Patents

Literature

38results about How to "Enhanced reducing atmosphere" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

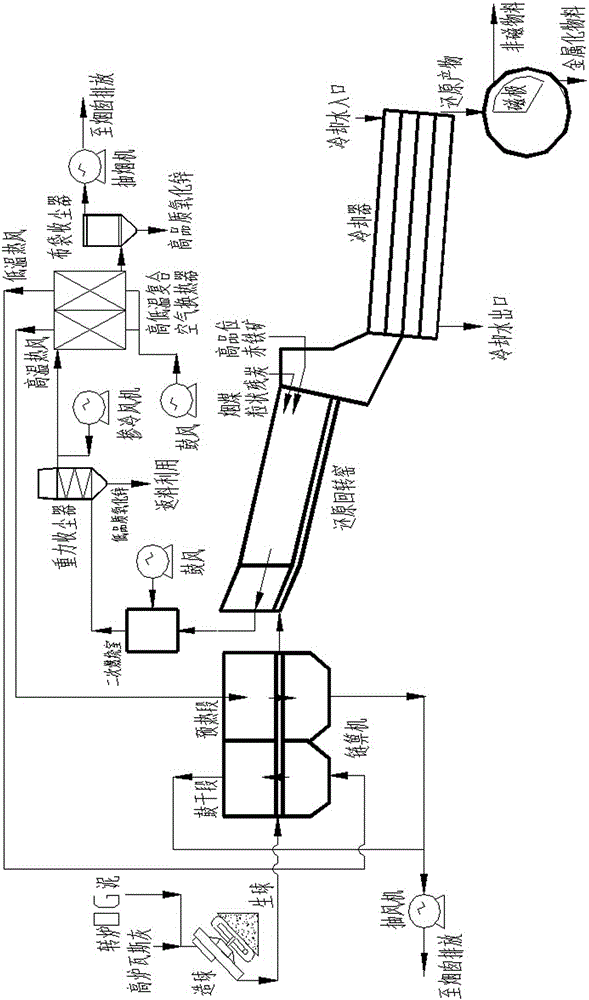

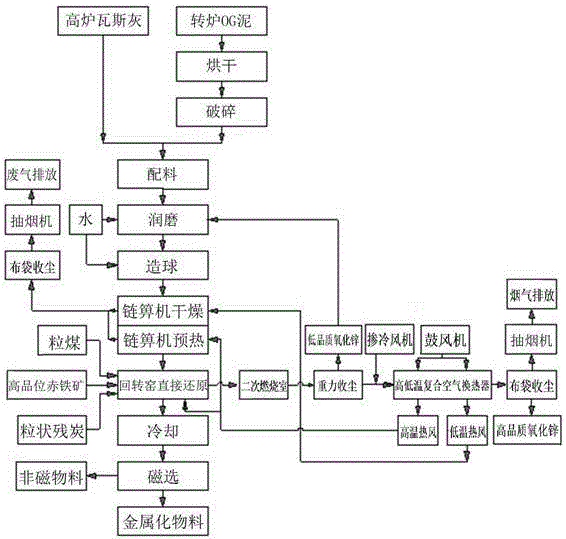

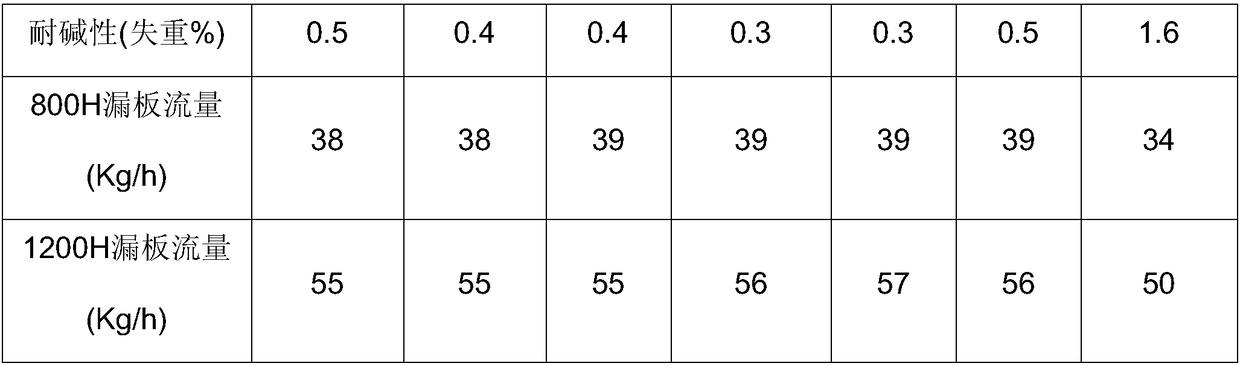

Method for treating high-zinc iron-containing slime through utilizing rotary kiln

ActiveCN106367600AEfficient use ofReduce loadRotary drum furnacesProcess efficiency improvementLarge particleMagnetic separation

The invention relates to a method for treating high-zinc iron-containing slime through utilizing a rotary kiln. The method comprises the steps that blast furnace gas ash and converter OG mud are mixed and pelletized; wet pellets are dried and preheated, and a drying and preheating heat source is hot air generated by high-temperature flue gas of the rotary kiln after passing through a high-low temperature composite air heat exchanger; a pea coal spray gun, a carbon residue spray gun and an ore grain spray gun are arranged at a kiln head of the rotary kiln, and high-volatile matter coal, residual carbon and high-grade iron ore are sprayed into the kiln; the dried pellets are fed into the rotary kiln, and high-temperature metallized pellets are obtained after the dried pellets are subjected to direct reduction and high-temperature solidification in the rotary kiln; after being cooled to the normal temperature, materials like the metallized pellets and excess carbon residue are subjected to magnetic separation, and metallized pellets are obtained; and large-particle dust is removed from the high-temperature flue gas of the rotary kiln, the high-temperature flue gas enters the high-low temperature composite air heat exchanger to be cooled, the cooled flue gas enters a bag-type dust collector, and zinc oxide powder is recycled. According to the method, the high-zinc iron-containing slime generated by iron and steel enterprises is efficiently utilized, and environmental pollution caused by stacking of the high-zinc iron-containing slime is solved.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

