Combined type filter vat component

A combined type and filter barrel technology, which is applied to loose filter material filters, filter separation, gravity filters, etc., can solve the problems of inconvenient polar filter material molecular sieve, filter material pollution, and raw water pretreatment, etc., to achieve Facilitate manual cleaning and reduce pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0029] Implementation mode 1: Rural household molecular sieve defluoridation water purifier with combined filter barrel

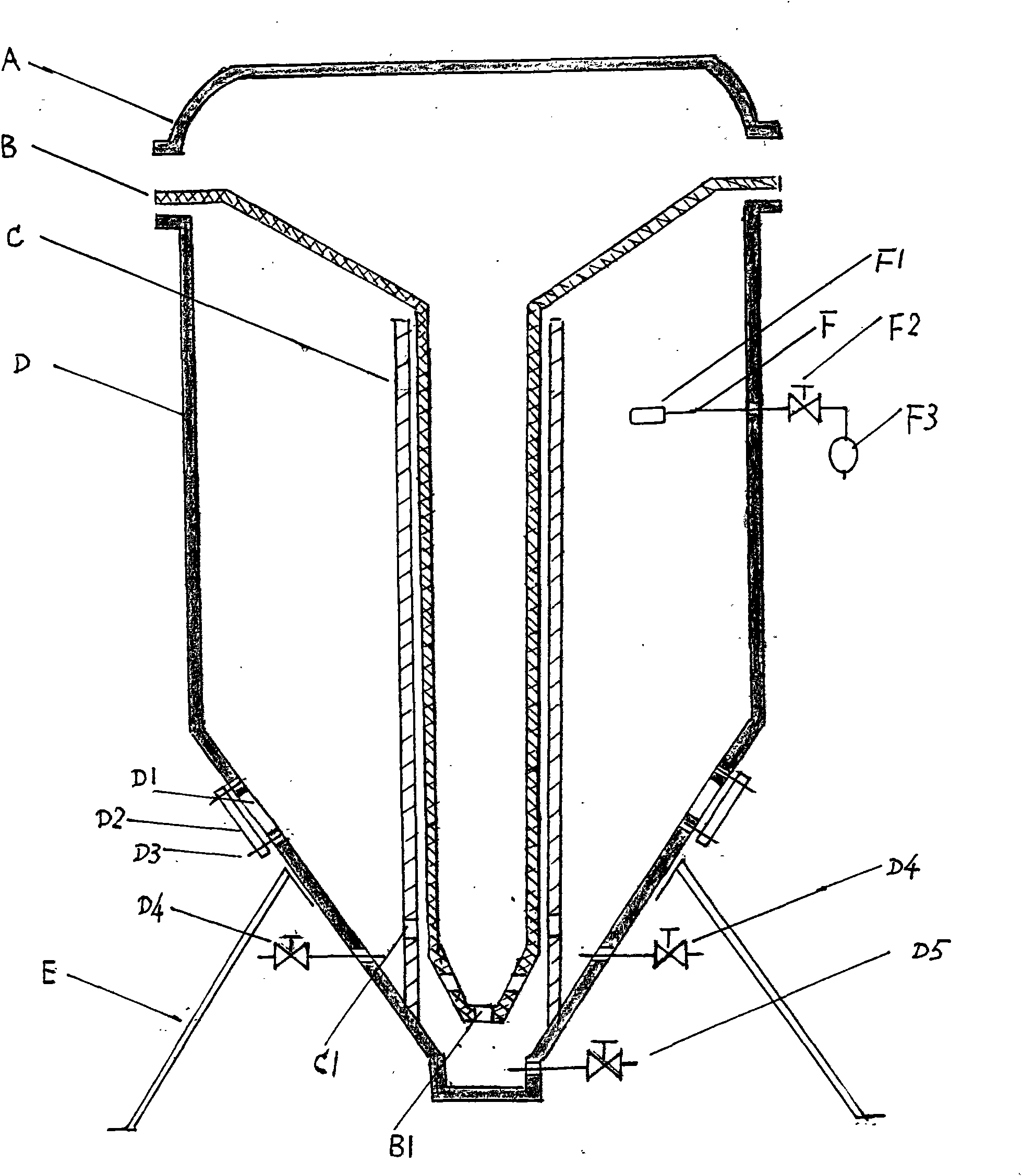

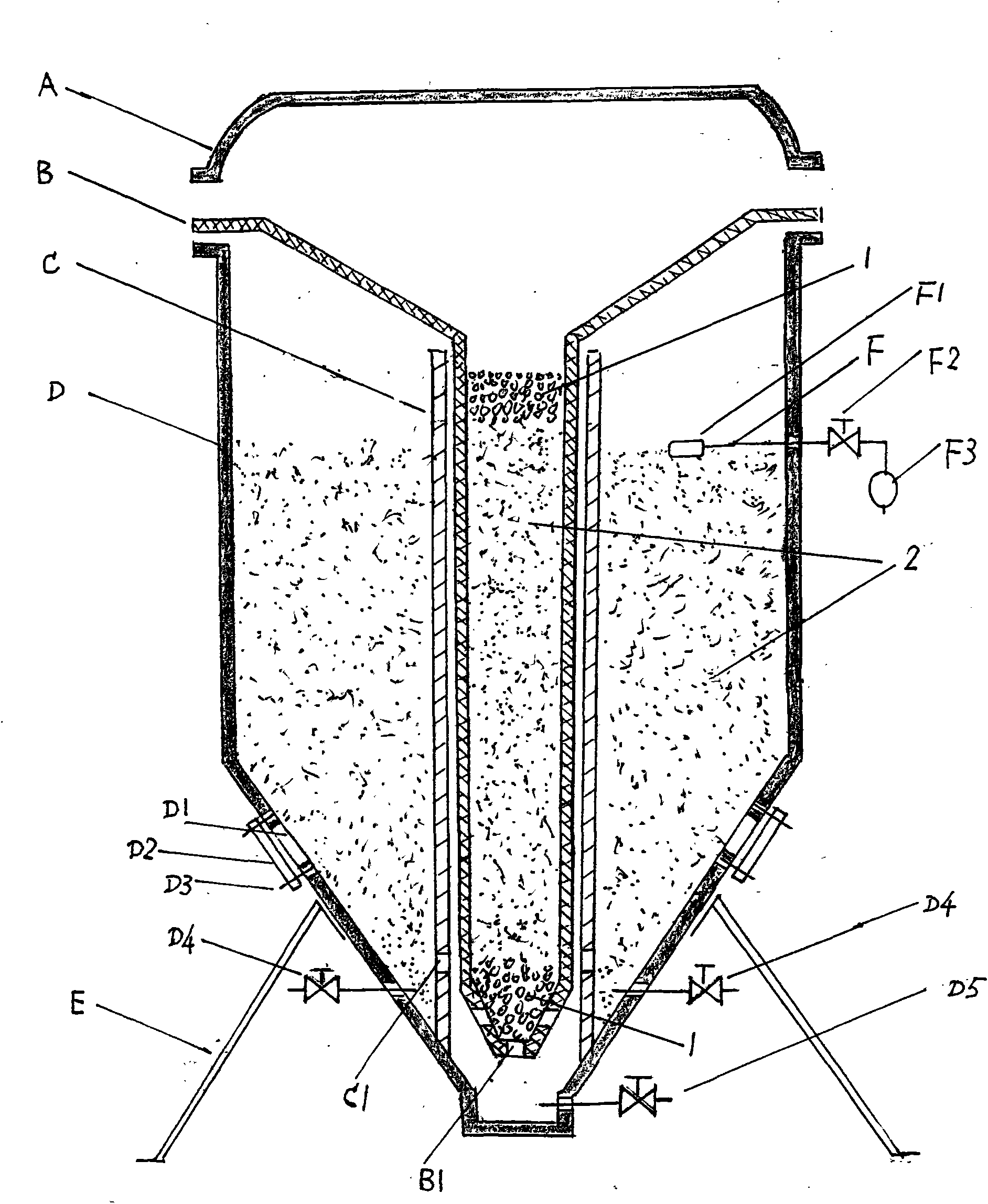

[0030] 1. The assembly method of the filter bucket: ① Since the fluorine-removing molecular sieve filter material loaded in the main processor (D) at this time requires the raw water to run countercurrently from bottom to top, the water flow direction control pipe (C) is densely covered with water outlet holes ( One end of C1) should be sealed and connected with the conical lower part of the main processor (D); ②The remaining part after the main processor (D) is filled with fluorine-removing molecular sieve filter material (2) is the place to store clean water , for this reason, a group of water purification pipelines (F) should be installed on the top of the filter material with common parts; ③In general, the filter material in the preprocessor (B) is composed of fiber balls (1) and the main processor (D The fluorine-removing molecular sieve filter materia...

