Patents

Literature

52results about How to "Real-time monitoring of pressure values" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

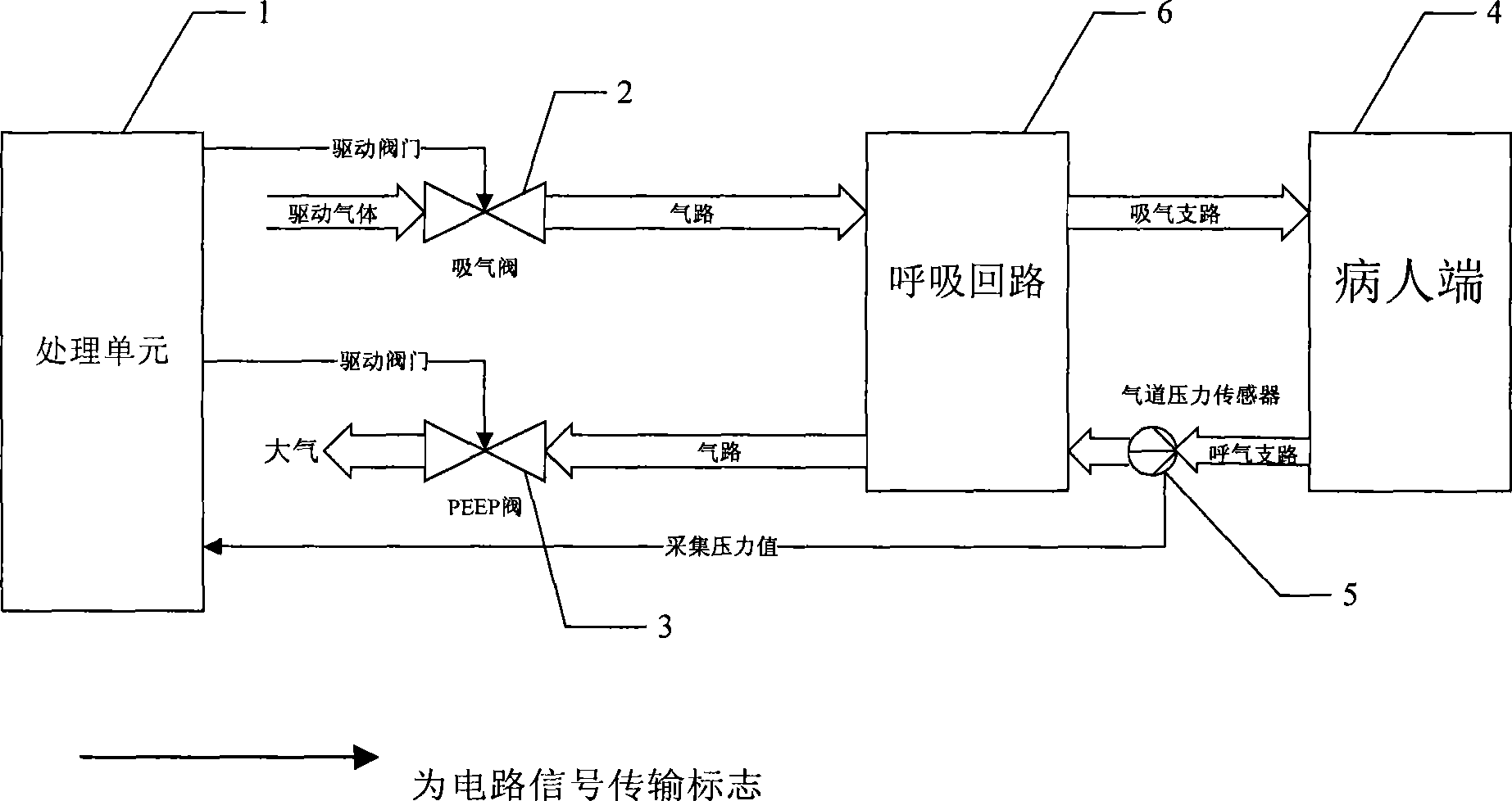

Method for improving working accuracy of PEEP valve

InactiveCN101468223AHigh precisionReal-time monitoring of pressure valuesRespiratorsValvesEngineeringAirway pressures

The present invention provides a method for increasing the working precision of PEEP valve for settling the problem that the PEEP valve can not obtain high working precision, wherein the method comprises the following steps: inputting anticipated pressure value P1 into a processing unit (1) which obtains a corresponding current value I1 according to the stored comparison table and controls the PEEP valve (3) with the current value I1 to open the PEEP valve to a certain opening by an operator; detecting the airway pressure in the exhalation branch line by a pressure sensor (5) at the end of exhalation period and conveying the airway pressure value P2 to the processing unit (1); calculating a deviation value deltaP=P2-P1 by the processing unit (1) for determining whether the deviation value deltaP is in the anticipated control area, if not, obtaining an adjustment value P1' according to the relationship P1'=P1+deltaP*K, and in the relationship the adjusted scaling factor K is controlled between 0.4 to 0.9; and executing the steps repeatedly according to adjustment value until the deviation value is in the anticipated control area. The method can quickly and accurately increase the working precision of PEEP.

