High-speed digital energy-saving forming machine and forming method thereof

An energy-saving, molding machine technology, applied in the molding machine and its molding field, can solve the problems of large amount of compressed air, slow cooling speed, easy blockage of feeding materials, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

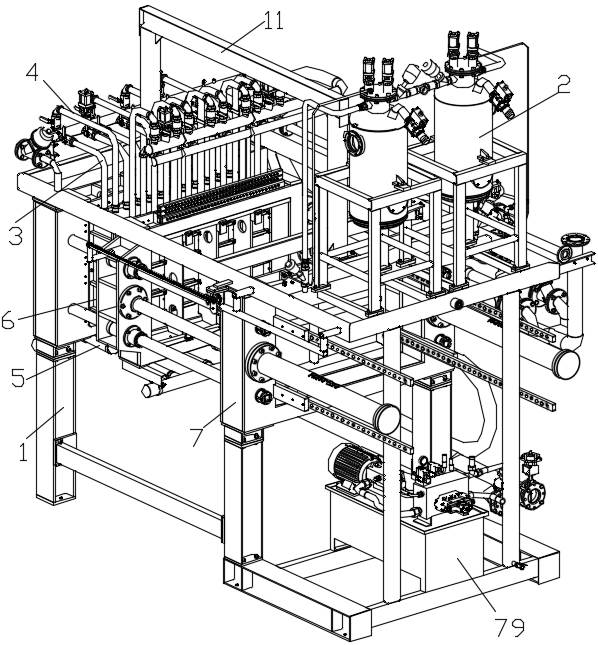

[0056] see Figure 1 to Figure 15 , the high-speed digital energy-saving molding machine in this embodiment includes a frame 1, a feeding device 2, a curing device 3, a cooling device 4, a discharge device 5, a mold frame 6 and a translation device 7; the feeding device 2 passes through the material gun It is connected with the mold frame 6; the frame 1 is also provided with a hanging mold frame 11; the hanging mold frame 11 is connected with the mold frame 6. The hanging mold frame 11 has an upward pulling force on the mold frame 6. Since the mold frame 6 and the translation device 7 are connected in the horizontal direction, the translation device 7 does not support the mold frame 6 in the vertical direction. The frame 11 can make the structure more stable.

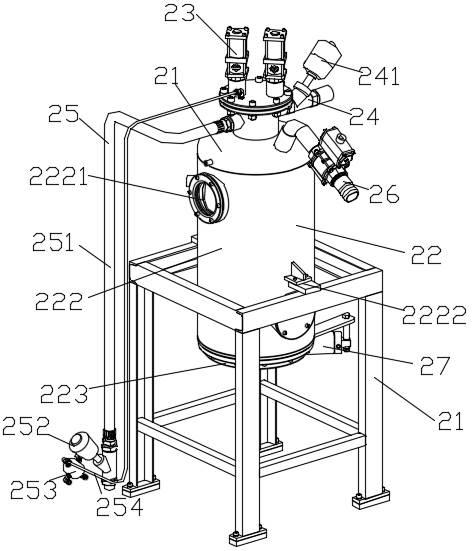

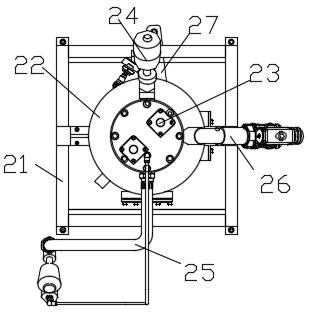

[0057] The feeding device 2 in the present embodiment comprises a bucket frame 21, a feed bucket 22, a vent valve 23, a negative pressure valve 24, a pressurizing mechanism 25, a feed pipe 26 and a cylinder 27; the buc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com