Patents

Literature

43results about How to "Safe and controllable operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

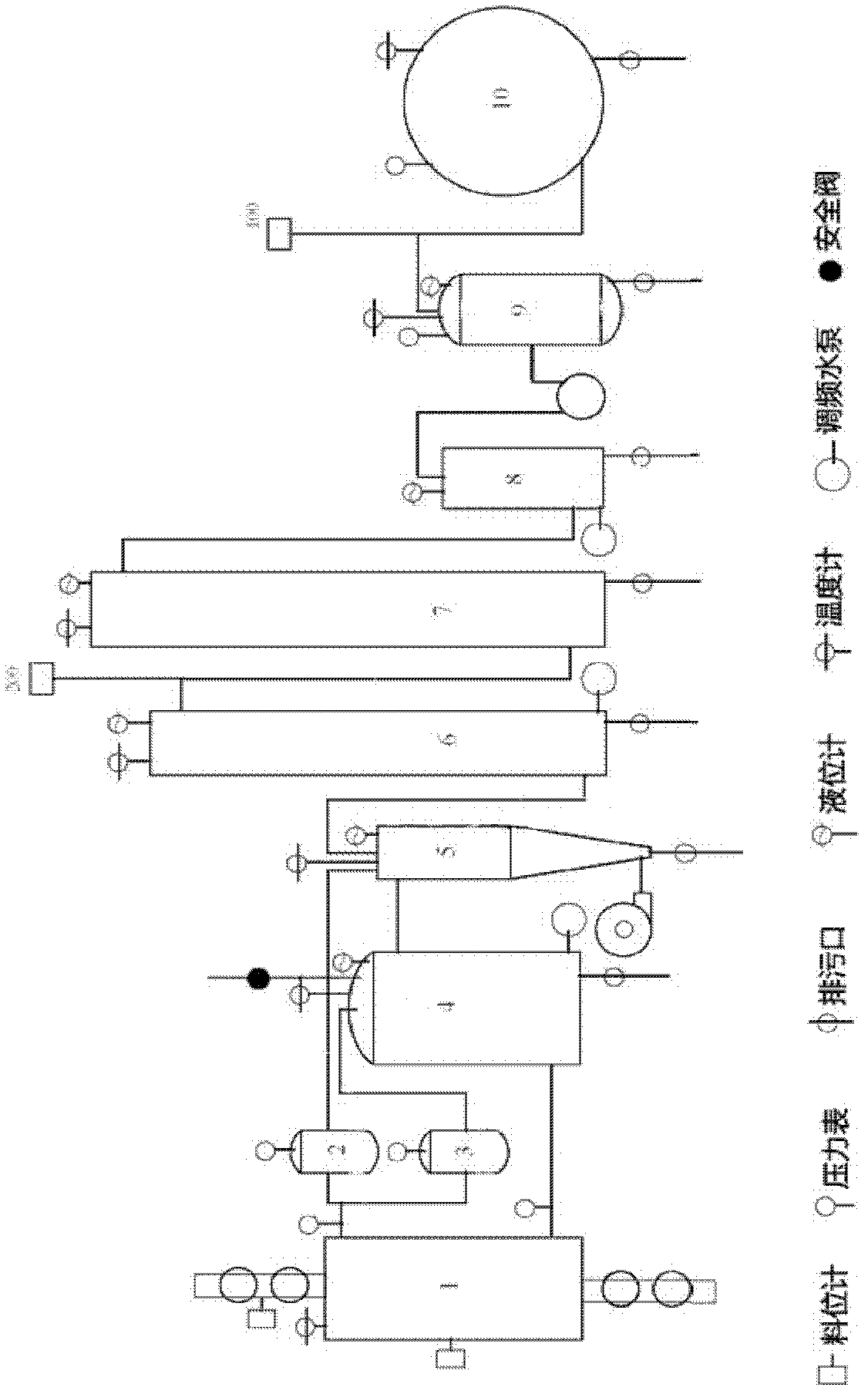

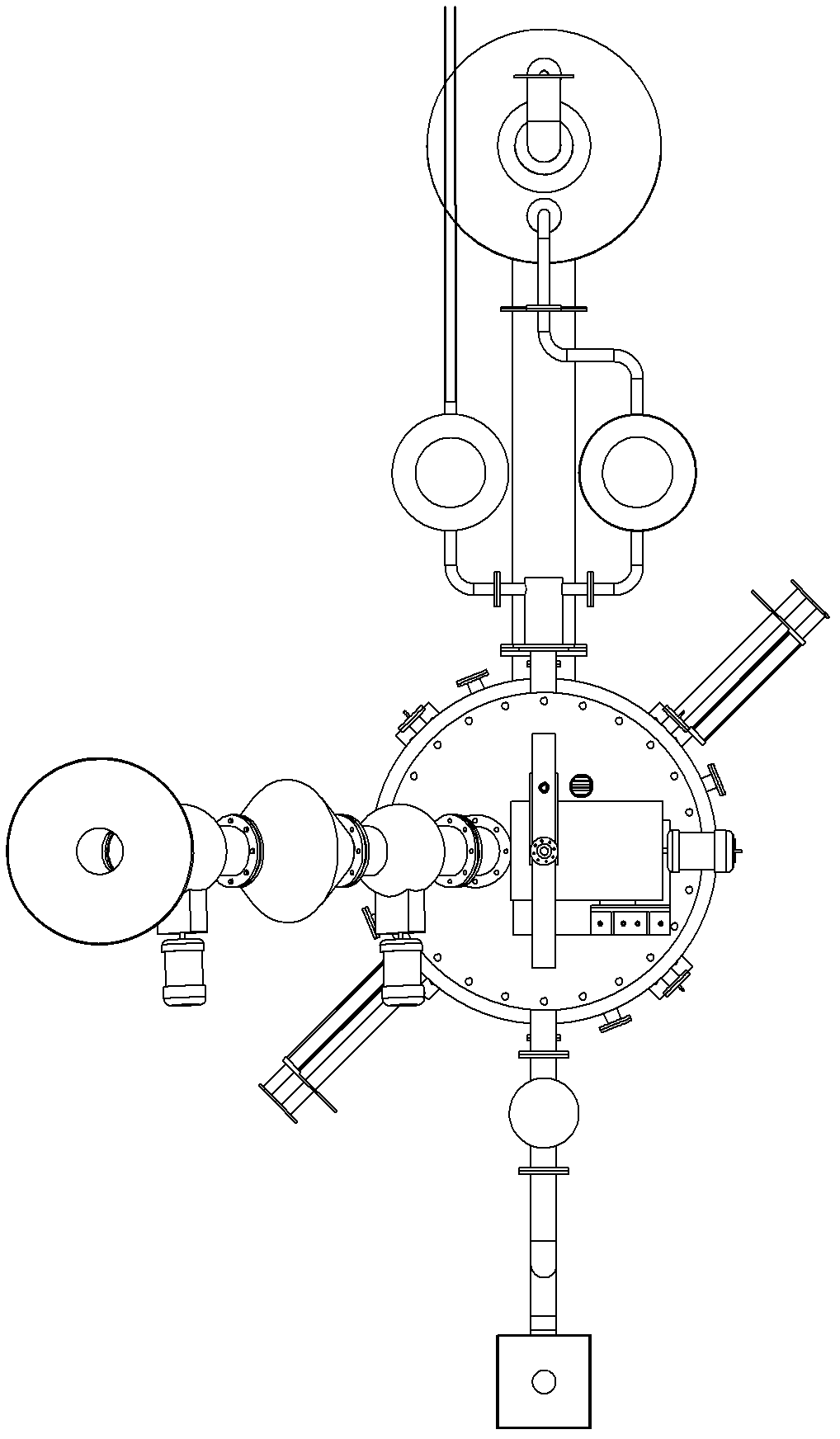

Plasma garbage gasification device and process

InactiveCN102329653AHigh operating valueReduce power consumptionChemical industryCombustible gas productionCooling towerHazardous substance

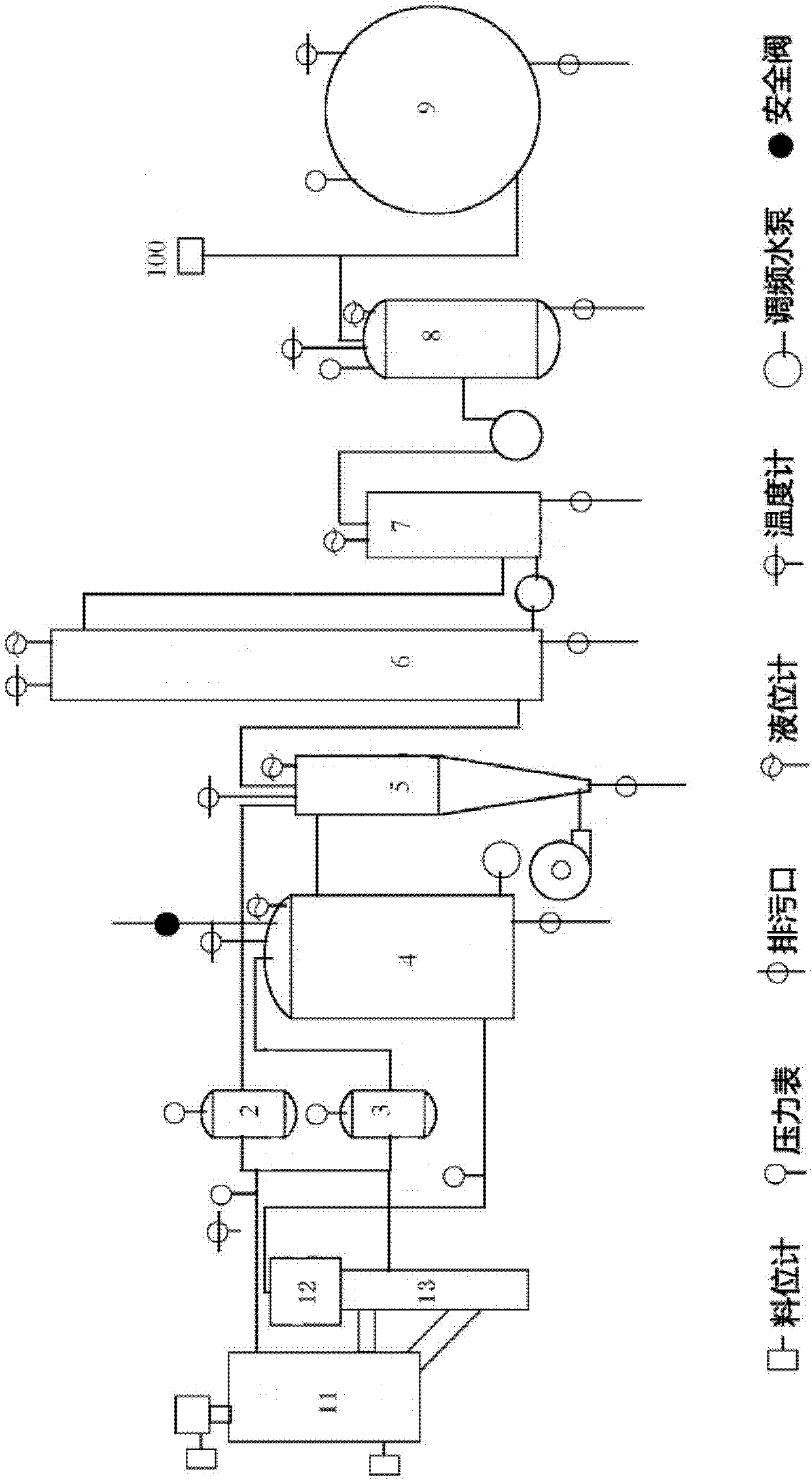

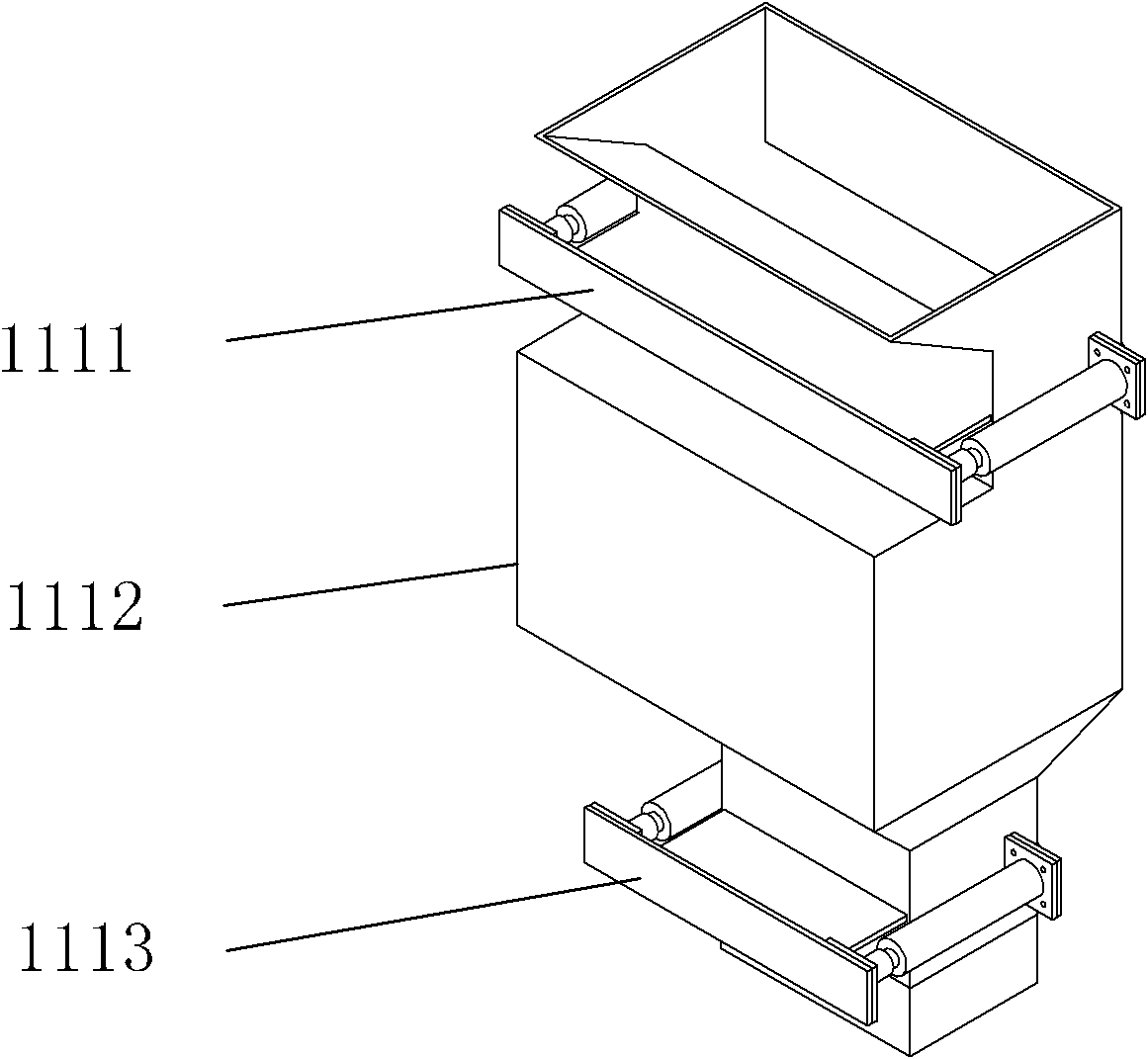

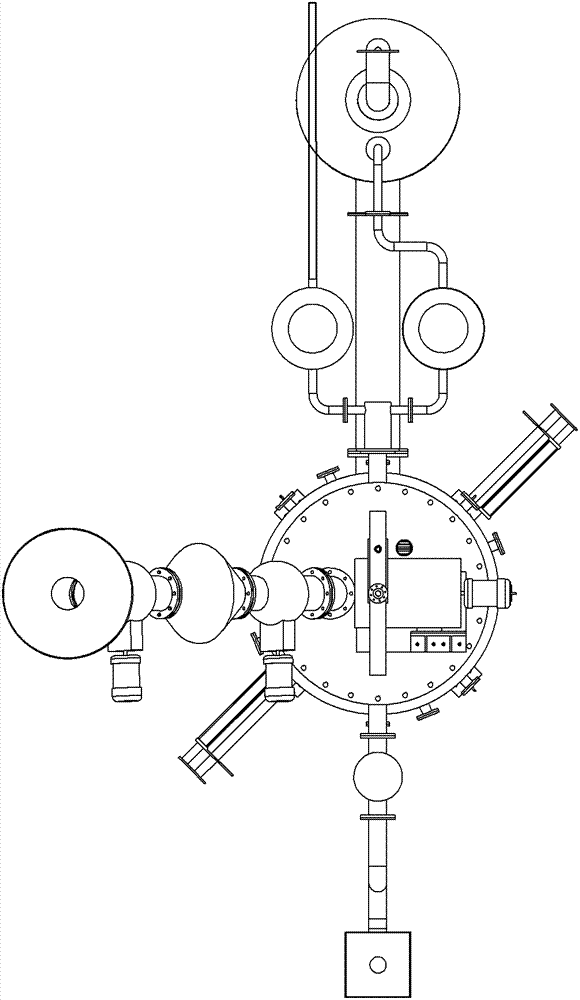

The invention relates to a plasma garbage gasification device and process. The device comprises a gasification reaction chamber, a steam heat exchanger, a steam buffer tank, an air buffer tank, an inner and outer double-cyclone heat exchanging dust collector, a cooling tower, a hydrogen sulfide removal sprayer, a water ring compressor, a gas-water separator, a gas storage tank and a control system of the device, which are connected through a gas pipeline; the gasification reaction chamber comprises an automatic feeding device, an automatic ignition device, a primary gasification zone and a plasma reaction zone; and the plasma reaction zone consists of a secondary refining zone and a gas refining zone. The process comprises the following steps of: gas generation; gasification medium preheating; gas purifying and filtering; and gas compression and storage. The invention has the characteristics of simple structural design, reasonable energy efficiency utilization, low primary input cost and low power consumption, and particularly, harmful substances such as dioxin and the like generated in the gasification process can be effectively removed, the volume reduction ratio is increased, and the waste is turned into the wealth.

