Integrated formation device and method of metal-based carbon nano-composite material parts

A composite material and carbon nanotechnology, which is applied in the direction of additive processing, process efficiency improvement, additive manufacturing, etc., can solve the problem of inability to accurately obtain carbon source gas and hydrogen content, inability to achieve precise control of carbon nanomaterial content, inability to achieve Problems such as real-time monitoring and emission of impurity gases, to achieve the effect of shortening the preparation cycle, realizing real-time monitoring and emission, and realizing the content of enhanced phase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

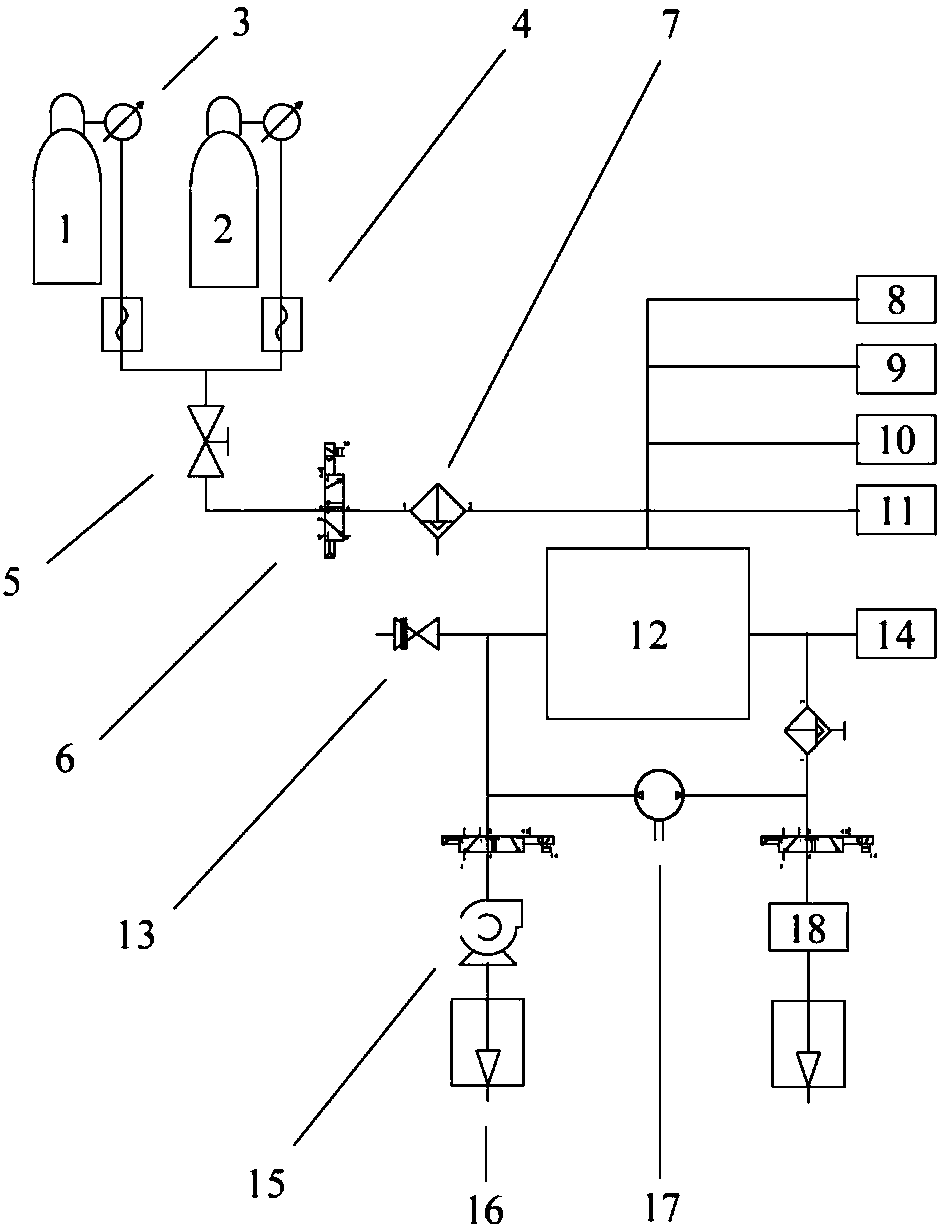

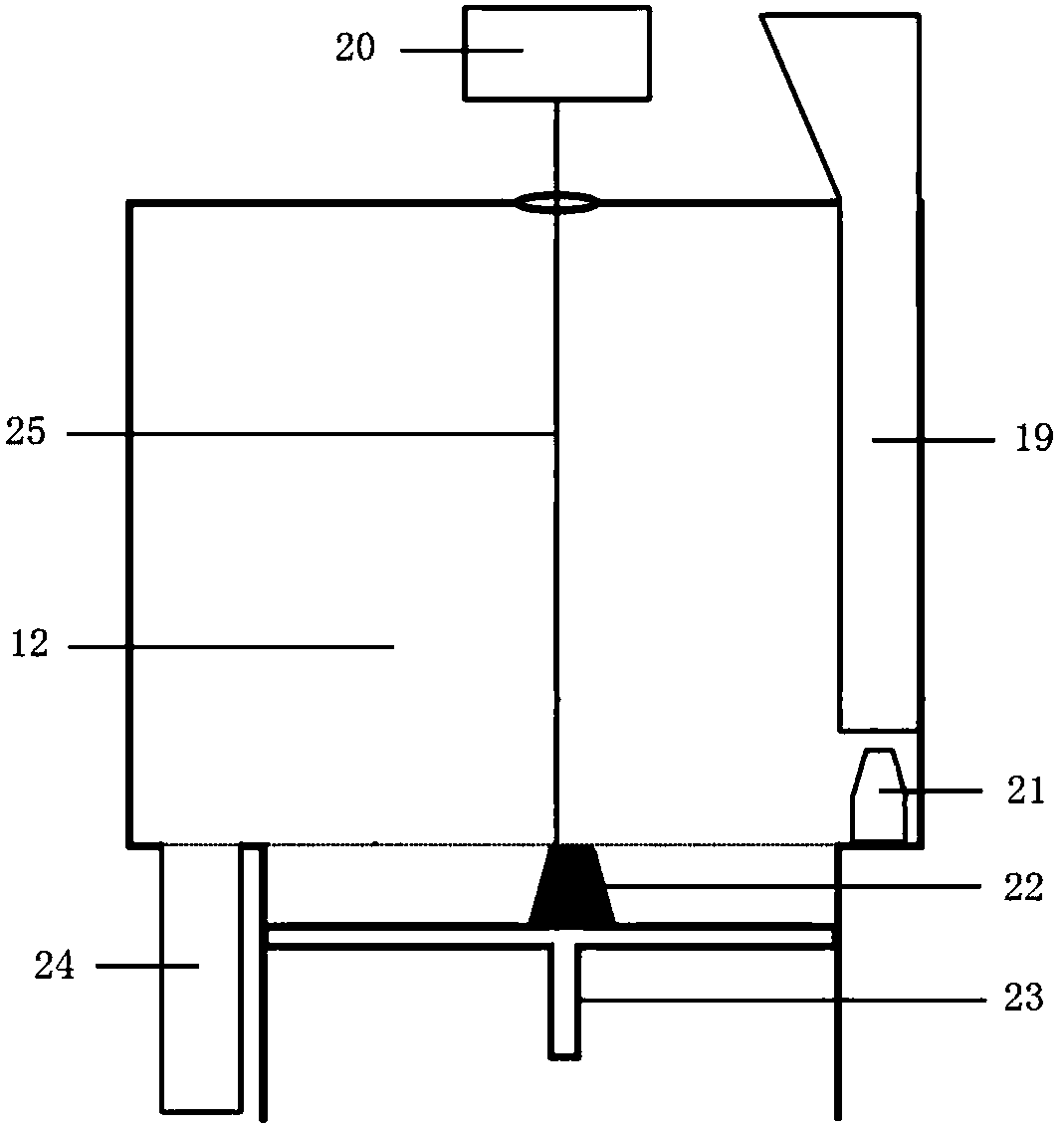

[0031] Embodiment 1. Integrated forming device for metal-based carbon nanocomposite parts

[0032] An integrated forming device for metal matrix carbon nanocomposite parts, its structure is as follows figure 1 As shown, it specifically includes a control system, a forming chamber 12, a vacuum system 15, a carbon source gas supply chamber 1, and a protective gas chamber 2; a carbon source gas detection device 14, a gas circulation system 17, an optical system 20, and a powder feeding system 19 ( like figure 2 shown), exhaust gas treatment system 18, wherein the optical system includes a laser, a laser transmission device, and is equipped with an optical path transmission element, a scanning galvanometer, a focusing lens, a light-transmitting mirror, a protective mirror, etc., and the laser parameters can be adjusted to make the carbon source gas flow in the laser Crack and catalyze various carbon nanomaterials under the action of the beam 25, and compound with the metal matri...

Embodiment 2

[0035] Embodiment 2, integrated forming method of metal-based carbon nanocomposite parts

