Porous medium penetration slip-casting multi-parameter monitoring device and test method thereof

A technology of porous media and monitoring device, which is applied in measurement devices, instruments, scientific instruments, etc., to achieve the effects of wide application range, high utilization rate of test devices, and simple device design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

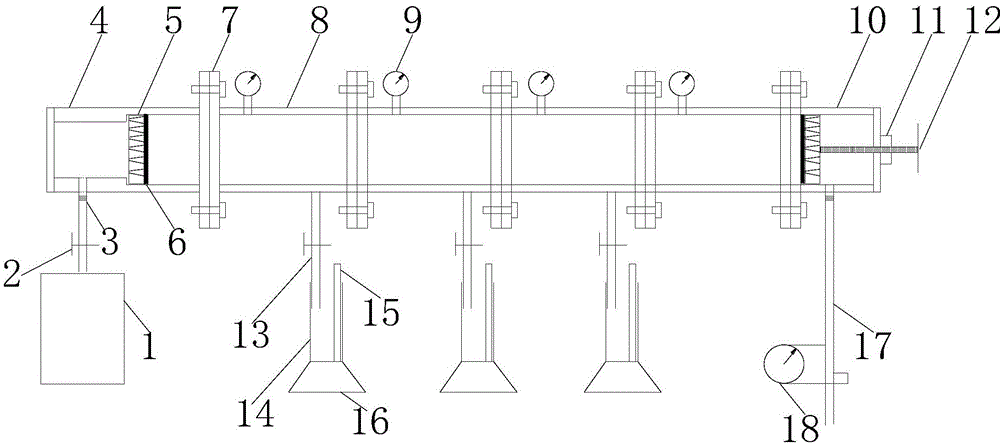

[0040] Such as figure 1 As shown, a multi-parameter monitoring device for permeable grouting in porous media and its test method, including grouting pump 1, inlet cabin 4, perforated plate 5, filter screen 6, steel ring welded quick clamp joint 7, single column Shaped steel pipe 8, pressure gauge 9, outlet compartment 10, measuring cylinder 14, thermometer 15, electronic scale 16, ultrasonic flowmeter 18, etc. The inlet cabin 4, the single cylindrical steel pipe 8, and the outlet cabin 10 are connected as a whole through the steel ring welded quick clamp joint 7, and the inlet cabin 4 and the outlet cabin 10 are placed with perforated plates 5 and filter screens 6, and the single cylinder A pressure gauge 9 and a slurry outlet pipe 13 are placed on the steel pipe 8, the slurry outlet pipe 13 and the thermometer 15 are placed in the measuring cylinder 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com