Owner:张建超

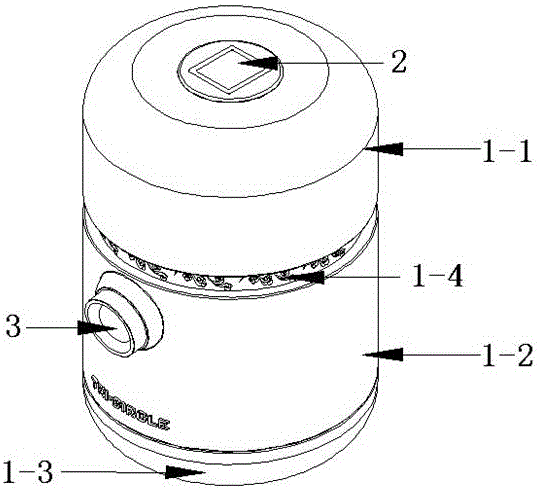

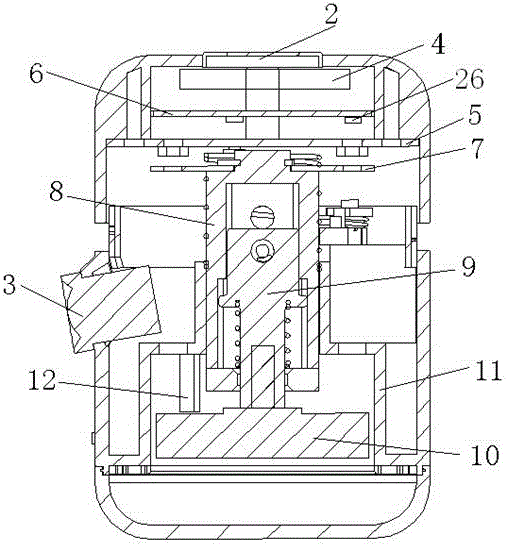

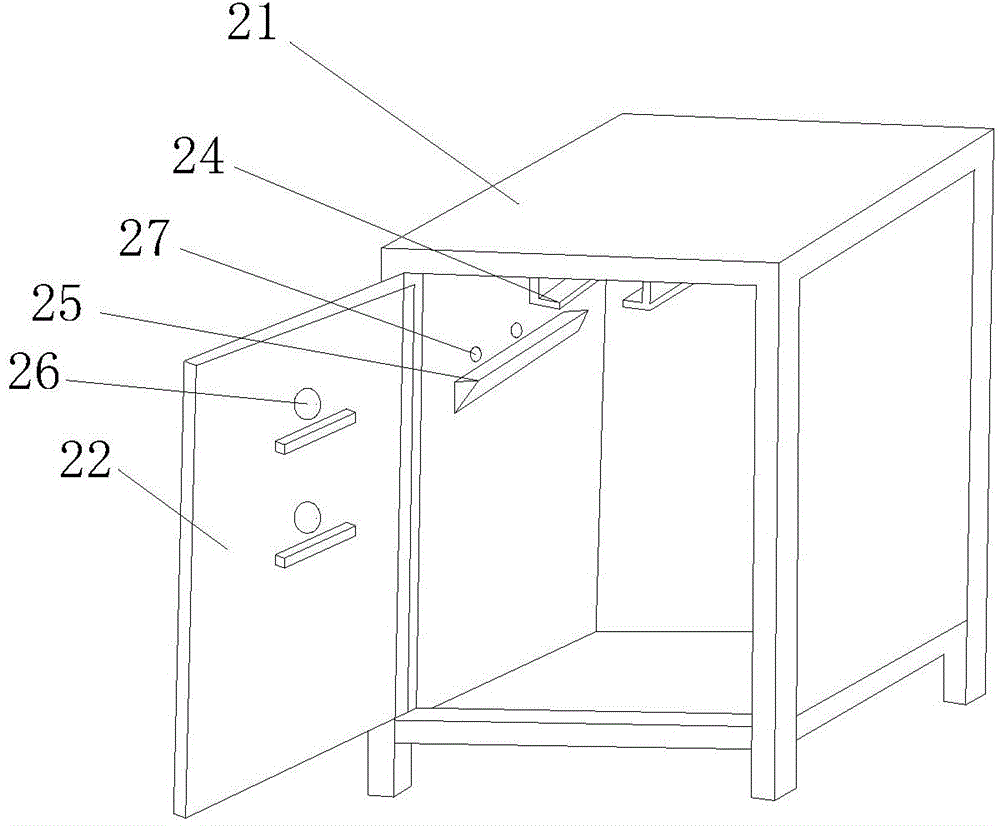

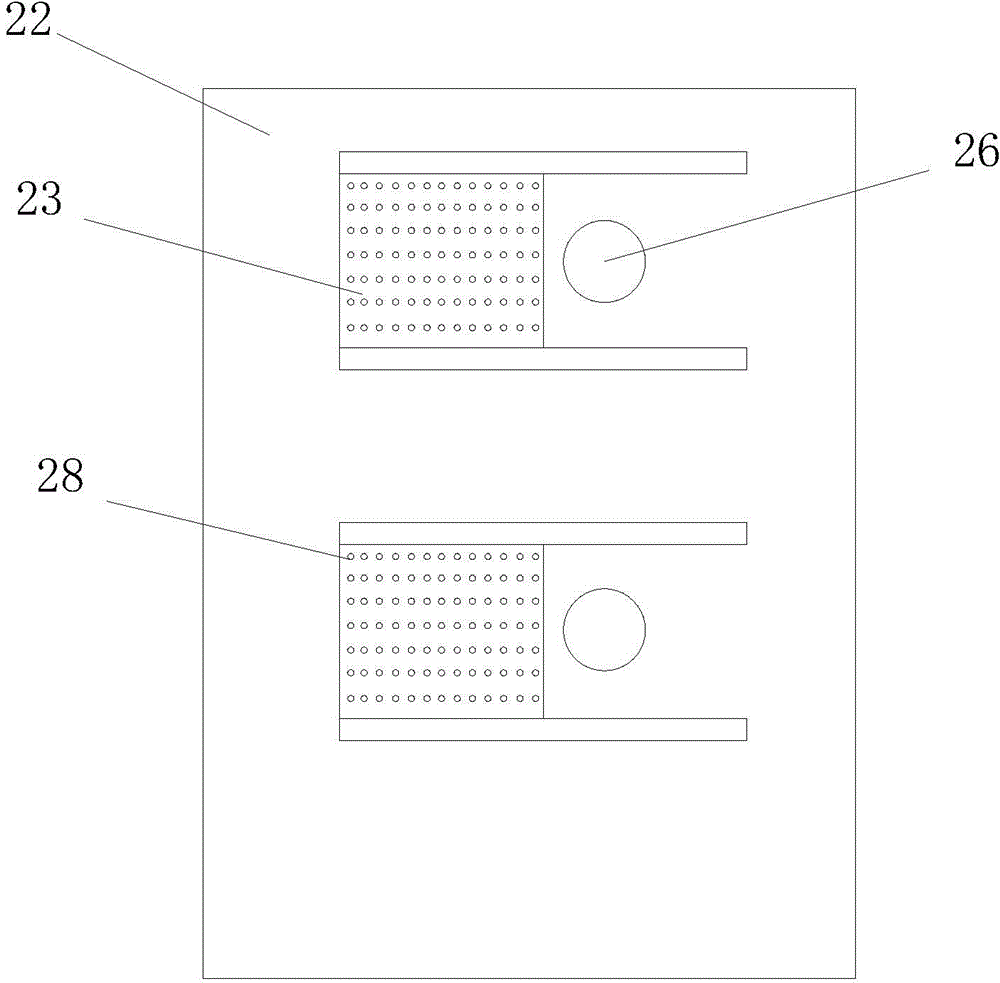

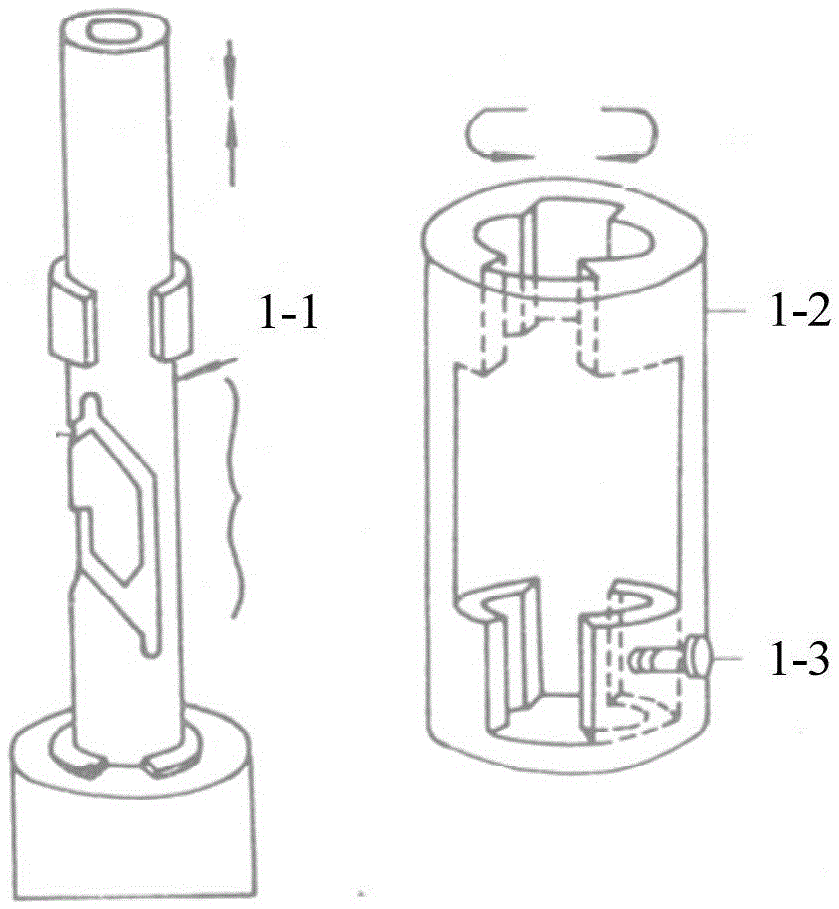

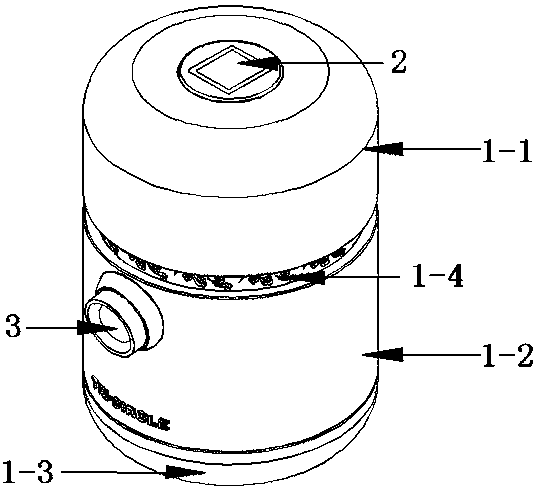

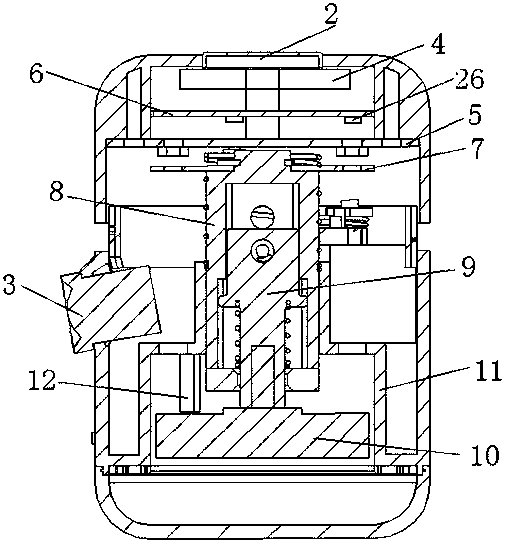

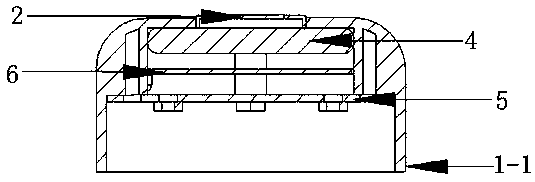

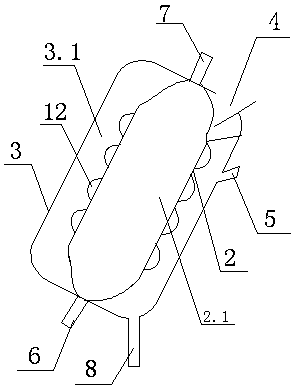

Seal lock

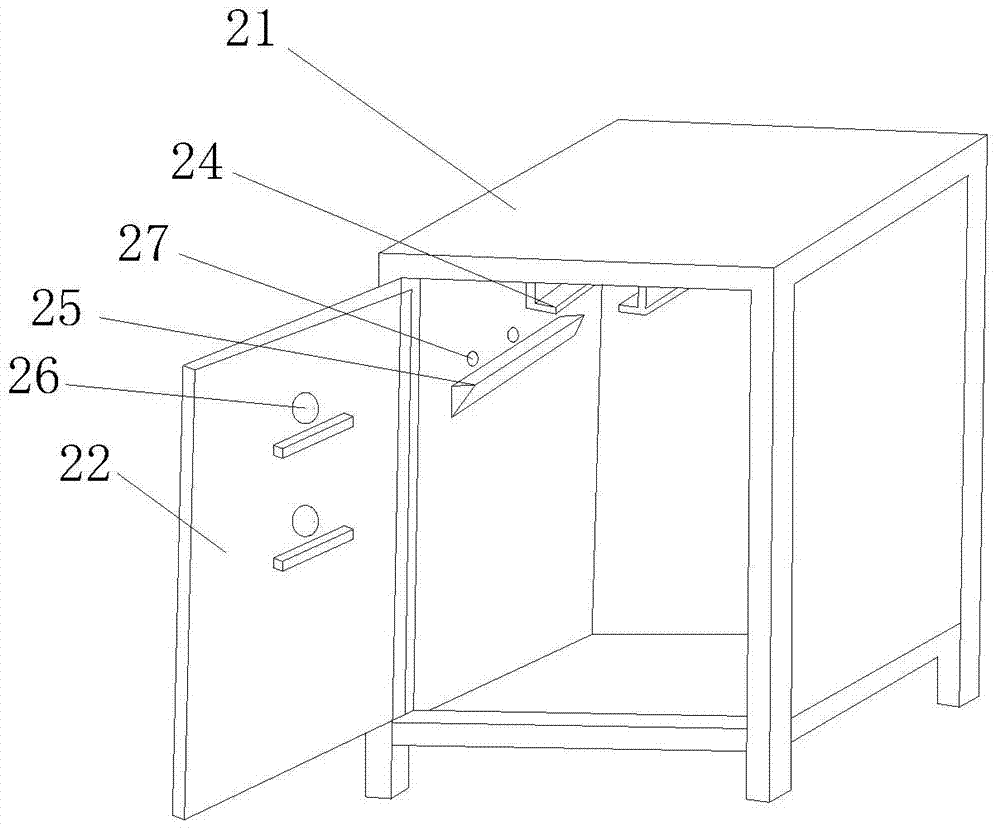

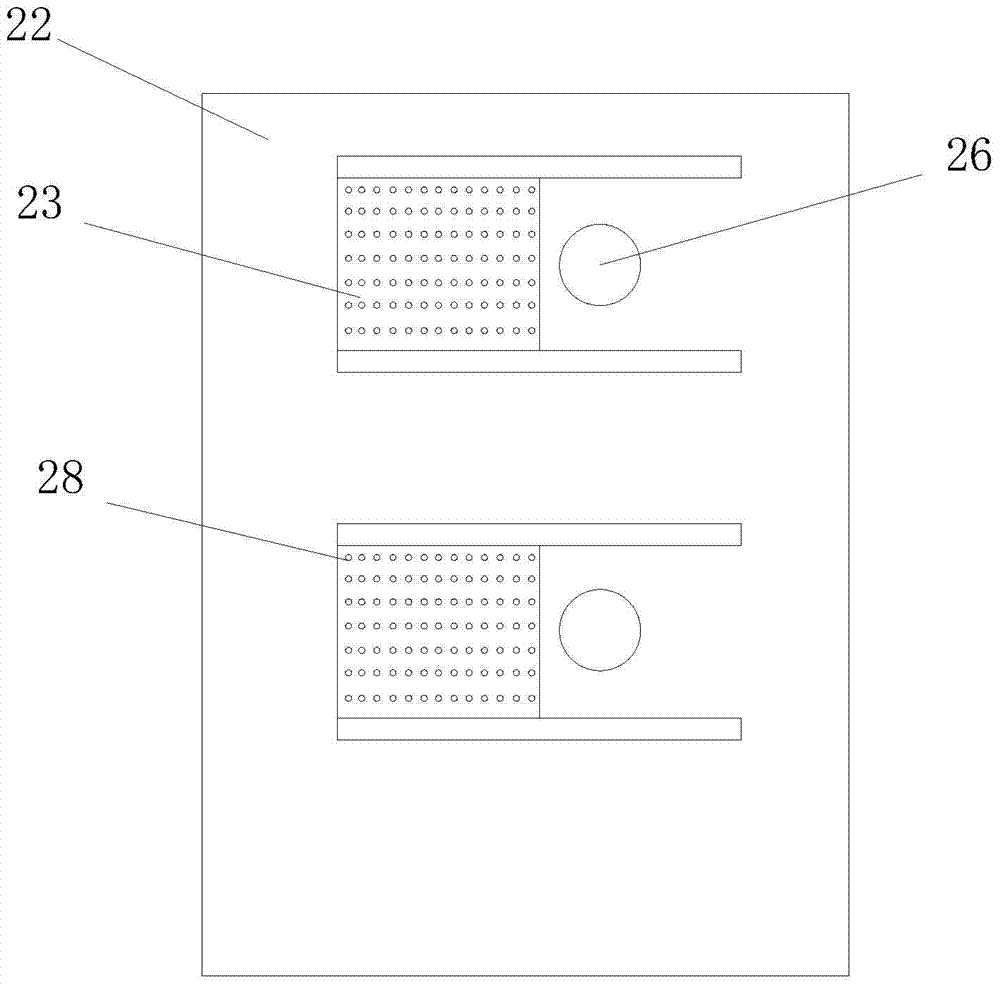

ActiveCN106079934ASimple and reasonable structural designSafe and controllable operationStampingMechanical engineeringFingerprint

The invention relates to a seal lock. The seal lock comprises a lock shell of a columnar structure. The seal lock is characterized in that a lock body control assembly for achieving an unlocking or locking function, and a pressing rebounding device for completing sealing operation through external force pressing in an unlocked state are installed in the lock shell; and the lower portion of the pressing rebounding device is connected with a seal. The seal lock is simple and reasonable in structural design and safe and controllable in operation; a lock body is controlled to be unlocked and locked through fingerprint recognition, and during manual pressing sealing, due to the design of the pressing rebounding device, the sealing frequency is effectively controlled; and a camera is installed on the lock body, so that sealed files and sealing processes are clearly recorded, and the controllable whole course of seal management is truly achieved.

Owner:YANTAI TRI CIRCLE SCI & TECH

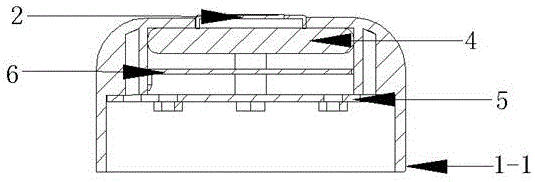

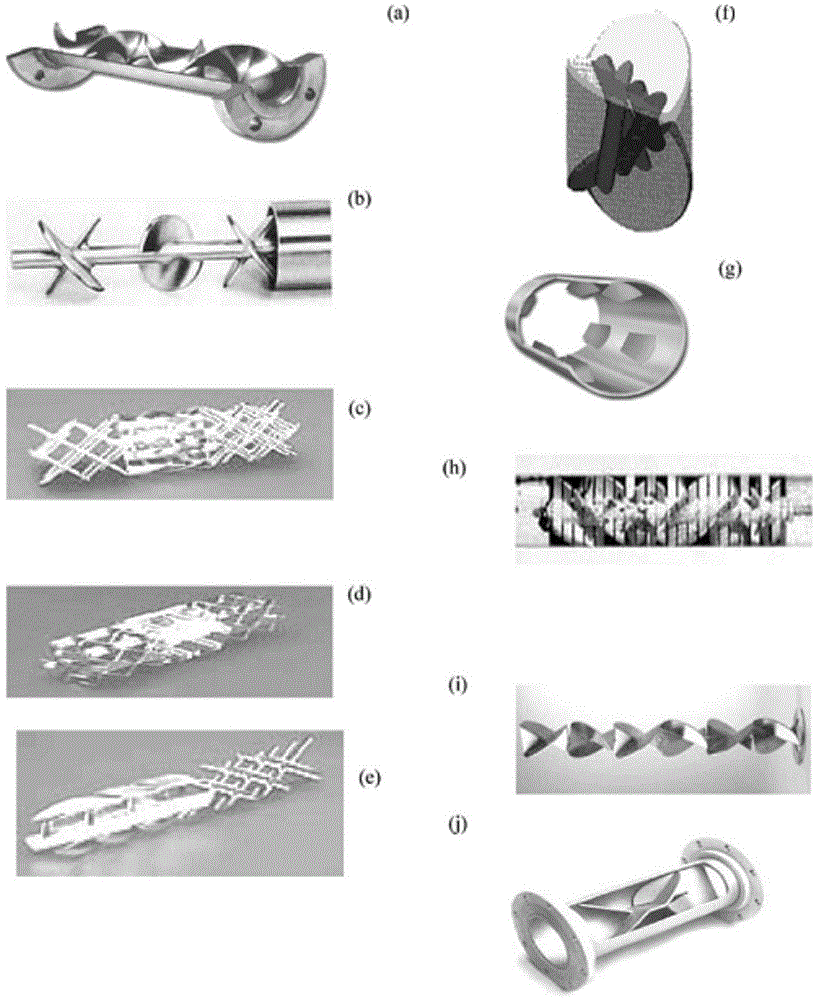

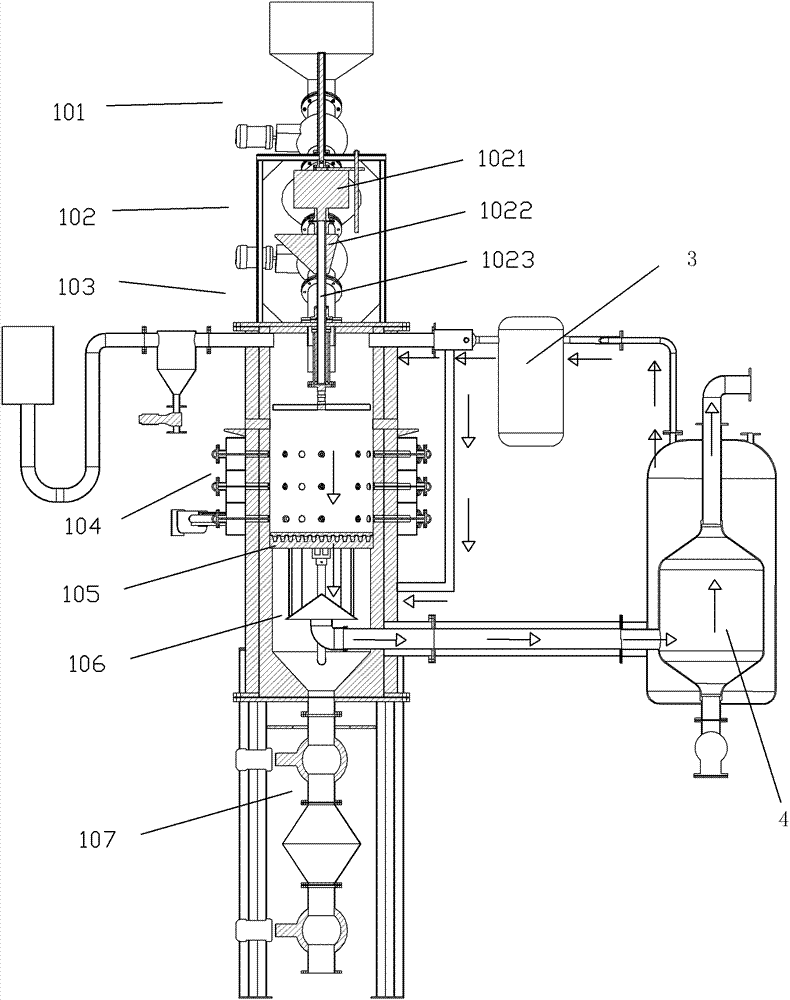

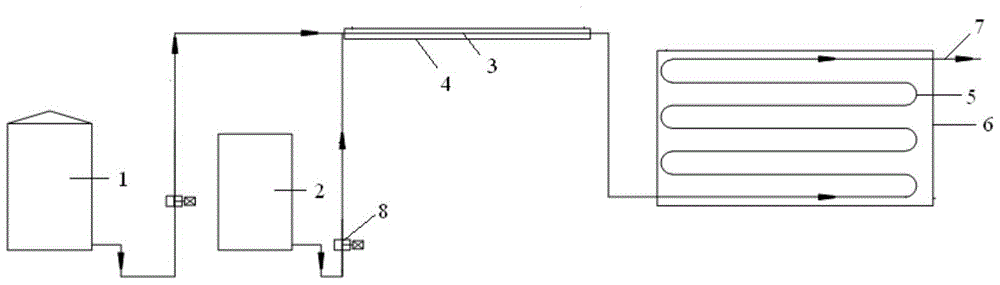

Biomass gasification device and process

InactiveCN102329654AImprove gasification efficiencySafe and controllable operationCombustible gas productionCooling towerSprayer

The invention relates to a biomass gasification device and process. The device comprises a gasification reaction chamber, a steam heat exchanger, a steam buffer tank, an air buffer tank, an inner and outer double-cyclone heat exchanging dust collector, a cooling tower, an electro tar precipitator, a hydrogen sulfide removal sprayer, a water ring compressor, a gas-water separator, a gas storage tank and a control system of the device, which are connected through a gas pipeline; the gasification reaction chamber comprises an automatic feeding device, a two-stage gasification zone, a vibrating grate, an automatic ignition device, an automatic slagging device and an automatic leveling device. The gasification process comprises the following steps of: gas generation; gasification medium preheating; gas purifying and filtering; and gas compression and storage. The biomass gasification device and process are scientific and environment friendly, have the remarkable characteristics of simple structural design, high degree of automation as well as stable, controllable and continuous gasification reaction, have high gasification efficiency and entire caloricity, are suitable for popularization and application on a large scale, and are particularly applicable to continuous and stable generation of the traditional gas generating set.

Owner:张建超

Method for artificially inducing wasps to kill insects

ActiveCN104904671AReduce labor costsReduce use costAnimal huntingPlant protectionControl mannerOperational safety

The invention discloses a method for artificially inducing wasps to kill insects. The method comprises the following steps of fixed cultivation of the wasps, mobile cultivation of the wasps and wasp stocking and insect killing. By the method for artificially inducing the wasps to kill the insects, various insect killing wasp populations are cultivated artificially; the method is targeted; insect killing of the wasps can be implemented all day long or all year round; the wasps are bred in mobile cultivation boxes in a managed and controlled manner; the method is operated safely in a controlled manner; and the insect killing cost is low.