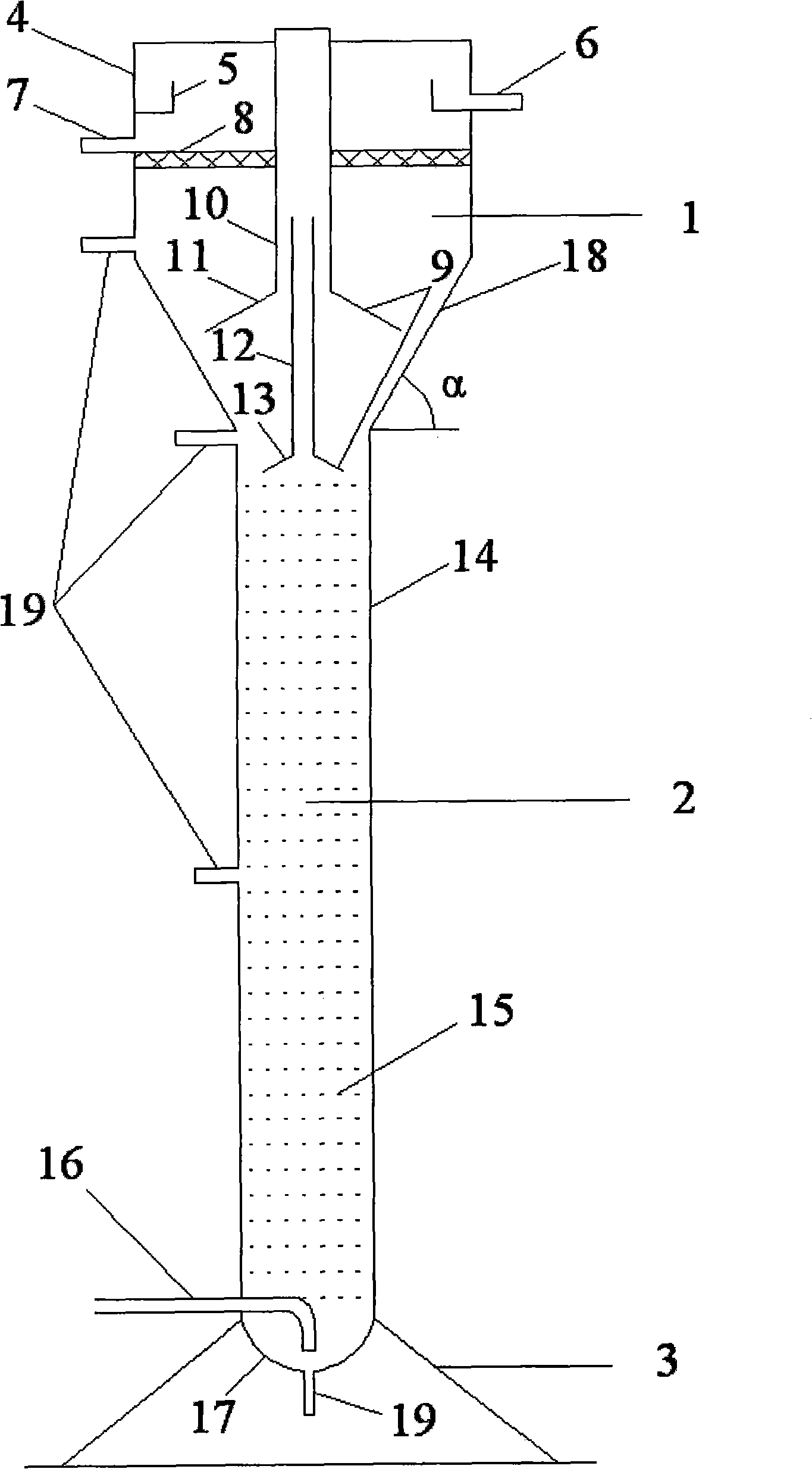

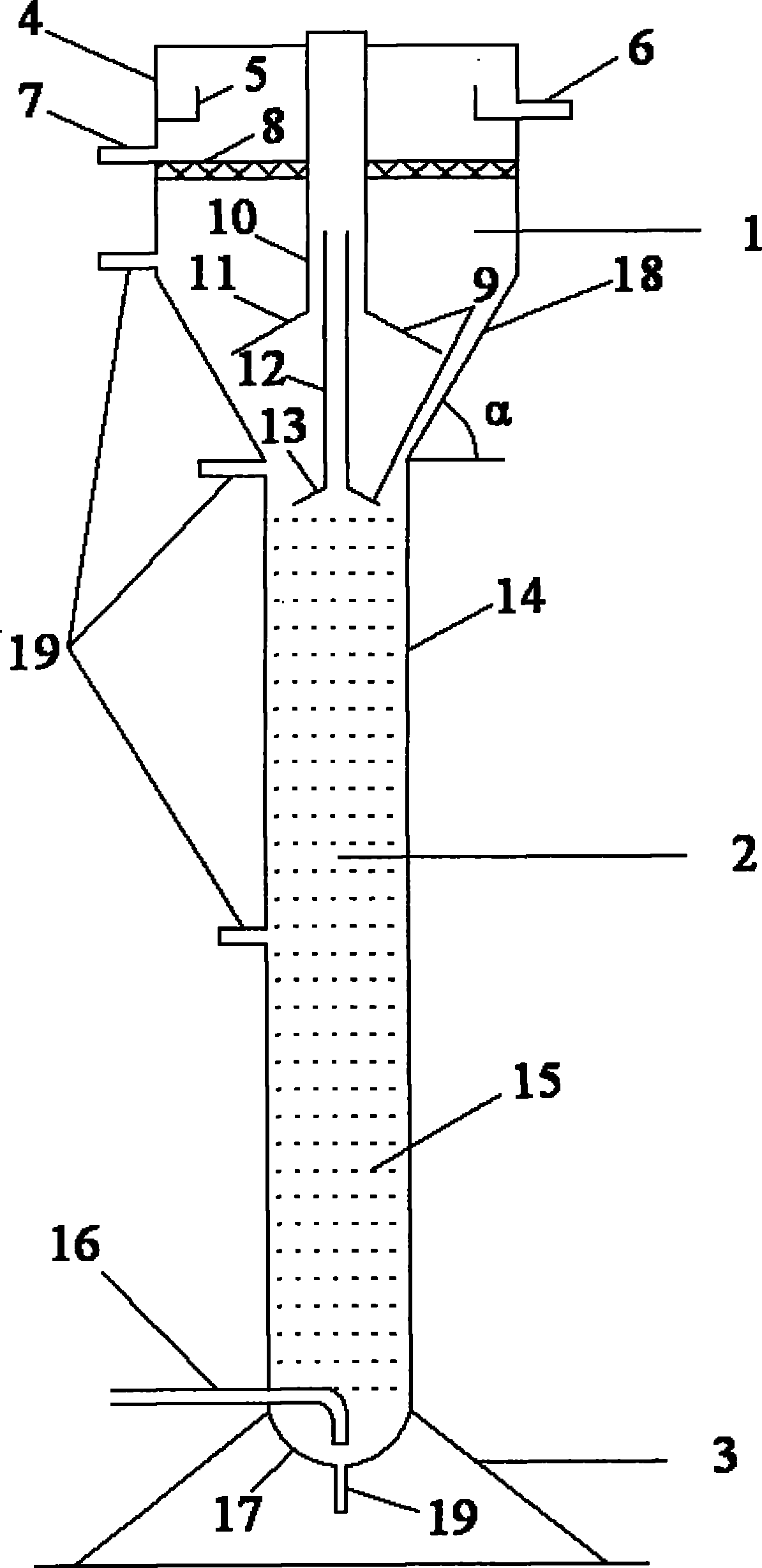

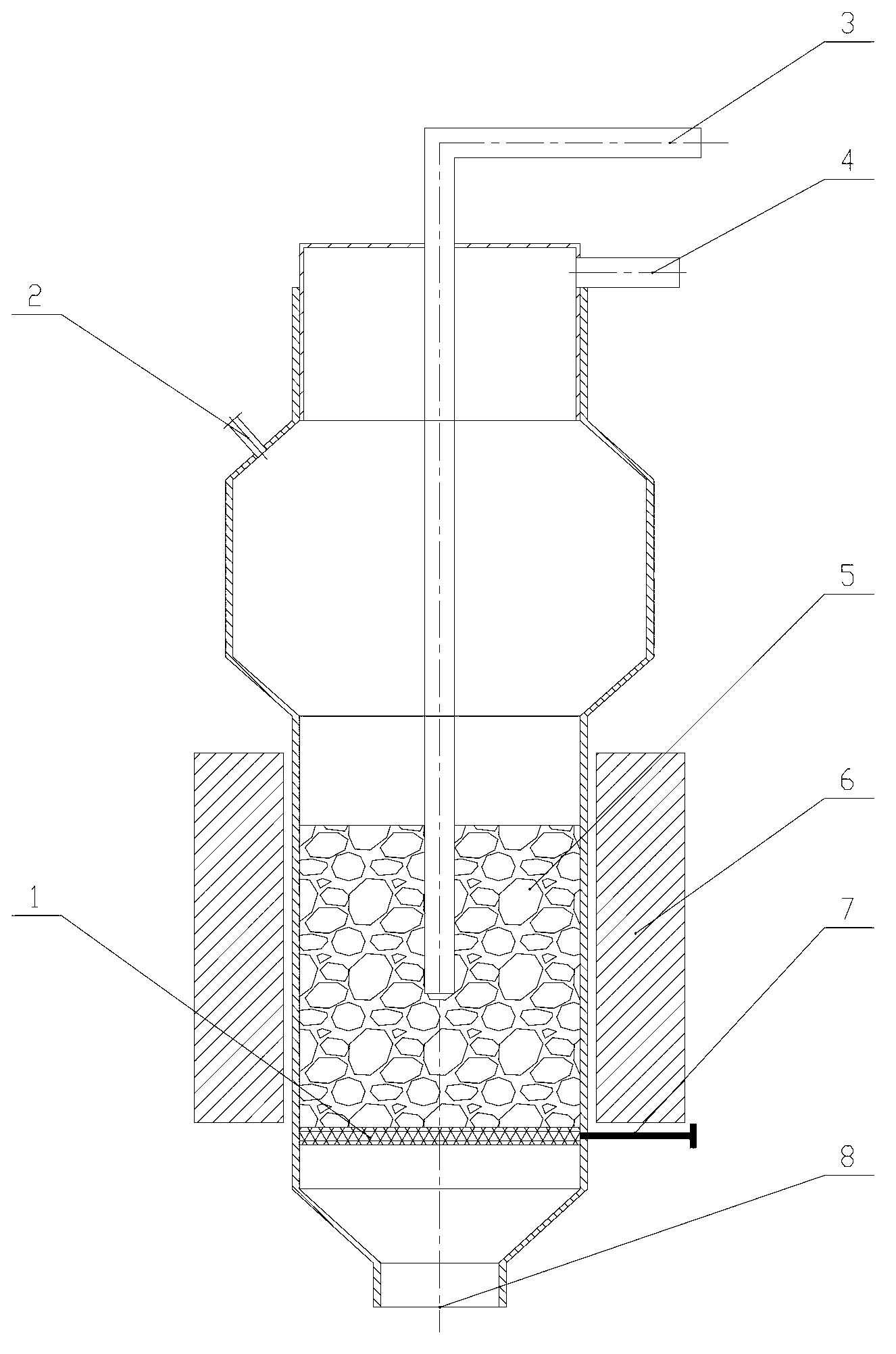

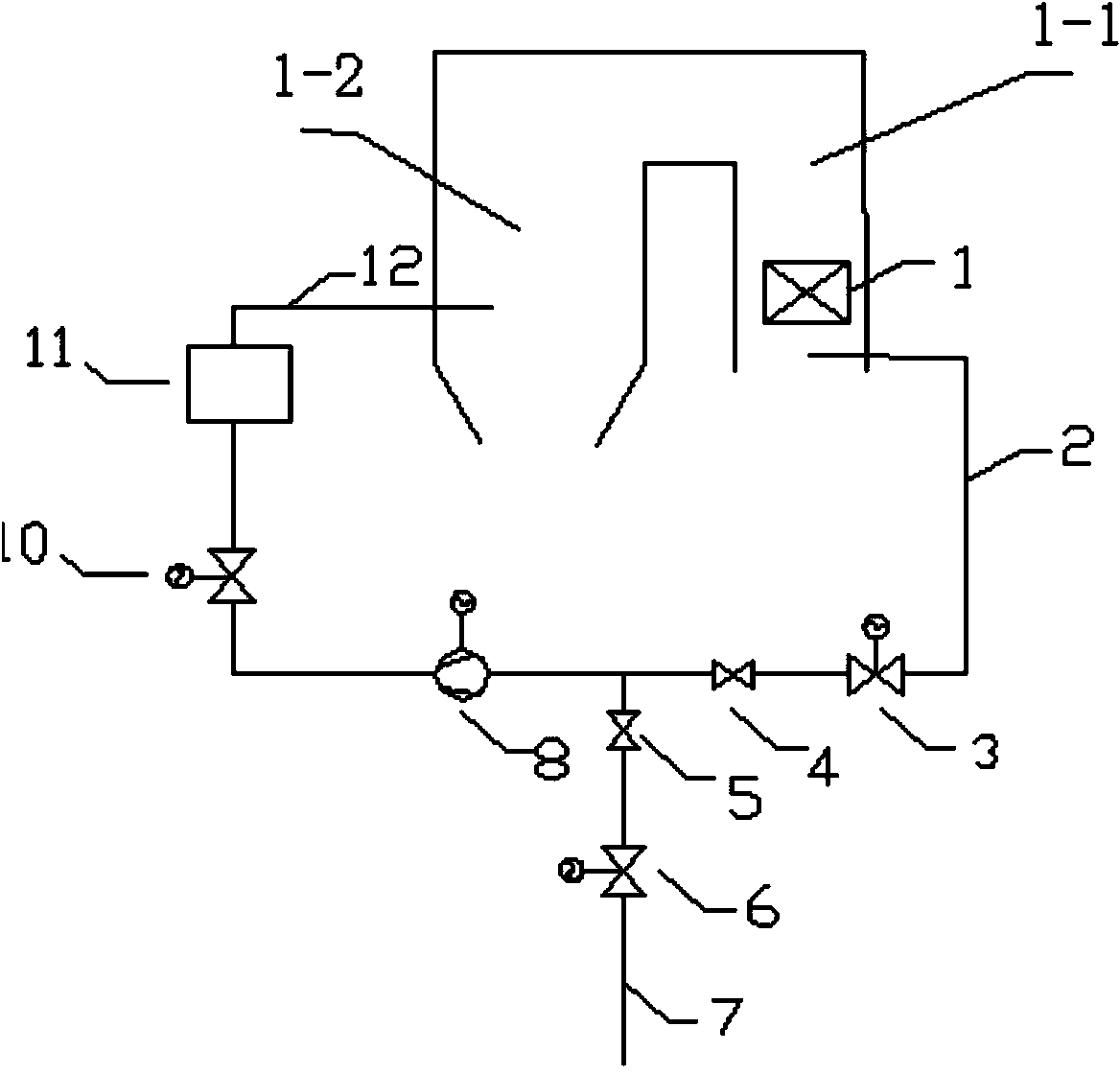

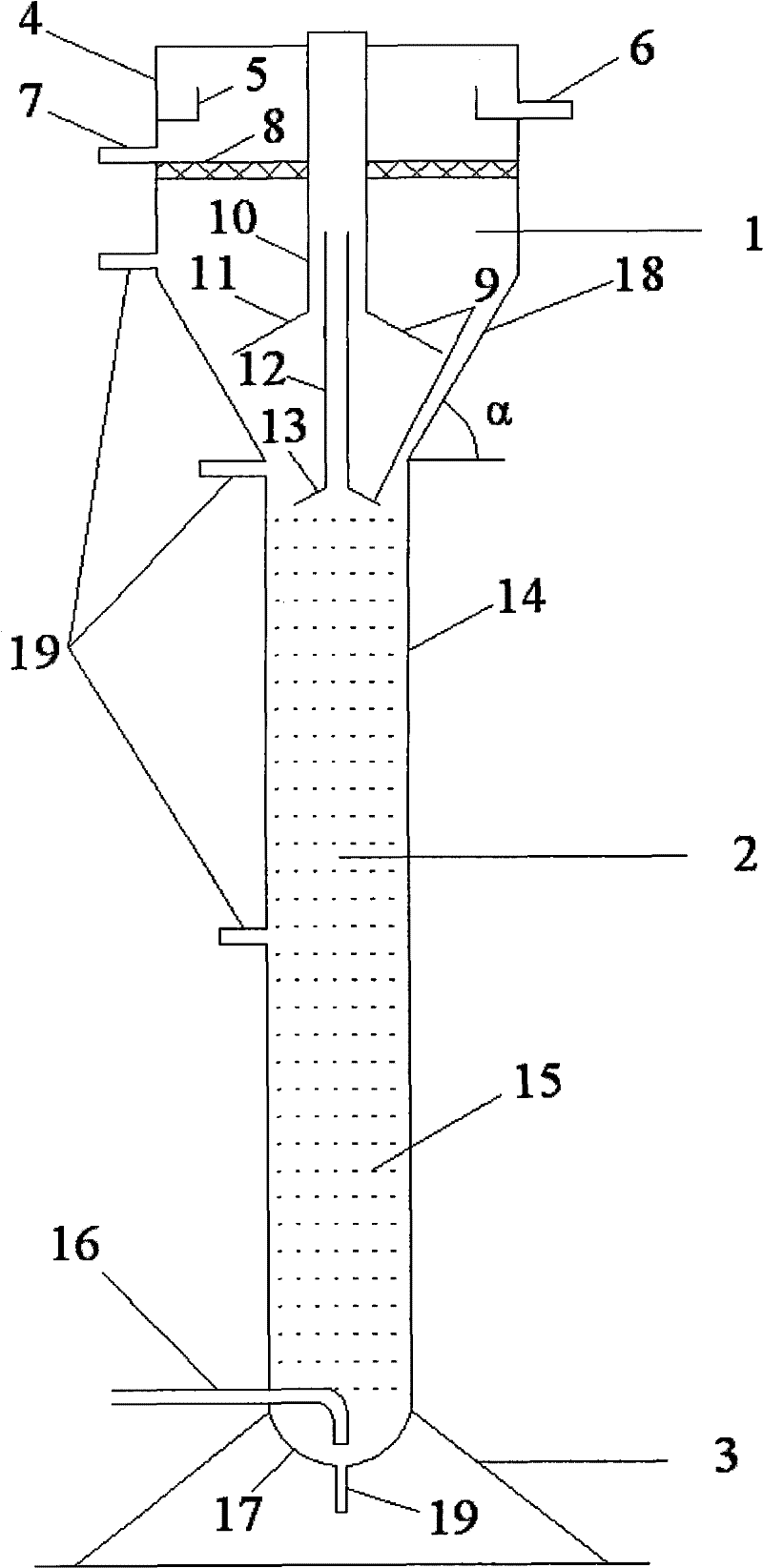

Superhigh-efficiency anammox reactor

ActiveCN101863554AAccelerated sludge settlingImprove sludge activityTreatment with anaerobic digestion processesEngineeringThree-phase

The invention discloses a superhigh-efficiency anammox reactor, which is provided with a sediment zone, a reaction zone and a bracket. The sediment zone is sequentially provided with a first outer cylinder, an overflow weir, a water outlet, a backflow port, an annular wire netting and a two-stage three-phase separator from top to bottom. The two-stage three-phase separator comprises a first gas collecting tube, a first reducing pipe, a second gas collecting tube and a second reducing pipe. The overflow weir is communicated with the water outlet, the backflow port is positioned between the overflow weir and the annular wire netting, the inner ring of the annular wire netting is connected with the outer wall of the first gas collecting tube, and the outer ring of the annular wire netting is connected with the inner wall of the first cylinder. The reaction zone comprises a second outer cylinder, an iron powder carrier, a water inlet tube and a hemispheroid. The reaction zone is connected with the sediment zone through an outer cylinder increasing coupling and is directly connected with the bracket, and both the reaction zone and the sediment zone are provided with dredge pipes. The invention effectively prevents sludge loss, reduces gas disturbance, promotes the natural sedimentation of granules, reduces the toxicity of the base material and ensures the operating performance of the reactor to be efficient and stable.

Owner:ZHEJIANG UNIV

Reducing roasting method for powdered iron ores in tunnel kiln

The invention discloses a reducing roasting method for powdered iron ores in a tunnel kiln, which is designed for solving the problems of low heat transfer efficiency, long reducing time, non-uniform material reduction quality, and the like when powdered iron ores are subjected to reducing roasting in a tunnel kiln. According to the invention, by reasonably selecting the particle size range and distribution of iron ores, iron ores with different particle sizes and reducing coal are mixed and distributed in layers, and then the obtained object is subjected to reducing roasting, so that the iron ores with different particle sizes achieve a same roasting effect, thereby increasing the metal recovery rate of roasted iron ores, improving the quality of roasting, shortening the roasting time, reducing the roasting temperature, and lowering the production cost.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

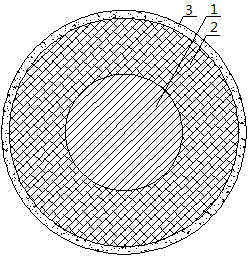

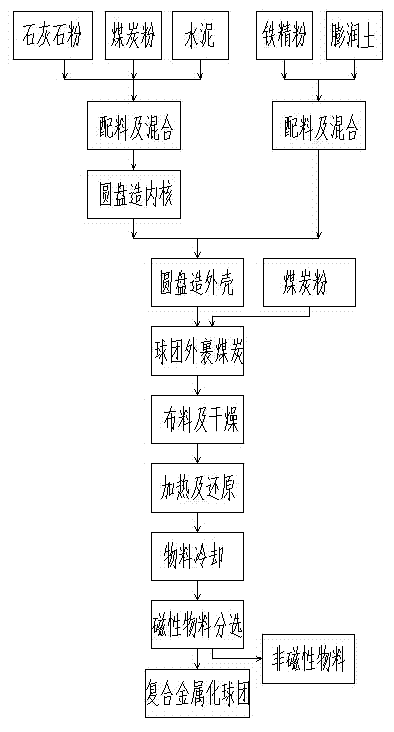

High-alkalinity composite metallized pellet for converter and production process thereof

InactiveCN104726630AEnhanced reducing atmosphereIncrease concentrationManufacturing convertersAlkalinityReduction rate

The invention relates to the technical field of metallurgical and mineral engineering and discloses a high-alkalinity composite metallized pellet for a converter and a production process thereof. The pellet comprises an inner core and a shell wrapping outside the inner core, wherein the inner core is prepared through mixing coal powder, limestone and cement according to the mass ratio of 100: (300-550): (4-7), the shell is prepared through mixing iron concentrate and bentonite according to the mass ratio of (1,500-1,800): (30-54), the granularity of the inner core is 20-25mm, and the thickness of the shell is 5-10mm; the outside of the shell is further covered with a layer of reducing agent. The production process comprises the steps of preparing the inner core, wrapping the shell to form the composite metallized pellet, wrapping the external wall of the composite metallized pellet with a reducing layer, distributing and drying the composite metallized pellet, carrying out reduction roasting on the composite metallized pellet, cooling and separating the high-temperature-reduction composite metallized pellet, and the like. According to the high-alkalinity composite metallized pellet and the production process thereof, through proportionally adding the limestone and the coal powder into the inner core, the internal reducing atmosphere of the pellet is strengthened, the reduction rate is increased, and the energy consumption is lowered.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

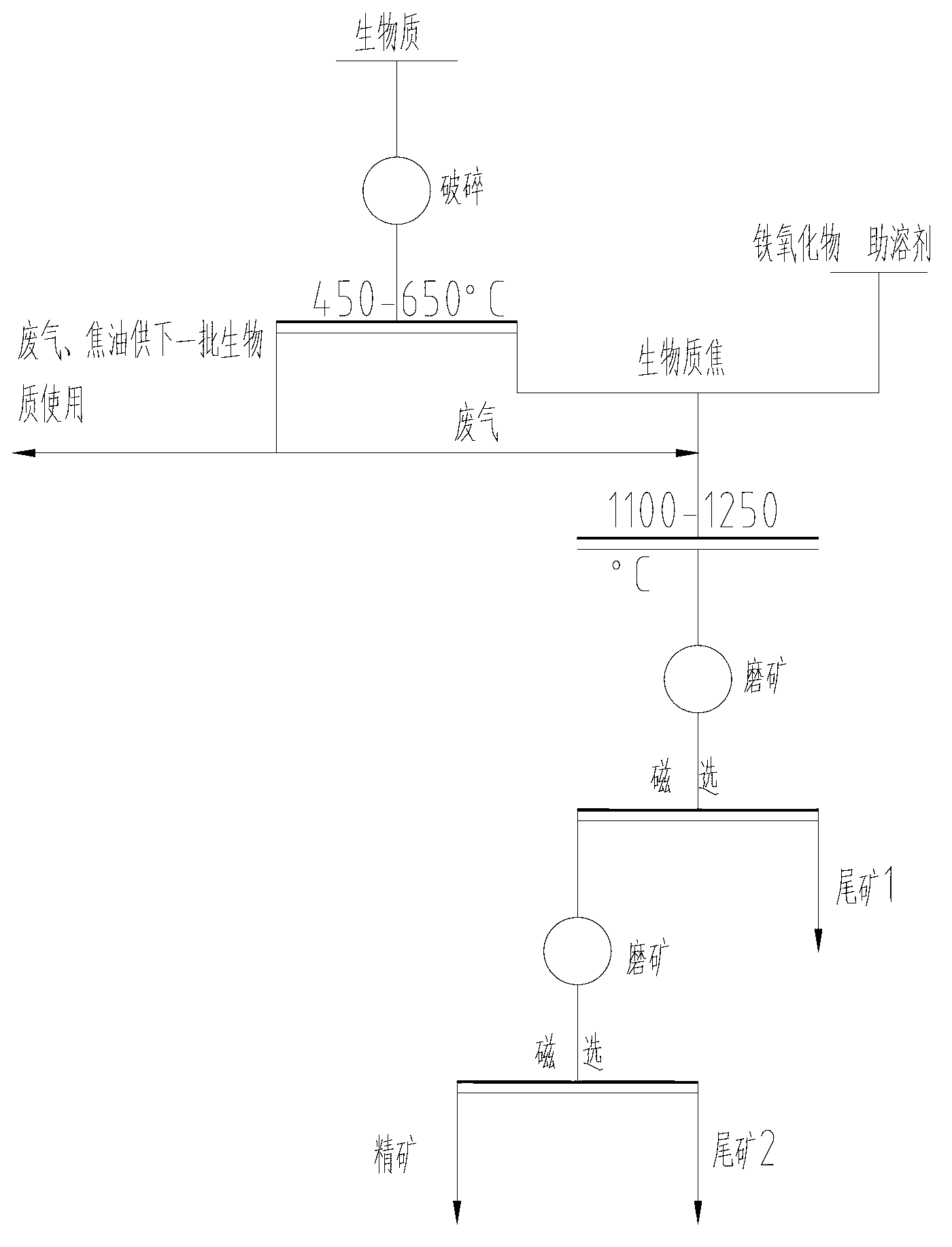

Method for preparing sponge iron by biomass char

InactiveCN103060504AImprove utilization efficiencyIncrease energy densityBiofuelsSpecial form destructive distillationManganeseReducing agent

The invention belongs to the technical field of mineral processing of direct reduction of iron oxide, and relates to a preparation of a biomass char and a method for preparing sponge iron by applying the biomass char to the direct reduction of iron oxide. The main technology comprises steps such as the preparation of the biomass char, the sponge iron preparation by using the biomass char to directly reduce iron oxide, ore grinding, low intensity magnetic separation and the like. The method is characterized by comprising the following steps of: heating biomass such as corn straw, pine sawdust, leaves, waste paper and the like in design equipment at 450-650 DEG C and thermally insulating, obtaining the biomass char and collecting tar, recycling exhaust gas, and using the prepared biomass char as a reducing agent at 1150-1250 DEG C to directly reduce iron oxide to prepare the sponge iron. The grade of the sponge iron reaches more than 90%, and the recovery rate of the sponge iron is more than 85%. The biomass char in the method has the advantages of low N and low S, and can reduce the discharge amount of CO2. The method also has good effects to metallic compounds such as manganese, chromium, vanadium and the like.

