Cone crusher with on-line temperature monitoring function

A cone crusher and functional technology, applied in the field of hydraulic cone crushers and cone crushers, can solve the problems of undetectable point data monitoring, temperature and pressure sensors cannot be installed, unfavorable equipment service life, etc., and achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

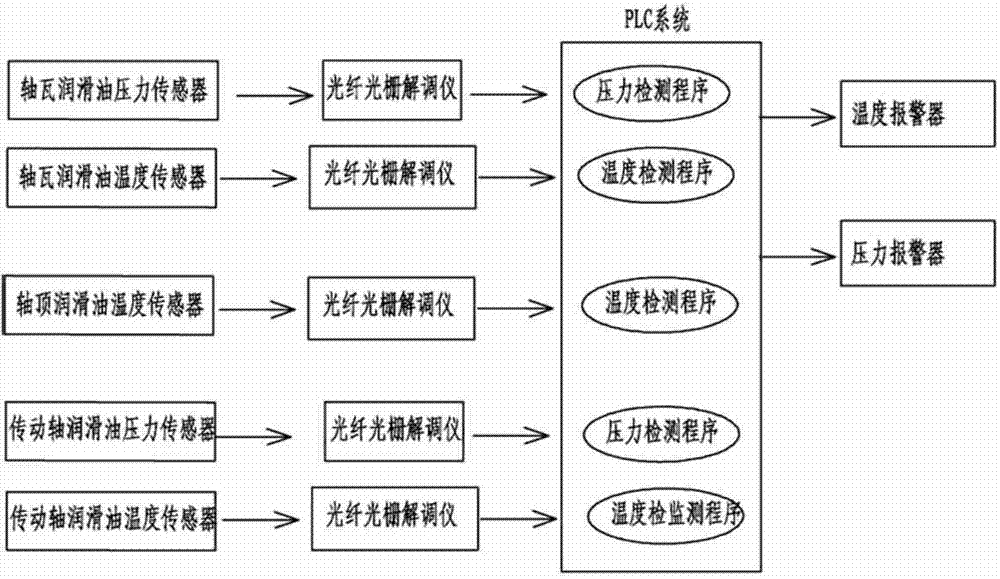

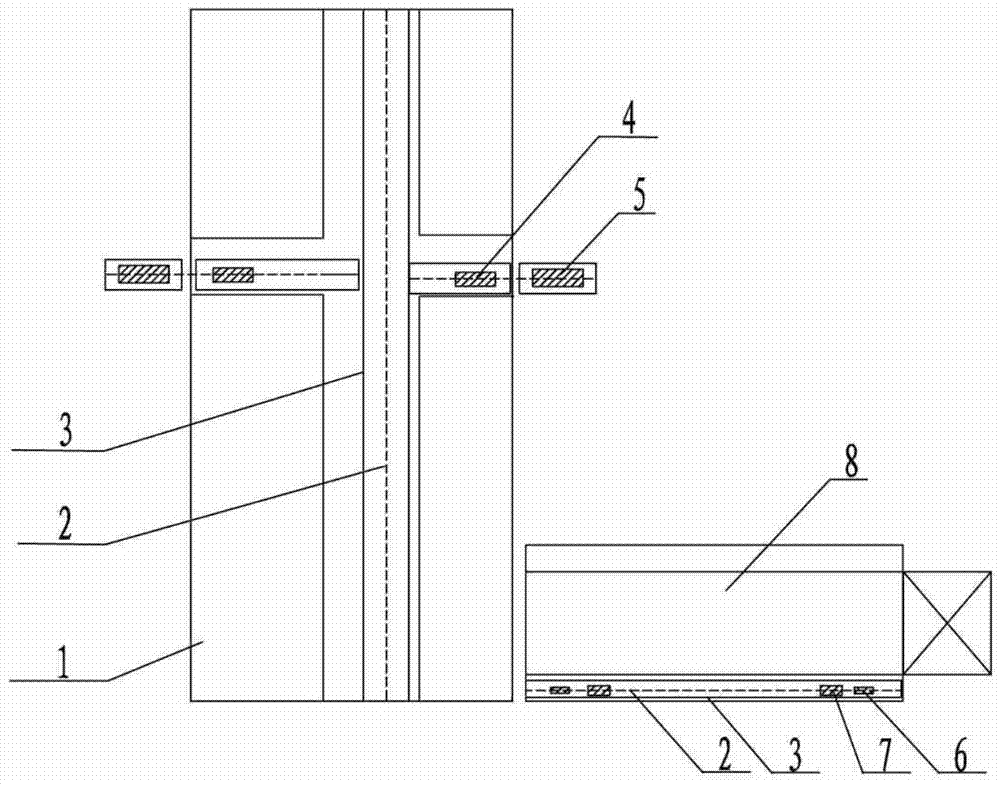

[0014] like figure 1 , figure 2 As shown, the cone crusher with on-line temperature monitoring function of the present invention includes a PLC system, which is characterized in that the PLC system is respectively connected with a temperature alarm, a pressure alarm, and an optical fiber grating demodulator. Through the optical fiber 2, the instrument is respectively connected with the bearing bush lubricating oil temperature sensor 4 and the bearing bush lubricating oil pressure sensor 5 arranged next to the bearing bush of the main shaft 1 of the cone crusher, the shaft top lubricating oil temperature sensor arranged on the top of the main shaft 1 of the cone crusher, and the shaft top lubricating oil temperature sensor arranged on the cone crusher The transmission shaft lubricating oil temperature sensor 6 on the crusher transmission shaf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com