Water sealing device

A water sealing and water tank technology, which is used in the sealing of engines, treatment of discharged materials, furnaces, etc., can solve the problems of sintered ore water tanks being blocked, falling into the water tank, and the opening of the water tank being exposed to the outside, so as to avoid environmental pollution and avoid sedimentation. , the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

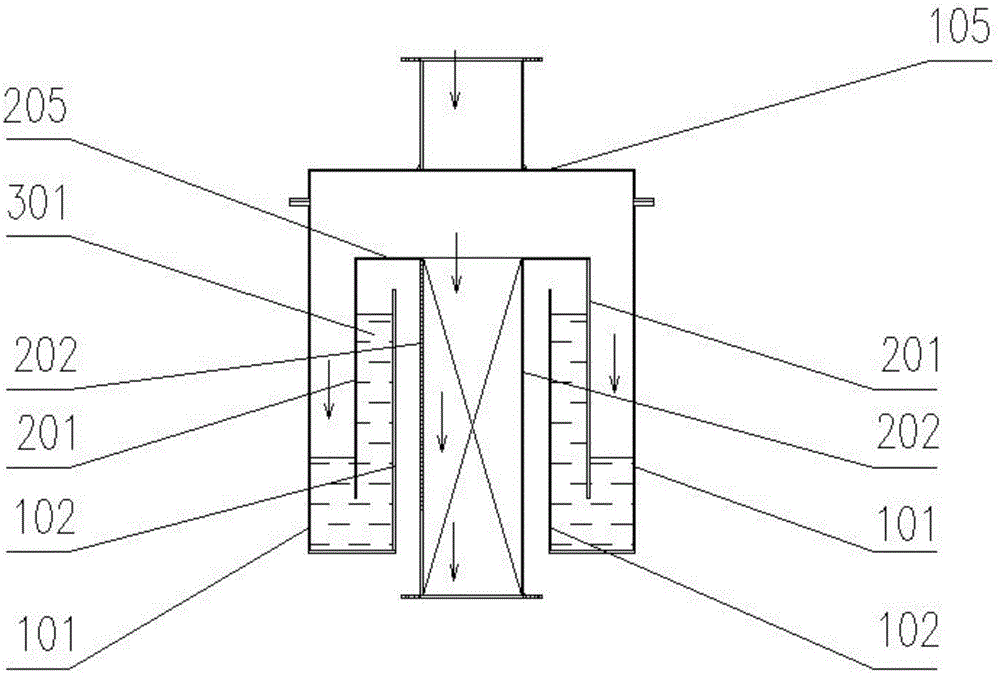

[0017] Such as Figure 1 to Figure 2 As shown, the annular upper sealing cover 105 is provided with an air inlet and is connected with the annular air inlet pipe 5. The two groups of sides of the annular upper sealing cover 105 are respectively vertically connected with the still water tank outer ring plate 101, and the two sets of still water tank outer ring plates 101 There are two sets of still water tank inner ring plates 102 arranged between them, the bottom side of the still water tank inner ring plate 102 is set at the same height as the bottom side of the still water tank outer ring plate 101, the still water tank inner ring plate 102 and the adjacent still water tank ring plate 102 The bottom side of the outer ring plate 101 of the water tank is jointly connected to the annular bottom plate to form two ring-shaped water tanks containing the sealing medium 301,

[0018] A set of sealing plates 201 are respectively inserted into the sealing medium 301 of the two still w...

Embodiment 2

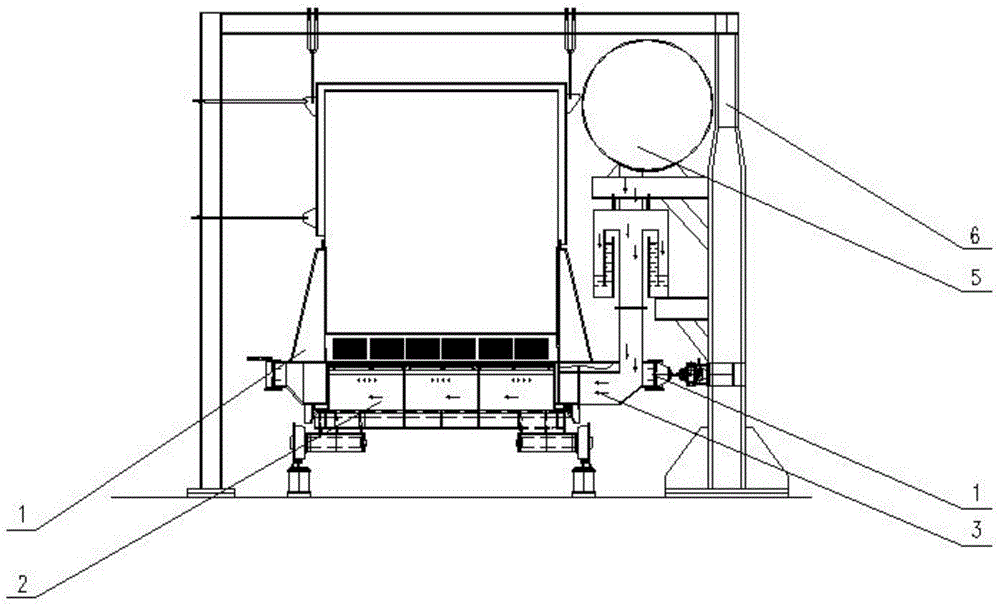

[0020] In the present invention, the static water tank can also be fixed on the frame 6 of the annular cooler to ensure the stability of the water tank, and the air duct can be fixed on the revolving frame 1 of the trolley to ensure the stability of the air duct movement.

Embodiment 3

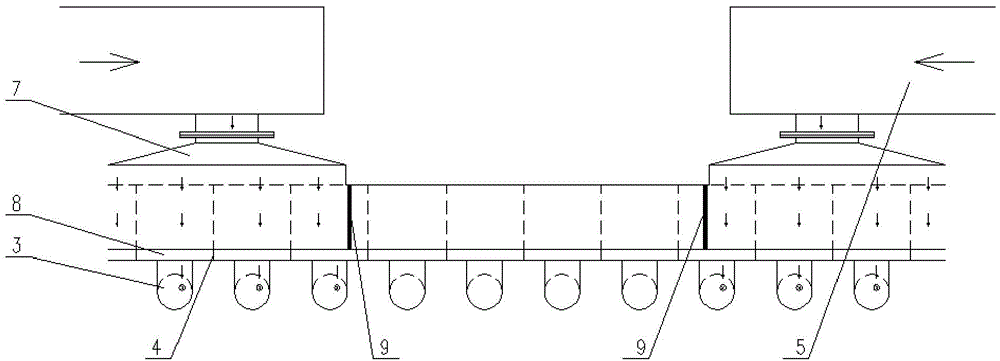

[0022] Such as image 3 As shown, in order to prevent the cooling air in the cooling section from entering the ore feeding and unloading section through the air duct to communicate with the atmosphere and obtain a better sealing effect, the sealing cover 105 on the still water tank can be provided with an air inlet in the cooling section of the ring cooler. The ore feeding and unloading section is a closed flat plate, and the end seal 9 is set at the ore feeding place and the ore unloading place of the static water tank, and the air duct partition 4 is set between the two groups of air inlet trough plates to connect the corresponding parts of each trolley. The air duct is divided and sealed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com