Embodiment approach 2

[0039] Embodiment 2: Coagulation and flocculation device with combined filter tank

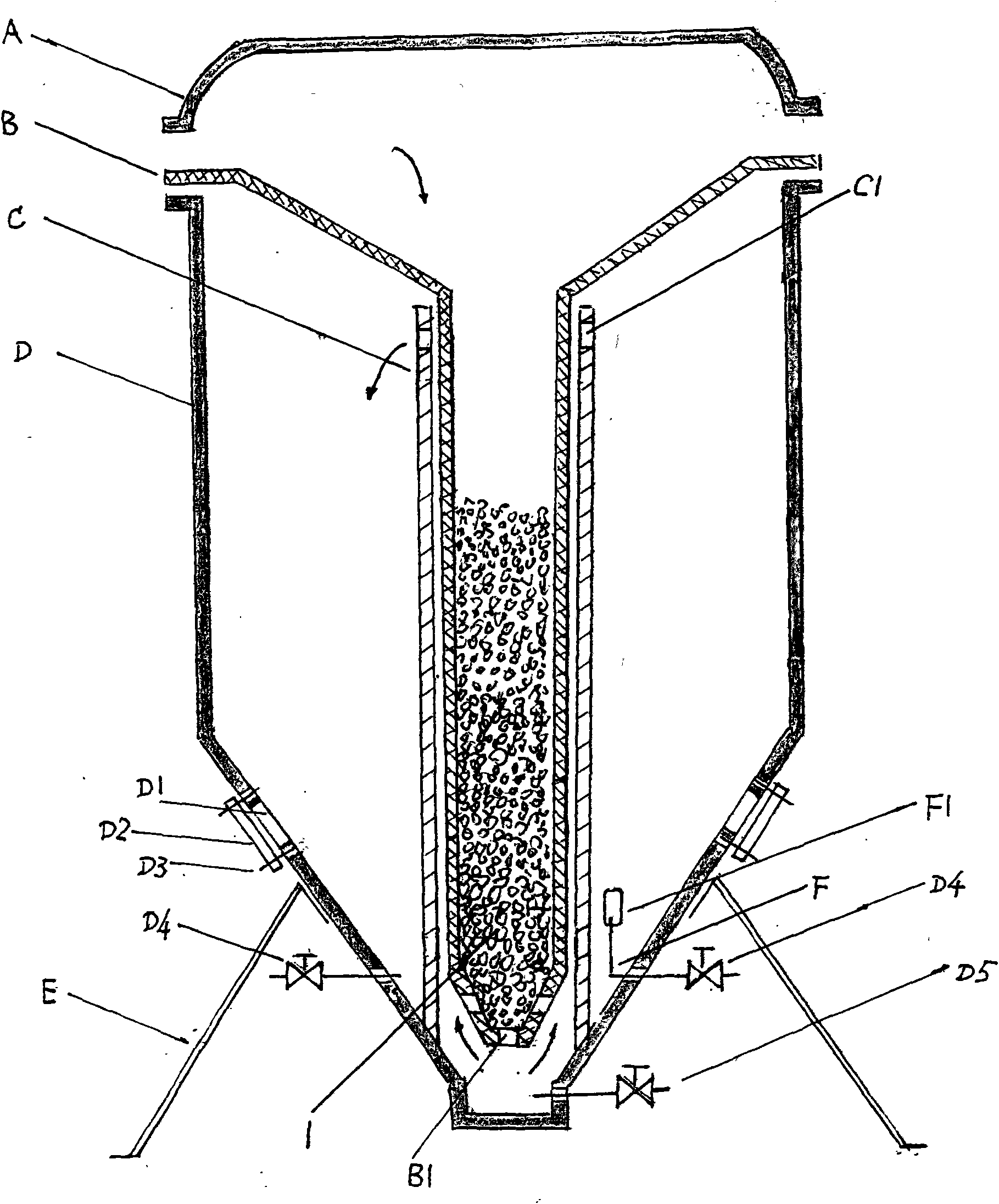

[0040]1. The assembly method of the filter bucket: ① Since the main processor (D) is used as a coagulation and flocculation bucket at this time, the raw water is required to run downstream from top to bottom, so the water flows to the control pipe (C) without water outlet holes. One end should be sealed and connected with the conical lower part of the main processor (D); ②At this time, no filter material is filled in the main processor (D), in order to use the drain faucet (D4) at the lower conical part as the clear water formed after flocculation Install a water distributor (F1) above the water inlet of the drain tap (D4); ③ An appropriate amount of fiber balls (1) can be placed in the preprocessor (B), thus producing image 3 The coagulation flocculator shown;

[0041] 2. The water treatment process flow of the coagulation flocculator: put the disinfection sheet and flocculant into the filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com