Patents

Literature

107results about How to "Easy to clean manually" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

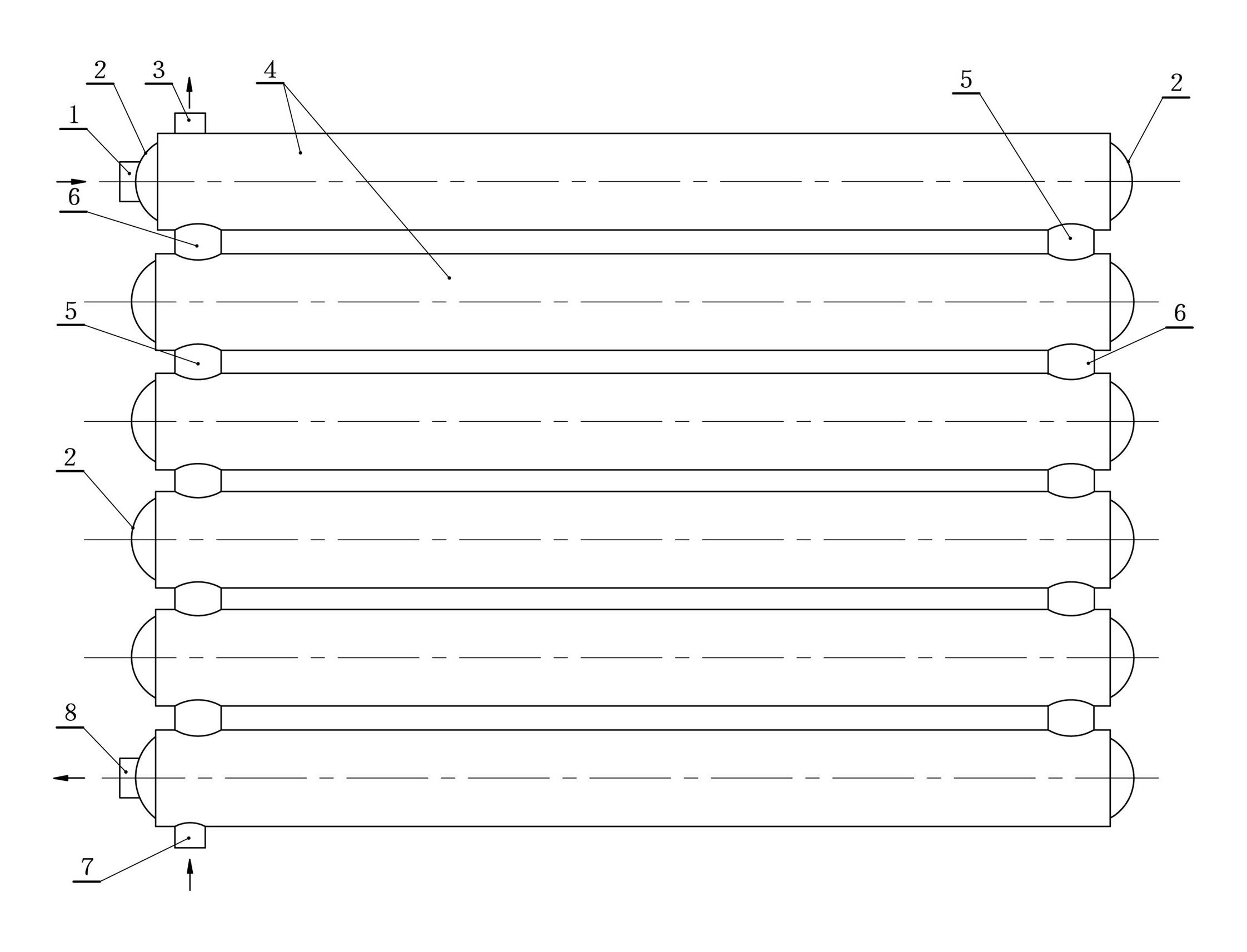

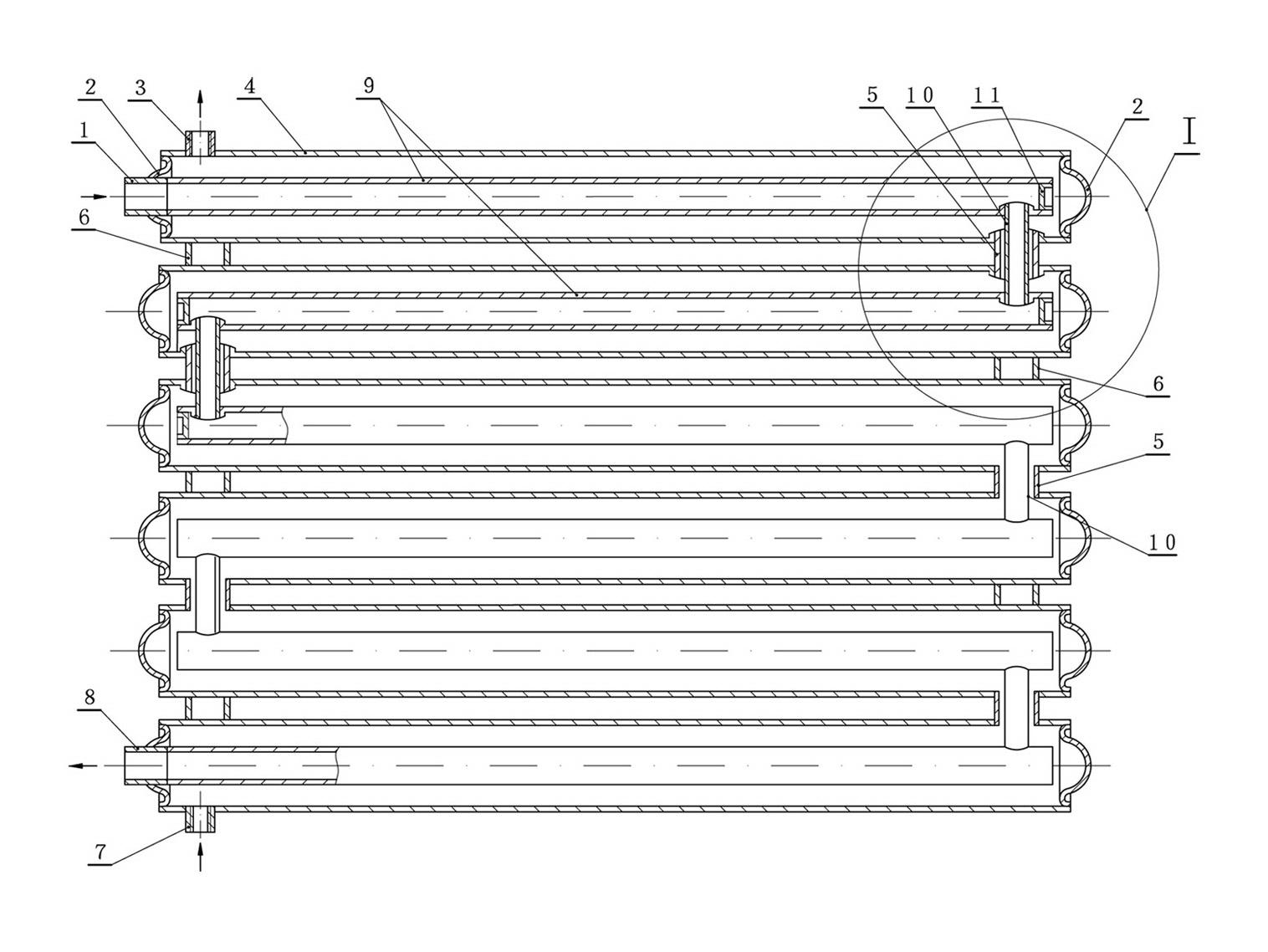

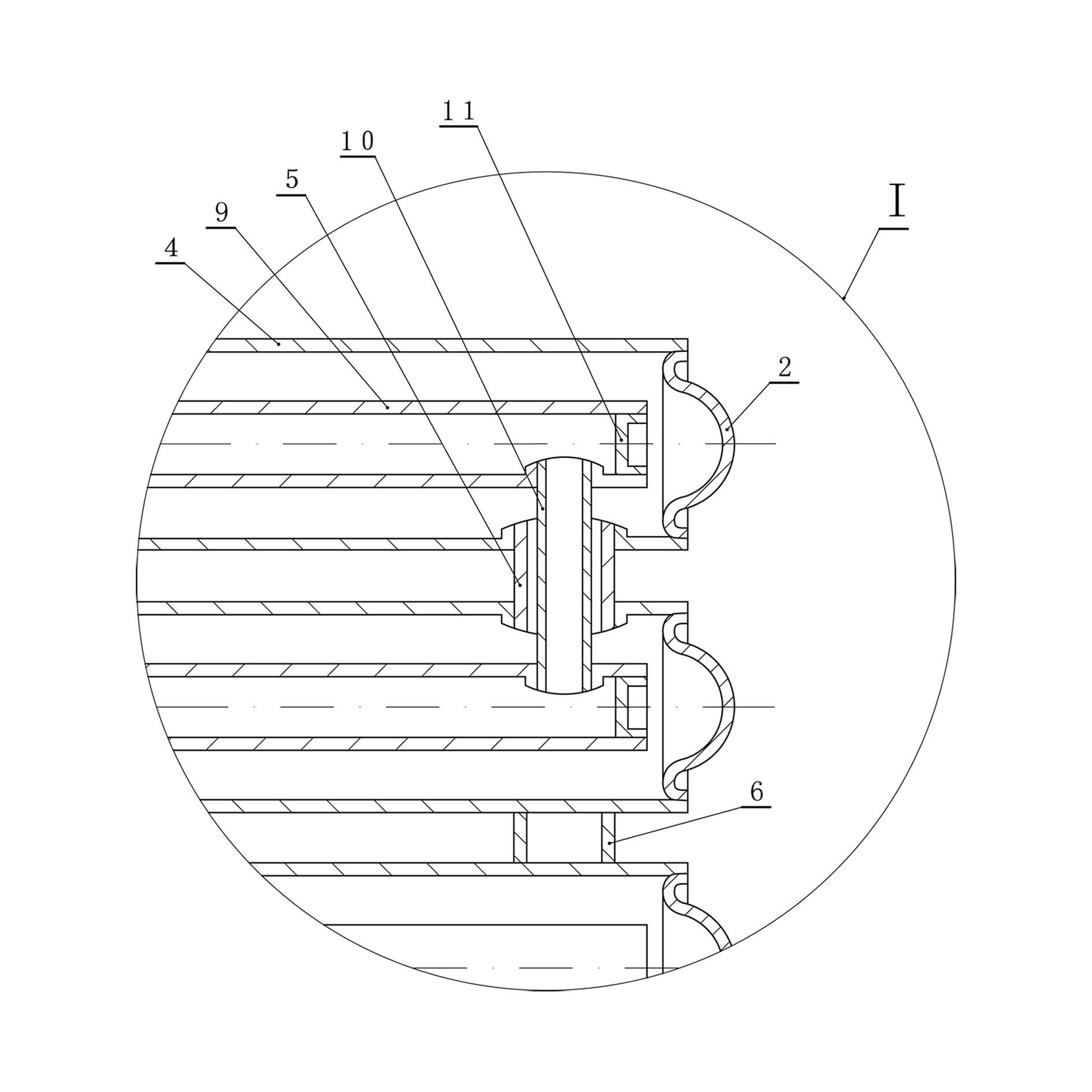

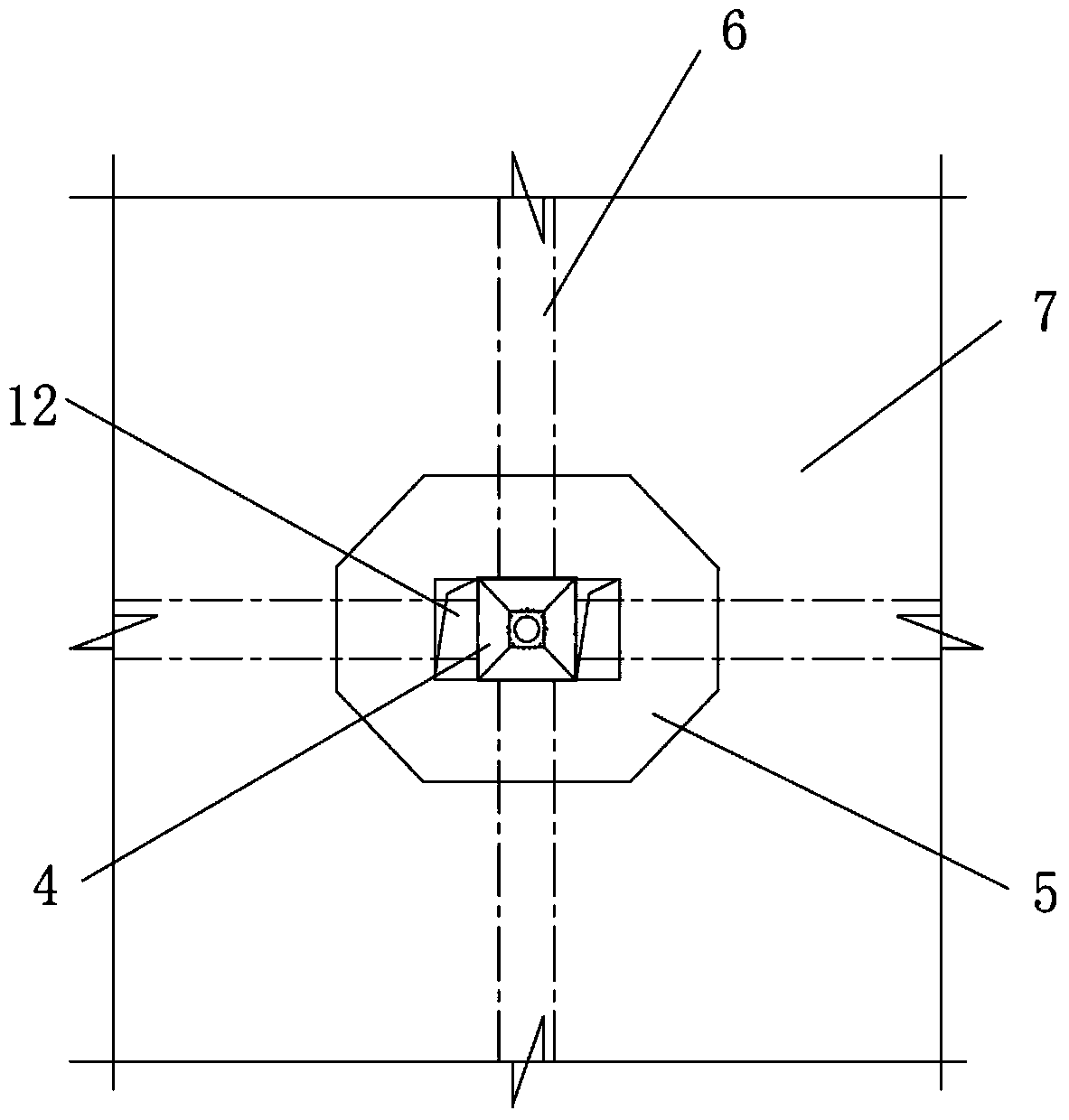

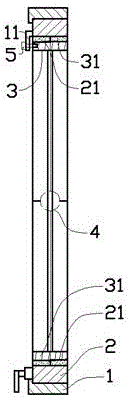

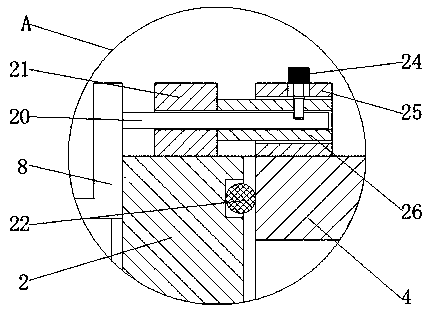

Pipe communication splice welding pressure-bearing type heat exchanger

InactiveCN102322754AIncrease heat transfer areaSolve the welding seam leakage rate is too highHeat exhanger sealing arrangementHeat exchanger casingsWater leakagePlate heat exchanger

The invention relates to a pipe communication splice welding pressure-bearing type heat exchanger, which comprises tap water heat absorption pipes. Heat supply pipes are arranged in the tap water heat absorption pipes. The tap water heat absorption pipes are communicated through tap water communication pipes. The heat supply pipes are communicated through heat supply pipe communication pipes. The seal heads of the tap water heat absorption pipes are outwardly flanged and embedded in the ports of the tap water heat absorption pipes. The flanges of the seal heads of the tap water heat absorption pipes and the port edges of the tap water heat absorption pipes are in splice bilateral alignment edge-kneading welding connection. The walls of the tap water heat absorption pipes are punched and inwardly flanged. The tap water communication pipes are inserted in the punches of the tap water heat absorption pipes. The port edges of the tap water communication pipes and the punched inward flanges of the tap water heat absorption pipes are in splice bilateral alignment edge-kneading welding connection. Heat supply pipe blocking plates are embedded in the ports of the heat supply pipes. The heat supply pipe blocking plates are outwardly flanged. The outward flanges of the heat supply pipe blocking plates and the port edges of the tap water heat absorption pipes are in splice alignment edge-kneading welding connection. According to the pipe communication splice welding pressure-bearing type heat exchanger disclosed by the invention, two technical defects of higher water leakage ratio of the welding line and incapability of continuously producing hot water of the original patent product can be solved; and the heat exchanger has the advantages of no leakage and continuous hot water production.

Owner:张伟

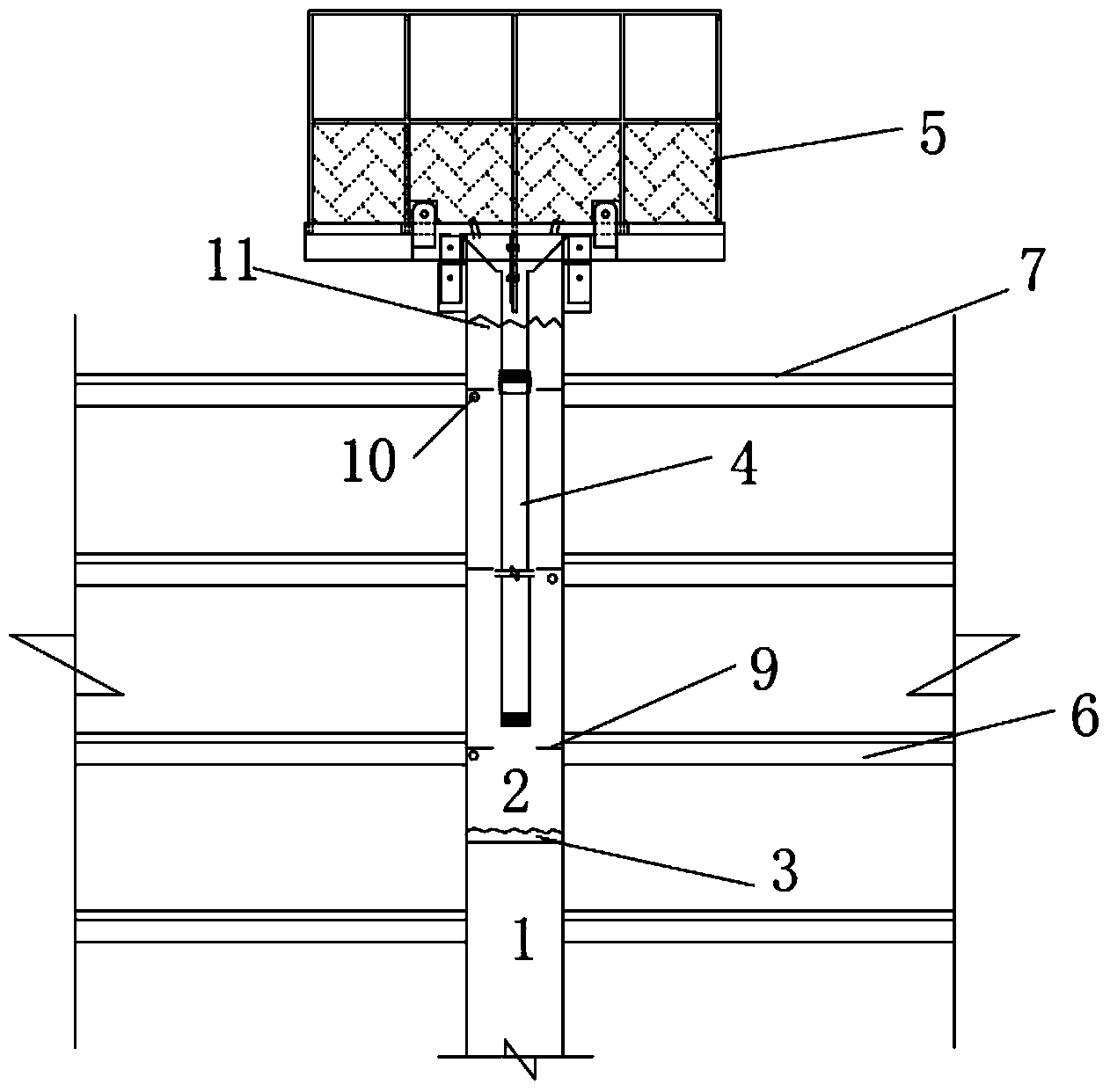

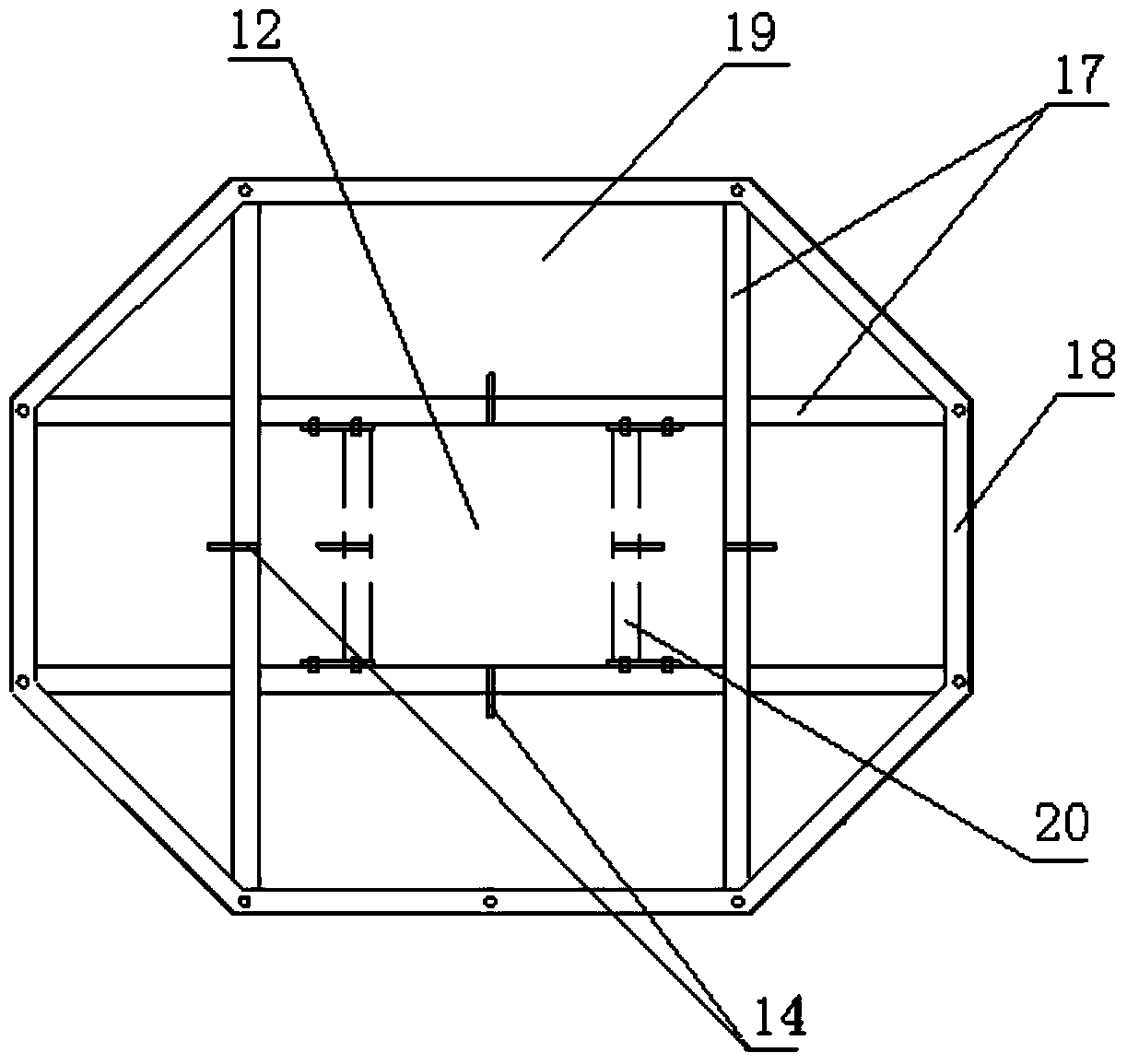

Super high-rise steel pipe column interior concrete pouring construction method

ActiveCN103526929ASimple and safe operationStrong construction applicabilityBuilding material handlingBuilding support scaffoldsSheet steelMaterial consumption

The invention discloses a super high-rise steel pipe column interior concrete pouring construction method. The method mainly comprises the steps of detaching a last section of steel pipe column top sealing hole thin steel plate; hoisting the present section of steel tube column; locating the present section of steel tube column after hoisting a first floor layer steel beam of the present section of steel tube column; arranging a detachable construction steel platform; enabling a sectional connectable serial barrel to extend into the steel pipe column through a locating hole of the construction steel platform; filling same-grade concrete protoplasmic into the steel pipe column; pouring concrete; when the concrete pouring height surpasses the single section serial barrel, detaching one section and continuing concrete pouring construction, and then conducting subsequent pouring; slowing down the speed of concrete discharging and the speed of pouring when a concrete puring face is close to a partition plate in the steel pipe column; pouring the concrete to a certain distance below the top of the steel pipe column and then stopping; adopting a thin steel plate to close the steel pipe column top pouring hole. By the adoption of the construction method, the concrete pouring construction is made to be more convenient, potential safety hazards are eliminated, the construction period is shortened, and manpower and turnover material consumption are reduced.

