Method for recovering valuable metals by smelting copper dross

A valuable metal, copper scum technology, applied in the direction of improving process efficiency, can solve the problems of high anti-corrosion requirements, high heavy metal content, large equipment investment, etc., to reduce the slag production rate, reduce industrial solid waste, collapse The effect of material phenomenon reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

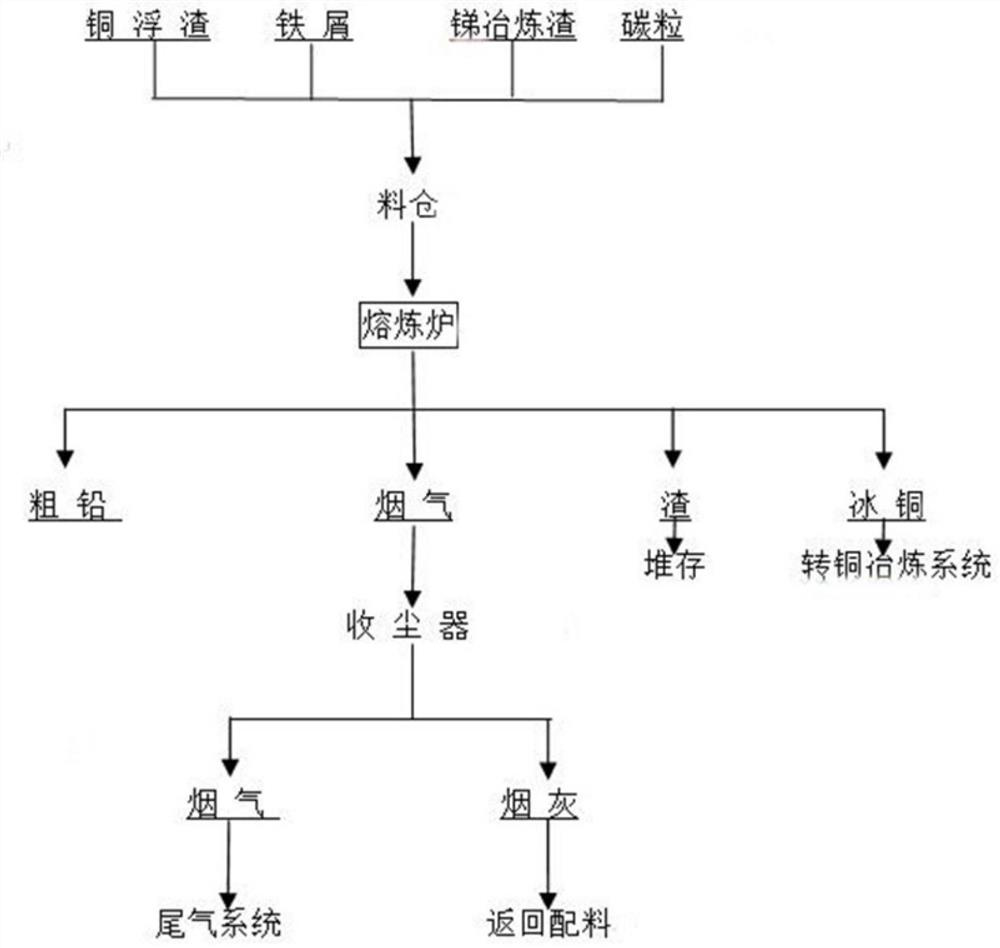

Image

Examples

Embodiment 1

[0048] The method for smelting and reclaiming valuable metals from copper dross of the present invention, the detailed steps of the method are as follows:

[0049] A, with copper scum, iron filings, slag-forming agent antimony smelting slag and reducing agent carbon particles as raw materials, the addition of the iron filings is 3% of the total weight of the copper scum, the addition of the slag-forming agent antimony smelting slag It is 7% of the total weight of the copper scum, and the addition of the reducing agent carbon particles is 4% of the total weight of the copper scum;

[0050] b. Carry out ingredients according to the dosage in step a, add the prepared materials into the smelting furnace for heating reduction smelting, and control the smelting temperature to be 1200°C and the smelting time to be 12h during the smelting process;

[0051] c. After reduction and smelting, crude lead, smelting slag, matte and flue gas are produced; the lead metal in the copper dross en...

Embodiment 2

[0054] The method for smelting and reclaiming valuable metals from copper dross of the present invention, the detailed steps of the method are as follows:

[0055] A, with copper scum, iron filings, slag-forming agent antimony smelting slag and reducing agent carbon particles as raw materials, the addition of the iron filings is 3% of the total weight of the copper scum, the addition of the slag-forming agent antimony smelting slag It is 6% of the total weight of the copper scum, and the addition of the reducing agent carbon particles is 4% of the total weight of the copper scum;

[0056] b. Carry out ingredients according to the dosage in step a, add the prepared materials into the smelting furnace for heating reduction smelting, and control the smelting temperature to be 1150°C and the smelting time to be 12h during the smelting process;

[0057] c. After reduction and smelting, crude lead, smelting slag, matte and flue gas are produced; the lead metal in the copper dross en...

Embodiment 3

[0060] The method for smelting and reclaiming valuable metals from copper dross of the present invention, the detailed steps of the method are as follows:

[0061] A, with copper scum, iron filings, slag-forming agent antimony smelting slag and reducing agent carbon particles as raw materials, the addition of the iron filings is 3% of the total weight of the copper scum, the addition of the slag-forming agent antimony smelting slag It is 8% of the total weight of the copper scum, and the addition of the reducing agent carbon particles is 4% of the total weight of the copper scum;

[0062] b. Carry out ingredients according to the dosage in step a, add the prepared materials into the smelting furnace for heating reduction smelting, and control the smelting temperature to be 1250°C and the smelting time to be 12h during the smelting process;

[0063] c. After reduction and smelting, crude lead, smelting slag, matte and flue gas are produced; the lead metal in the copper dross en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com