System for power generation by utilizing thermal decomposition gas of domestic garbage

A gas-fired power generation and domestic waste technology, applied in the direction of solid waste removal, etc., can solve the problems that the next process cannot be processed, the production line cannot run normally, and it is not conducive to the effective use of fuel gas extracted by chemical industry, so as to avoid the effect of sedimentation of sewage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

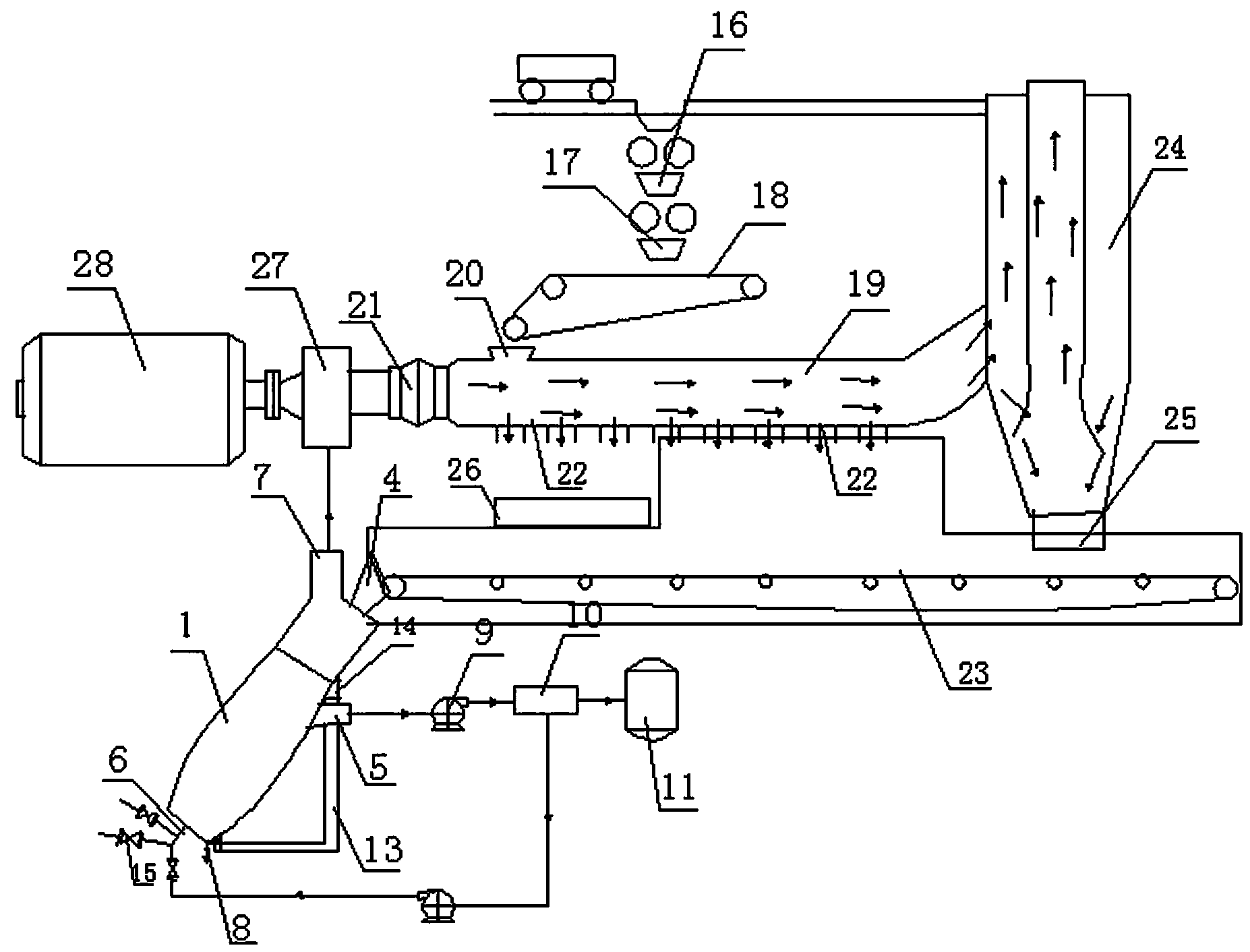

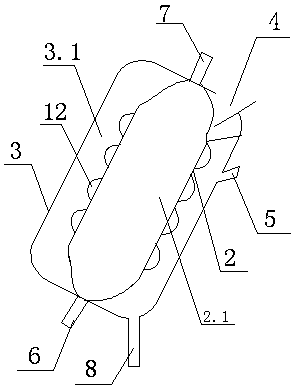

[0033] Such as figure 1 , figure 2 Shown is a system for generating electricity by thermal decomposition of domestic waste, which includes a waste screening device, a waste thermal decomposition device and a power generation device. The garbage thermal decomposition device includes a furnace body 1. The furnace body 1 includes an inner cylinder 2 and an annular tank 3. The inner cylinder 1 is sleeved in the annular tank 3. The inner cylinder 2 and the annular tank 3 are not connected, and the inner cylinder 1 is hollow. Combustion chamber 2.1, an annular cavity 3.1 for thermally decomposing garbage is formed between the outer wall of the inner cylinder 2 and the inner wall of the annular tank 3, and the two ends of the inner cylinder 1 connected to the annular tank 3 are respectively provided with fuel gas inlets 6 and The high-temperature gas outlet 7, and the fuel gas inlet 6 and the high-temperature gas outlet 7 communicate with the combustion chamber 2.1; the annular tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com