Owner:ZHEJIANG CONSTR ENG GRP CO LTD

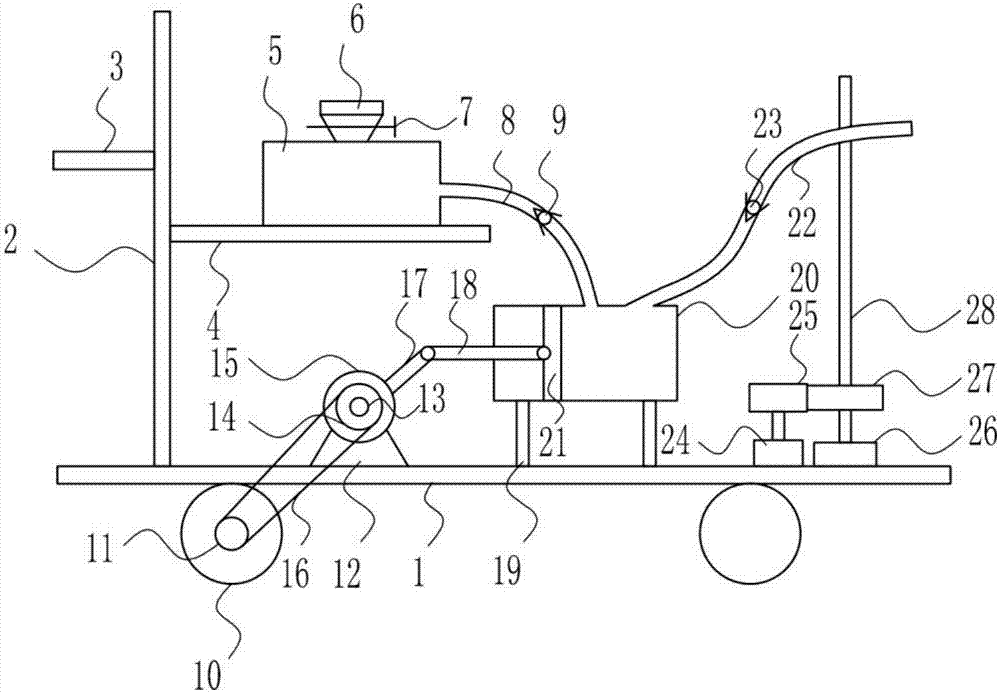

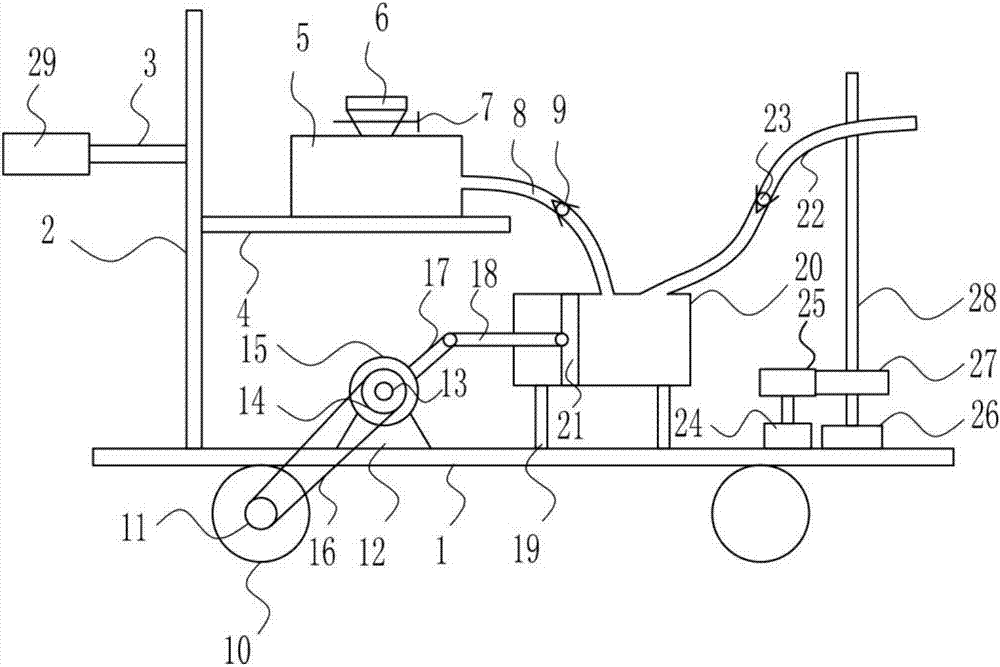

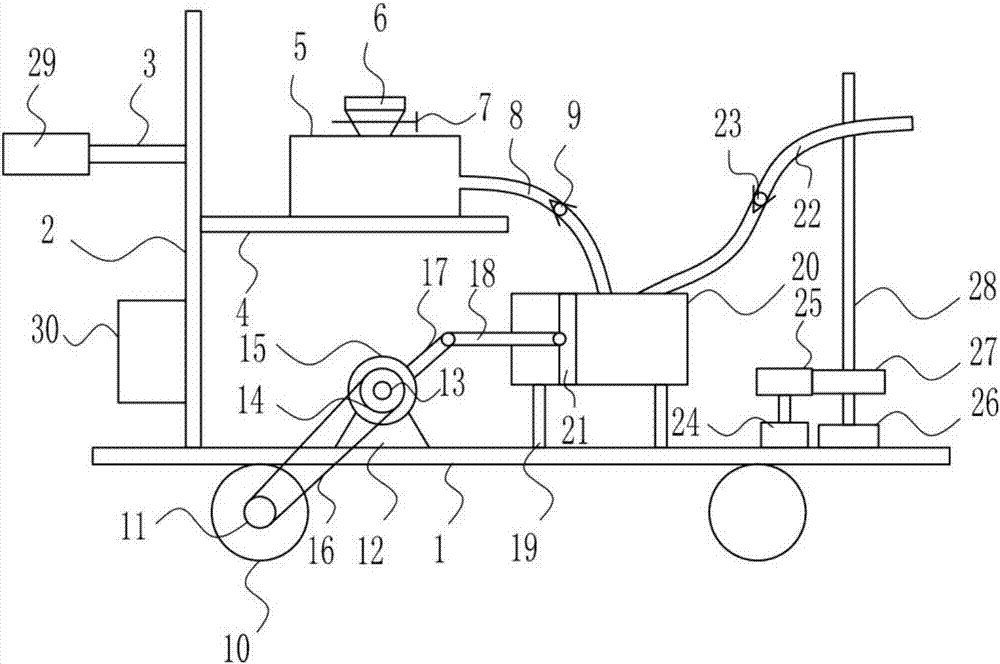

Spraying device on municipal green shade road

The invention relates to a spraying device, in particular to a spraying device on a municipal green road. The technical problem to be solved by the present invention is to provide a spraying device on municipal green roads that effectively reduces dust and is convenient for manual cleaning. In order to solve the above-mentioned technical problems, the present invention provides such a sprinkler equipment on municipal green roads, which includes a bottom plate, a left frame, a push handle, a fixed plate, a water tank, a water inlet bucket, an electric control valve, a first pipeline, a first one-way Valves, wheels, small pulleys, the first bearing seat, etc.; the left frame is welded on the left side of the top of the bottom plate, the push handle is welded on the left side above the left frame, the fixing plate is welded in the middle of the right side of the left frame, and the water tank is welded on the fixing plate. A water inlet bucket is welded, and an electric control valve is arranged on the water inlet bucket. The invention achieves the effect of effectively reducing the dust on the green road and facilitating manual cleaning. The invention can spray water by deactivating the motor, and the rotating motor works through the cooperation of the first gear and the second gear.

