Icing preventing and ice melting method for high speed railway and system for realizing method

An ice-melting method and high-speed railway technology, applied in the installation of cables, electrical components, overhead lines, etc., can solve the problems of catenary system paralysis, evolution into social unrest events, affecting social stability, etc., to ensure safety and system operation. Convenient and flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

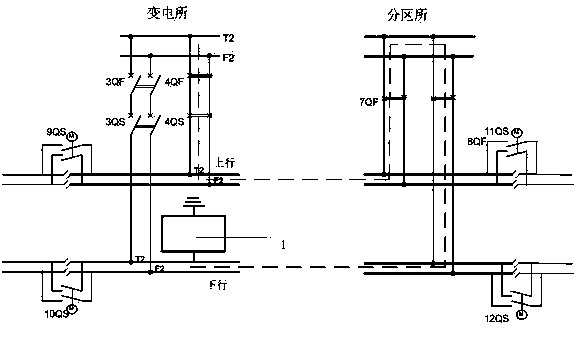

[0055] Such as figure 1 , figure 2 As shown, this embodiment is mainly designed for the needs of ice melting, and the anti-icing and ice-melting device 1 is installed in the traction substation:

[0056] The anti-icing and ice-melting device 1 is installed in the traction substation, and uses the uplink and downlink contact lines to form an ice-melting circuit. At this time, the phase separation where the traction substation is located is separately included in the anti-icing circuit (such as figure 1 shown) and the two separate phases of the substation and the divisional substation are included in the ice-melting circuit (such as figure 2 Shown) two operating modes, the latter operating mode can reduce the blind area of the ice-melting circuit.

[0057] Multiple circuit breakers and / or isolating switches are installed in the ice-melting circuit to realize opening, closing and control of the circuit. For details, see the circuit diagram of the anti-icing system.

[005...

Embodiment 2

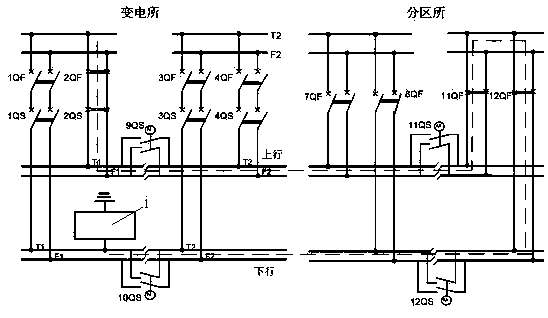

[0060] Such as image 3 , Figure 4 As shown, this embodiment is also designed for the needs of ice melting, and the anti-icing and ice-melting device 1 is installed in the partition:

[0061] Use up / down lines and steel rails to form an ice-melting circuit. At this time, the phase separation where the traction substation is located is separately included in the anti-icing circuit (such as image 3 shown) and the two separate phases of the substation and the divisional substation are included in the anti-icing circuit (such as Figure 4 As shown,) two operating modes, the latter operating mode can reduce the blind area of the ice-melting circuit.

[0062] by Figure 4 As an example, explain the principle of circuit conduction. If the catenary has been frozen due to bad weather or other reasons, it is necessary to melt the ice on the catenary. You can close 2QF, 2QS, 9QS, 11QS, 11QF to melt the ice on the uplink separately, or close 1QF and 1QS respectively. , 10QS, 12Q...

Embodiment 3

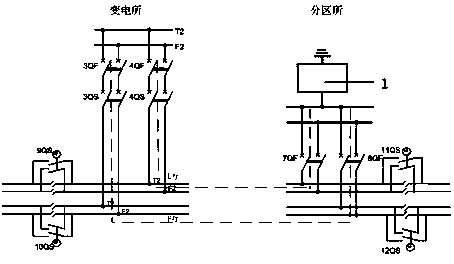

[0065] Such as Figure 5 As shown, this embodiment is mainly designed for online anti-icing, and the anti-icing circuit when the anti-icing and ice-melting device 1 is installed in a partition:

[0066] Close the 7QF and 8QF circuit breakers of the division respectively to realize the online anti-icing of the uplink or downlink. Combined with environmental conditions, when there is no need for high current offline ice melting, online anti-icing of catenary can be realized. According to the parameters obtained by the ice melting judgment system, the gear of the anti-icing device is adjusted to the preset online anti-icing gear of the catenary, so that the catenary can obtain the required anti-icing current to prevent the catenary from being covered with ice. At this time, the locomotive needs to run according to the preset operation mode (limiting the number of trains or limiting the speed of trains).

[0067] The anti-icing and ice-melting device 1 used in this embodiment is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com