is unreliable is solved.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

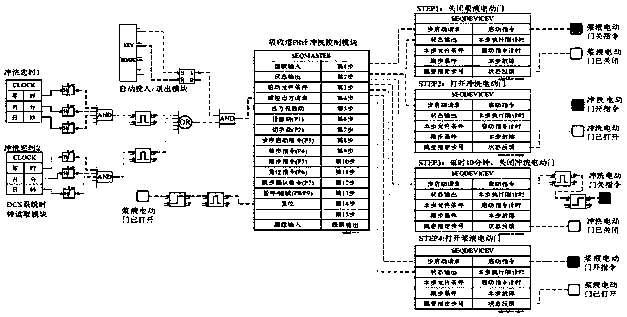

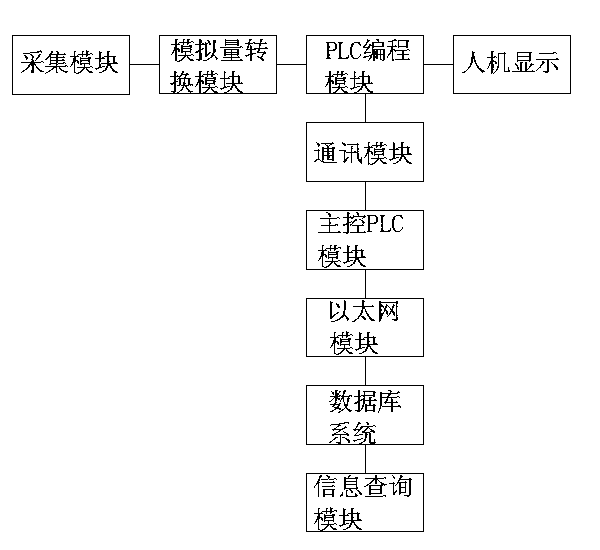

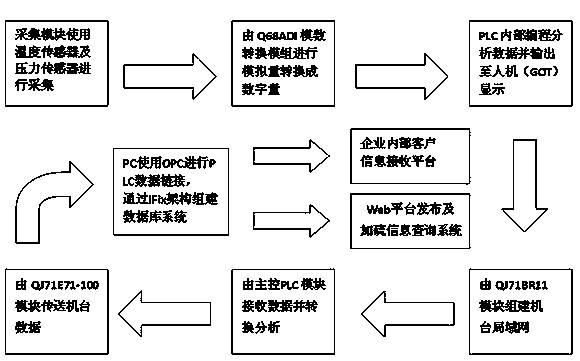

Tire vulcanization group control system

ActiveCN103454987AReduce testing costsLow costTotal factory controlProgramme total factory controlVulcanizationComputer module

The invention discloses a tire vulcanization group control system. The tire vulcanization group control system has the advantages that remote monitoring and inquiring functions can be realized by the aid of an acquisition module, an analog quantity conversion module, a PLC (programmable logic control) programming module, a communication module, a master control PLC module, an Ethernet module, a database system and an information inquiry module, all tire vulcanization production procedures can be monitored, the temperature, the pressure, vulcanizing moments, cooking numbers and abnormal data can be monitored in real time, notification for mails with abnormal codes can be extracted, daily vulcanization data can be duplicated, daily statements can be automatically generated from abnormity summary statements, single-shift yield statements can be generated, and the statements can be inquired via a Web platform; the detection cost and the detection time can be saved for enterprises, and the monitoring efficiency can be improved; efficient production can be implemented in a total-control state, the quality of tire products can be effectively improved, the cost can be saved for the production enterprises, the efficiency can be improved, and problems of scrapping and poor quality can be solved.

Owner:KENDA RUBBER CHINA

Small-size gas collecting device

ActiveCN102879234ASmall footprintSimple and fast operationWithdrawing sample devicesGas analysisMultiple forms

The invention discloses a small-size gas collecting device. The device comprises a gas circuit system and an electric circuit system, wherein the gas circuit system comprises a sample collecting container, a connecting device and an air exhaust device; the air exhaust device is connected with the sample collecting container through the connecting device; the electric circuit system comprises a pressure sensor used for measuring the pressure in the gas circuit system, a data acquisition device and a data processing device. According to the small-size gas collecting device, the electric circuit system is arranged for monitoring the gas pressure in the sampling device in real time; and moreover, the good connection between the gas circuit system and various gas analysis technologies is realized through joints in multiple forms, a sampling tank serves as a container for a gas sample and is used for small-size sampling of positive-pressure or negative-pressure gas, and the collected gas sample can be used for gas chromatography and solid phase microextraction, gas chromatography / mass spectrometry combined analysis.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Pole piece and isolating membrane thermal compounding equipment

PendingCN110993862AImproving the quality of hot rolling laminationMonitor pressure in real timeLi-accumulatorsCell component detailsPole pieceDust control

The invention discloses pole piece and isolating membrane thermal compounding equipment, which comprises at least two sets of preheating mechanisms, a hot rolling mechanism, a connecting rod tensioning mechanism, a shaping roller, a magnetic strip, a dust collection cavity and a material receiving roll. The preheating mechanisms are sequentially arranged on the side wall of a rack in parallel at intervals. The hot rolling mechanism is arranged at the side part of the preheating mechanism. The connecting rod tensioning mechanism is arranged at the side part of the hot rolling mechanism. The film-coated pole piece is tensioned by the connecting rod tensioning mechanism. The shaping roller, the magnetic strip and the dust collection cavity are sequentially arranged at intervals, and when thefilm-coated pole piece sequentially penetrates through the shaping roller, the magnetic strip and the dust collection cavity, shaping is conducted to magnetically adsorb metal on the surface of the pole piece and remove dust on the surface of the pole piece. The number of the material receiving rolls is two, the two material receiving rolls are arranged up and down at an interval, and the end parts of the protective films on the surfaces of the isolating films on the upper surface and the lower surface of the film-coated pole piece are connected to the material receiving rolls. Automatic preheating, hot rolling compounding, automatic tensioning, pole piece surface metal and dust removal and automatic protection film winding functions of the pole piece and the isolation film are achieved.