Owner:万俊

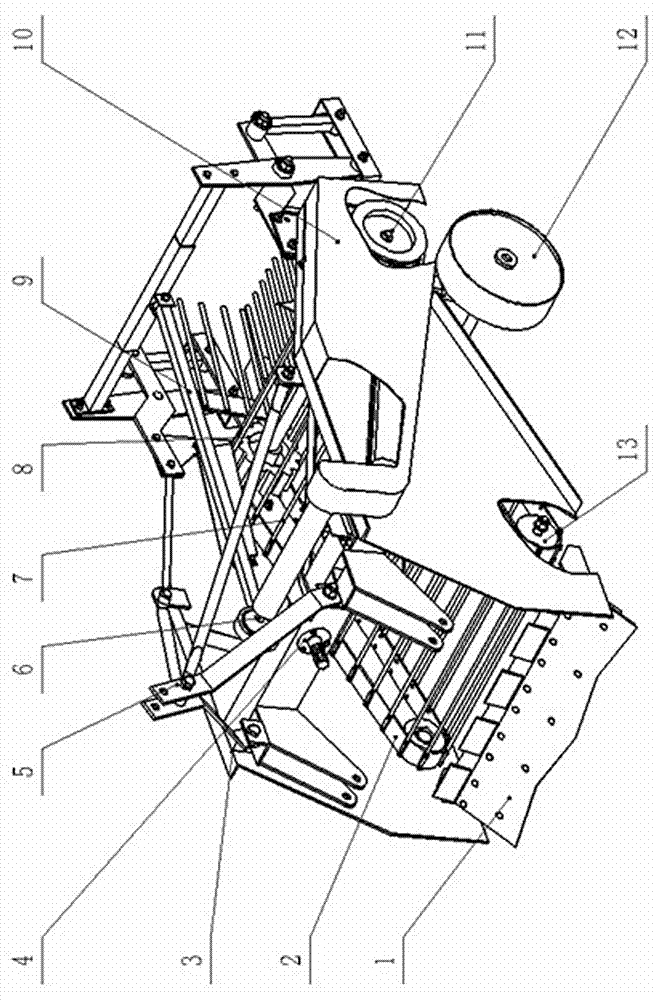

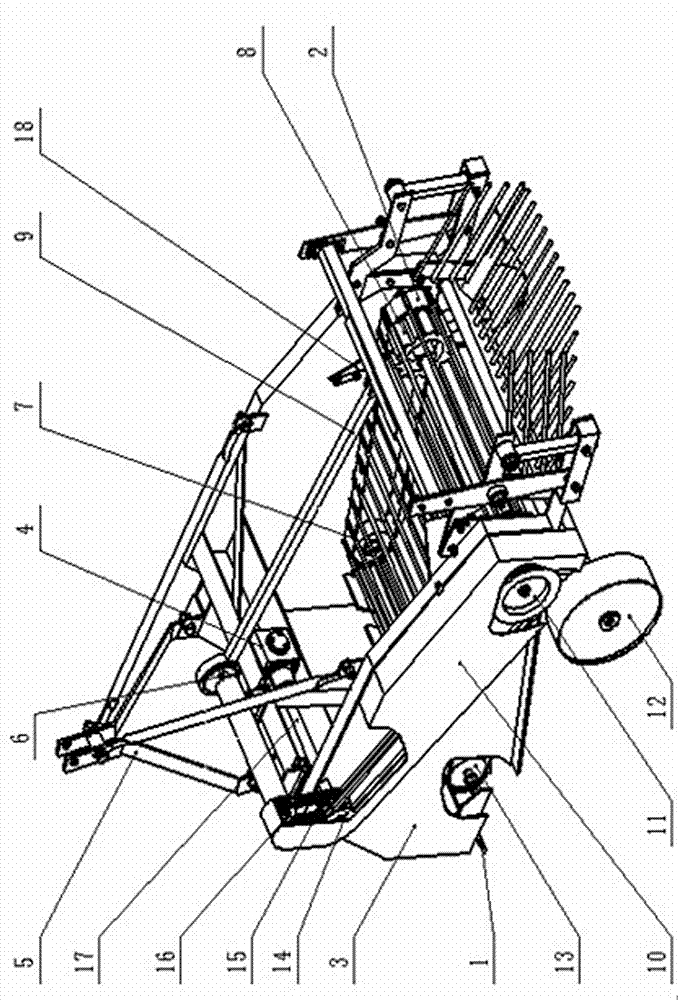

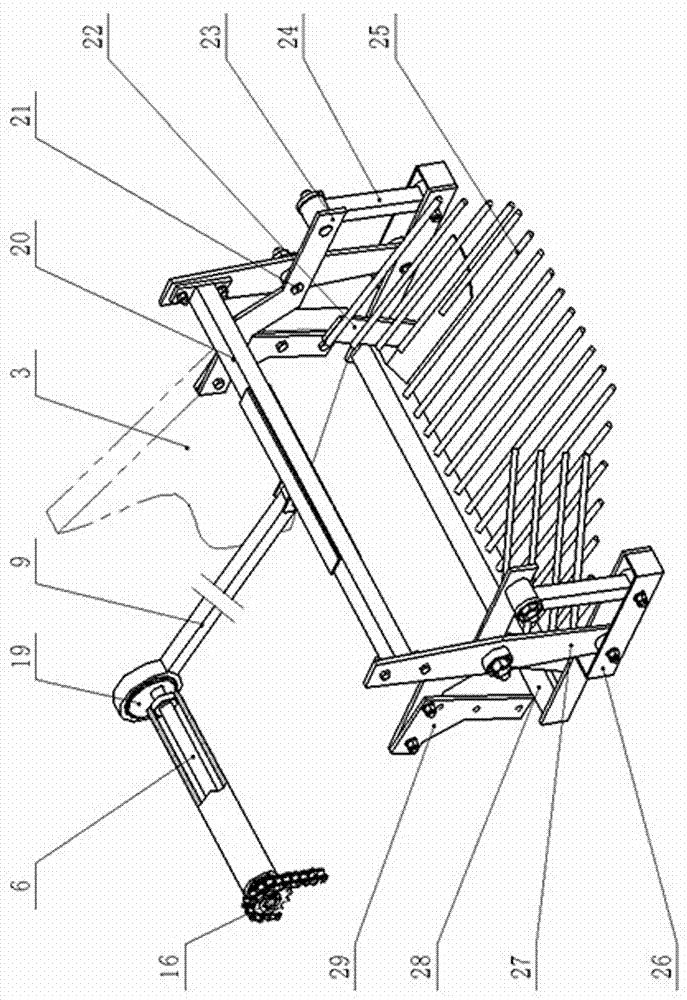

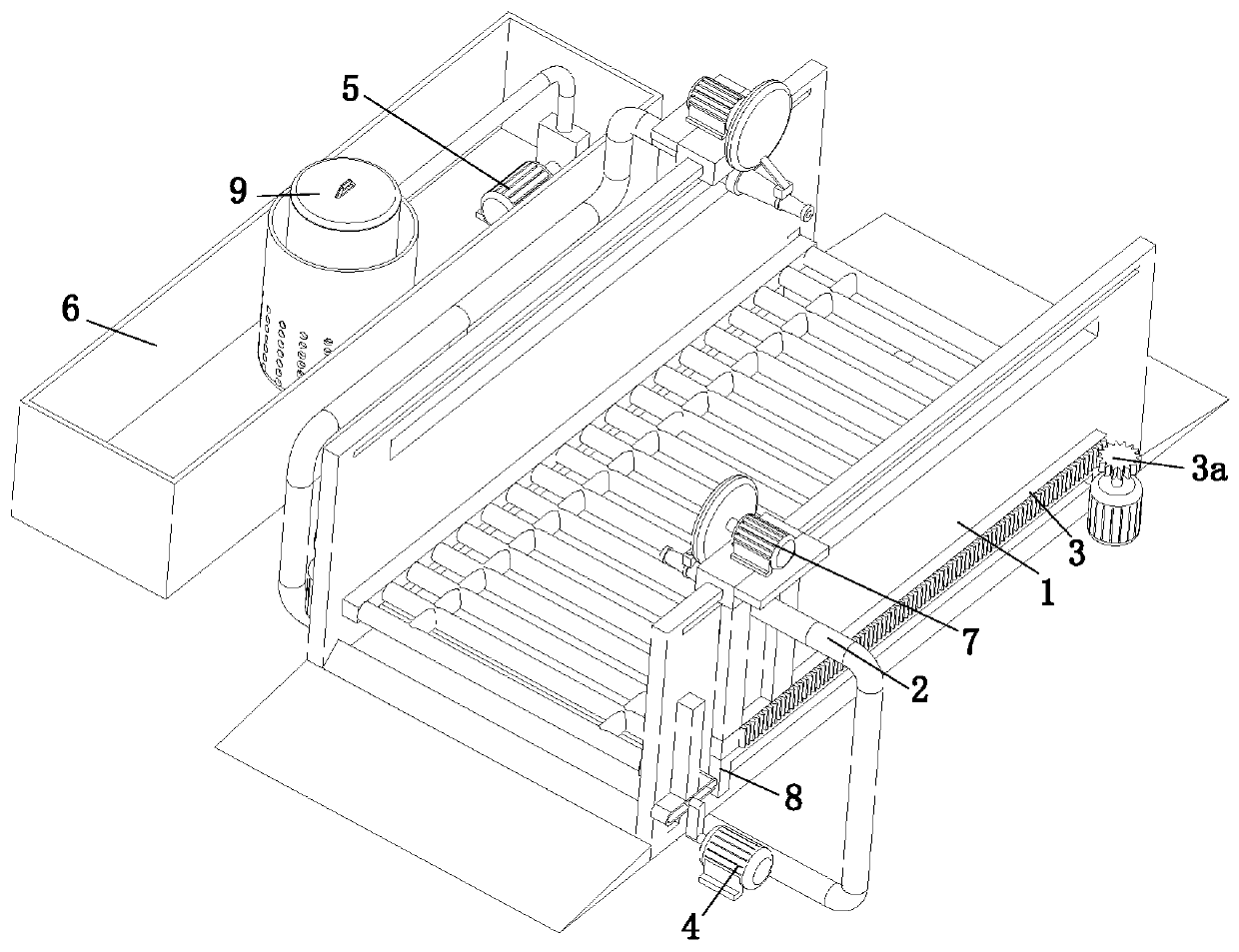

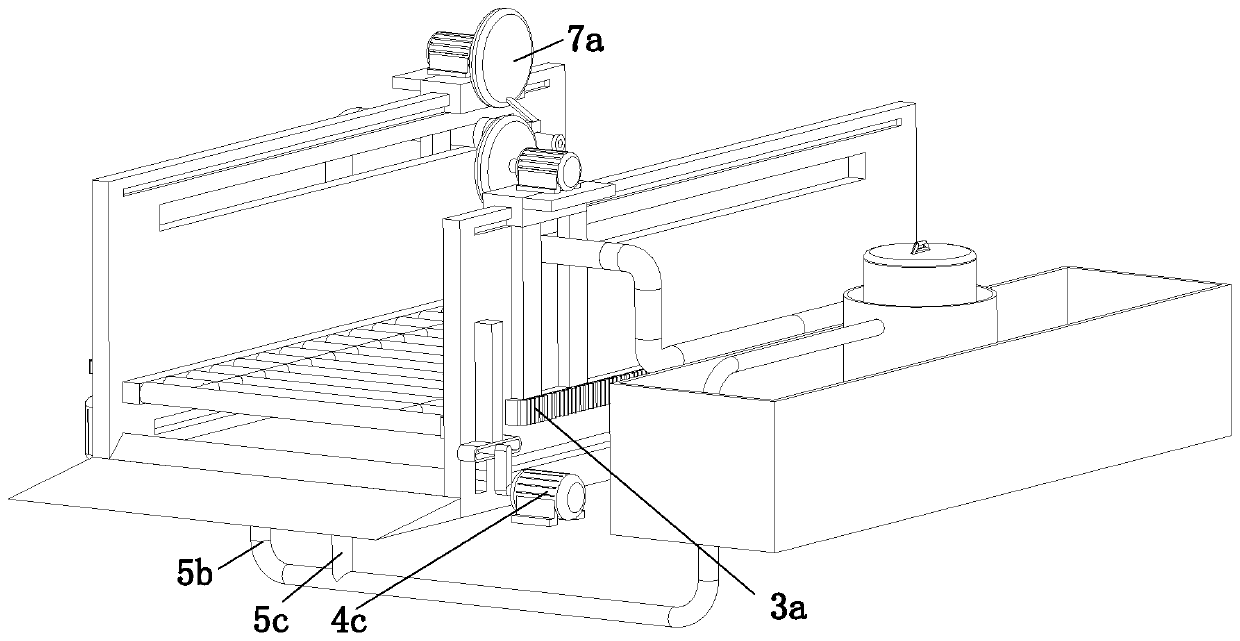

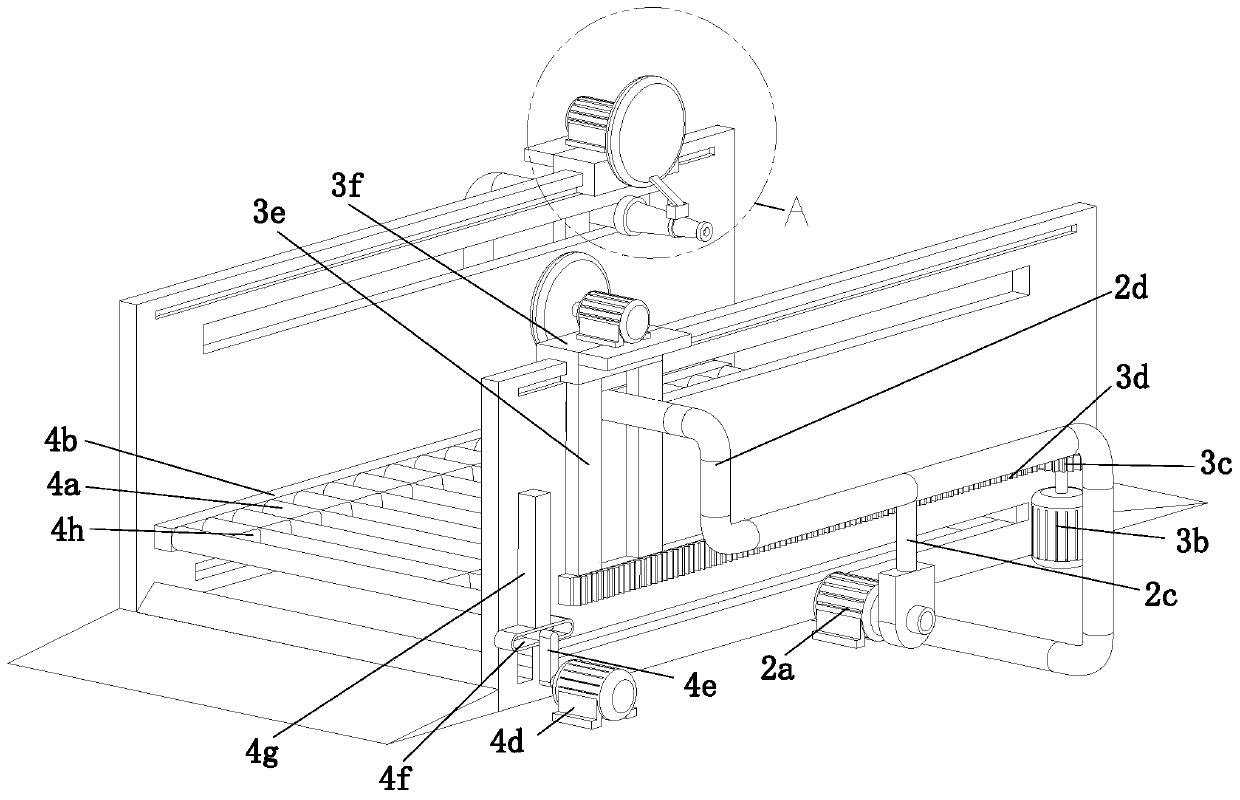

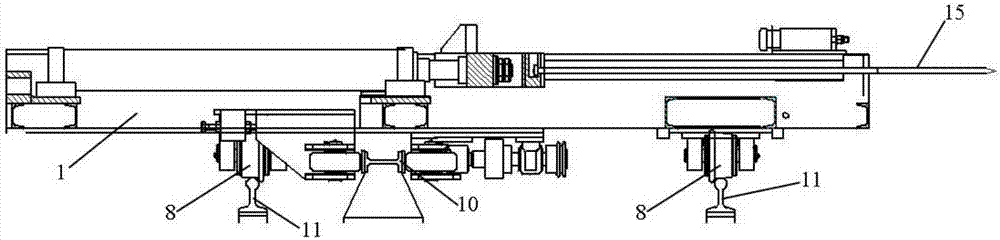

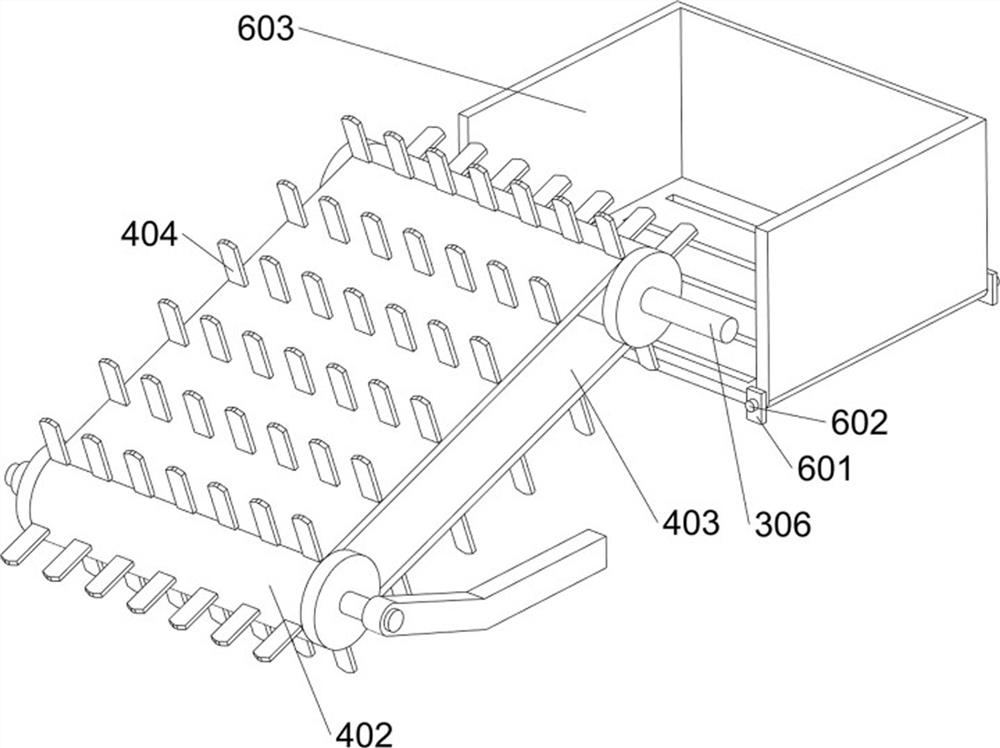

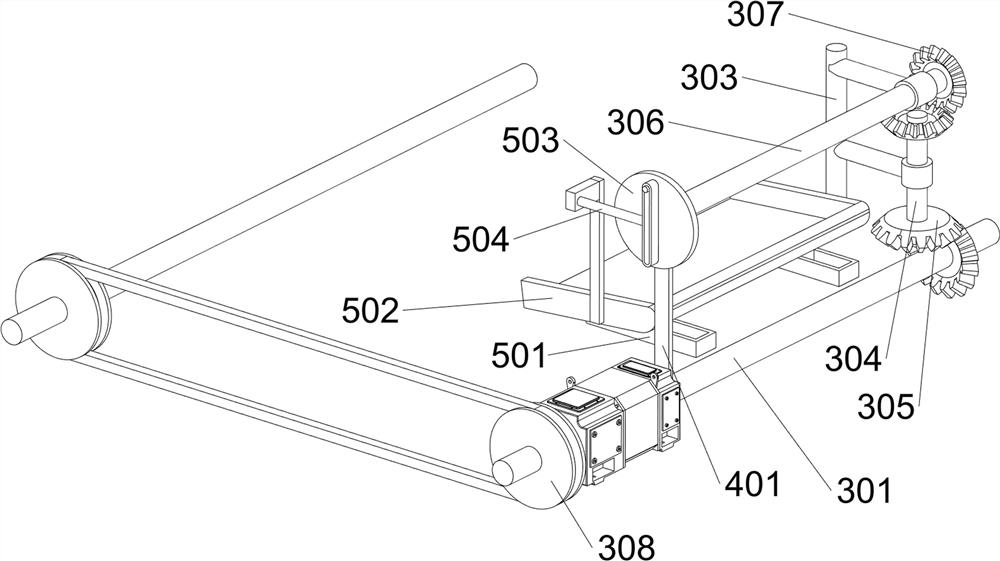

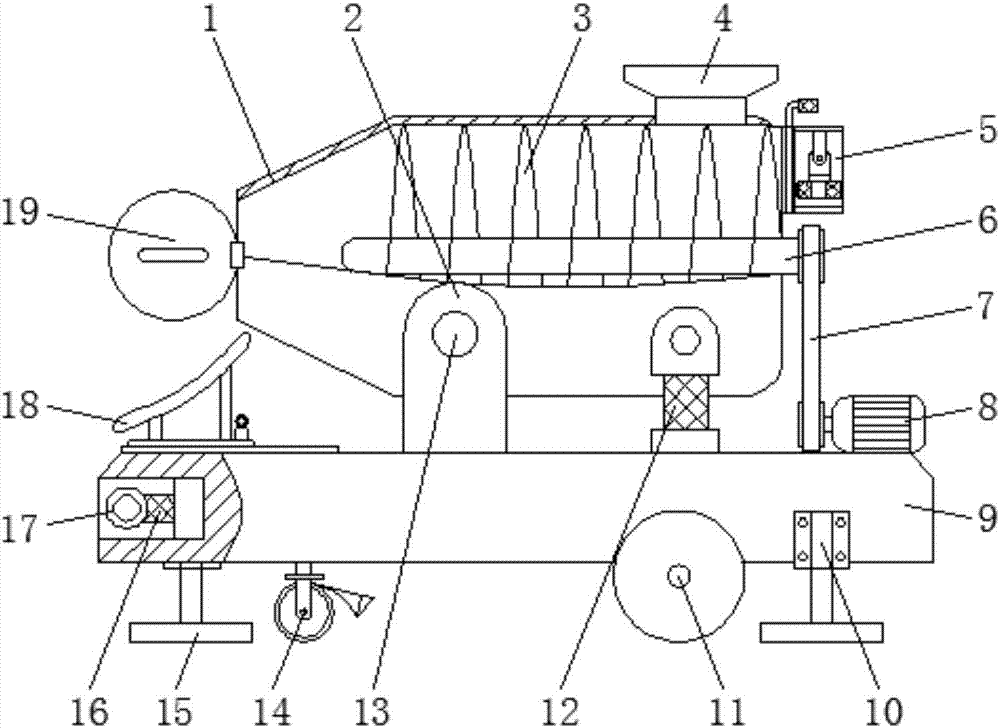

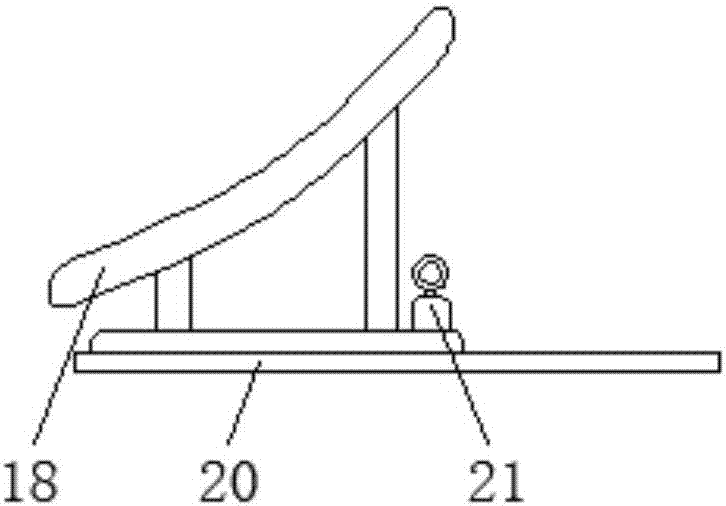

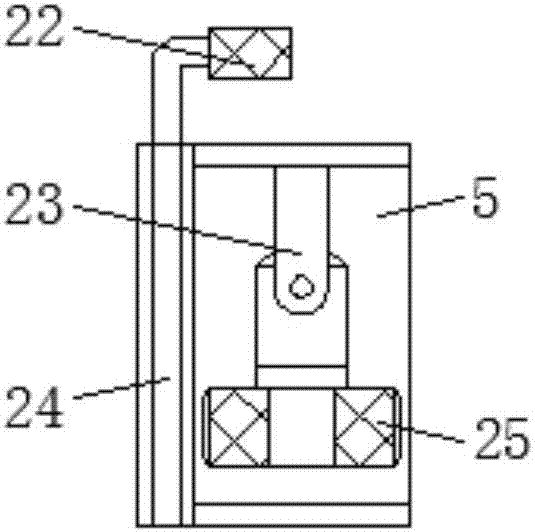

Tuber type crop excavating harvester

The invention relates to a tuber type crop excavating harvester and belongs to the field of agricultural machinery. The tuber type crop excavating harvester comprises an excavating shovel, a rack and a transmission mechanism, wherein a hanging frame is arranged above the front of the rack, the excavating shovel is arranged below the front of the rack, a conveying mechanism is arranged behind the excavating shovel, the conveying mechanism is arranged below the middle part of the rack, a secondary separating mechanism is arranged behind the conveying mechanism, and the secondary separating mechanism is arranged at the rear end of the rack. According to the tuber type crop excavating harvester provided by the invention, a U-shaped cross beam is adopted for protecting a reversing gear case, so that crop stalks or weeds are prevented from tangling the reversing gear case and a power shaft in an operation process of the machine tool; and an eccentric mechanism and a planar four-link mechanism are adopted to jointly form the secondary separating mechanism, and an eccentric rotational motion is converted into a planar four-link motion to drive a shaking sieve to shake, so that clay on the surfaces of tuber type crops is reduced, and manual cleaning in a later period is convenient. The tube type crop excavating harvester provided by the invention is reasonable in the whole structure arrangement, high in operational reliability, complete in function and adaptability and is applicable to excavating harvesting operation of tuber type crops.

Owner:甘肃省农业机械化技术推广总站

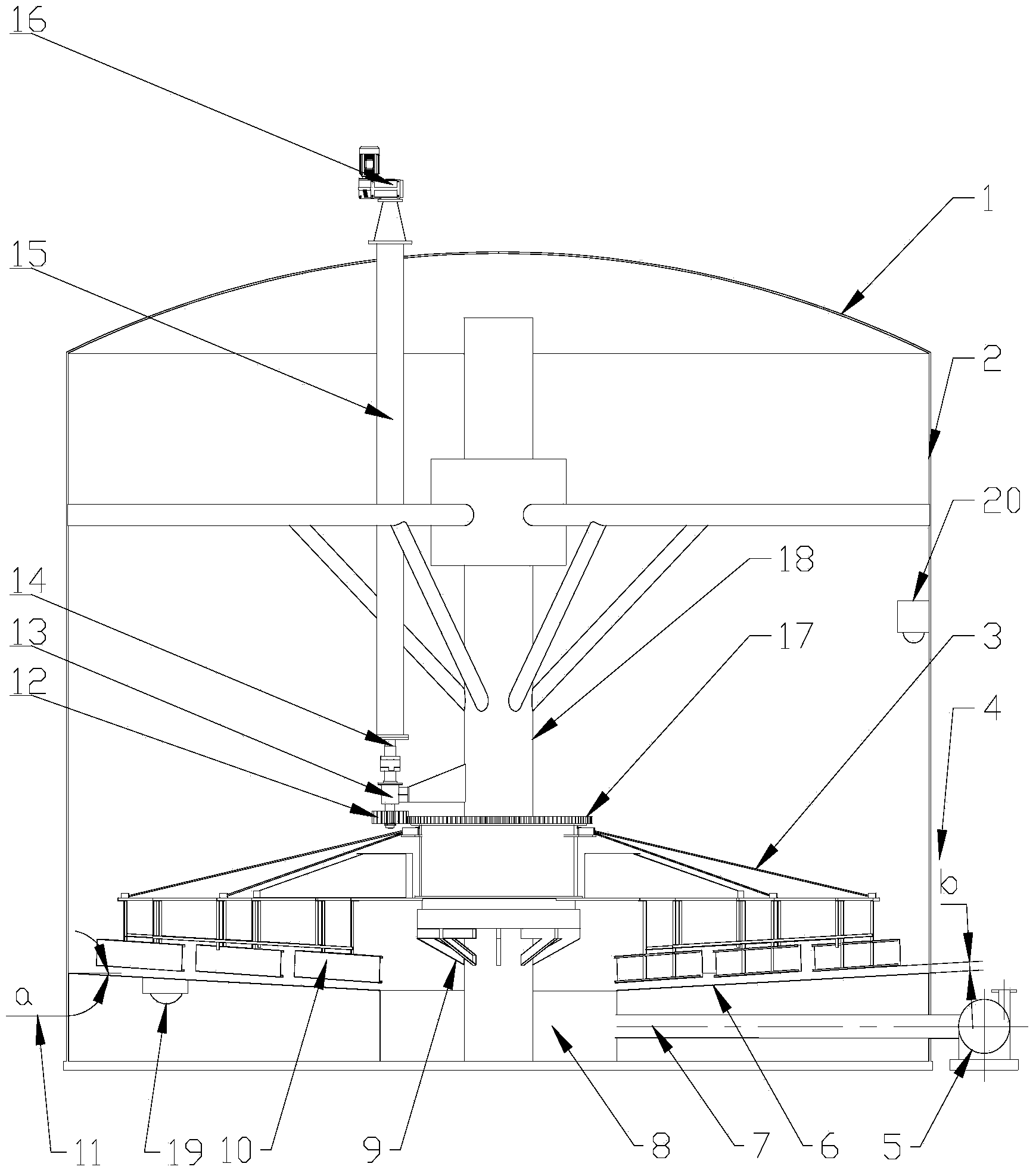

Tank bottom sludge discharging device for oilfield sedimentation tank

The invention provides a tank bottom sludge discharging device for an oilfield sedimentation tank. A tank body is provided with a sludge bearing bottom plate and a sludge collection chamber, the sludge collection chamber is connected with a sludge discharging pump, a sedimentation tank center pipe is connected with a center support connected with a driven gear, the driven gear is in meshed connection with a driving gear, a shaft of the driving gear is connected with a gear motor through a coupling, the gear motor is fixedly connected with a sleeving pipe outside the tank top, four groups of frameworks are fixedly and radially connected around a shaft of the driven gear, bottoms of the frameworks are connected with sludge scraping plates. Sludge is discharged through a tank bottom sludge removal system, the problem of sludge sedimentation at the tank bottom is solved, sludge is discharged thoroughly, no dead zone exists, water resources are saved, the device adopts a mechanical structure and is stable in operation and reliable in performance, a mechanical part of the tank bottom of the sedimentation tank is free of welding structures, a bolt fastening connection method is adopted, an ultrasonic interface sensor is arranged, the automatic tank bottom sludge removal system sets parameters such as the starting frequency, the working time and the like of the device through programs, sludge collection and sludge discharging are controlled automatically and regularly through the programs, and full-automatic operation of the system is realized.

Owner:大庆市考维尔自动化设备制造有限公司

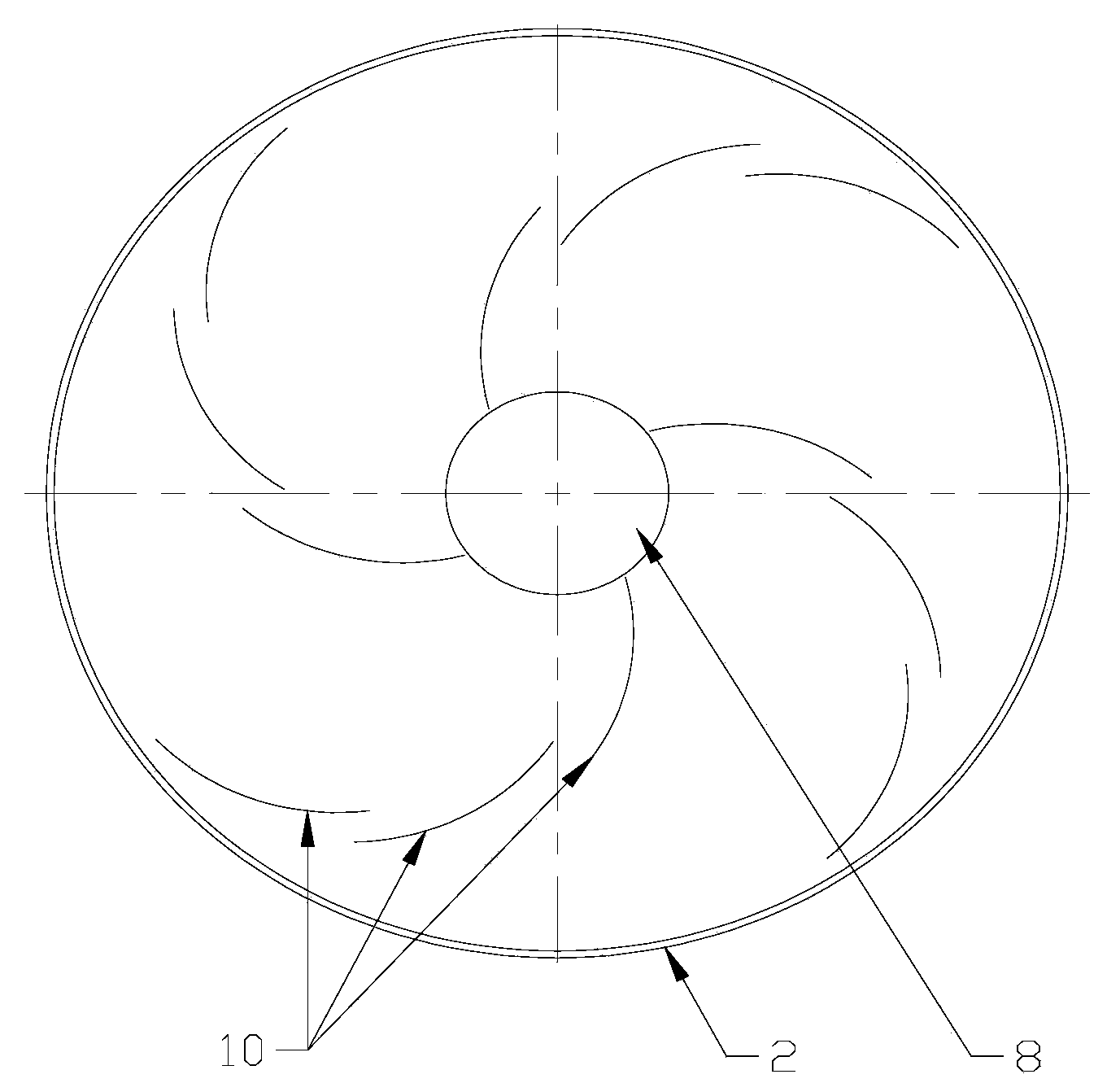

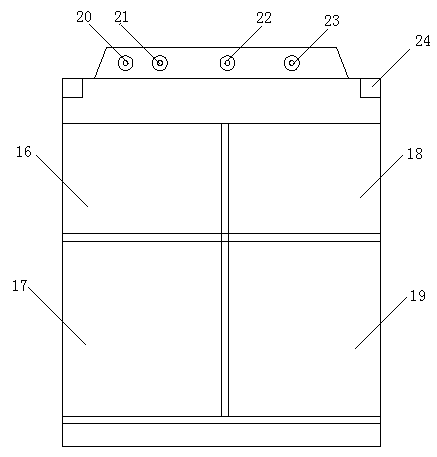

Curtain wall window with double frames capable of being overturned

The invention provides a curtain wall window with double frames capable of being overturned. The curtain wall window comprises a square frame, a window frame and a glass frame. The frame is fixed on a curtain wall; the upper portion of the window frame is hinged to an upper border of the frame; a handle is designed on the lower portion of the window frame; the glass frame is assembled in the middle position of the window frame through intermediate hinged shafts symmetrically assembled on the two sides of the glass frame; and the upper portion of the glass frame is fixed to the window frame through screws. The curtain wall window can be used as a traditional curtain wall window, meanwhile, and a user can conveniently conduct manual cleaning, so that the curtain wall window always keeps clean, cleaning personnel does not need to clean the position outside of the curtain wall, and manpower is greatly saved.

Owner:苏州缔绿电子科技有限公司

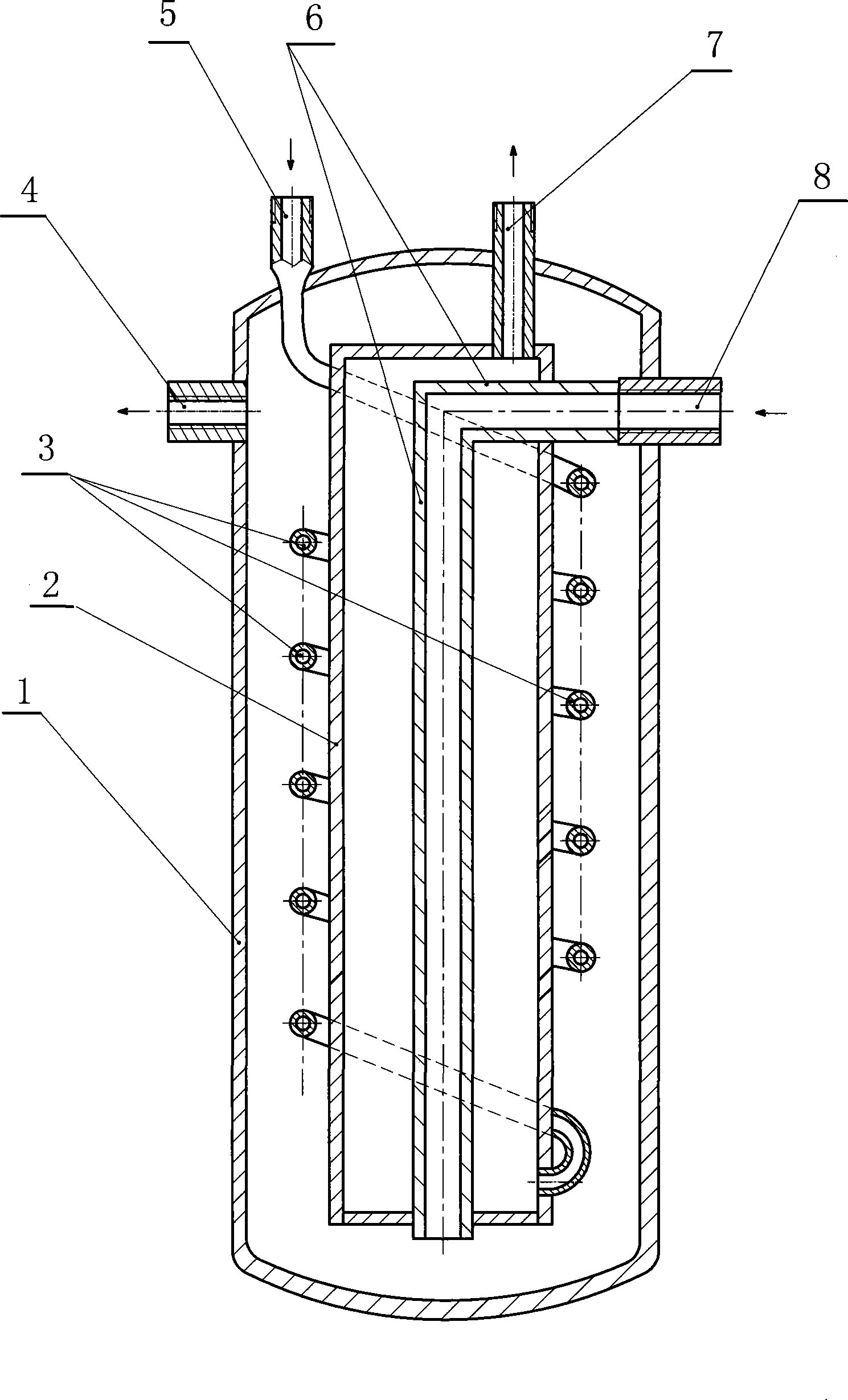

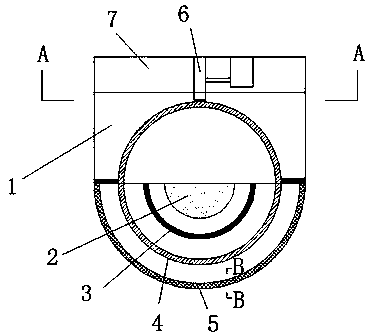

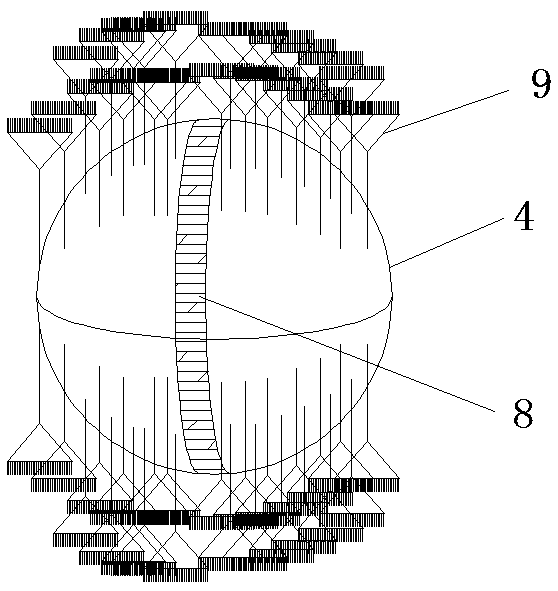

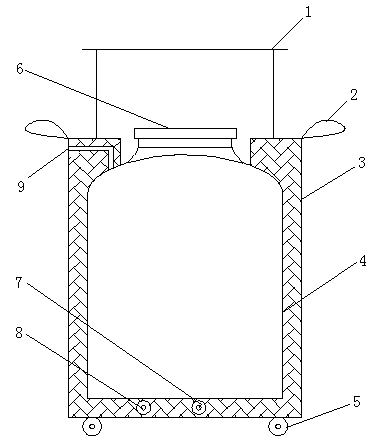

Second adverse current barrel type heat exchanger

InactiveCN101118129AAvoid badIncrease the temperature of the heat exchange outlet waterStationary tubular conduit assembliesHeat exchange apparatusCounter flowEngineering

The present invention relates to a secondary counter flow barrel type heat exchanger, which comprises an outer barrel body with the upper part connected with a hot air inlet, a hot air outlet, a tap water inlet and a tap water outlet respectively. The hot air outlet is communicated with the inner cavity of an outer barrel body; an inner barrel body is arranged in the outer barrel body, the upper end of the inner barrel body is connected with the tap water outlet, and the tap water outlet is communicated with the inner cavity of the inner barrel body; the hot air inlet is connected with a heating pipe, the heating pipe is inserted into the inner barrel body and penetrates form the bottom part of the inner barrel body and is communicated with the inner cavity of the outer barrel body. The periphery of the inner barrel body is coiled with a screwy tap water heat absorbing pipe, the head end of the tap water heat absorbing pipe is connected with the tap water inlet, and the tail end is connected with the bottom part of the inner barrel body and is communicated with the inner cavity of the inner barrel body, and the present invention forms a secondary counter flow heat exchanging structure. The present invention saves the heat absorbing copper pipe in the original patent, thereby the cost is low, the volume is small, the space is small, the installation is easy and the acid cleaning is convenient. The water temperature can reach more than 38 DEG C, and is incessant. The materials are chosen stainless steel and a red copper pipe, and the service life is as long as 10 years.