Owner:UNIV OF SCI & TECH BEIJING

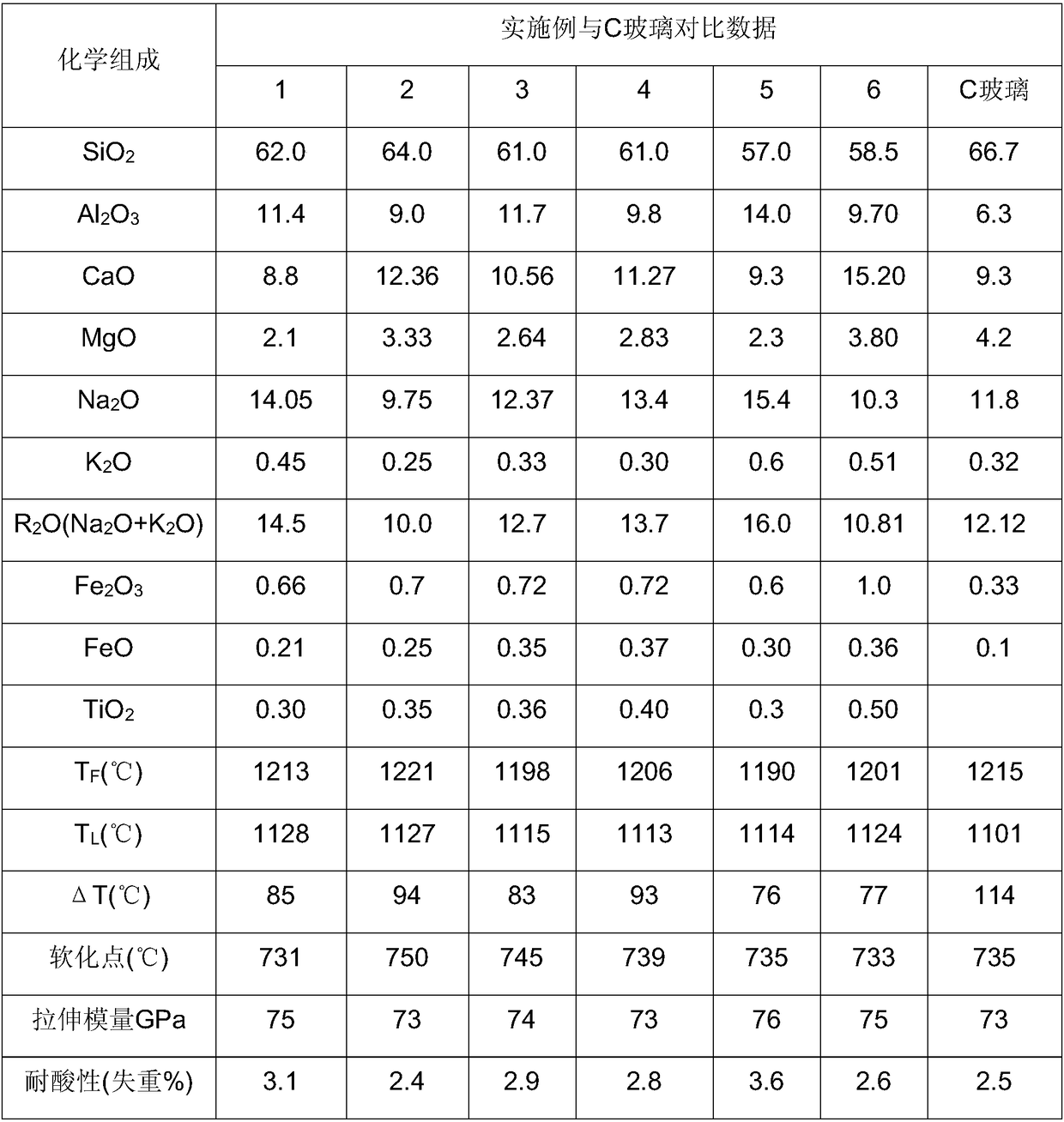

Fiberizable glass composition and preparation method

ActiveCN108545949AReduce the use of soda ashReduce formulation costsGlass making apparatusInorganic ChemicalMaterials science

Owner:ТАЙ'АНЬ ШУНЬМАО НЬЮ МЕТЕРИАЛ ТЕХНОЛОДЖИ КО., ЛТД.

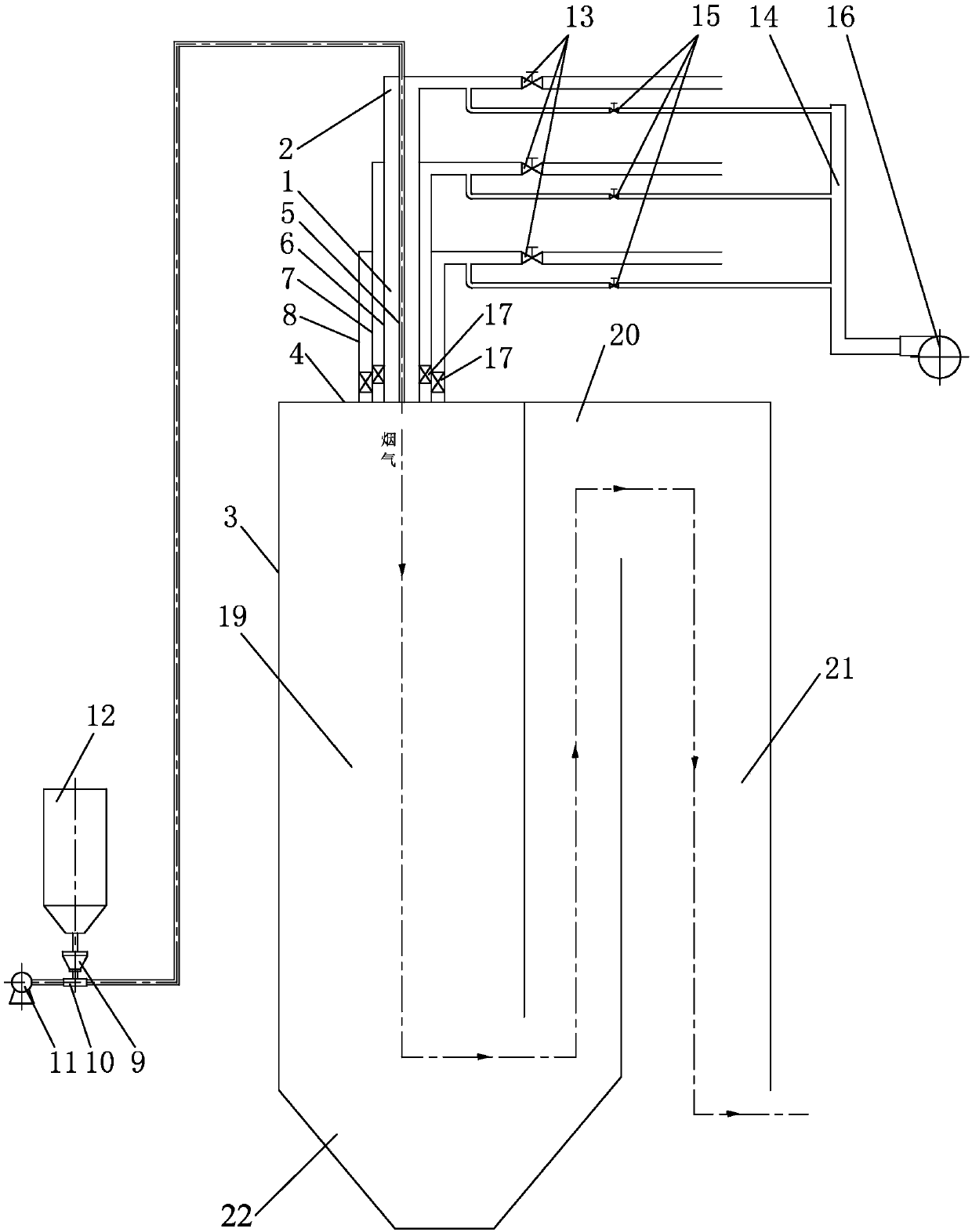

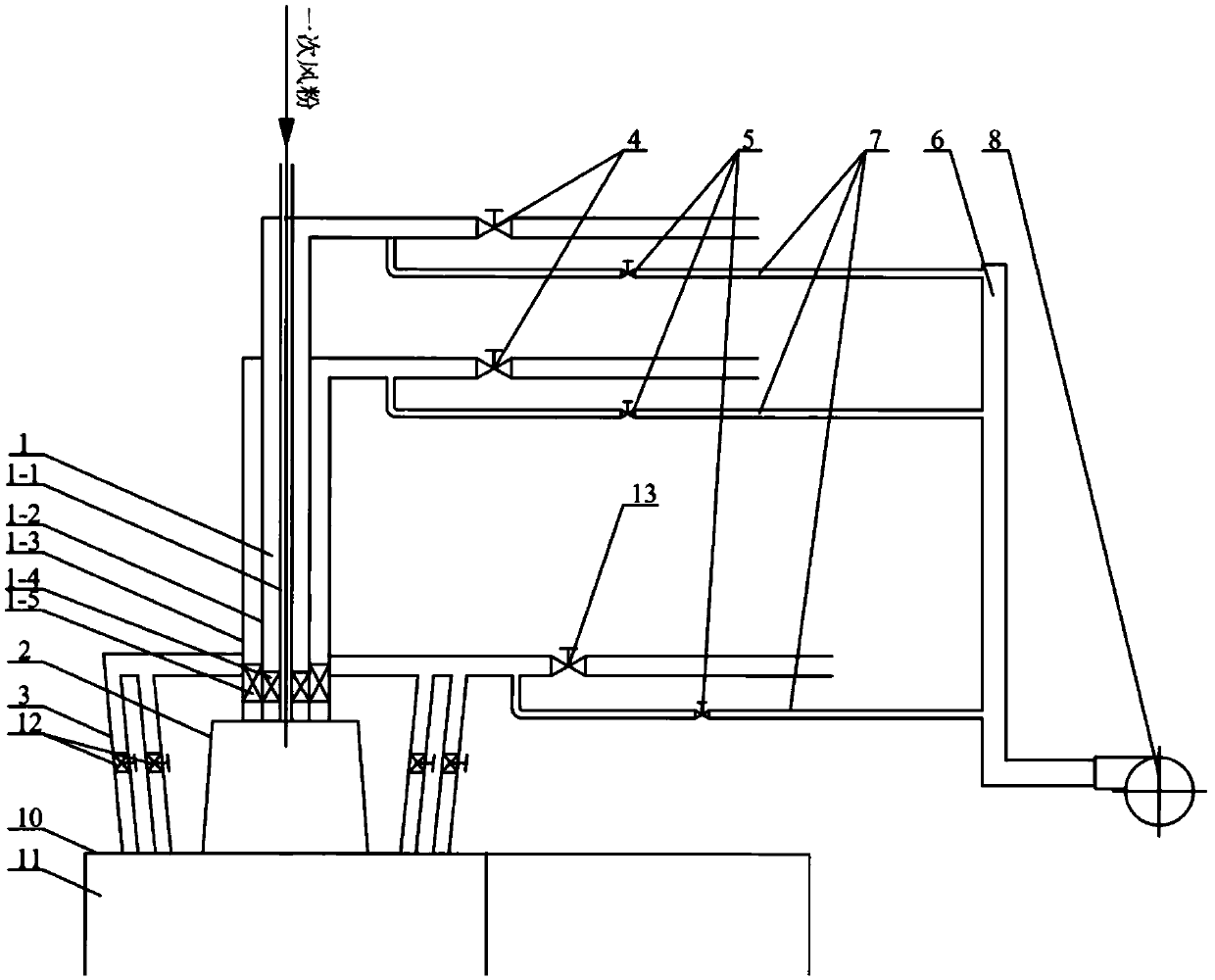

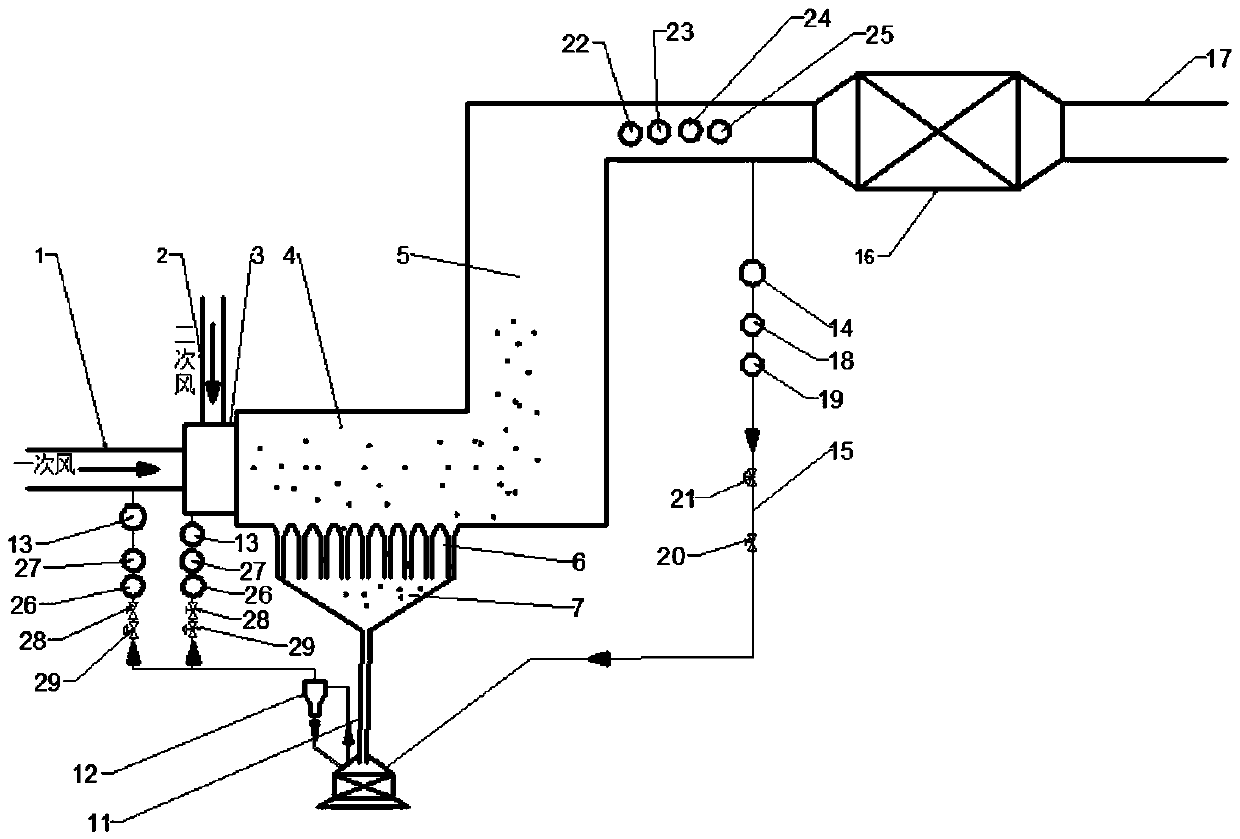

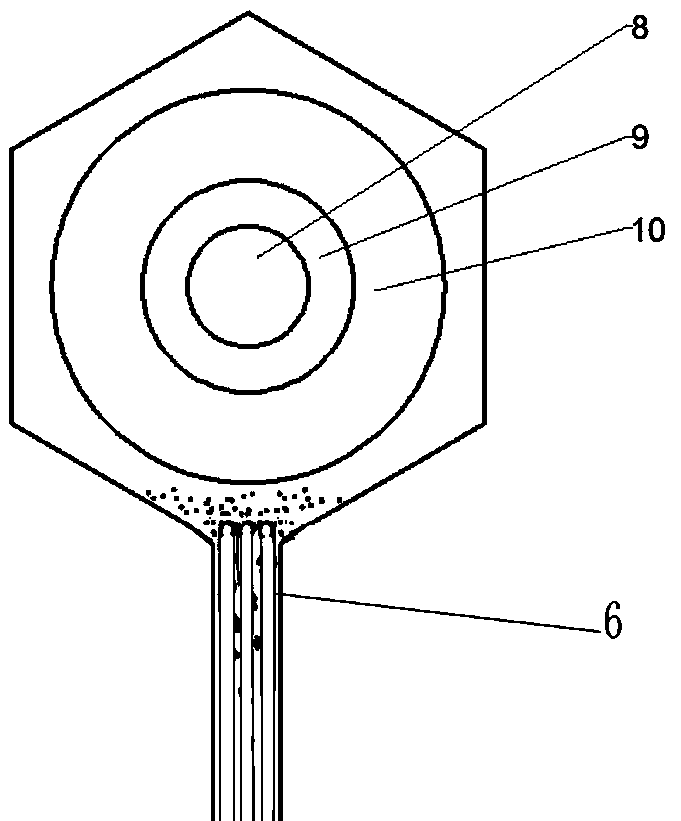

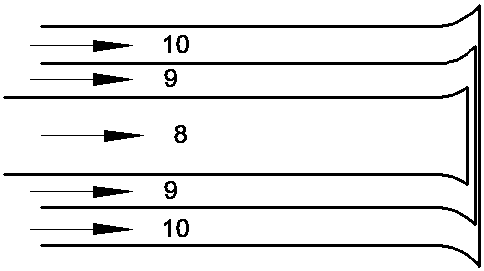

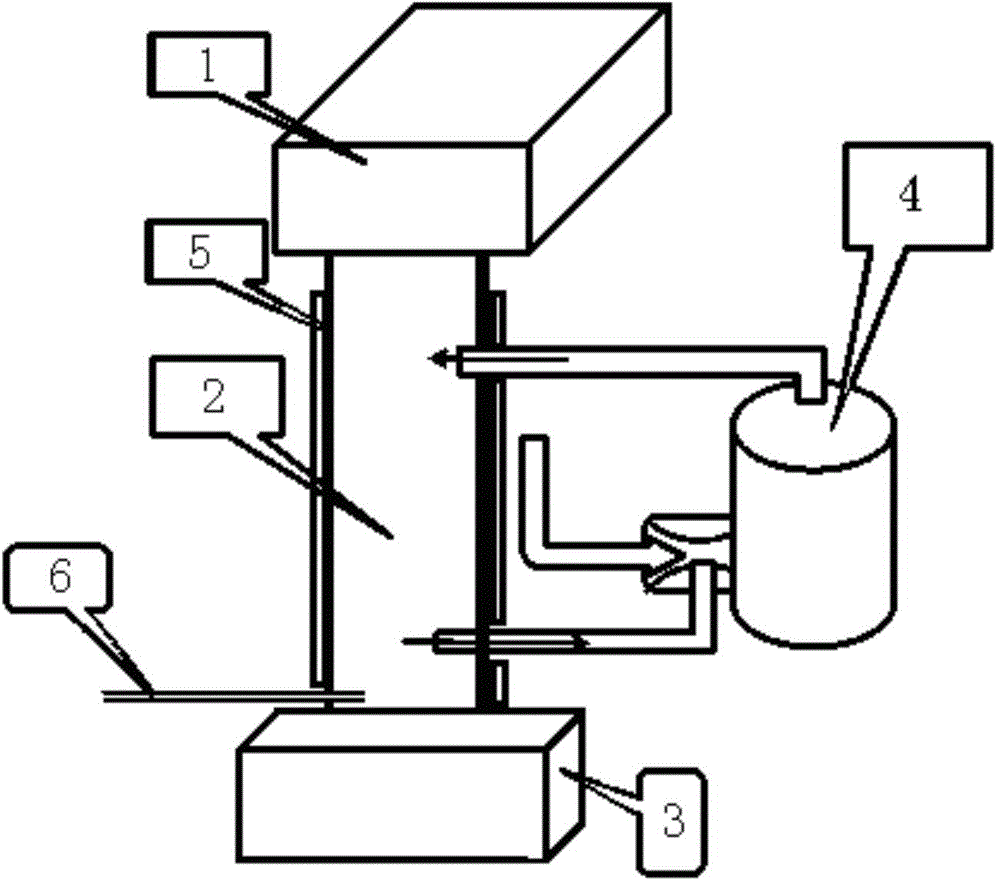

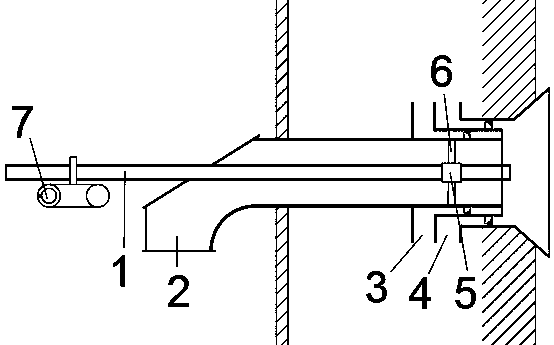

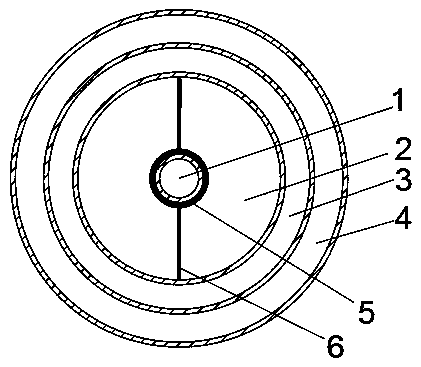

Multi-pass industrial pulverized coal boiler with flue gas recirculation technology and swirl pulverized coal burner on top

ActiveCN107559821AReduce generationIncrease concentrationPulverulent fuel combustion burnersAir/fuel supply for combustionFlue gasEnvironmental engineering

The invention discloses a multi-pass industrial pulverized coal boiler with a flue gas recirculation technology and a swirl pulverized coal burner on the top, and relates to an industrial pulverized coal boiler. The multi-process industrial pulverized coal boiler aims to solve the problems that a NOx emission load is high and burnout performance is poor in the existing industrial pulverized coal boiler. The multi-pass industrial pulverized coal boiler comprises a primary air pipe, a straight-flow secondary air pipe, a swirl inner secondary air pipe and a swirl outer secondary air pipe, and a boiler body is internally provided with a zigzag channel with three flue gas passes; the primary air pipe is arranged in the straight-flow secondary air pipe, the straight-flow secondary air pipe is arranged in the swirl inner secondary air pipe, and the swirl inner secondary air pipe is arranged in the swirl outer secondary air pipe; axial swirl blades are mounted in the swirl inner secondary airpipe and the swirl outer secondary air pipe; nozzles of the primary air pipe, the straight-flow secondary air pipe, the swirl inner secondary air pipe and the swirl outer secondary air pipe are flushwith a boiler top of the boiler body; a flue gas recirculation system communicates with the straight-flow secondary air pipe, the swirl inner secondary air pipe and the swirl outer secondary air pipe;and an outlet of an air-pulverized coal system communicates with the boiler body through the primary air pipe. The multi-pass industrial pulverized coal boiler is used for the manufacturing field ofthe coal-fired industrial boiler.

