Automatic press-connecting machine for sleeve and guide ring

A guide ring and crimping machine technology, applied in the field of optical communication, can solve the problems of low production efficiency, inability to complete the device, difficult to control, etc., to achieve the effect of improving labor productivity and ensuring the quality of crimping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

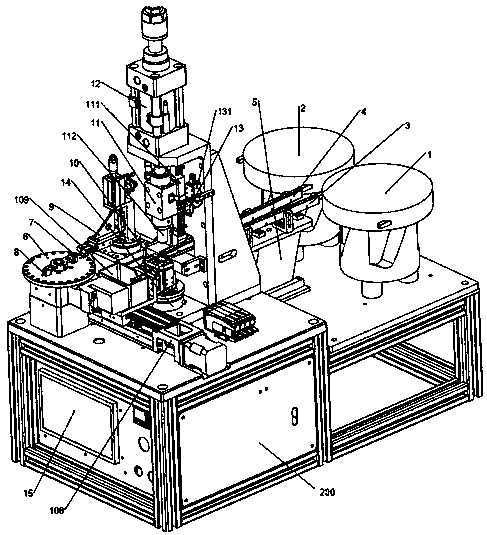

[0017] see Figure 1 to Figure 3 , sleeve and guide ring automatic crimping machine, including machine 200 and the loading and unloading device, crimping device and control system located on the machine 200. The control system is respectively connected with the loading and unloading device and the crimping device, the loading and unloading device is docked with the crimping device, and the loading and unloading device provides crimping materials for the crimping device.

[0018] The loading and unloading device includes a sleeve and guide ring feeding device and a metal parts loading and unloading device. The sleeve and guide ring feeding device includes a sleeve vibrating plate 1, a guide ring vibrating plate 2, and a sleeve connected to the sleeve vibrating plate 1. The linear guide rail 3, the guide ring linear guide rail 4 connected with the guide ring vibrating plate 2, and the linear vibrator 5 for maintaining the linear vibration of the sleeve linear guide rail 3 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com