Owner:张伟

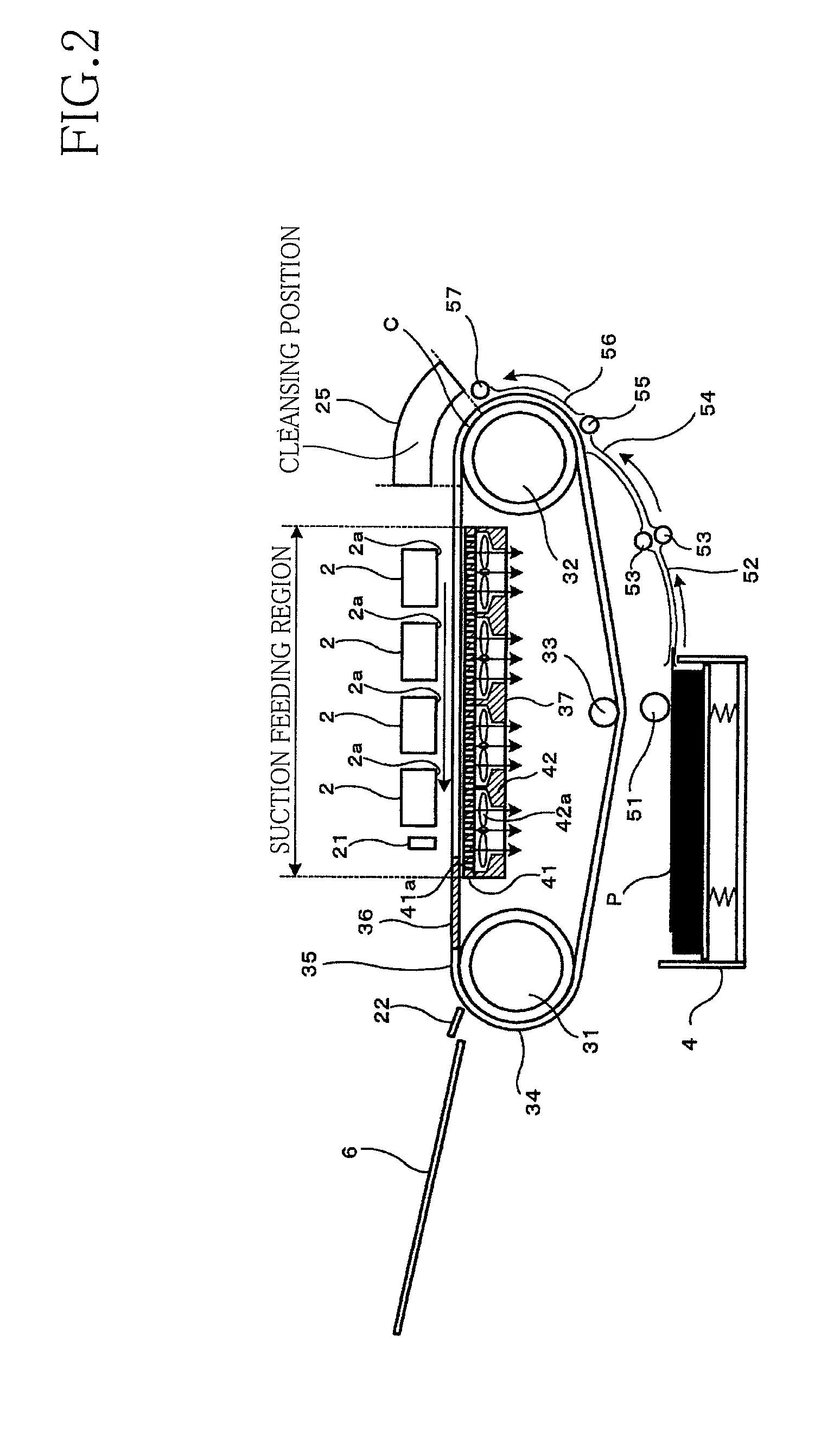

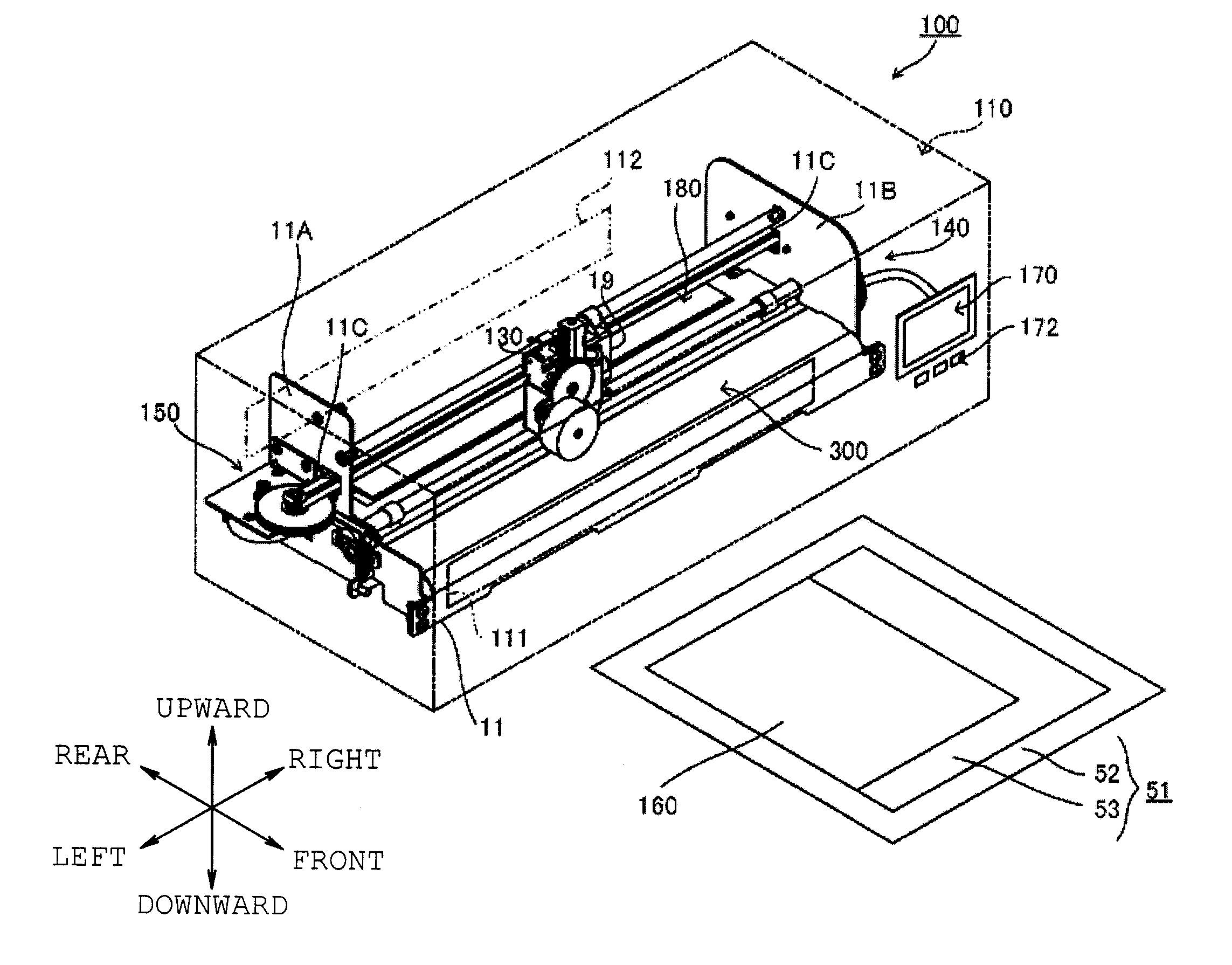

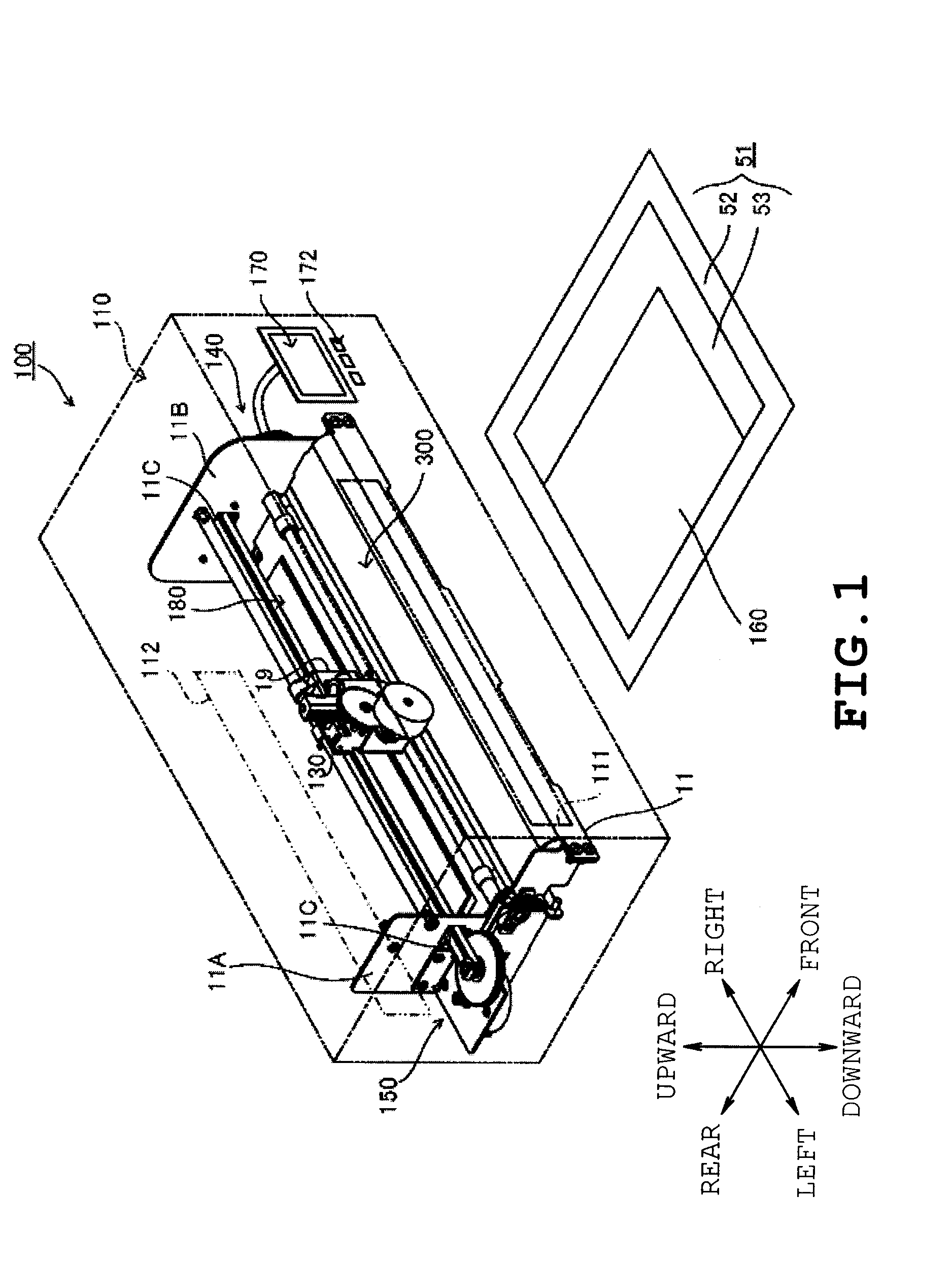

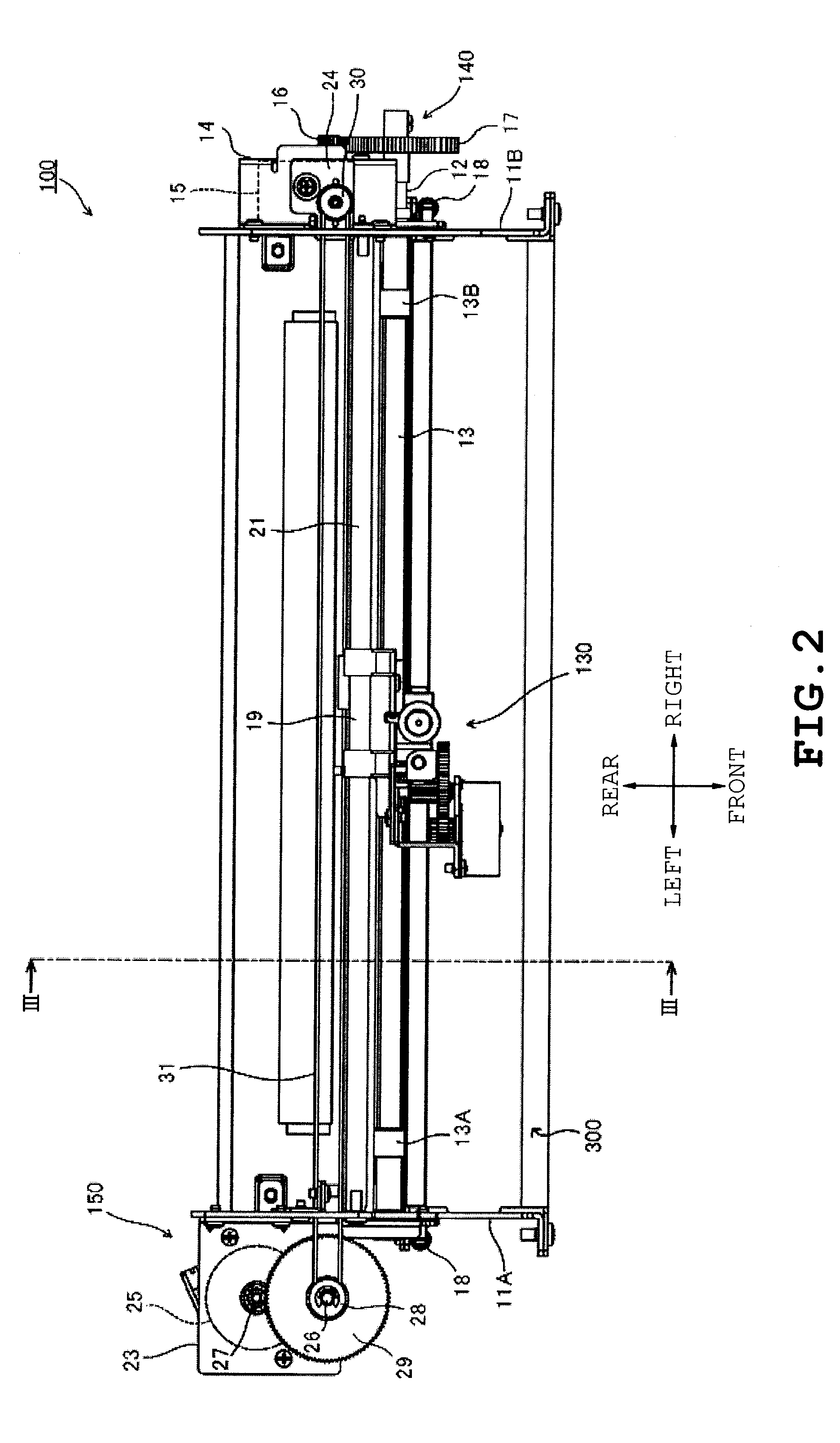

Recording apparatus

ActiveUS8287084B2Facilitates a manual cleansing of a liquid-droplet ejection areaAvoid contactOther printing apparatusEngineeringMechanical engineering

Owner:BROTHER KOGYO KK

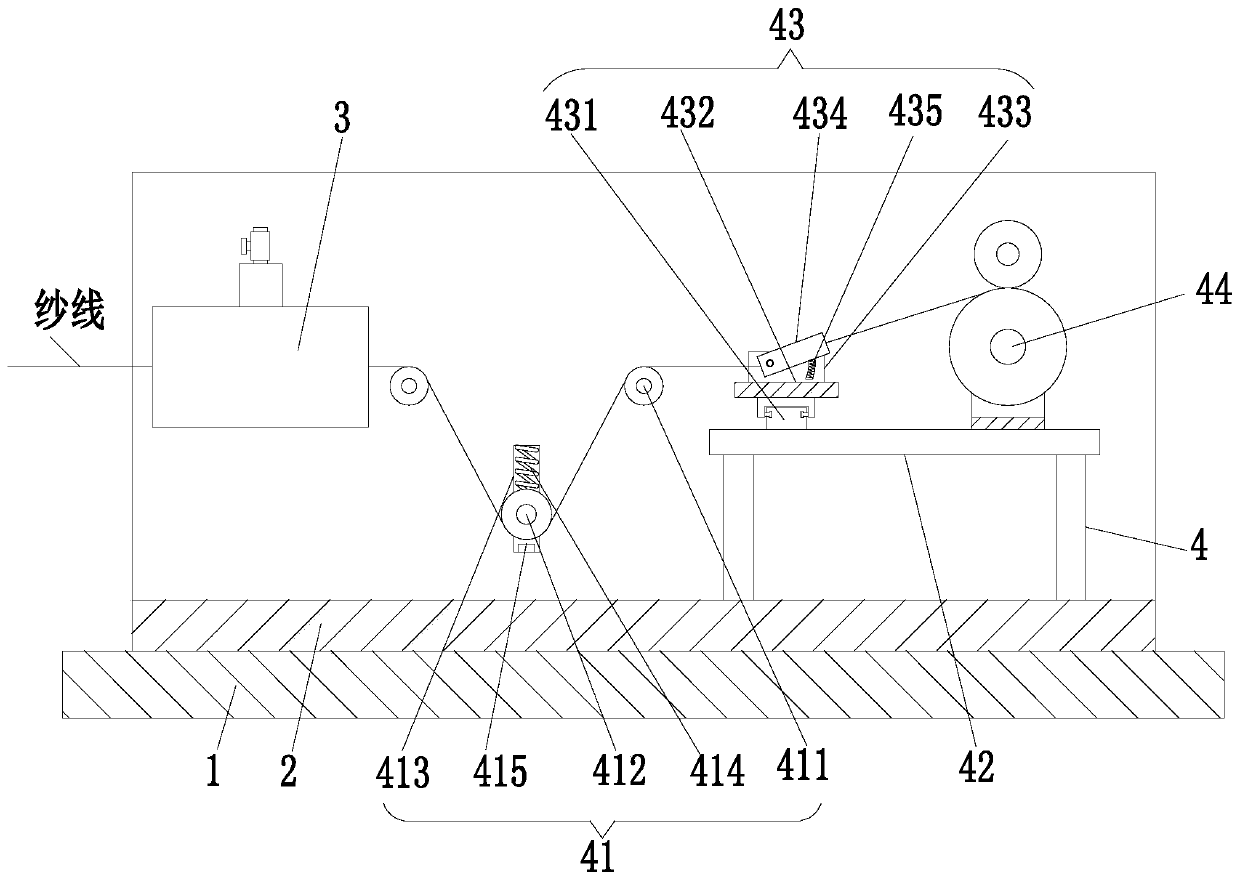

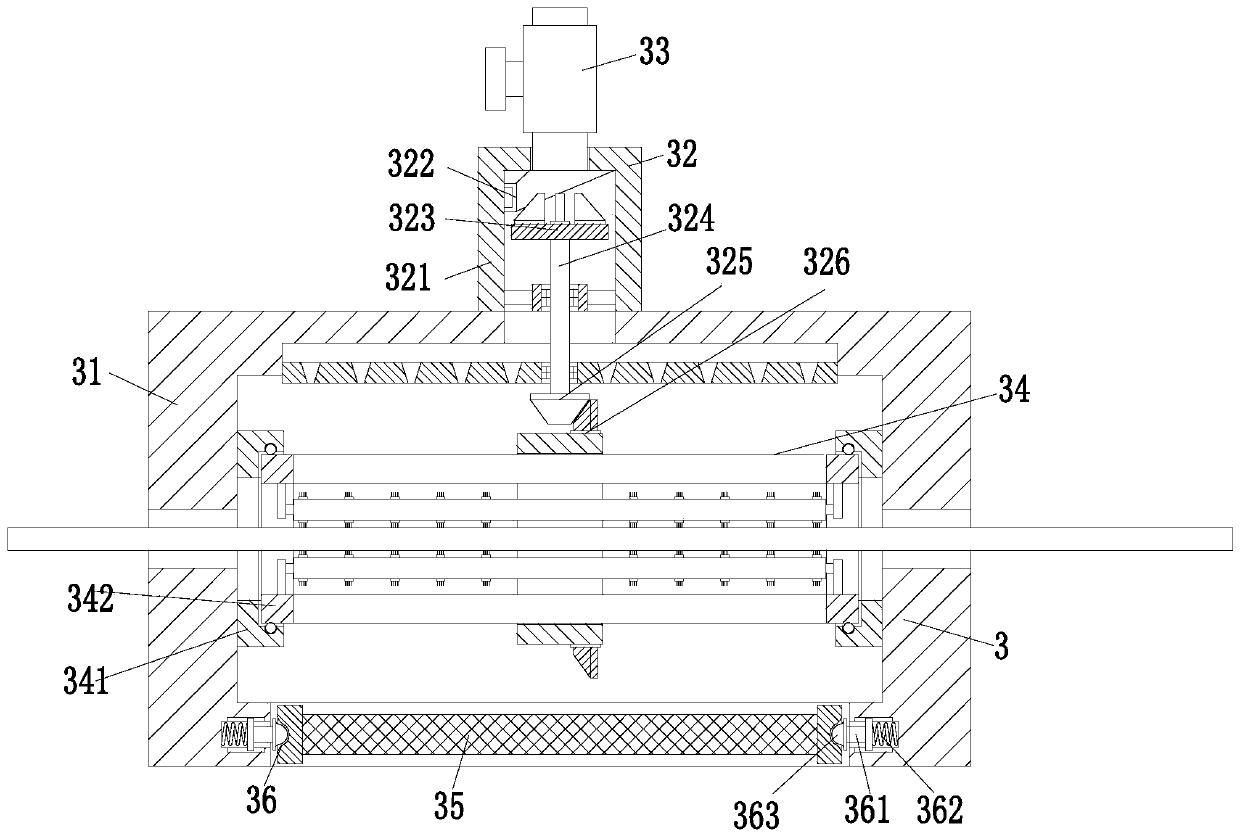

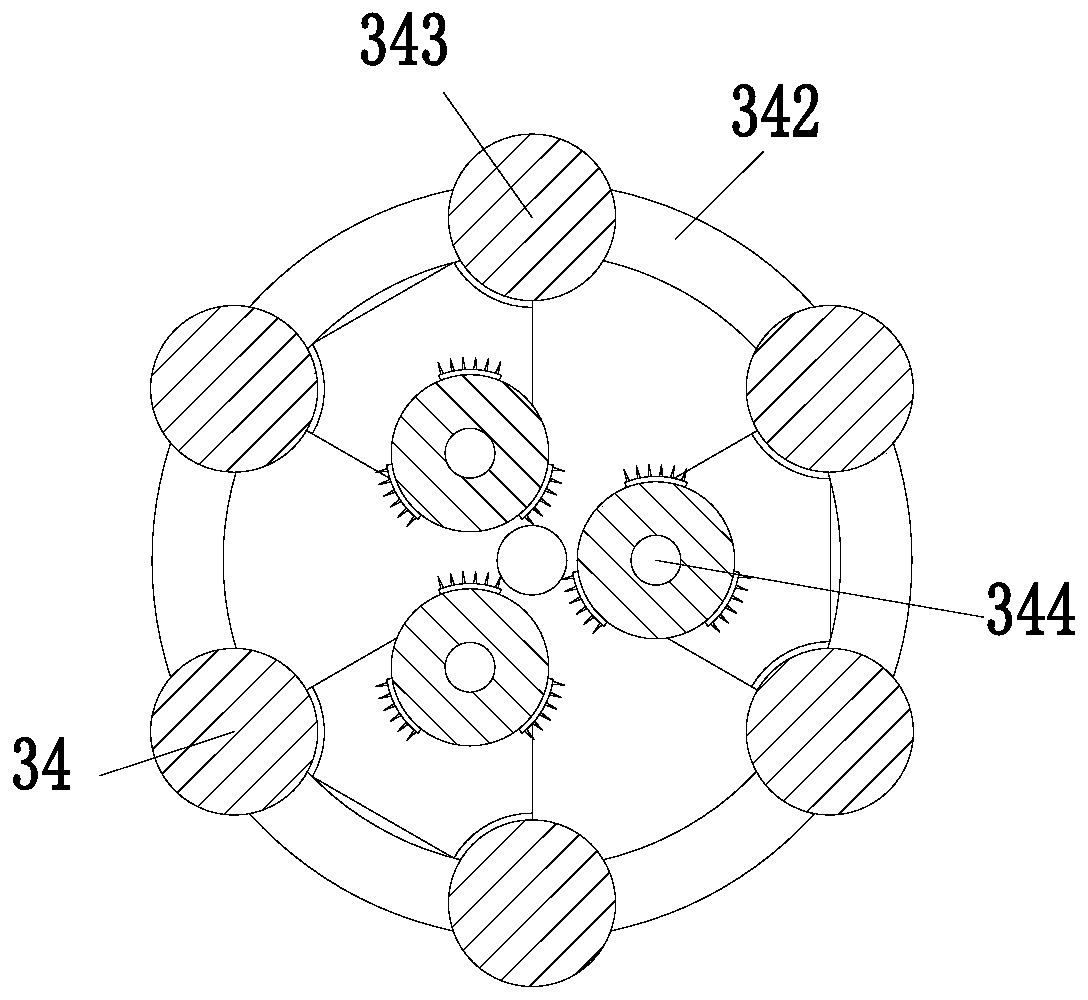

Bobbin yarn winding equipment and bobbin yarn winding process

The invention relates bobbin yarn winding equipment and a bobbin yarn winding process. The bobbin yarn winding equipment comprises a bottom plate, a supporting frame, a cleaning device and a winding device; and the supporting frame is installed at the upper end of the bottom plate, the section of the supporting frame is of a U-shaped structure, the cleaning device is installed on the left side ofthe interior of the supporting frame, and the winding device is installed on the right side of the interior of the supporting frame. According to the bobbin yarn winding equipment and the bobbin yarnwinding process, the problems that when existing equipment is used for winding yarn, the yarn cannot be cleaned generally, fluff attached to the yarn is prone to causing yarn knotting, and the follow-up use effect of the yarn is affected can be solved; and the problem that when the existing equipment is used for winding the yarn, the wound yarn cannot be pressed generally so that the yarn is proneto loosening can be solved; and in addition, the problem that when the yarn is conveyed, the yarn is prone to breakage due to large friction coefficient of the yarn, and then the winding efficiency of the yarn is affected can be solved.