Owner:HARBIN INST OF TECH

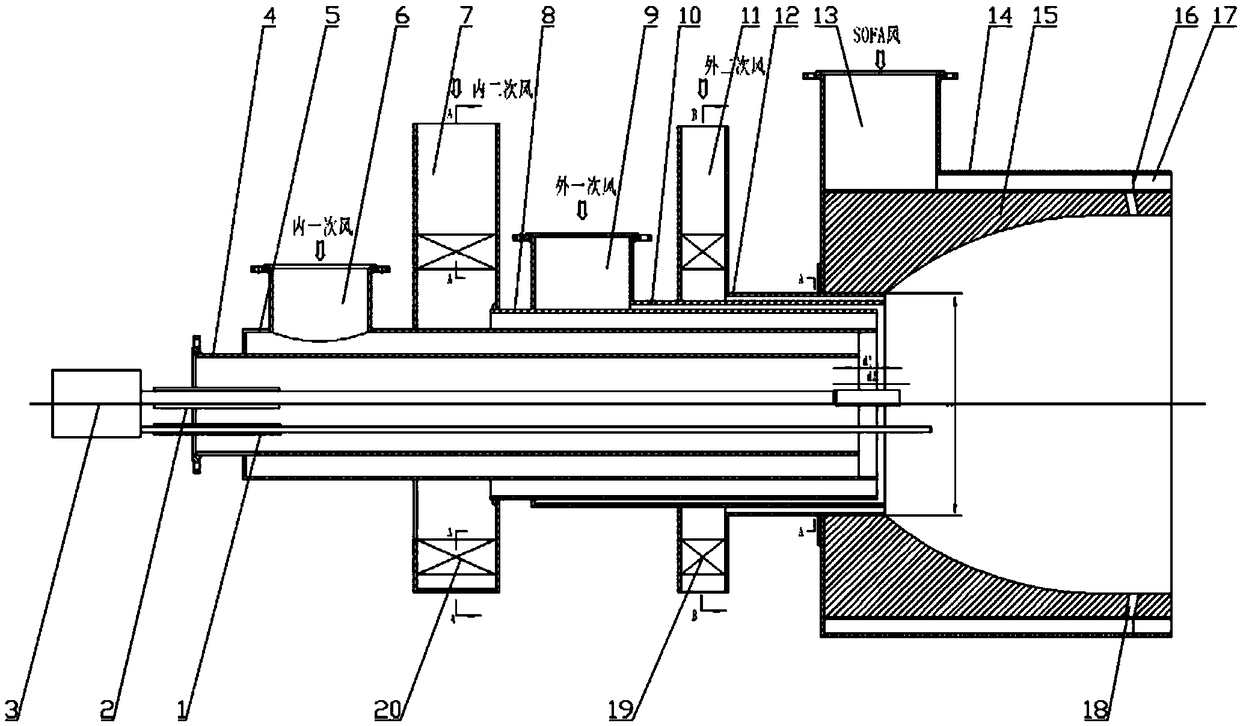

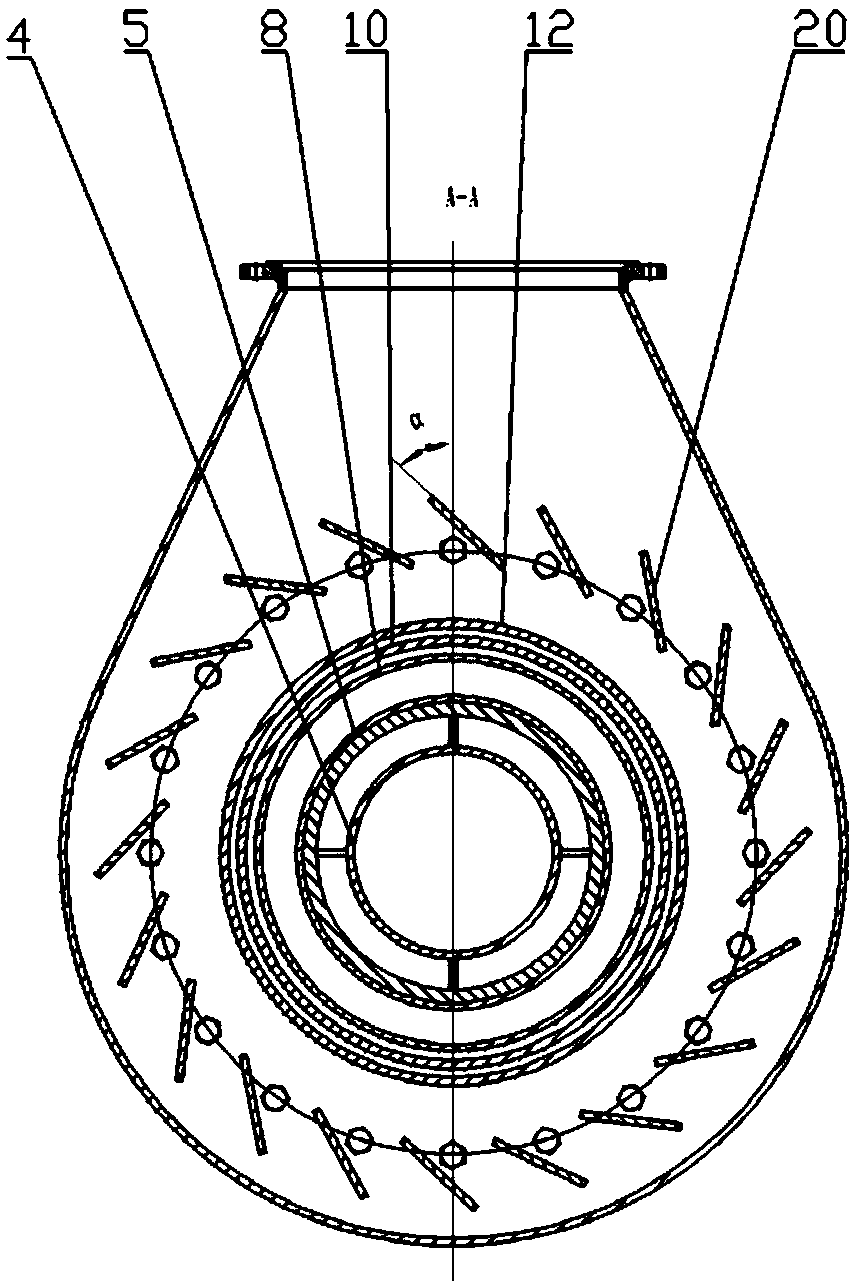

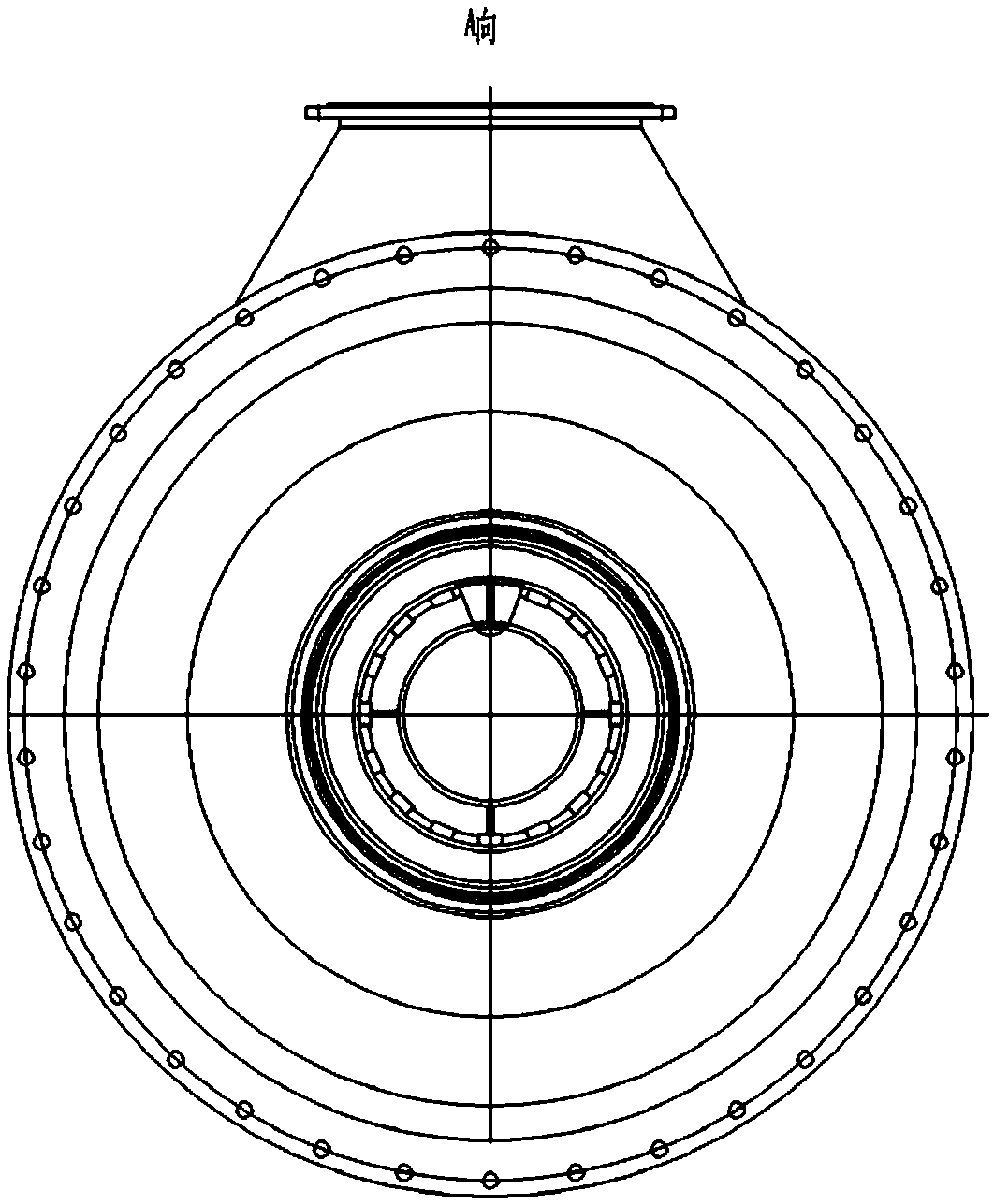

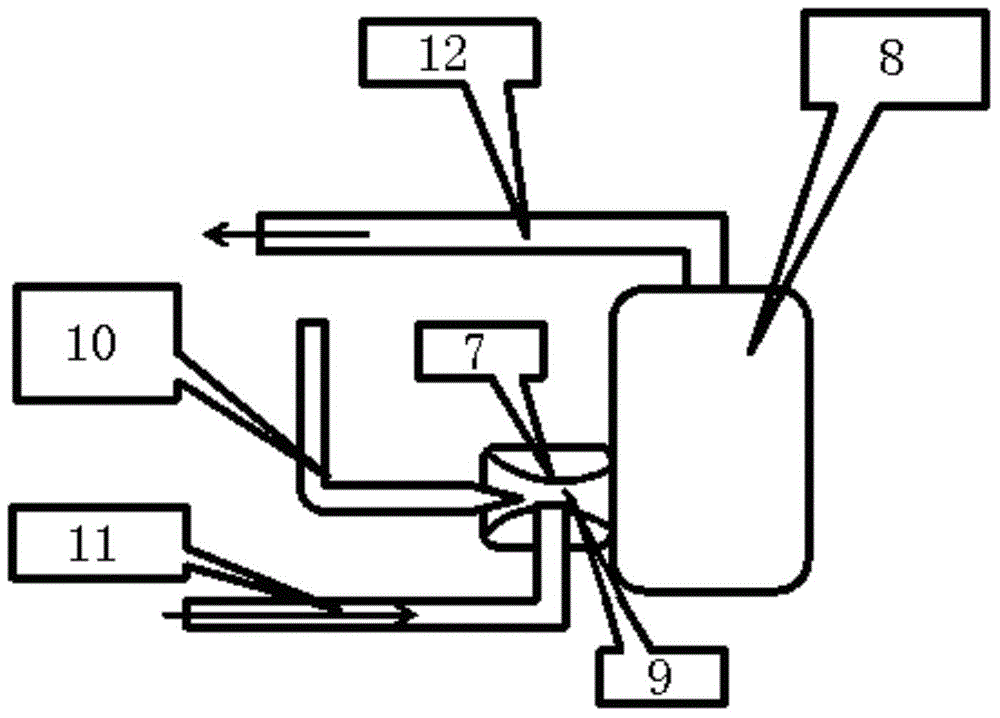

Swirling combustion device provided with pre-combustion chamber and adopting flue gas recirculation multiple radial grading

InactiveCN109631023AReduce generationControl combustion temperaturePulverulent fuel combustion burnersCombustion apparatusCombustion systemCombustion chamber

The invention relates to a swirling combustion device, in particular to a swirling combustion device provided with a pre-combustion chamber and adopting flue gas recirculation multiple radial grading.The problems of poor low-load stable combustion performance, high NOx emission, high fly ash combustible matter content and serious slagging of an industrial pulverized coal boiler at present are solved. The swirling combustion device comprises a pulverized coal combustion system and a flue gas recirculation system, the pulverized coal combustion system comprises a swirling pulverized coal burner, the pre-combustion chamber and a plurality of separation air spraying openings, the flue gas recirculation system comprises a recirculation flue gas pipeline valve, a recirculation flue gas pipeline, a recirculation flue gas branch pipeline and a recirculation fan, the swirling pulverized coal burner is arranged on a boiler through the pre-combustion chamber, the swirling pulverized coal burnercomprises a primary air pipe, a swirling inner secondary air pipe, a swirling outer secondary air pipe, a secondary air pipeline valve and a separation air pipeline valve, one end of the swirling inner secondary air pipe is mounted in one end of the primary air pipe in an inserted mode, and one end of the swirling outer secondary air pipe is mounted in the other end of the swirling inner secondaryair pipe in an inserted mode. The invention belongs to the field of industrial boiler equipment.

Owner:HARBIN INST OF TECH

Low NOx combustor allowing cross-load regulation and used for biomass or pulverized coal

PendingCN109058980AControl the combustion processFlexible adjustment of blending ratioCombustion apparatusIndirect carbon-dioxide mitigationAutomotive engineeringBiomass

The invention discloses a low NOx combustor allowing cross-load regulation and used for biomass or pulverized coal. The low NOx combustor comprises a secondary air sleeve connected to a pre-combustionchamber shell body, and a pre-combustion chamber is sleeved with an SOFA air sleeve; and an outer primary air sleeve, an inner secondary air sleeve and an inner primary air sleeve are sequentially arranged in the secondary air sleeve in a sleeved mode, a central tube is sleeved in the inner primary air sleeve, the end part of the central tube is fixedly provided with an ignition system which is composed of an oil gun or a fuel gas gun, a high-energy igniter and an ignition thruster used for pushing the oil gun or the fuel gas gun and the high-energy igniter to move forwards and backwards in the central tube, and the oil gun or the fuel gas gun and the high-energy igniter extend into the pre-combustion chamber from the tail end of the central tube. The low NOx combustor selects to enable secondary air use to be put into use to meet the cross-load regulation according to actual load requirements; and the adaptability of the combustor to different combustion modes of the biomass / the pulverized coal is enhanced through fuel staged distribution. The low NOx combustor is compact in structure, high in adaptability, good in pulverized coal combustion stability and capable of effectively reducing the generation and emission of NOx.

