Ultrahigh-pressure automatic stretching pump

A technology of ultra-high pressure and high-pressure pumps, which is applied in the field of hydraulic pressure, can solve problems such as poor precision, low efficiency, and cumbersome operation, and achieve the effects of reducing deviation, reducing difficulty, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

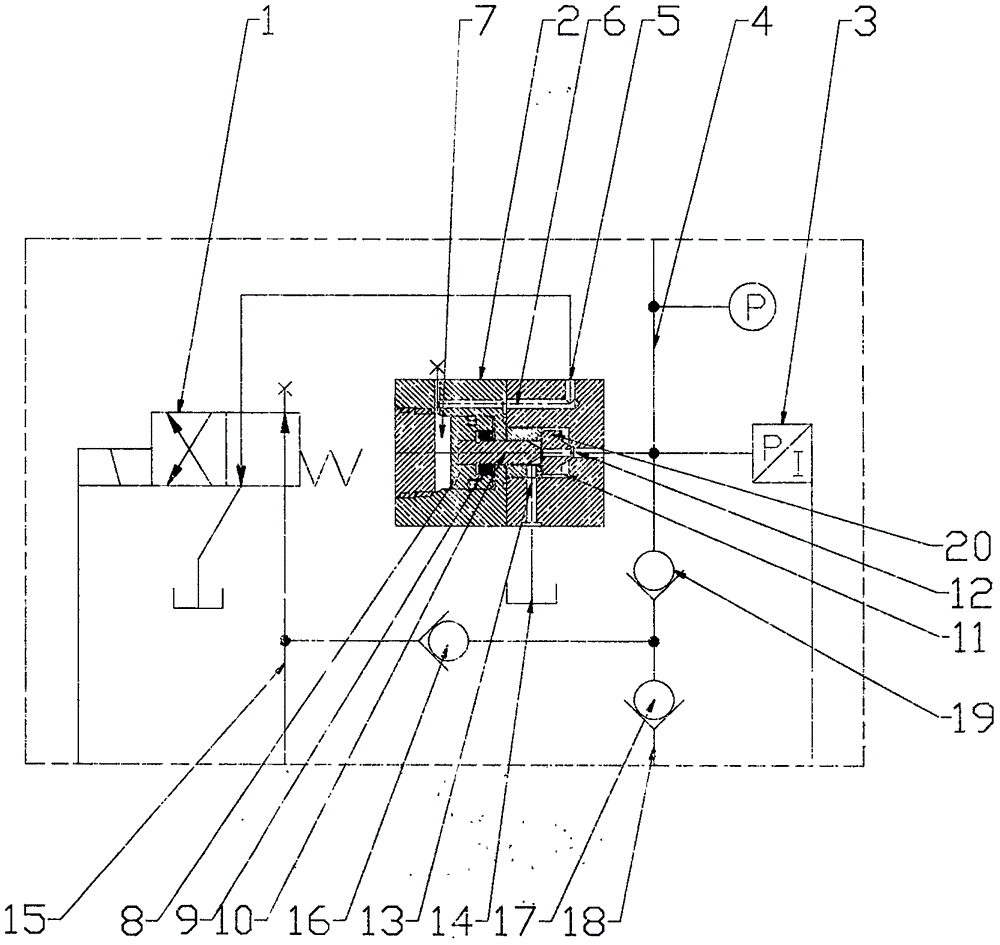

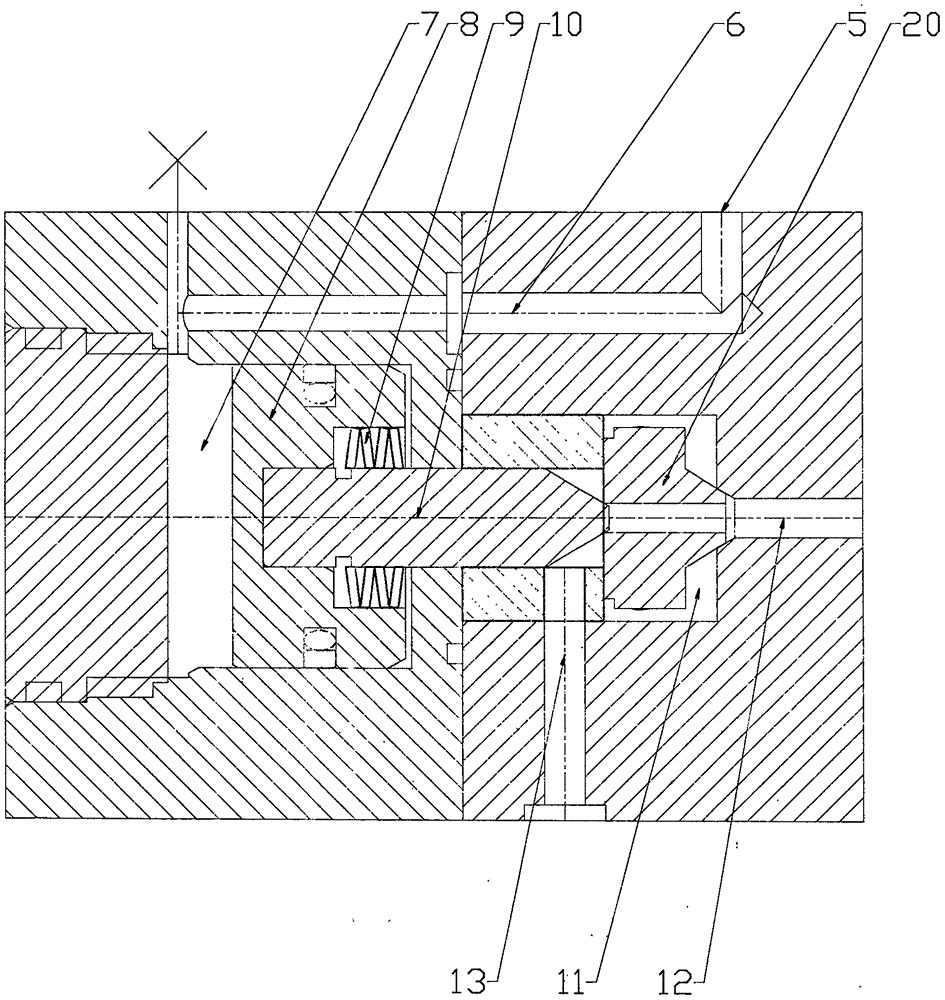

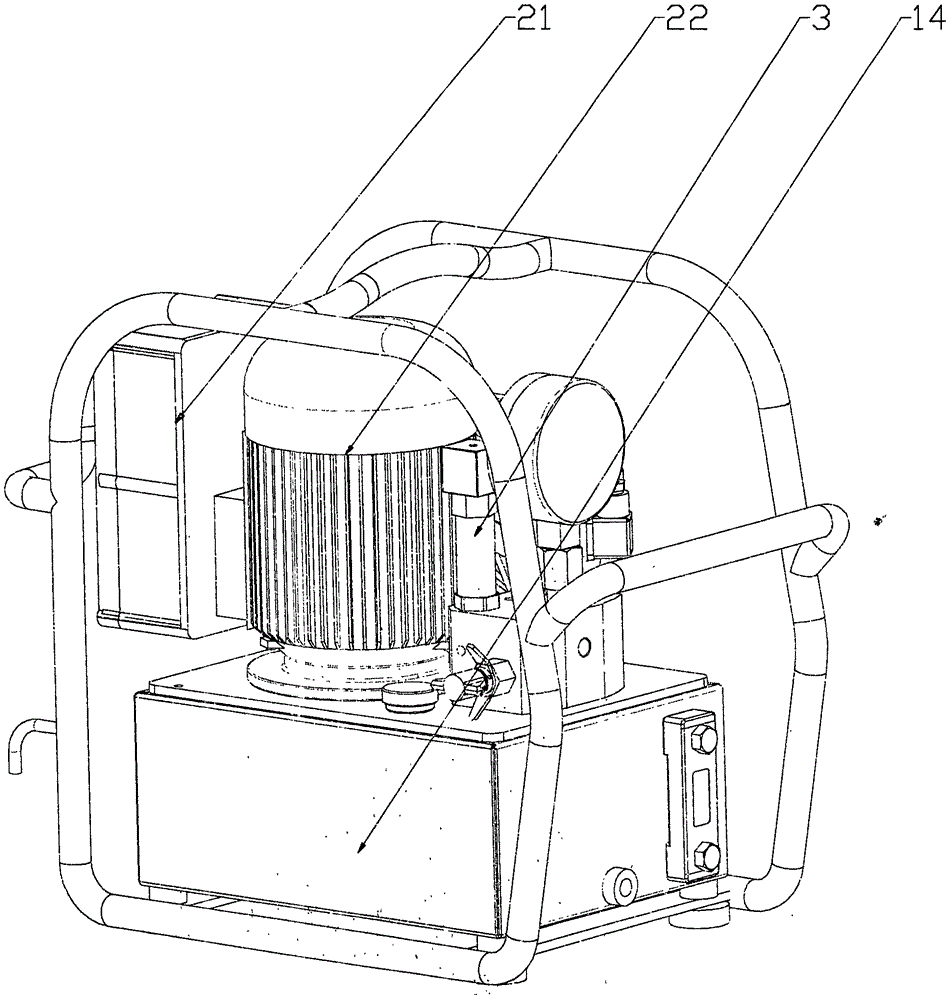

[0015] Such as figure 1 , figure 2 with image 3 As shown, the ultra-high pressure automatic stretching pump includes a control box 21, a motor 22, a low-pressure pump, a high-pressure pump, a pilot solenoid valve 1, an ultra-high pressure control valve 2, a pressure transmitter 3 and a remote control handle. The motor 22 is respectively Connect the low-pressure pump and the high-pressure pump, the low-pressure pump and the high-pressure pump are respectively communicated with the output oil circuit 4 through pipelines, and the low-pressure oil circuit 15 communicated between the low-pressure pump and the output oil circuit 4 is provided with a low-pressure check valve 16, A high-pressure check valve 17 is provided on the high-pressure oil circuit 18 connected between the high-pressure pump and the output oil circuit 4, and an ultra-high pressure maintenance check valve 19 is provided on the output oil circuit 4. The pilot solenoid valve 1 controls the low-pressure oil The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com