Owner:广东互信生物科技有限公司

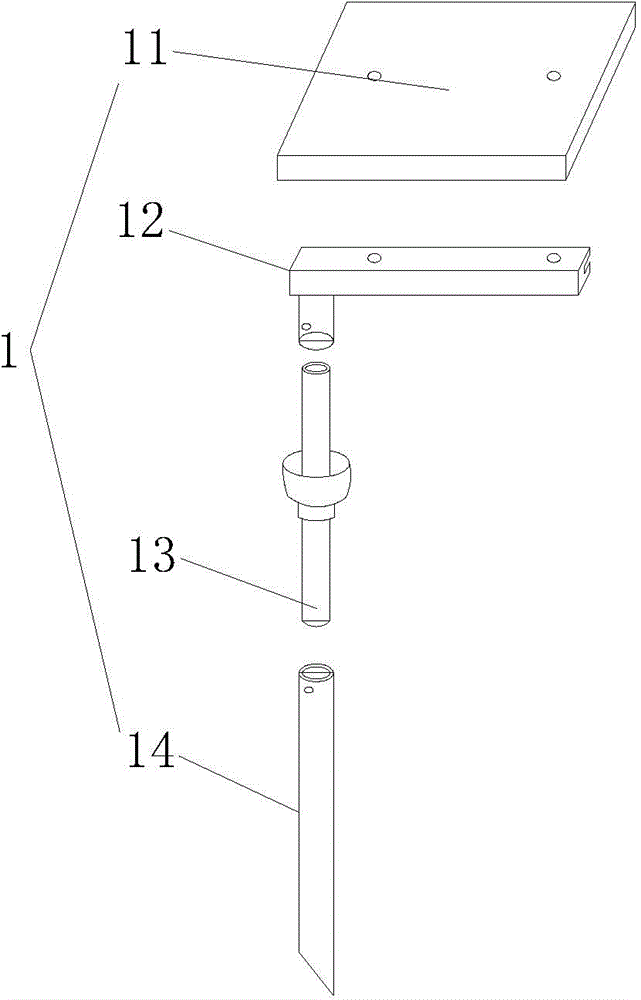

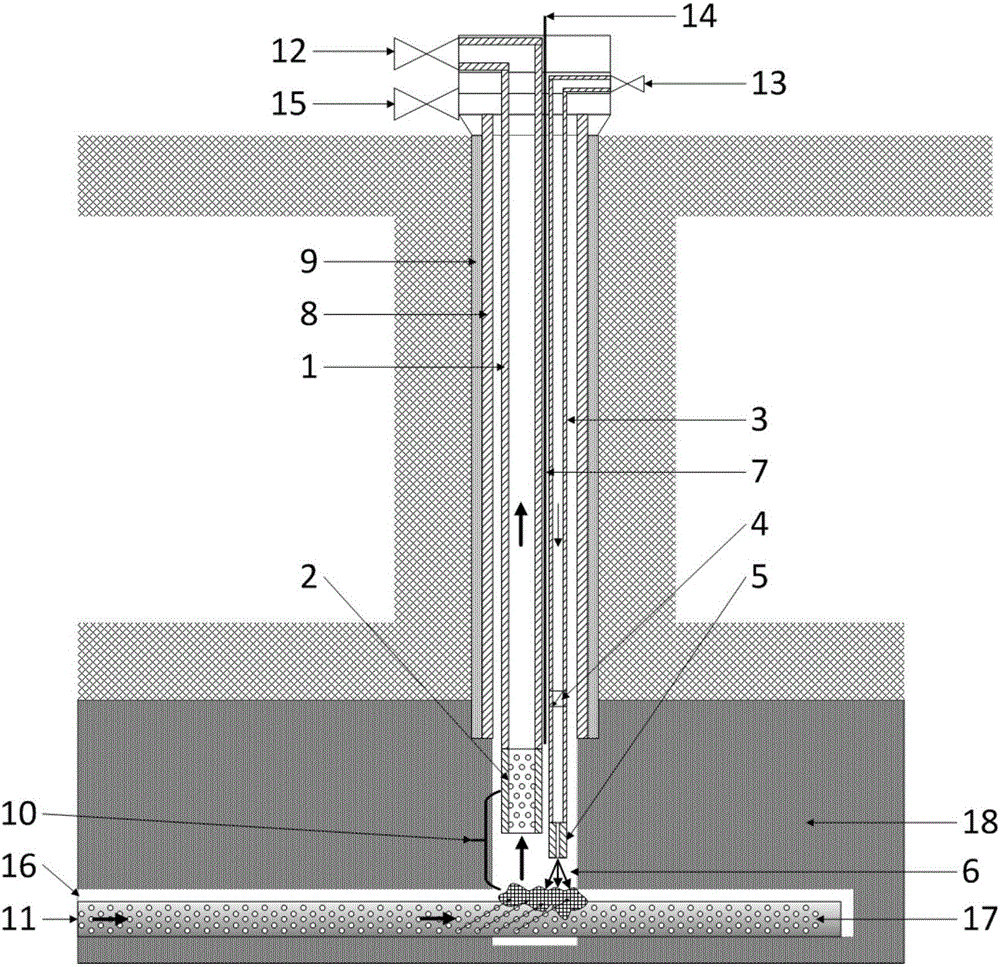

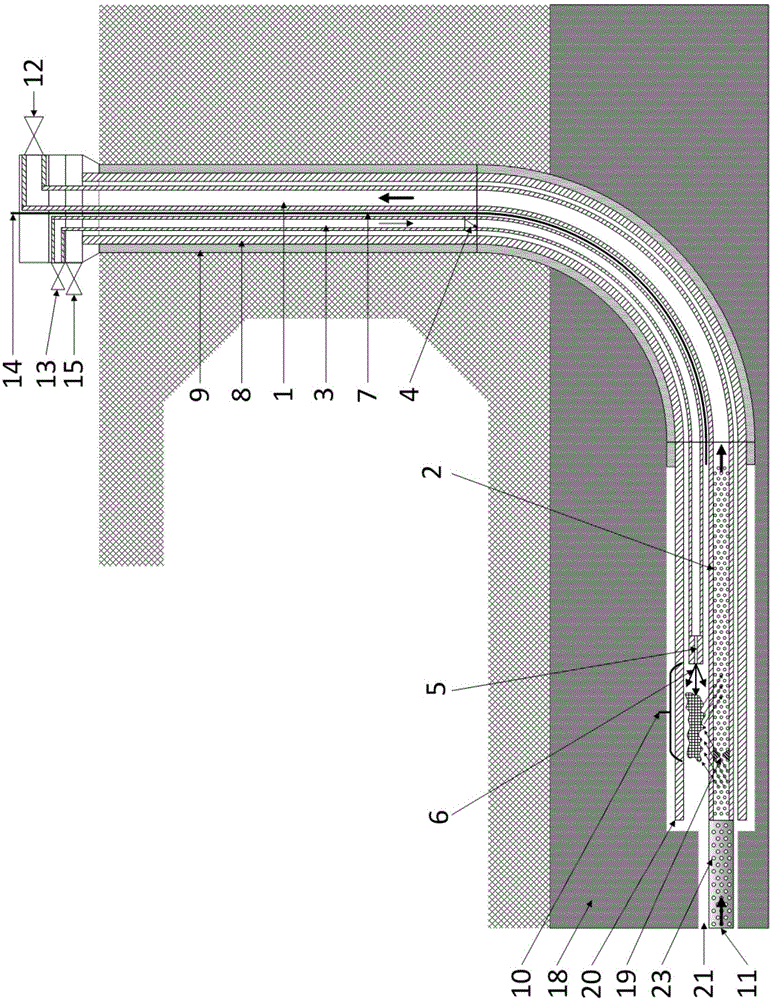

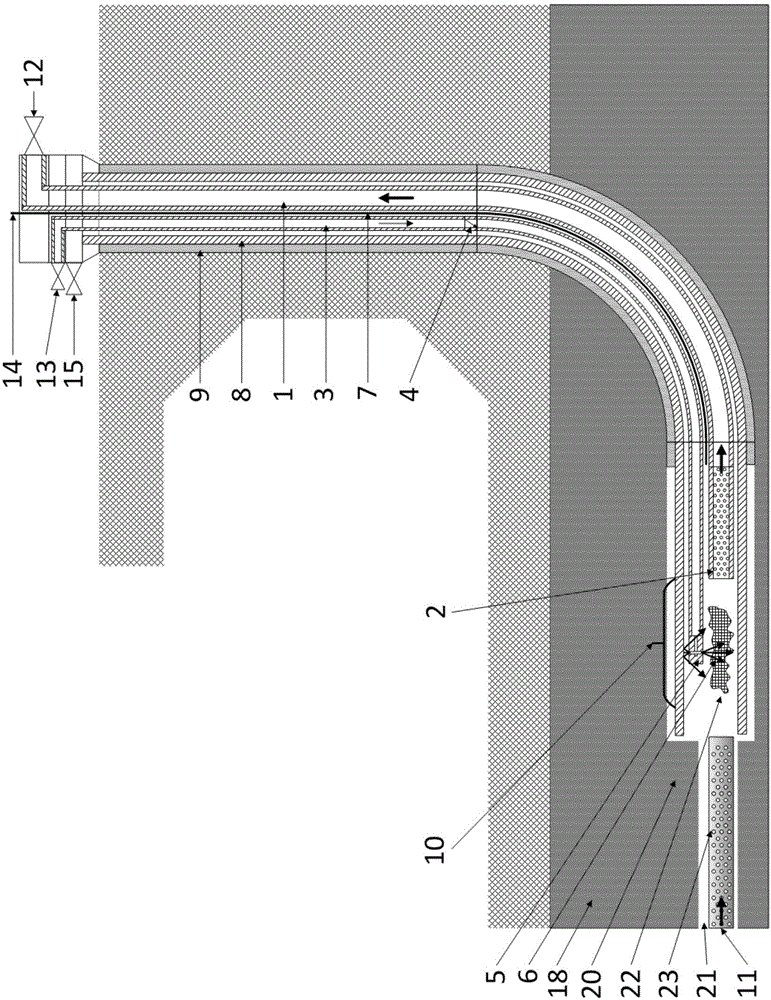

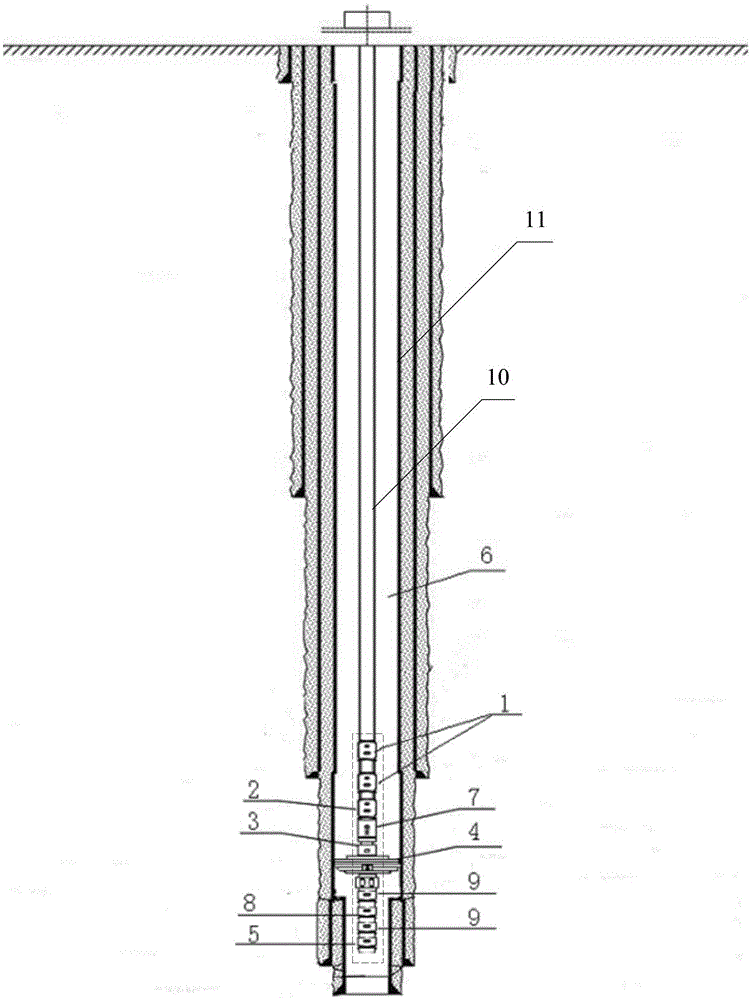

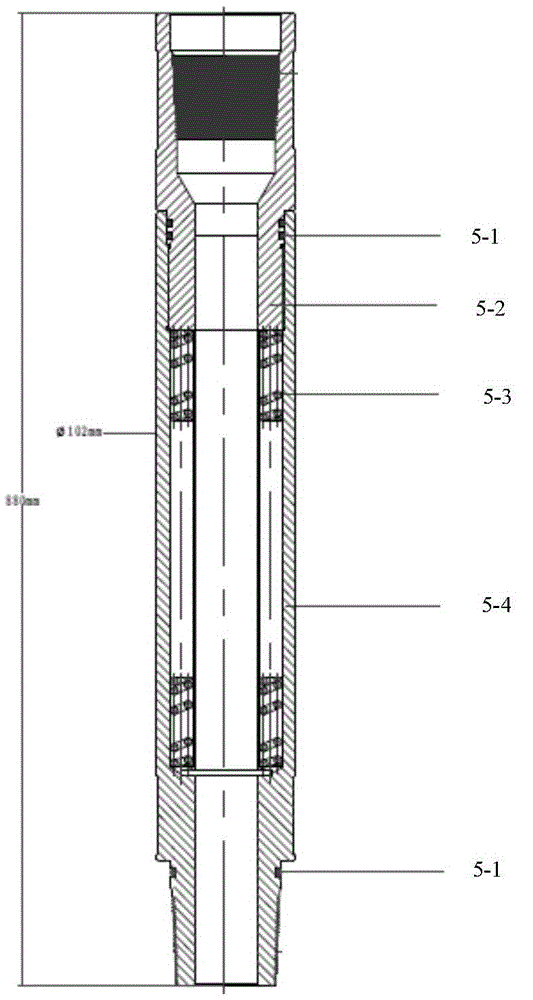

Withdrawal well equipment for underground coal gasification process and application of withdrawal well equipment

ActiveCN106089179AImprove the operating environmentIncreased operating lifeSurveyConstructionsProduct gasProcess engineering

The invention provides withdrawal well equipment for an underground coal gasification process. Particularly, in the underground coal gasification process, the withdrawal well equipment can remove product gas after a cooling agent is injected for cooling. The invention further provides application of the withdrawal well equipment in the underground coal gasification process. Through design, material selection and application of all components of the withdrawal well equipment and optimization of the application of a withdrawal well, operation of the withdrawal well equipment is safer and more controllable, and most components such as wellhead equipment, product pipes, cooling agent pipes and a monitoring instrument system of the withdrawal well equipment can be completely or partially recycled and reutilized after the gasification process is finished.

Owner:ZHONGWEI SHANGHAI ENERGY TECH CO LTD

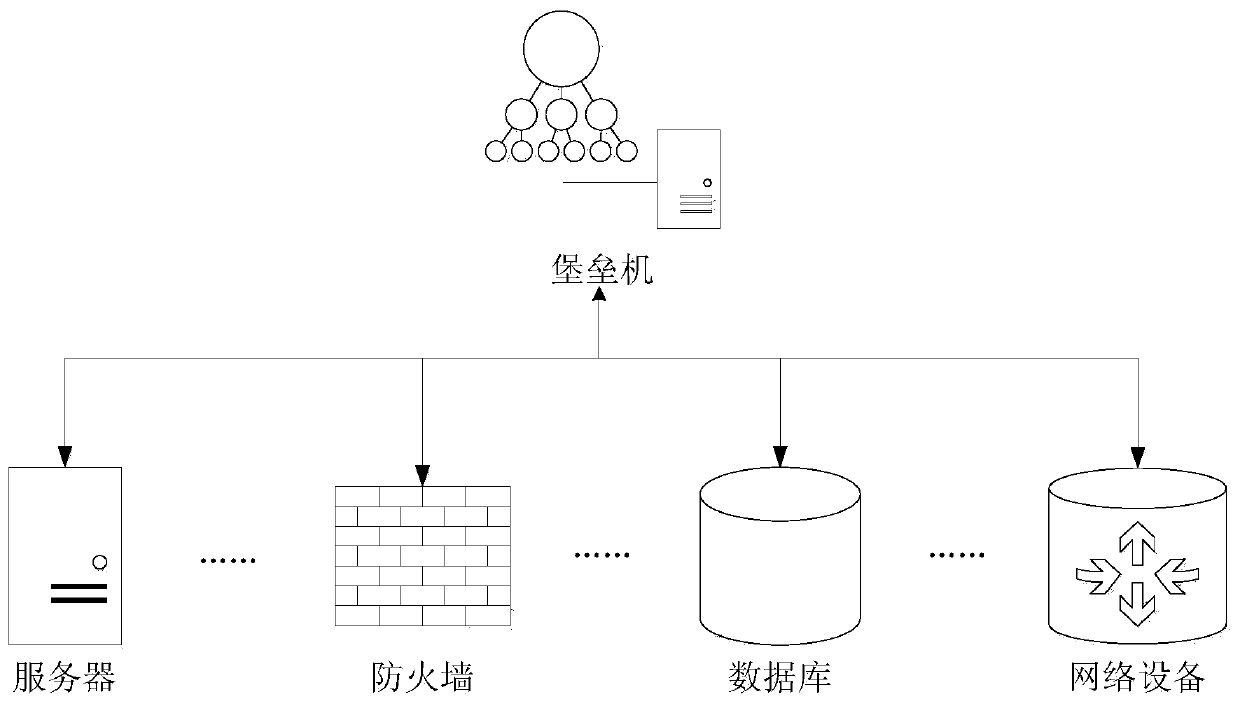

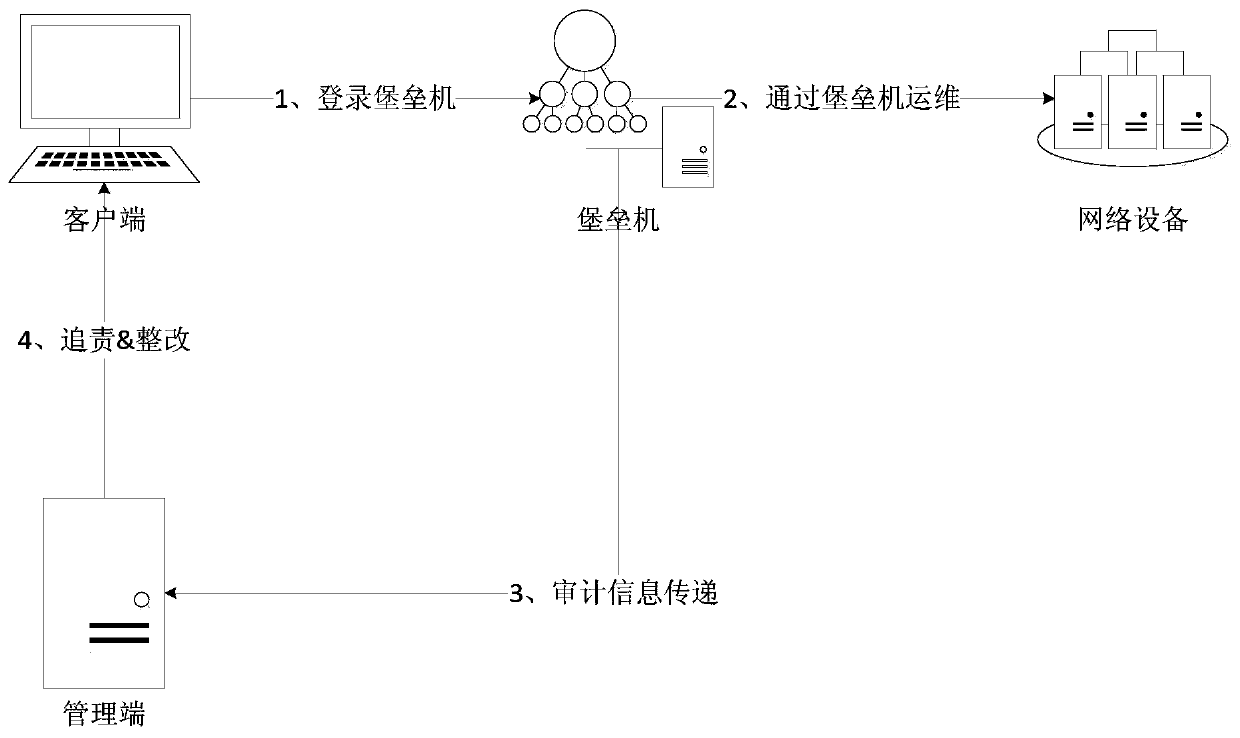

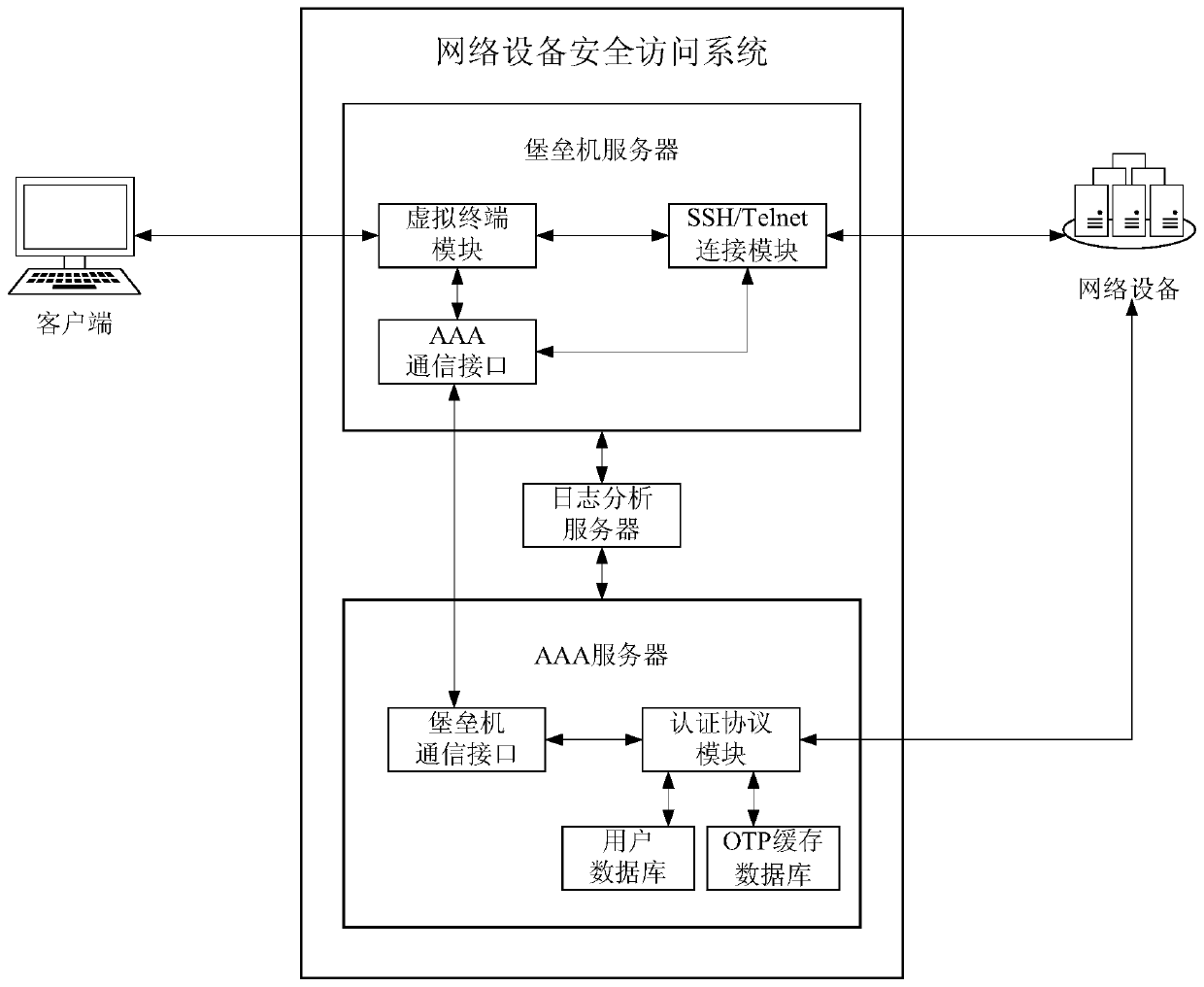

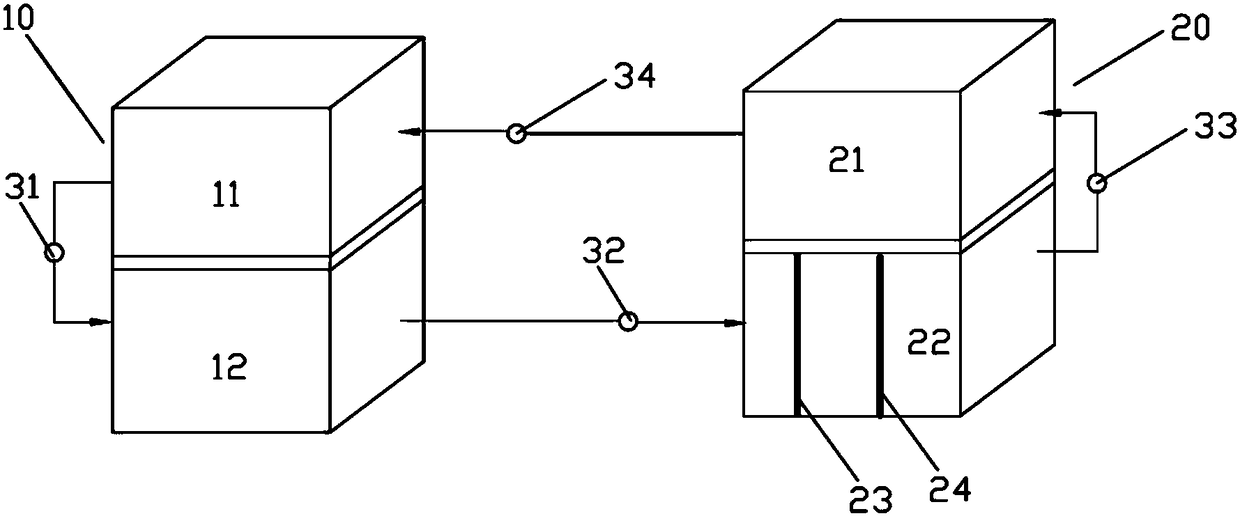

Systems and methods for secure access to network device based on one-time access credentials

The invention discloses a system and a method for secure access to a network device based on one-time access credentials. The system is provided with a bastion host server, an AAA server, a log analysis server, a client and managed network equipment, wherein the structures of the bastion host server and the AAA server are respectively improved. The system is innovatively characterized in that an AAA server randomly and dynamically generates one-time access evidences for SSH / telnet connection each time in real time, and the one-time access evidences are used for authentication; and the traditional local storage and local authentication mode of account password and authority setting of the network device is replaced. the one-time access credential is transmitted in an encrypted manner and isdiscarded after being used each time, and the network device only allows the user to access after passing the authentication of the one-time access credential, so that the safety and reliability of the login account password of the network device can be enhanced and ensured. The AAA server realizes centralized management of local authentication information dispersed in numerous network devices. The user management authority is finely divided, and the user behavior is limited in a legal management control range, so that the security of the network equipment is ensured.