Owner:兰溪市文萱纺织有限公司

Muck truck cleaning device used at construction site

ActiveCN109878466ASolve the technical problem of slow cleaning efficiencyImprove secondary utilization efficiencyCleaning apparatus for vehicle exteriorsWater storage tankEngineering

The invention discloses a muck truck cleaning device used at a construction site and belongs to the technical field of environmental protection equipment. The muck truck cleaning device comprises a cleaning platform, a cleaning assembly, a translation assembly, a lifting assembly, a recovery assembly, a water storage tank, an adjusting assembly, a mud clearing assembly and a filtering assembly, wherein the water storage tank and the cleaning platform are both arranged on the ground, the cleaning assembly is arranged between the cleaning platform and the water storage tank, the recovery assembly is arranged in the water storage tank, and one of the recovery assembly is connected with the cleaning platform, the lifting assembly is arranged on the side of the cleaning platform, the translation assembly is arranged on the cleaning platform and located on the side of the lifting assembly, the adjusting assembly is arranged on the cleaning platform and located above the translation assembly,the mud clearing assembly is arranged on the translation assembly and located at the bottom of the cleaning platform, the filtering assembly is arranged in the water storage tank and communicated with the recovery assembly, and mud baffles are arranged at two ends of the cleaning platform. The muck truck cleaning device not only achieves multi-angle cleaning of construction site vehicles, but also improves the cleaning efficiency, saves energy and is environmentally friendly.

Owner:ANQING NORMAL UNIV

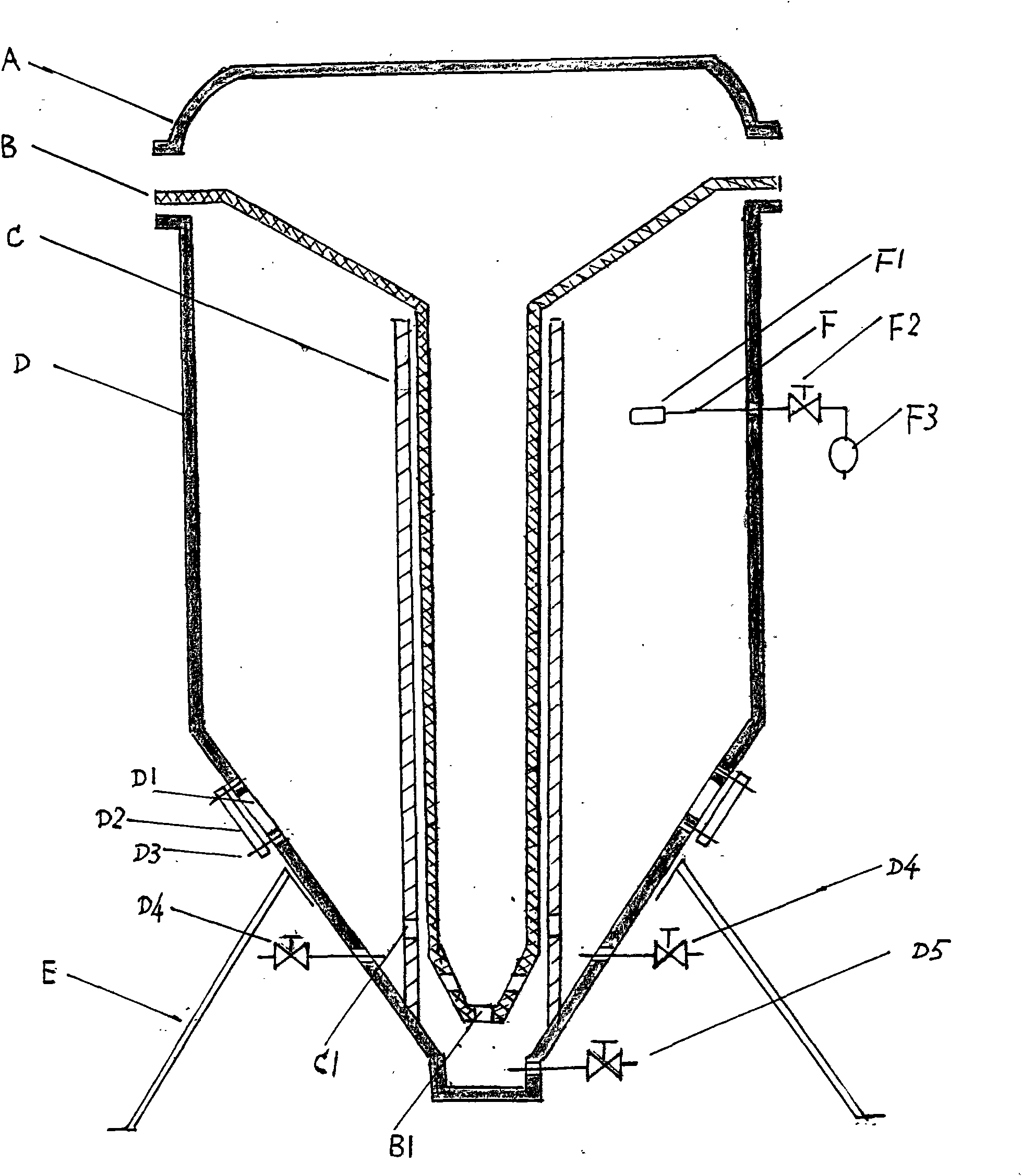

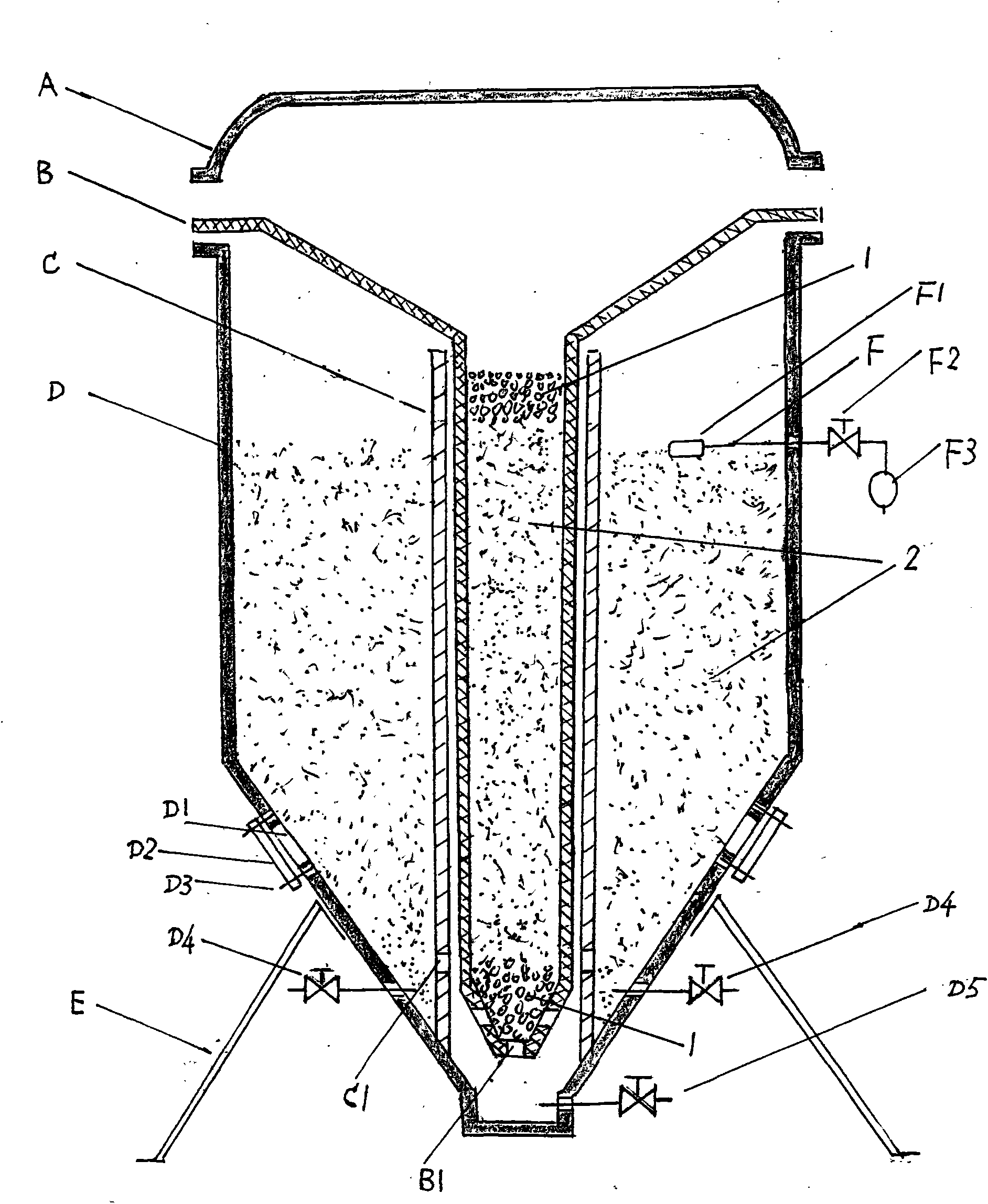

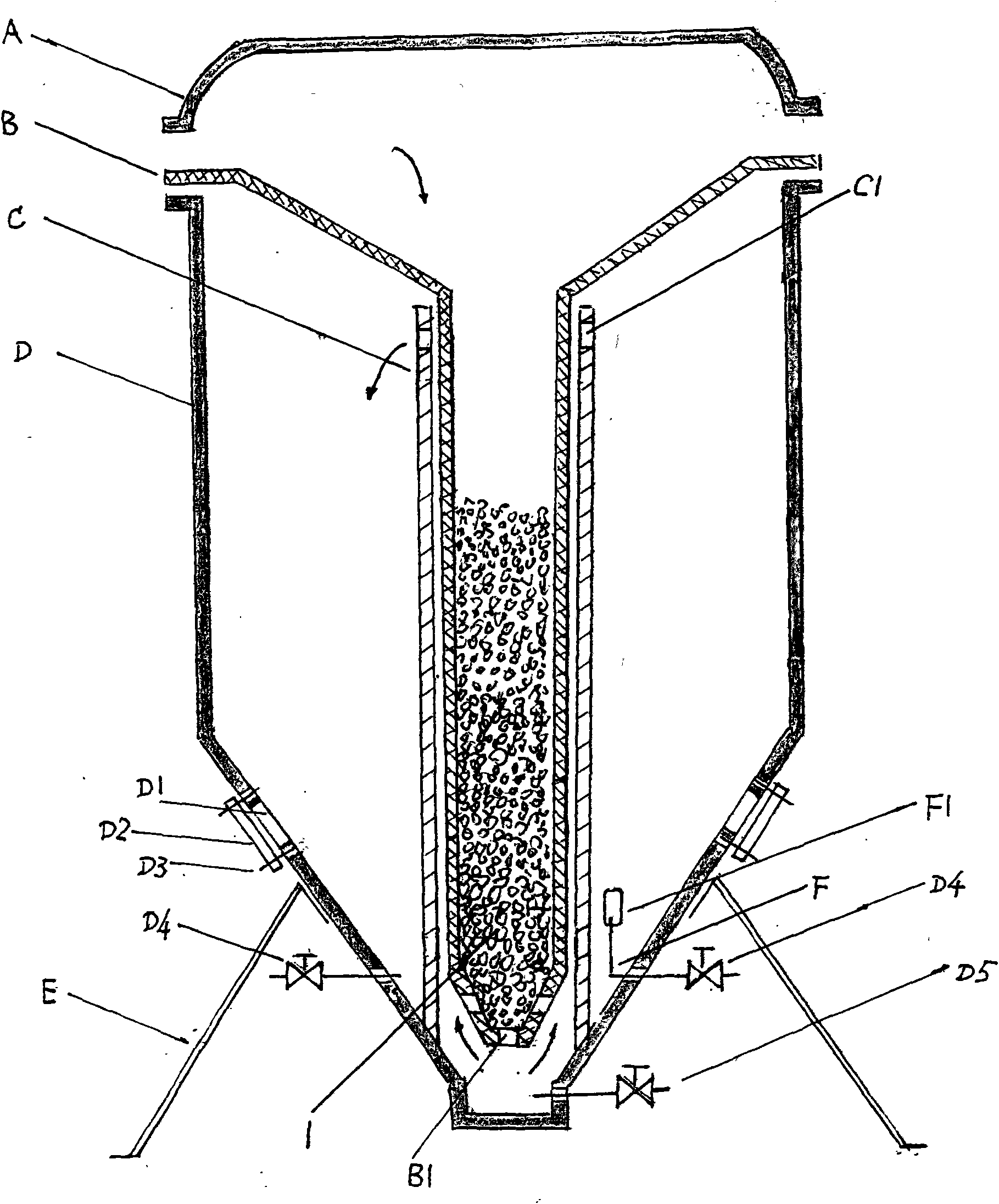

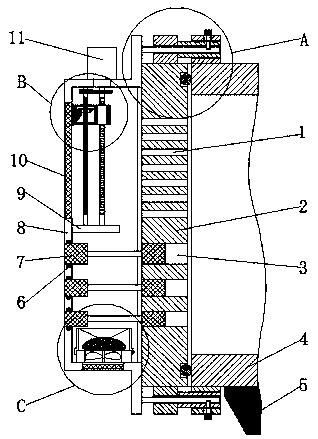

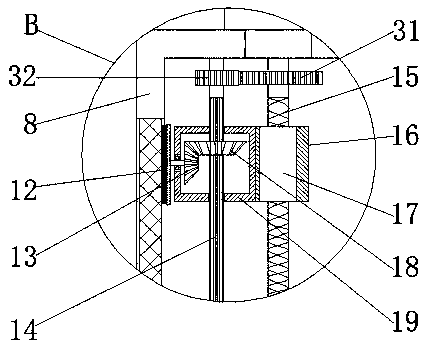

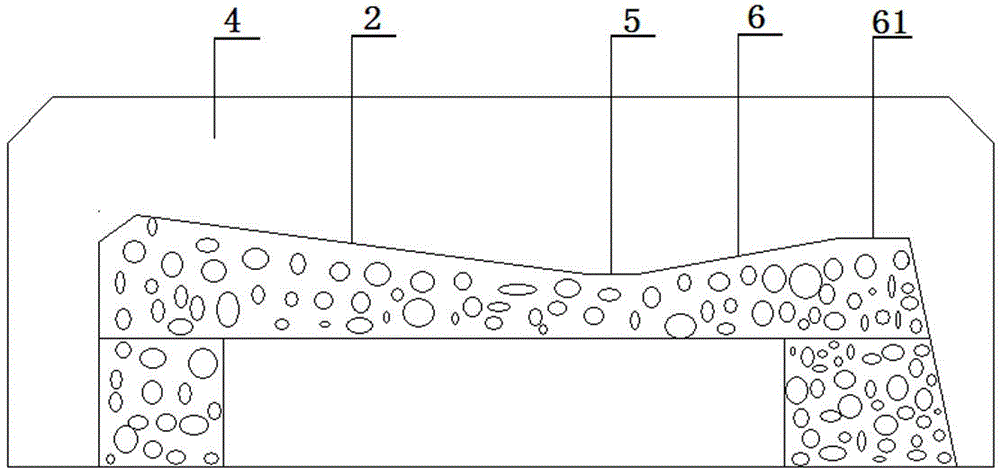

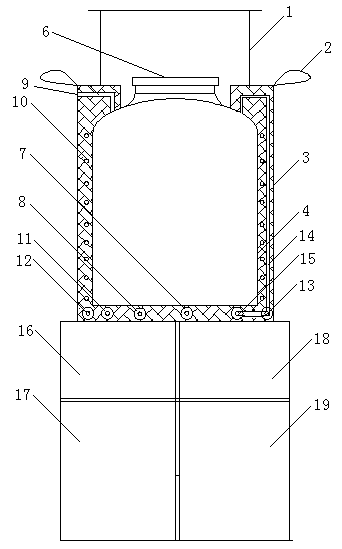

Combined type filter vat component

InactiveCN101785936AGuaranteed uptimeReduce pollutionLoose filtering material filtersGravity filtersDisaster areaWater security

The invention relates to the water treatment field and in particular aims to solve the problem of how to realize the functional diversity and structural module of the manual injection type filter vat of various polar or non-polar filter materials for coagulation and flocculation. The combined type filter vat component comprises a filter vat cover (A), a preprocessor (B), a flow direction control tube (C), a main processor (D1), a support (E) and a purifying pipeline (F) which consists of universal pipe fittings according to the demand; the component of the invention can be conveniently assembled to a rural household water purification device capable of removing fluorine and arsenic according to demands and can also be assembled to a disinfection and coagulation-flocculation device when natural disasters are suddenly happened. The component is convenient to use, has low production cost and long life and can be directly assembled in site, thus playing an important role in the drinking water security of rural areas and disaster areas.

