Converter wind eye pipe inner bonding cleaning tool

A wind eye and tool technology, applied in the manufacture of converters and other directions, can solve problems such as wind eye blockage and refractory brick damage, and achieve the effects of convenient manual cleaning, low error rate, and reduction of abnormal loss rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

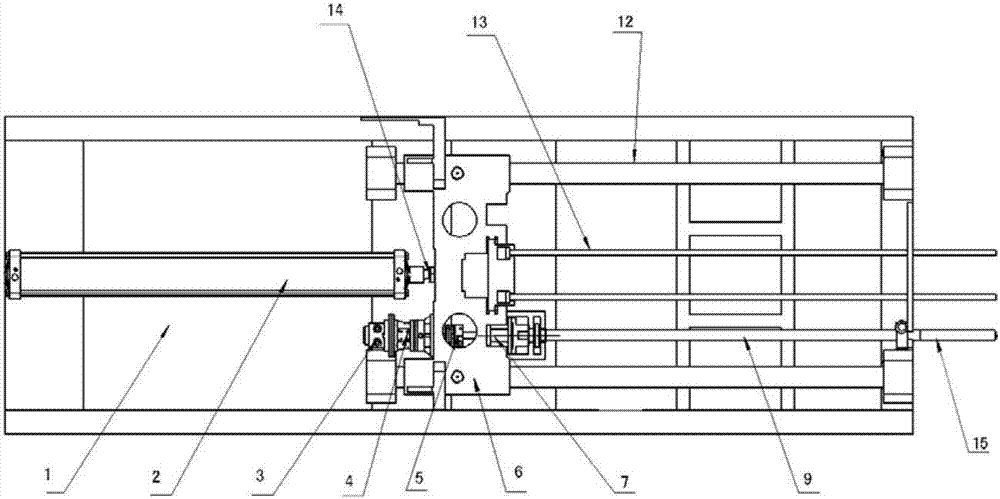

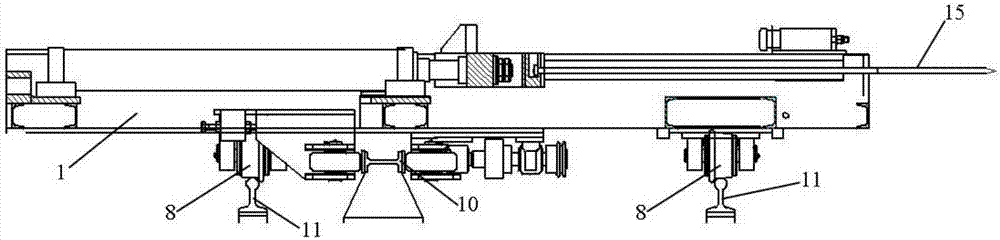

Image

Examples

Embodiment 1

[0034] A cleaning method using the adhesive cleaning tool inside the converter tuyere tube of the present invention under manual control, which specifically includes the following steps:

[0035] 1. Manual operation is adopted to realize the horizontal parallel movement of the base assembly, and the base assembly is pushed to the desired position along the guide rail by manual pushing, so that the twist drill bit is aligned with the wind eye to be cleaned;

[0036] 2. Turn on the air cylinder to make the air cylinder generate thrust, which pushes the sliding seat to move forward, and at the same time turns on the air motor to drive the twist drill bit to rotate. When the twist bit drills into the wind hole to be cleaned, it will adhere to the wind hole After the cleaning is completed, the cylinder generates a pulling force to pull the sliding seat to slide backward, and the twist drill exits the wind eye;

[0037] 3. If there are still burrs left in the wind eye after cleaning, remov...

Embodiment 2

[0039] A cleaning method using the adhesive cleaning tool inside the blower tube of the present invention under automatic control, which specifically includes the following steps:

[0040] 1. Move the cleaning tool to the leftmost side of the lateral direction, start the controller, and set the speed of each lateral movement of the cleaning tool, the time of lateral movement and the interval between two cleanings on the controller , Setting the forward speed, advancing time, retreating speed, retreating time and the interval between two cleanings of the cylinder, and setting the rotation speed of the air motor, the opening time, and the time interval between two cleaning openings;

[0041] 2. After the setting is completed, press the controller run button, the controller outputs instructions to the servo motor according to the set speed and time, and controls the servo motor to rotate a certain angle so that the twist drill bit is aligned Eyes to be cleaned;

[0042] 3. After the co...

Embodiment 3

[0045] A cleaning method using the adhesive cleaning tool inside the blower tube of the present invention under automatic control, which specifically includes the following steps:

[0046] 1. Move the cleaning tool to the leftmost side of the lateral direction, start the controller, and set the speed of each lateral movement of the cleaning tool, the time of lateral movement and the interval between two cleanings on the controller , Setting the forward speed, advancing time, retreating speed, retreating time and the interval between two cleanings of the cylinder, and setting the rotation speed of the air motor, the opening time, and the time interval between two cleaning openings;

[0047] 2. After the setting is completed, press the controller run button, the controller outputs instructions to the servo motor according to the set speed and time, and controls the servo motor to rotate a certain angle so that the twist drill bit is aligned Eyes to be cleaned;

[0048] 3. After the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com