Tuber type crop excavating harvester

A harvester and tuber technology, applied in the field of tuber crop digging and harvesting machines, to achieve the effects of easy cleaning, improved work efficiency, and reduced clay rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing, the present invention is described in further detail:

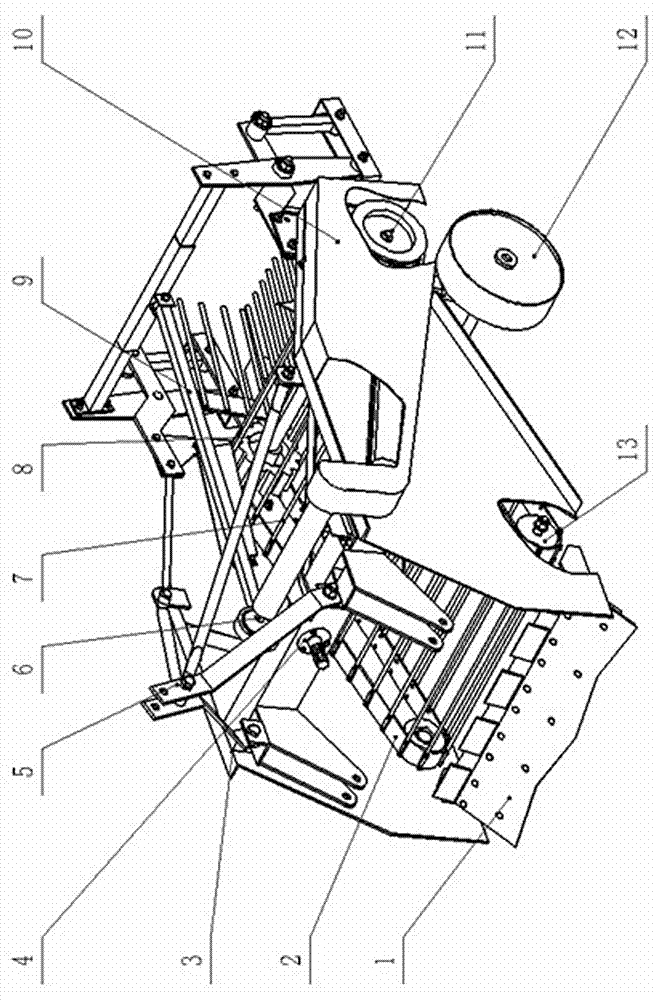

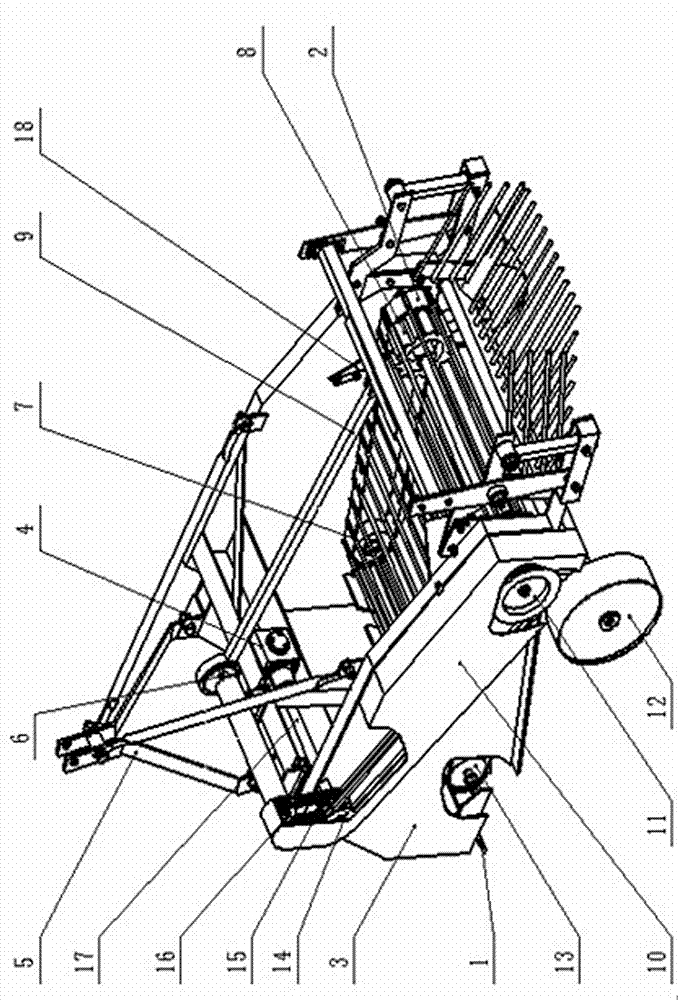

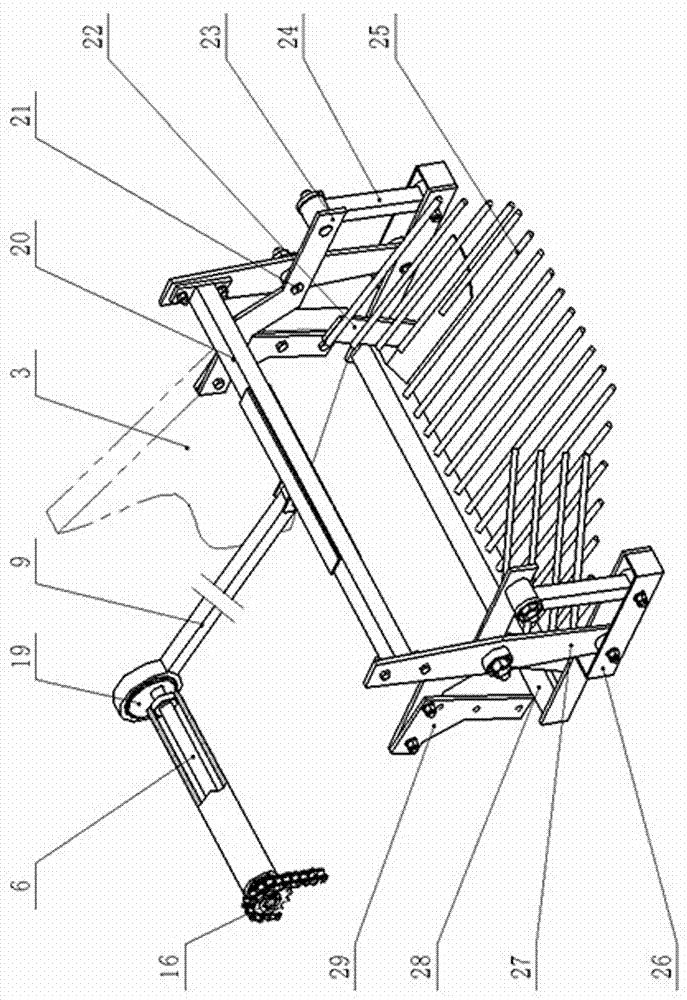

[0022] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a tuber crop digging and harvesting machine includes a digging shovel 1, a frame 3, a reversing gearbox 4, a suspension frame 5, a protective cover 10, a depth-limiting wheel 12, a conveying mechanism, a transmission mechanism and a secondary separation mechanism and other mechanism components. Suspension frame 5 is fixed on the front top of frame 3. The position behind the lower part of the frame 3 is equipped with a depth gauge wheel 12. The rear position of the frame 3 inner side is provided with a welding guide plate 18, and the guide plate 18 is installed above the conveying mechanism. The excavating shovel 1 is fixed at the front bottom of the frame 3, and a conveying mechanism is installed behind the excavating shovel 1, and the conveying mechanism is fixed at the middle bottom of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com