Owner:刘韬

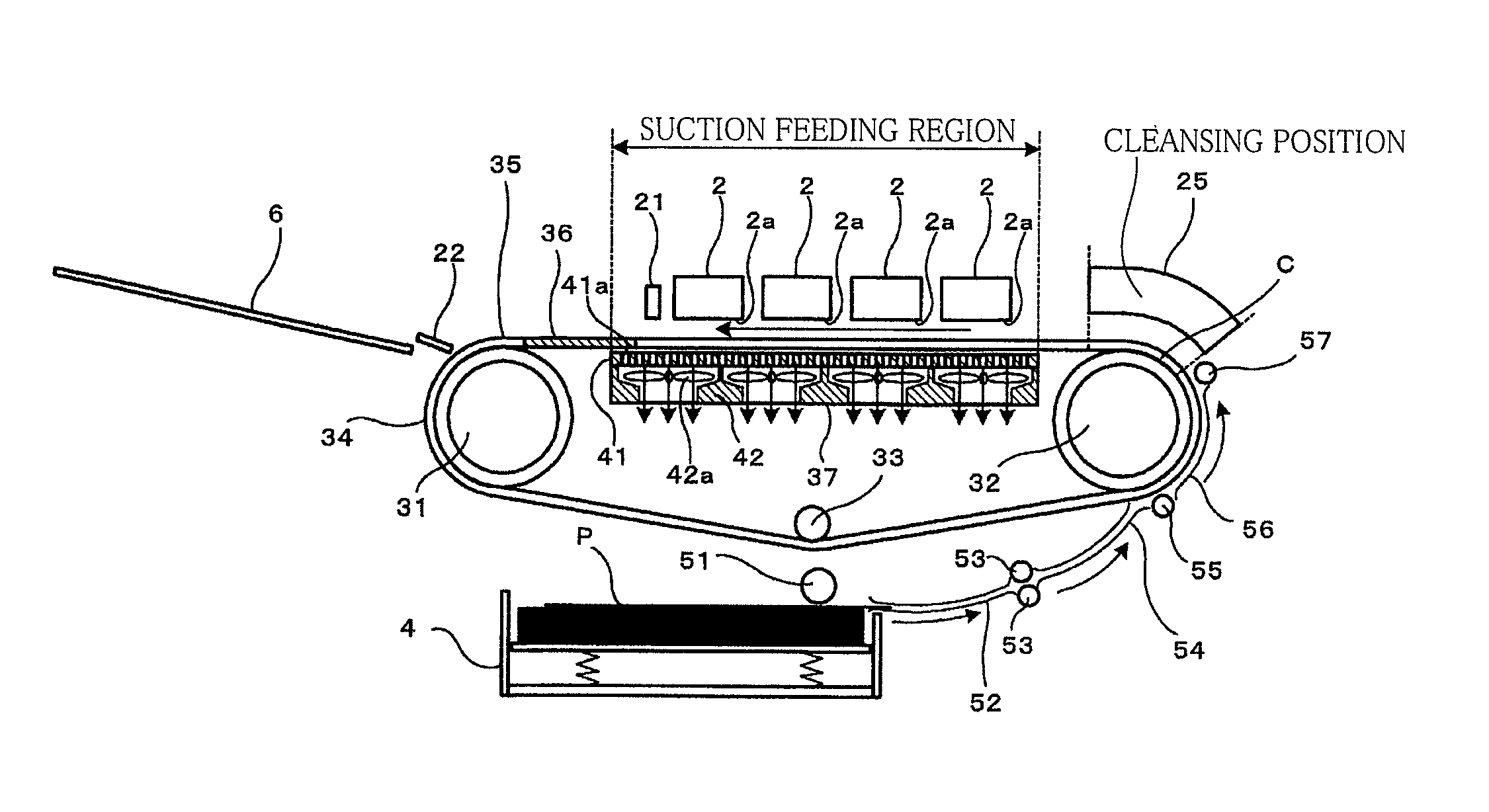

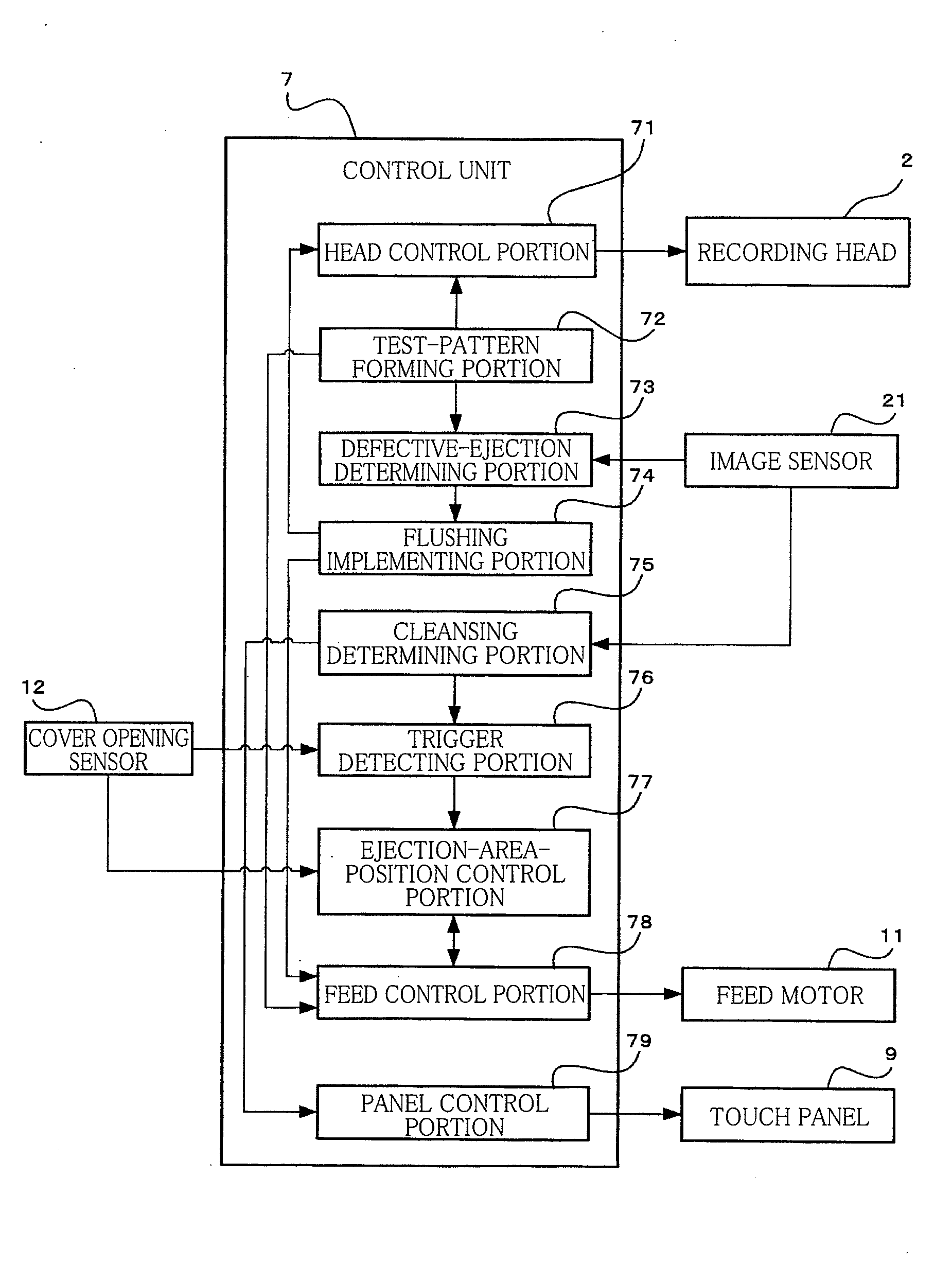

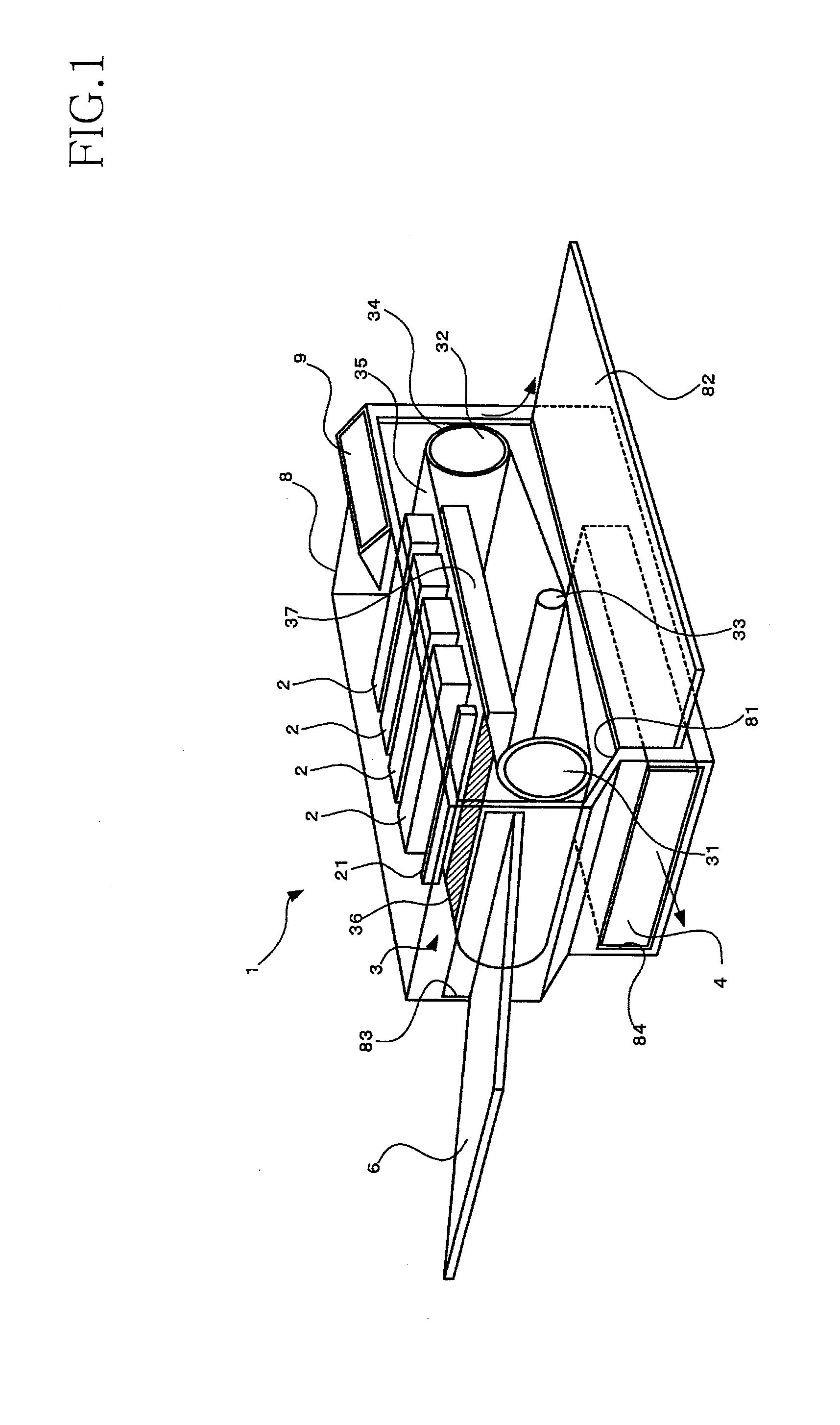

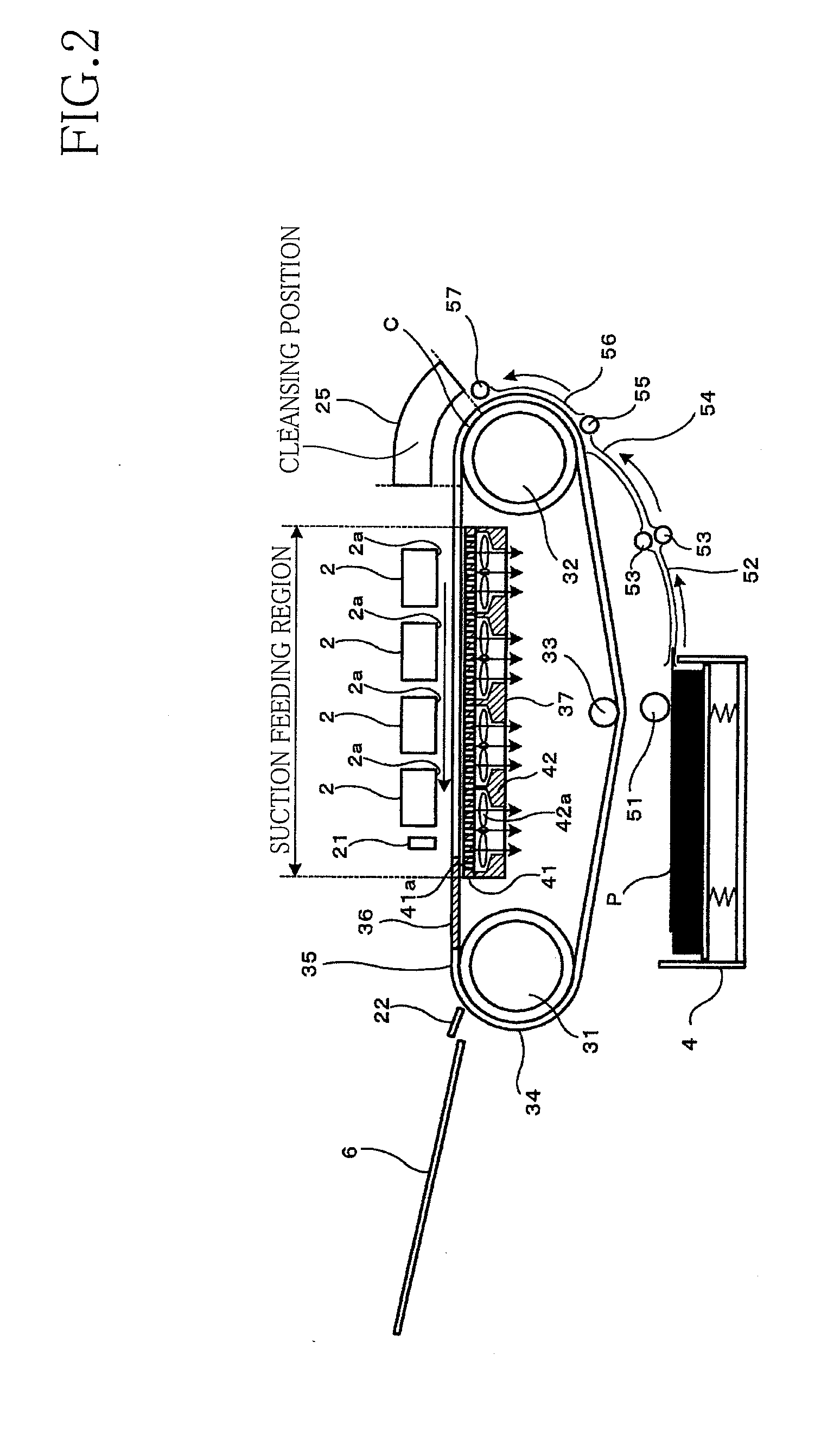

Recording apparatus

ActiveUS20100053254A1Easy to clean manuallyPrevent accidental contactOther printing apparatusMechanical engineeringRecording media

There is disclosed a recording apparatus including a recording head, a feeding mechanism, a detector, and a controller. The recording head has an ejection surface from which a droplet of a liquid is ejected. The feeding mechanism includes a plurality of rollers and an endless feeder belt wound around the rollers and having a feeding surface opposed to the ejection surface, and feeds a recording medium placed on the feeding surface a part of which serves as a liquid-droplet ejection area onto which a droplet of the liquid is ejected. The detector detects a trigger for initiating a manual cleansing of the liquid-droplet ejection area. The controller controls the feeding mechanism such that when the detector detects the trigger, the liquid-droplet ejection area is located at a cleansing position where the liquid-droplet ejection area is not opposed to the ejection surface of the recording head.

Owner:BROTHER KOGYO KK

Converter wind eye pipe inner bonding cleaning tool

ActiveCN107164601ASo as not to damageReduce abnormal attrition rateManufacturing convertersBrickDrive shaft

The invention discloses a converter wind eye pipe inner bonding cleaning tool. The converter wind eye pipe inner bonding cleaning tool comprises a base assembly, a poking and beating device and a rotation device. The base assembly comprises bearing wheels, guiding wheels, a support and guide rails. The base assembly can transversely move on the guide rails in a reciprocating manner. The poking and beating device is fixedly arranged on the support and comprises an air cylinder, a sliding base, guiding rods and drill rods and is used for poking and beating a converter wind eye. The rotation device comprises a pneumatic motor, a speed reducer, a coupler, a transmission shaft, a rotation rod and a twist drill. The pneumatic motor is fixedly arranged on the sliding base, a rotation shaft of the pneumatic motor is connected with the speed reducer, the torque output end of the speed reducer is connected with the transmission shaft through the coupler, and the transmission shaft is connected with the rotation shaft. The torque is transmitted to the rotation shaft to drive the rotation rod to rotate, and the tail end of the rotation rod is detachably provided with the twist drill. According to the converter wind eye pipe inner bonding cleaning tool, for the problem of wind eye blockage of a PS large converter wind gap, drilling is used for replacing a poking and beating manner, and the technical problem that due to existing design, refractory bricks in a wind eye area in a converter are likely to be damaged abnormally is solved.

Owner:JIANGXI COPPER (DEXING) CHEMICAL CO LTD

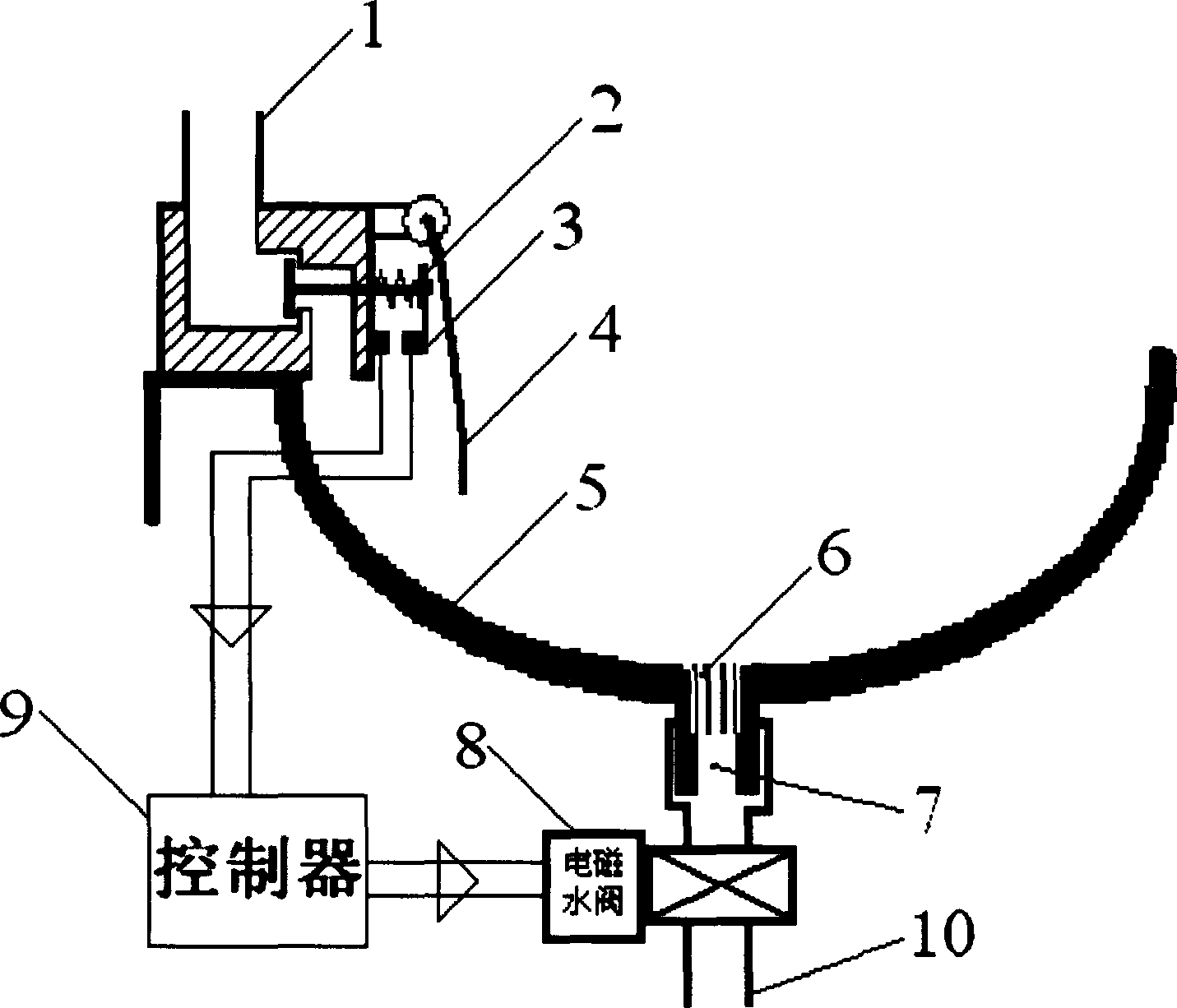

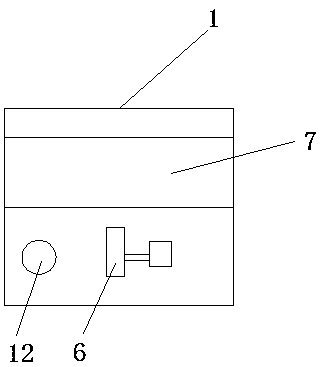

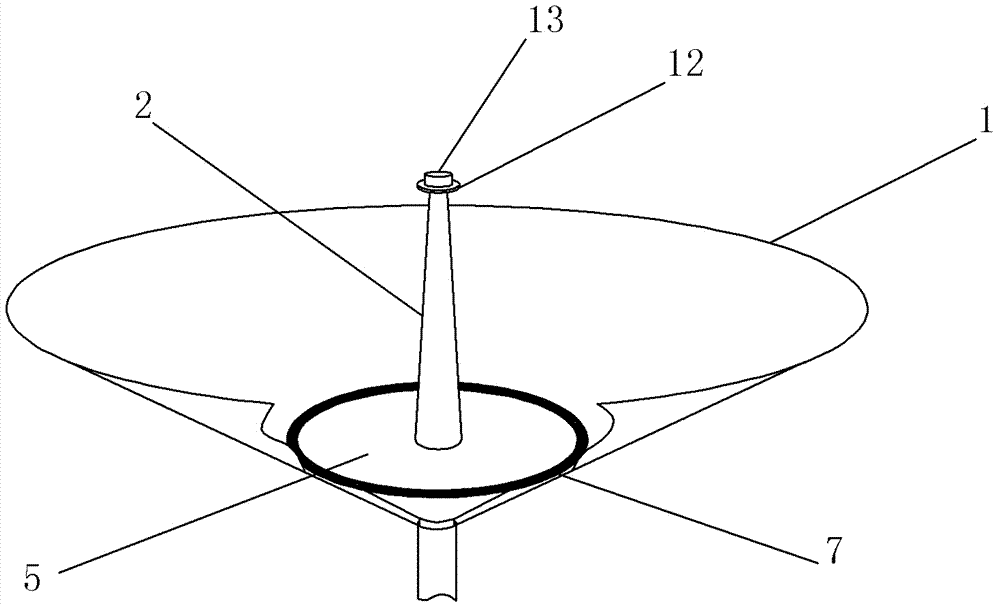

Self-cleaning type bowl for cows to drink water

ActiveCN102696501AGuarantee the quality of drinking waterAvoid pollutionAnimal watering devicesLeaking waterFiber

The invention relates to the field of livestock production and discloses a self-cleaning type bowl for cows to drink water. The self-cleaning type bowl for cows to drink water is characterized by being composed of a water control valve, a water bowl with water leaking holes and a water leakage control system. The water control valve is composed of a water inlet 1, a valve sheet 2 and a pressing plate 4. The water bowl with water leaking holes is composed of a water bowl body 5, a perforaled strainer 6 and the water leaking holes 7. The water leakage control system is composed of moving and fixed contacts 3, a controller 9 and an electromagnetic valve 8. Under the control of the water leakage control system, the water bowl stores water when the cows drink water and leaks water when the cows do not drink water. Residual water and concentrate residues in the water bowl are leaked out, only a little water can be evaporated rapidly, and only some fiber feed residues are remained so as to enable the water bowl to maintain states of water deficiency and nutritional deficiency whichrestrain growth and reproduction of microorganism and guarantee that the cows cannot drink metamorphic water. The self-cleaning type bowl for cows to drink water achieves self-cleaning functions after the cows drink water, artificial cleaning is convenient, and drinking water quality of the cows is improved greatly.

Owner:杨光

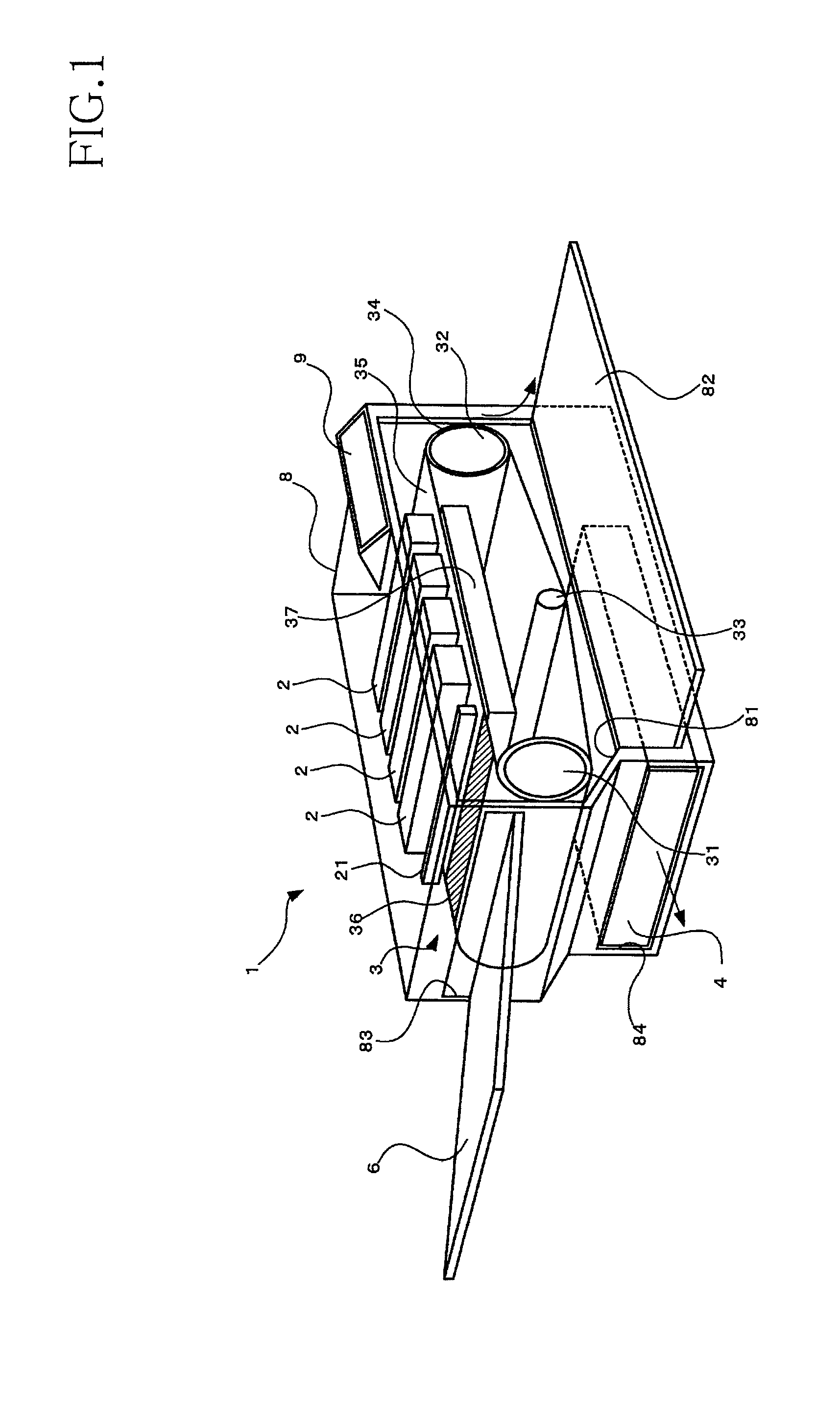

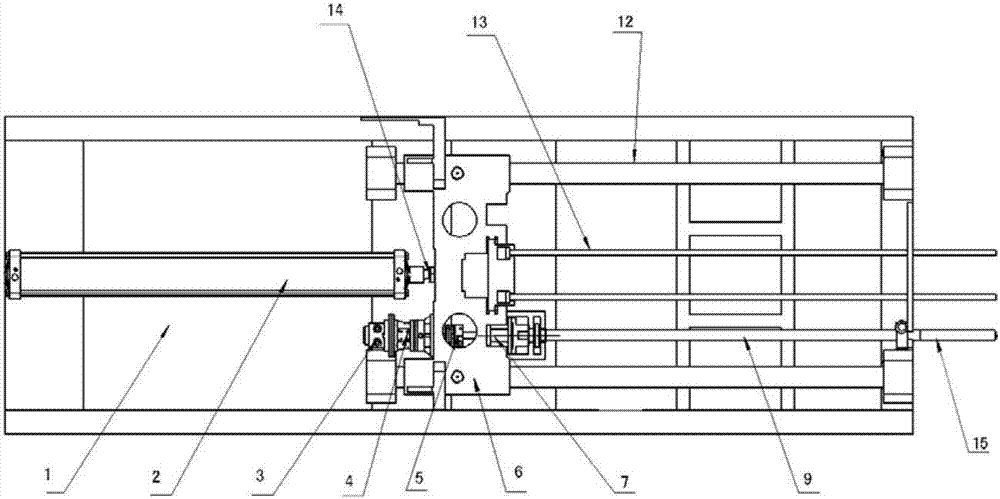

Cutting apparatus

ActiveUS20140251103A1Easy to cleanEasy to clean manuallyElectrographic process apparatusOther printing apparatusEngineeringElectrical and Electronics engineering

A cutting apparatus includes a housing formed with an insertion hole through which a sheet-shaped object is inserted, a transfer unit configured to transfer the inserted object along a transfer path, a reading unit configured to read an image of the transferred object, a platen located opposite the reading unit with the transfer path being interposed between the platen and the reading unit, the platen having a flat surface on which the object is placeable and a cutting unit disposed nearer the insertion hole than the reading unit on the transfer path, thereby cutting the object. The reading unit includes a light-transmitting plate through which light passes. The housing encloses the reading unit, the transfer unit, the platen and the cutting unit. The platen includes at least a part openable and closable so that a surface of the light-transmitting plate, located at the object side is externally exposed.