[0036] An integrated forming method for metal-based carbon nanocomposite parts, comprising the following steps:

[0037] (1) Establish the three-dimensional graphics file of the parts, and carry out hierarchical discretization, generate scanning path data, and import it into the control system;

[0038] (2) First evacuate the forming cavity, and when the oxygen content is less than 0.1vol.%, pass in the protective gas, then supply the carbon source gas and stabilize its concentration at 0-100vol.%, and recycle the protective gas and gas through the gas circulation system carbon source gas;

[0039] (3) The powder feeding system controls the scraper to evenly spread a layer of spherical metal powder on the substrate;

[0040] (4) The laser beam realizes the selective melting of the metal powder according to the three-dimensional graphics file, forms a focused spot on the processing plan...

Embodiment 3

[0044] Embodiment 3. Integrated forming method for functionally graded components of metal-based carbon nanocomposites

[0045] An integrated forming method for functionally graded components of metal-based carbon nanocomposites, comprising the following steps:

[0046] (1) Establish the three-dimensional graphics file of the parts, and carry out hierarchical discretization, generate scanning path data, and import it into the control system;

[0047] (2) Vacuum the forming cavity first, and pass in the protective gas when the oxygen content is lower than a certain concentration value (usually <0.1vol.%), and then control the gas flow meter to continuously supply the carbon source gas according to a certain gas flow value, In order to realize the continuous change of the carbon source gas concentration from 0 to 100vol.%, the protection gas and carbon source gas are recycled through the gas circulation system;

[0048] (3) The powder feeding system controls the scraper to even...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com