Fly ash and slag reburning system suitable for coal-fired boiler with horizontally-arranged hearth

A coal-fired boiler, a horizontal technology, applied in the field of coal-fired boilers, can solve the problems of increasing cost and system complexity, high carbon content in fly ash, reducing boiler efficiency, etc., to avoid condensation corrosion, improve boiler efficiency, and improve boiler efficiency. The effect of system security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

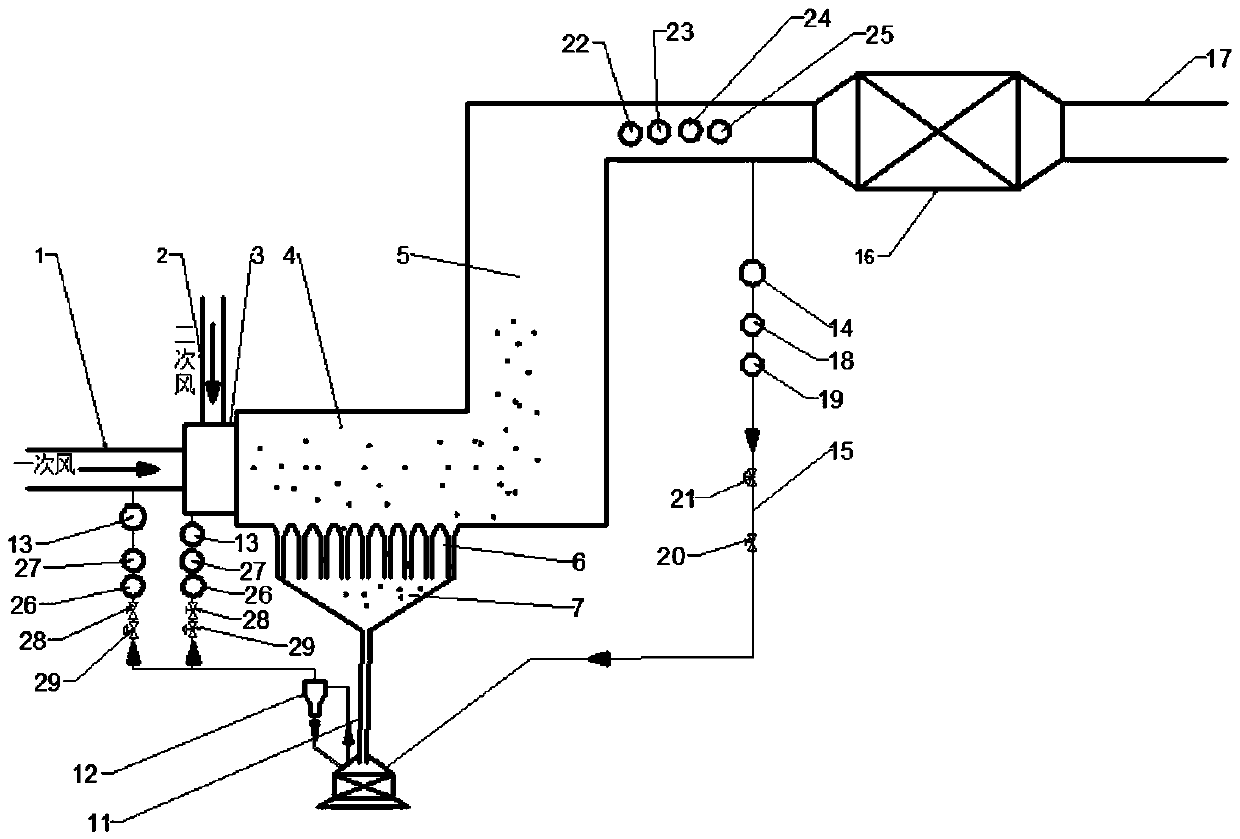

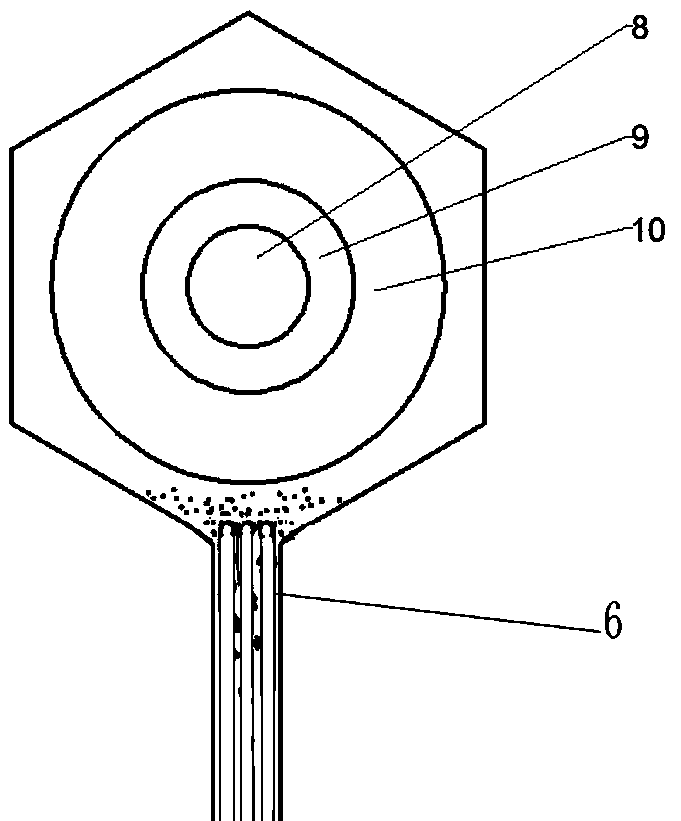

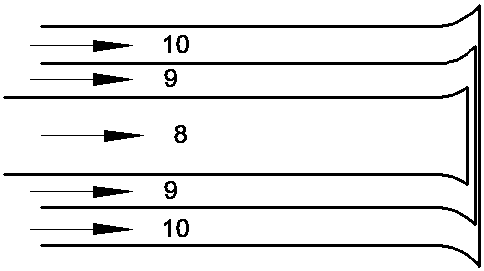

[0030] like Figure 1-Figure 3 As shown, a fly ash and slag reburning system suitable for a coal-fired boiler with a horizontally arranged furnace, the horizontally arranged furnace inlet is provided with a burner 3, the burner 3 includes a central primary air pipe 8, and the central primary air pipe 8 carries pulverized coal The horizontally arranged furnace 4 is connected to the vertically arranged furnace 5, and the outlet of the vertically arranged furnace 5 is connected to the flue 17 for exhausting smoke. 4 Connected ash hopper 7, ash hopper 7 collects the slag settled in the furnace 4 arranged horizontally, the lower end of ash hopper 7 is connected with a coal mill 11, the collected slag is sent to the coal mill 11 for crushing, and the flue gas recirculation pipe 15 Also connected to the coal mill 11, the coal mill 11 is connected to the cyclone separator 12, the pulverized slag powder and the recirculated flue gas go to the cyclone separator 12 for separation, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com