Owner:BROTHER KOGYO KK

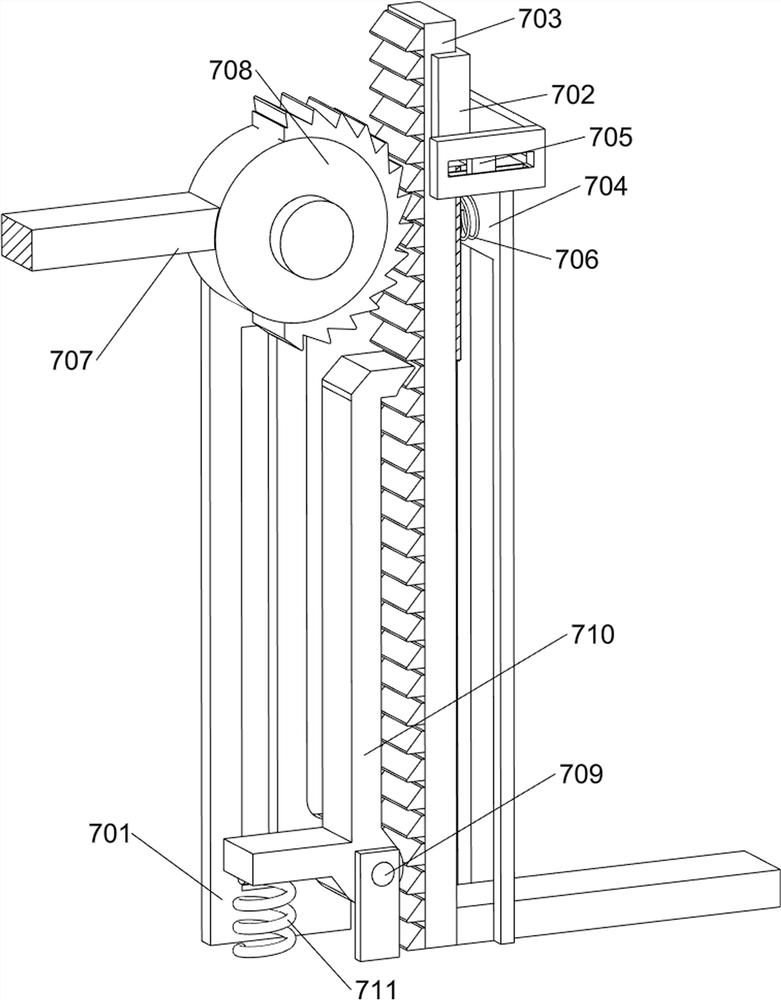

River channel garbage salvaging device

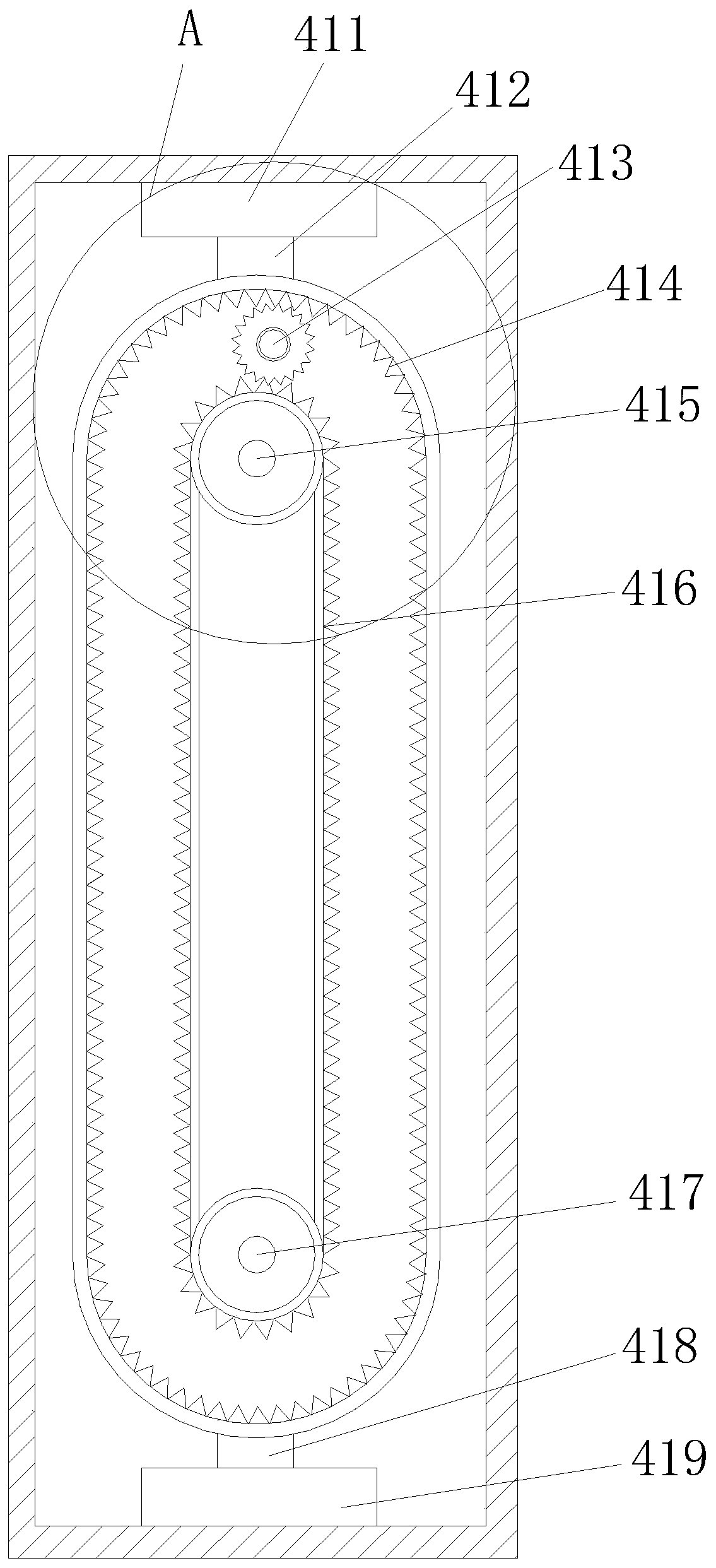

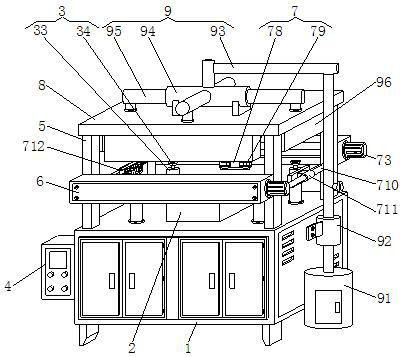

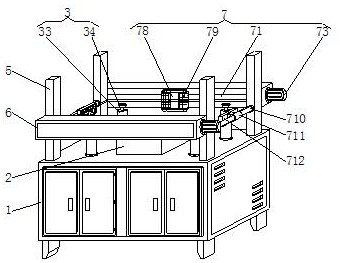

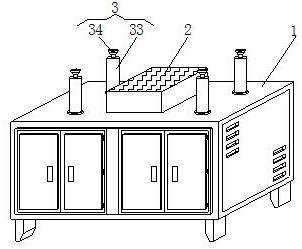

PendingCN113356165AEasy to storeAutomatic salvage with high safetyWater cleaningWaterborne vesselsAnimal scienceRiver routing

The invention relates to a salvaging device, in particular to a river channel garbage salvaging device. According to the technical aim, the river channel garbage salvaging device is high in automatic salvaging safety and convenient to store garbage. According to the technical scheme, the river channel garbage salvaging device comprises a base, a double-shaft motor, a driving assembly and a salvaging assembly; the double-shaft motor is arranged on the rear side of the left portion of the base, the driving assembly is arranged on the front side of the middle portion of the base, and the salvaging assembly is arranged on the left side of the base. Effects that the automatic salvaging safety is high, and the garbage is convenient to store are achieved; according to the river channel garbage salvaging device, people start the double-shaft motor, the double-shaft motor drives the driving assembly and the salvaging assembly to rotate, the salvaging assembly can bring the garbage onto a ship body during rotation, people can manually clean the garbage conveniently, and the effect of high automatic salvaging safety is achieved.

Owner:曾伟明

Computer dustproof device

InactiveCN110032255AEasy accessImprove sealingDigital processing power distributionLocking mechanismComputer engineering

The invention discloses a computer dustproof device. The computer dustproof devic comprises a case body, a rear cover is detachably connected to the side wall of the case body; a plurality of heat dissipation holes are uniformly formed in the side wall of the rear cover; a plurality of notches are formed in the side wall of the rear cover; each notch is internally and detachably connected with a patch cord. A dustproof cover is arranged on the side wall of the rear cover; the dustproof cover, the rear cover and the case body are jointly provided with a locking mechanism; a motor is fixedly connected to the side wall of the dustproof cover, an output shaft of the motor penetrates through the side wall of the dustproof cover, a brushing and sweeping mechanism is arranged on the inner wall ofthe dustproof cover, the output shaft of the motor is matched with the input end of the brushing and sweeping mechanism, and a dust suction mechanism is arranged on the inner wall of the dustproof cover. The computer dustproof devic is tight in sealing, dust is not prone to entering a computer, a dustproof window can be automatically cleaned, a dust suction mechanism is further arranged, dust accumulation is avoided, heat dissipation is prevented from being affected, and disassembling and manual cleaning are convenient.

Owner:JIANGSU MARITIME INST

Method for manufacturing composite marble-imitated coating based on elastic multicolor paint

InactiveCN111484780AExtend your lifeAchieve decorative effectPaints with biocidesPolyurea/polyurethane coatingsSpray coatingVarnish

The invention relates to a method for manufacturing a composite marble-imitated coating based on elastic multicolor paint, which comprises the following steps: a, forming a putty layer on a wall body,and applying an alkali-penetration-resistant primer by roll coating to form an alkali-penetration-resistant primer layer; b, spraying middle coating paint once to form a middle coating layer; c, after drying, applying an elastic multicolor paint by spray coating or roll coating to form a multicolor layer; and d, applying varnish once or multiple times by brushing or roll coating to form a finishing layer, wherein the multicolor layer is used as a marble-imitated main color layer, and the elastic multicolor paint comprises the following components in parts by weight: 50 parts of a pigment component, 20 parts of a dispersion medium and 30 parts of varnish. The elastic multicolor paint is adopted to form marble texture and marble veins, so that the service life of a building is prolonged while the decorative effect of the building is achieved. Meanwhile, the elastic multicolor paint has elasticity at normal temperature through emulsion type selection and an emulsion blending modificationtechnology, and the risks of cracking and peeling of the outer wall can be reduced.

Owner:上海磐彩环保科技股份有限公司

Stirring machine specially used for producing dry-mixed mortar

InactiveCN107253274AEasy to moveEasy to cleanHollow article cleaningCement mixing apparatusRolloverTerrain

The invention discloses a mixer specially used for producing dry powder mortar, which comprises a mixer body and a bottom plate. A stirring rod is arranged inside the mixer body, and a stirring blade is fixed on the outside of the stirring rod. One side of the mixer body is connected with a Cover plate, and the other side of the mixer body is provided with a nozzle installation chamber. In the present invention, a pull ring is installed at one end of the bottom plate, and the purpose of convenient movement can be achieved by pulling the pull ring. In addition, an auxiliary plate is installed on the outside of the bottom plate, which is used to assist the fixing of the bottom plate and prevent the entire device from sliding due to terrain or other reasons. or rollover; there is a deflector installed at the discharge place of the device, and the flow guide through the deflector can avoid side leakage during dumping and avoid waste. At the same time, the deflector can be moved back and forth along the guide rail and fixed. built in to prevent it from getting in the way of other work.

Owner:CHENGDU KECHUANGGU TECH CO LTD

Novel green and healthy home ornament article

InactiveCN109499191AEasy to clean manuallyDispersed particle filtrationTransportation and packagingEngineeringIndoor air

The invention discloses a novel green and healthy home ornament article, and belongs to the field of green home. The novel green and healthy home ornament article comprises a horizontal fixing disc, wherein a through hole is formed in the middle of the horizontal fixing disc; a gas suction device is arranged in the through hole position; a filtering film is arranged on the outer surface of the gassuction device; a filtering screen is arranged on the outer surface of the filtering film; a hollow cover is arranged outside the filtering screen. Firstly, through a reduction pipe, dirty materialsare possibly sucked into the device; then, through purification layer by layer, indoor air is thus purified; meanwhile, the dirty materials in the device can be cleaned and stored in a concentrated way; the artificial cleaning is convenient.

Owner:NANJING YRD ECO DEV RI CO LTD

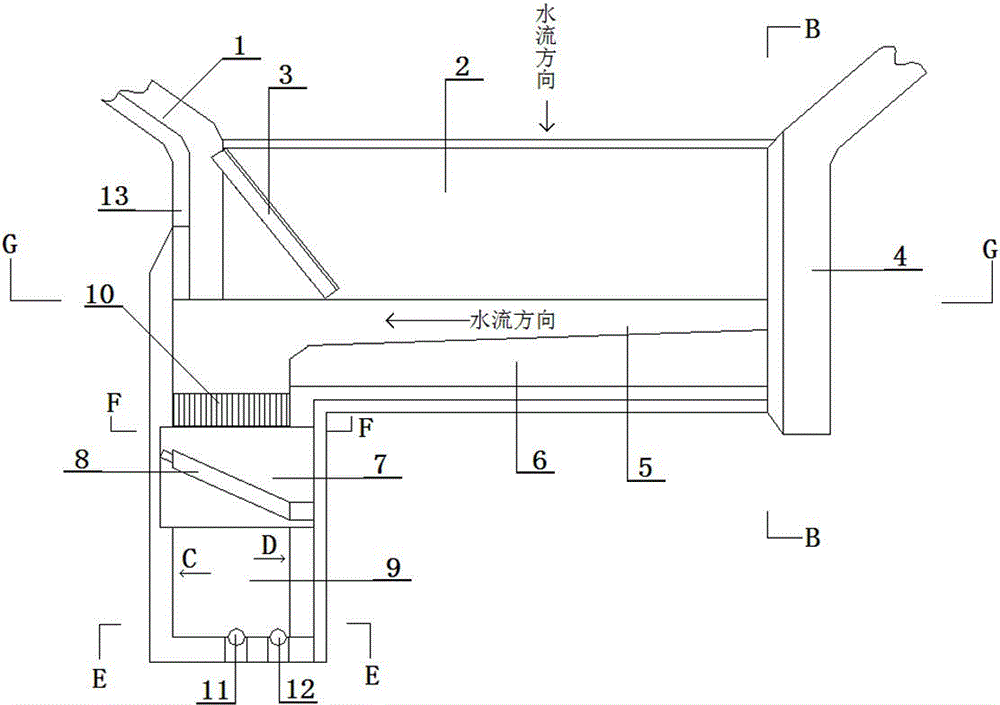

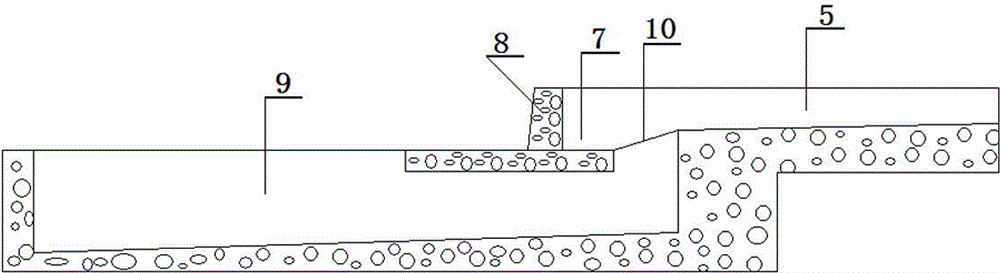

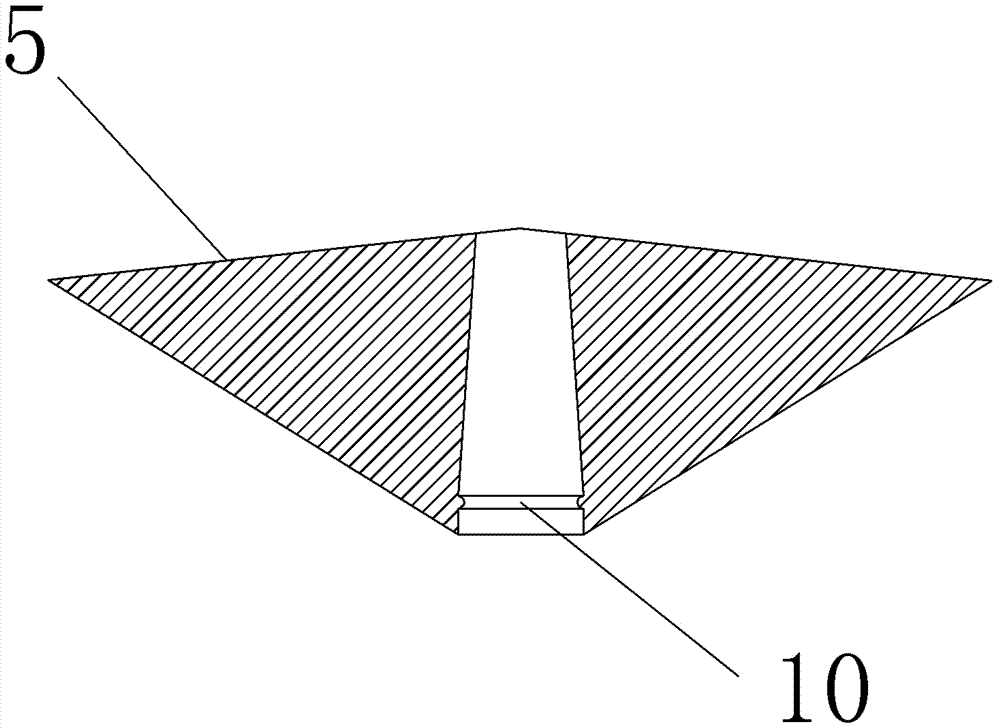

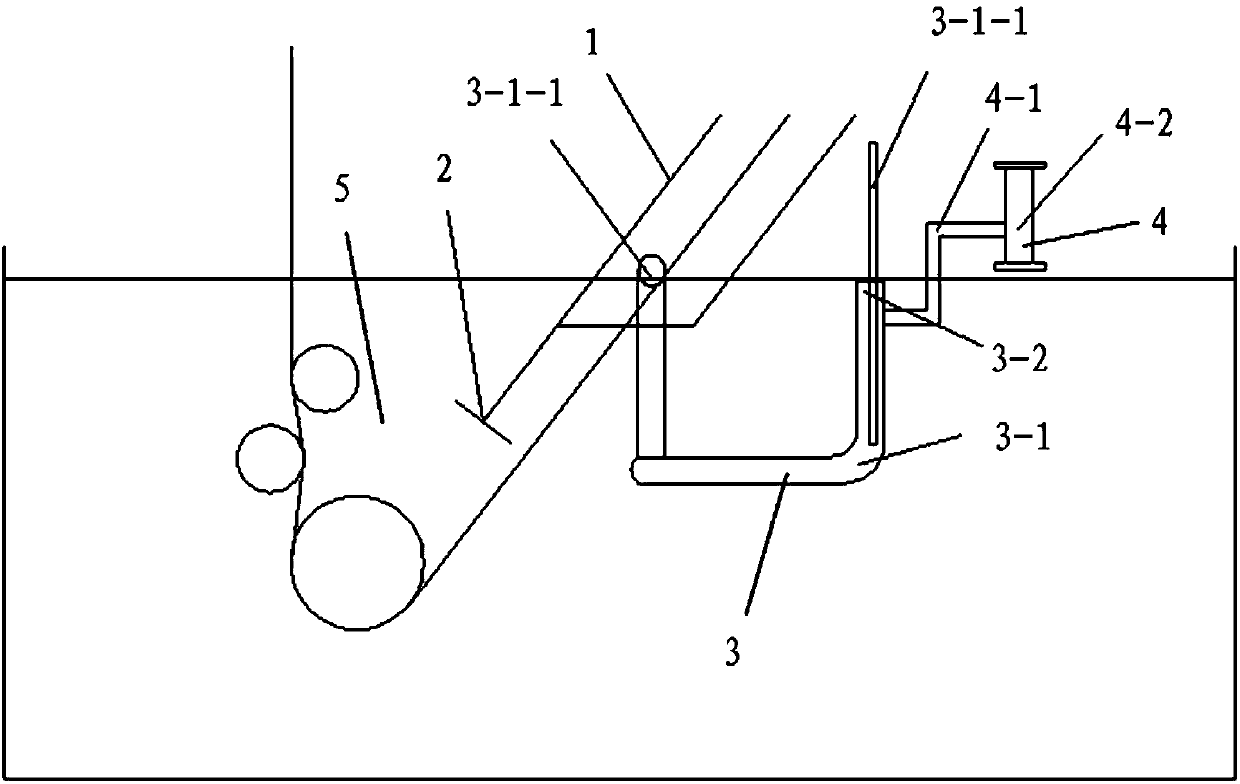

Siltation-preventing water intake facility achieving automatic flood prevention and pollution discharge

InactiveCN104831689AImprove anti-clogging effectEasy to clean manuallyBarrages/weirsTap waterWater flow

The invention discloses a siltation-preventing water intake facility achieving automatic flood prevention and pollution discharge. The siltation-preventing water intake facility comprises a sand flushing slope, an overflow dam, a water collection groove and a setting basin. The sand flushing slope is arranged between connected mountains. A flood-preventing dam is arranged on the left side of the sand flushing slope, the overflow dam is arranged on the right side of the sand flushing slope, a sand turning nozzle is arranged between the sand flushing slope and the flood-preventing dam, the water collection groove is formed in the sand flushing slope in the water flow direction and matched with the sand flushing slope in a bearing mode, an overflow slope is arranged in the direction, parallel to the sand flushing slope, of the water collection groove, the right side of the water collection groove is provided with the overflow dam, the left side of the water collection groove is led to a residue filter bed, the residue filter bed is provided with an overflow groove in the water flow direction and matched with the overflow groove in a bearing mode, a water stop dam is arranged at the front end of the overflow groove, the overflow groove is connected with the setting basin, and the setting basin is provided with a water intake gate and a sand discharge gate. The water intake problems of a mountain river hydropower station, a tap water plant and farm irrigation are fundamentally solved, and the purposes that siltation and blockage are never caused on a water intake dam in the flood period, and natural water intake is achieved in the drought period are achieved.

Owner:杨建能

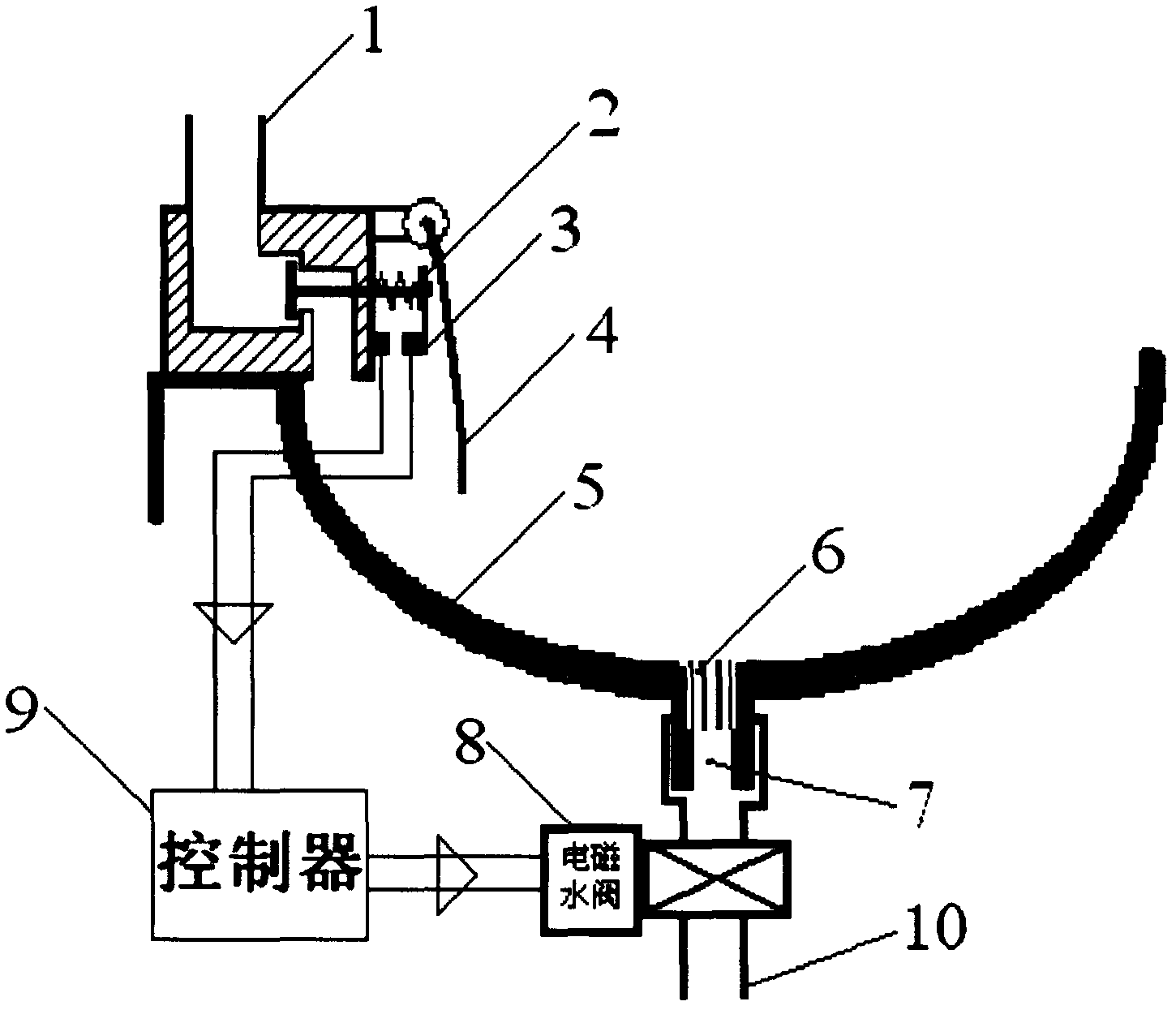

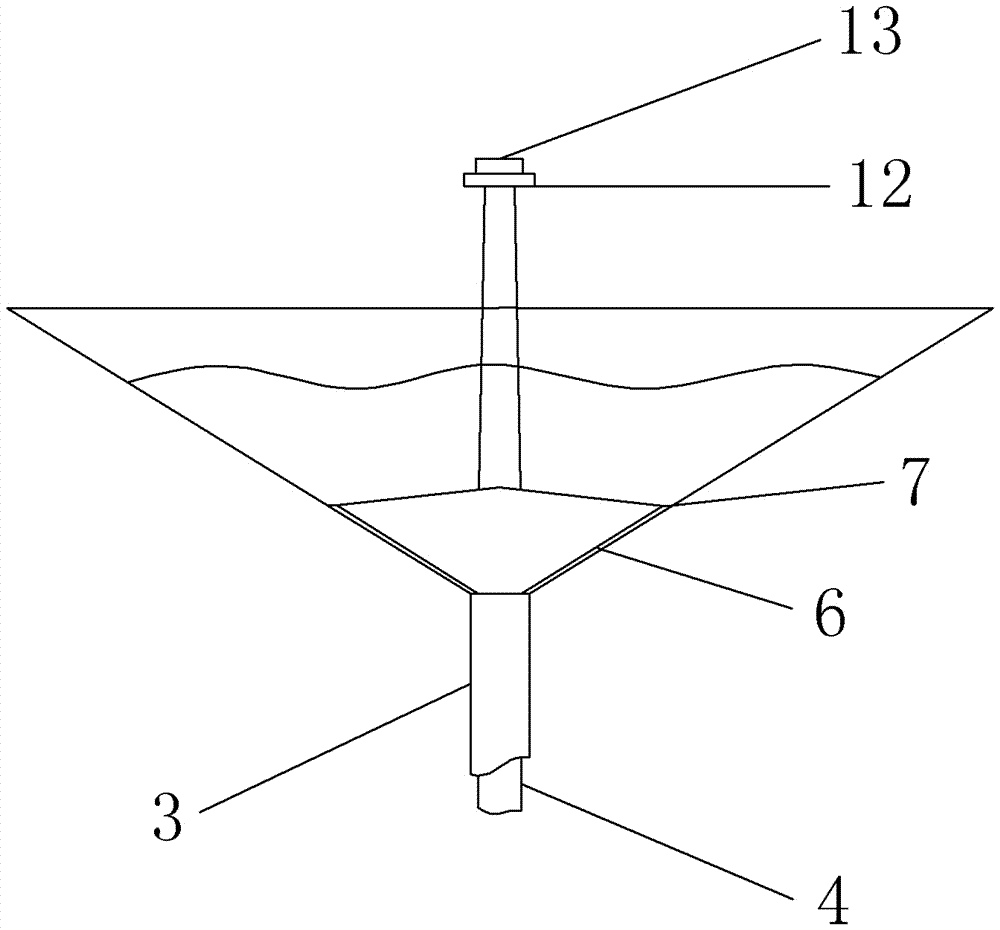

Self-cleaning water-drinking device used for dairy cattle

InactiveCN107094644ANo need for artificial water supplyQuick changeAnimal watering devicesSolenoid valveEngineering