Owner:BEIJING WANGRUIDA TECH CO LTD

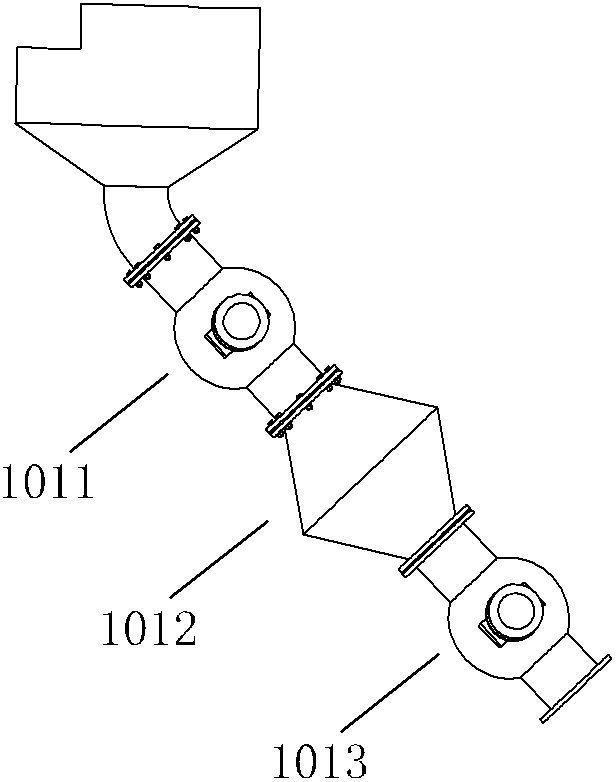

Oil testing device and oil testing pipe column

InactiveCN106812521ASafe and efficient oil testSafe and controllable operationDrilling rodsWell/borehole valve arrangementsControllabilityHigh pressure gas

The invention provides an oil testing device and an oil testing pipe column. The oil testing device comprises an integrated pipe column which is provided with an electronic manometer holding barrel, a packer, an E valve, a second circulating valve and at least one first circulating valve from bottom to top. The electronic manometer holding barrel is used for suspension of a temperature manometer for recording well bottom temperature and pressure; the packer is in a settable structure and used for packing an oil jacket annulus between an oil pipe and a casing pipe; after setting of the packer, drilling fluid is replaced with well completion fluid trough the E valve by circulation, and then the E valve is turned off to realize isolation of the oil pipe and the casing pipe; the oil jacket annulus above the packer and a stratum below the packer are communicated by the second circulating valve through radial communication to realize unsetting of the packer; the first circulating valve realizes well bottom static temperature and static pressure measurement through radial communication and axial closure. The oil testing device has advantages that by integration of multiple functions, safety and controllability of each step in an oil test period are guaranteed, well control risks are low, and safety and high efficiency in oil testing of ultra-deep high-temperature high-pressure gas wells are realized.

Owner:PETROCHINA CO LTD

Device and method for recovering tin of circuit board

PendingCN108300872AIncrease productivityAvoid corrosionPhotography auxillary processesProcess efficiency improvementBiochemical engineeringTin

The invention relates to a device and method for recovering tin of a circuit board. The device comprises a first working groove and a second working groove. The first working groove comprises a tin removing groove and a liquid storage groove. The second working groove comprises a supplementing groove and an electrolysis groove. A negative electrode plate and a positive electrode plate are arrangedin the electrolysis groove. The tin removing groove pumps liquid into the liquid storage groove through a first liquid pump. The liquid storage groove pumps the liquid into the electrolysis groove through a second liquid pump. The electrolysis groove pumps the liquid into the supplementing groove through a third liquid pump. The supplementing groove pumps the liquid into the tin removing groove through a fourth liquid pump. The device is compact and reasonable in layout, continuous production is realized, operation is safer and more controllable, and the device has better use performance.

Owner:昆山雅鑫化工有限公司

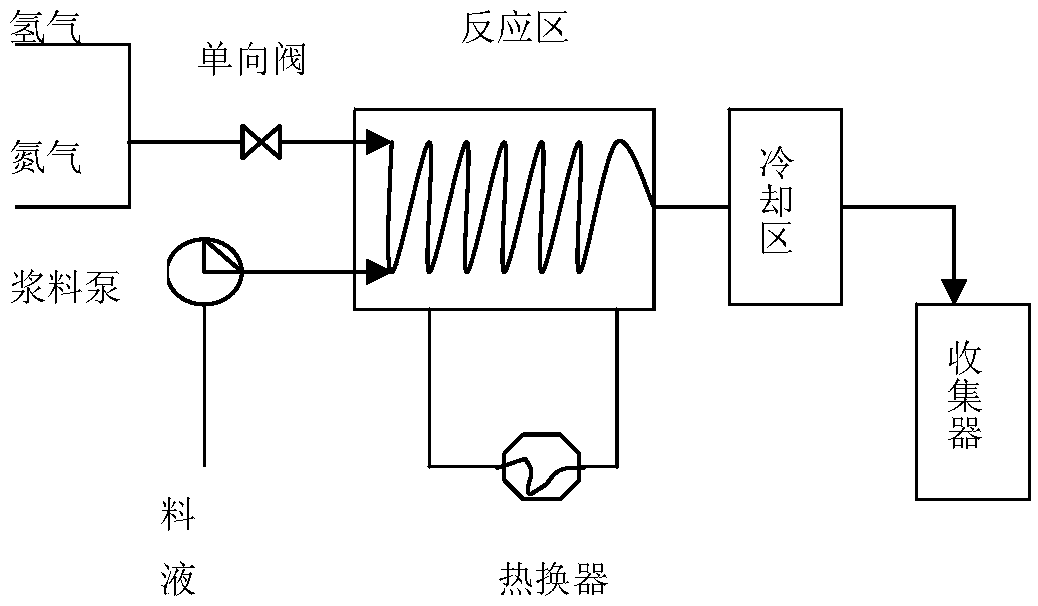

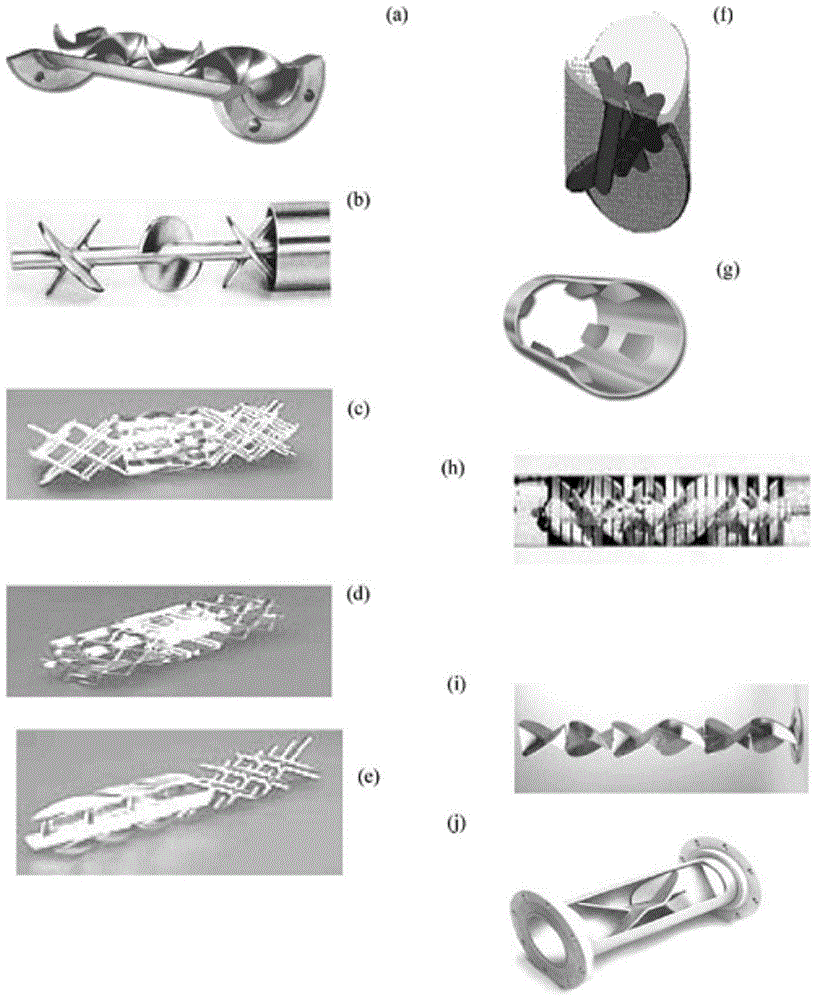

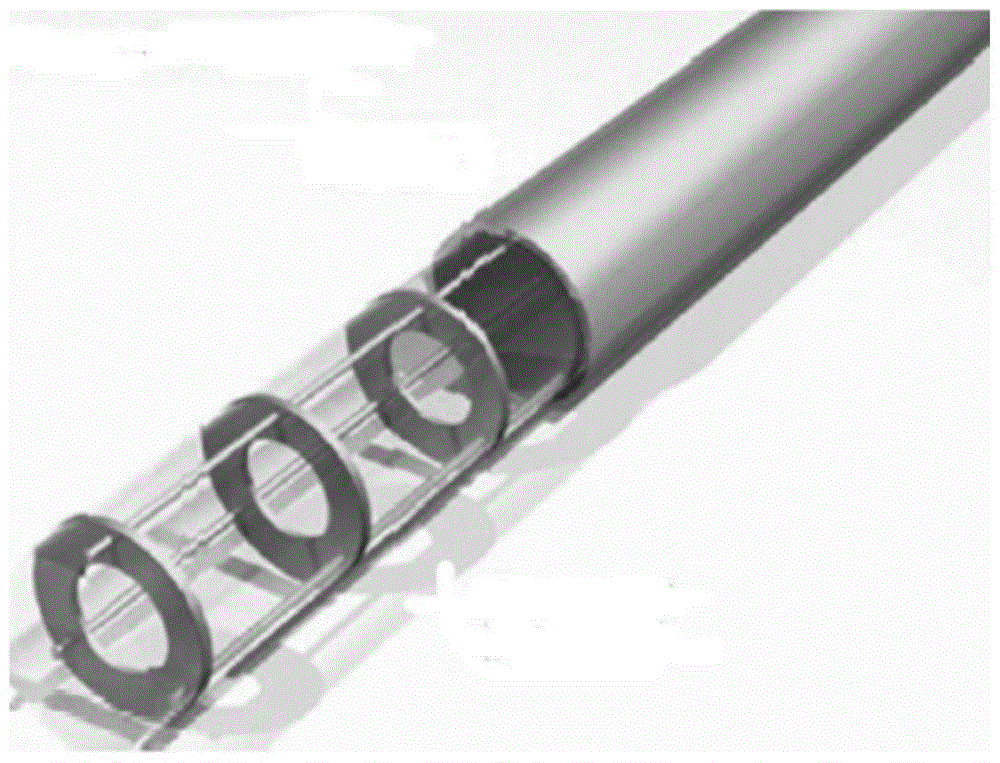

Method for continuously synthesizing O,S-dimethyl phosphoroamidothioate based on pipe type reaction device

InactiveCN104558025AImprove responseThe transfer process is easy to controlGroup 5/15 element organic compoundsChemical/physical/physico-chemical stationary reactorsEngineeringDimethyl sulfate

The invention discloses a method for continuously synthesizing O,S-dimethyl phosphoroamidothioate based on a pipe type reaction device. According to the method, O,O-dimethyl phosphoroamidothioate and dimethyl sulfate are used as raw materials, and O,S-dimethyl phosphoroamidothioate is continuously synthesized by virtue of the pipe type reaction device; the pipe type reaction device comprises two sections of pipe type reactors which are connected in series, and the temperature in each pipe type reactor is set to be appropriate during reaction; and O,O-dimethyl phosphoroamidothioate and dimethyl sulfate are continuously pumped into the first section of the pipe type reactors after being metered to perform mixing and reaction, and then flow through the second section of the pipe type reactors for further reaction, so that an O,S-dimethyl phosphoroamidothioate product is continuously obtained from a material outlet of the second section of the pipe type reactors. The method is high in reaction efficiency and high in equipment utilization ratio, a single set of reaction device is high in productivity, the reaction process is easy to control, the safety performance is good, and the requirements for industrial production can be met.