Owner:BEIJING AEONMED

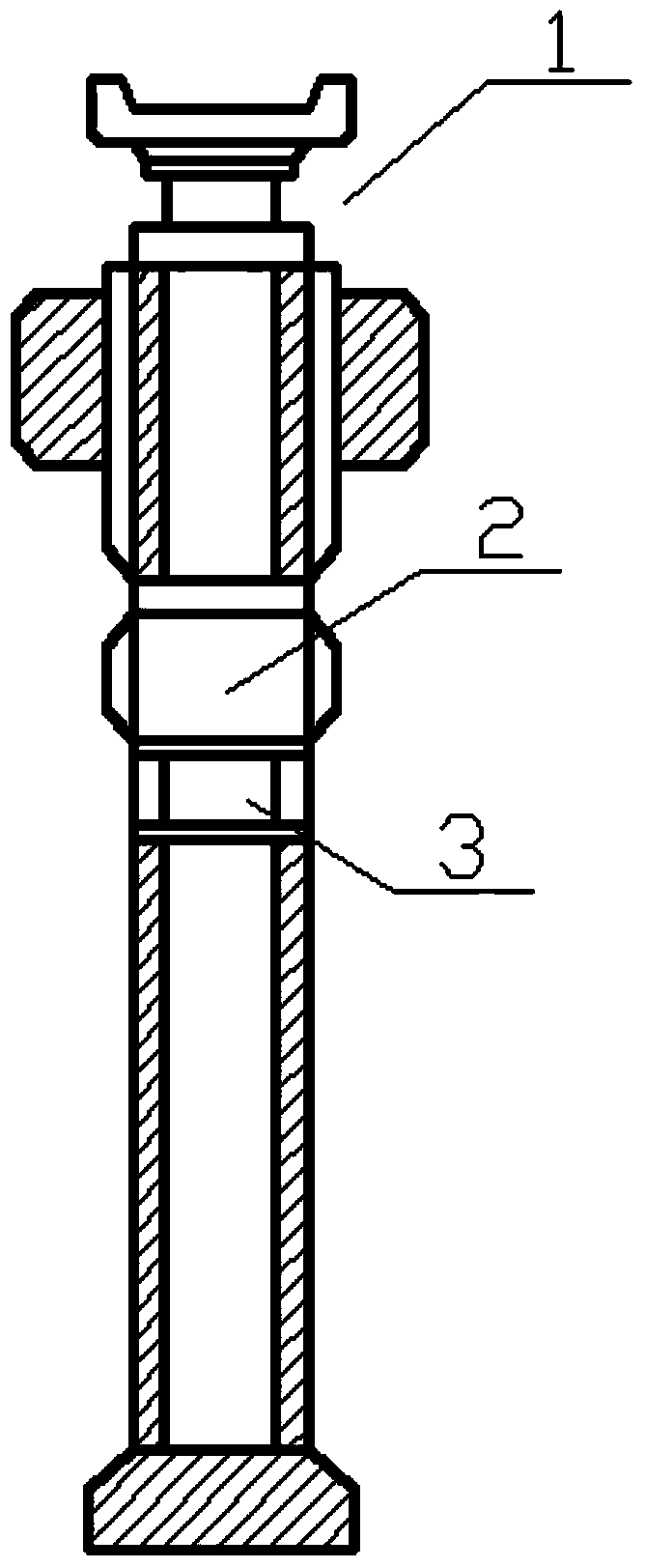

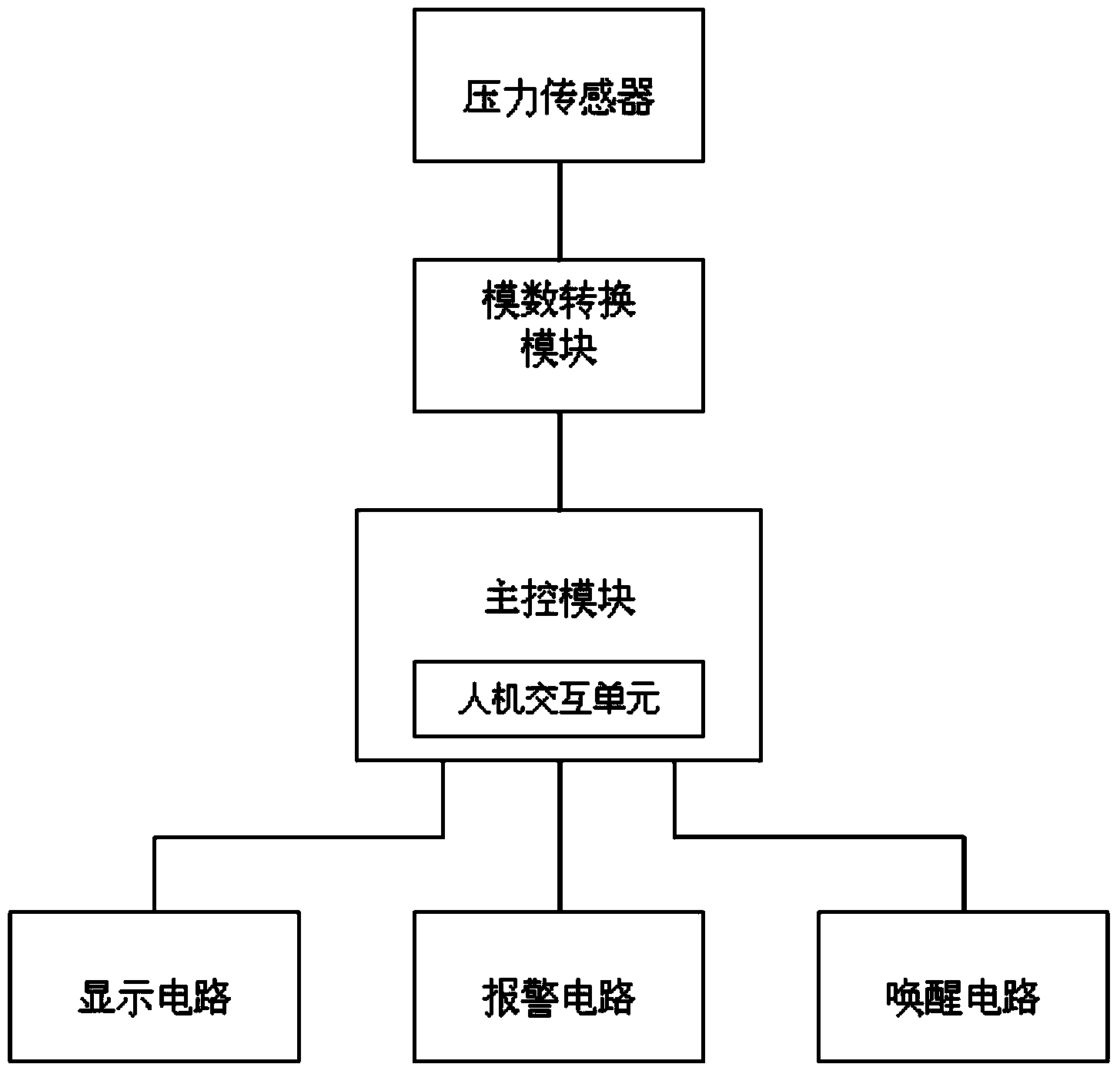

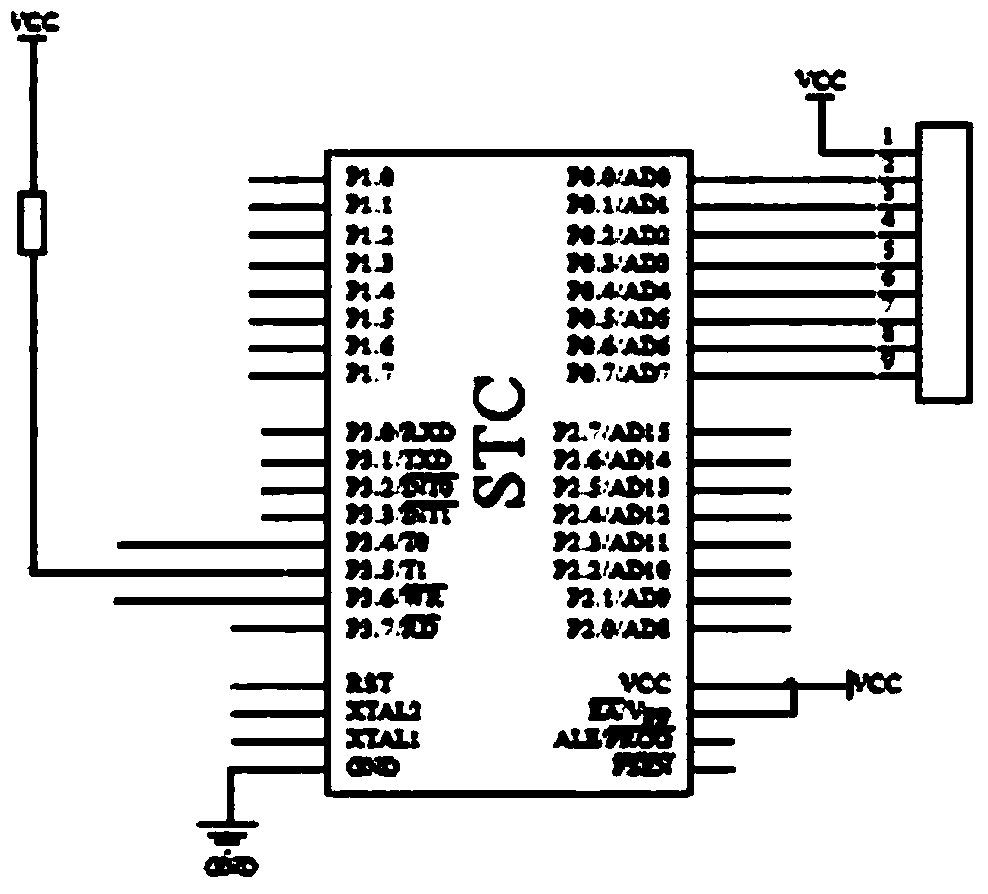

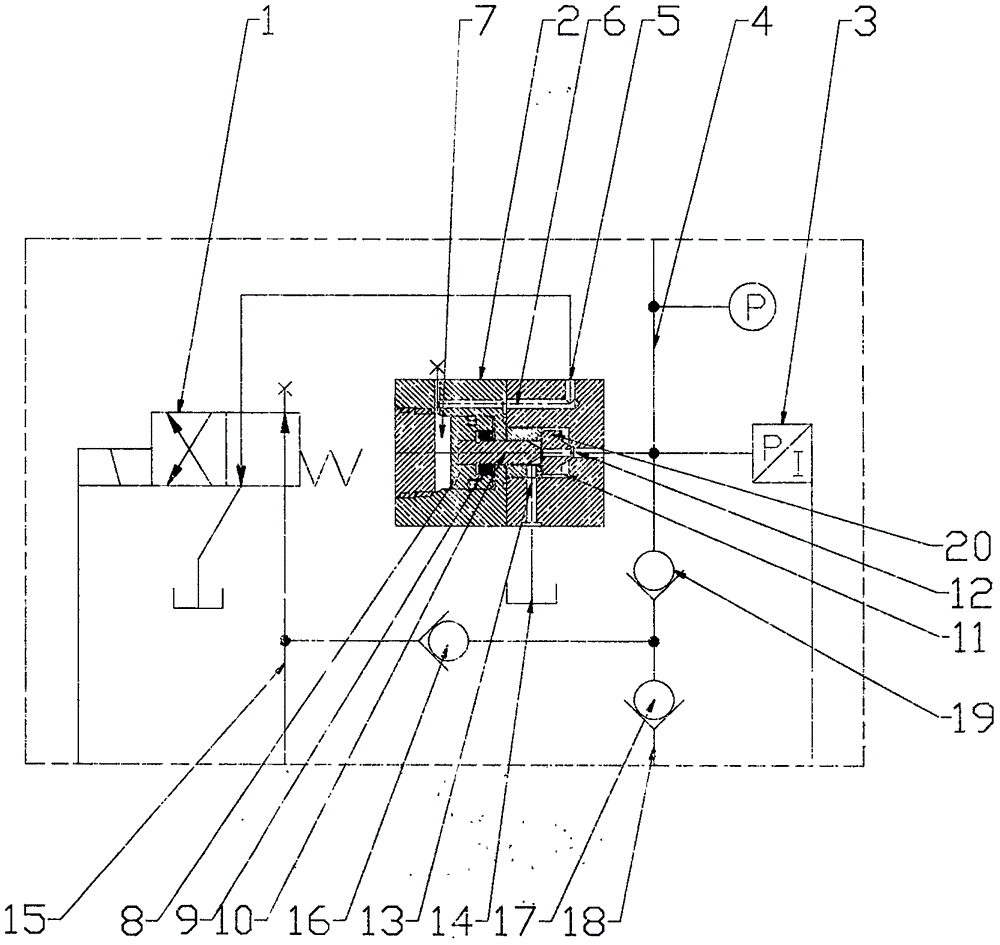

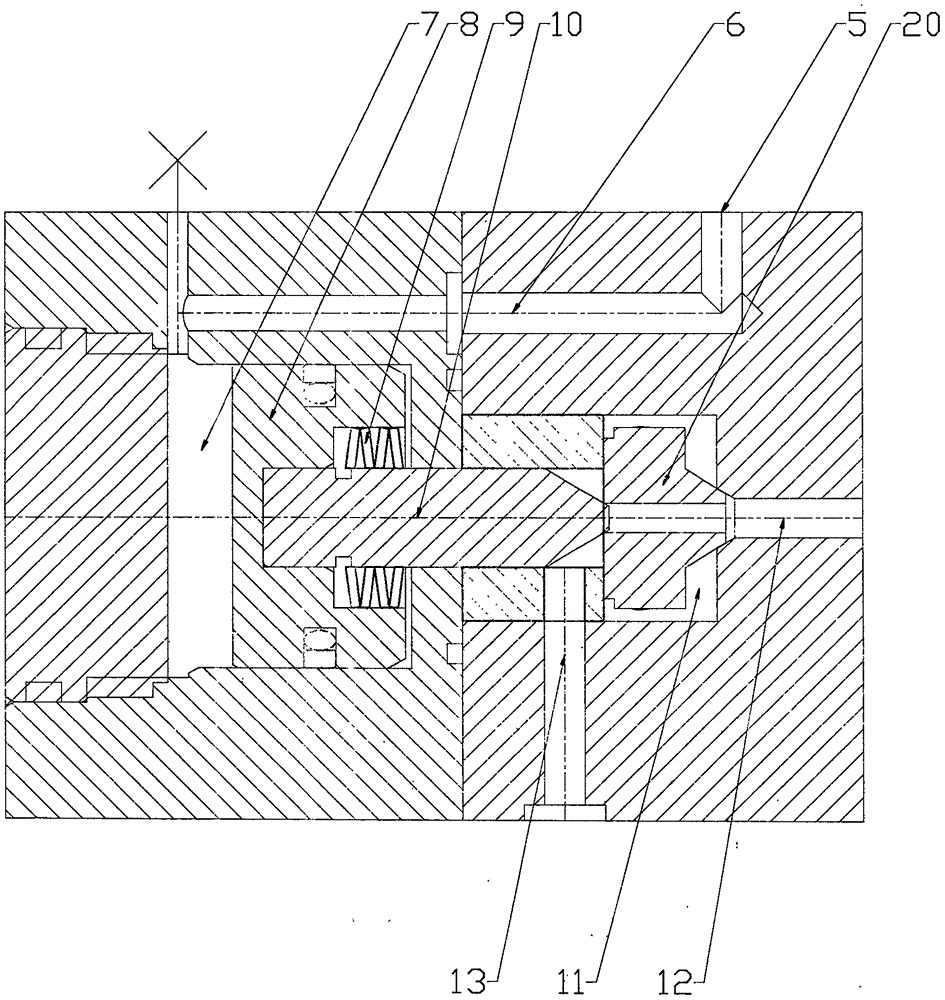

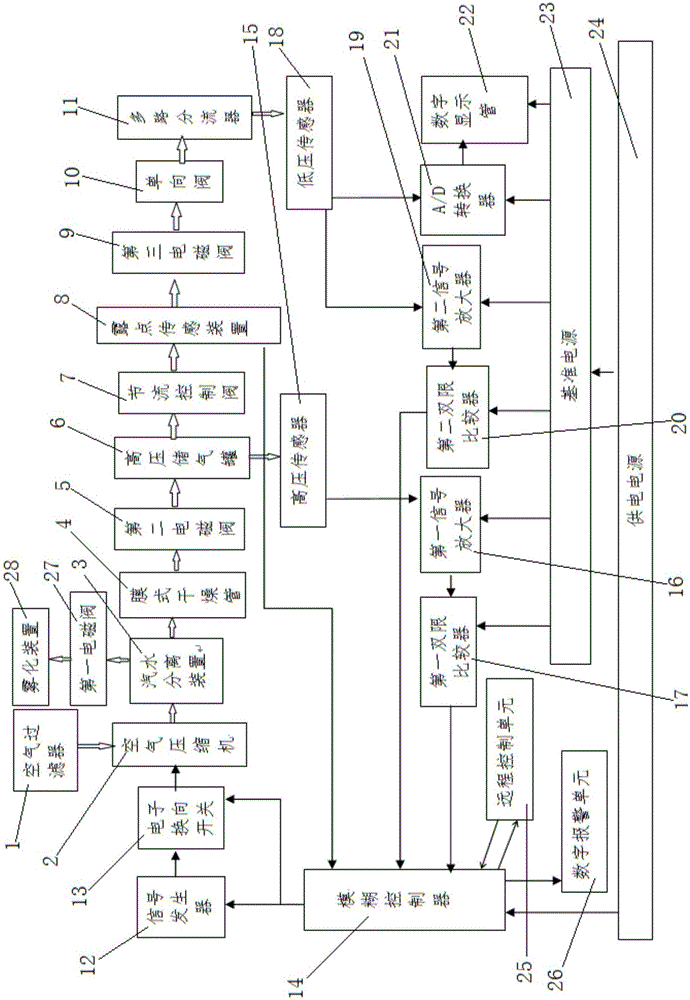

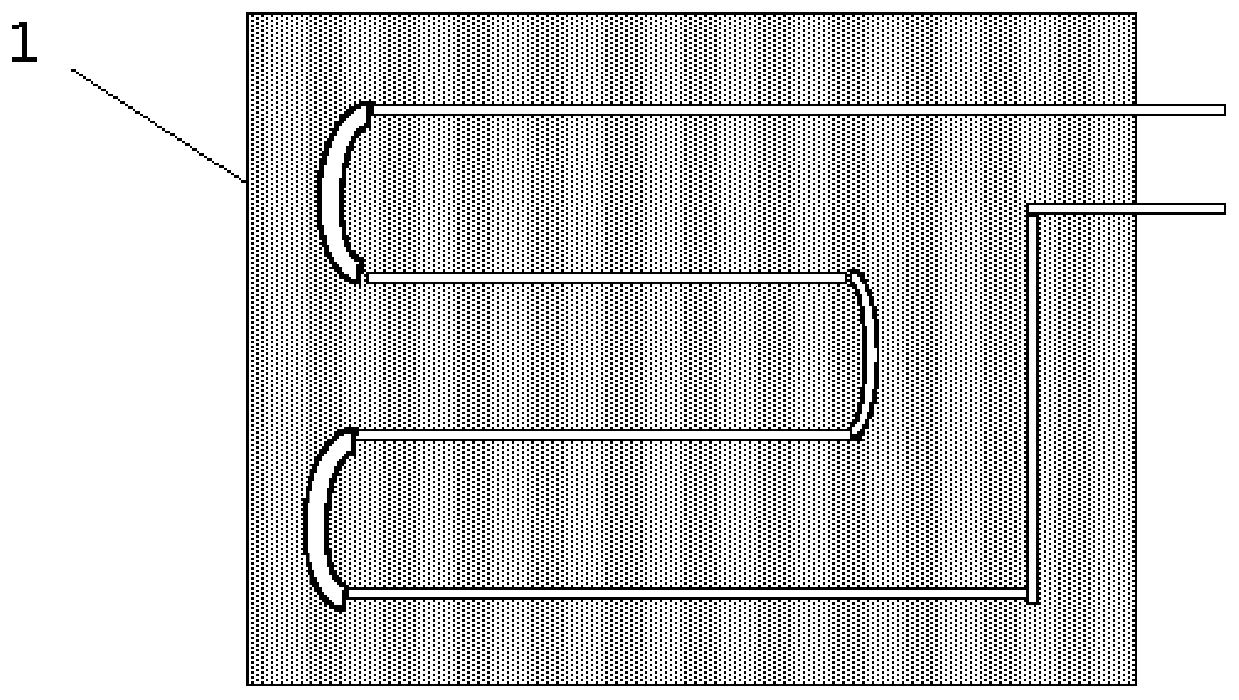

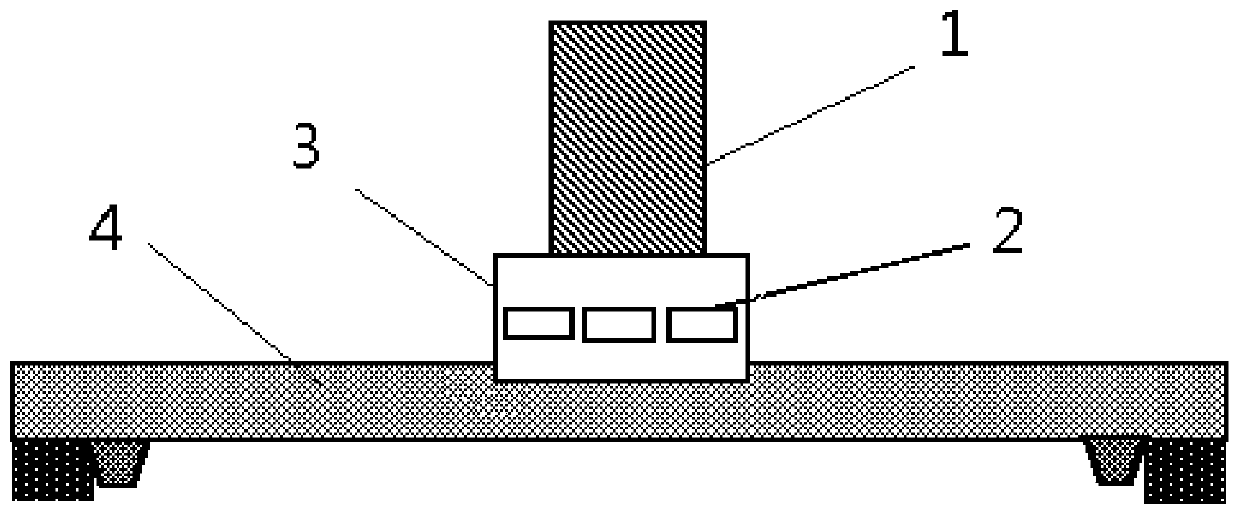

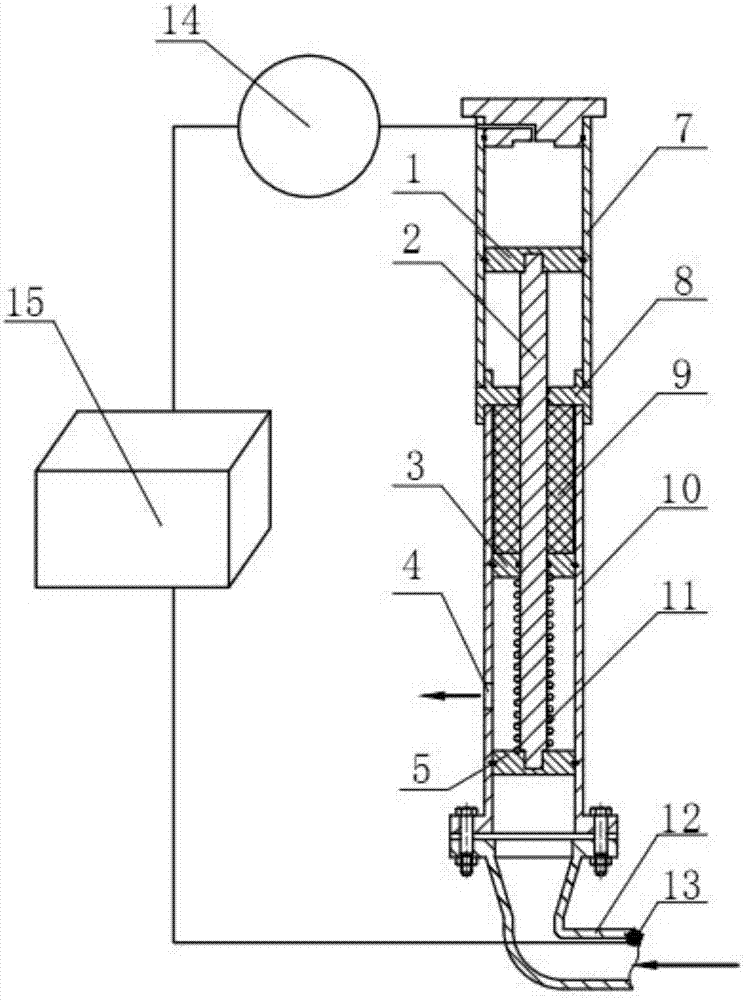

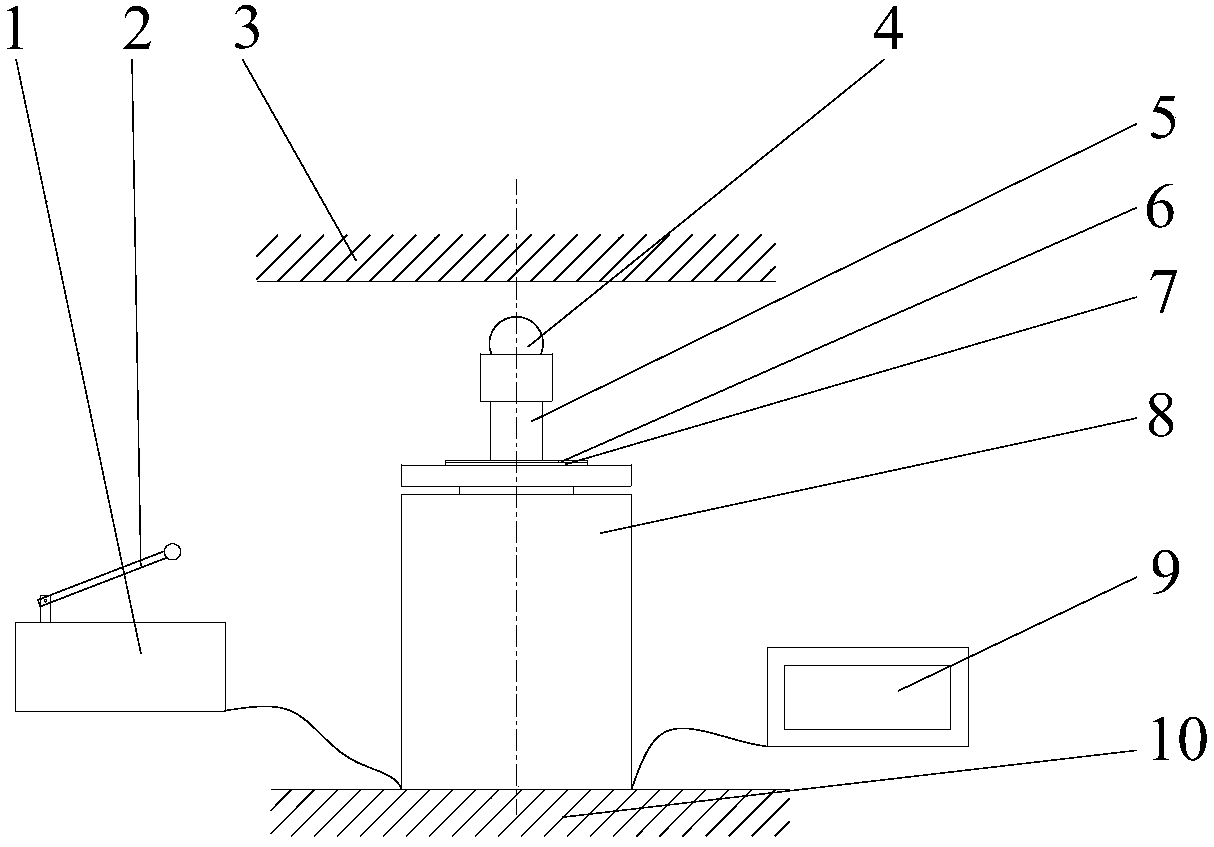

Intelligent single-body hydraulic prop

InactiveCN104074532AReal-time monitoring of pressure valuesMonitor pressure in real timeProps/chocksComputer moduleEngineering

The invention discloses an intelligent single-body hydraulic prop, which belongs to the technical field of support equipment. A man-machine interaction unit (2) and a main control module (3) are arranged on a prop main body (1); the main control module (3) controls the man-machine interaction unit (2); the main control module (3) monitors signals of a pressure sensor through an analog-to-digital module; and the main control module (3) controls a display circuit, a warning circuit and a wake-up circuit. The intelligent single-body hydraulic prop has the advantages that the pressure condition of the single-body hydraulic prop can be effectively monitored, potential safety hazards can be discovered in advance, and the safety performance is enhanced; and meanwhile, the man-machine interaction function of the single-body hydraulic prop is realized, so the use of the single-body hydraulic prop is more intelligent and humanized.