Owner:XI AN JIAOTONG UNIV

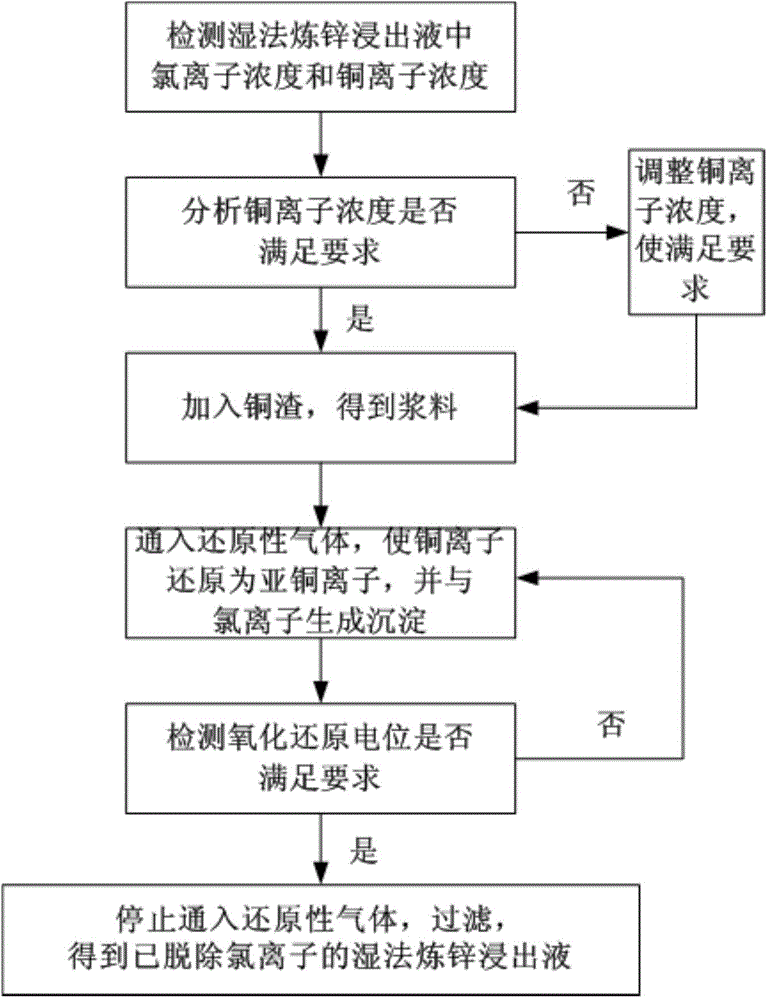

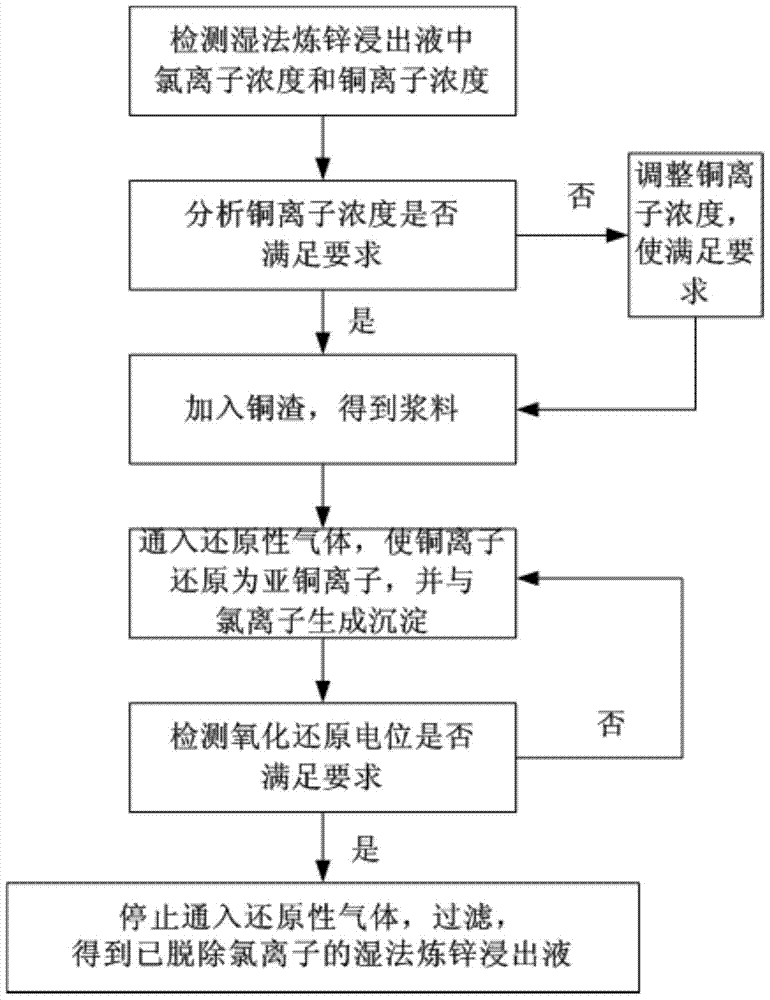

Method for removing chloride ion from lixivium of zinc hydrometallurgy

ActiveCN104694751AEnhanced reducing atmosphereReduce Chloride ContentProcess efficiency improvementPregnant leach solutionPhysical chemistry

The invention discloses a method for removing chloride ion from lixivium of zinc hydrometallurgy. The method for removing the chloride ion from the lixivium of zinc hydrometallurgy includes steps that 1, detecting the concentration of the chloride ion and concentration of copper ion in the lixivium of zinc hydrometallurgy; 2, analyzing the copper ion concentration of the step 1; 3, adding copper slag to the lixivium of zinc hydrometallurgy to obtain slurry; 4, filling reductive gas to the slurry to enable the chloride ion to form sediment; 5, detecting the oxidation reduction potential of the slurry, if the oxidation reduction potential meets the demand, stopping filling reductive gas, and filtering to obtain the lixivium of zinc hydrometallurgy without chloride ion; otherwise, returning to the step 4. The method for removing the chloride ion from the lixivium of zinc hydrometallurgy is featured with short flow, low cost and high chloride removing efficiency, other impurities are not led in, the original zinc hydrometallurgy technique is kept, and the popularization value is high.

Owner:XIAN RAREALLOYS

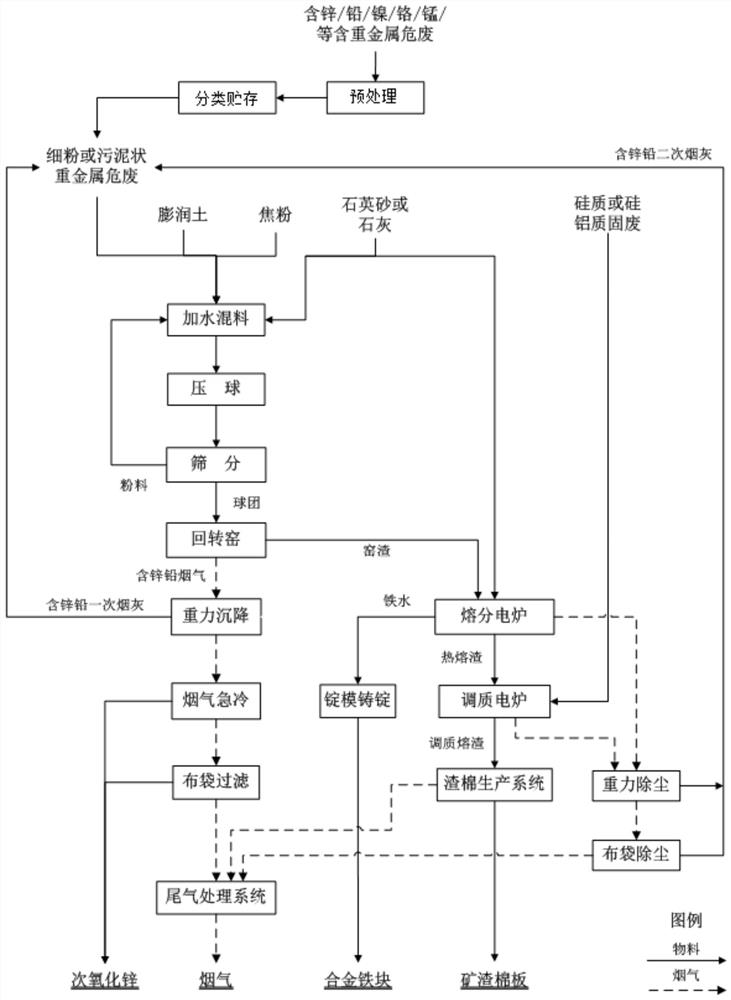

New process for comprehensive utilization of hazardous waste resources containing heavy metal

PendingCN112941324AEfficient disposalReduce heating and melting timeGlass making apparatusRotary drum furnacesTemperingPtru catalyst

The invention discloses a new process for comprehensive utilization of hazardous waste resources containing heavy metal. The process comprises the following steps of S1, the hazardous waste containing the heavy metal is subjected to pretreatment and classified storage; S2, the hazardous waste containing the heavy metal, coke powder, bentonite, quartz sand or lime are mixed with water to form a mixture; S3, the mixture is subjected to ball pressing and drying; S4, pellets enter a rotary kiln after being screened, and powder returns to the step S2; S5, the operation temperature of the rotary kiln is reduced, and flue gas is treated to produce primary soot containing zinc and lead and secondary zinc oxide; S6, kiln slag is subjected to hot conveying o a melting electric furnace for smelting, residual zinc and lead are subjected to secondary reduction to volatilize to enter the flue gas, iron, nickel, chromium and manganese are reduced to produce molten iron, and molten slag is subjected to hot conveying to a step S7 for hardening and tempering; S7, solid waste is added into a hardening and tempering electric furnace to conduct hardening and tempering on the molten slag; and S8, a mineral wool board is produced from the qualified quenched and tempered molten slag. According to the method, the technical problems that thorough harmlessness and recycling of Waelz kiln slag and a waste catalyst are difficult, and ring formation is prone to occurring in the Waelz kiln are solved.

Owner:赵江晨

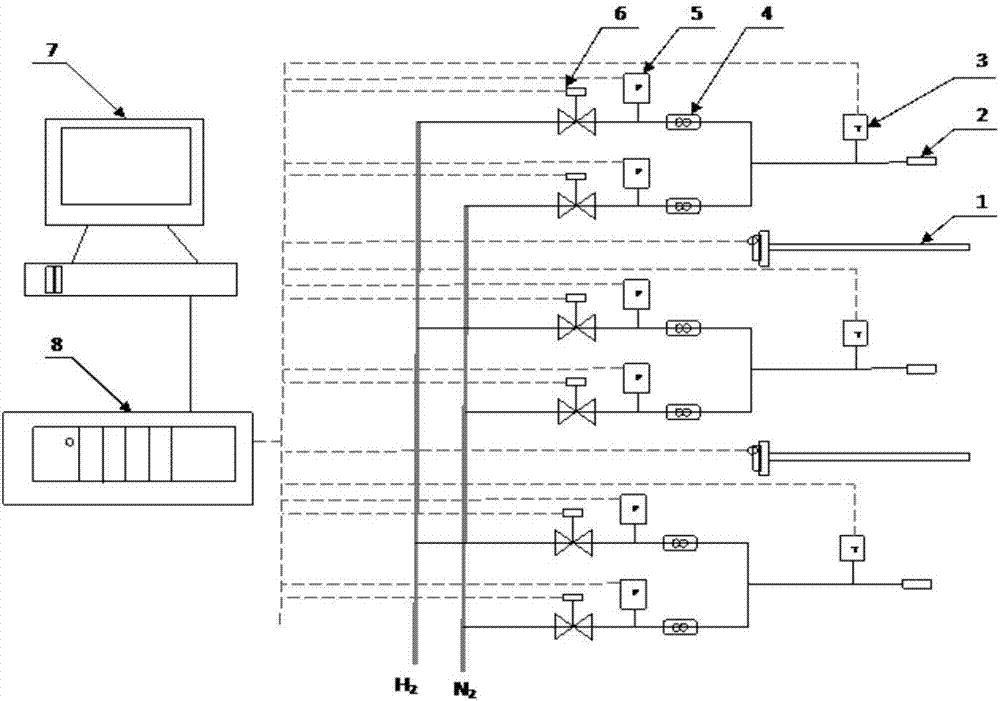

Tin bath atmosphere control system and float glass tin bath

The invention provides a tin bath atmosphere control system and a float glass tin bath. The tin bath atmosphere control system comprises an oxygen content probe, a protection gas supplying pipeline and a controller, wherein the oxygen content probe is used for detecting oxygen content and is arranged in the tin bath; the protection gas supplying pipeline is used for supplying protection gas into the tin bath; the controller is used for controlling the content of hydrogen gas in the protection gas in the tin bath through controlling the protection gas supplying pipeline in real time according detection information of the oxygen content probe. According to the control system provided by the invention, a nitrogen-hydrogen ratio is adjusted by the controller in real time according to the measured concentration of oxygen in tin liquid and / or a space of the tin bath, a reducing atmosphere of the tin bath is strengthened directly aiming at oxidization and reduction properties on tin and oxygen interfaces and reaction of the hydrogen and the oxygen is promoted to be efficiently and rapidly carried out; the content of the oxygen in the space of the tin bath and the tin liquid can be effectively reduced and oxidization of the tin liquid is reduced so that the aim of improving tin impregnation of glass is realized.

Owner:河北视窗玻璃有限公司

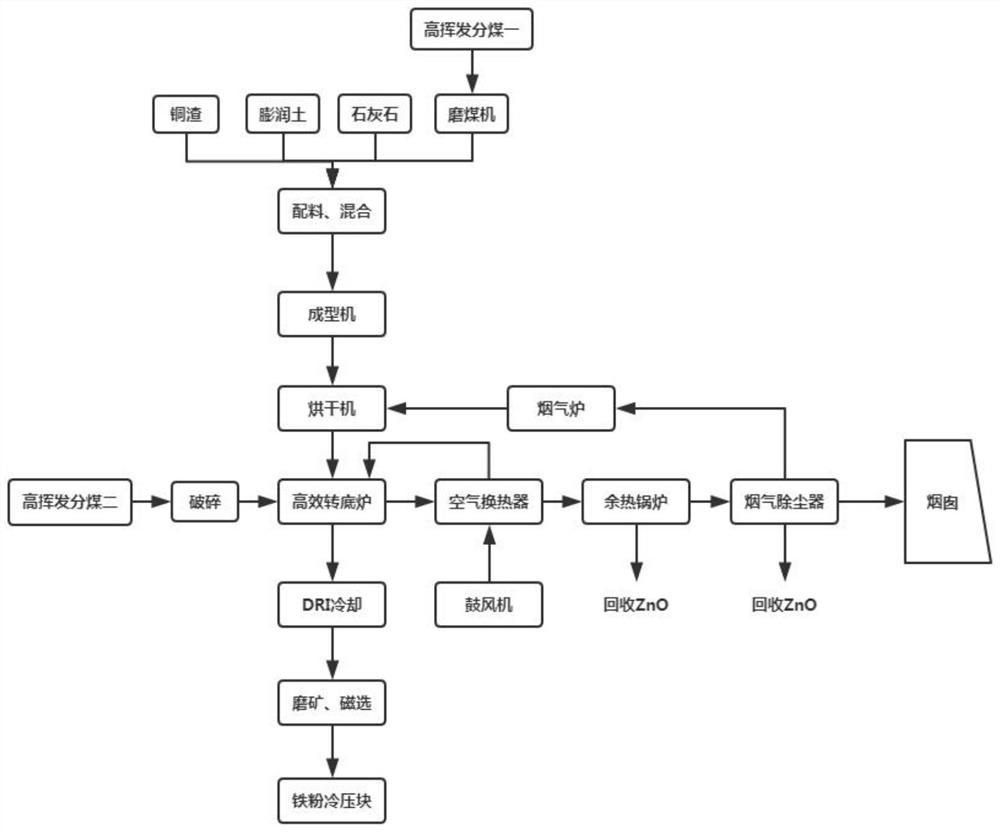

Method for treating copper slag by rotary hearth furnace

ActiveCN113736940AEfficient reductionLow reduction temperatureProcess efficiency improvementIron powderFlue gas

The invention relates to a method for treating copper slag by a rotary hearth furnace. The method comprises the steps of raw material treatment, burdening, mixing, forming, material drying, roasting reduction, flue gas treatment, finished product cooling, ore grinding, magnetic separation and iron powder cold pressing, and adopts a hydrocarbon combined reduction technology to reduce iron oxide into metal iron, reduce zinc oxide into metal zinc, volatilize, oxidize and collect, so that Fe2SiO4 in the copper slag can be efficiently reduced, the metallization rate of direct reduction iron of an intermediate product can reach 90% or above, the zinc removal rate reaches 95% or above, and the iron recovery rate of the whole process reaches 85% or above; the hydrocarbon combined reduction technology is adopted, the reduction temperature is low, and the energy consumption is low. according to the process, the reduction temperature is 800-1230 DEG C; hydrogen is adopted as a main reducing agent in the later stage of reduction, a by-product is water, green and environment-friendly effects are achieved, and the carbon emission amount of treated copper slag per ton is 50-70% of that of a carbon metallurgy rotary hearth furnace process; and the reduction coal in the process is low-rank coal instead of anthracite, so that the cost is low.

