Mine water-inrush treatment multiplex system and treating method thereof

A technology for mine water gushing and treatment methods, applied in mining wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of shortening the service life of gobs, industrial water hazards, unsuitable use, etc. problems, to achieve good water purification effect, prolong the service life and save energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

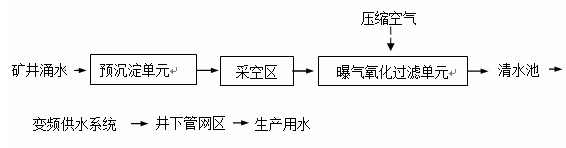

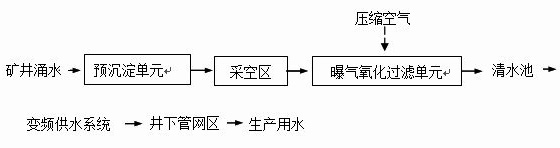

[0030]Embodiment 1: The mine water gushing treatment and reuse system includes a pre-sedimentation unit, a goaf, an aeration oxidation filter unit, a clear water tank, a frequency conversion water supply system and an underground pipe network area connected in sequence, and the production line is drawn from the underground pipe network area. use water. The bottom of the pre-sedimentation unit is laid with a light rail for the movement of the sedimentation mine car. The filter material of the aeration oxidation filter unit is natural manganese sand or quartz sand.

[0031] The method for using the system to treat mine water gushing includes the following steps:

[0032] 1) Mine gushing water is guided into the pre-sedimentation unit and drawn out after staying in the pre-sedimentation unit for 4-24 hours to remove larger suspended solids in the water, so that the suspended solids in the water drawn from the pre-sedimentation unit are less than <200mg / L;

[0033] 2) The water ...

Embodiment 2

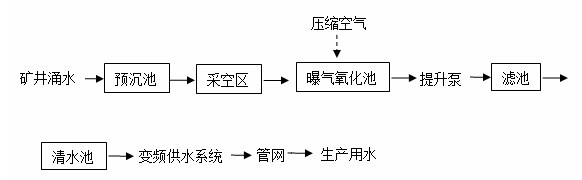

[0036] Embodiment 2: The mine water gushing treatment reuse system includes a pre-sedimentation unit, a gob, an aeration oxidation filtration unit, a filter tank, a clear water tank, a frequency conversion water supply system and a pipe network connected in sequence, and the aeration oxidation treatment unit is treated. The mine gushing water flows into the clear water pool after being lifted by the lift pump. The bottom of the pre-sedimentation unit is laid with a light rail for the movement of the sedimentation mine car. The filter material of the aeration oxidation filter unit is natural manganese sand or quartz sand.

[0037] The water gushing in a coal mine has been stable at 350-550m 3 / h, the maximum amount of reused water in the well is 200 m 3 / h, the influent and effluent water quality of the treatment reuse system is shown in Table 1. The mine water flows into the pre-sedimentation tank by itself. The pre-sedimentation tank is 3 arch-shaped roadways with a width o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com