Owner:XUZHOU ZHONAN SCI & TECH CO LTD

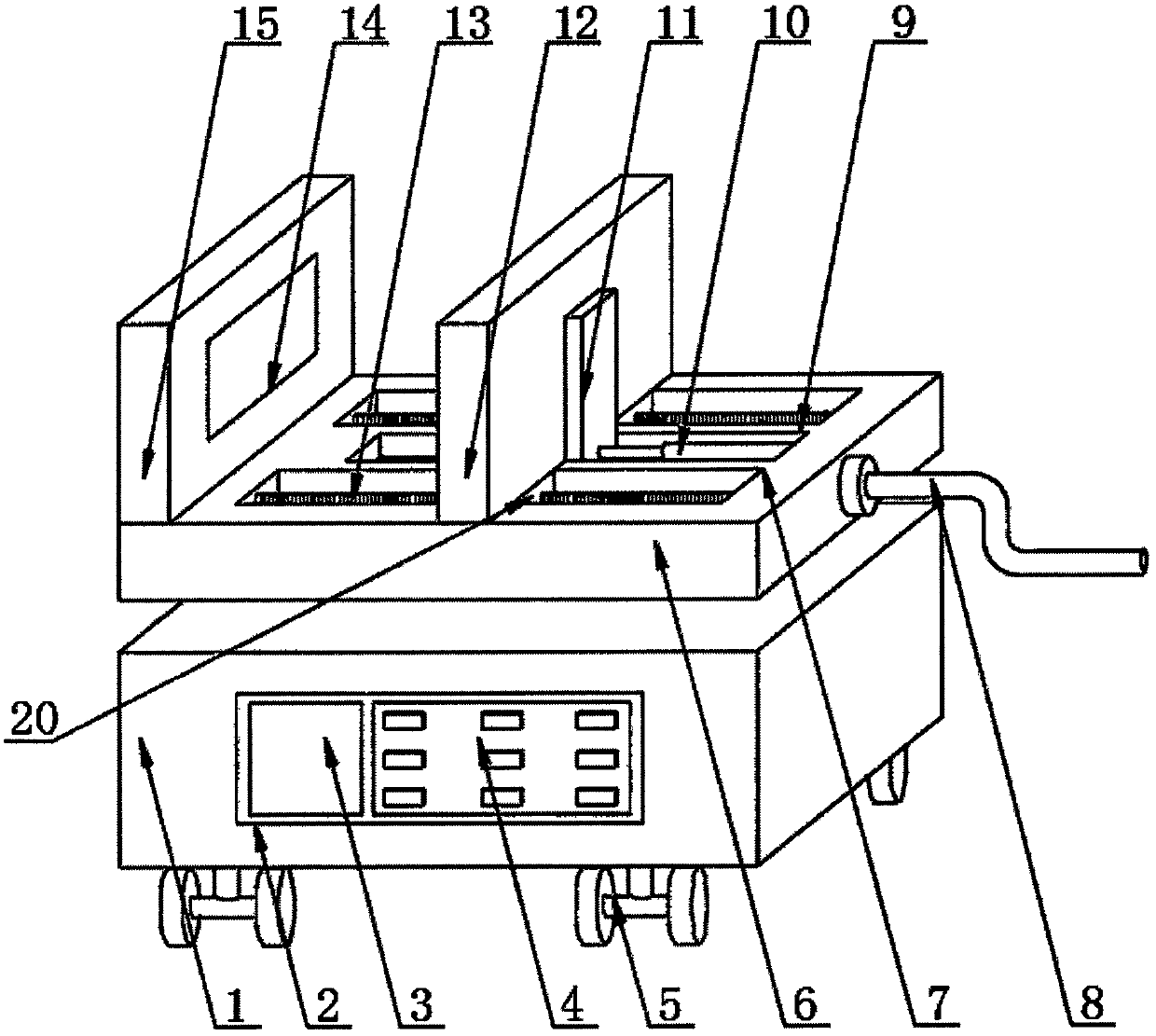

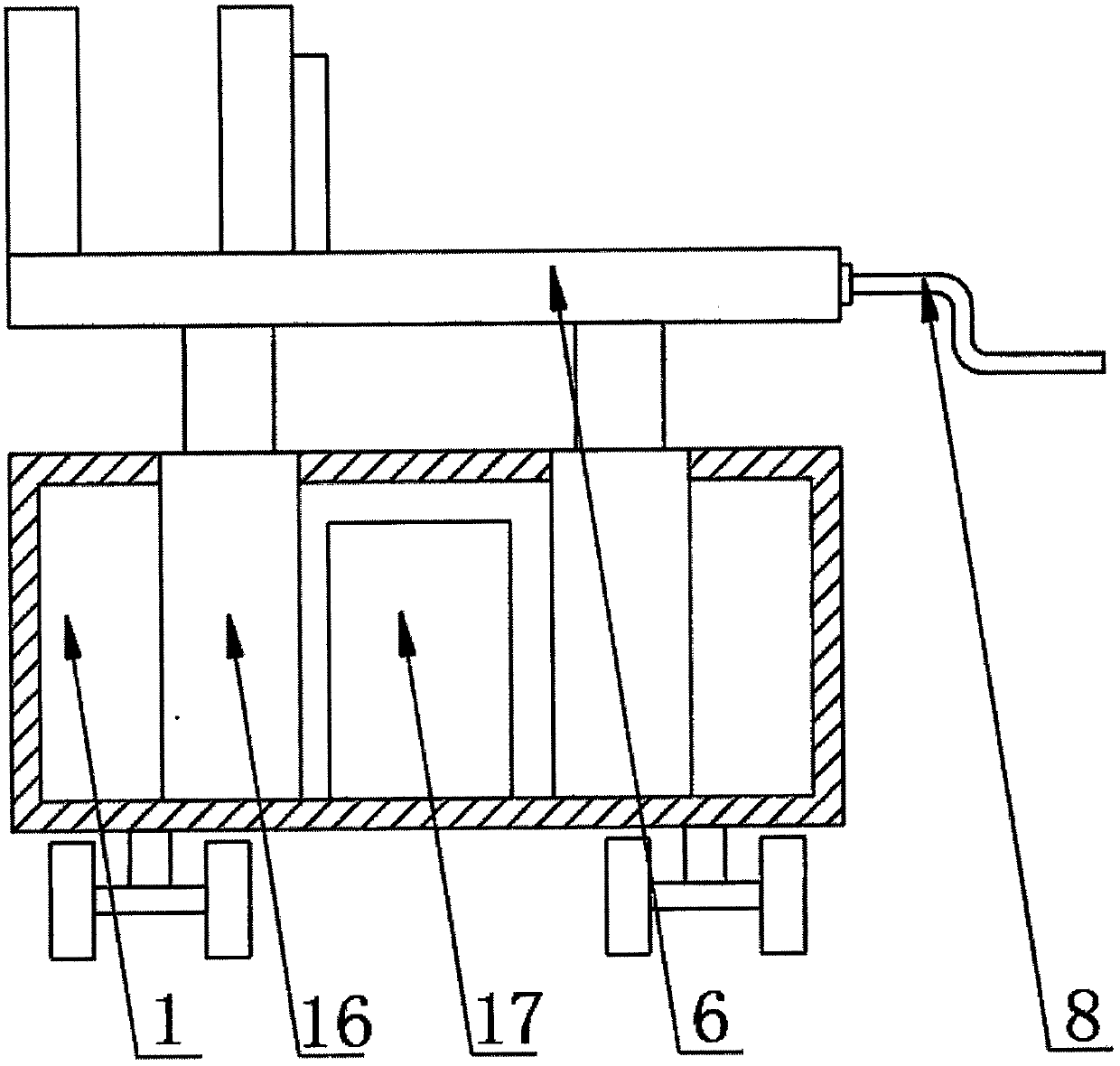

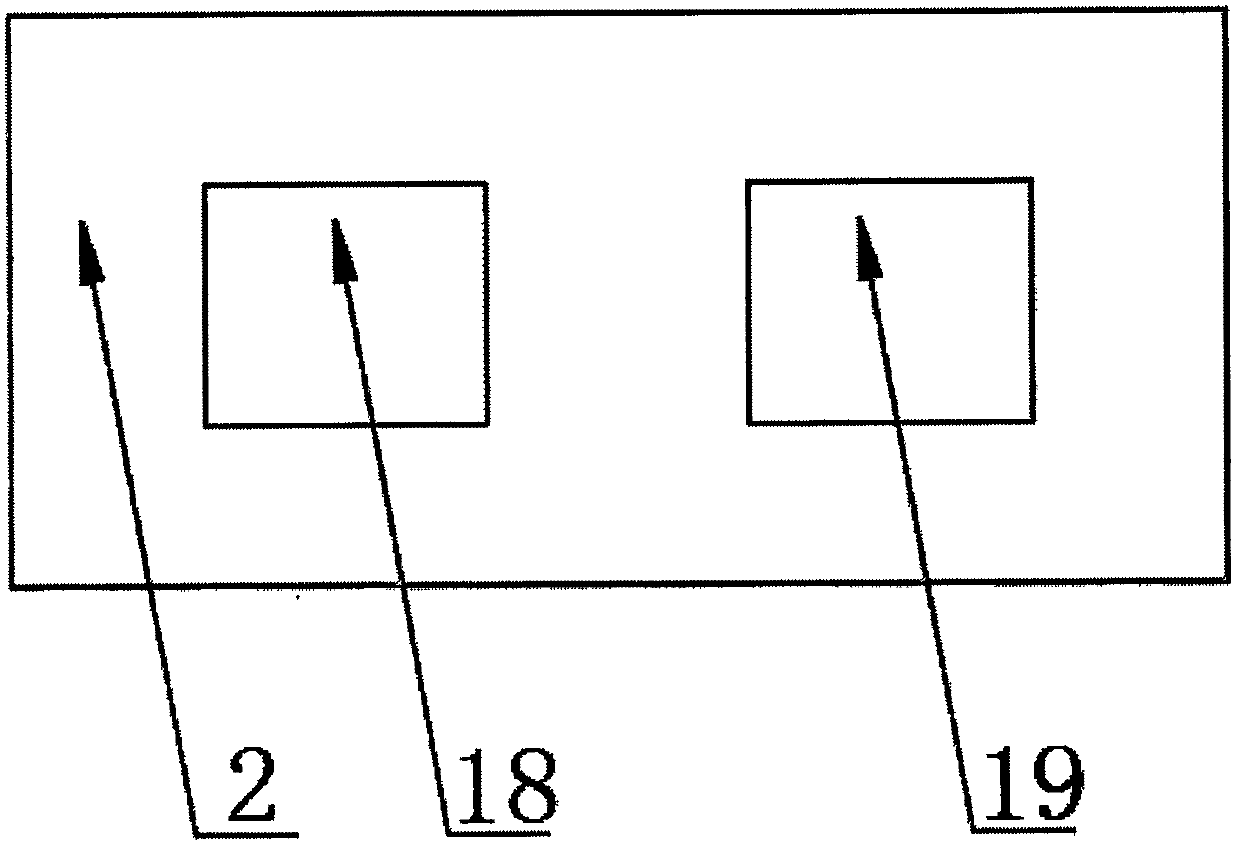

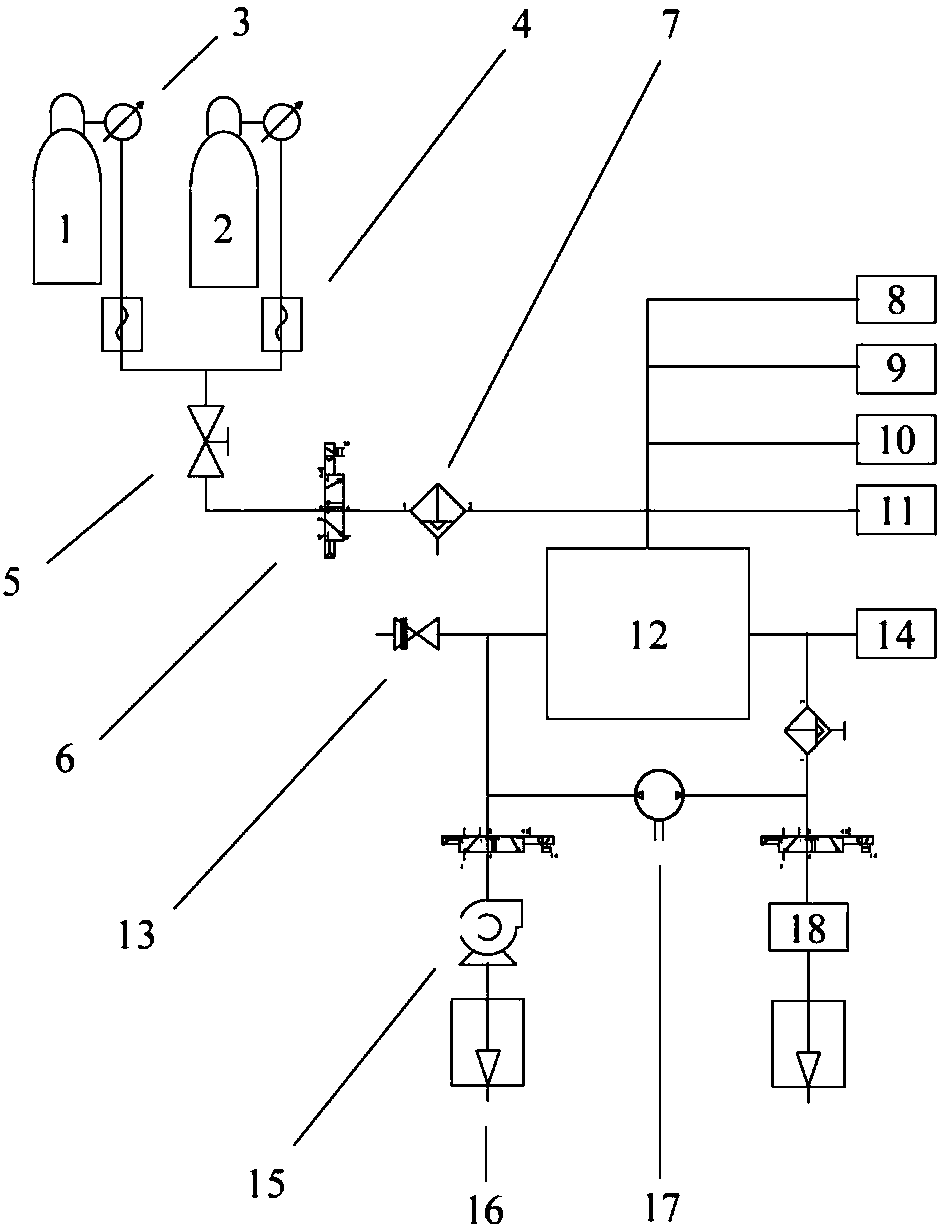

Automobile part clamping device

The invention discloses a clamping device for auto parts, which comprises a base, an electric control box, a display screen, a control panel, a moving wheel, a bottom plate, a first electric push rod, a limit block, a splint, a screw rod, a pressure sensor, a fixed Plate, second electric push rod, counterweight, alarm, PLC controller and slider, the four corners of the bottom of the base are fixed with moving wheels by bolts, and an electric control box is embedded in one side of the base , one side of the electric control box is embedded with a display screen, one side of the display screen is fixed with a control panel by bolts, and the center of the bottom inner wall of the base is fixed with a counterweight by bolts, and the counterweight A second electric push rod is fixed on both sides by bolts, and the top of the second electric push rod passes through the top of the base and is fixed with a bottom plate by bolts, and a fixed plate is fixed on one side of the top of the bottom plate by welding. The device has a simple structure and is convenient to use, thereby effectively improving the convenience of use.

Owner:GUANGXI HONGXING MACHINERY CO LTD

Integrated formation device and method of metal-based carbon nano-composite material parts

InactiveCN108465813AShort manufacturing cycleImprove production efficiencyAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingCarbon nanocomposite

The invention relates to an integrated formation device and method of metal-based carbon nano-composite material parts. The integrated formation device comprises a control system, a formation cavity,a vacuum system, a carbon source gas supply and detection system, a gas circulation system, a laser and an optical system, a powder feeding and paving system and a tail gas treatment system. Accordingto the device disclosed by the invention, metal powder is uniformly paved on a base plate by adopting a scraper, then laser beams are focused on the metal powder, a gaseous carbon source is controlled to be split under an effect of the laser beams and carbon nano-materials are deposited on the surface of a matrix, and the metal-based carbon nano-composite material parts are directly formed in a layer-by-layer working way through selective laser melting formation technology. By adopting the device, concentration values of the carbon source gas and the hydrogen can be accurately acquired, the content of the carbon nano-materials can be quantitatively controlled, and real-time monitoring and emission of impure gas in the formation device also can be realized. Carbon-nano reinforced phases generated in a way of gaseous carbon source diffusion-splitting-deposition are uniformly dispersed and are difficultly aggregated, so that the mechanical performance of the composite material can be effectively enhanced.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

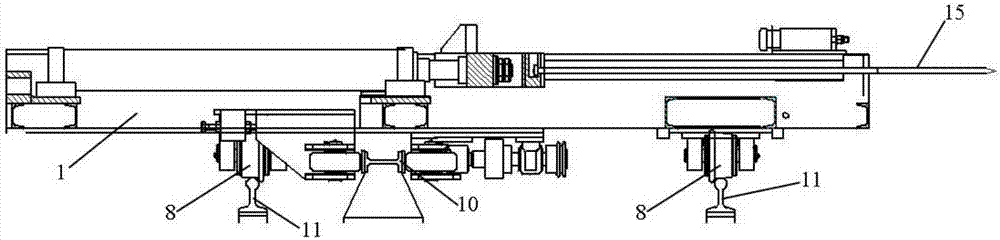

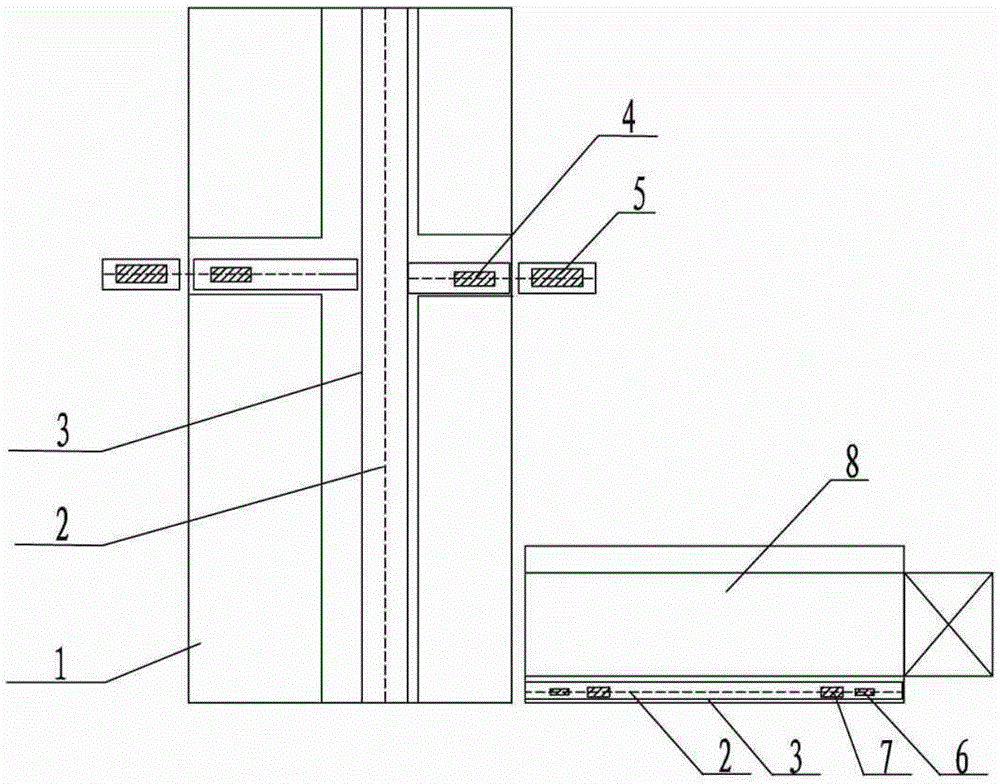

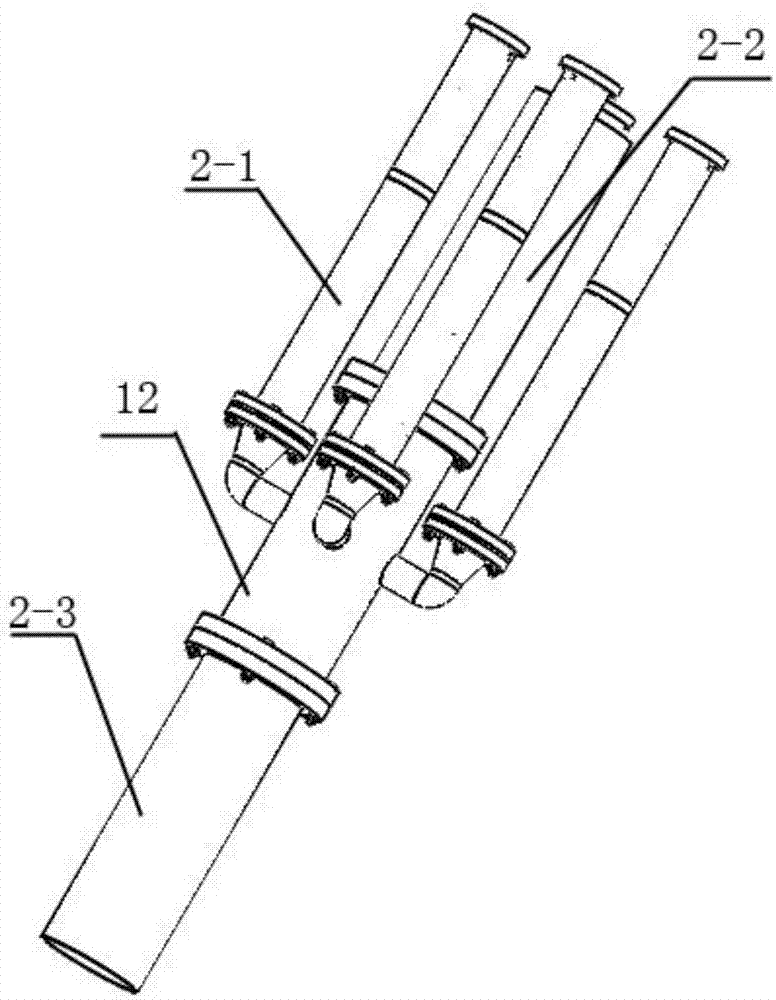

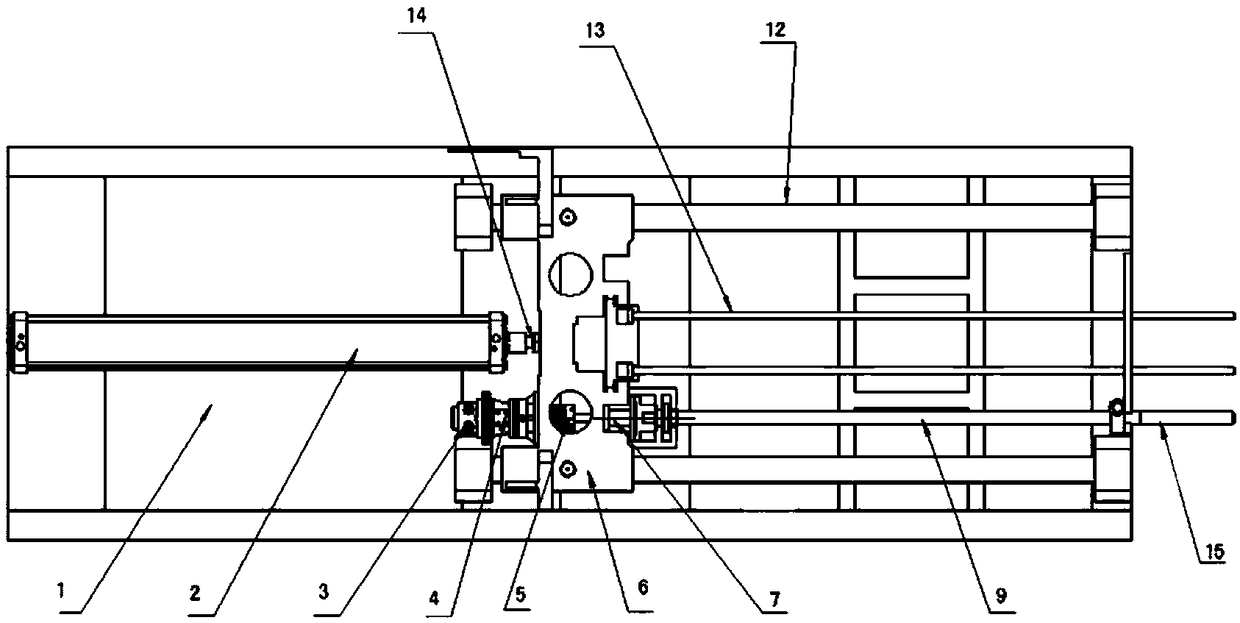

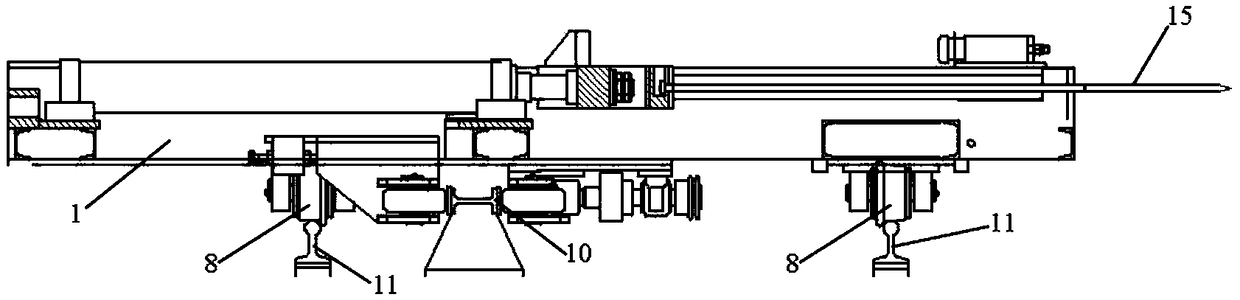

Converter wind eye pipe inner bonding cleaning tool

ActiveCN107164601ASo as not to damageReduce abnormal attrition rateManufacturing convertersBrickDrive shaft

The invention discloses a converter wind eye pipe inner bonding cleaning tool. The converter wind eye pipe inner bonding cleaning tool comprises a base assembly, a poking and beating device and a rotation device. The base assembly comprises bearing wheels, guiding wheels, a support and guide rails. The base assembly can transversely move on the guide rails in a reciprocating manner. The poking and beating device is fixedly arranged on the support and comprises an air cylinder, a sliding base, guiding rods and drill rods and is used for poking and beating a converter wind eye. The rotation device comprises a pneumatic motor, a speed reducer, a coupler, a transmission shaft, a rotation rod and a twist drill. The pneumatic motor is fixedly arranged on the sliding base, a rotation shaft of the pneumatic motor is connected with the speed reducer, the torque output end of the speed reducer is connected with the transmission shaft through the coupler, and the transmission shaft is connected with the rotation shaft. The torque is transmitted to the rotation shaft to drive the rotation rod to rotate, and the tail end of the rotation rod is detachably provided with the twist drill. According to the converter wind eye pipe inner bonding cleaning tool, for the problem of wind eye blockage of a PS large converter wind gap, drilling is used for replacing a poking and beating manner, and the technical problem that due to existing design, refractory bricks in a wind eye area in a converter are likely to be damaged abnormally is solved.

Owner:JIANGXI COPPER (DEXING) CHEMICAL CO LTD

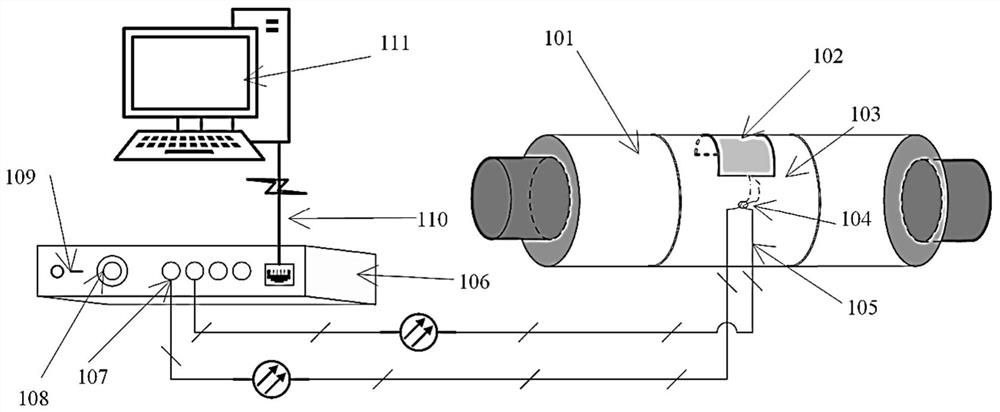

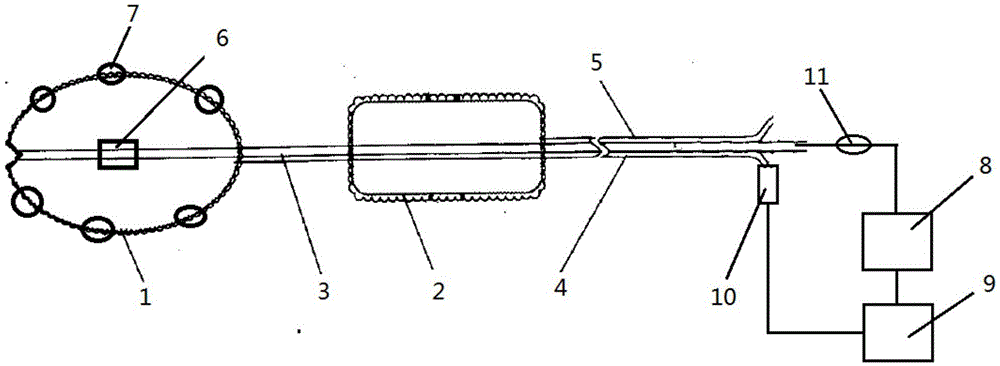

System and method for measuring the interface pressure of cable and an accessory on line

