High-alkalinity composite metallized pellet for converter and production process thereof

A composite metal, high alkalinity technology, applied in the manufacture of converters, etc., can solve the problems of long production time, high energy consumption, small particle size of metallized pellets, etc., to reduce the amount of use, increase the reduction speed, and strengthen the reduction atmosphere Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

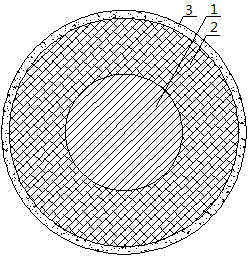

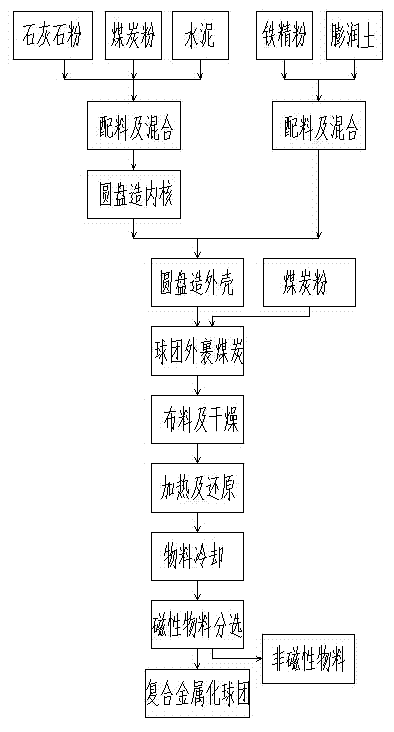

[0031] Such as figure 1 A high-alkalinity composite metallized pellet for a converter is shown, which includes an inner core 1 and a shell 2 wrapped outside the inner core 1. The inner core 1 is made of coal powder, limestone, and cement in a mass ratio of 100:300 to 550:4 It is made by mixing the ratio of ~7, the outer shell 2 is made of iron concentrate and bentonite according to the mass ratio of 1500~1800:30~54, the particle size of the inner core 1 is 20~25mm, and the thickness of the outer shell 2 is 5~10mm .

[0032] The outer casing 2 is also covered with a layer of coal powder as the reducing agent 3. The mass of the coal powder is 5-8% of the mass of the iron concentrate in the casing 2, and the mass percentage of the coal powder particles with a particle size of -120 mesh is greater than 80%.

[0033] The iron grade of the iron concentrate is 64-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com