A system and method for abnormal pressure monitoring during pipe expansion

A pressure monitoring and pressure technology, applied in safety equipment, manufacturing tools, metal processing, etc., to achieve accurate results, improve production efficiency, and prevent product quality problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to further understand the features, technical means, and specific objectives and functions achieved by the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

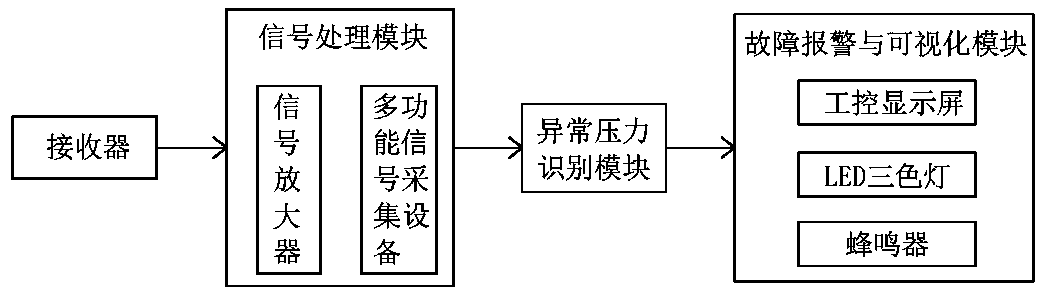

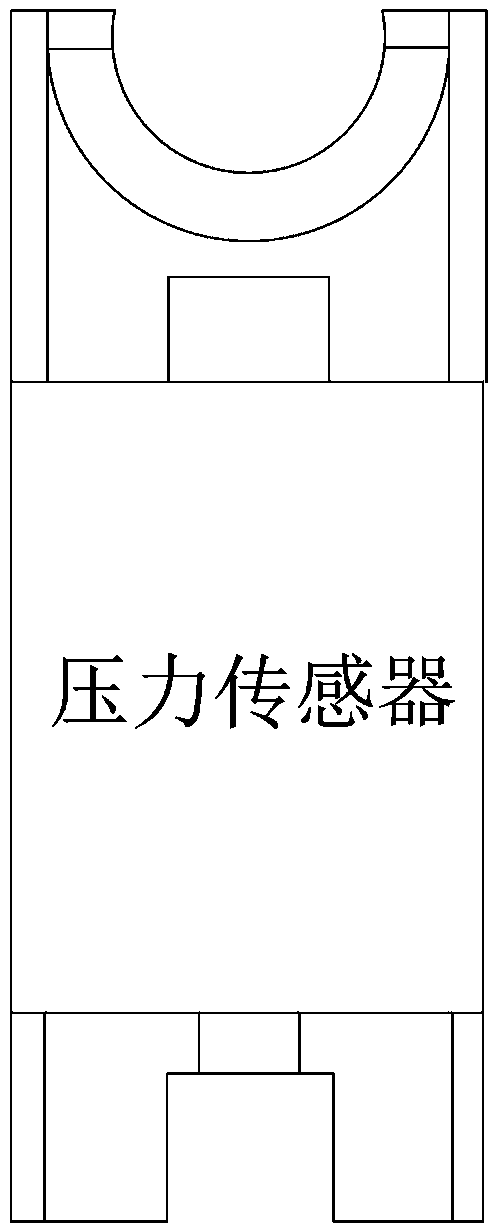

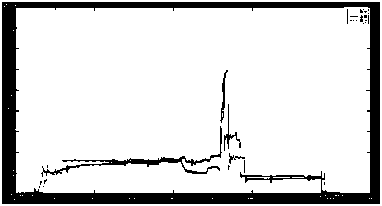

[0037] as attached figure 1 and 2 As shown, the present invention discloses an abnormal pressure monitoring system used in the process of tube expansion, the system includes: a receiver with pressure detection function, set at the bottom of a single U-shaped copper tube, used to measure the pressure of a single U-shaped copper tube The pressure value of the type copper tube; the signal processing module is used to precisely amplify the output signal of the sensor, and convert the mechanical quantity into a standard voltage signal, which is built in the industrial computer; the abnormal pressure identification module is used to identify the process of expanding the tube. The abnormal pressure value of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com