Owner:THERMONERGY HIGH TECH CO LTD

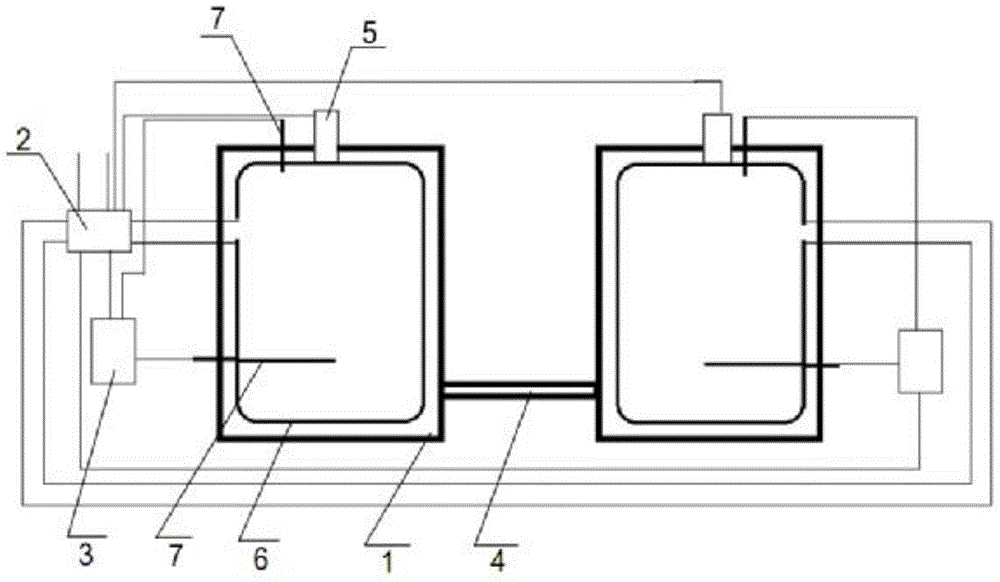

A double-body kiln for Nixing pottery

ActiveCN103983108BEnhanced reducing atmosphereImprove kiln change rateThermometer detailsFurnace componentsElectricityTransducer

The invention discloses a double-body kiln for Nixing pottery, which includes a control cabinet and two kilns arranged side by side. The two kilns are provided with ventilation ports, and the two ventilation ports are connected through hot air pipes; Each kiln is also equipped with an air exchange port, and a fan is provided on the air exchange port, and the fan is respectively connected to the output end of the control cabinet; each kiln is equipped with a heating element and a thermocouple, and the heating The thermocouples are respectively connected to the output ends of the control cabinet, and the thermocouples are respectively connected to the input ends of the control cabinet through the transmitter. According to the characteristics of Nixing pottery firing process, the present invention matches the energy level of each stage of firing process; at the same time, the twin-body kiln is used to transform the current single shuttle kiln, and the gas from the high-temperature cooling kiln is pumped to the low-temperature kiln. The program-controlled preheating of the green body in the kiln makes full use of the waste heat of the high-temperature gas, improves the heat utilization rate of the kiln, and achieves the goal of saving electricity.

Owner:GUANGXI QINZHOU NIXING POTTERY ART +1

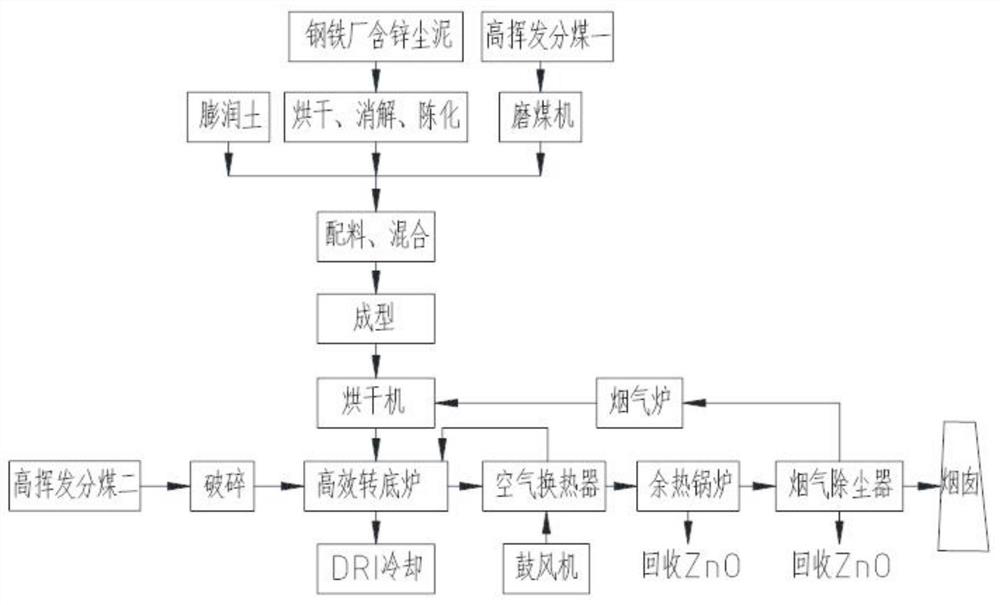

Efficient rotary hearth furnace direct reduction treatment process for zinc-containing dust and sludge in iron and steel plant

ActiveCN113528806AIncrease metallization rateLow reduction temperatureRotary drum furnacesProcess efficiency improvementReduction treatmentSludge

The invention discloses an efficient rotary hearth furnace direct reduction treatment process for zinc-containing dust and sludge in an iron and steel plant. The process comprises the steps of carrying out raw material treatment, carrying out burdening, carrying out mixing, carrying out forming, carrying out material drying, carrying out roasting reduction, carrying out flue gas treatment and carrying out finished product cooling. According to the process, CO and H2 are used as reducing agents, and H2 is derived from low-rank coal pyrolysis. The process has the beneficial effects that iron oxide is reduced into metal iron through hydrocarbon combined reduction, zinc oxide is reduced into metal zinc and then volatilized, oxidized and collected, the metallization ratio of a product can reach more than 90%, the metallization ratio is increased by 30% compared with that of an existing product, and the dezincification rate is larger than 95%. A hydrocarbon combined reduction technology is adopted, the reduction temperature is low, and the energy consumption is low. The reduction temperature of a traditional rotary hearth furnace is 1250-1350 DEG C, while the reduction temperature of the process is 800-1230 DEG C, so that the application range is wider. According to the process, reduction coal is added in the burdening stage and the deep reduction stage respectively, the reducing atmosphere of later hydrogen reduction is enhanced, the reduction efficiency and the metallization ratio are improved, meanwhile, the reduction coal in the process adopts low-rank coal instead of anthracite, and the cost is low.

Owner:THERMONERGY HIGH TECH CO LTD

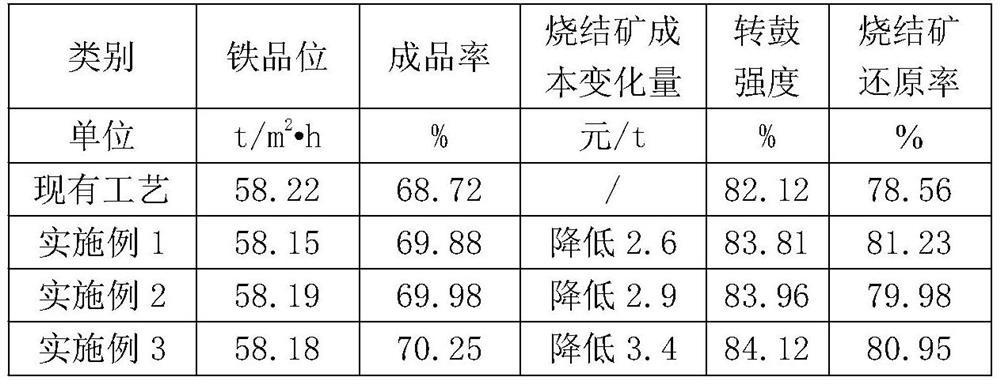

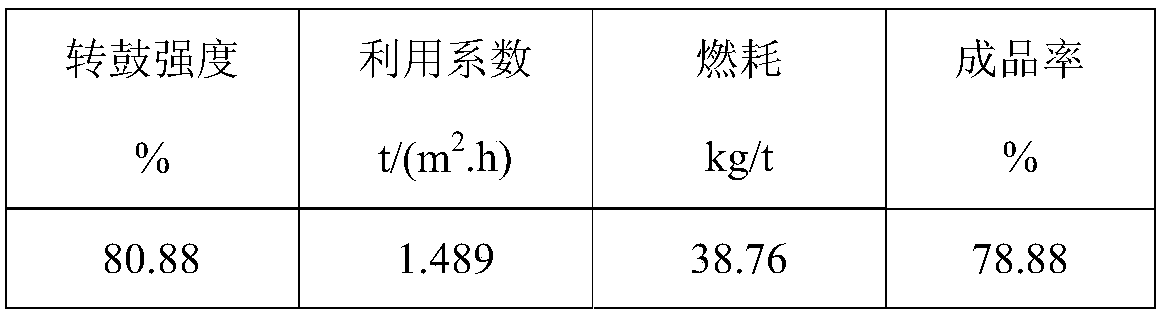

Method for improving quality of sintered ore

ActiveCN113801991AImprove reducibilityImprove breathabilityProcess efficiency improvementMaterial distributionMaterials science

The invention discloses a method for improving the quality of sintered ore. The method mainly solves the technical problem that the quality of sintered ore produced through an existing process is poor. According to the technical scheme, the method for improving the quality of the sintered ore comprises the following steps that (1) a sintering material layer middle mixture is prepared; (2) a sintering material layer upper portion mixture is prepared; (3) material distribution is conducted, wherein limonite lump ores are evenly distributed at the bottom of a sintering trolley, the particle size of the limonite lump ores is 8-20 mm, and the thickness of a limonite lump ore material layer is 25-35 mm; the sintering material layer middle mixture is distributed on the surface of the limonite lump ore layer, and the thickness of the sintering material layer middle mixture is 70-85% of the total height of the sintering trolley; and then the sintering material layer upper portion mixture is distributed on the surface of the sintering material layer middle portion mixture; and (4) air draft sintering is conduced, wherein the sintered material is subjected to ignition and air draft sintering, and the sintered ore is produced. The sintered ore produced by the method is excellent in metallurgical performance and low in cost.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

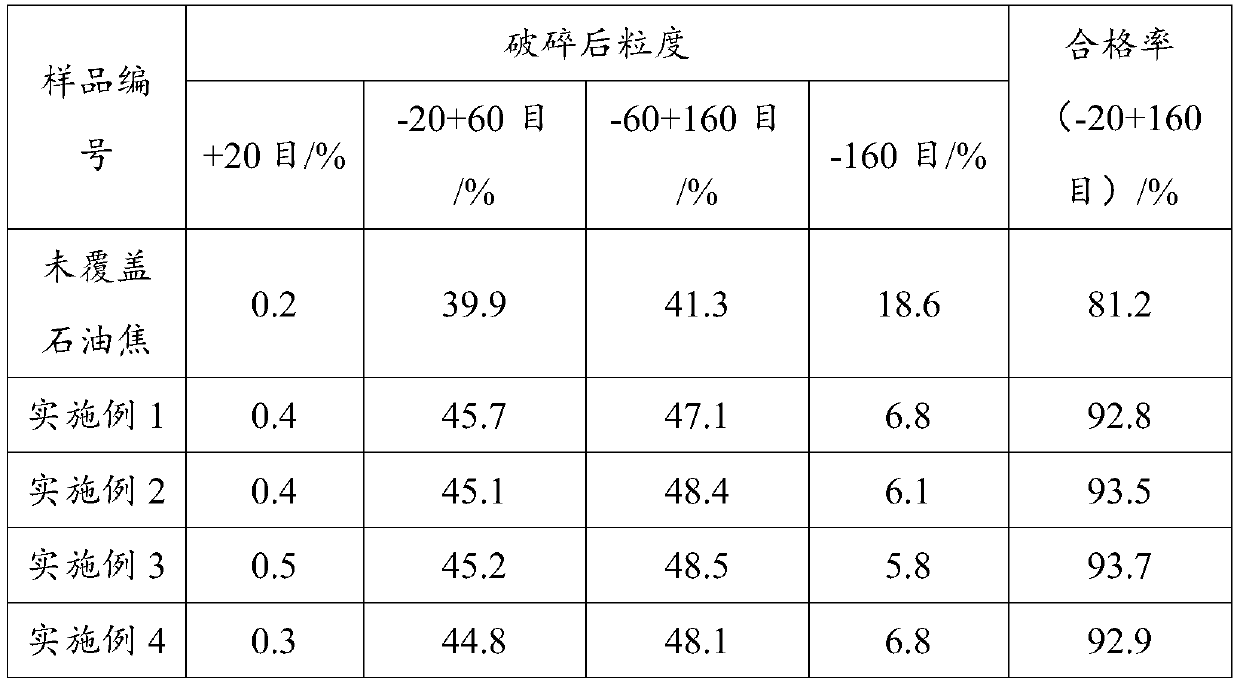

Method for preparing TiO2 raw material for chlorination process from titanium-rich fine powder

The invention provides a method for preparing a TiO2 raw material for a chlorination process from titanium-rich fine powder. The method comprises the following steps: S1, weighing the titanium-rich fine powder, and uniformly mixing the titanium-rich fine powder with a solid organic binder and petroleum coke at room temperature; S2, uniformly covering the surface of a mixed material obtained in thestep S1 with petroleum coke, and then performing low-temperature coking at 380-420 DEG C for 2.5-4 hours; and S3, crushing the material having undergone low-temperature coking in the step S2 into particles for the first time, then carrying out high-temperature coking at 900-1200 DEG C for 20-60 minutes, and crushing a coked material into particles again so as to obtain the TiO2 raw material for the chlorination process. The method can prepare the TiO2 raw material with high yield (higher than 92%) and qualified granularity for the chlorination process and realizes the cyclic utilization of the titanium-rich fine powder; and the batching procedure of a later chlorination reaction is reduced by adding the petroleum coke in advance.

Owner:HENAN BILLIONS NEW MATERIAL CO LTD

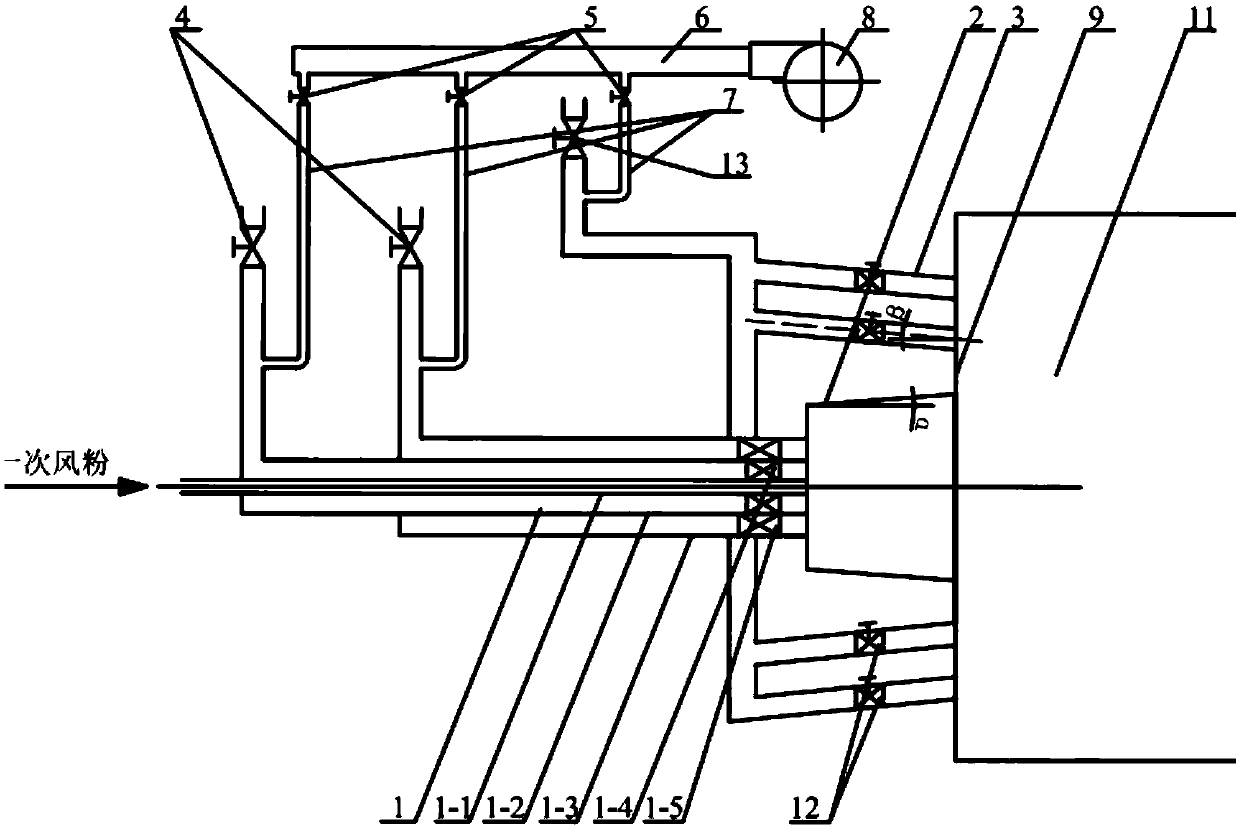

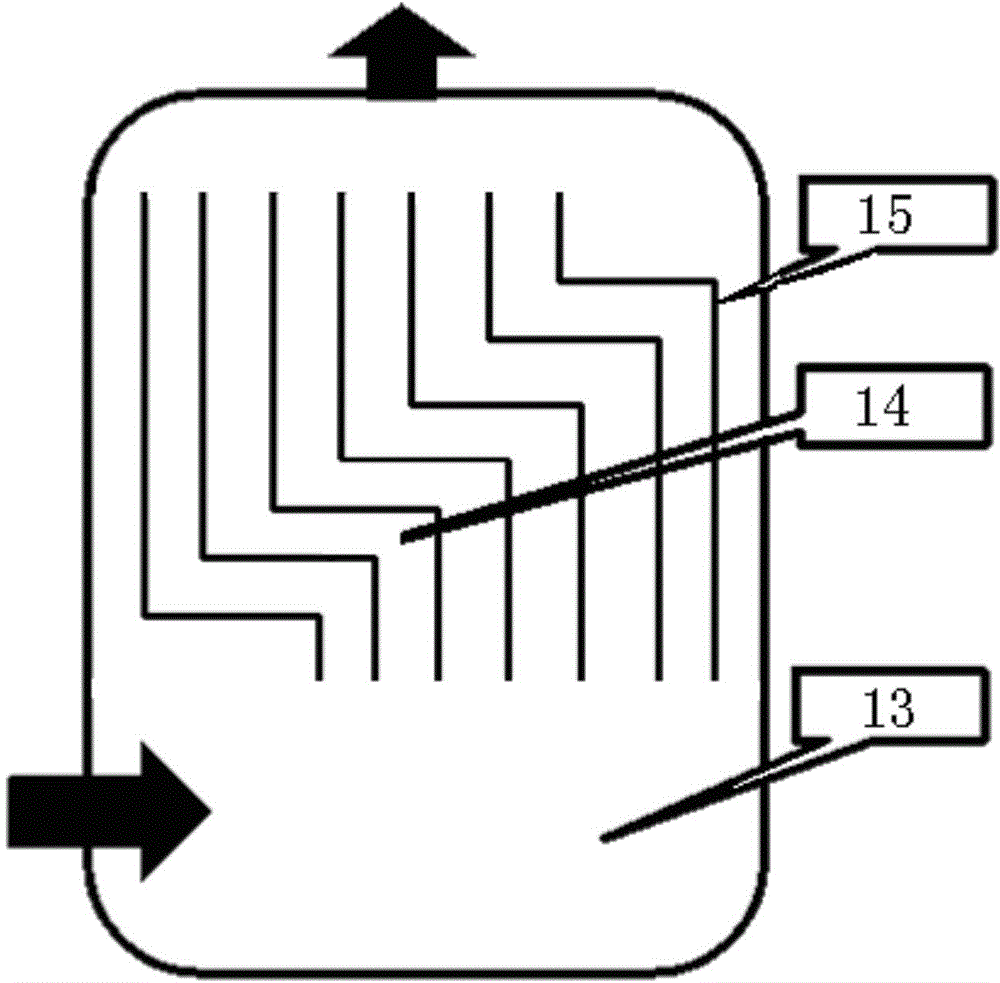

Fly ash and slag reburning system suitable for coal-fired boiler with horizontally-arranged hearth

PendingCN109737392AImprove efficiencyTake advantage ofFluidized bed combustionNon-combustible gases/liquids supplyCombustorSlag

The invention provides a fly ash and slag reburning system suitable for a coal-fired boiler with a horizontally-arranged hearth. Sufficient burning of pulverized coal fuel is facilitated. A burner isarranged at an inlet of the horizontally-arranged hearth and comprises a center primary air pipe, and the center primary air pipe carries pulverized coal. An outlet of the horizontally-arranged hearthis connected with a flue for discharging smoke. The flue is connected with a recirculation smoke pipeline. An ash bucket communicating with the horizontally-arranged hearth is arranged below the horizontally-arranged hearth. The ash bucket collects slag settled in the horizontally-arranged hearth. The lower end of the ash bucket is connected with a coal mill. The collected slag is fed to the coalmill to be crushed. The recirculation smoke pipeline is also connected with the coal mill. The coal mill is connected with a cyclone separator. Slag powder generated by crushing and recirculation smoke enter the cyclone separator together. An outlet in the upper end of the cyclone separator is connected with an inlet of the center primary air pipe of the burner. The recirculation smoke enters thecenter primary air pipe of the burner together by carrying separated-out qualified fly ash and fine ash.