The invention discloses a self-cleaning water-drinking device used for dairy cattle. The self-cleaning water-drinking device comprises a water storage bowl, a water outlet column and a drainage sleeve pipe, wherein the water storage bowl and the drainage sleeve pipe is in detachable connection; the inner cavity of the drainage sleeve pipe is sleeved with a tap water pipe; the water outlet column and the tap water pipe are molded into one piece; the bottom part of the water outlet column is externally sleeved with a water storage part; the interior of the water storage part is provided with a convex ring; the water outlet column is provided with a groove matching with the convex ring; the water storage part adjoins the water storage bowl; a gap channel is arranged between the water storage part and the water storage bowl; an annular filter screen is arranged between the water storage part and the water storage bowl; the top part of the water outlet column is provided with a water spray cake; the water spray cake and the water outlet column are in mutual communication; the upper end of the water spray cake is provided with a water outlet control system which comprises a thermal sensor, a controller and a solenoid valve arranged inside the water spray cake; and the thermal sensor, the controller and the solenoid valve arranged inside the water spray cake are in connection through signal wires. The self-cleaning water-drinking device provided by the invention has simple structure and can effectively avoid deterioration of drinking water from influencing the health of the dairy cattle.

Owner:重庆市长寿区莲莲奶牛养殖场

Method for manufacturing composite type imitation marble coating by colorful stone-like paint

InactiveCN111364710AExtend your lifeAchieve decorative effectCovering/liningsAntifouling/underwater paintsSlurryVarnish

The invention relates to a method for manufacturing a composite type imitation marble coating by colorful stone-like paint. The method comprises the following steps that a, a putty layer is formed ona base material layer of a wall, then a smooth-surface putty layer is formed, and the smooth-surface putty layer is dried, ground and leveled by 240-mesh abrasive paper to form an alkali-resistant permeating primer layer; b, floating coat coating is sprayed for once to form a floating coat layer; c, a thick-slurry type latex paint is sprayed or rolled after drying to form a color point layer; andd, one-channel or multi-channel varnish is sprayed or rolled to form a finish coat. The color point layer is used as an imitation marble main color layer, and is constructed by adopting the colorful stone-like paint for multiple times. The colorful stone-like paint comprises base materials, colorful stone sand particles, water-based resin and addition agents. Compared with the prior art, the stone-like paint is matched with color point layer water-based environmental coatings to form textures with marble textures and marble, a building reaches a decorative effect, and meanwhile, the life of the building is prolonged; and the risk of outer wall cracking and peeling off is reduced.

Owner:上海磐彩环保科技股份有限公司

Mineral water barrel and water drinking device

InactiveCN104192403ASolve the difficulty of handlingSolve the problem of direct drinkingBeverage vesselsLinings/internal coatingsEngineeringWater drinking

Provided are a mineral water barrel and a water drinking device. The mineral water barrel comprises a casing and an inner container. Wheels are arranged at the bottom of the casing, a pull-and-push hand rod and a hand lifting rope are arranged at the upper portion of the casing, and a mineral water outlet is formed in the lateral wall of the casing. A bottle neck is arranged at the upper end of the inner container, a seal bottle cover is arranged on the bottle neck and is in threaded connection with the bottle neck, a ventilating connecting port is formed in the top of the inner container and connected to an air hole in the upper edge of the lateral wall of the casing through a pipeline, a seal cover is arranged on the air hole, wherein the size of the caliber of the seal cover can be adjusted manually, the lower end of an inner container is connected with a hand valve through a connecting port and a pipeline, the hand valve is connected with the mineral water outlet through a pipeline, and the hand valve is arranged on the lateral wall of the casing. The inner container is arranged in the casing, and the position between the inner container and the casing is filled with foam filler. The invention further discloses the water drinking device. The mineral water barrel and the water drinking device have the advantages of being movable, capable of avoiding secondary pollution and the like. In addition, mineral water can be directly drunk.

Owner:陈旆

Disease-preventing breeding method of live pigs

InactiveCN107466964AImprove the effect of disease preventionEffective and healthy growthAntibacterial agentsAntipyreticDiseaseAnimal science

The invention belongs to the technical field of livestock breeding, and particularly discloses a disease-preventing breeding method of live pigs. The invention belongs to the technical field of livestock breeding, and particularly discloses the disease-preventing breeding method of the live pigs. The disease-preventing breeding method of the live pigs comprises the following steps of (1) pigsty building, (2) live pig seedling selection, (3) live pig feeding, wherein disease-preventing fodder is adopted for feeding of the live pigs, and the disease-preventing fodder comprises certain amounts of basal fodder and disease-preventing components, wherein the disease-preventing components comprise certain amounts of Prunella vulgaris L, radix bupleuri, Glycyrrhiza, dandelions, Gardenia jasminoides ellis, cordate houttuynia, fennel and hawthorn; (4) pigsty management. The disease-preventing breeding method of the live pigs starts with combination of improvement of a breeding environment of the live pigs and the green disease-preventing fodder of live pig feeding, and not only is the disease-preventing effect of the live pigs effectively improved, but also the quality of live pig products is guaranteed.

Owner:贵港正邦农牧科技有限公司

Cutting apparatus

ActiveUS9386176B2Easy to clean manuallyElectrographic process apparatusOther printing apparatusComputer engineering

A cutting apparatus includes a housing formed with an insertion hole, a transfer unit configured to transfer an object inserted through the insertion hole, a reading unit configured to read an image of the object, a platen located opposite the reading unit, and a cutting unit. The reading unit includes a light-transmitting plate. The housing encloses the reading unit, the transfer unit, the platen and the cutting unit. The platen includes a part openable and closable so that a surface of the light-transmitting plate is externally exposed. The platen includes a first platen having a flat surface and a second platen which has a flat surface and is opposed to the surface of the light-transmitting plate and is openable and closable. The second platen is engaged with the first platen so that the flat surface of the second platen is flush with the flat surface of the first platen.

Owner:BROTHER KOGYO KK

Electrical cabinet

ActiveCN110165590AAvoid enteringEasy to clean manuallySubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsEngineeringRadiation

The invention discloses an electrical cabinet. The electrical cabinet includes an outer cabinet body and an inner cabinet body, wherein the inner cabinet body is arranged at the middle in the outer cabinet body, the outer cabinet body is provided with an air inlet chamber, the air inlet chamber is internally provided with multiple air holes, each air hole is internally equipped with a micro fan for blowing the air to the air inlet chamber, the middle of a bottom portion of the outer cabinet body is provided with a mounting base, the inner cabinet body is arranged on the mounting base, the other three side surfaces of the inner cabinet body are all provided with heat radiation ports, the bottom of the outer cabinet body at an outer side of the mounting base is provided with a mounting member for mounting a baffle plate, the bottom of the mounting member is fixed at the bottom of the outer cabinet body through screws, an insertion block at a lower end of the baffle plate is fixed in a slot of the mounting member, the outer cabinet body at an outer side of the baffle plate is internally provided with an outer baffle plate, the outer cabinet body is provided with an air hole convex ring having multiple air outlets, and an outer sealing plate is fixed on the air hole convex ring through a screw. The electrical cabinet is advantaged in that simple structure and reasonable design areachieved, fast heat radiation can be achieved, and cleaning of dust in the internal part is facilitated.

Owner:NANTONG CHUNGUANG AUTOMATIC CONTROL EQUIP ENG

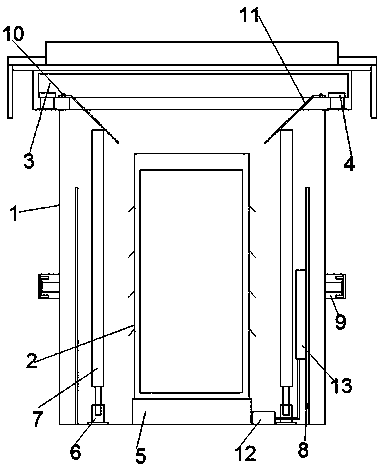

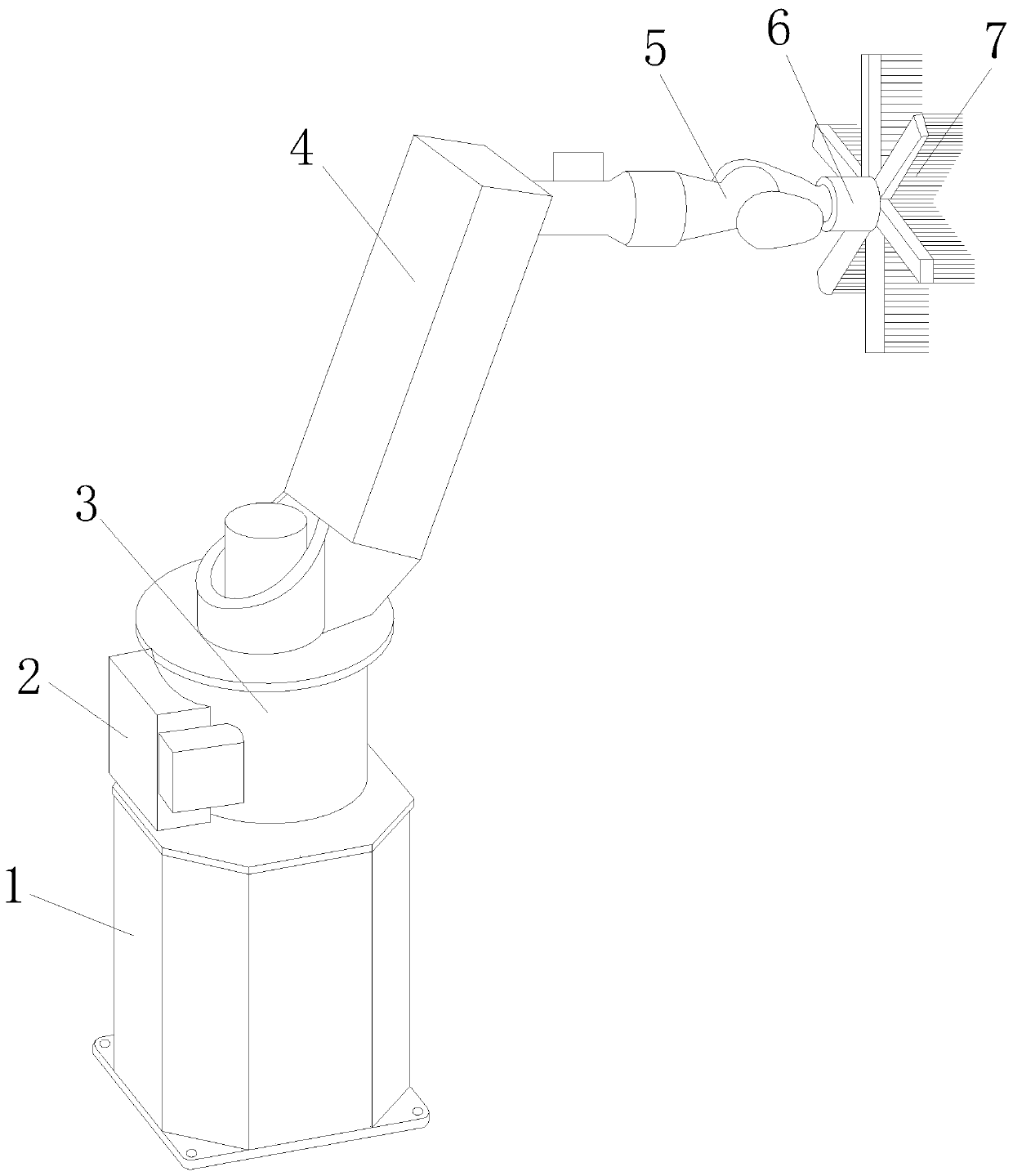

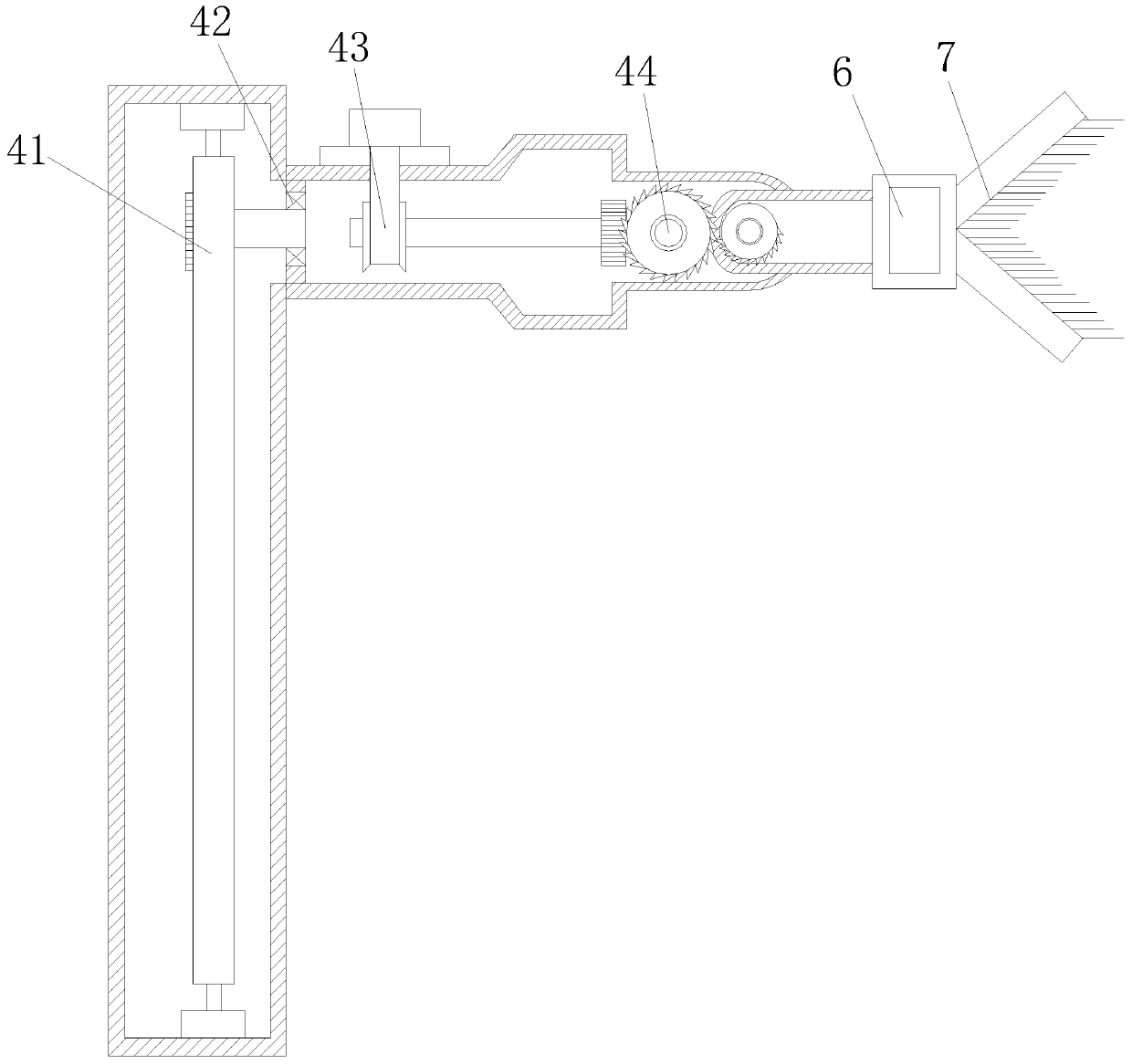

Air conditioner external cleaning device for air conditioning refrigeration equipment

The invention discloses an air conditioner external cleaning device for air conditioning refrigeration equipment. The air conditioner external cleaning device structurally comprises a fixed base, an electric control cabinet, a rotary column, a large arm, a small arm, a rotary driver and a brush. Compared with the prior art, the cleaning device is designed as a mechanical arm type cleaning device,compared with manual labor force, the mechanical cleaning device has the advantages that the time consumed by manual labor is reduced on the basis of the original foundation, the manual labor intensity is effectively reduced, the intelligentization is realized, the cleaning brush is of a star-shaped structure design, effective cleaning of the left and the right surface and the upper end surface outside the air conditioner are realized under the cooperation of a small arm and a large arm, so that comprehensive cleaning of the left end surface and the right end surface of the air conditioner isrealized; meanwhile, the small arm is designed to be folded when the upper end surface of the air conditioner is cleaned, the folding of the small arm is indirectly controlled through an electric cabinet, so that the upper end surface of the air conditioner can be effectively cleaned, the brush has the absorption performance, the brush can be wetted in the cleaning process, and the cleanliness ofthe cleaning is guaranteed.

Owner:黄志民

Glass processing device with automatic trimming function

InactiveCN112847004APrevent fallingAvoid displacementEdge grinding machinesGrinding drivesFixed frameElectric machinery

The invention discloses a glass processing device with an automatic trimming function. The glass processing device comprises a box body, a placing table is bolted to the center of the top of the box body, a lifting positioning mechanism is arranged in an inner cavity of the box body, a controller is bolted to the left side of the box body, and support frames are bolted to the periphery of the top of the box body; and fixing frames are connected to the centers of the front face and the back face of the supporting frame in a bolted mode. Through cooperation of an electric air cylinder, a lifting base and a lifting cylinder, the height of a suction cup can be adjusted, the lifting adjustment requirement of the glass trimming position is met, through cooperation of the suction cup, a suction pump, a hose, a three-way connector and a branch pipe, glass to be trimmed can be strongly and evenly adsorbed and fixed, falling and displacement in the glass trimming process are prevented, and a trimming accident at the glass edge is avoided, and through cooperation of a through groove, a sliding groove, a stepping motor, a lead screw, a threaded sleeve, a sliding rod, a connecting rod, a connecting frame and a trimming grinding roller, trimming operation can be conducted on the edge positions of the front face and the back face of the glass.

Owner:泗阳垠创运营管理有限公司

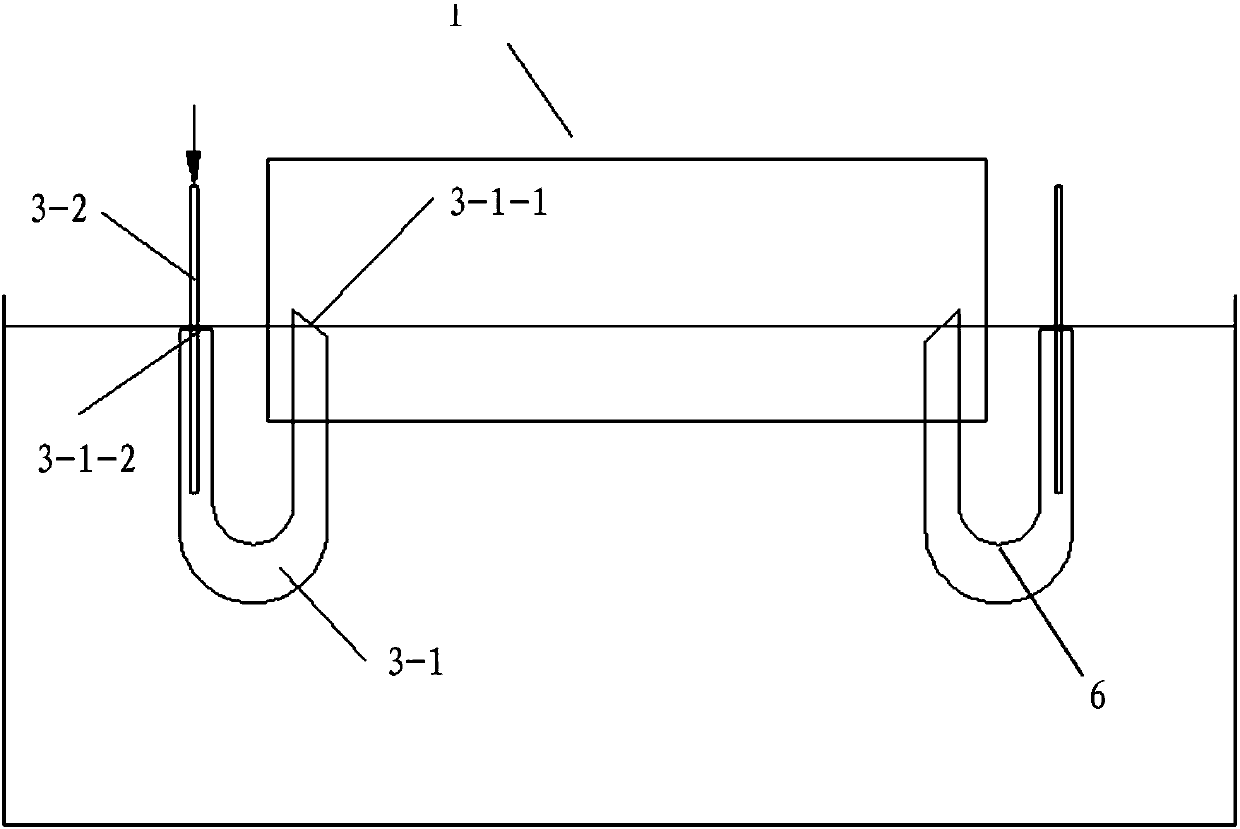

Removing device and method for cadmia in furnace nose of galvanizing line

InactiveCN107675116AEasy to clean manuallyReduce economic costsHot-dipping/immersion processesFailure rateEngineering

The invention discloses a removing device and method for cadmia in a furnace nose of a galvanizing line and belongs to the technical field of hot galvanizing. The removing device for the cadmia in thefurnace nose of the galvanizing line comprises a cadmia resisting plate, a first cadmia extracting mechanism and a second cadmia extracting mechanism, wherein the cadmia resisting plate is connectedwith the furnace nose and arranged in a zinc pot; the first cadmia extracting mechanism is arranged on the operation side of the furnace nose and the edge of the zinc pot, the first end of the first cadmia extracting mechanism is arranged in the furnace nose, and the second end of the first cadmia extracting mechanism is arranged at the galvanizing zinc surface position outside the furnace nose; and the second cadmia extracting mechanism is arranged on the drive side of the furnace nose and on the edge of the zinc pot, the first end of the second cadmia extracting mechanism is arranged in thefurnace nose, and the second end of the second cadmia extracting mechanism is arranged at the galvanizing zinc surface position outside the furnace nose. The removing device and method for the cadmiain the furnace nose of the galvanizing line are simple, reasonable, economical, low in cost and failure rate, high in purification efficiency and suitable for being installed and used on a galvanizingproduction line.

Owner:WUHAN UNIV OF SCI & TECH

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com