Pressing structure for correcting warping of plastic package flat plate and semiconductor device

A semiconductor and flat-panel technology, used in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as adverse effects, impact on service life or performance, and achieve the effect of ensuring thermal insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

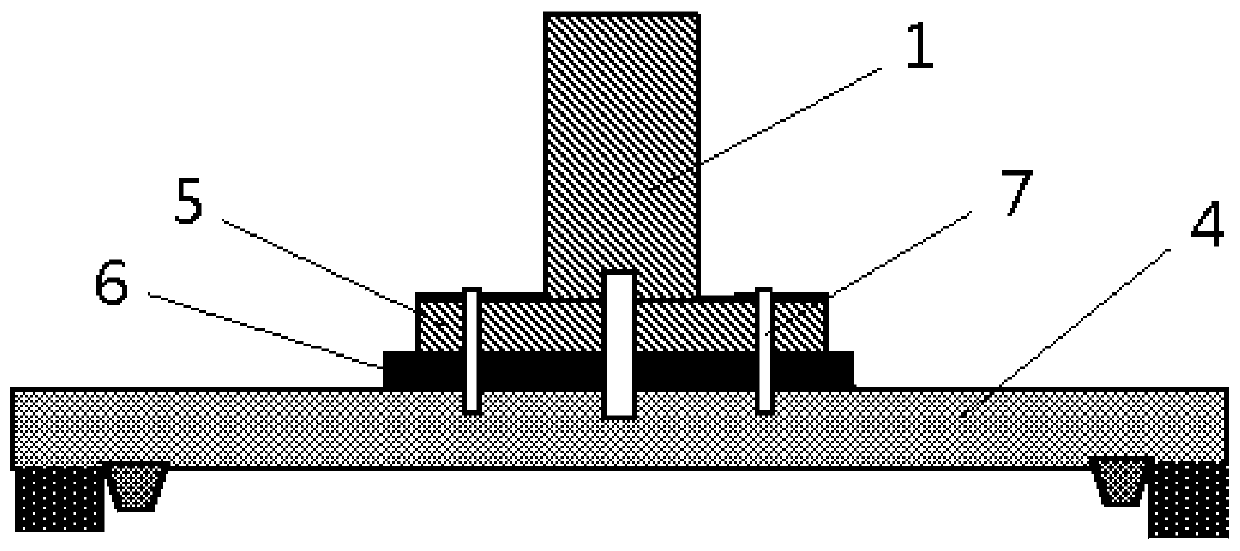

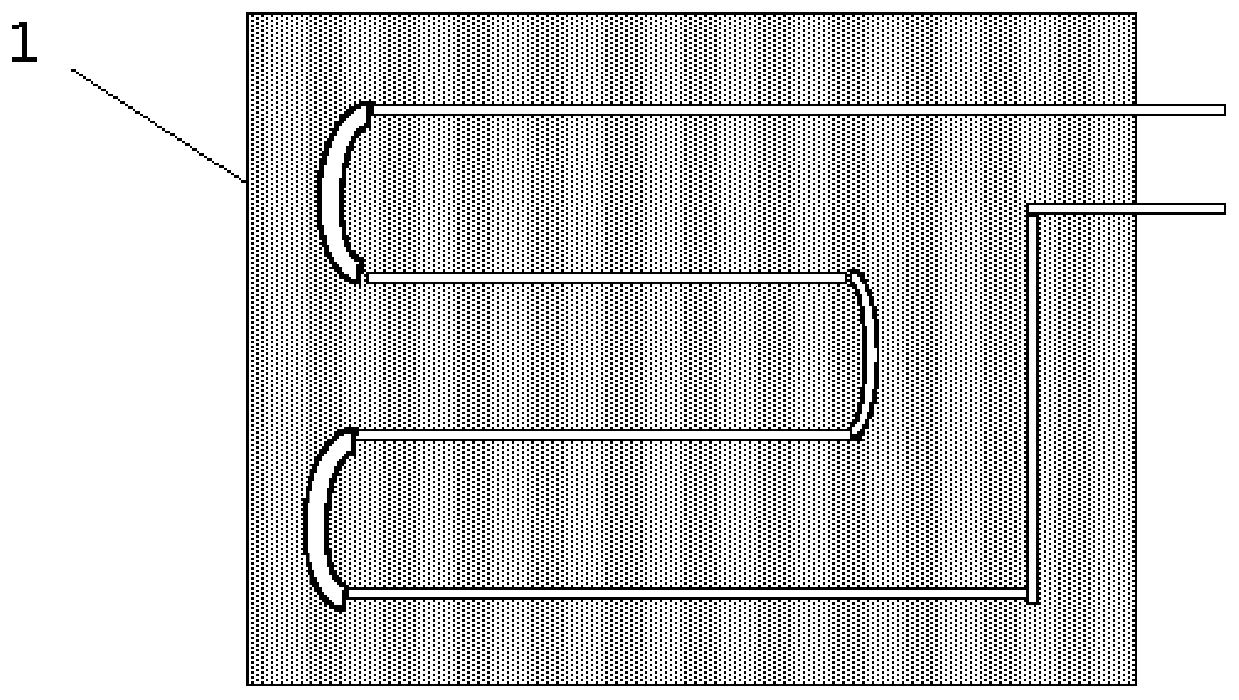

[0034] Such as figure 1 As shown in -2, the present invention provides a pressing structure for correcting warpage of a plastic-encapsulated flat panel semiconductor device, which includes a pressing platform 4, a connection structure and a heat insulation structure.

[0035] In this embodiment, the pressing platform 4 moves back and forth along the direction perpendicular to the plastic-encapsulated flat panel, and is used to apply pressure to the plastic-encapsulated flat panel 9 located below. The pressing end where the above-mentioned plastic sealing flat plate 9 contacts, the pressing platform 4 can be driven by electric, pneumatic or oil pressure to move.

[0036] In this embodiment, one end of the connecting structure is connected to the pressing platform 4, and the other end is connected to a driving device for driving the pressing platform 4 to and fro, and the connecting structure is arranged on the side of the pressing platform 4. Above, in order to apply pressure ...

Embodiment 2

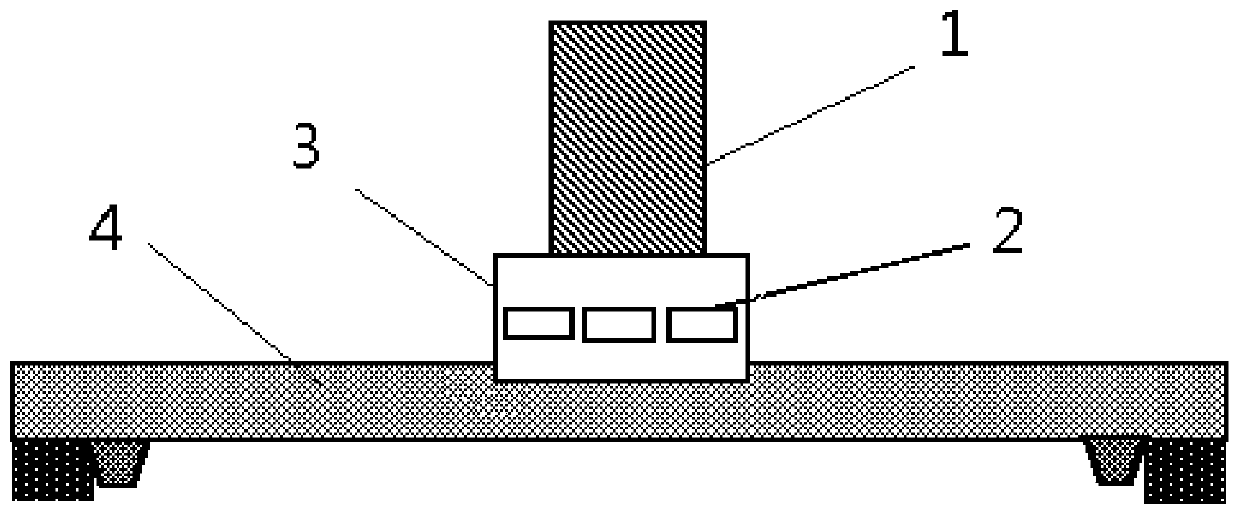

[0045] Such as image 3 As shown, the connecting structure includes a connecting rod 1 and a joint 3 connected to the connecting rod 1 and the pressing platform 4 respectively. The difference from Example 1 is that the heat insulation structure is arranged on the joint 3 Several holes in the interior 2. The joint 3 is made of low heat conduction material. In this embodiment, the joint 3 is made of stainless steel, and a plurality of small cavities are processed inside the joint 3, which can reduce heat conduction, so that the heat transmitted through the joint to other structures A small amount of heat will not affect other structures. Further, the joint 3 is screwed to the pressing platform 4 and the connecting rod 1 .

Embodiment 3

[0047] Such as Figure 4 As shown, this embodiment provides a semiconductor device for correcting a warped plastic-encapsulated flat panel, including the pressing structure described in Embodiment 1 and Embodiment 2, and further comprising The carrying platform 8 of the flat plate 9, the second heating device is arranged on the said carrying platform 8, the design of the first heating device and the second heating device can heat it from the upper surface and the lower surface of the plastic sealing flat plate respectively, so that the plastic sealing The heating effect of the flat plate is better.

[0048] In this embodiment, a support frame 10 is also provided below the carrying platform 8 to provide highly stable and flat surface support for the carrying platform 8. key structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com