Waveguide aerator

An inflator and waveguide technology, applied in the direction of electrical components, antenna parts, circuits, etc., to reduce the difficulty of installation, prolong the service life, and save product costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

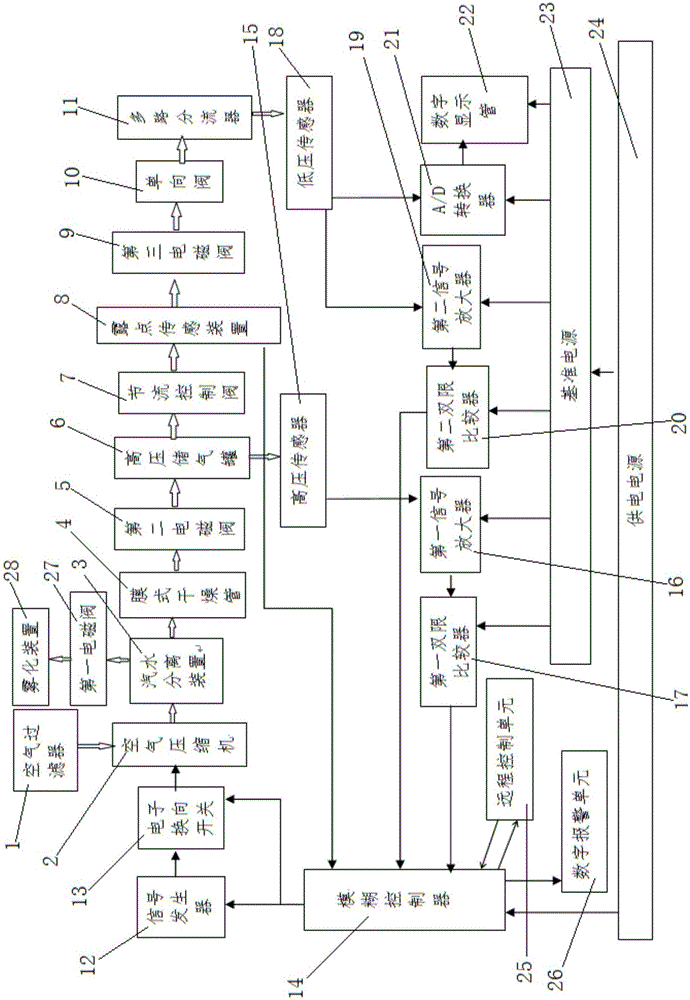

[0021] The structure of a waveguide inflator provided by the present invention is as follows: figure 1 As shown, it includes an air filter 1, an air compressor 2, a steam-water separator 3, a membrane drying pipe 4, a second solenoid valve 5, a high-pressure gas storage tank 6, a throttle control valve 7, and a dew point sensor connected in sequence 8. The third solenoid valve 9, the one-way valve 10 and the multi-way shunt 11, the air compressor 2 is also connected to the electronic reversing switch 12 and the signal generator 13 in sequence, and the electronic reversing switch 12 and the signal generator 13 are connected together There is a fuzzy controller 14, and the high-pressure gas storage tank 6 is also connected with a high-pressure sensor 15, a first signal amplifier 16 and a first double-limit comparator 17 in sequence, and the mul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com