Tank bottom sludge discharging device for oilfield sedimentation tank

A technology of sludge discharge device and settling tank, which is applied to the feeding/discharging device of settling tank, etc., can solve the problems of shortening the service period of filter material, affecting the sewage treatment system, filter material pollution, etc., and achieves quick and convenient sludge cleaning. , the effect of saving water resources and running stably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing:

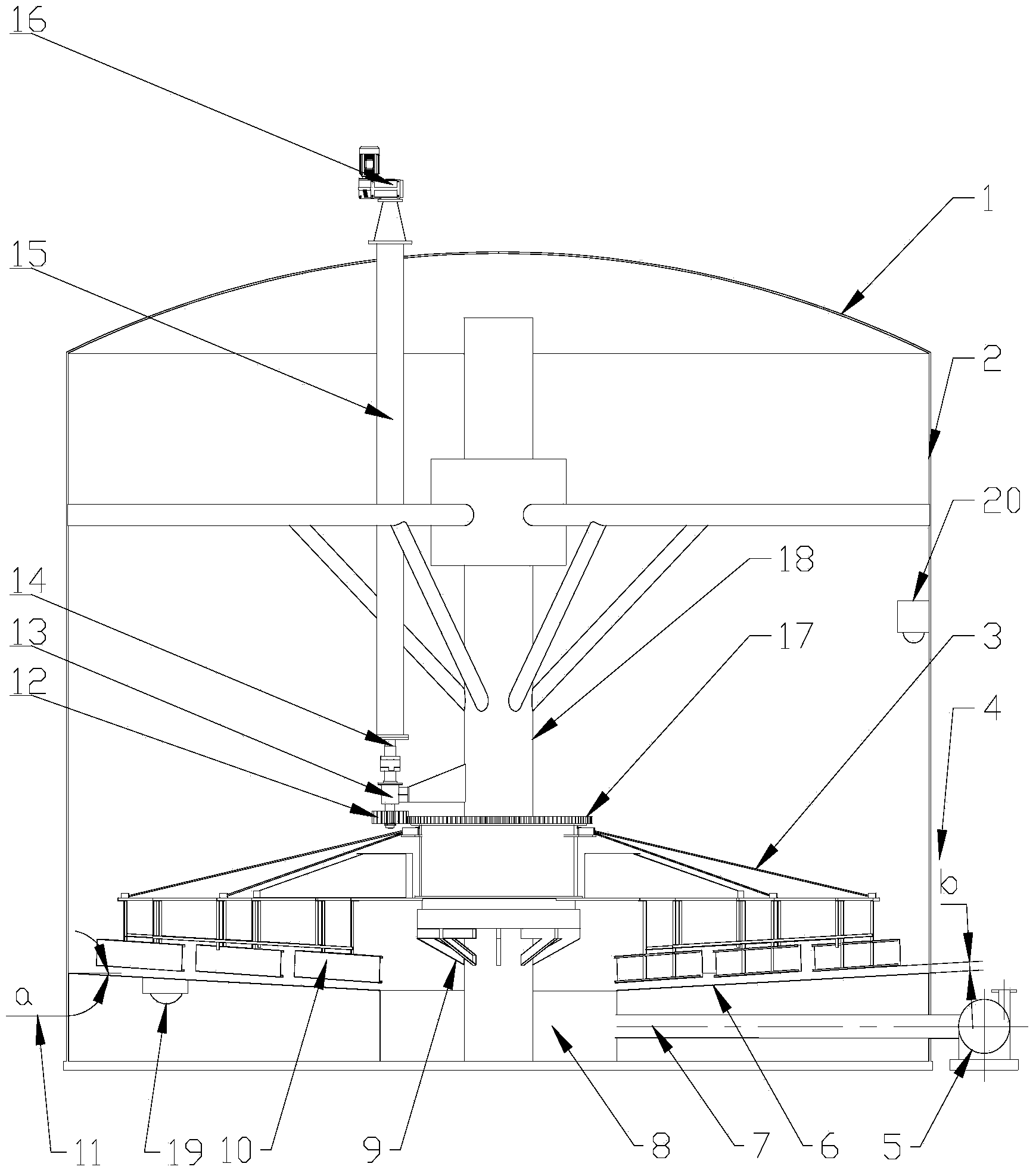

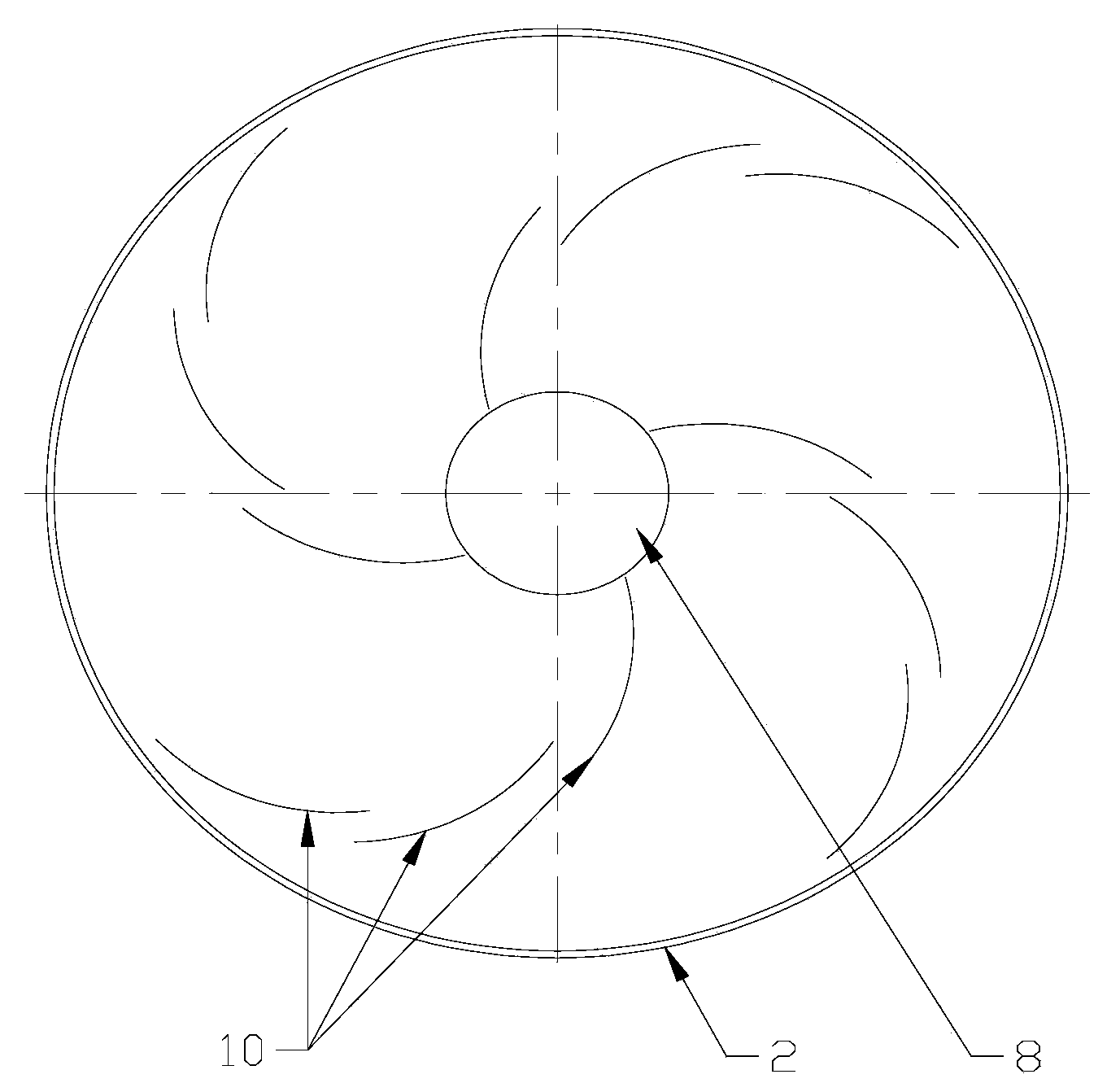

[0015] Depend on figure 1 combine figure 2 As shown, the mud discharge device at the bottom of the oilfield settling tank includes the tank roof 1 and the tank body 2 of the settling tank. The bottom of the tank body 2 is sealed and connected to a mud bearing bottom plate 6 along the inner wall of the tank body 2. The mud bearing bottom plate 6 is in a centripetal direction It is a circular steel plate in the shape of a downhill. There is a round hole in the center of the mud bearing bottom plate 6. The round hole elevation and the bottom plate of the settling tank are welded into a cylindrical mud collection chamber 8 with steel plates. The barrel wall of the mud collection chamber 8 is opened. There are through holes, which are airtightly welded with the mud discharge pipe 7. The mud discharge pipe 7 extends out of the tank body 2 and is connected to the inlet of the mu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| velocity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com