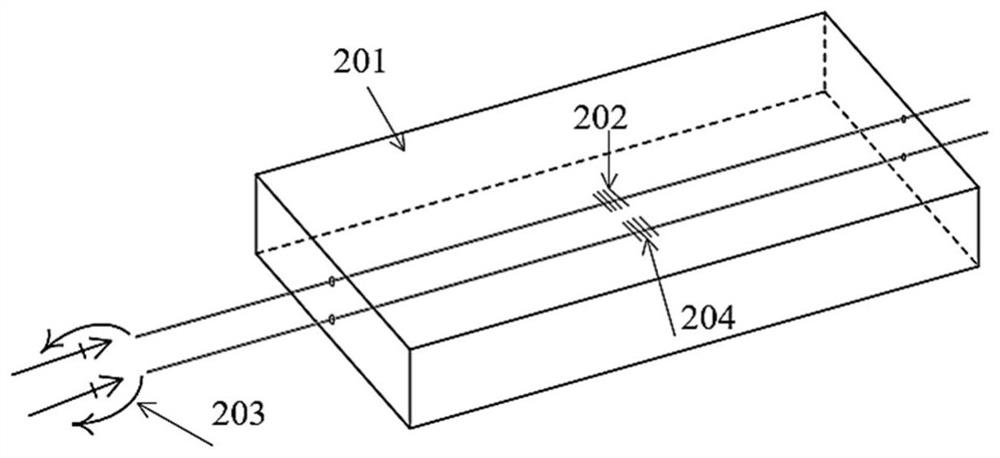

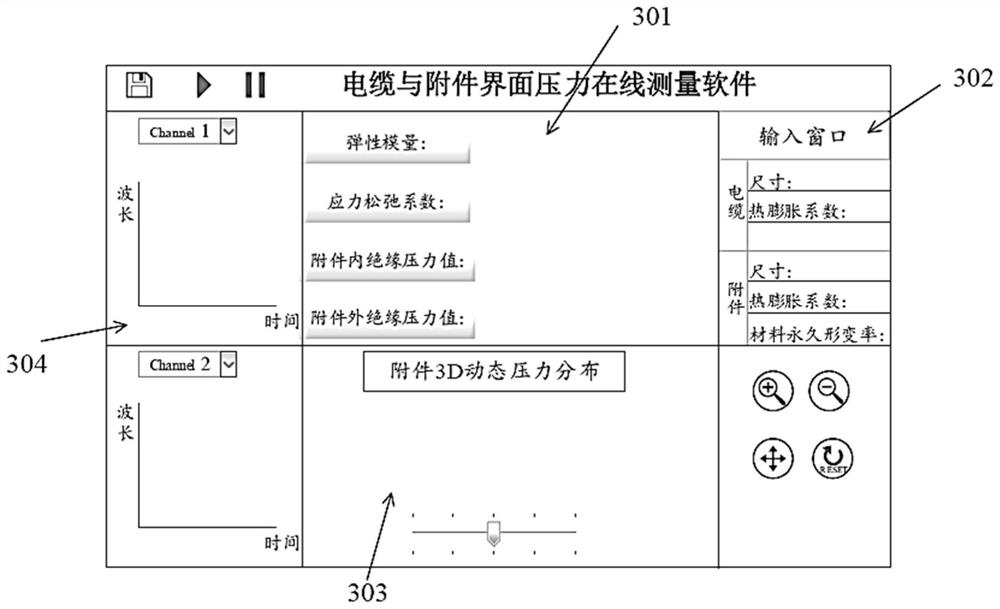

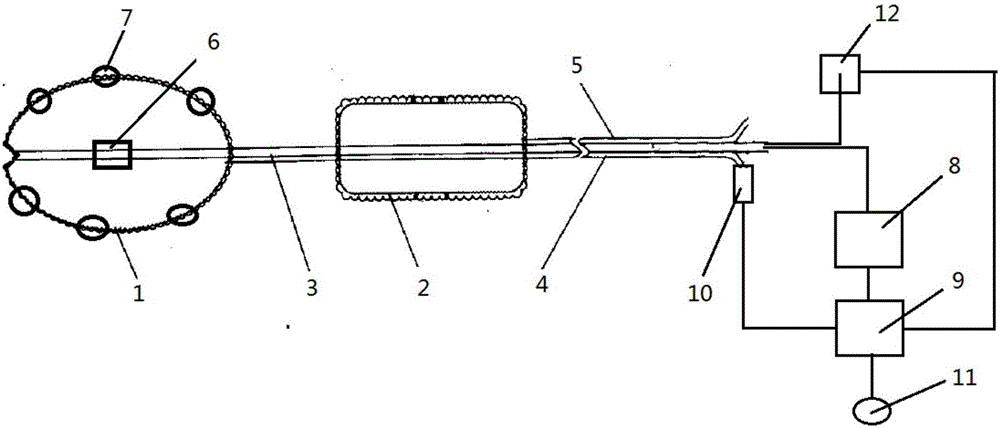

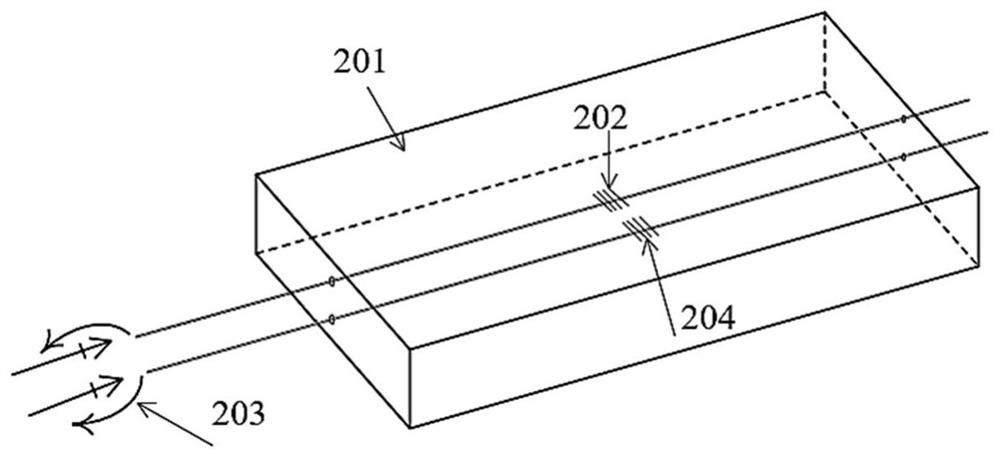

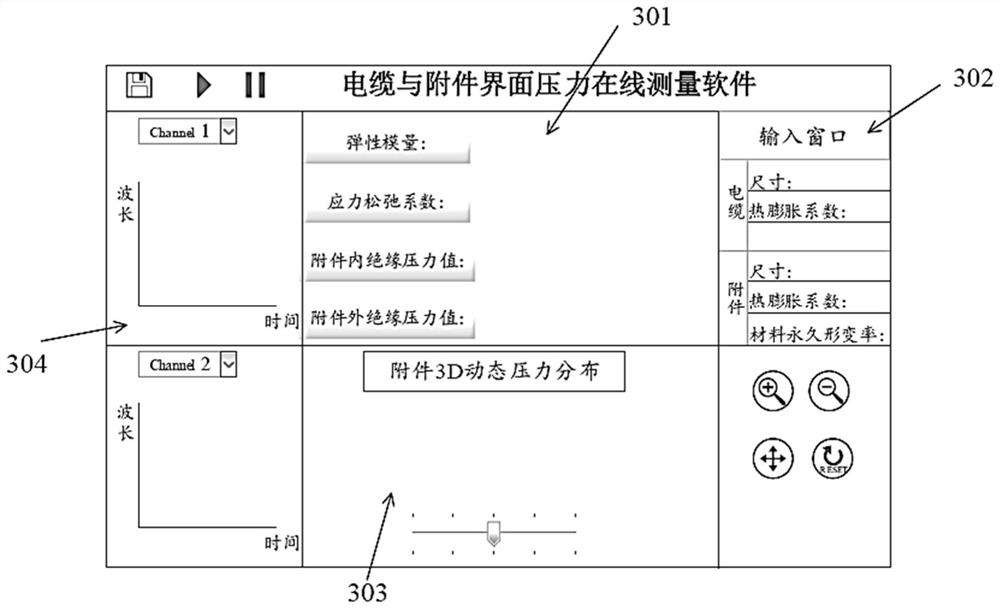

ActiveCN111879449ASimple structureProbability of predicting failures in timeForce measurement by measuring optical property variationUsing optical meansGratingInterference resistance

The invention discloses a system and a method for measuring the interface pressure of a cable and an accessory on line. The system comprises an optical fiber curvature sensing subsystem, a temperatureinterference resisting subsystem and a data analysis subsystem, the optical fiber curvature sensing subsystem obtains the curvature change condition of the outermost layer of the cable accessory andtransmits data to the data analysis subsystem, the temperature interference resistance subsystem avoids the influence of temperature on a measurement result, and the data analysis subsystem converts the data through an established cable accessory inner and outer layer stress-strain equation, and displays internal and external pressure values of the accessory in real time. The optical fiber sensoris wound on the outer layer of the cable accessory, after the cable accessory is bent and expanded, the polyimide film is bent along with the cable accessory, the optical fiber Bragg gratings pasted on the polyimide film are extended and shortened respectively, and the corresponding Bragg center wavelength drifts; and the fiber bragg grating demodulator detects the reflection wavelength signal toobtain a value of the fiber bragg grating after wavelength drift. According to the invention, on-line measurement and visual display of the interface pressure of the cable and the accessory can be achieved.

Owner:XI AN JIAOTONG UNIV

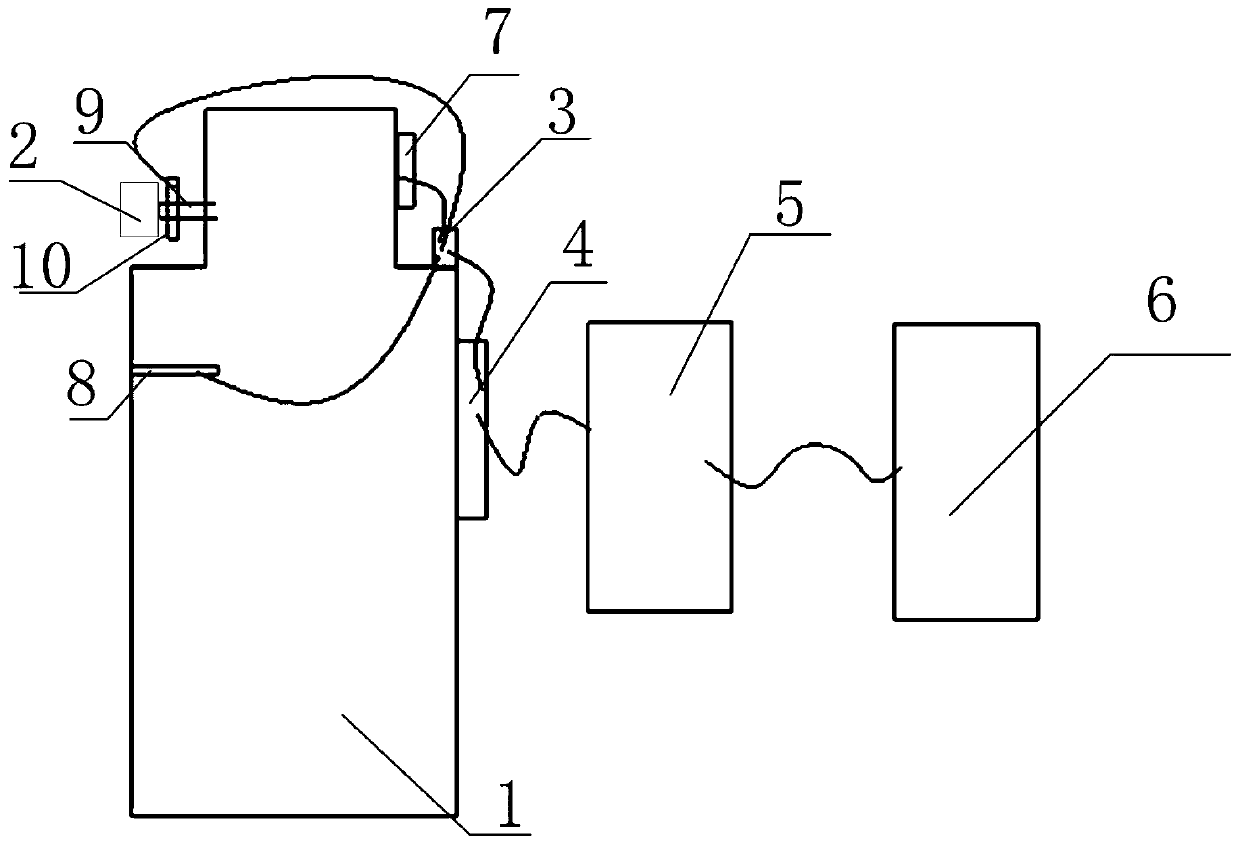

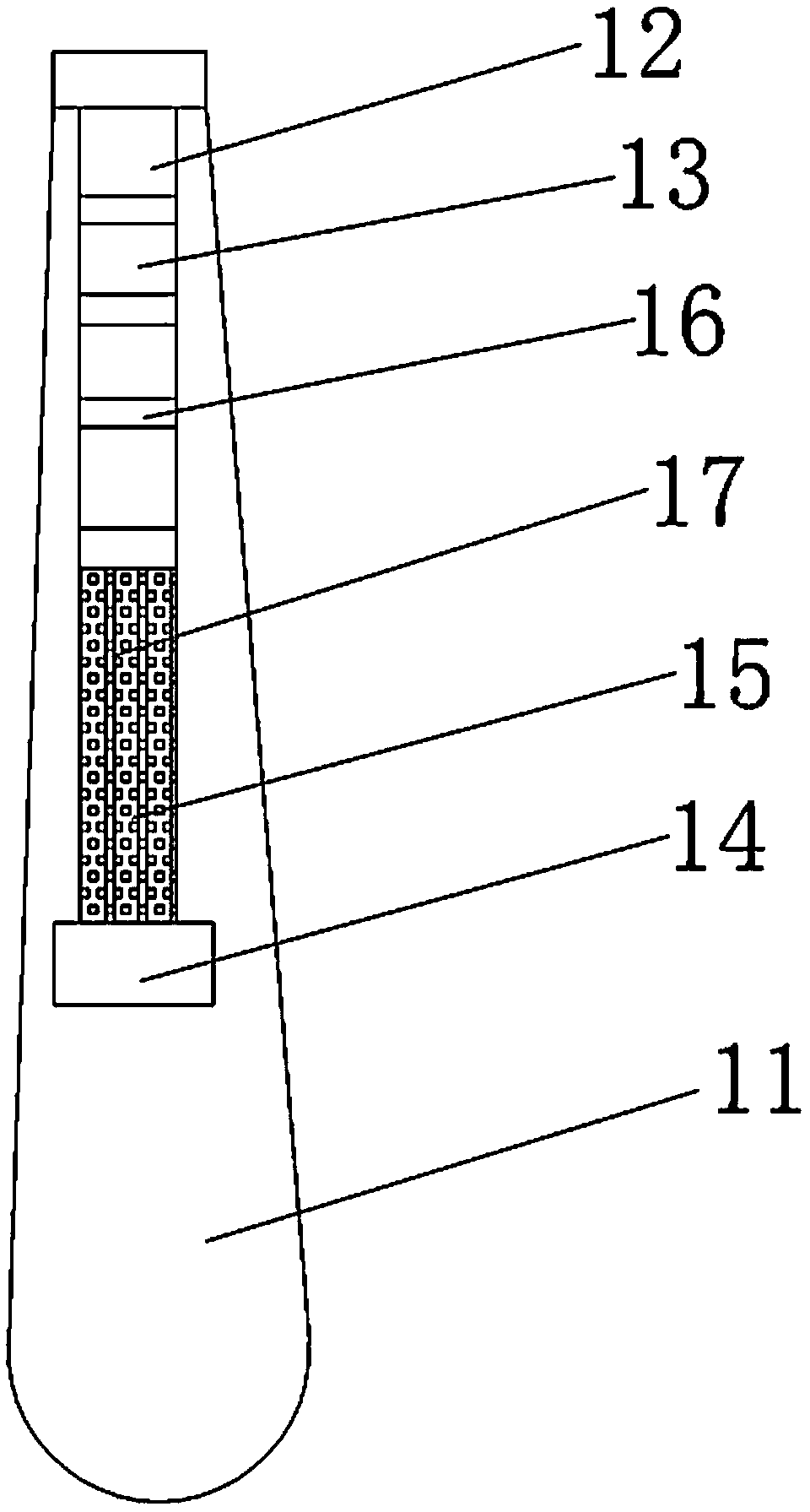

Intelligent uterus hemostasis air bag

InactiveCN105662518AReal-time monitoring of pressure valuesCause secondary damageMedical devicesObstetrical instrumentsEngineeringVagina

The invention discloses an intelligent uterus hemostasis air bag, and belongs to the technical field of medical instruments.The intelligent uterus hemostasis air bag comprises a uterus air bag, a vagina air bag and a guide pipe penetrating through the uterus air bag and the vagina air bag, a uterus air bag inflating channel and a vagina air bag inflating channel which are communicated with the uterus air bag and the vagina air bag are formed in the guide pipe, and the intelligent uterus hemostasis air bag further comprises an intelligent pressure adjusting system and an intelligent detecting system, a pressure value in the hemostasis air bag can be monitored in real time and automatically adjusted at the reasonable level by the intelligent pressure adjusting system to achieve the good hemostasis effect, and it is avoided that the uterus is injured secondarily as pressure is too high, or the hemostasis effect is poor as the pressure is too low.The hemorrhage condition of an inner cavity of the uterus is monitored in real time through an intelligent imaging system, operation staff can learn the conditions in the uterine cavity in real time and take various corresponding measures, operation quality and safety are improved, and the whole hemostasis is intelligent.

Owner:THE FIRST AFFILIATED HOSPITAL OF THIRD MILITARY MEDICAL UNIVERSITY OF PLA

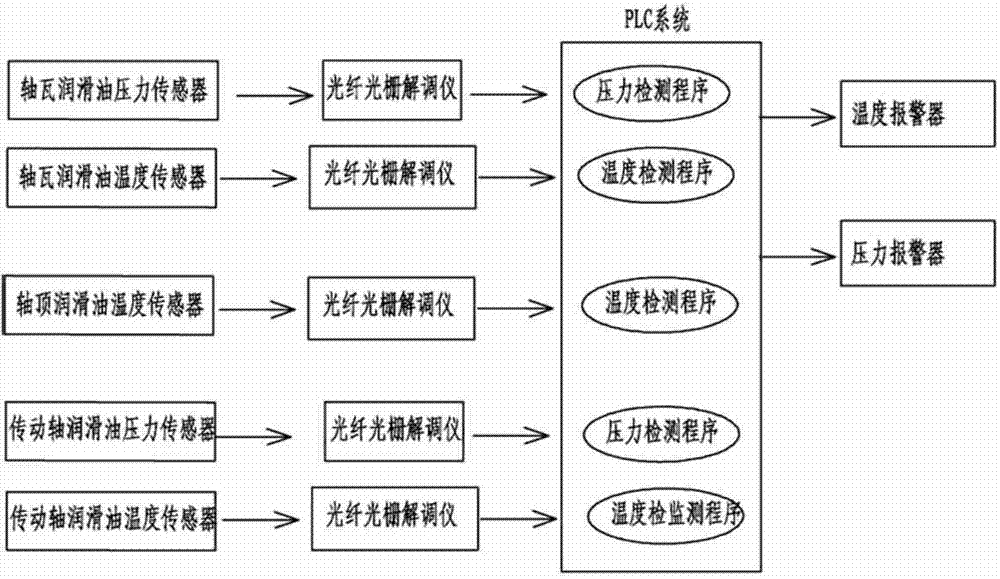

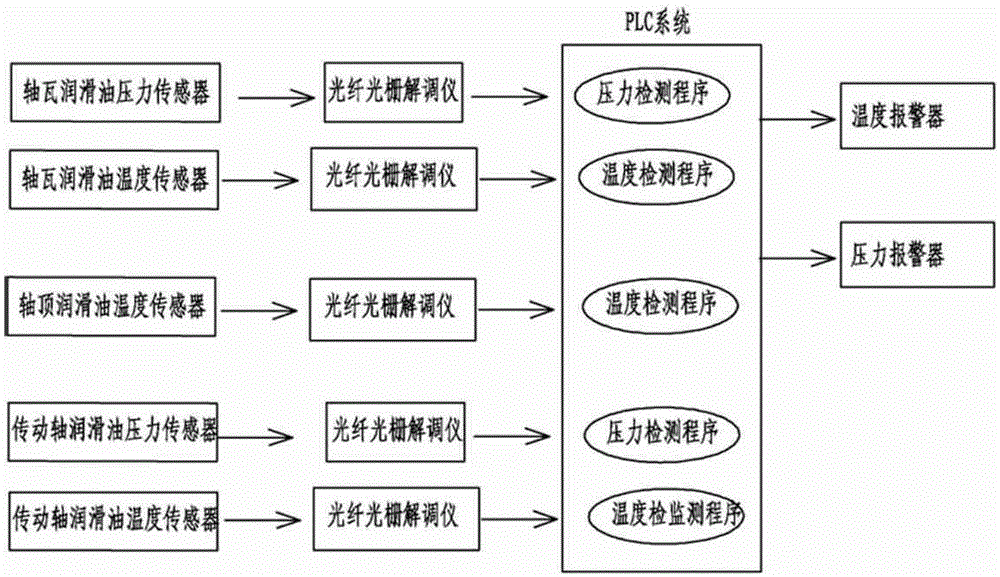

Cone crusher with on-line temperature monitoring function

ActiveCN103894258AExtended service lifeMonitor changes in real timeGrain treatmentsOil pressureAlarm device

The invention relates to the technical field of a hydraulic cone crusher, and in particular relates to a cone crusher with an on-line temperature monitoring function. A programmed logical controller (PLC) system is respectively connected with a temperature alarm device, a pressure alarm device and a fiber bragg grating demodulation device; the fiber bragg grating demodulation device is respectively connected with a bearing bush lubricating oil temperature sensor, a bearing bush lubricating oil pressure sensor, a shaft top lubricating oil temperature sensor, a transmission shaft lubricating oil temperature sensor and a transmission shaft lubricating oil pressure sensor by virtue of optical fibers, wherein the bearing bush lubricating oil temperature sensor and the bearing bush lubricating oil pressure sensor are arranged besides a bearing bush of a main shaft of the cone crusher, the shaft top lubricating oil temperature sensor is arranged on the top of the main shaft of the cone crusher, and the transmission shaft lubricating oil temperature sensor and the transmission shaft lubricating oil pressure sensor are arranged on a transmission shaft of the cone crusher; the PLC system is internally provided with a temperature detection program and a pressure detection program; the optical fibers are respectively arranged in a titanium alloy guide pipeline. The cone crusher is capable of monitoring the change of data in real time; when the temperature and the pressure exceed set threshold values, alarm processing is carried out, and the cone crusher can be monitored and protected.