Owner:XIANGTAN UNIV

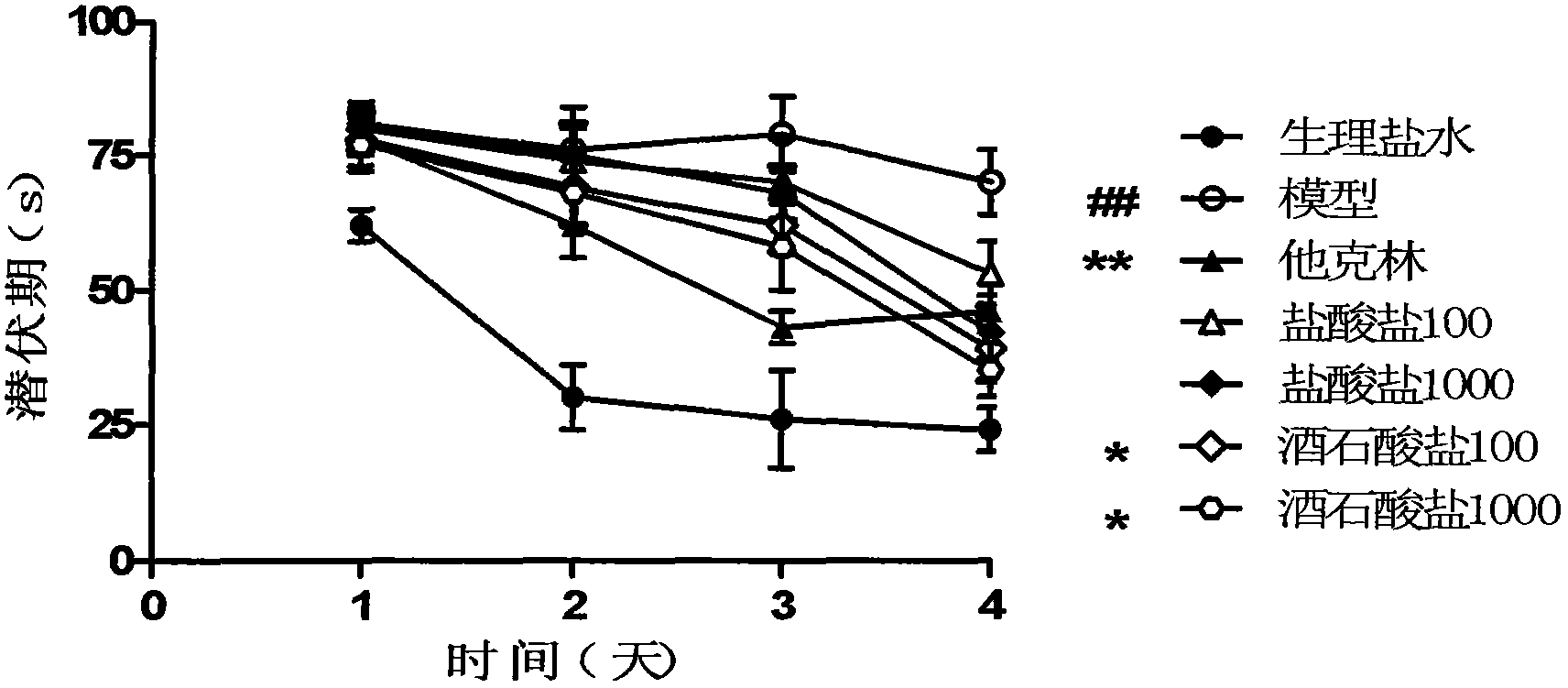

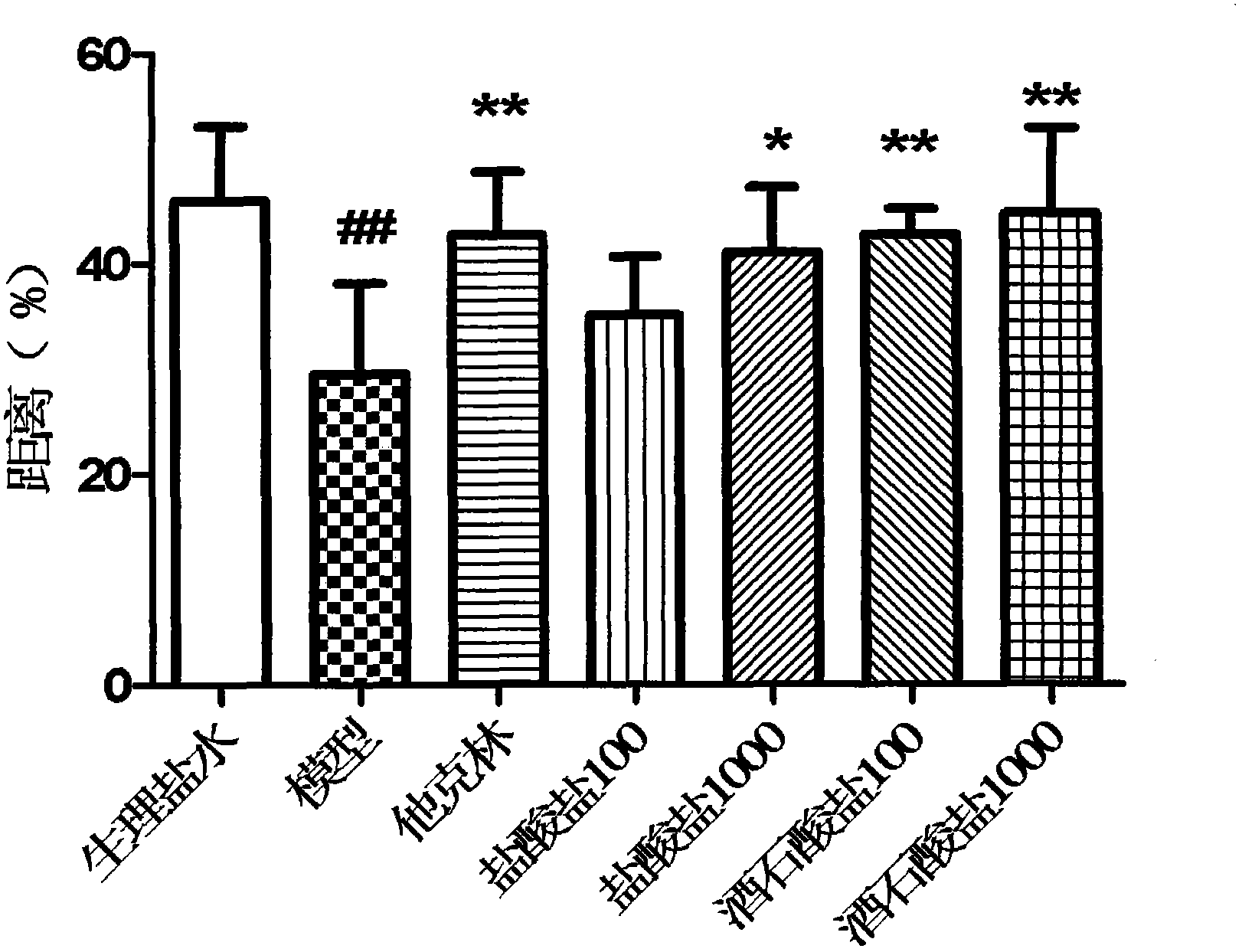

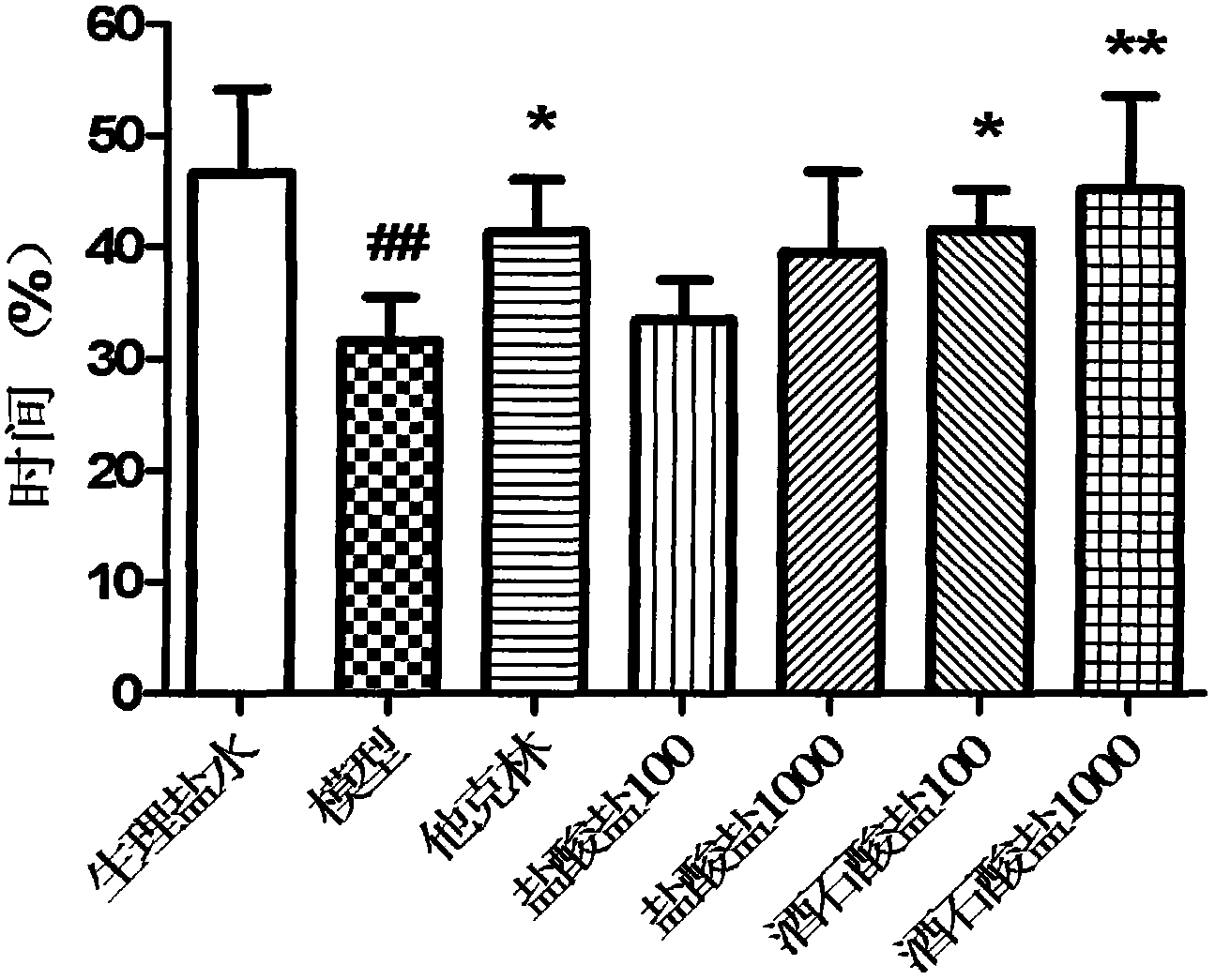

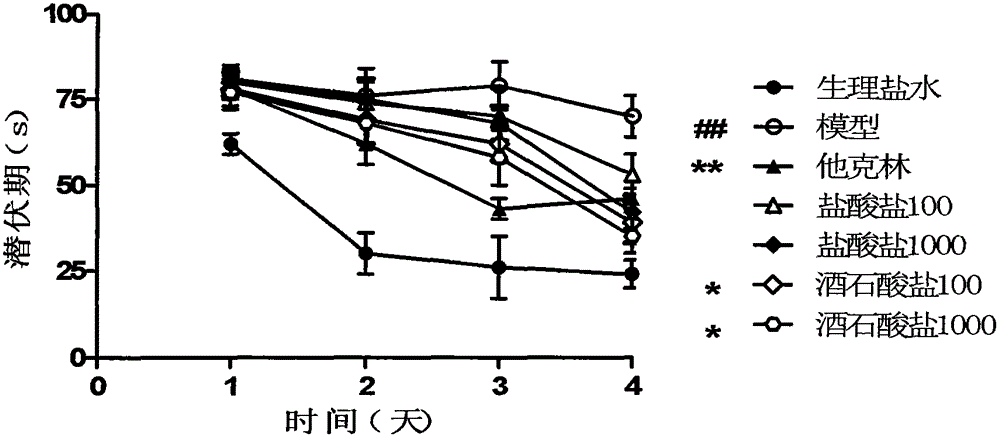

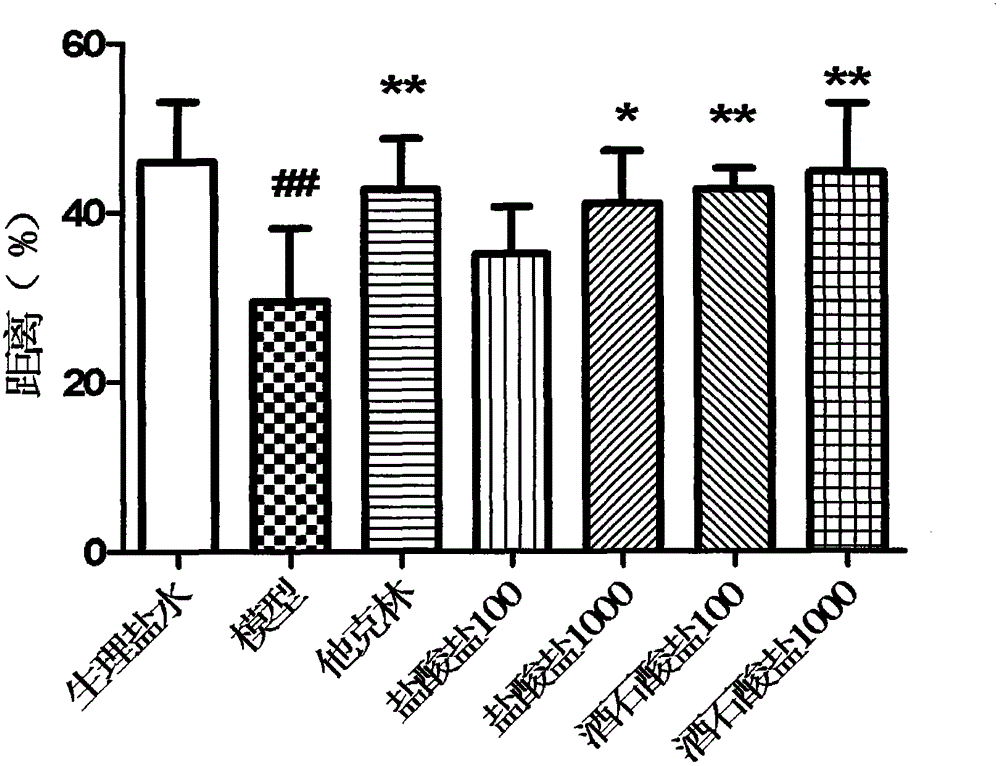

L-meptazinol phenyl carbamate-L-(+)-tartrate and preparation method thereof

InactiveCN103420911ASimplify recrystallization operationsReduce usageNervous disorderCarboxylic acid salt preparationCarbamateTartrate

The invention relates to a levo-meptazinol phenylamino carbamate-L-(+)-tartrate type-I crystal and a preparation method thereof. The levo-meptazinol phenylamino carbamate-L-(+)-tartrate type-I crystal provided by the invention is stable and is characterized in that the degrees of angles 2[theta] of characteristic peaks shown in an X-ray powder diffractogram are respectively 10.1, 11.9, 13.4, 14.9, 15.4, 17.5, 17.9, 18.7, 19.6, 20.5, 21.7, 22.1, 22.6, 23.3, 24.4, 25.4, 26.9, 27.2, 27.6, 29.0, 29.8, 30.0 and 30.3, and corresponding relative intensities are respectively 42, 14, 26, 43, 66, 28, 14, 20, 33, 100, 25, 31, 51, 14, 15, 10, 10, 12, 16, 10, 12, 11 and 10. The melting point of the levo-meptazinol phenylamino carbamate-L-(+)-tartrate type-I crystal provided by the invention is 101.6-103.8 DEG C.

Owner:DISHA PHARMA GRP +1

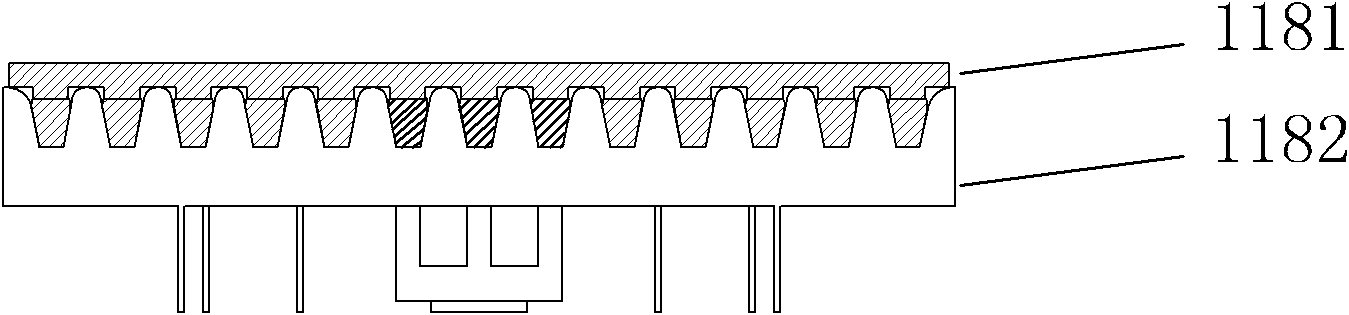

Travelling type grain dewatering and drying machine

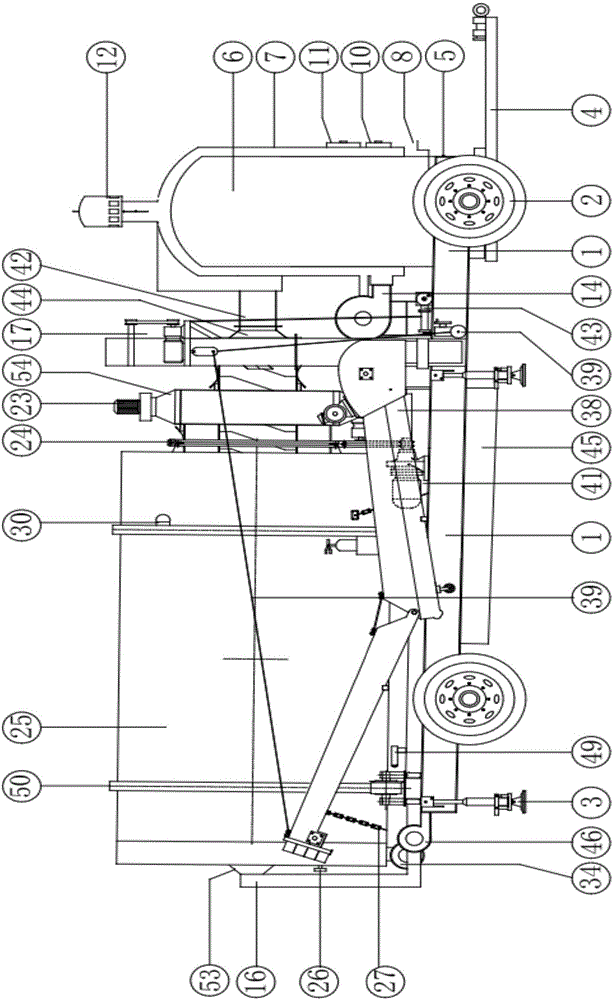

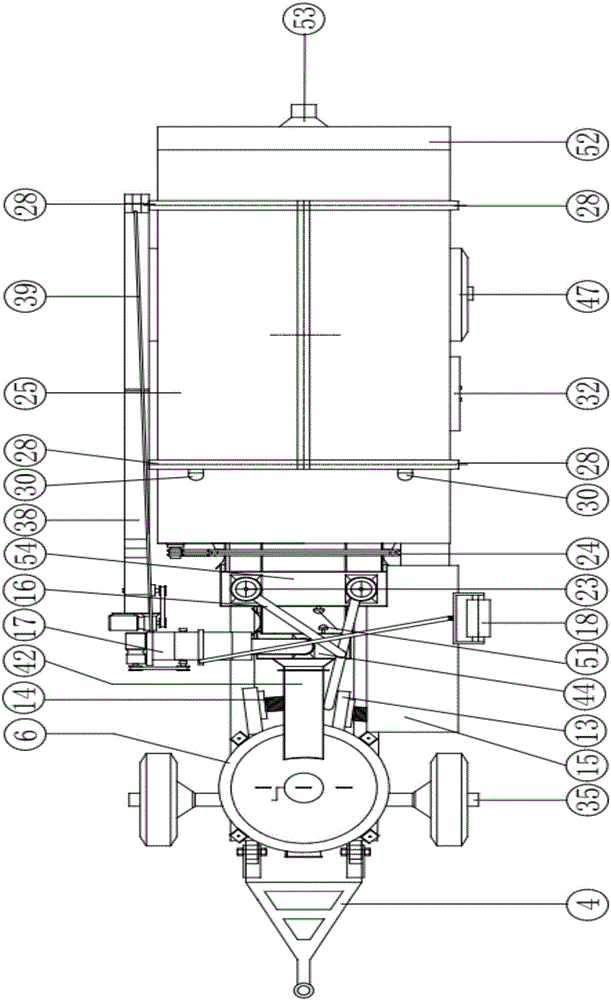

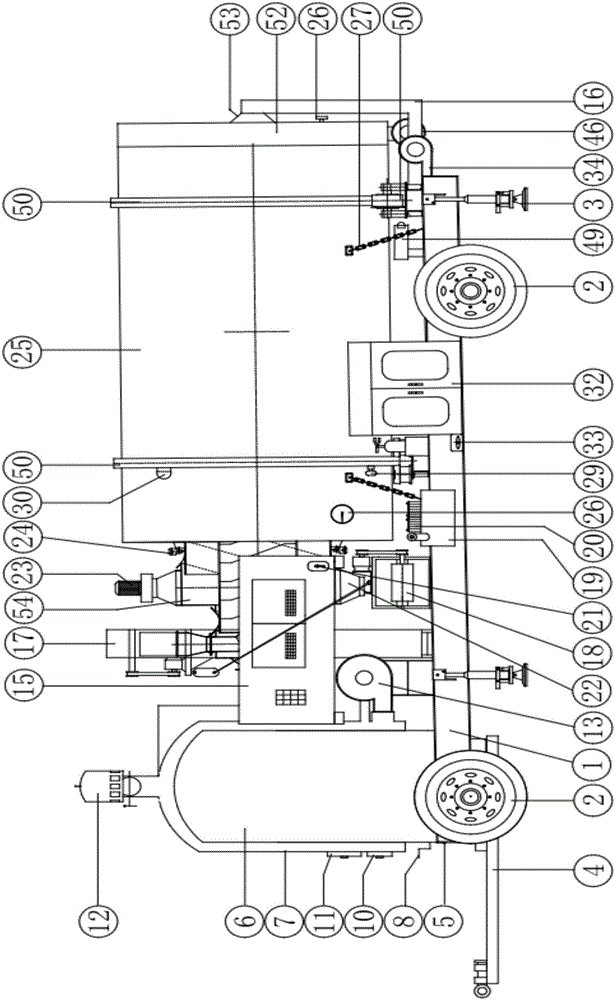

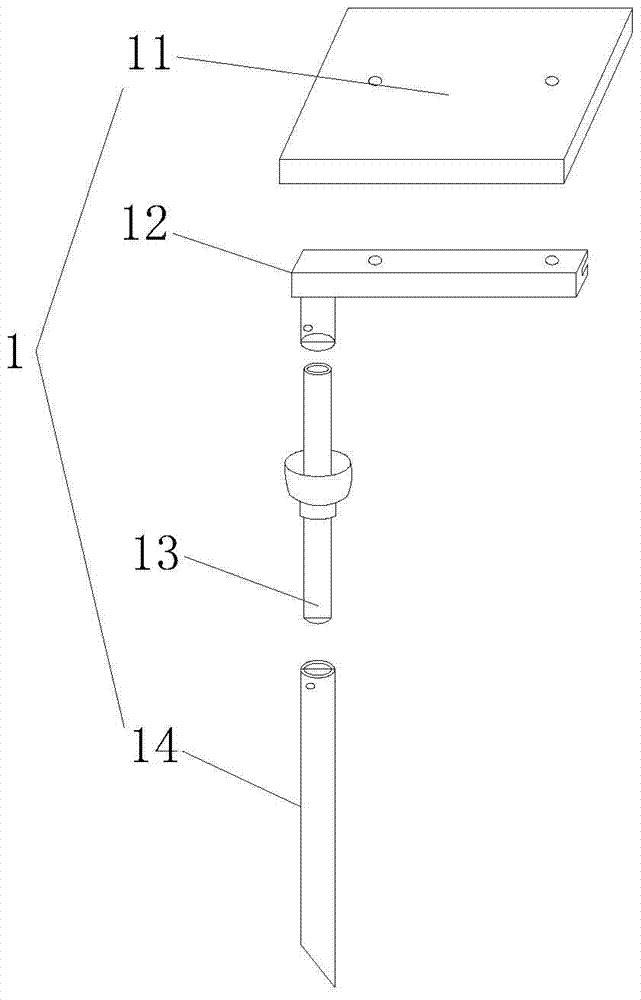

PendingCN106106724ACompact structureImprove efficiencyClimate change adaptationSeed preservation by dryingHot blastVariable frequency control

The invention discloses a travelling type grain dewatering and drying machine comprising a travelling chassis assembly, a hot-blast furnace, a six-set drying bin, a retainer wheel component, a generator set, a fan-shaped grain scraper, a multi-angle discharge machine and an intelligent frequency conversion control cabinet. The travelling type grain dewatering and drying machine has the advantages that the travelling type grain dewatering and drying machine is compact in structure, high in detection efficiency as all components and assemblies adopt current cutting-edge technology, safe and controllable in operation and innovative and attractive in appearance, is energy saving and environment friendly as a coke burning gas furnace is adopted, is convenient to use and low in processing cost, can be dragged to user sites for operation, and is unlimited to tons of grain, fast in drying speed of parking operation, uniform in single-grain shrinkage, good in quality and the like, data of temperature, humidity and the like can be collected and judged visually in good time, the problems that grain drying is difficult and unordered for small farm holders in the production mode, the drying machine has air holes and stagnation leading to bin blockage and the quality is hard to control are solved, labor is saved, and labor intensity of workers is reduced.

Owner:冷瑞卿

A kind of method of artificially inducing wasps to disinfest

ActiveCN104904671BDeworming can be continuously adjustedDeworming is continuously adjustable and controllableAnimal huntingPlant protectionControl mannerInsect

The invention discloses a method for artificially inducing wasps to kill insects. The method comprises the following steps of fixed cultivation of the wasps, mobile cultivation of the wasps and wasp stocking and insect killing. By the method for artificially inducing the wasps to kill the insects, various insect killing wasp populations are cultivated artificially; the method is targeted; insect killing of the wasps can be implemented all day long or all year round; the wasps are bred in mobile cultivation boxes in a managed and controlled manner; the method is operated safely in a controlled manner; and the insect killing cost is low.

Owner:广东互信生物科技有限公司

Method for preventing and controlling alien plants of spartina alterniflora Loisel.

InactiveCN110235706AReduce adverse effectsSafe and controllable operationHops/wine cultivationTurf growingMangroveSeawater

The invention discloses a method for preventing and controlling alien plants of spartina alterniflora Loisel.. Aiming at the protection for local mangrove plans and sensitivity of the spartina alterniflora Loisel. to acid matrices, organic acid or / and inorganic acid is / are added to improve the acidity of soil, pesticide is sprayed on the day with the lowest tidal level or the low tidal level without rain, or irrigation is conducted when seawater with the height of 1-5 cm is left, so that the spartina alterniflora Loisel. is poisoned by metal ions, wither and die. The method is designed with sufficient consideration and utilization of tide features of mudflats, the method is simple, the operation is easy, raw materials are easy to obtain, and the method is low in cost, takes effect quickly, and is ecological and environmentally friendly; the prevention and control effect is good, the survival rate of mangrove forests can be effectively increased, the planting and breeding management value of coastal and river mudflats is increased, and the method has high economic benefits, social benefits and ecological benefits.

Owner:GUANGXI MANGROVE RES CENT

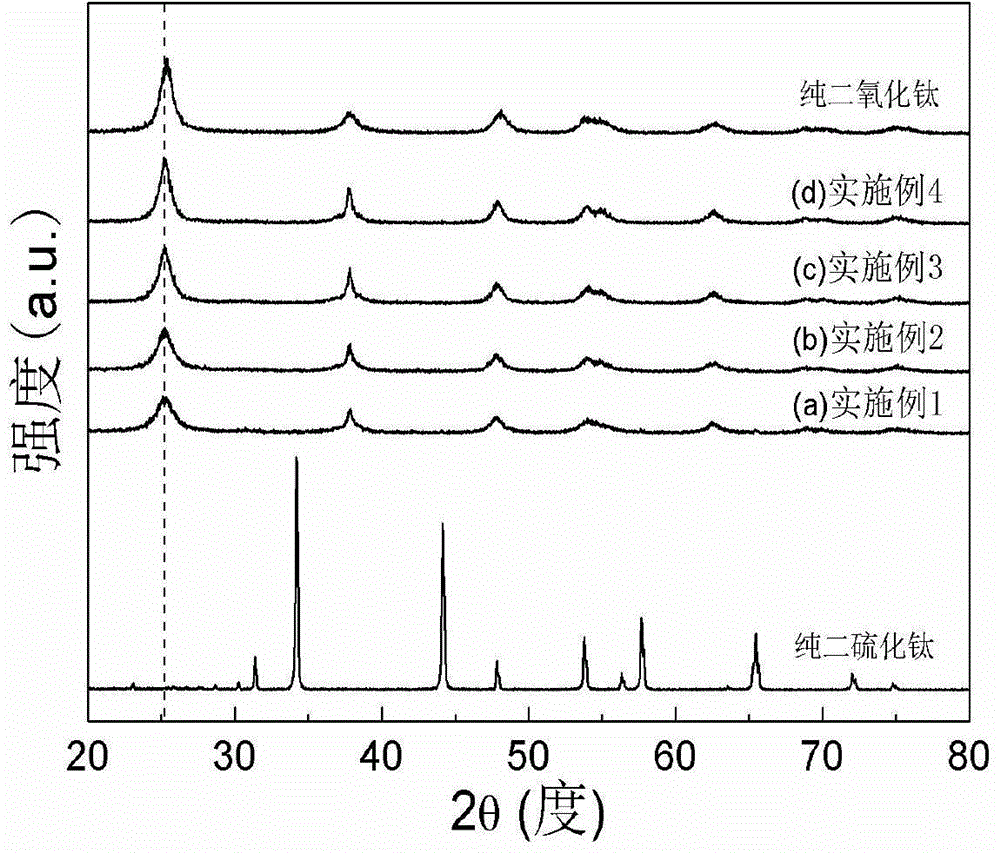

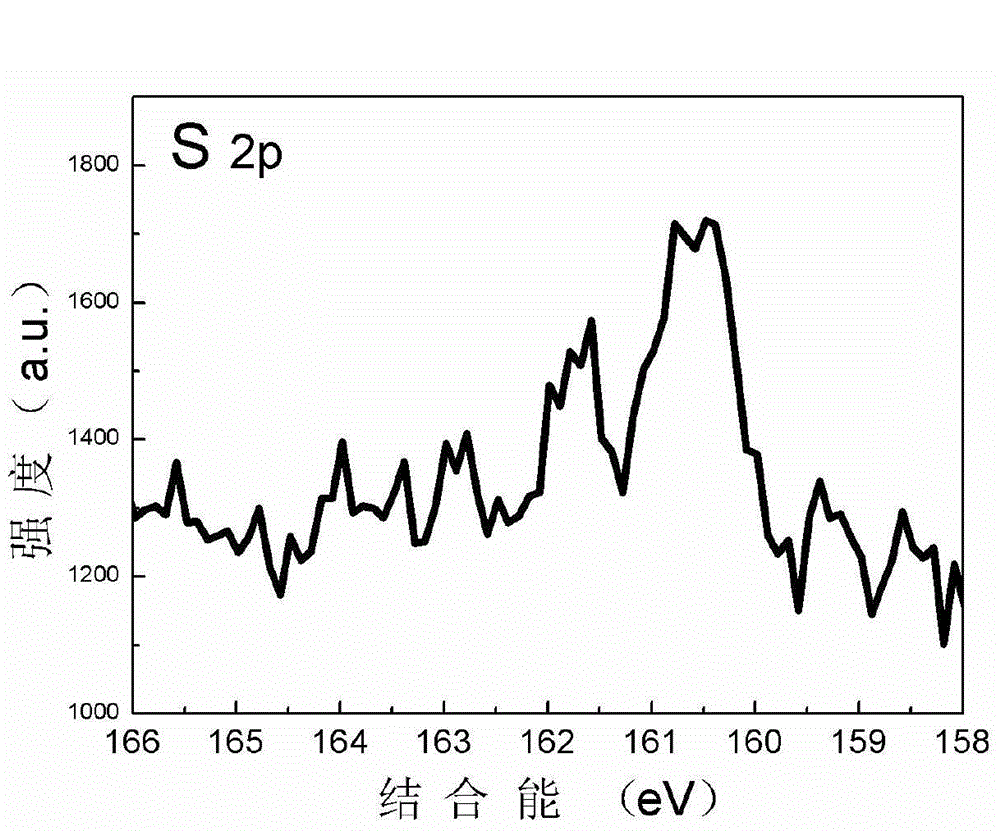

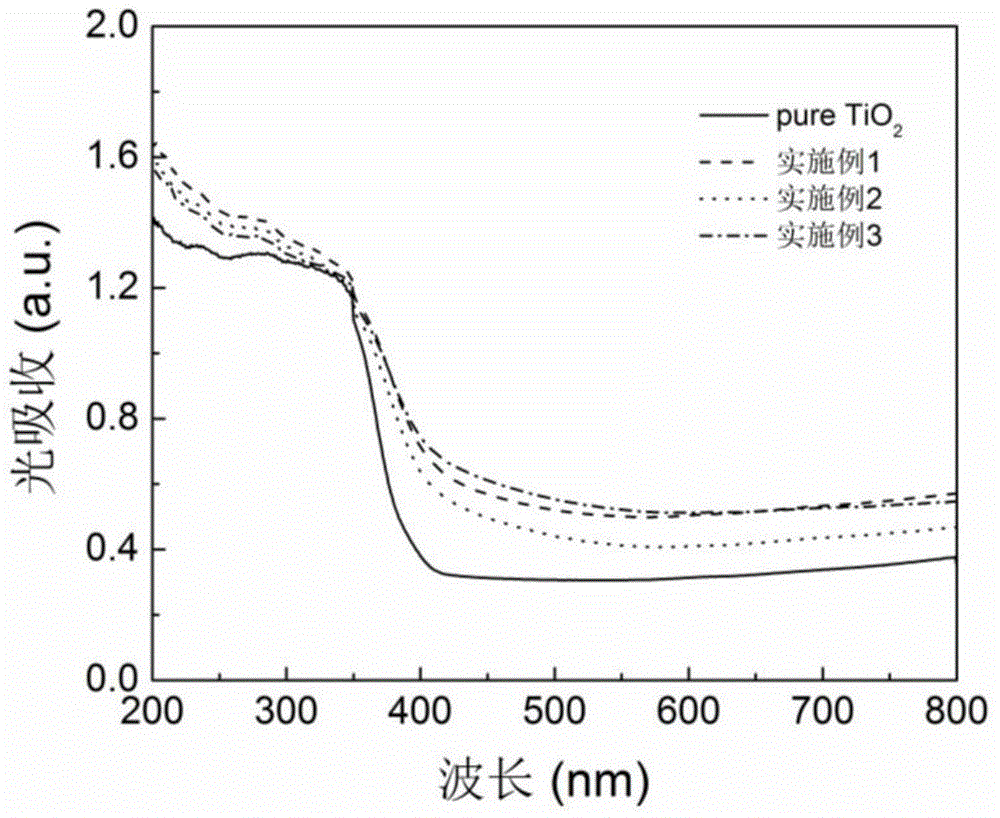

Method for preparing sulfur auto-doped titanium dioxide photocatalyst

InactiveCN104549369AEasy to prepareRaw material environmental protectionPhysical/chemical process catalystsTitanium disulfideRoom temperature

The invention discloses a method for preparing a sulfur auto-doped titanium dioxide photocatalyst. The method comprises the following steps: a. fully mixing a reaction source of a titanium disulfide powder body with water to obtain a titanium disulfide suspension; b. transferring the titanium disulfide suspension to an autoclave, and reacting at a temperature of 120-180 DEG C for 4-12 hours; c. after the reaction in a step b is finished, cooling to a room temperature, washing a reaction product and drying to obtain the sulfur auto-doped titanium dioxide photocatalyst. Raw materials used in the preparation scheme provided by the invention are simple and environmentally friendly, the product is single, and the separation and the purification are easy. The preparation method is simple, the high temperature operation and the complex process are avoided, the reaction conditions are mild, the operation is safe and controllable, an existing sulfur-doped titanium dioxide photocatalyst preparation process is simplified, and the mass production is easily performed.