Owner:河南省锅炉压力容器安全检测研究院

Device and method for reducing discharging of boiler NOx in powder mode

InactiveCN104141950ALow oxygenSuppression of NOx generationDrying gas arrangementsCombustion apparatusEconomizerSmoke

The invention discloses a device and method for reducing discharging of boiler NOx in a powder mode. The device comprises a first smoke pipeline and a second smoke pipeline. The initial end of the first smoke pipeline is arranged behind an economizer in a smoke channel, and the tail end of the first smoke pipeline is arranged in a hearth. A first check valve, a boiler smoke draught fan, a third electrically operated valve and a coal mill are connected to a pipe way of the first smoke pipeline in sequence. The second smoke pipeline is connected to the pipe way between the first check valve and the boiler smoke draught fan. When mixed smoke carrying coal dust enters the hearth to burn, burning is carried out in an oxygen deficient state, combination between N and O is reduced, the reducing atmosphere of the hearth is enhanced, the production of NOx is restrained intensely, and the content of NOx in the smoke is reduced. The device and method are combined with the tail smoke denitrition technology, the usage amount of catalyst and reductant can be saved, denitration cost and energy consumption are reduced, the denitration efficiency is guaranteed, and a denitration system can safely run in an economical mode. The device and method can be widely applied to smoke denitration systems in the electric power industry, the petrochemical industry and the like.

Owner:SOUTH CHINA UNIV OF TECH

A method for removing chloride ions from hydrometallurgy zinc leaching solution

ActiveCN104694751BEnhanced reducing atmosphereReduce Chloride ContentProcess efficiency improvementPregnant leach solutionPhysical chemistry

The invention provides a method for removing chloride ions from the leaching solution of zinc hydrometallurgy, comprising the following steps: 1. detecting the concentration of chloride ions and the concentration of copper ions in the leaching solution of zinc hydrometallurgy; Analyze the copper ion concentration obtained; 3. Add copper slag to the zinc hydrometallurgy leaching solution to obtain a slurry; 4. Then feed reducing gas into the slurry to make chloride ions form precipitation; 5. Detect the concentration of the slurry Oxidation-reduction potential, if meet the requirements, then stop feeding the reducing gas, filter to obtain the hydro-smelting zinc leaching solution from which chloride ions have been removed; otherwise, return to step 4. The invention has the characteristics of short process, low cost, high chlorine removal efficiency, no introduction of other impurities, maintaining the original zinc hydrometallurgy process, etc., and has wide popularization value.

Owner:XIAN RAREALLOYS

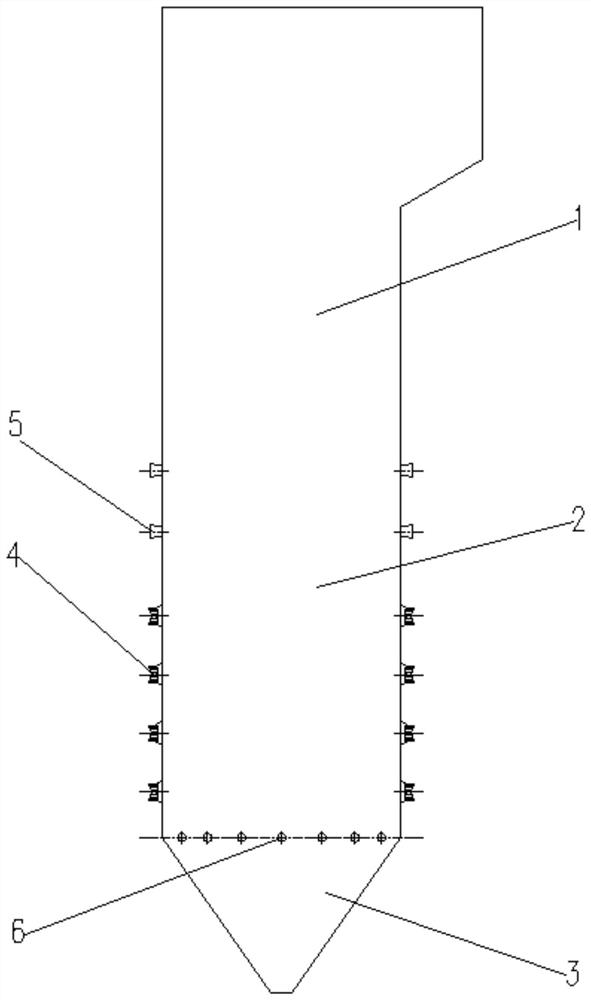

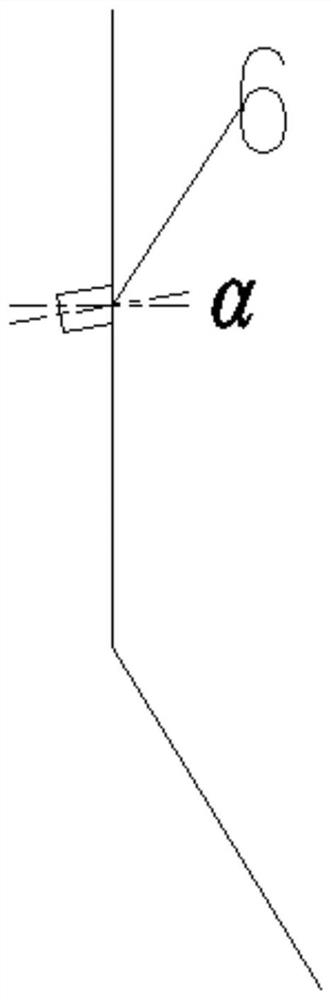

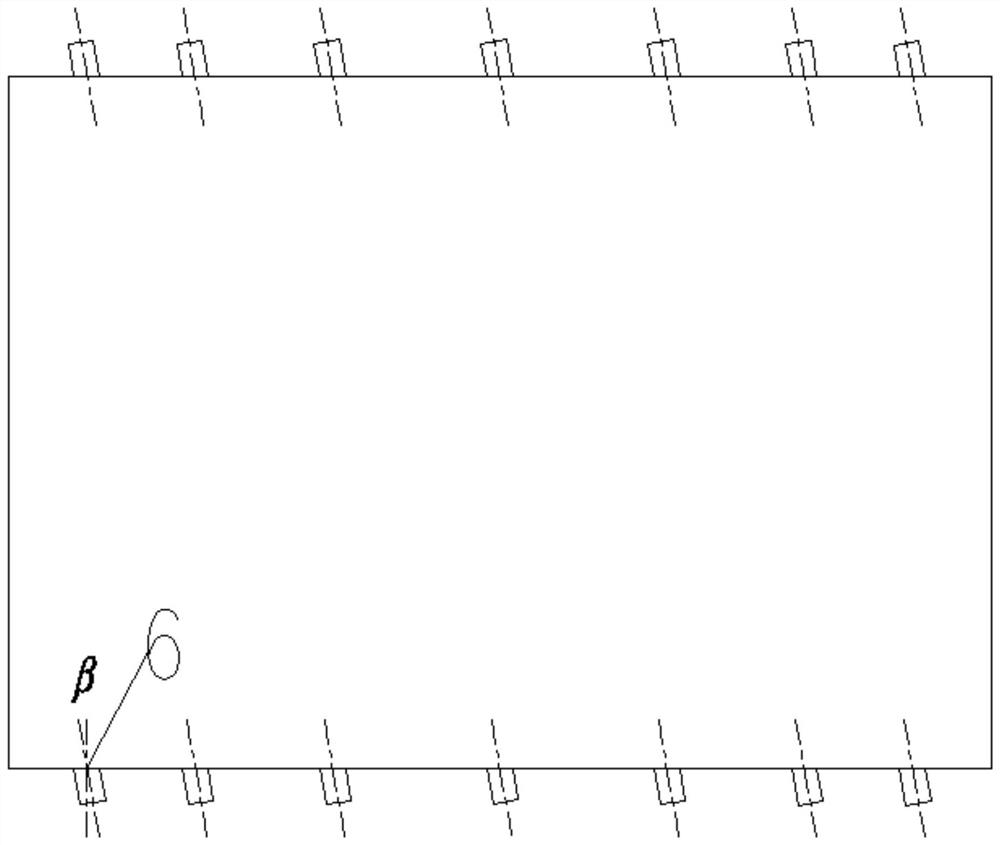

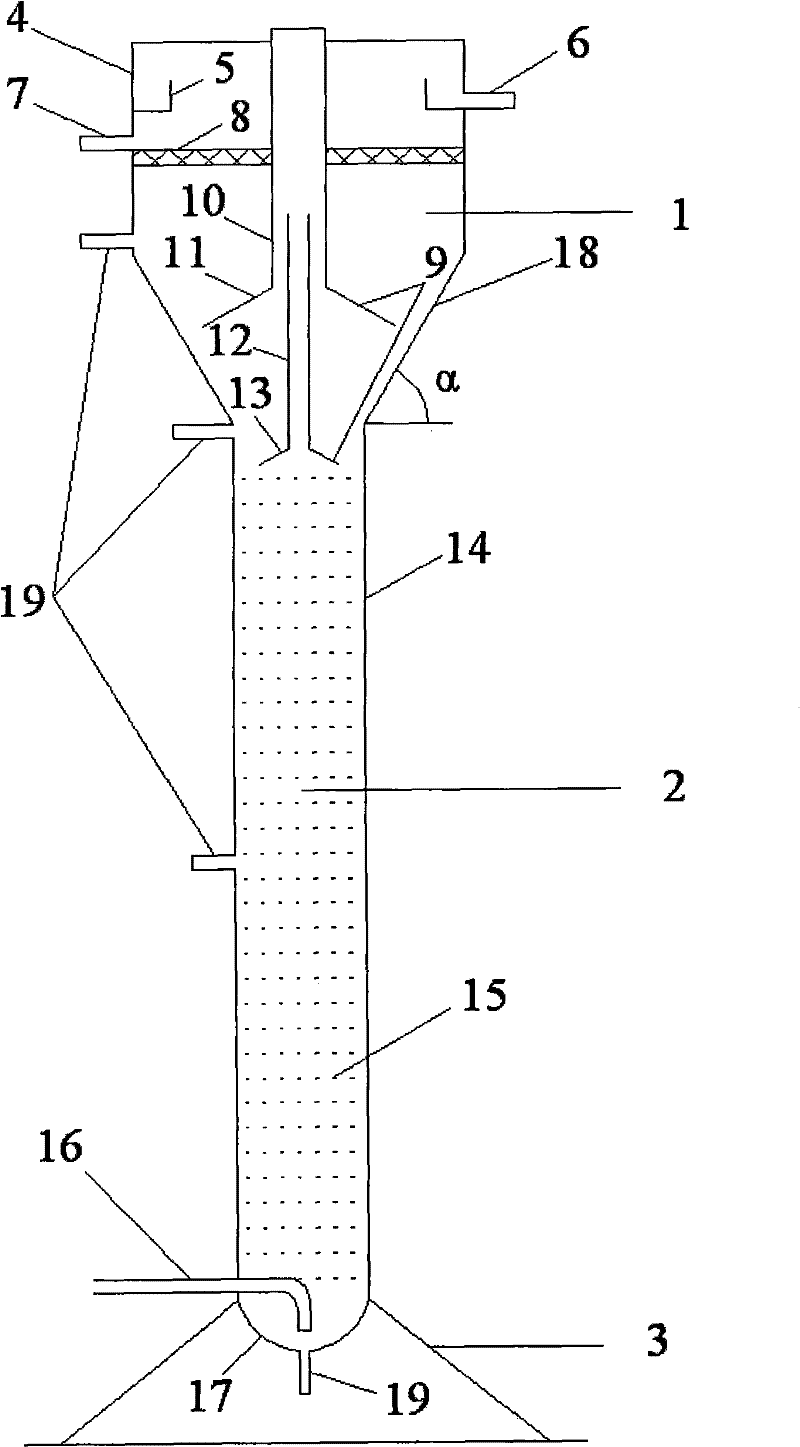

Furnace bottom air supplement type opposed firing pulverized coal furnace

PendingCN113154366AImprove combustion conditionsIncrease oxygen concentrationCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelThermodynamicsNitrogen oxides

The invention discloses a furnace bottom air supplement type opposed firing pulverized coal furnace. The furnace bottom air supplement type opposed firing pulverized coal furnace comprises a furnace body (1), a main combustion area (2) located in the furnace body (1), a dry bottom hopper (3) located at the bottom of the furnace body (1), a combustor (4) and an over fire air nozzle (5), the combustor (4) and the over fire air nozzle (5) are arranged on the furnace body (1), and the combustor (4) is located below the over fire air nozzle (5). A plurality of air supplementing nozzles (6) are mounted on the wall surface between the dry bottom hopper (3) and the main combustion area (2); and sprayed air enters the bottom of the furnace body (1) through the air supplementing nozzles (6). According to the furnace bottom air supplement type opposed firing pulverized coal furnace, collaborative optimization of the pulverized coal burn-off rate, high-temperature corrosion of the dry bottom hopper and nitrogen oxide emission is achieved, and good economic benefits and environmental benefits are achieved.

Owner:润电能源科学技术有限公司

A method for manufacturing hot-dip galvanized steel sheet without strip zinc dust and bright spot defects on the surface

ActiveCN103556095BEnhanced reducing atmosphereDoes not cause oxidationHot-dipping/immersion processesSheet steelHydrogen

The invention relates to the technical field of hot galvanized steel sheet manufacturing, particularly to a manufacturing method for a hot galvanized steel sheet without strip zinc ash and bright spot defects on the surface. The method is characterized by: installing a condensation precipitation device outside a furnace nose to form negative pressure at a zinc pot side in the furnace nose, at the same time, heating a furnace nose side wall to raise the temperature to 450-550DEG C, making the zinc vapor over the zinc pot sucked away continuously and unable to accumulate on the side wall in the region, keeping the dew point of the nitrogen and hydrogen protective gases in the furnace nose in the range from -70DEG C to -20DEG C without additional humidification, cooling the zinc vapor in the condensation precipitation device, and precipitating and depositing zinc powder. Compared with the prior art, according to the method provided by the invention, the zinc vapor over the zinc pot is sucked away, and no zinc powder precipitates out, so that a high dew point method is no longer needed to inhibit the zinc vapor. Therefore, the strip zinc ash and bright spot defects are maximumly controlled.

Owner:ANSC TKS GALVANIZING

Composite additive for reinforcing nickel laterite ore briquette and preparation method and application thereof

The invention provides a composite additive for reinforcing a nickel laterite ore briquette and a preparation method and application thereof. The composite additive comprises 5-10 wt% of water glass, 50-65 wt% of anthracite, 5-10 wt% of sodium humate and 10-30 wt% of limestone. The preparation method is to weigh and uniformly mix anthracite, sodium humate and limestone according to the mass ratios to obtain a mixture; and then, water glass is singly mixed. The composite additive can prominently improve the yield and the cold / hot-state strength of the nickel laterite ore briquette, and can be applied to the nickel laterite ore briquette.