Owner:ANSTEEL GRP MINING CO LTD

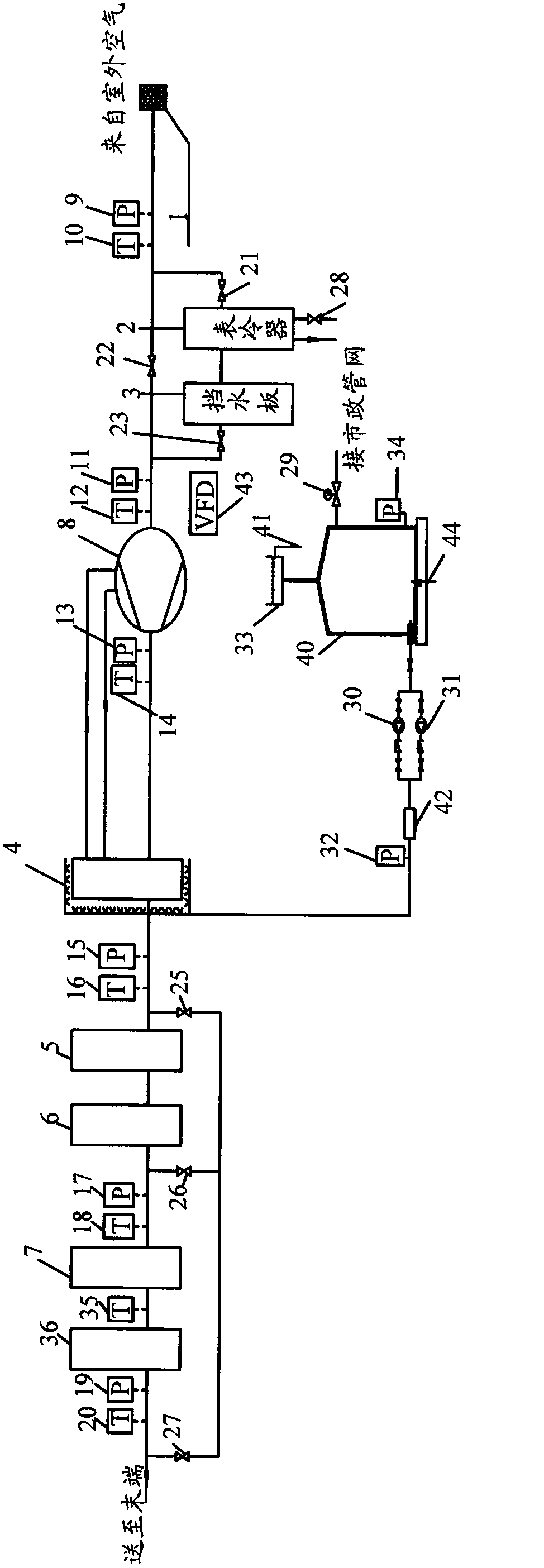

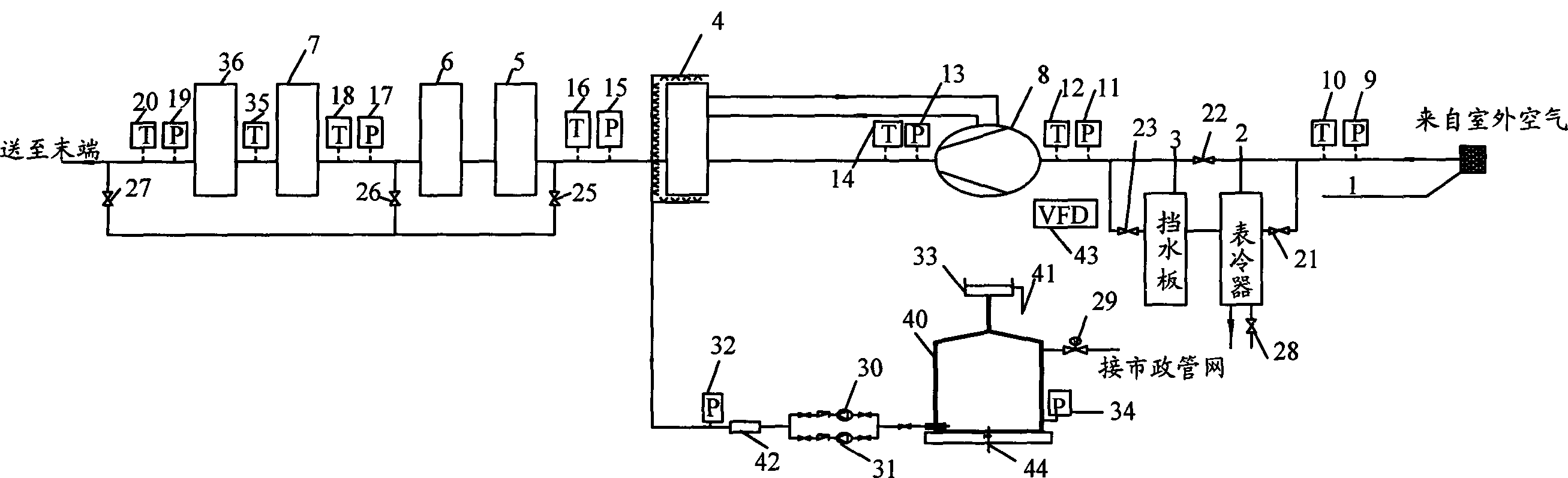

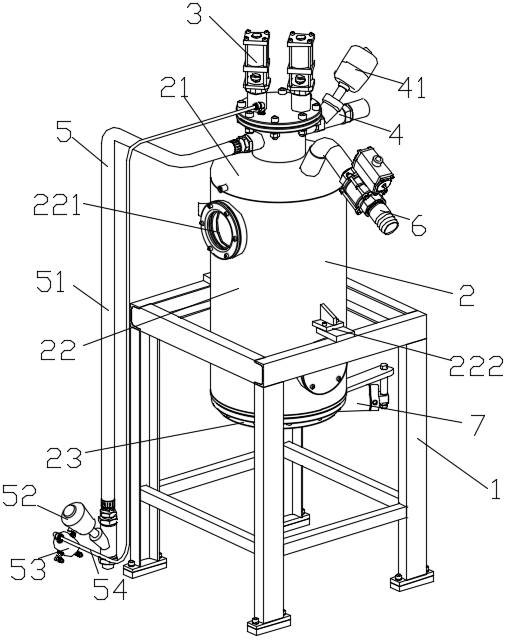

Pre-treating and variable-flow device of air compression system

ActiveCN102705205AMonitor temperature in real timeReal-time monitoring of pressure valuesPump installationsPositive-displacement liquid enginesElectric heatingWater storage tank

The invention provides a pre-treating and variable-flow device of an air compression system, wherein the wind outlet of an air pre-cooling machine set is connected with an air compressor; the wind outlet of the air compressor is connected with an air / oil cooler; a cold spray evaporation nozzle of the air / oil cooler is connected with a water softening device; the water inlet of a water storage tank is connected with municipal water supply network; the water outlet of the water storage tank is connected with the water softening device; the wind outlet of the air / oil cooler is connected with a separator; a frequency changer is connected with the air compressor; the separator is also connected with a defoaming device; the defoaming device is also connected with a drying and dehumidifying machine set; and the drying and dehumidifying machine is connected with an electric heating device. According to the invention, air temperature values and pressure values of each section are monitored in real time; efficiency of a compressor is increased completely; variable flow regulation of the compressor and a cooler blower is realized; pressure fluctuation on a tail end is reduced; compressed air separated from the outlet end of the compressor satisfies a humidity demand; in addition, the drying and dehumidifying machine set and an electric heating machine set can be cancelled so as to save energy preferably.

Owner:福建佰时德能源科技有限公司

Uterus hemostatic air bag with automatically adjustable pressure

InactiveCN105559846AReal-time monitoring of pressure valuesCause secondary damageEndoscopesOcculdersControl systemDisplay device

The invention discloses a uterus hemostatic air bag with automatically adjustable pressure, and belongs to the technical field of medical instruments. The uterus hemostatic air bag comprises a uterus air bag, a vagina air bag and a guiding catheter running through the uterus air bag and the vagina air bag, wherein a uterus air bag air filling passage and a vagina air bag air filling passage, which are communicated with the uterus air bag and the vagina air bag respectively, are arranged in the guiding catheter. The uterus hemostatic air bag also comprises a pressure automatic adjusting system comprising a pressure sensor arranged in the uterus air bag, a display and a PLC control system which are communicated with the pressure sensor through a data wire and are arranged outside the uterus air bag, and an air filling device which is arranged at the uterus air bag air filing passage and is communicated with the PLC control system. By virtue of the pressure automatic adjusting system, the uterus hemostatic air bag can monitor and automatically adjust the value of the pressure in the air bags to be at a reasonable level in real time, thereby achieving a relatively good hemostatic effect, and avoiding the problems of secondary damage to a uterus due to an excessive pressure, and poor hemostatic effect due to a too small pressure.

Owner:THE FIRST AFFILIATED HOSPITAL OF THIRD MILITARY MEDICAL UNIVERSITY OF PLA

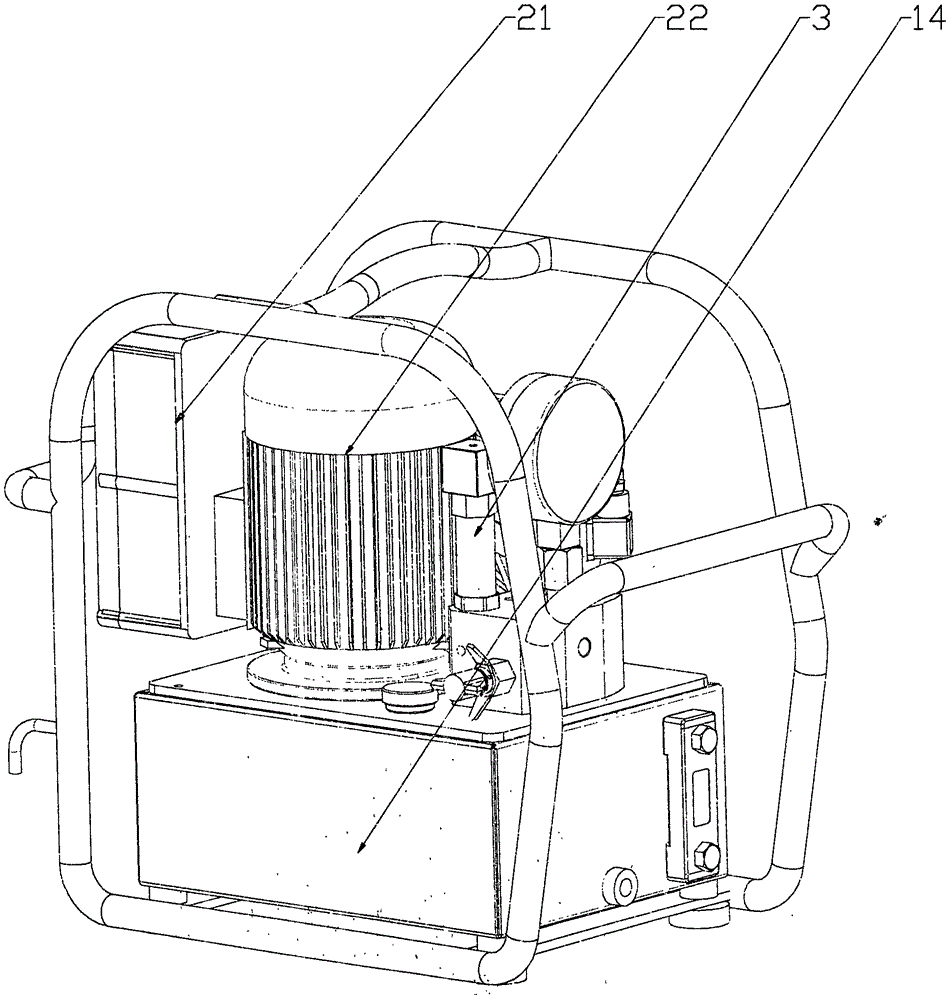

Ultrahigh-pressure automatic stretching pump

ActiveCN106762511AReduce biasReduce difficultyFluid parameterPump controlElectromagnetic valveHigh pressure

The invention discloses an ultrahigh-pressure automatic stretching pump, and relates to the technical field of hydraulic pressure. The ultrahigh-pressure automatic stretching pump comprises a control box, a motor, a low-pressure pump, a high-pressure pump, a pilot electromagnetic valve, an ultrahigh-pressure control valve, a pressure transducer and a remote control handle; the motor is connected with the low-pressure pump and the high-pressure pump; the pilot electromagnetic valve controls connection and disconnection of an oil way between a low-pressure oil way and a control oil port of the ultrahigh-pressure control valve; the pressure transducer is arranged on an output oil way; the ultrahigh-pressure control valve includes a valve body, a control oil port, a piston, a piston rod and a return spring; a control cavity and a pressure relief cavity are formed in the valve body; two ends of the piston rod are separately positioned in the control cavity and the pressure relief cavity; the piston rod in the control cavity is provided with a control piston and the return spring; and a pressure relief piston is arranged on the piston rod in the pressure relief cavity. The ultrahigh-pressure automatic stretching pump adopts a double-speed design, is high in automation degree and efficiency, and can realize remote control.

Owner:PINGYUAN JKYEYA HYDRAULLO TOOLS TECH CO LTD

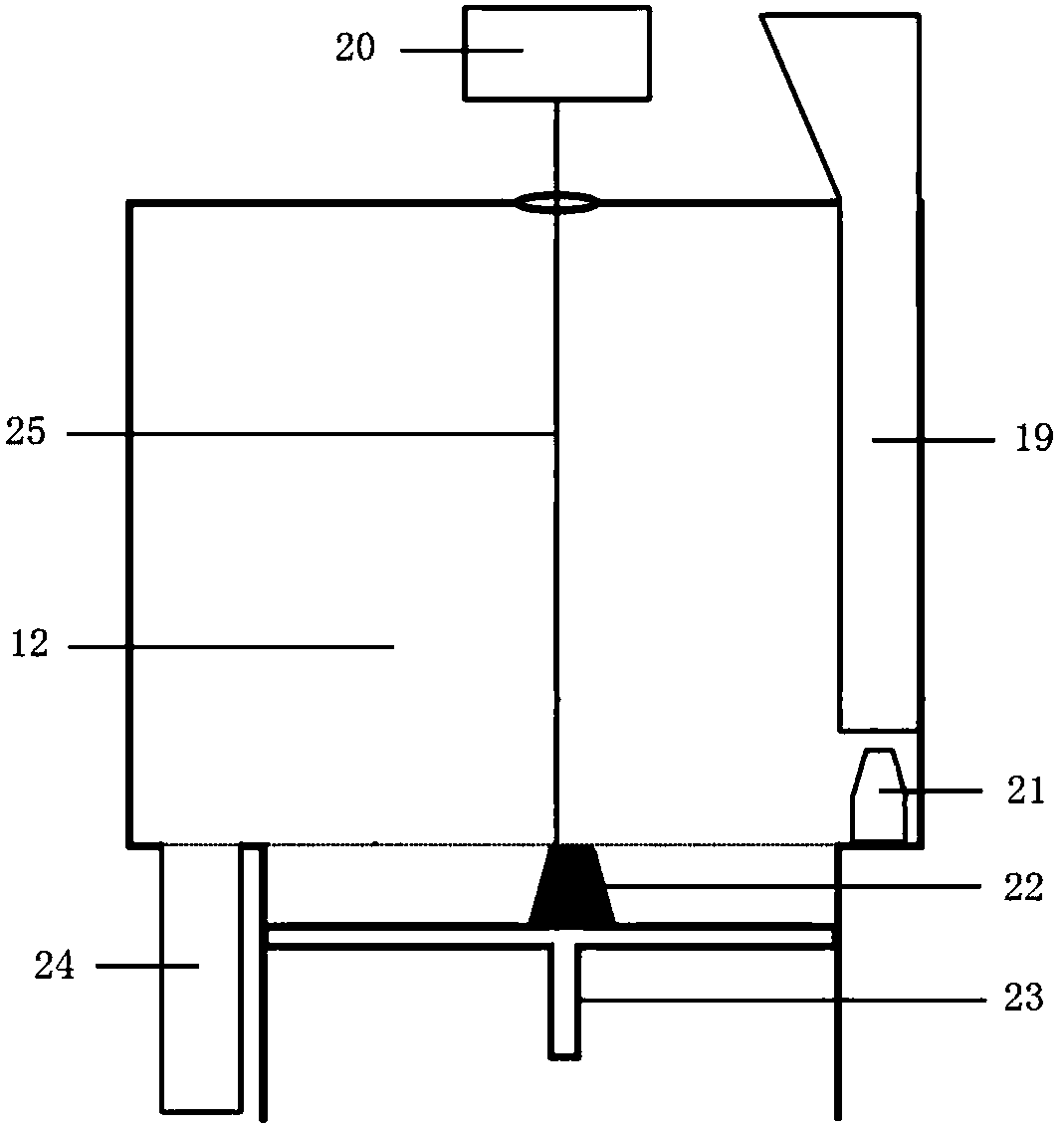

Waveguide aerator

ActiveCN105720346AReal-time monitoring of pressure valuesExtended service lifeAntenna detailsThrottle controlGas compressor

The invention discloses a waveguide aerator. The waveguide aerator comprises an air filter, an air compressor, a steam-water separating device, a film-type drying tube, a second electromagnetic valve, a high-pressure air storage tank, a throttle control valve, a dew point sensing device, a third electromagnetic valve, a one-way valve and a multi-path splitter, which are sequentially connected with one another, wherein the air compressor is also sequentially connected with an electronic commutator switch and a signal generator; the commutator switch and the signal generator are connected with a fuzzy controller; the high-pressure air storage tank is also sequentially connected with a high-pressure sensor, a first signal amplifier and a first double-limit comparator; and the multi-path splitter is also sequentially connected with the low-pressure sensor, a second signal amplifier and a second double-limit comparator. The waveguide aerator monitors a pressure value of a feeder system in real time and adjusts the pressure value through the electromagnetic valves, so that the compressor of the waveguide aerator works only when needed; the influence of the air damping effect on the feeder system is reduced; and water after steam-water separation is atomized and is directly discharged into external air.