Owner:山西师范大学

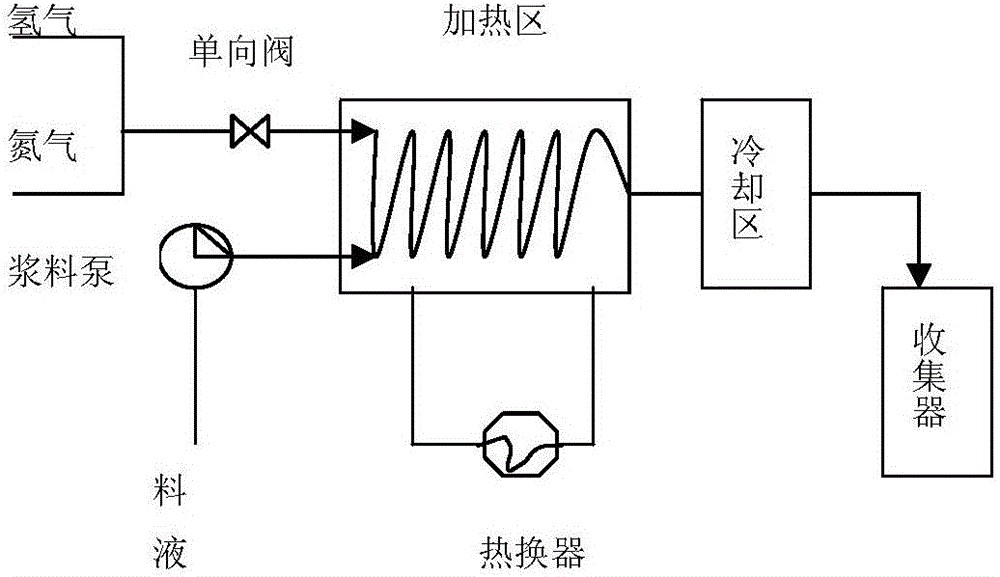

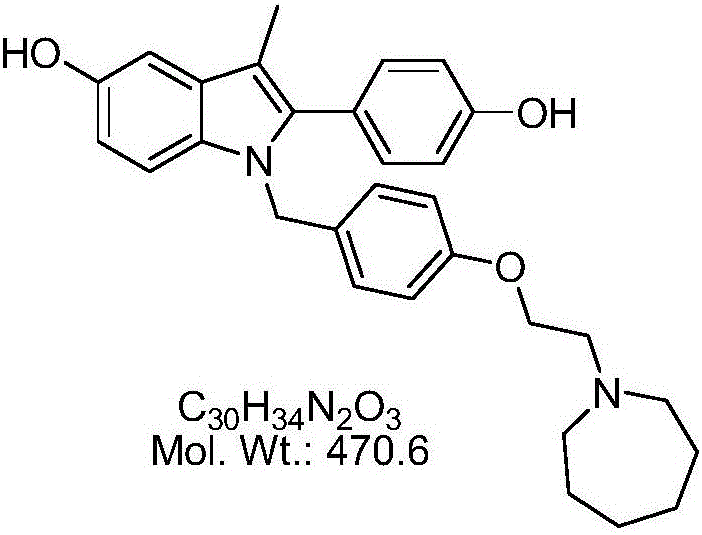

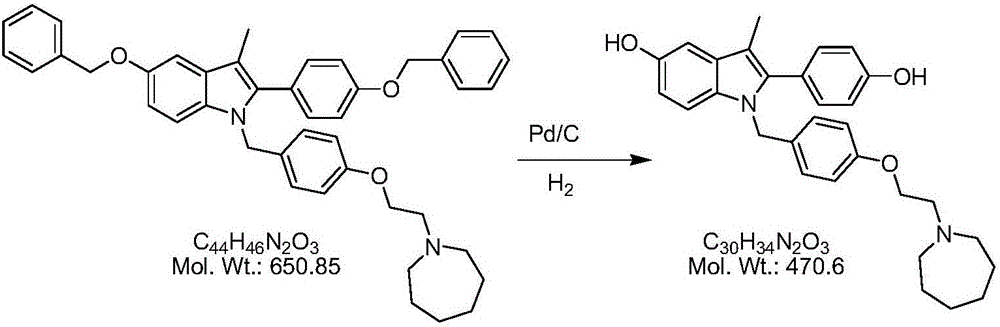

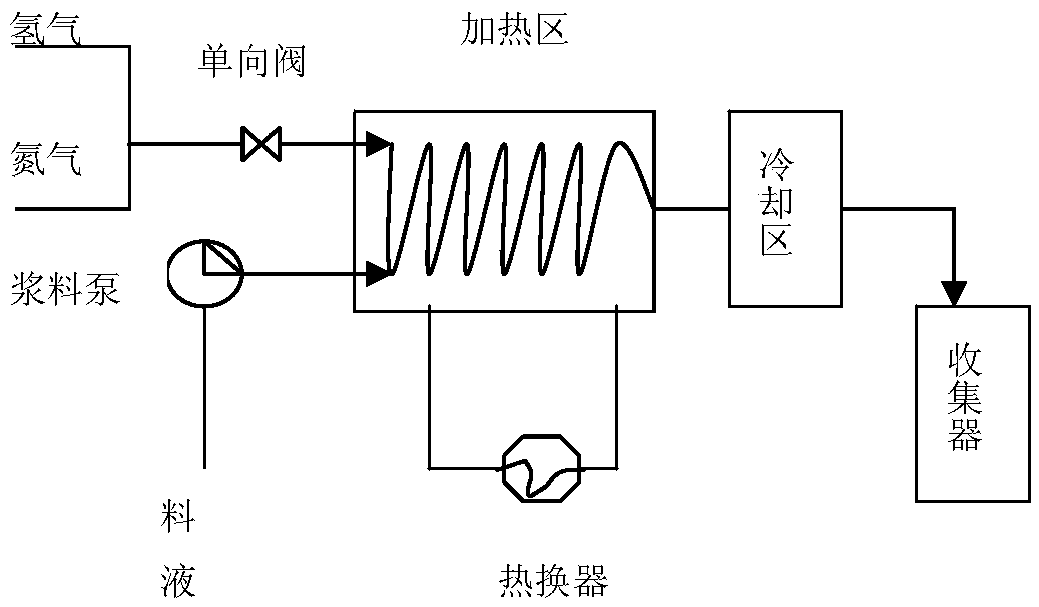

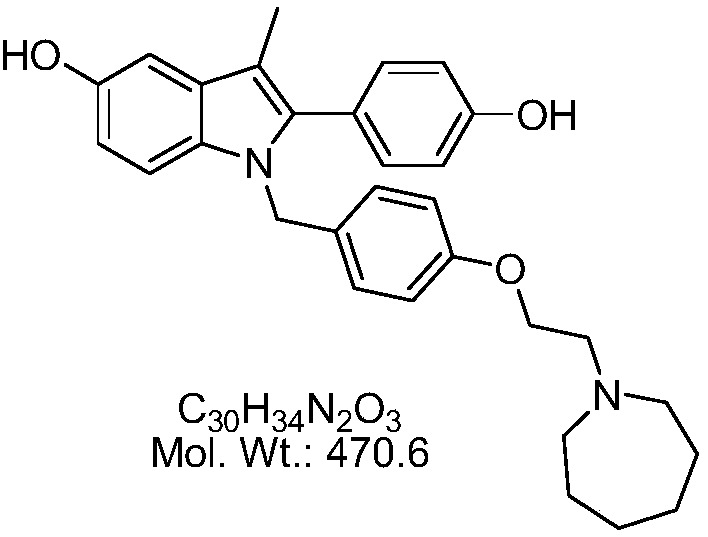

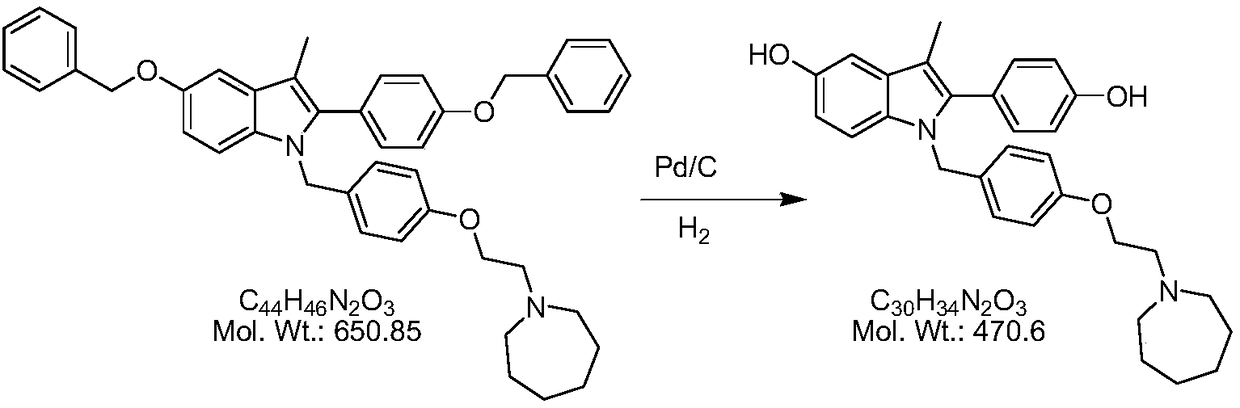

Preparation method of bazedoxifene acetate

The invention discloses a preparation method of bazedoxifene acetate. The method is characterized in that raney nickel is used as a catalyst, and a compound I and hydrogen react in a microreactor to obtain bazedoxifene under the conditions that the temperature is 20 to 40DEG C and the hydrogen pressure is controlled to be 0.1 to 0.5Mpa. According to the method, the raney nickel with lower price is used to replace expensive palladium carbon, so that the production cost is effectively reduced, the microreactor is used and the production is in streamline operation; an obtained product is high in yield and good in quality; the preparation method has the advantages of high reaction efficiency, mild reaction conditions, safe and controllable operation, short reaction time and low cost; the method is easier for industrial production (The formula is shown in the description).

Owner:山东安信制药有限公司

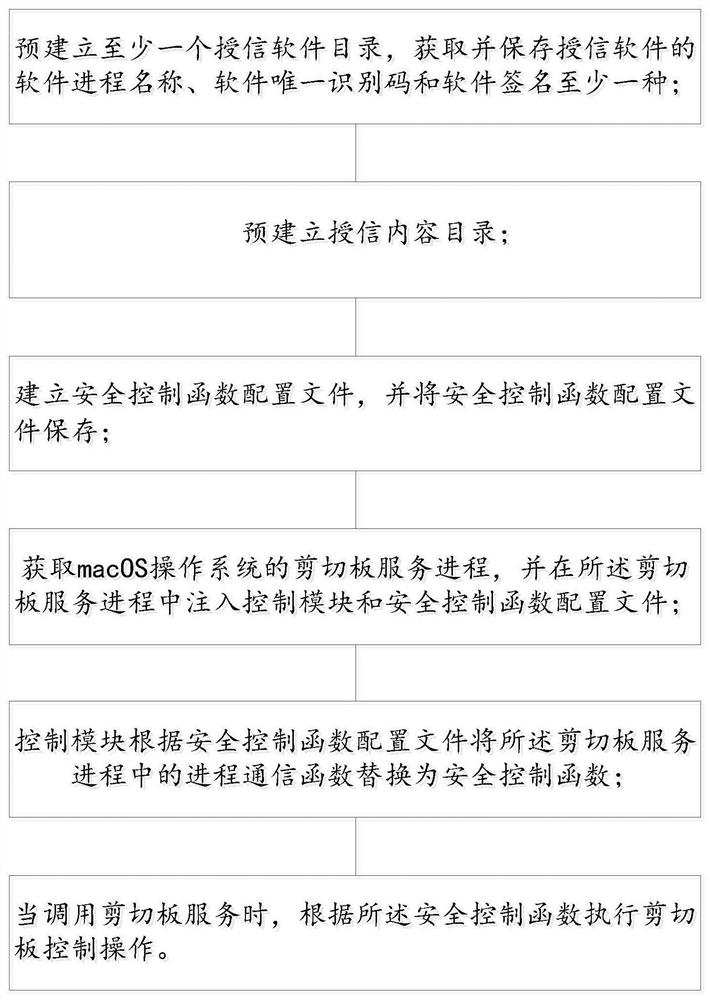

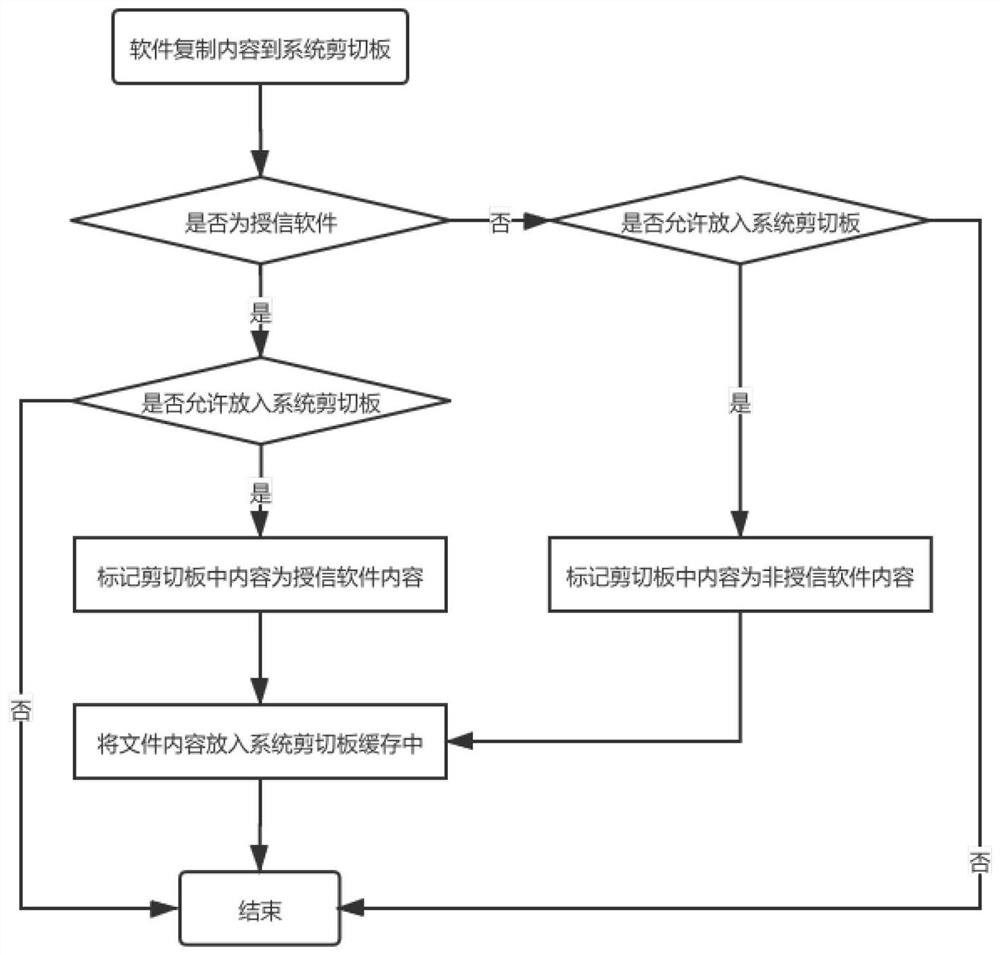

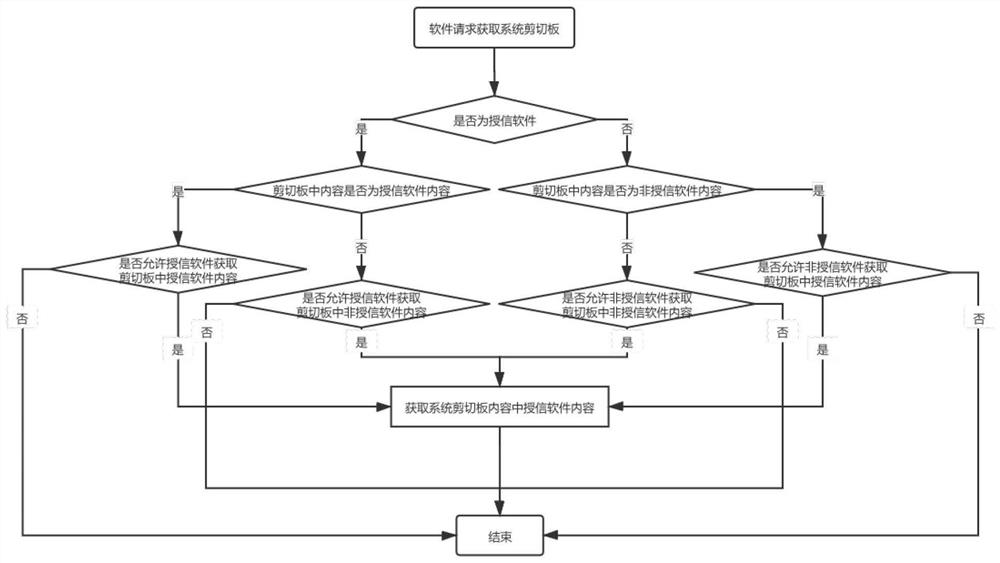

Shear plate control method and system based on macOS operating system

PendingCN112463402ASafe and controllable operationPaste operation prohibitedInterprogram communicationOperational systemSoftware engineering

The invention discloses a shear plate control method and system based on a macOS operating system, and the method comprises the following steps: pre-establishing at least one credit granting softwaredirectory, and obtaining at least one of a software process name, a software unique identification code and a software signature of credit granting software; pre-establishing a credit granting contentdirectory; establishing a safety control function configuration file, and storing the safety control function configuration file; obtaining a clipboard service process of a macOS operating system, and injecting a control module and a security control function configuration file into the clipboard service process; enabling the control module to replace a process communication function in the shearplate service process with a safety control function according to a safety control function configuration file; and when the clipboard service is called, executing clipboard control operation according to the safety control function.

Owner:浙江华途信息安全技术股份有限公司

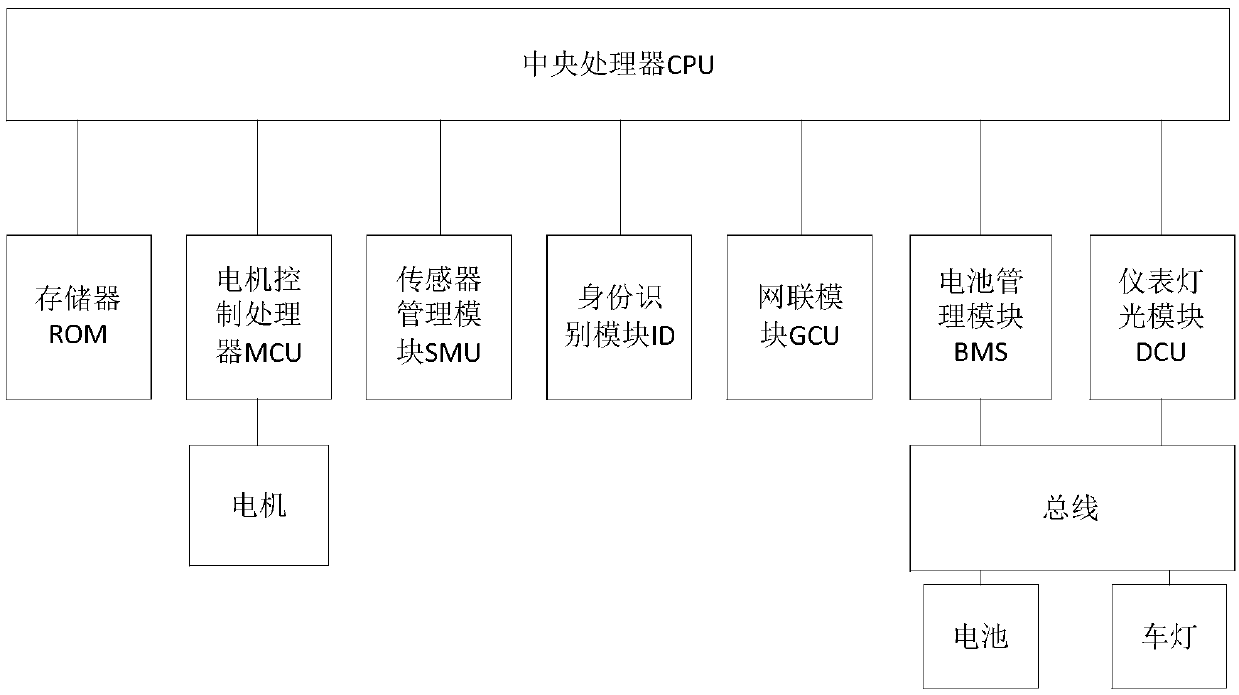

Intelligent network connection controller of electric bicycle

PendingCN111198517ASafe and controllable operationEnsure safetyProgramme controlComputer controlIntelligent NetworkNetwork connection

The invention provides an intelligent network connection controller of an electric bicycle. The controller comprises a central processor CPU, the central processing unit CPU is electrically connectedwith a memory ROM, a motor control processing module MCU, a sensor management module SMU, an identity recognition module ID, a network connection module GCU, a battery management module BMS and an instrument light module DCU. According to the intelligent network connection controller of the electric bicycle, a traditional electric bicycle is transformed and upgraded, and perception, networking andintelligent control of the electric bicycle are achieved.