Owner:SHENZHEN XING GRAIN AUTOMATION CO LTD

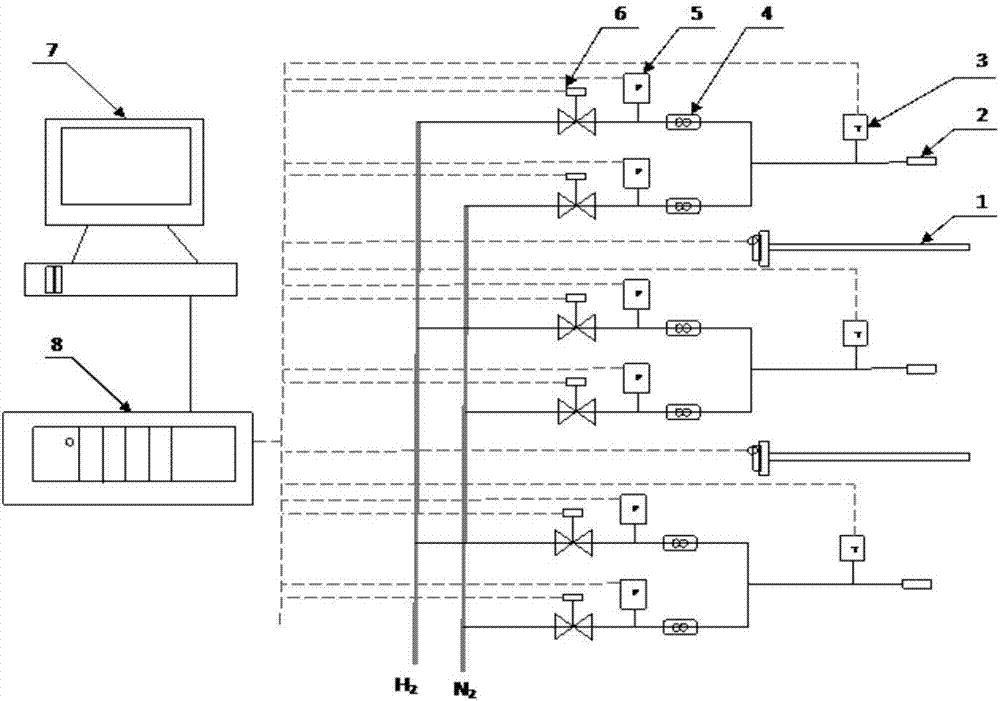

Tin bath atmosphere control system and float glass tin bath

The invention provides a tin bath atmosphere control system and a float glass tin bath. The tin bath atmosphere control system comprises an oxygen content probe, a protection gas supplying pipeline and a controller, wherein the oxygen content probe is used for detecting oxygen content and is arranged in the tin bath; the protection gas supplying pipeline is used for supplying protection gas into the tin bath; the controller is used for controlling the content of hydrogen gas in the protection gas in the tin bath through controlling the protection gas supplying pipeline in real time according detection information of the oxygen content probe. According to the control system provided by the invention, a nitrogen-hydrogen ratio is adjusted by the controller in real time according to the measured concentration of oxygen in tin liquid and / or a space of the tin bath, a reducing atmosphere of the tin bath is strengthened directly aiming at oxidization and reduction properties on tin and oxygen interfaces and reaction of the hydrogen and the oxygen is promoted to be efficiently and rapidly carried out; the content of the oxygen in the space of the tin bath and the tin liquid can be effectively reduced and oxidization of the tin liquid is reduced so that the aim of improving tin impregnation of glass is realized.

Owner:河北视窗玻璃有限公司

Low-permeability reservoir nitrogen composition huff and puff physical simulation experiment device and method

ActiveCN109538176ASolve the problem of not being able to enterIncrease the buffer systemFluid removalTemperature controlRock core

The invention provides a low-permeability reservoir nitrogen composition huff and puff physical simulation experiment device and method. The device comprises a core saturation system, an injection system, a core clamping system and a recovery metering system. The core saturation system is connected to the core clamping system, formation water saturation and crude oil saturation are performed on acore, the injection system is connected to the core clamping system, a certain amount of gas or water or a surface active agent solution is injected into the core, the core clamping system is arrangedinside a constant temperature control cabinet, the balance of the core is maintained, certain confining pressure is applied to the periphery of the core so as to ensure that fluid can only flow inside the core, the recovery metering system is connected to the core clamping system, and gas production and oil production changes in the recovery process are metered. According to the low-permeabilityreservoir nitrogen composition huff and puff physical simulation experiment device and method, the problem that a solution cannot be injected in the injection process is solved, pressure and temperature changes in the simulation process can be monitored in real time, and injection-production parameter optimization can be achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com