Owner:XIAN JIAODA KAIDA NEW TECH

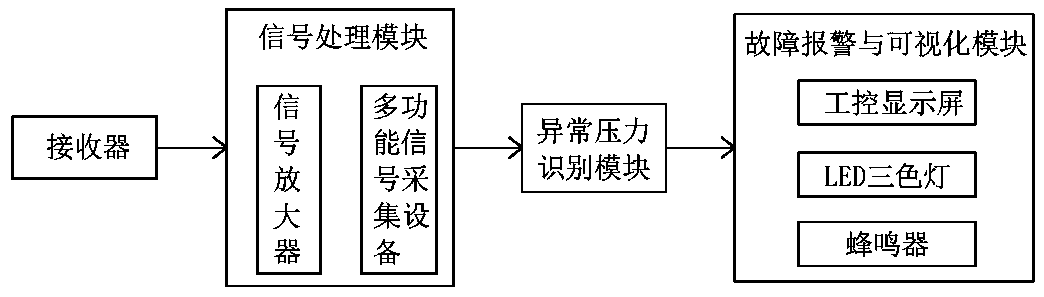

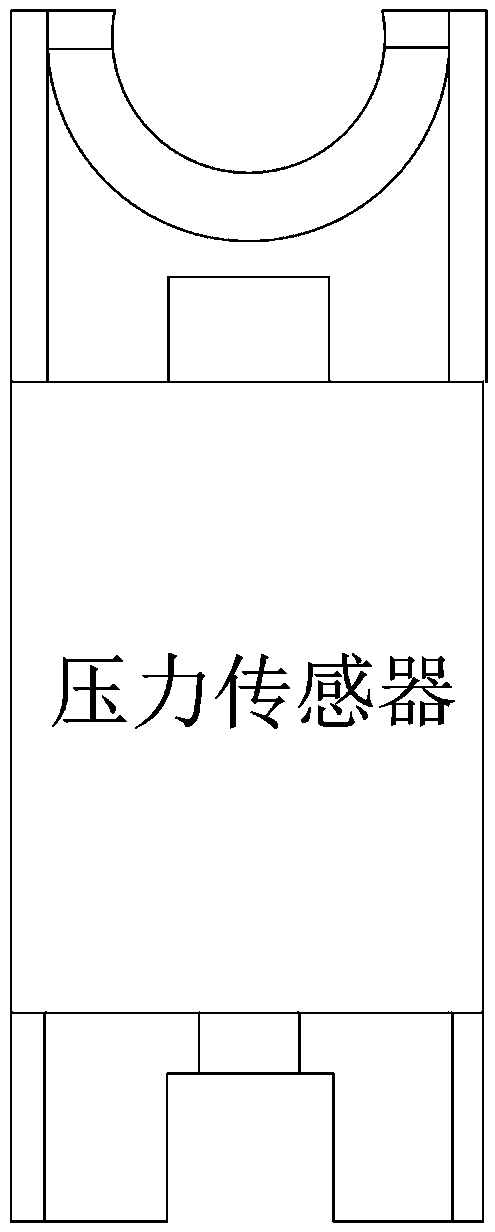

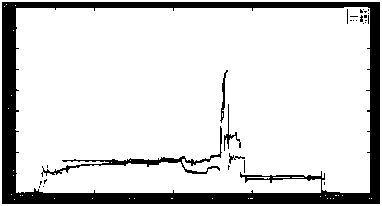

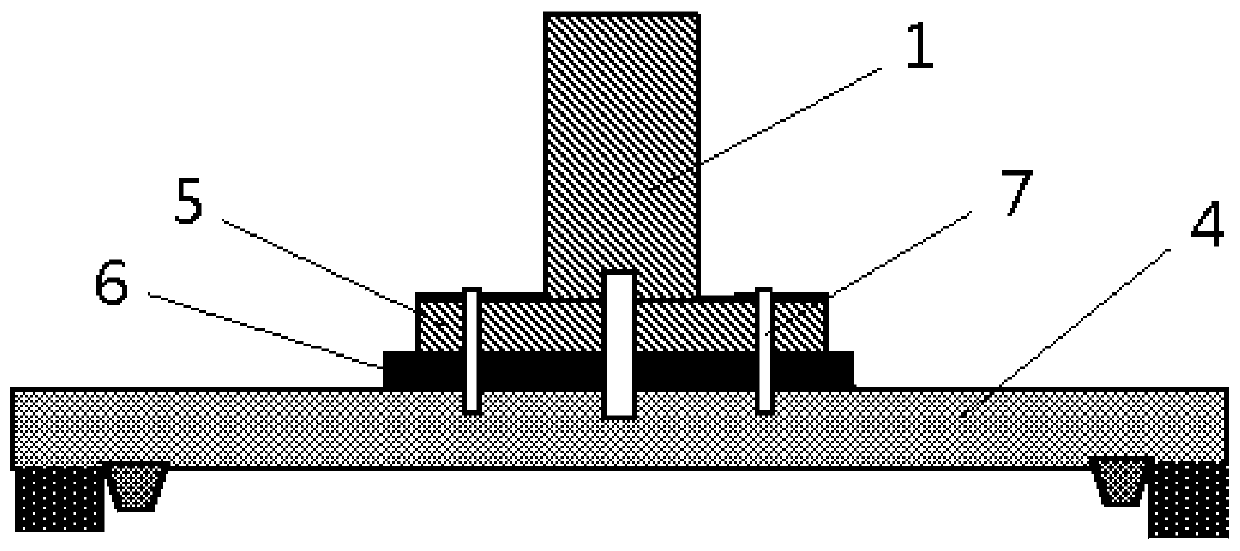

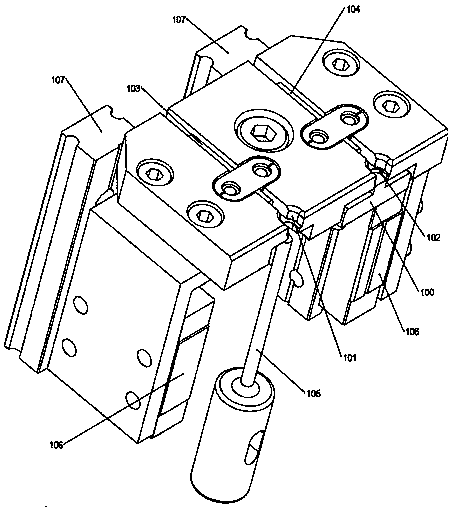

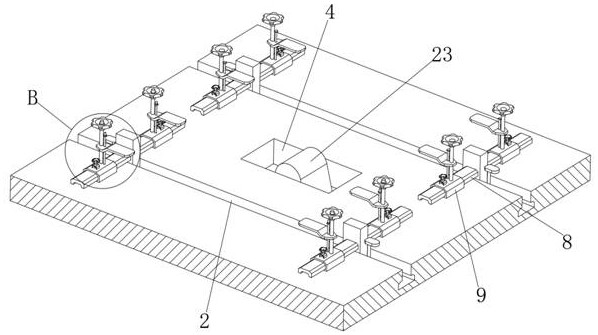

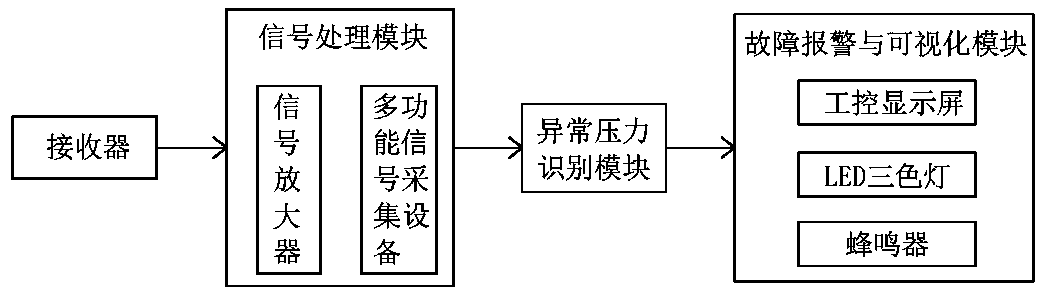

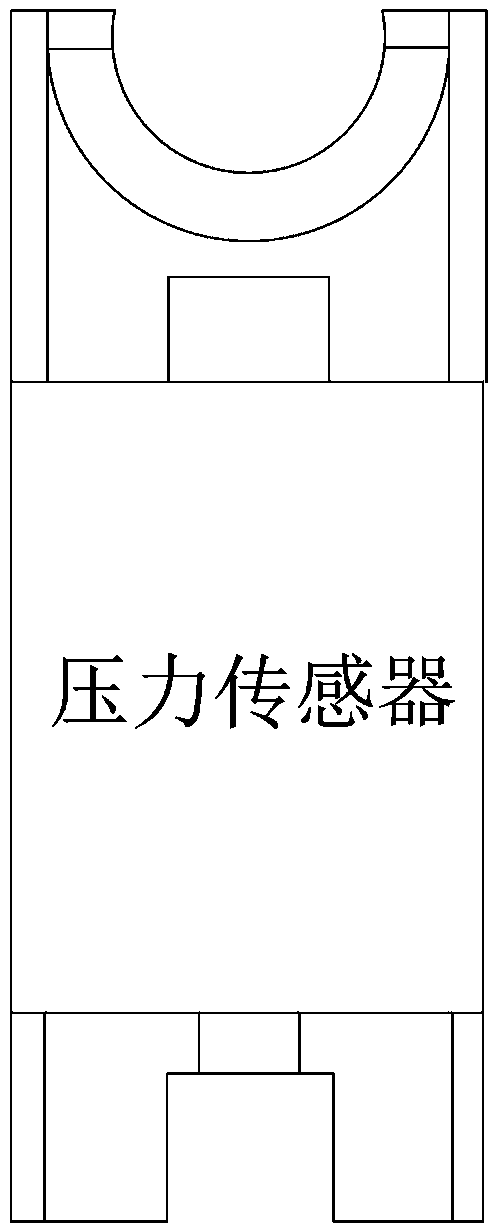

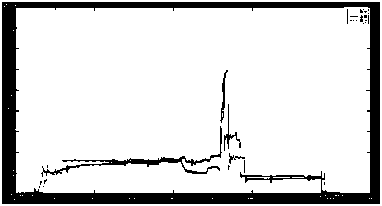

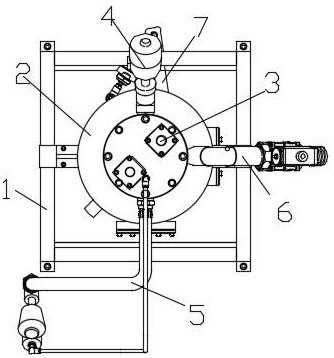

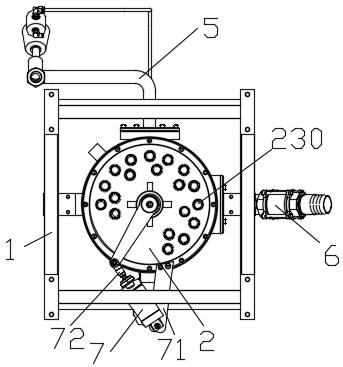

System and method for monitoring abnormal pressure in tube expanding process

ActiveCN109482753APressure real-time monitoringThe effect is accurateShaping safety devicesMetal working apparatusComputer modulePersonal computer

A system for monitoring abnormal pressure in a tube expanding process comprises: a receiver with a pressure detection function, which is arranged at a bottom of a single U-shaped copper pipe and usedfor measuring a pressure value of the single U-shaped copper pipe; a signal processing module used for accurately amplifying output signals of a sensor and converting mechanical quantity into standardvoltage signals, and built in an industrial personal computer; an abnormal pressure identifying module used for identifying an abnormal pressure value of the single U-shaped copper pipe at a pressurepeak in the tube expanding process; and a failure alarm and visualization module used for displaying data and alarm; the receiver, the signal processing module, the abnormal pressure identifying module and the fault alarm and visualization module are connected in sequence by means of communication. By the system and the method of the present invention, real-time pressure monitoring of the singleU-shaped copper pipe is achieved when a stress form of the single U-shaped copper pipe is not changed, the monitoring effect is more accurate, a plurality of copper pipes can be monitored simultaneously, a product quality problem caused by failure to key parts of equipment is effectively prevented, and the production efficiency is improved.

Owner:GUANGDONG INTELLIGENT ROBOTICS INST

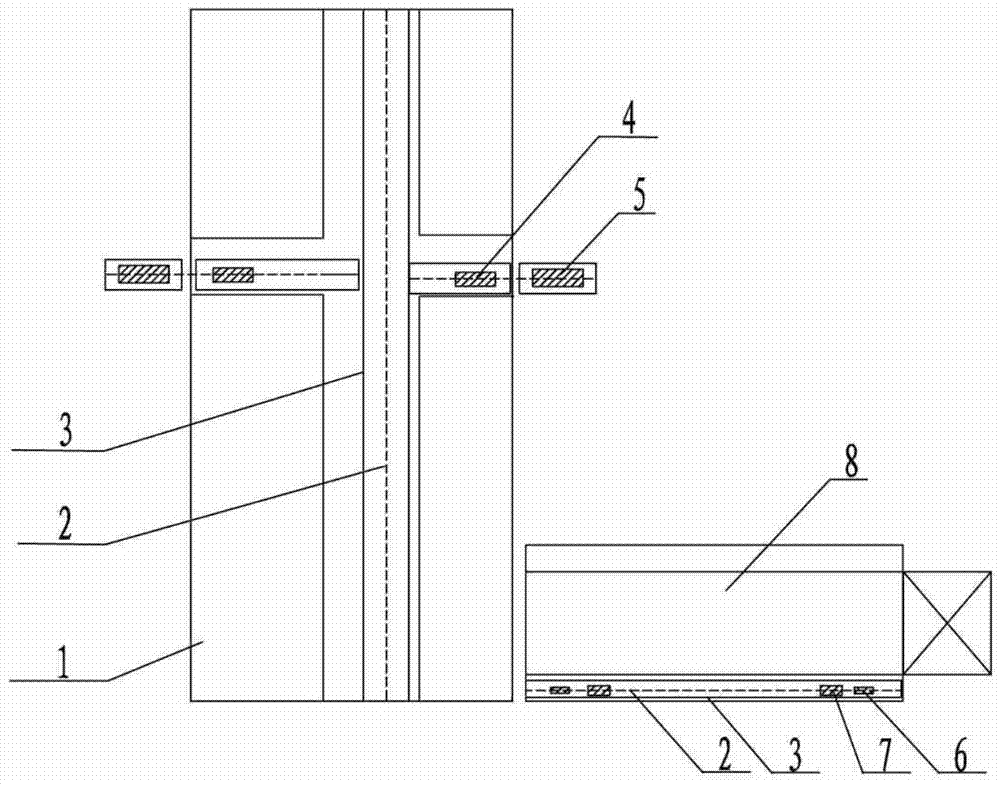

Pressing structure for correcting warping of plastic package flat plate and semiconductor device

InactiveCN109817551AGuarantee the effect of corrective processBlock deliverySemiconductor/solid-state device manufacturingPlastic packagingEngineering

The invention relates to the technical field of plastic package flat plate correction, in particular to a pressing structure of a semiconductor device for correcting the warping of a plastic package flat plate and the semiconductor device. The pressing structure comprises a pressing platform which moves back and forth in the direction perpendicular to the plastic packaging flat plate and is used for applying pressure to the plastic packaging flat plate arranged below; and a connection structure, wherein one end of the connecting structure is connected with the pressing platform, the other endof the connecting structure is connected with a driving device used for driving the pressing platform to move back and forth, and a heat insulation structure used for preventing heat in the pressing platform from being transmitted outwards from the pressing platform through the connecting structure is arranged between the connecting structure and the pressing platform. The semiconductor device comprises a pressing structure and a bearing platform arranged below the pressing structure and used for bearing a plastic package flat plate. According to the pressing structure of the semiconductor device for correcting the warping of the plastic package flat plate, when the plastic package flat plate is heated, heat can be prevented from being transferred into other structures through the heat insulation structure, and therefore the influence on other structures is reduced or eradicated.

Owner:NAT CENT FOR ADVANCED PACKAGING

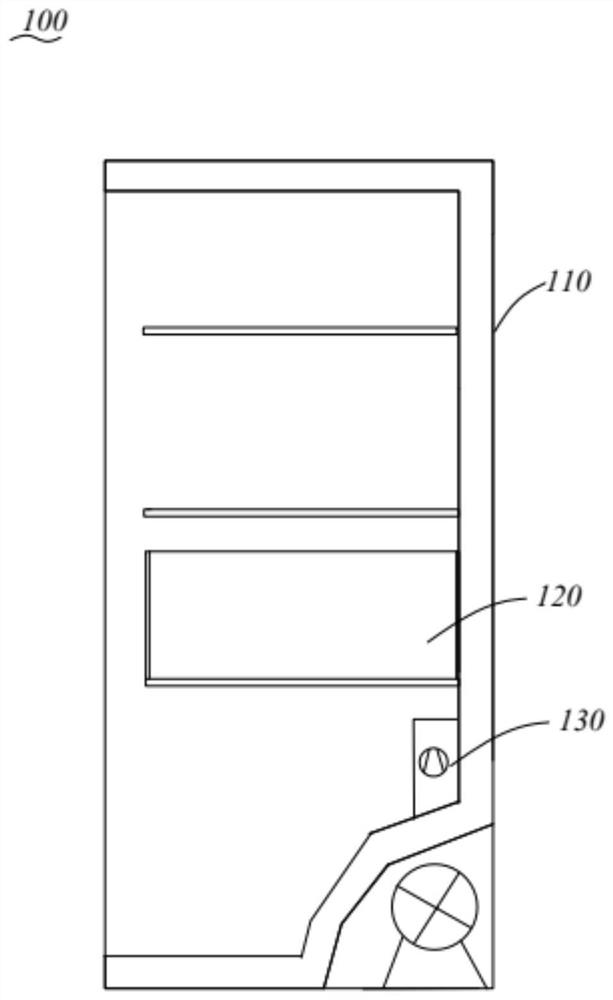

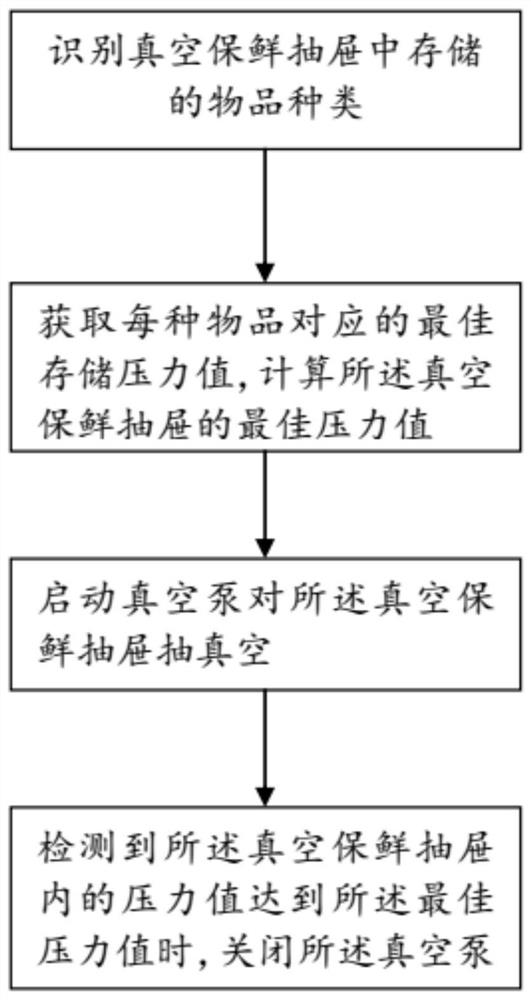

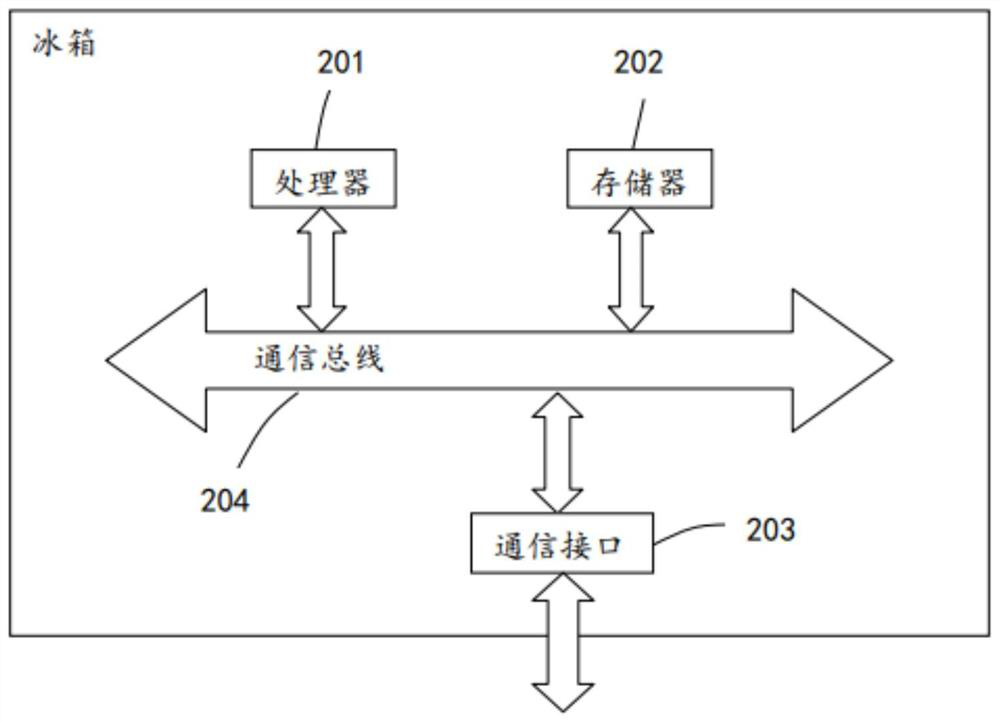

Vacuum fresh-keeping refrigerator pressure value control method, refrigerator and storage medium

PendingCN113218137AMonitor freshness in real timeGood fresh-keeping effectLighting and heating apparatusCooling fluid circulationIceboxProcess engineering

The invention provides a vacuum fresh-keeping refrigerator pressure value control method, a refrigerator and a storage medium. The vacuum fresh-keeping pressure value control method comprises the steps of identifying the types of articles stored in a vacuum fresh-keeping drawer; acquiring an optimal storage pressure value corresponding to each type of articles, and calculating an optimal pressure value of the vacuum fresh-keeping drawer; starting a vacuum pump to vacuumize the vacuum fresh-keeping drawer; and shutting down the vacuum pump when detecting that the pressure value in the vacuum fresh-keeping drawer reaches the optimal pressure value. The method has the beneficial effects that the optimal pressure value in the vacuum fresh-keeping drawer is calculated according to the types of the articles stored in the vacuum fresh-keeping drawer, and the fresh-keeping effect is good.

Owner:QINGDAO HAIER REFRIGERATOR CO LTD +1

Cone Crusher with Online Temperature Monitoring

The invention relates to the technical field of a hydraulic cone crusher, and in particular relates to a cone crusher with an on-line temperature monitoring function. A programmed logical controller (PLC) system is respectively connected with a temperature alarm device, a pressure alarm device and a fiber bragg grating demodulation device; the fiber bragg grating demodulation device is respectively connected with a bearing bush lubricating oil temperature sensor, a bearing bush lubricating oil pressure sensor, a shaft top lubricating oil temperature sensor, a transmission shaft lubricating oil temperature sensor and a transmission shaft lubricating oil pressure sensor by virtue of optical fibers, wherein the bearing bush lubricating oil temperature sensor and the bearing bush lubricating oil pressure sensor are arranged besides a bearing bush of a main shaft of the cone crusher, the shaft top lubricating oil temperature sensor is arranged on the top of the main shaft of the cone crusher, and the transmission shaft lubricating oil temperature sensor and the transmission shaft lubricating oil pressure sensor are arranged on a transmission shaft of the cone crusher; the PLC system is internally provided with a temperature detection program and a pressure detection program; the optical fibers are respectively arranged in a titanium alloy guide pipeline. The cone crusher is capable of monitoring the change of data in real time; when the temperature and the pressure exceed set threshold values, alarm processing is carried out, and the cone crusher can be monitored and protected.

Owner:ANSTEEL GRP MINING CO LTD

Annular pressure monitoring and controlling device for deepwater oil-gas well

ActiveCN107420091AReal-time monitoring of pressure valuesCause corrosionSurveyFlushingHydraulic pumpOxygen

The invention relates to an annular pressure monitoring and controlling device for a wellhead of a deepwater oil-gas well. An upper piston in an upper hydraulic cylinder is connected with a lower piston in a lower hydraulic cylinder through a piston rod; the upper hydraulic cylinder is connected with the lower hydraulic cylinder through a connector; a pressure relief opening is formed in the side wall of the lower hydraulic cylinder; the bottom of the lower hydraulic cylinder is connected with a plurality of annular pressure tubes arranged on the periphery of a device mounting sleeve; an annular fluid inlet of the device mounting sleeve is provided with a pressure sensor; the output end of the pressure sensor is connected with a logic control system, the output end of the logic control system is connected with a hydraulic pump, and an oil outlet of the hydraulic pump is connected with an oil inlet of the upper hydraulic cylinder; when the device is used, the logic control system receives a pressure signal of the pressure sensor, and when the annular pressure signal is lower than a preset lower limit pressure value, the fluid is pressed into a sleeve annulus to be pressurized. The device has the advantages of preventing the situation that the annular air pressure is too low and accordingly oxygen is sucked in and the sleeve is corroded, and improving the air tightness.