Owner:邹渝 +1

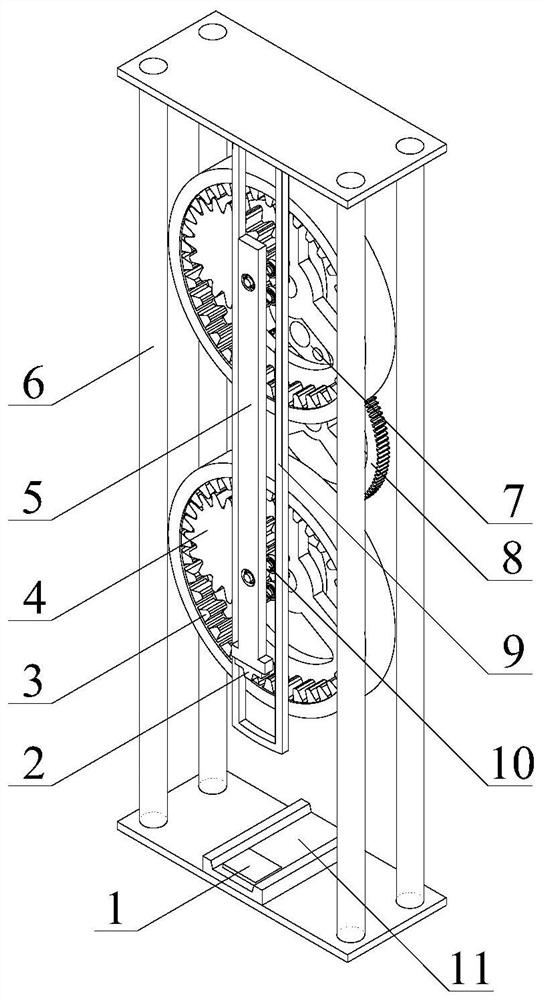

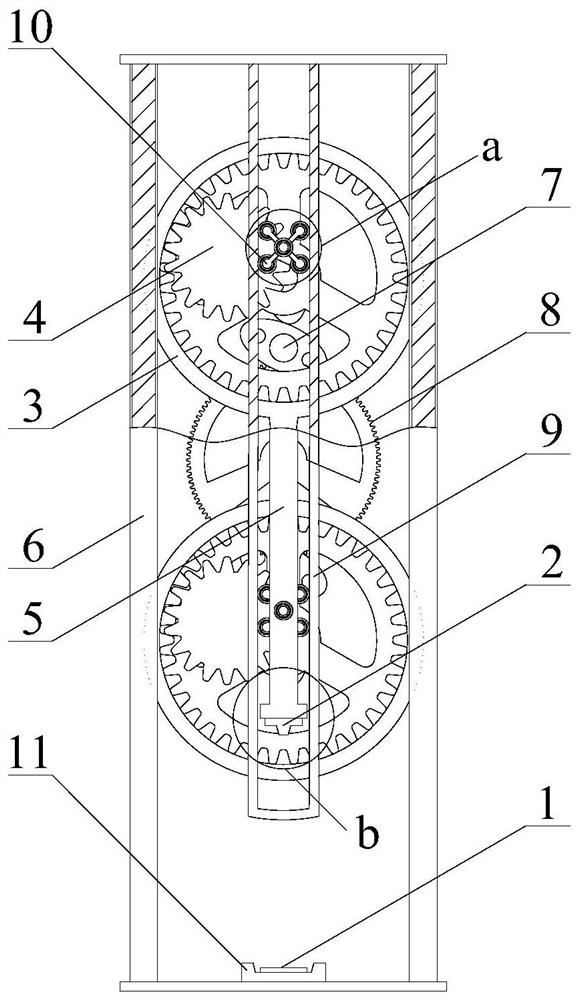

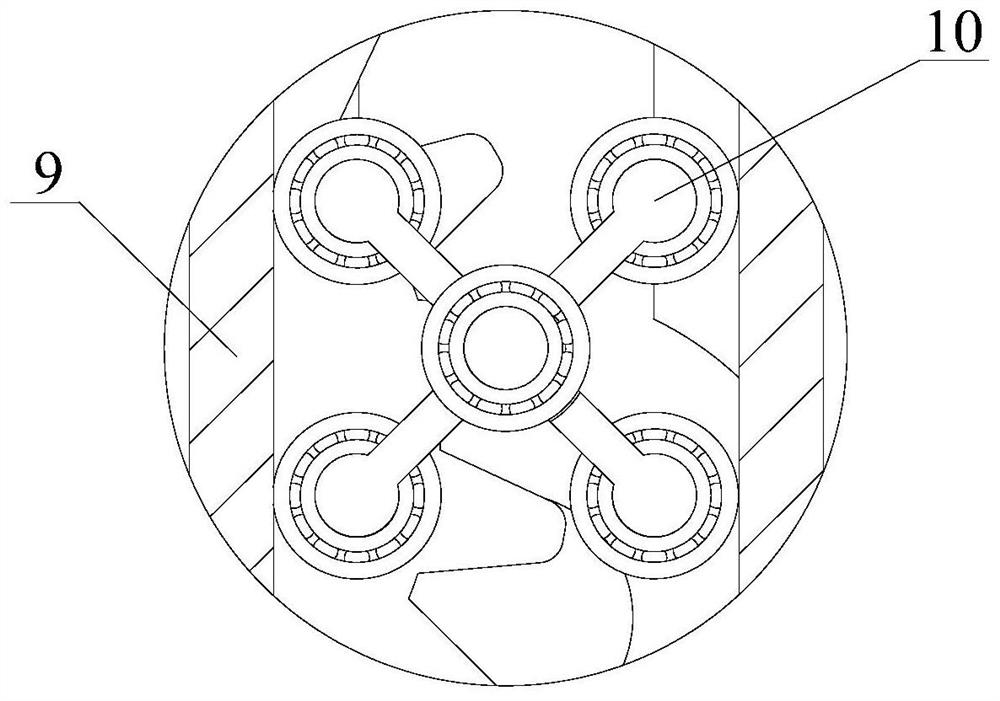

A test device and method for applying continuous impact load

ActiveCN109001061BAdjustable sizeAdjustable frequencyMaterial strength using repeated/pulsating forcesGear driveGear wheel

The invention discloses a test device for applying continuous impact load and a method thereof, which comprises an internal gear, an external gear, a guide bearing group, a guide rail, an impact rod, an action head, an elliptical gear group and a power gear. The top of the guide rail is fixed on the overall support, and the test piece is placed in the test bench at the bottom. The power gear drives the elliptical gear set, and transmits power through the internal gear, external gear and guide bearing set. The impact rod and the action head reciprocate vertically along the guide rail to exert continuous impact load on the specimen. The ratio of the inner diameter of the internal gear to the outer diameter of the external gear is 2:1, and the hypocycloid trajectory of any given point on the external gear is linear reciprocating motion. The variable rotation speed can be obtained by adjusting the meshing mode of the elliptical gear set, thereby realizing the continuous application of impact loads of different sizes and frequencies; the invention has simple structure, convenient operation, and safe and controllable operation.

Owner:HOHAI UNIV

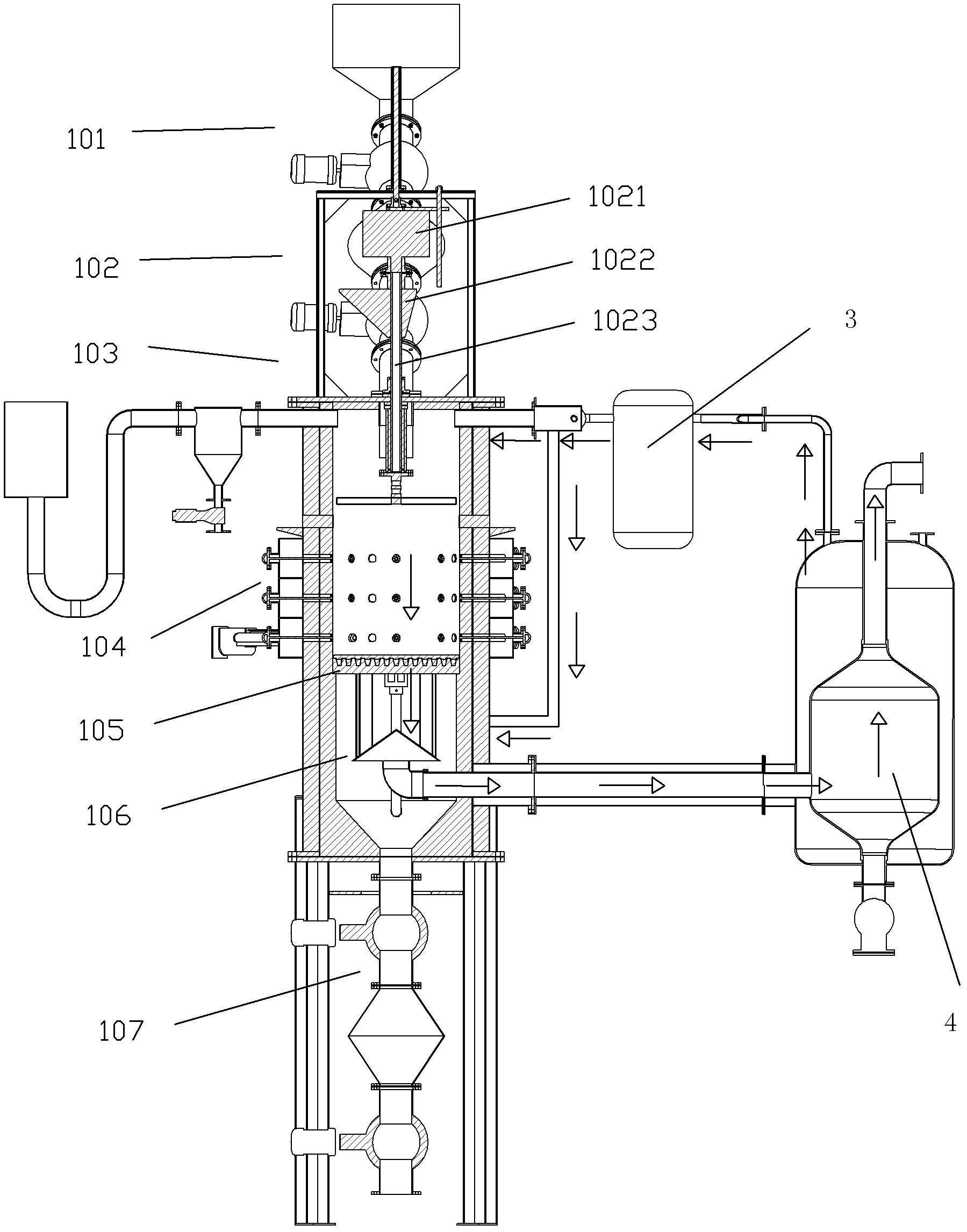

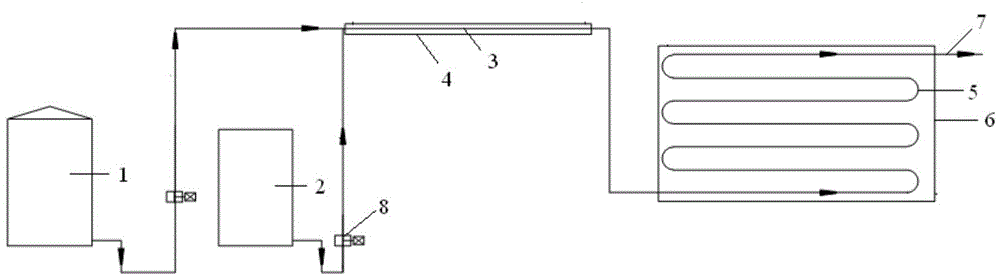

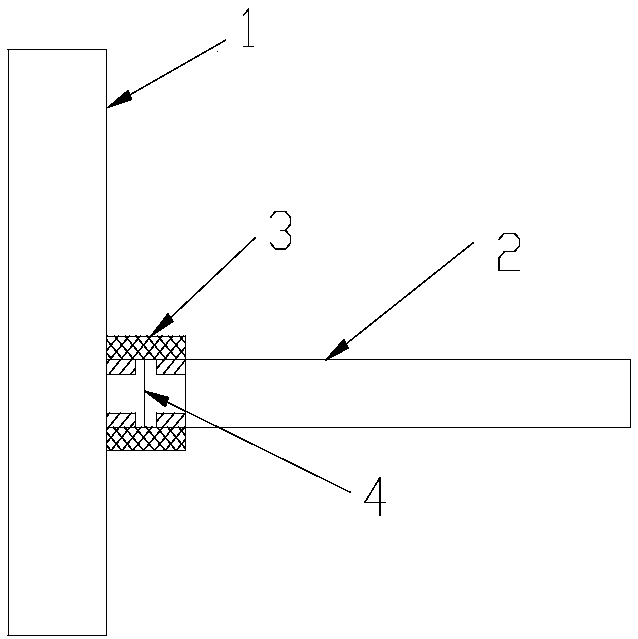

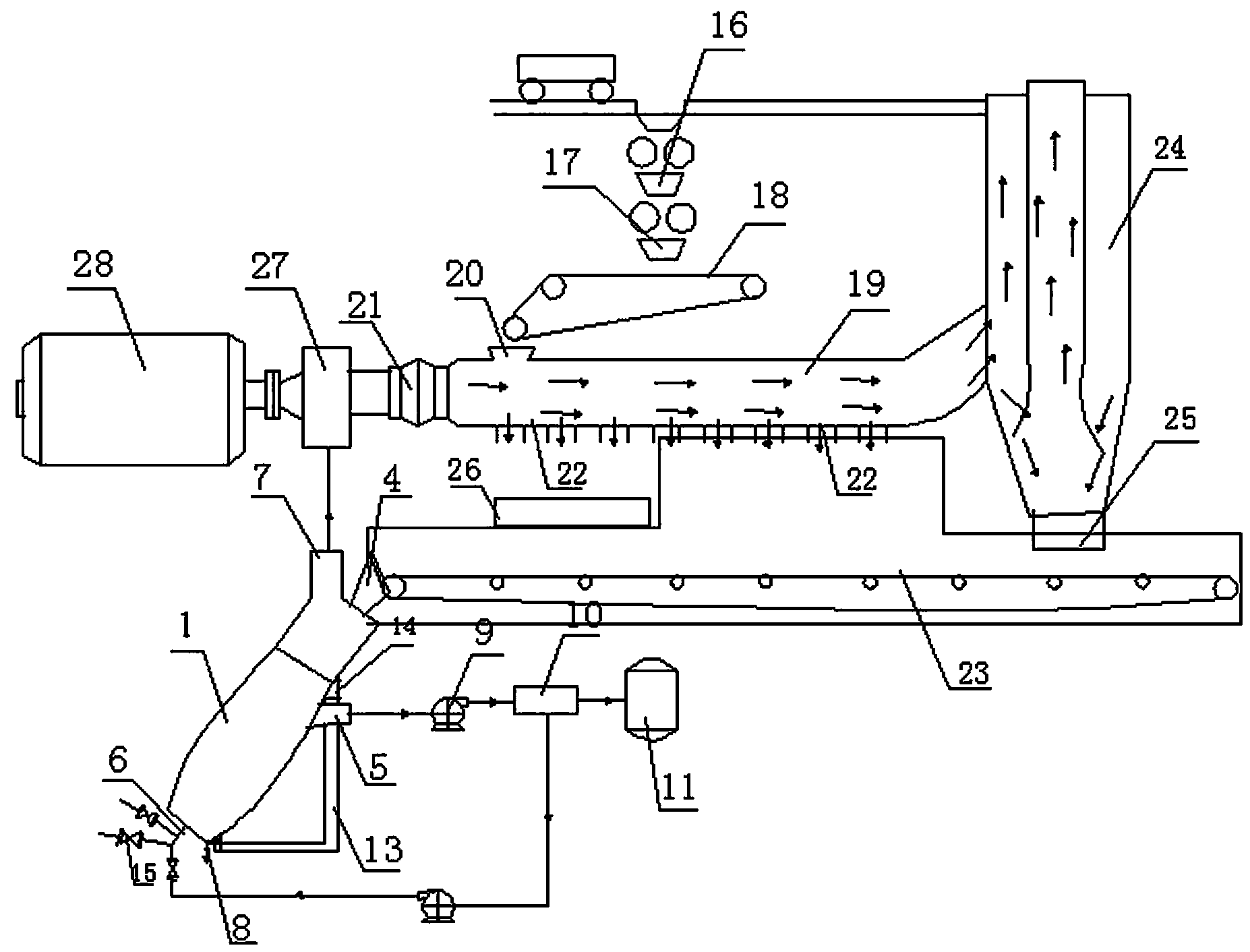

Downdraft biomass gasification reaction chamber and gasification process thereof

InactiveCN102329656BImprove gasification efficiencySafe and controllable operationEnergy inputCombustible gas productionFurnace temperatureMonitoring system

The invention relates to a downdraft biomass gasification reaction chamber and a gasification process thereof. The downdraft biomass gasification reaction chamber comprises an automatic feeding device, a gasification region consisting of a primary gasification region and a secondary gasification region which are integrated, an automatic leveling device, a vibration grate, an automatic ignition device, an automatic deslagging device, an in-furnace pressure regulating system, a furnace temperature monitoring system, an in-furnace material level monitoring system, an inlet and output gas temperature monitoring system, an inlet and outlet pressure monitoring system and a flame monitoring system. The production process comprises the following steps of: automatically feeding and introducing gas, primarily gasifying, secondarily gasifying, and automatically deslagging. The downdraft biomass gasification reaction chamber is scientific and environmentally-friendly, has the remarkable characteristics of reasonable structure design, high automation, stable and controllable gasification reaction, continuity and no interruption, has high gasification efficiency and high integral heat value, issuitable for large-area popularization, and especially can be applied to continuous and stable power generation of the existing gas generator.

Owner:张建超

a seal lock

ActiveCN106079934BSimple and reasonable structural designSafe and controllable operationStampingMechanical engineeringFingerprint

The invention relates to a seal lock. The seal lock comprises a lock shell of a columnar structure. The seal lock is characterized in that a lock body control assembly for achieving an unlocking or locking function, and a pressing rebounding device for completing sealing operation through external force pressing in an unlocked state are installed in the lock shell; and the lower portion of the pressing rebounding device is connected with a seal. The seal lock is simple and reasonable in structural design and safe and controllable in operation; a lock body is controlled to be unlocked and locked through fingerprint recognition, and during manual pressing sealing, due to the design of the pressing rebounding device, the sealing frequency is effectively controlled; and a camera is installed on the lock body, so that sealed files and sealing processes are clearly recorded, and the controllable whole course of seal management is truly achieved.

Owner:YANTAI TRI CIRCLE SCI & TECH

A kind of preparation method of venlafaxine hydrochloride intermediate

ActiveCN106866434BImprove reaction efficiencyHigh yieldOrganic compound preparationChemical recyclingHydrogenSulfate

The invention discloses a preparation method of a venlafaxine hydrochloride intermediate. The preparation method comprises the following steps of in a micro-reactor loaded with a raney nickel screen net catalyst, enabling a compound I and hydrogen to react at the temperature of 20 to 40 DEG C, so as to obtain a compound II; adding the compound II into sulfuric acid, and forming salt, so as to obtain a target product, namely 1-[2-amino-1-(4-methoxyphenyl)ethyl]cyclohexanol sulfate (compound III). The preparation method has the advantages that on the basis of the original micro-reactor, the raney nickel screen net catalyst is creatively clamped to the connecting part of a pipeline, so that the catalyzing effect is enhanced, and the catalyst can be recycled; the damage to a slurry pump of the micro-reactor and the blockage of a reaction pipeline due to mixing of the catalyst into material liquid are avoided.

Owner:山东安信制药有限公司

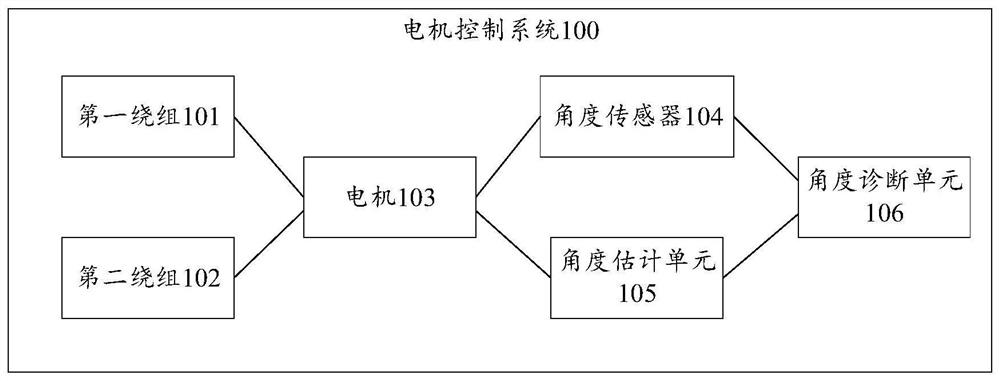

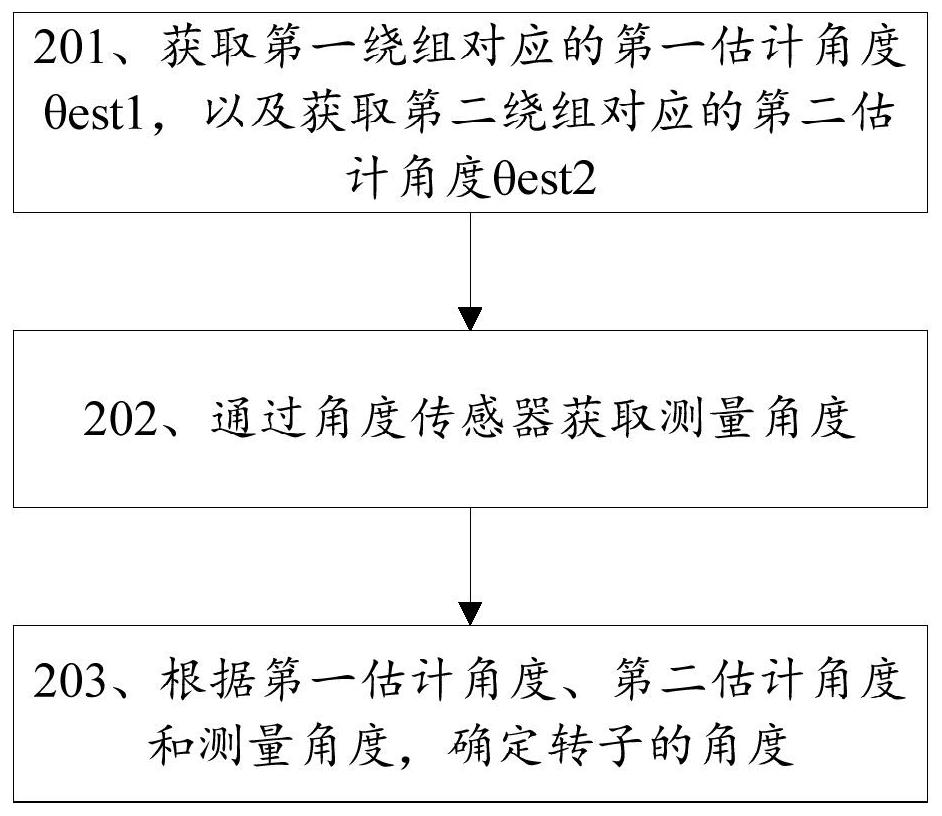

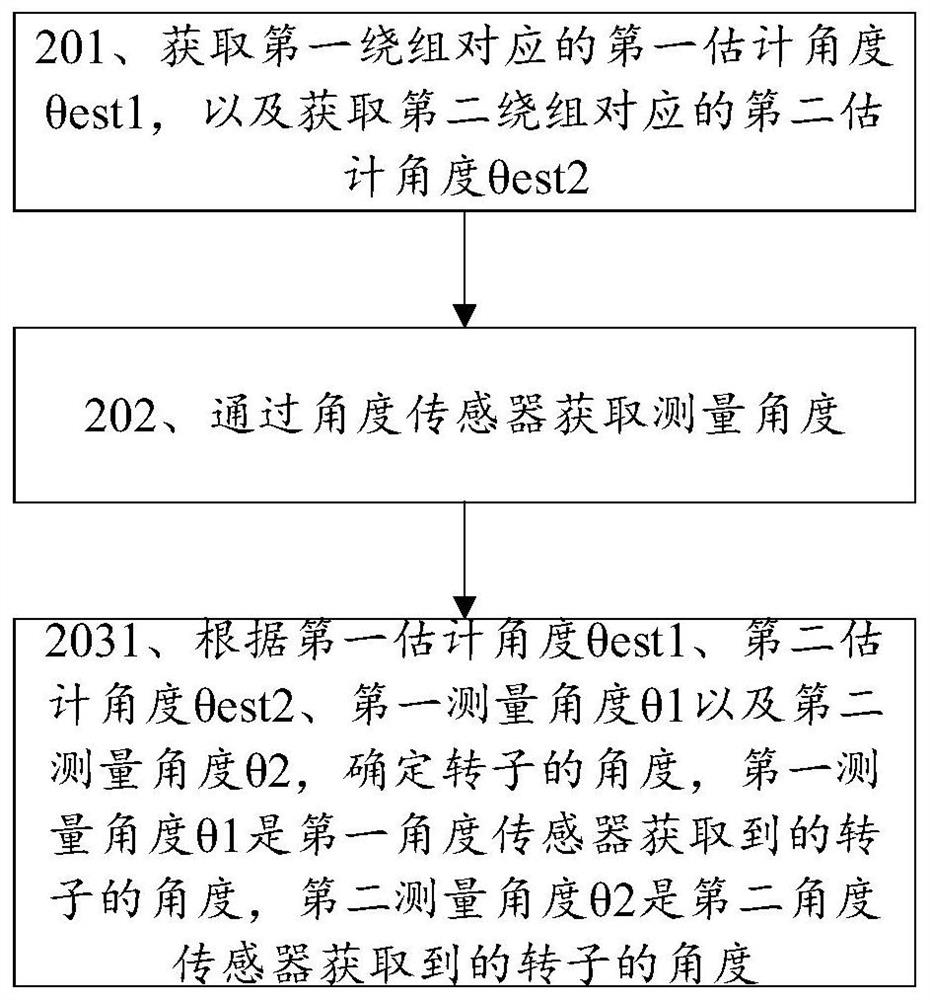

Angle acquisition method and related device

InactiveCN112689953ASimple hardware structureLow costElectronic commutation motor controlVector control systemsControl systemElectric machinery

The invention discloses an angle acquisition method and a related device. The angle acquisition method is used for the motor control system, and is characterized in that the motor control system comprises a motor and an angle sensor; and the motor comprises a first winding, a second winding and a rotor. The method comprises steps of obtaining a first estimation angle corresponding to a first winding, obtaining a second estimation angle corresponding to a second winding, wherein the first estimation angle is acquired according to the current of the first winding, and the second estimation angle is acquired according to the current of the second winding; obtaining a measurement angle through an angle sensor, wherein the measurement angle is the rotor angle obtained by the angle sensor; and determining the angle of the rotor according to the first estimated angle, the second estimated angle and the measurement angle, so that the reliability of the obtained angle of the rotor can be guaranteed, the safe and controllable operation of the motor can be guaranteed, excessive addition of angle sensors can be avoided, simplification of a hardware structure of a motor control system is facilitated, and cost is reduced.

