Method for manufacturing composite type imitation marble coating by colorful stone-like paint

A technology imitating marble and real stone paint, applied in multi-color effect coatings, coatings, anti-fouling/underwater coatings, etc., can solve problems such as toughness, unfavorable wall decoration effects, etc., to prolong life, smooth and anti-pollution, strong decorative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

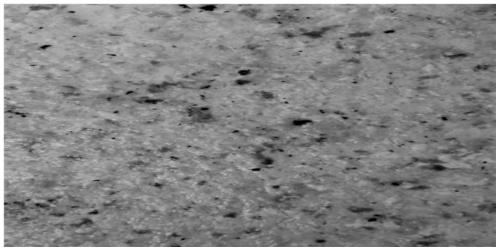

Image

Examples

Embodiment

[0042] A method for making a composite imitation marble coating with colorful real stone paint, comprising the following steps:

[0043] a. Scrape one layer of putty for leveling on the base material layer of the wall to form a putty layer, and then scrape two smooth putty layers to form a smooth putty layer. After the smooth putty layer is dry, sand it with 240-grit sandpaper and roll it Apply an anti-alkali penetration primer to form an anti-alkali penetration primer layer;

[0044] b. Spray the intermediate coating once to form an intermediate coating;

[0045] c. After drying, spray or roll the high-build latex paint to form a color dot layer;

[0046] d. Brush or roll one or more coats of varnish to form a finish layer;

[0047] The color dot layer, as the main color layer imitating marble, is constructed by multi-pass multicolor real stone lacquer paint, which includes base material, colored stone sand particles, water-based resin and additives. The content of each co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com