Owner:XI'AN PETROLEUM UNIVERSITY +3

On-line pressure monitoring system for power oil-less equipment

PendingCN111623918AReal-time monitoring of pressure valuesObserve in timeFluid pressure measurementData setWireless transmission

The invention discloses an on-line pressure monitoring system for power oil-less equipment. A plurality of pressure detection units are arranged in the oil reservoir and are electrically connected with a data acquisition terminal; the data acquisition terminal is electrically connected with wireless transmission equipment; the wireless transmission equipment is connected with a central processingunit through a wireless signal; the central processing unit comprises a data concentration unit; the central processing unit is connected with background monitoring software through a wireless transmission signal; the pressure detection unit comprises a sensor base; the upper end of the sensor base is fixedly connected with a sensor. According to the design, the pressure value of the electric power oil shortage equipment can be monitored in real time, through background processing and analysis, watch men can observe in time, the safety is improved, and through cooperation of the sensor base, the annular clamping groove, the limiting groove, the threaded rod, the lifting plate, the limiting column, the fixing rod and the clamping block, the sensor base and the sensor can be rapidly connected with the side wall of the oil storage device.

Owner:GUANGAN POWER SUPPLY COMPANY STATE GRID SICHUANELECTRIC POWER +1

Pressure film calibrating method and device

InactiveCN108593201ASimple structureEasy to testForce/torque/work measurement apparatus calibration/testingEngineeringSteel ball

The invention provides a pressure film calibrating method and device. The device includes a load sensor, a hydraulic jack, a soft film, a special cylinder and a small steel ball, the hydraulic jack isplaced on a fixed plane, the calibrated pressure film is placed on the hydraulic jack, the special cylinder is located on the pressure film, and the small steel ball is placed on the upper end face of the special cylinder. The upper fixed plane is in contact with the small steel ball, so that the contact between the cylinder and the jack is stressed uniformly, and a calibration test requirement can be met; the soft film is placed between the pressure film and the special cylinder to prevent the pressure film from being polluted; the hydraulic jack is provided with the load sensor, so that theworking load value can be monitored in real time; multiple tests can be carried out under the same pressure, and test errors can be reduced.

Owner:CHANGZHOU UNIV

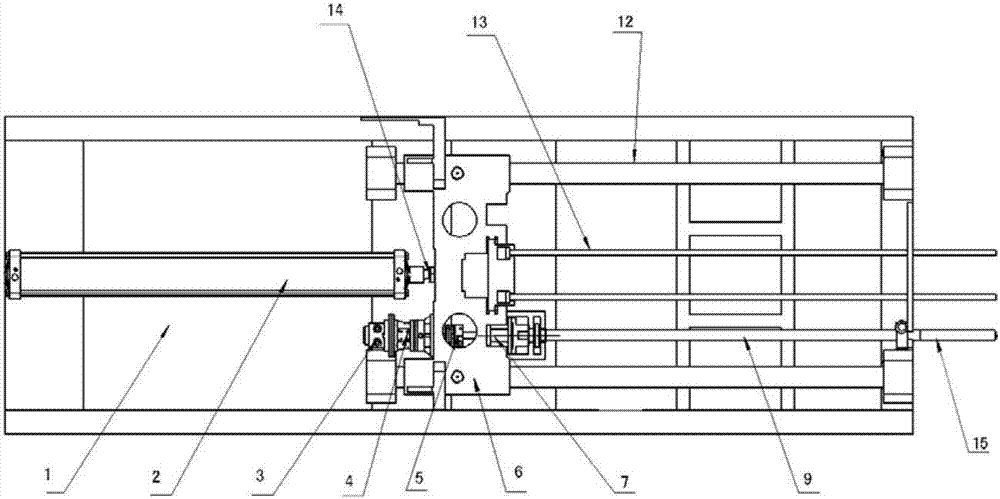

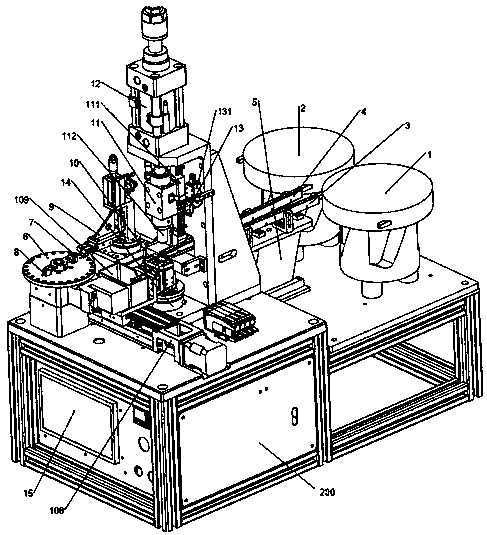

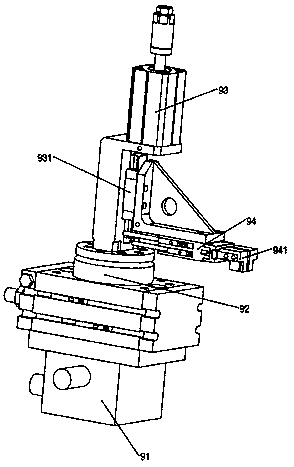

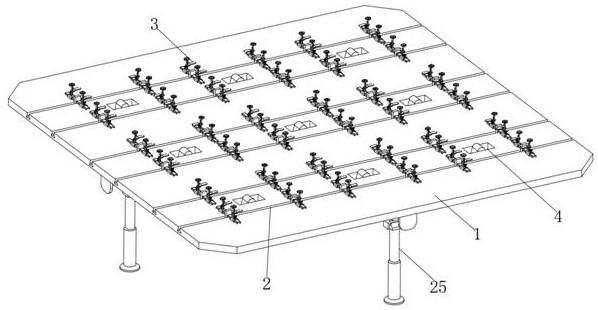

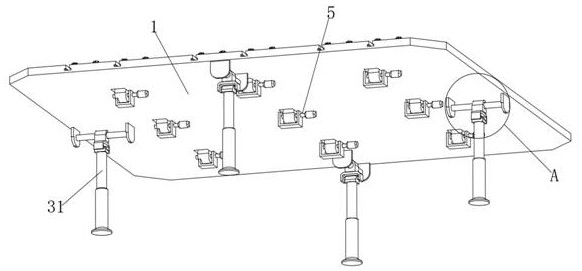

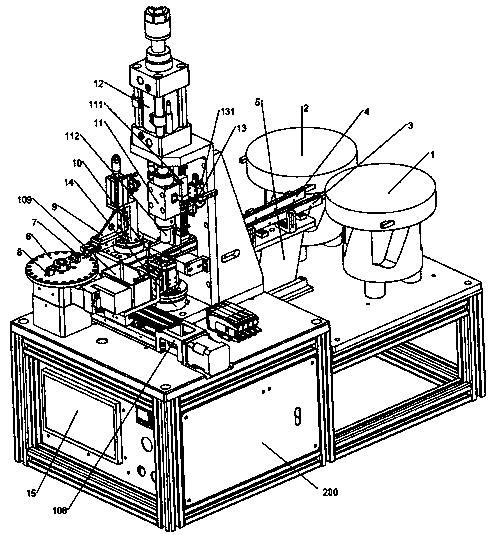

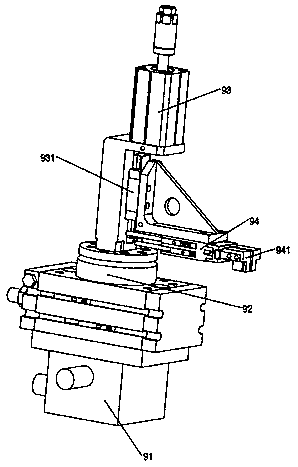

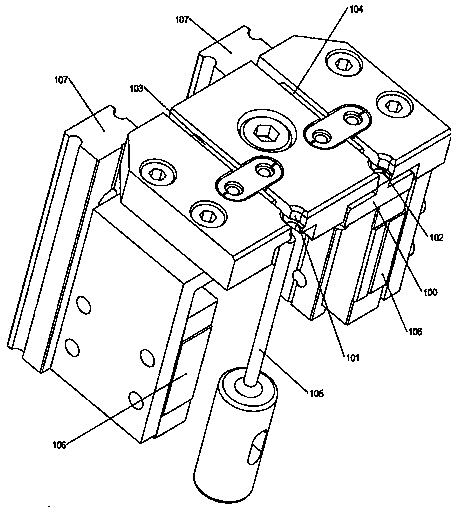

Automatic press-connecting machine for sleeve and guide ring

ActiveCN108436433AReal-time monitoring of pressure valuesImprove labor productivityMetal working apparatusIndustrial engineeringPressure sensor

The invention provides an automatic press-connecting machine for a sleeve and a guide ring. The automatic press-connecting machine for the sleeve and the guide ring comprises a machine table, a feeding and discharging device and a press-connecting device, wherein the feeding and discharging device and the press-connecting device are arranged on the machine table; the press-connecting device comprises a positioning block, a pressing block, a press-connecting cylinder, photoelectric sensors and a pressure sensor, wherein the pressing block is positioned on the positioning block; the press-connecting cylinder is connected with the pressing block; the photoelectric sensors are arranged at the two sides of the pressing block; the pressure sensor is used for detecting the press-connection force;the positioning block is provided with a sleeve positioning hole and a guide ring positioning hole; a sleeve jack-out rod is arranged below the sleeve positioning hole; a guide ring press-connectingjack block is arranged below the guide ring positioning hole; a positioning slide table and a press-connecting slide table are arranged below the positioning block; and the press-connecting slide table is connected with an electric linear guide rail. According to the automatic press-connecting machine provided by the invention, the overall sleeve and guide ring press-connection process is automatically implemented and needs not to be operated step by step separately, so the labor productivity is improved; and meanwhile a press-connection sensor is used for monitoring a pressure value in real time in the overall press-connection process so as to guarantee the press-connection quality.

Owner:JIANGSU ALLRAY

A tool for cleaning the internal adhesion of the wind eye tube of the converter

ActiveCN107164601BSo as not to damageReduce abnormal attrition rateManufacturing convertersDrive shaftCoupling

The invention discloses a converter wind eye pipe inner bonding cleaning tool. The converter wind eye pipe inner bonding cleaning tool comprises a base assembly, a poking and beating device and a rotation device. The base assembly comprises bearing wheels, guiding wheels, a support and guide rails. The base assembly can transversely move on the guide rails in a reciprocating manner. The poking and beating device is fixedly arranged on the support and comprises an air cylinder, a sliding base, guiding rods and drill rods and is used for poking and beating a converter wind eye. The rotation device comprises a pneumatic motor, a speed reducer, a coupler, a transmission shaft, a rotation rod and a twist drill. The pneumatic motor is fixedly arranged on the sliding base, a rotation shaft of the pneumatic motor is connected with the speed reducer, the torque output end of the speed reducer is connected with the transmission shaft through the coupler, and the transmission shaft is connected with the rotation shaft. The torque is transmitted to the rotation shaft to drive the rotation rod to rotate, and the tail end of the rotation rod is detachably provided with the twist drill. According to the converter wind eye pipe inner bonding cleaning tool, for the problem of wind eye blockage of a PS large converter wind gap, drilling is used for replacing a poking and beating manner, and the technical problem that due to existing design, refractory bricks in a wind eye area in a converter are likely to be damaged abnormally is solved.

Owner:JIANGXI COPPER (DEXING) CHEMICAL CO LTD

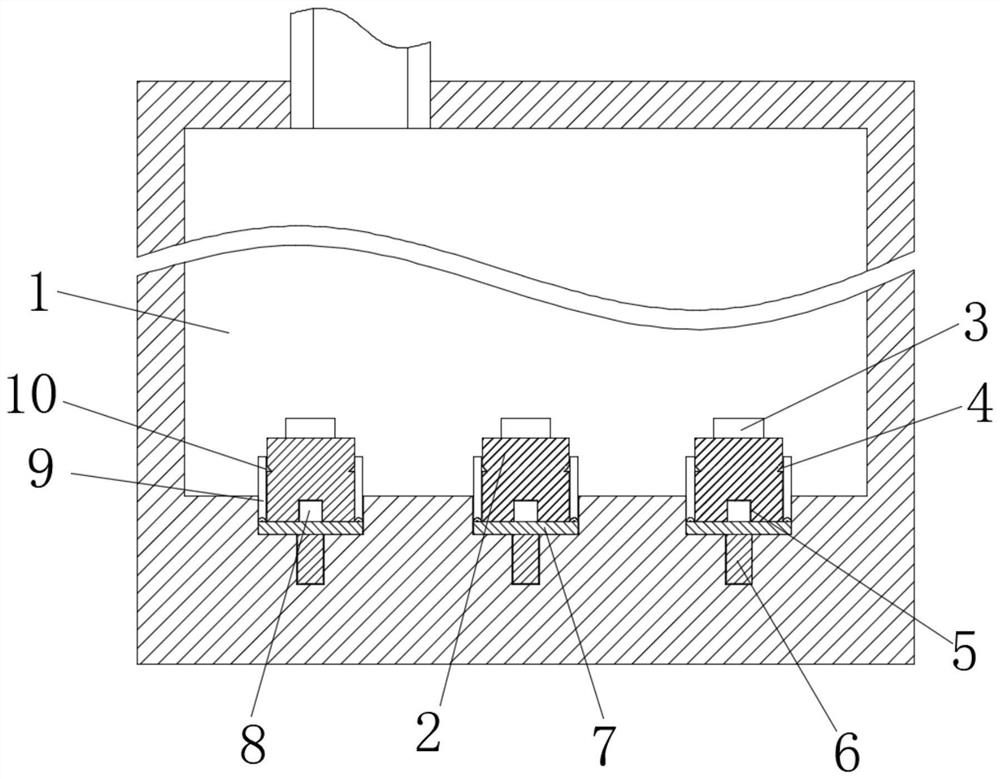

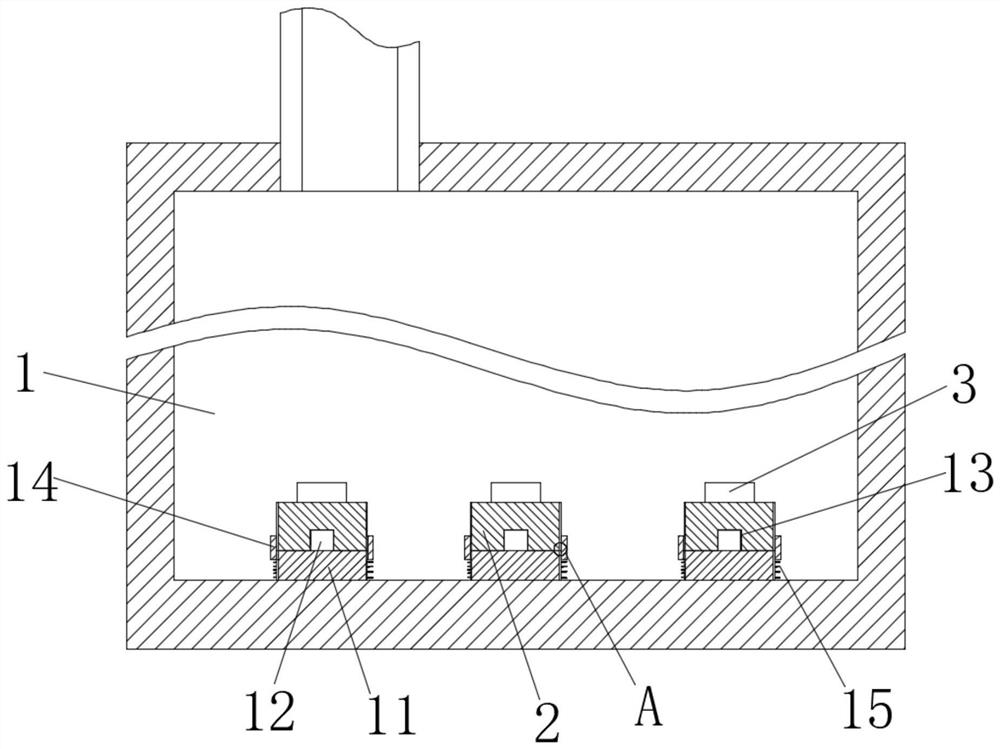

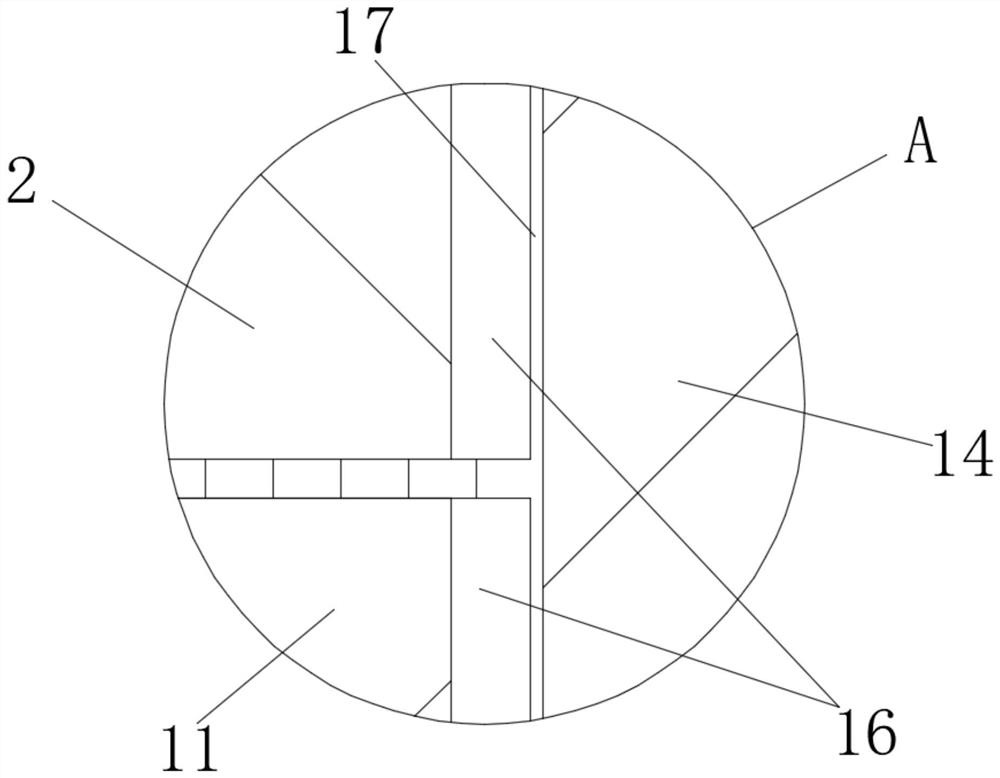

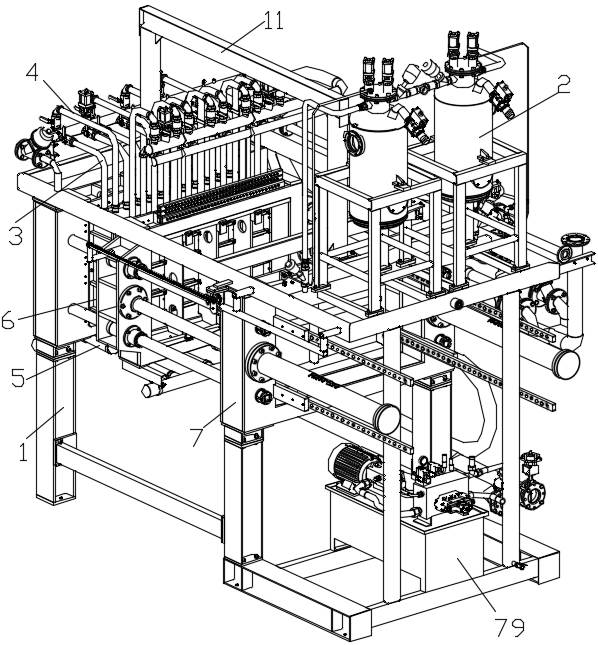

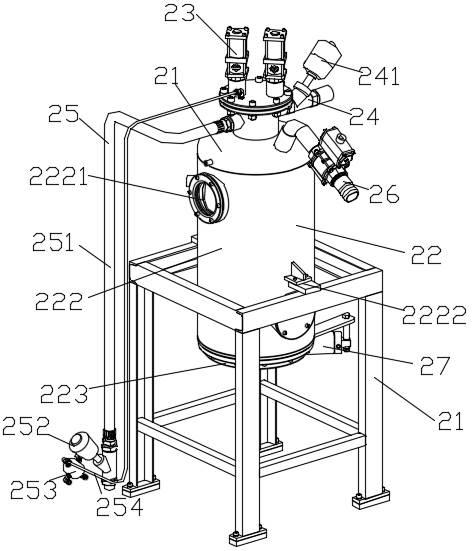

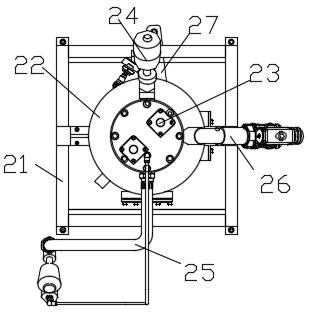

A device for isostatic pressing process

ActiveCN111300630BPrevent filling dissatisfaction and insufficiencyEasy to moveFeeding arrangmentsAuxillary shaping apparatusEngineeringMechanical engineering

The invention discloses a device for isostatic pressing process, which comprises a support plate, on which a plurality of moving rail grooves are opened, and a plurality of sets of moving rail grooves are installed in the plurality of moving rail grooves for materials in an elastic mold. The clamping detection device for filling fullness detection, the support plate has a rectangular opening corresponding to the area of the clamping detection device, and the bottom of the rectangular opening is equipped with an auxiliary material adding component. position, so as to meet the clamping and positioning of elastic molds of different shapes and sizes, and monitor the pressure value at the corner of the elastic mold in real time through the patch pressure sensor on the pressure plate, so as to prevent the filling of the material at the corner of the elastic mold from being insufficient. Through the cooperation of multiple supporting leg components, the supporting plate can be tilted to facilitate the material to move to the corner of the elastic mold, and the auxiliary material adding component can have a shaking effect on the elastic mold to assist the material to move in the elastic mold.