Owner:HUAWEI TECH CO LTD

System for power generation by utilizing thermal decomposition gas of domestic garbage

InactiveCN103551361AAvoid sedimentation of sewageSolve processing problemsSolid waste disposalExhaust gasProcess engineering

The invention discloses a system for power generation by utilizing thermal decomposition gas of domestic garbage. The system comprises a garbage sieving device, a garbage thermal-decomposition device and a power generating device, wherein sorted garbage is conveyed into a garbage feeding port of the garbage thermal-decomposition device by a garbage conveying belt; a high-temperature gas outlet of the garbage thermal-decomposition device is connected with a gas turbine; a gas exhausting port of the gas turbine is connected with a high-speed gas inlet of the garbage sieving device; moderate-heat-value fuel gas generated by thermal decomposition is used for heating and burning of a garbage sealing and thermal-decomposition furnace. The system disclosed by the invention has the advantages that the heat is utilized for continuous thermal decomposition of the garbage in the sealed thermal-decomposition furnace so as to implement continuous self-feeding and self-use purposes of the fuel gas, and is utilized for driving the gas turbine to do work and generate power, and high-temperature and high-speed tail gas exhausted by the gas turbine is used for sieving the garbage, and by repeated circulation, the difficulty in treating the domestic garbage in most cities can be solved, the garbage burning can be prevented from exhausting dioxin-polluted gas and dust to the atmosphere, and deposited sewage generated by garbage landfill is also avoided.

Owner:DEYANG DONGXING MACHINERY MFG

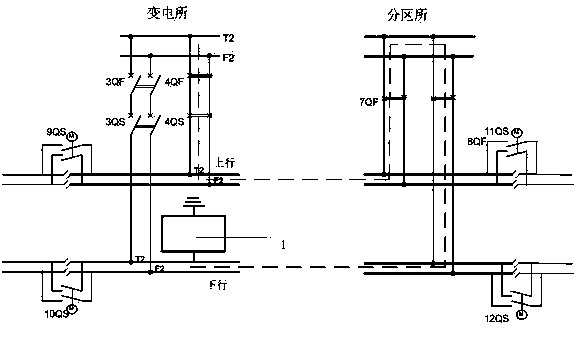

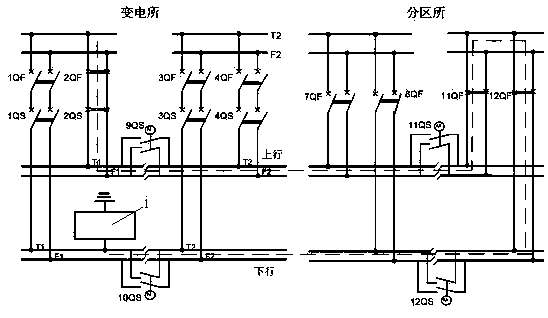

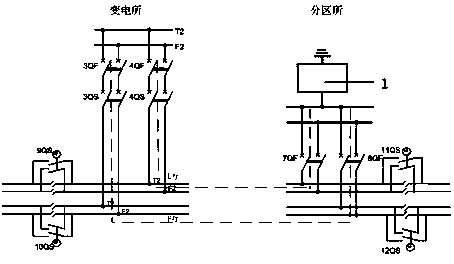

Icing preventing and ice melting method for high speed railway and system for realizing method

InactiveCN102431468BMeet site needsEasy and flexible operationOverhead installationTrolley linesEngineeringContact line

The invention discloses an icing preventing and ice melting method for a high speed railway. The method comprises the following steps of: 1, establishing the icing preventing and ice melting loop of a catenary; 2, adjusting the impedance of the icing preventing and ice melting loop and controlling icing preventing and ice melting current to prevent contact lines and carrier cables from being burnt by the excessive current of the catenary; and 3, implementing icing preventing and ice melting control. The invention also comprises an icing preventing and ice melting system for realizing the method. The system comprises the icing preventing and ice melting loop and an icing preventing and ice melting device (1). The invention complies with the icing preventing and ice melting combined principle of primarily preventing icing by using alternating current on line and secondarily melting ice off line, and grounding resistors or inducers are additionally connected at a power substation or a section post, so that certain alternating current passes through the catenary, icing is prevented by heat which is generated by the current, and the technical problem that a mechanical deicing mode is not suitable for the high speed railway any more is solved.

Owner:CHENGDU SOUTHWEST JIAOTONG UNIV XUJI ELECTRIC +1

A method for continuously synthesizing O, S-dimethylphosphorothioate based on a tubular reaction device

InactiveCN104558025BImprove responseThe transfer process is easy to controlGroup 5/15 element organic compoundsChemical/physical/physico-chemical stationary reactorsEngineeringDimethyl sulfate

The invention discloses a method for continuously synthesizing O,S-dimethyl phosphoroamidothioate based on a pipe type reaction device. According to the method, O,O-dimethyl phosphoroamidothioate and dimethyl sulfate are used as raw materials, and O,S-dimethyl phosphoroamidothioate is continuously synthesized by virtue of the pipe type reaction device; the pipe type reaction device comprises two sections of pipe type reactors which are connected in series, and the temperature in each pipe type reactor is set to be appropriate during reaction; and O,O-dimethyl phosphoroamidothioate and dimethyl sulfate are continuously pumped into the first section of the pipe type reactors after being metered to perform mixing and reaction, and then flow through the second section of the pipe type reactors for further reaction, so that an O,S-dimethyl phosphoroamidothioate product is continuously obtained from a material outlet of the second section of the pipe type reactors. The method is high in reaction efficiency and high in equipment utilization ratio, a single set of reaction device is high in productivity, the reaction process is easy to control, the safety performance is good, and the requirements for industrial production can be met.

Owner:XIANGTAN UNIV

A kind of preparation method of bazedoxifene acetate

The invention discloses a preparation method of bazedoxifene acetate. The method is characterized in that raney nickel is used as a catalyst, and a compound I and hydrogen react in a microreactor to obtain bazedoxifene under the conditions that the temperature is 20 to 40DEG C and the hydrogen pressure is controlled to be 0.1 to 0.5Mpa. According to the method, the raney nickel with lower price is used to replace expensive palladium carbon, so that the production cost is effectively reduced, the microreactor is used and the production is in streamline operation; an obtained product is high in yield and good in quality; the preparation method has the advantages of high reaction efficiency, mild reaction conditions, safe and controllable operation, short reaction time and low cost; the method is easier for industrial production (The formula is shown in the description).

Owner:山东安信制药有限公司

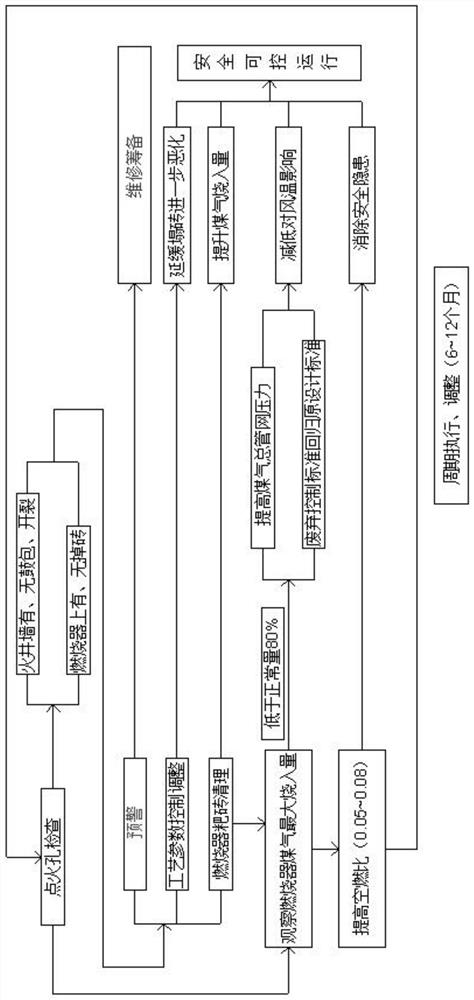

Blast furnace hot blast stove fire well wall brick collapse early warning and control process

ActiveCN111710135AIncrease pressureIncrease burn-inBrick-hot blast stovesAlarmsBrickHazardous substance

The invention relates to a blast furnace hot blast stove fire well wall brick collapse early warning and control process which comprises the following steps: opening an ignition hole above a hot blaststove combustor in a planned manner for visual inspection by utilizing a blast furnace regular repair hot blast stove stop operation opportunity; if it is confirmed that bricks fall off from the upper portion of the combustor, giving an early warning prompt, meanwhile, reducing the arch crown temperature of the combustion furnace by 5-10 DEG C according to conditions, and delaying further deterioration of collapsed bricks through technological parameter adjustment; observing the maximum coal gas burning amount of the brick collapse hot-blast stove under normal coal gas pressure; under the condition that the residual oxygen content in the flue gas is normal, increasing the air-fuel ratio of the burning furnace by 0.05-0.08%, and increasing the excess air coefficient of the burning furnace;and periodically executing the steps 1 to 4, carrying out early warning and prompting according to the brick collapse condition of the fire well wall, and carrying out process parameter control adjustment according to trend change. The process has good economic benefits in the aspects of increasing the productivity and reducing the fuel consumption; and hazardous substances such as a flue pipeline, waste heat recovery and thinning generated by a chimney can be eliminated, and good popularization significance is achieved.

Owner:SGIS SONGSHAN CO LTD

A kind of levomaprotamol phenylcarbamate-l-(+)-tartrate and its preparation method

InactiveCN103420911BSimplify recrystallization operationsReduce usageNervous disorderCarboxylic acid salt preparationCarbamateTartrate

The invention relates to a levo-meptazinol phenylamino carbamate-L-(+)-tartrate type-I crystal and a preparation method thereof. The levo-meptazinol phenylamino carbamate-L-(+)-tartrate type-I crystal provided by the invention is stable and is characterized in that the degrees of angles 2[theta] of characteristic peaks shown in an X-ray powder diffractogram are respectively 10.1, 11.9, 13.4, 14.9, 15.4, 17.5, 17.9, 18.7, 19.6, 20.5, 21.7, 22.1, 22.6, 23.3, 24.4, 25.4, 26.9, 27.2, 27.6, 29.0, 29.8, 30.0 and 30.3, and corresponding relative intensities are respectively 42, 14, 26, 43, 66, 28, 14, 20, 33, 100, 25, 31, 51, 14, 15, 10, 10, 12, 16, 10, 12, 11 and 10. The melting point of the levo-meptazinol phenylamino carbamate-L-(+)-tartrate type-I crystal provided by the invention is 101.6-103.8 DEG C.

Owner:DISHA PHARMA GRP +1

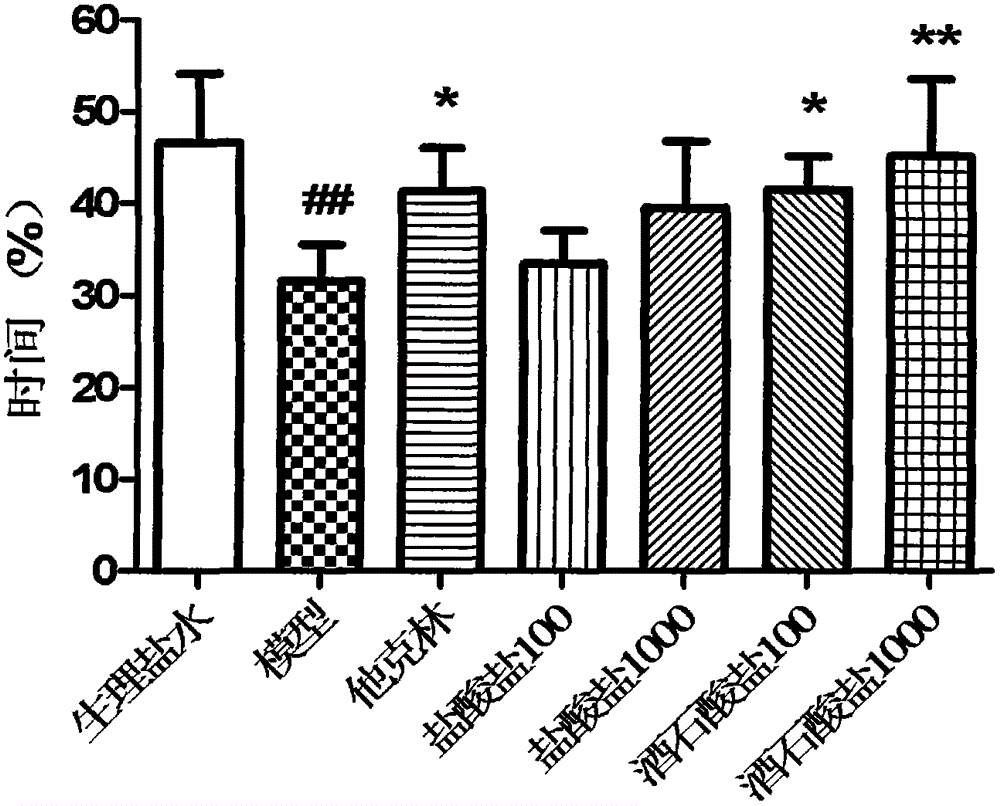

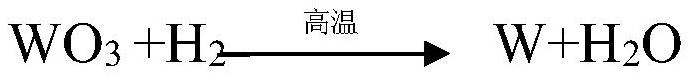

Method for directly producing tungsten oxide powder by adopting sodium tungstate solution

PendingCN114835165AAchieve separationReduce generationTungsten oxides/hydroxidesProcess efficiency improvementHydrometallurgySlurry

The invention relates to a method for directly producing tungsten oxide powder by adopting a sodium tungstate solution, which comprises the following steps: by taking the sodium tungstate solution separated by tungsten ore hydrometallurgy as a raw material, adding a tungsten precipitation reagent into the sodium tungstate solution while stirring to generate calcium tungstate precipitate, and washing to remove impurities; the method comprises the following steps: preparing a tungsten dissolving reagent, adding calcium tungstate into the tungsten dissolving reagent, stirring and dissolving, precipitating to remove impurities to obtain a tungsten solution, adding a calcium precipitating agent into the tungsten solution, stirring and standing to precipitate calcium, adjusting the pH value of the solution to 5-8, and filtering to remove calcium; the decalcified filtrate is transferred to a hydrothermal kettle for a hydrothermal reaction, and tungsten oxide slurry is obtained; filtering, washing and drying the tungsten oxide slurry to prepare tungsten oxide; and reducing the tungsten oxide through hydrogen to prepare tungsten oxide powder. The separation of tungsten and impurities is realized by utilizing the dissolution characteristic of the tungsten compound after form transformation. According to the method, ammonia water and an ion adsorption or extraction impurity removal device are not needed, the process is simple, the flow is short, less wastewater is generated, environmental pollution is small, and operation is safe and controllable.

Owner:云南锡业集团(控股)有限责任公司研发中心

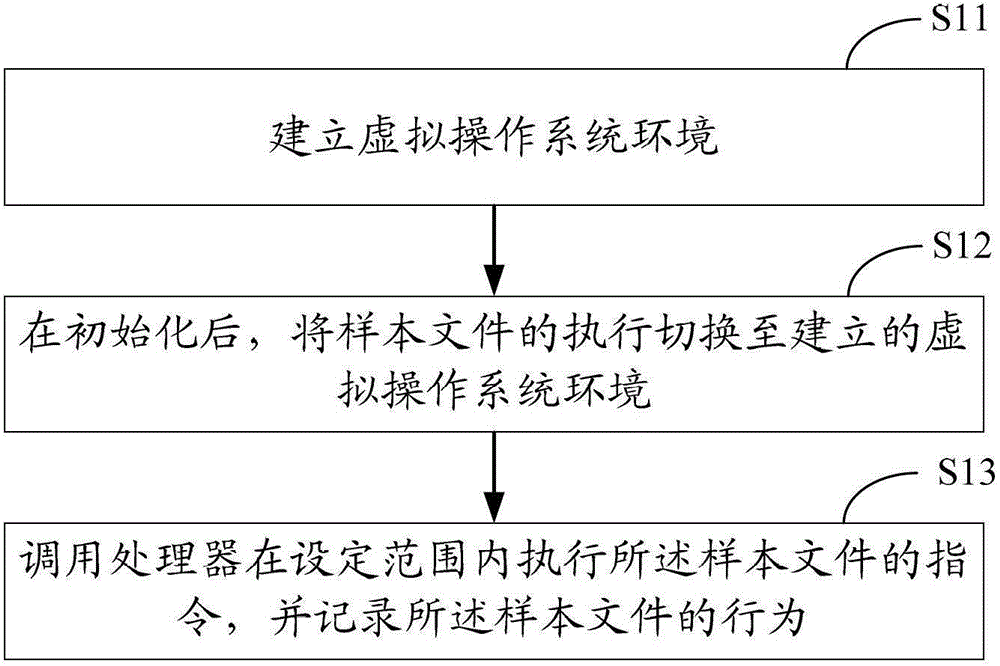

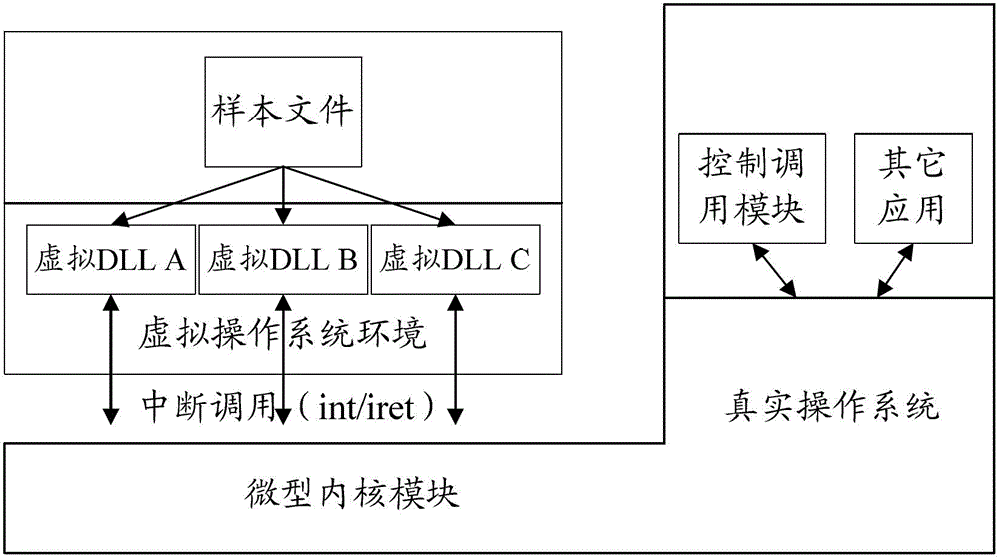

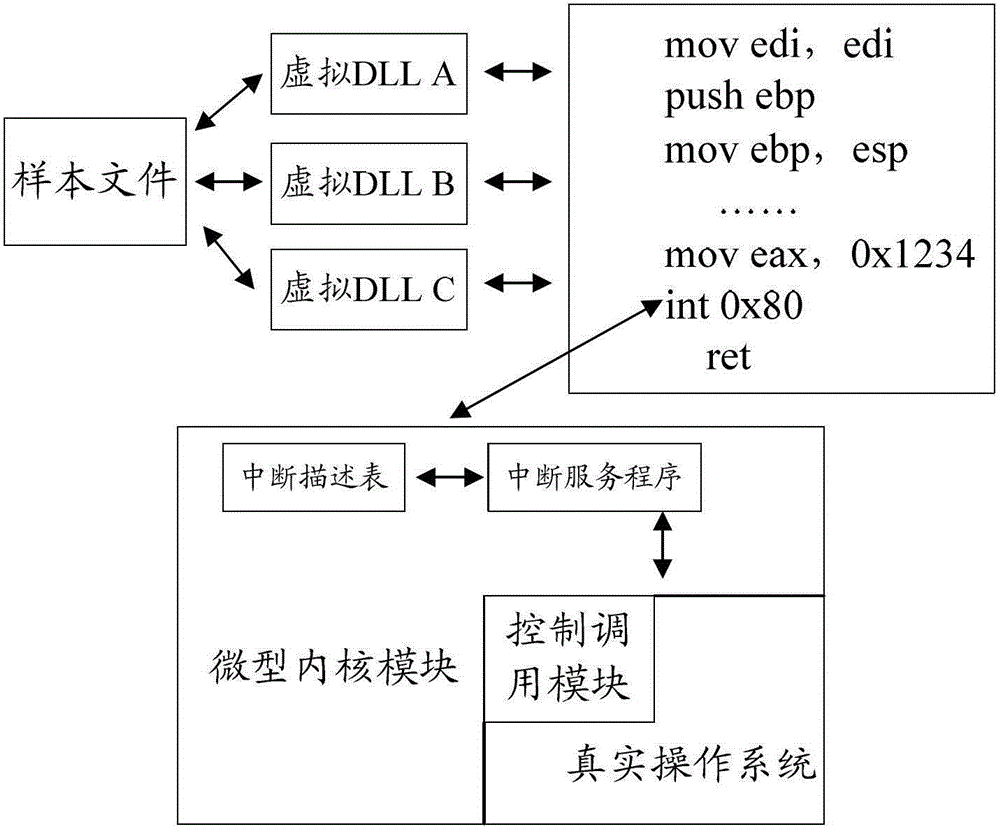

Detection method and virtual machine for controllable execution of files

ActiveCN102779250BSafe and controllable operationReduce consumptionPlatform integrity maintainanceSoftware simulation/interpretation/emulationOperational systemPhysics processing unit

Owner:TENCENT CLOUD COMPUTING BEIJING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com