Owner:CENT SOUTH UNIV

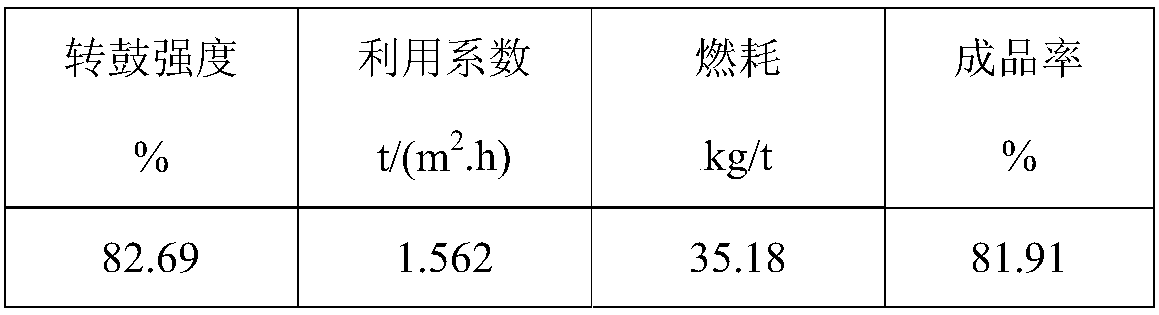

A method for improving the heat uniformity of pre-sintering process

ActiveCN106467934BReduced vertical sintering speedReduce fuel consumptionSolid fuelMaterial distribution

The invention provides a method for improving homo-heating property in a pre-sintering process. The method includes the steps of burdening, uniformly mixing of sintering materials, granulation, bottom material pavement, material distribution, ignition and sintering. During the sintering production process, a sintering mixture material is subjected to two-stage material distribution. Firstly, for the first time, a lower-layer sintering mixture material is distributed, material distribution thickness being 500-900 mm; and after ignition, the material is pre-sintered for a preset time, and then an upper-layer sintering mixture material is secondarily distributed on the surface of the material being sintered, material distribution thickness being 100-700 mm; and then ignition sintering is carried out again until sintering terminal, wherein the total thickness of the material layers is not less than 1000 mm; water content of the lower-layer sintering mixture material is controlled to be 5.9-6.7% and the water content of the upper-layer sintering mixture material is controlled to be 6.8-8.6%. By means of the method for sintering ore, quality is significantly improved and sintering solid fuel consumption is reduced, thus achieving the objects of homogenizing sintering, reducing cost and improving efficiency.

Owner:ANGANG STEEL CO LTD

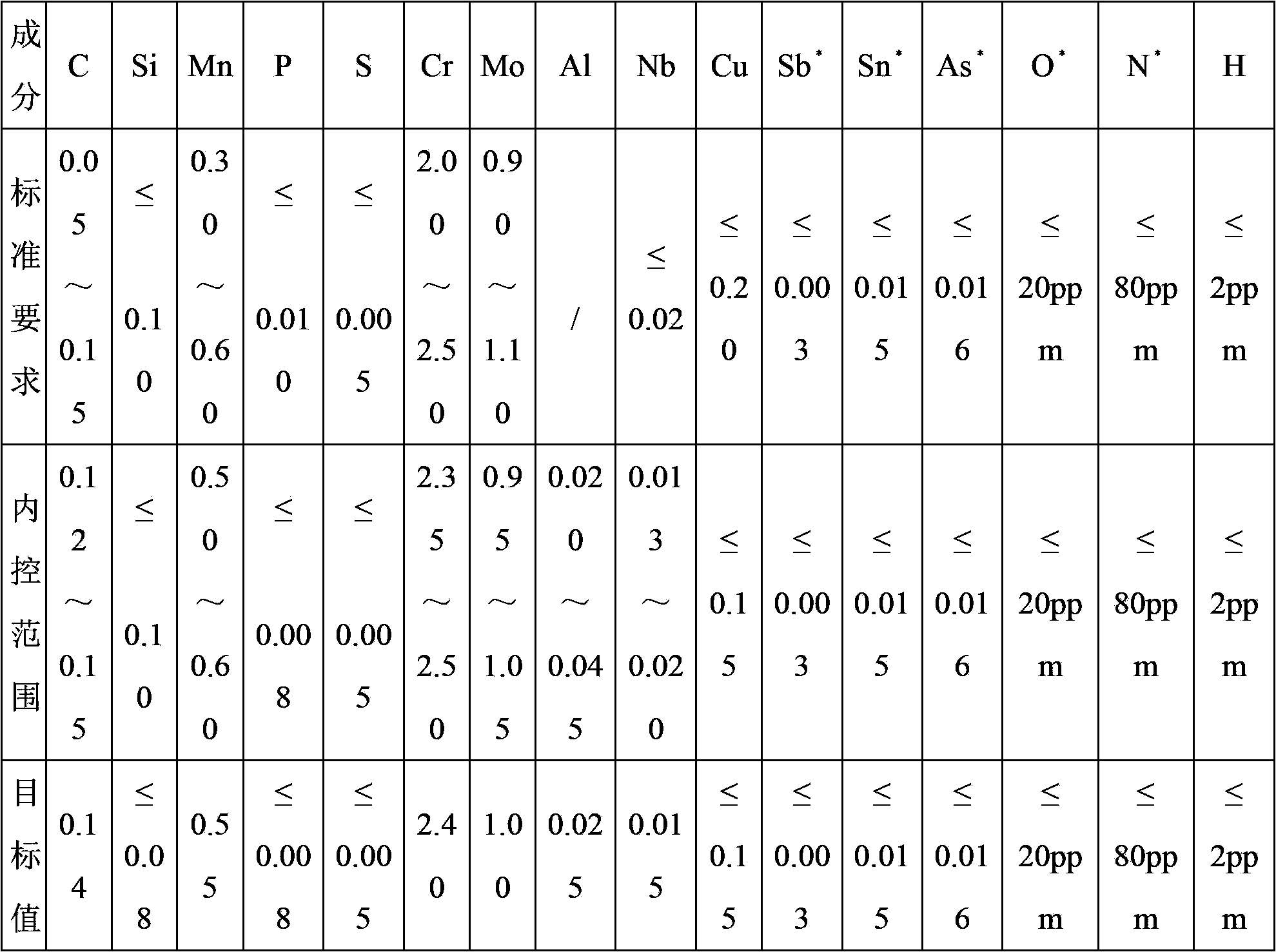

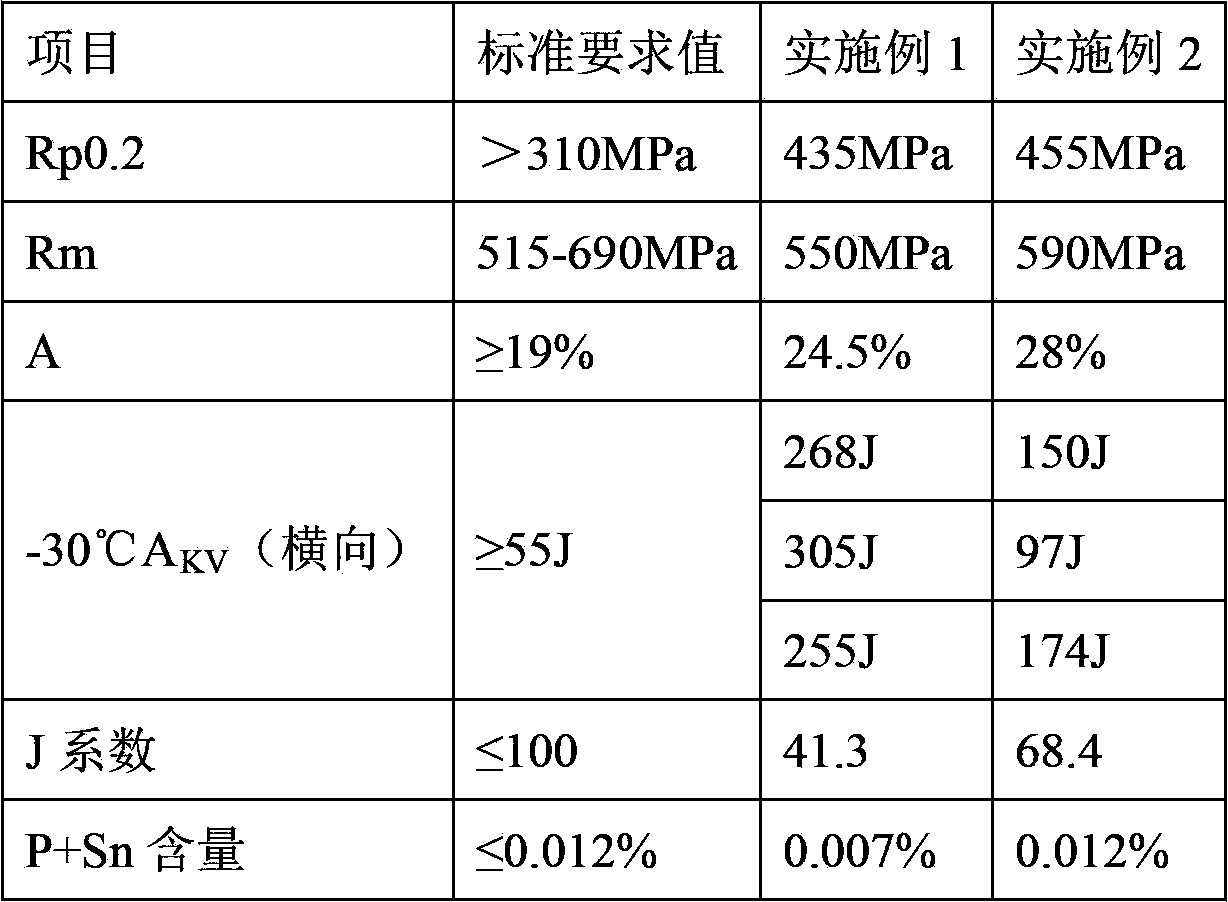

Low-cost smelting silicon-controlling method for hydro-chrome-molybdenum steel

InactiveCN102851594BImprove deoxidation strengthSilicon increase decreasedProcess efficiency improvementSmelting processReducing atmosphere

Owner:WUYANG IRON & STEEL +1

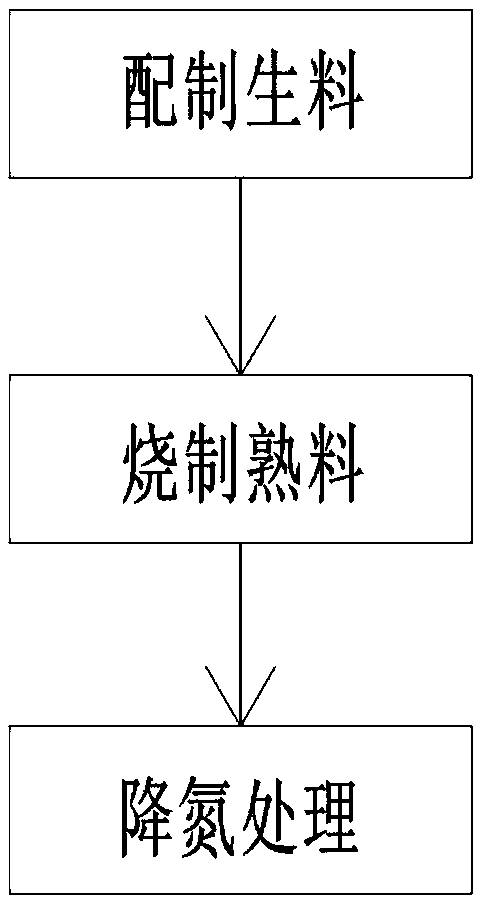

Coal-fired nitrogen reduction method for cement kiln

The invention discloses a coal-fired nitrogen reduction method for a cement kiln, which belongs to the field of preparation of building consumables and comprises the following steps: preparing a raw material; firing the raw material to obtain clinker; and carrying out nitrogen reduction treatment. In the clinker firing process, the charging temperature of the necking of a smoke chamber needs to becontrolled, the charging temperature of the necking of the smoke chamber is controlled as low as possible on the basis that the firing effect is ensured, and the charging temperature of the necking of the smoke chamber is controlled to be not higher than 1100 DEG C. Thus, the reducing atmosphere can be increased, the production of nitrogen oxides can be reduced, the consumption of ammonia water can be reduced, the cost of nitrogen removal is greatly reduced, and the use of fuel is reduced. By adopting a novel raw material formula, the cyclic utilization of the construction waste is greatly increased, the cost is reduced, the waste is turned into wealth, the development of circular economy is promoted, the pollution is reduced, the ecological environment is protected, and the method has agood market prospect.

Owner:三明金牛水泥有限公司

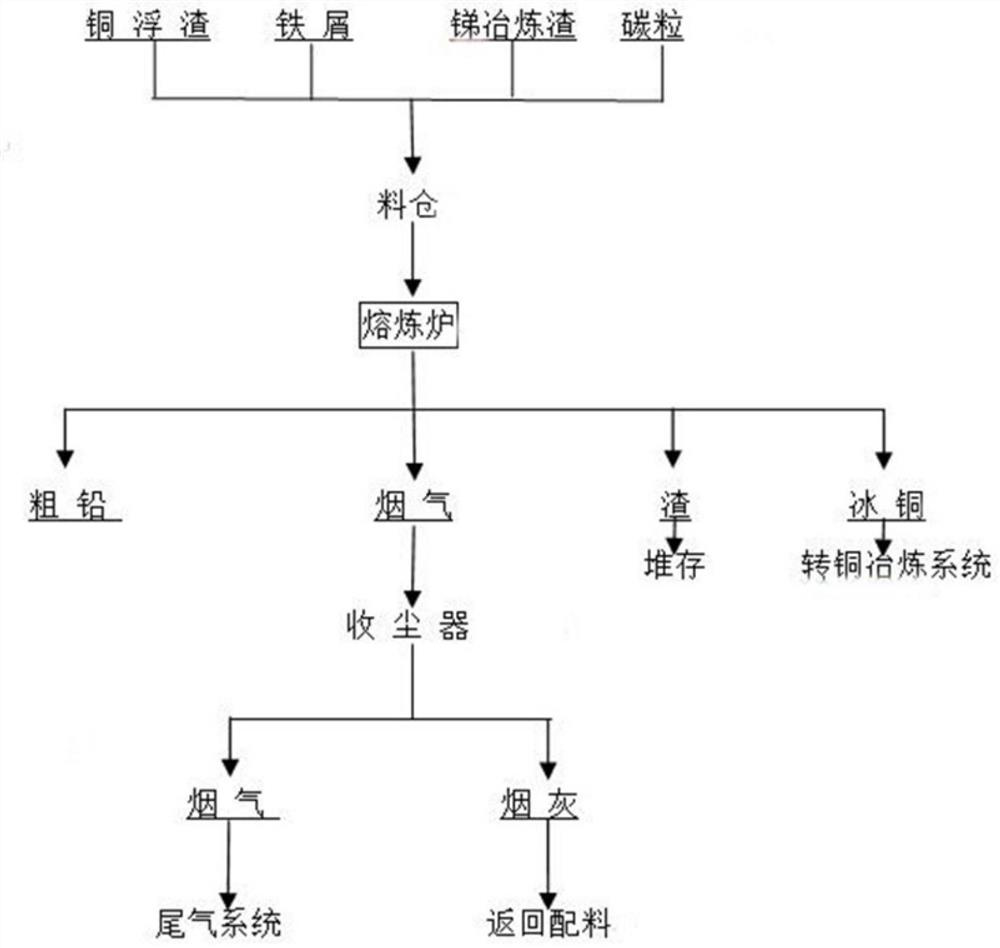

Method for recovering valuable metals by smelting copper dross

PendingCN114540631AEfficient separationImprovement of slag copper content indexProcess efficiency improvementExhaust gasScrap

The invention discloses a method for recovering valuable metals by smelting copper dross. The method comprises the following steps: proportioning copper dross, scrap iron, a slag former and a reducing agent as raw materials; the prepared materials are added into a smelting furnace for heating reduction smelting, and crude lead, smelting slag, matte and flue gas are generated through reduction smelting; lead metal in the copper dross enters lead bullion, tin metal enters lead bullion, and copper metal enters matte; the generated lead bullion enters a tin removal process, and enters a lead bullion electrolysis process to produce electrolytic lead after tin slag is produced; transferring the matte into a copper smelting system for recycling; the flue gas is subjected to dust collection treatment, the treated flue gas enters a tail gas system to be emptied, and the obtained soot returns to the smelting process to be reused as an ingredient. According to the technical scheme, the fluidity of the copper dross smelting slag can be obviously improved, the layering effect of slag, matte and lead bullion in the furnace in the smelting process is enhanced, the phenomena of slag adhesion and material collapse in the furnace are reduced, the slag index is obviously reduced, the operation is safe and controllable, and the labor intensity is reduced.

Owner:HENAN YUGUANG GOLD & LEAD

Low-nitrogen swirling burner based on out-phase reduction of superfine pulverized coal and transformation method

PendingCN110186036AInhibitivePlay a role in reducingPulverulent fuel combustion burnersLump/pulverulent fuel feeder/distributionCombustorLow nitrogen

The invention discloses a low-nitrogen swirling burner based on out-phase reduction of superfine pulverized coal and a transformation method, and belongs to power generating equipment of a thermal power plant. According to the low-nitrogen swirling burner based on out-phase reduction of the superfine pulverized coal and the transformation method, the low-nitrogen swirling burner based on out-phasereduction of the superfine pulverized coal mainly comprises a swirling burner body, a central superfine pulverized coal tube and other components; a specific mounting method of the swirling burner comprises steps as follows: a sleeve fixing device is welded; a sleeve is welded; the central superfine pulverized coal tube is inserted into the center of the burner; an adjusting hand wheel is mountedand the position is marked. The distance between the central superfine pulverized coal tube and an outlet of the burner can be directly adjusted by the hand wheel, and NOx produced when the pulverized coal is burnt by the swirling burner is controlled deeply, so that one transformation method of the low-nitrogen swirling burner is provided for realization of ultralow emission of a coal-fired power plant.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Superhigh-efficiency anammox reactor

ActiveCN101863554BAccelerated settlementHigh densityTreatment with anaerobic digestion processesGas collecting tubeIron powder

The invention discloses a superhigh-efficiency anammox reactor, which is provided with a sediment zone, a reaction zone and a bracket. The sediment zone is sequentially provided with a first outer cylinder, an overflow weir, a water outlet, a backflow port, an annular wire netting and a two-stage three-phase separator from top to bottom. The two-stage three-phase separator comprises a first gas collecting tube, a first reducing pipe, a second gas collecting tube and a second reducing pipe. The overflow weir is communicated with the water outlet, the backflow port is positioned between the overflow weir and the annular wire netting, the inner ring of the annular wire netting is connected with the outer wall of the first gas collecting tube, and the outer ring of the annular wire netting isconnected with the inner wall of the first cylinder. The reaction zone comprises a second outer cylinder, an iron powder carrier, a water inlet tube and a hemispheroid. The reaction zone is connectedwith the sediment zone through an outer cylinder increasing coupling and is directly connected with the bracket, and both the reaction zone and the sediment zone are provided with dredge pipes. The invention effectively prevents sludge loss, reduces gas disturbance, promotes the natural sedimentation of granules, reduces the toxicity of the base material and ensures the operating performance of the reactor to be efficient and stable.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com