Owner:浙江吉成新材股份有限公司

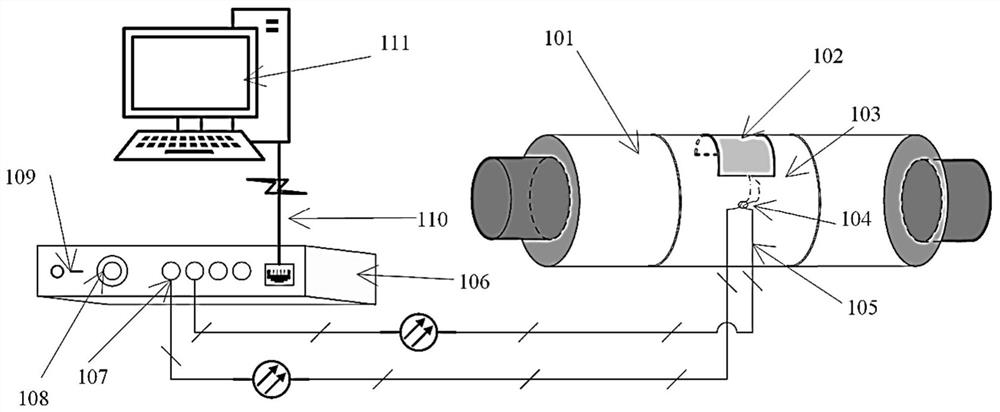

A system and method for abnormal pressure monitoring during pipe expansion

ActiveCN109482753BPressure real-time monitoringThe effect is accurateShaping safety devicesMetal working apparatusControl engineeringMonitoring system

A system for monitoring abnormal pressure in a tube expanding process comprises: a receiver with a pressure detection function, which is arranged at a bottom of a single U-shaped copper pipe and usedfor measuring a pressure value of the single U-shaped copper pipe; a signal processing module used for accurately amplifying output signals of a sensor and converting mechanical quantity into standardvoltage signals, and built in an industrial personal computer; an abnormal pressure identifying module used for identifying an abnormal pressure value of the single U-shaped copper pipe at a pressurepeak in the tube expanding process; and a failure alarm and visualization module used for displaying data and alarm; the receiver, the signal processing module, the abnormal pressure identifying module and the fault alarm and visualization module are connected in sequence by means of communication. By the system and the method of the present invention, real-time pressure monitoring of the singleU-shaped copper pipe is achieved when a stress form of the single U-shaped copper pipe is not changed, the monitoring effect is more accurate, a plurality of copper pipes can be monitored simultaneously, a product quality problem caused by failure to key parts of equipment is effectively prevented, and the production efficiency is improved.

Owner:GUANGDONG INTELLIGENT ROBOTICS INST

High-speed digital energy-saving forming machine and forming method thereof

The invention relates to a high-speed digital energy-saving forming machine and a forming method thereof, and aims to solve the problems that a forming machine in the prior art is likely to be blocked, low in working efficiency and high in energy consumption. According to the technical scheme, the high-speed digital energy-saving forming machine comprises a rack, feeding devices, a curing device, a cooling device, a discharging device, a mold frame and a translation device. The feeding devices are connected with the mold frame through material guns. A mold hanging bracket is further arranged on the rack and connected with the mold frame. Each feeding device comprises a material barrel stand, a feeding barrel, emptying valves, a negative pressure valve, a pressurizing mechanism, a feeding pipe and an air cylinder, wherein the material barrel stand is mounted on the rack, the feeding barrel is mounted on the material barrel stand, the emptying valves, the negative pressure valve and the feeding pipe are all mounted on the feeding barrel, the pressurizing mechanism comprises a pressurizing pipe, a pressurizing balance valve, a pressure sensor and a pressure feedback pipe, the pressurizing pipe is connected with the feeding barrel, and the pressurizing balance valve is mounted on the pressurizing pipe. The high-speed digital energy-saving forming machine is high in curing and cooling speed, high in working efficiency and low in energy consumption.

Owner:HANGZHOU FUYANG DONGSHAN PLASTIC MACHINERY

A system and method for online measurement of cable and accessory interface pressure

ActiveCN111879449BSimple structureProbability of predicting failures in timeForce measurementUsing optical meansGratingFiber gratings

A system and method for online measurement of interface pressure between a cable and an accessory. The system includes an optical fiber curvature sensing subsystem, an anti-temperature interference subsystem, and a data analysis subsystem; The data is transmitted to the data analysis subsystem. The anti-temperature interference subsystem avoids the influence of temperature on the measurement results. The data analysis subsystem converts the data through the established stress-strain equation of the inner and outer layers of the cable accessories, and displays the pressure values inside and outside the accessories in real time. Wrap the optical fiber sensor on the outer layer of the cable accessory. After the cable accessory is bent and expanded, the polyimide film is bent accordingly, and the fiber Bragg grating pasted on the polyimide film is elongated and shortened respectively, and the corresponding Bragg center wavelength occurs For drift, the fiber Bragg grating demodulator detects the reflected wavelength signal to obtain the value after the wavelength drift of the fiber Bragg grating. The invention can realize the on-line measurement and visual display of the interface pressure between the cable and the accessory.

Owner:XI AN JIAOTONG UNIV

Carbon dioxide device with automatic supercharging protection function

PendingCN111101995AReal-time monitoring of pressure valuesRealize the function of superchargingMining devicesDust removalIntrinsic safetyLiquid state

The embodiment of the invention provides a carbon dioxide device with an automatic supercharging protection function. A user monitors the pressure value in an equipment body through a client side in real time, the Internet of Things is effectively used in liquid carbon dioxide equipment under a mine, and when the pressure value in the equipment body is smaller than the preset pressure value, the user can know the situation in time; and in order to guarantee that the state of liquid carbon dioxide in the equipment body does not change along with changes of gas pressure, an intrinsic safety typegas supercharging pump is externally arranged outside an opening of the equipment body so as to achieve the function of supercharging the equipment body when the pressure value in the equipment bodyis smaller than the preset pressure value.

Owner:西安森兰科贸有限责任公司

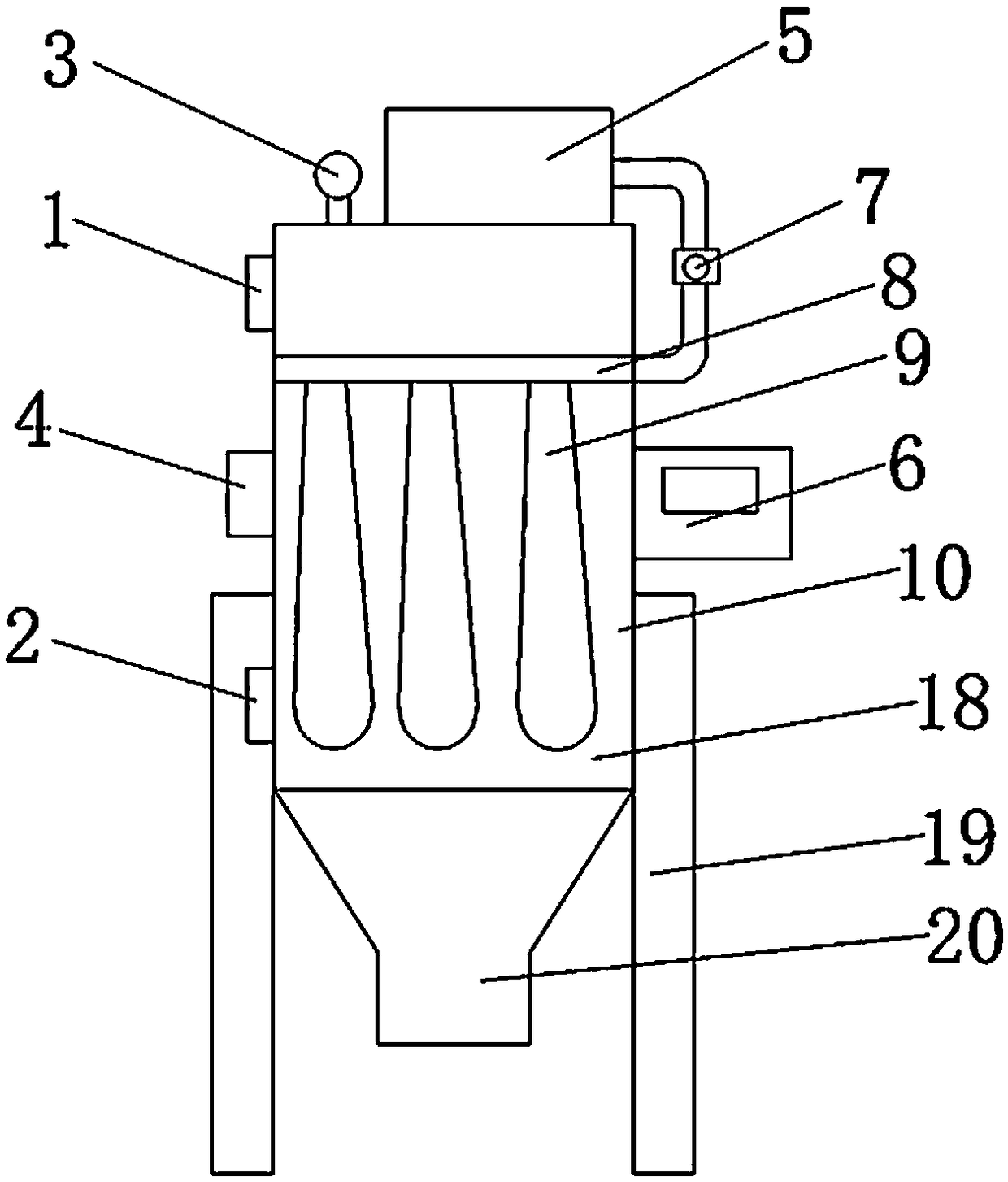

Pulse filter bag type explosion-proof dust removing equipment

InactiveCN109481998AReal-time monitoring of pressure valuesImprove filter and dust removal effectDispersed particle filtrationTransportation and packagingBiochemical engineeringElectromagnetic pulse

The invention discloses pulse filter bag type explosion-proof dust removing equipment which comprises an air inlet, an air outlet, an explosion-proof valve, a pressure sensor, a pressure pump, a controller, an electromagnetic pulse valve, a venturi tube, filter dust bags and a dust remover body, wherein the pressure pump is arranged on the dust remover body; the multiple filter dust bags are arranged in parallel on the dust remover body; the venturi tube is arranged between the pressure pump and the filter dust bags; the electromagnetic pulse valve is arranged on the venturi tube; the air inlet and the air outlet are arranged on the dust remover body; the explosion-proof valve is arranged on the dust remover body; the pressure sensor is arranged on the dust remover body; and the controlleris arranged on the dust remover body and is in signal connection with the pressure sensor, the electromagnetic pulse valve and the explosion-proof valve. According to the pulse filter bag type explosion-proof dust removing equipment disclosed by the invention, the pressure value in the dust remover body can be monitored in real time by an intelligent device so as to conveniently dynamically regulate the pressure input, and the explosion-proof performance of the equipment is stable and controllable by virtue of a two-stage explosion-proof device.

Owner:SHENZHEN MEIPUDA ENVIRONMENTAL PROTECTION EQUIP CO LTD

Exhaust and pressurization combined feeding device and feeding method thereof

ActiveCN112707171AReasonable structural designEasy to operatePlastic recyclingLarge containersEngineeringPressure feedback

The invention relates to an exhaust and pressurization combined feeding device and a feeding method thereof. In order to solve the problems that a feeding device in the prior art is slow in material falling and prone to blockage, the following technical scheme is provided: the exhaust and pressurization combined feeding device comprises a rack, a feeding barrel, an emptying valve, a negative pressure valve, a pressurization mechanism, a feeding pipe and an air cylinder. The feeding barrel is mounted on the rack. The emptying valve, the negative pressure valve and the feeding pipe are all mounted on the feeding barrel. The pressurizing mechanism comprises a pressurizing pipe, a pressurizing balance valve, a pressure sensor and a pressure feedback pipe. The pressurizing pipe is connected with the feeding barrel. The pressurizing balance valve is mounted on the pressurizing pipe. The pressure sensor is mounted on the pressurizing balance valve. One end of the pressure feedback pipe is connected with the feeding barrel, and the other end is connected with the pressure sensor. The feeding barrel sequentially comprises an upper cover, a barrel body and a lower cover from top to bottom, the upper cover and the lower cover are fixedly connected with the barrel body, and a discharge hole is formed in the lower cover. The exhaust and pressurization combined feeding device and the feeding method thereof are fast in material falling, not prone to blockage and capable of saving energy.

Owner:HANGZHOU FUYANG DONGSHAN PLASTIC MACHINERY

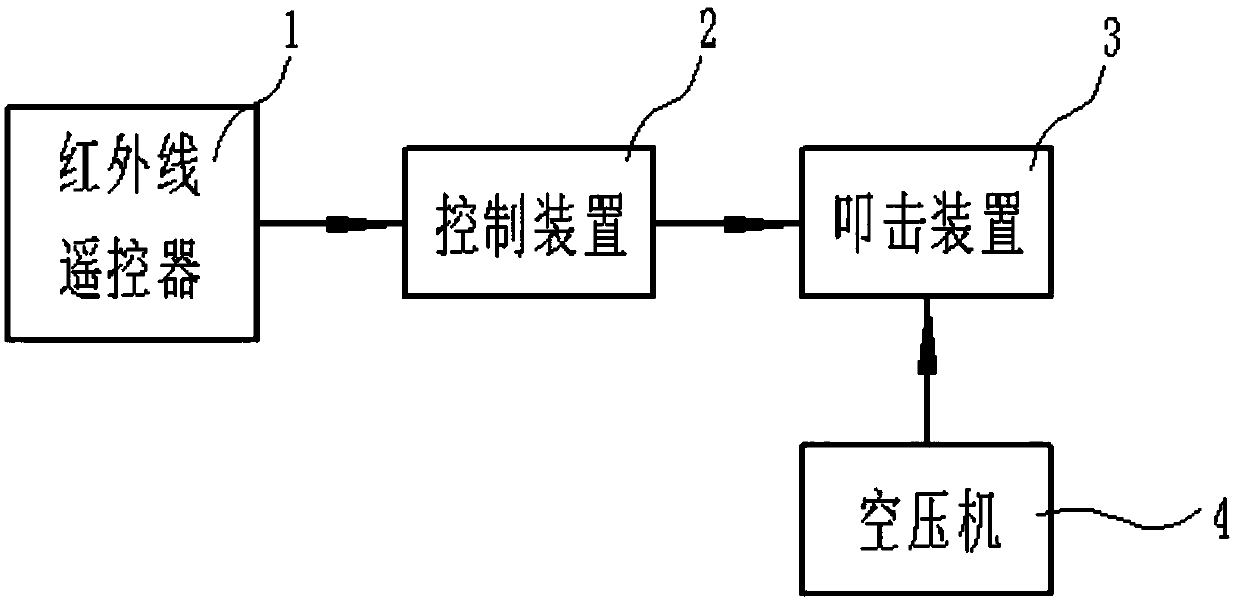

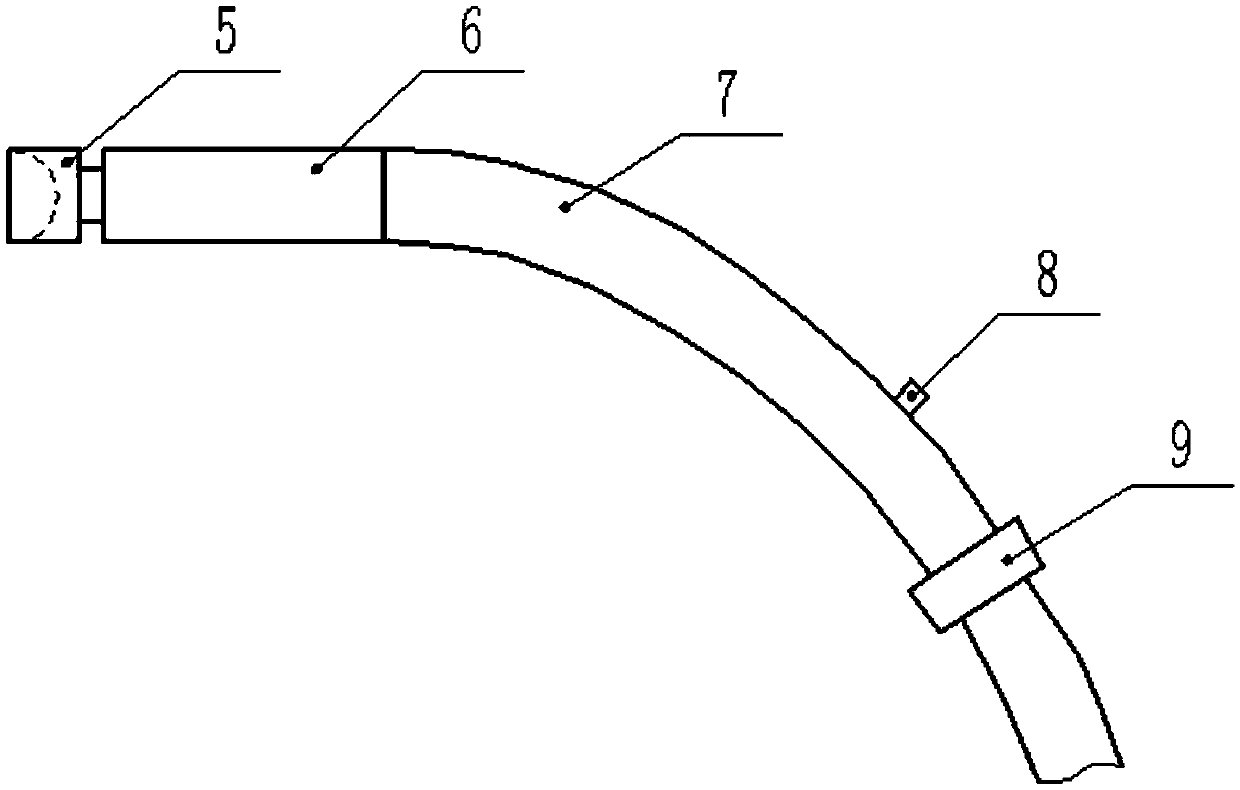

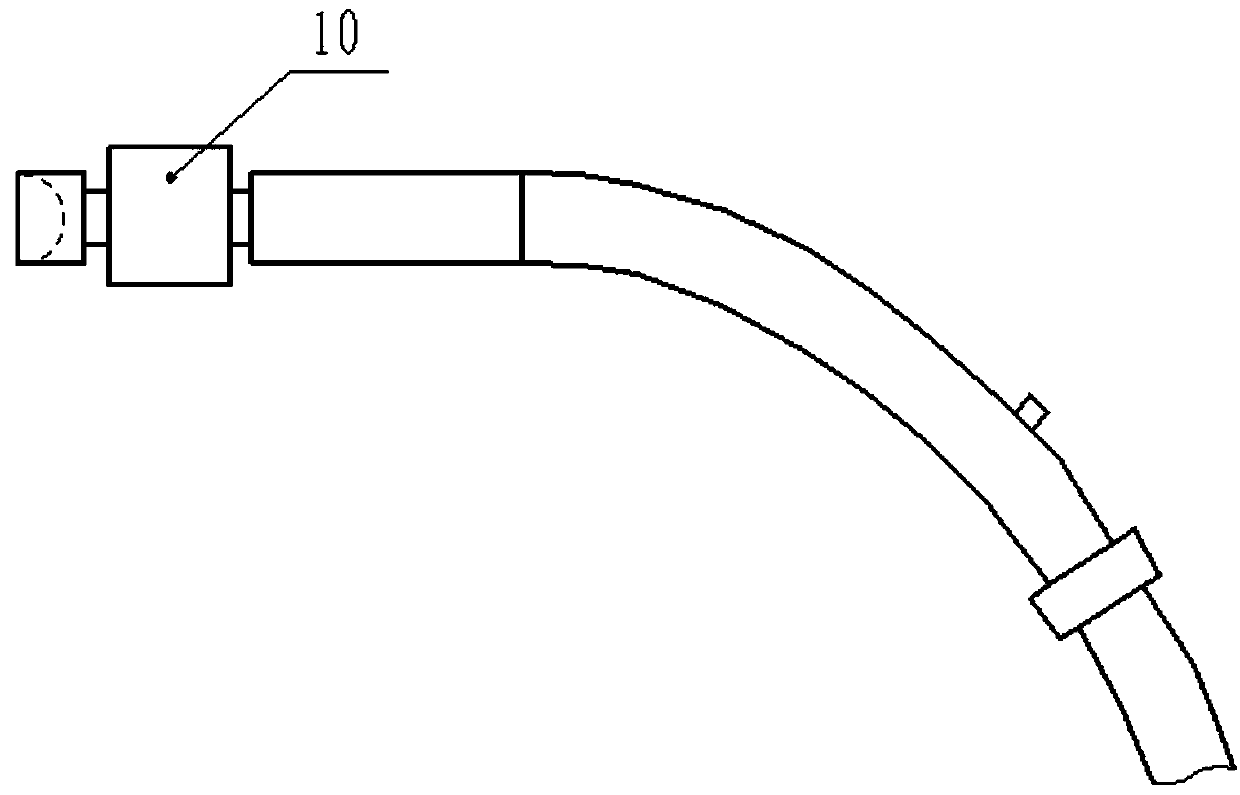

Knock back expectoration machine

ActiveCN105662830BReduce labor intensityEasy to operateVibration massageRespiratory organ evaluationRemote controlMagnetic valve

The invention discloses a back percussion and sputum excretion machine which comprises a control device, a percussion device, an air compressor and an infrared remote controller. The percussion device is connected with the control device and the air compressor respectively, and the control device is in communication with the infrared remote controller in an infrared ray remote control mode. The percussion device comprises at least one percussion group, each percussion group comprises at least one percussion branch, the percussion branch comprises a percussion head, an elastic tube and a flexible tube, the percussion head, the elastic tube and the flexible tube are connected in sequence, a branching magnetic valve is arranged on the flexible tube, the flexible tube is connected with a high-pressure outlet of the air compressor, and the branching magnetic valve is connected with the control device. The operations of all parts of the back percussion and sputum excretion machine are controlled and adjusted in the infrared ray remote control mode, the operations are convenient, the automation degree is high, and the controllability is good. In addition, the back percussion and sputum excretion machine has impact percussion and vibratory percussion functions to a patient and can effectively prevent the wound dehiscence of the patient during cough.

Owner:卢雯 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com