Material stacking system and control method thereof

A palletizing system and control method technology, applied in the field of material palletizing, can solve the problems of low installation accuracy, easy wear and tear of gear and rack, and low adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In the following, referring to the accompanying drawings, through the description of the embodiments, the specific embodiments of the present invention, such as the shape and structure of each component involved, the mutual position and connection relationship between each part, the function and working principle of each part, etc. will be further described. Details of:

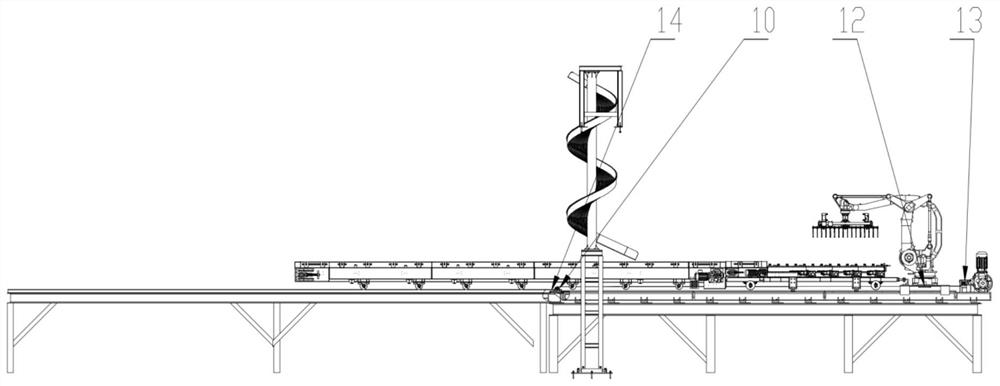

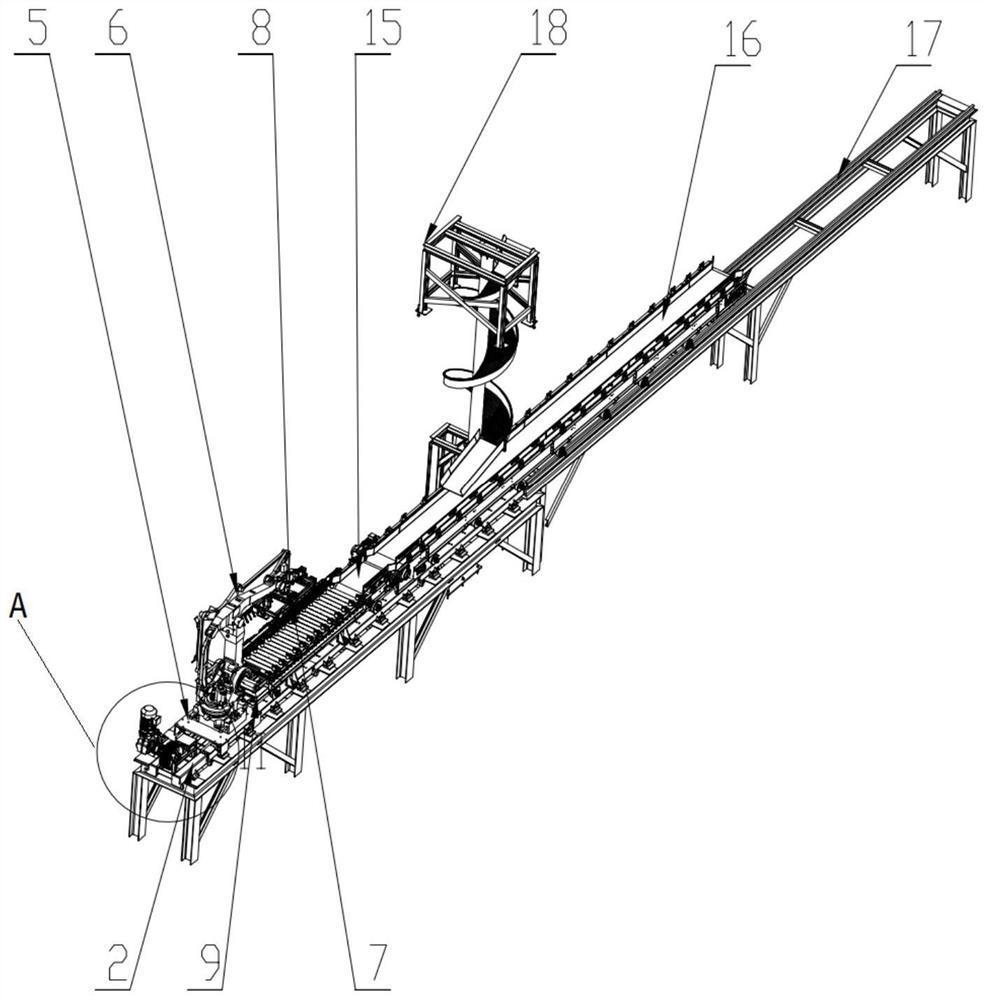

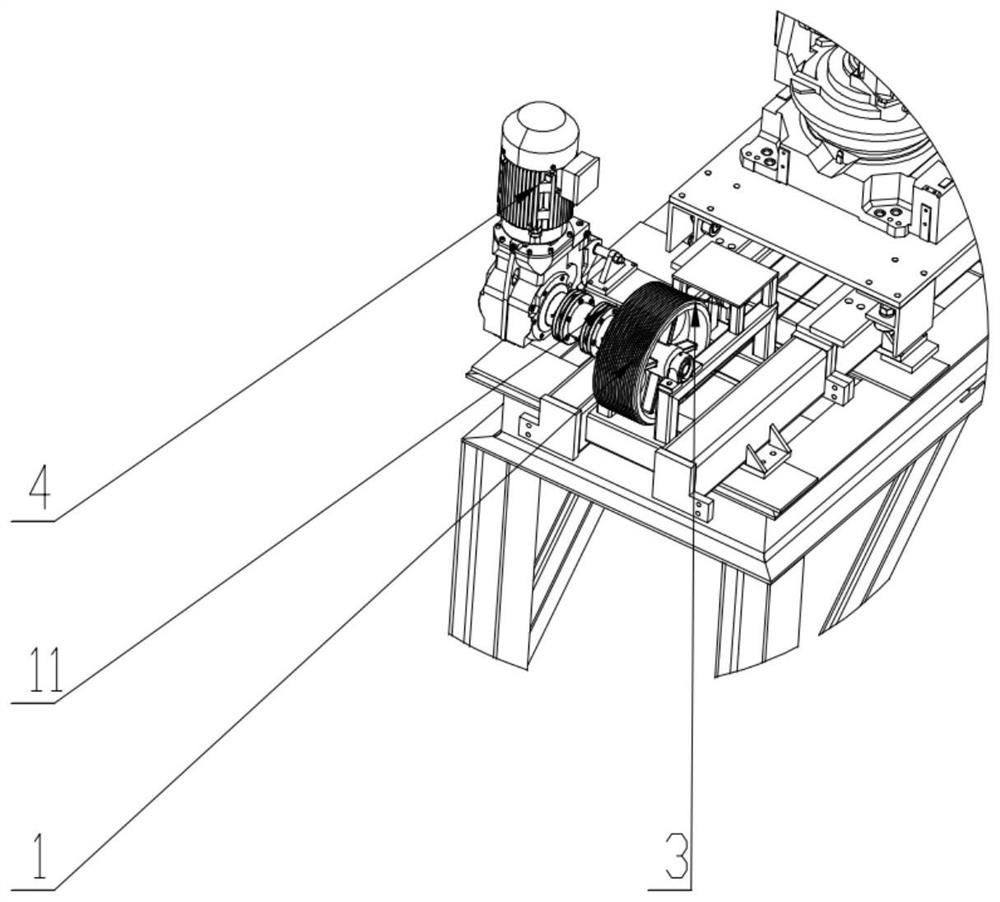

[0029] as attached figure 1 -Attached image 3 As shown, the present invention is a material stacking system. The frame 2 and the horizontal feeding belt conveyor 16 of the material stacking system are installed on the platform 17, and the outlet of the rotating chute 18 is located above the horizontal feeding belt conveyor 16. Position; the wire rope reel 1, the moving slide assembly 5, and the accompanying trolley 9 are installed on the frame 2, the deceleration motor 4 is connected with the wire rope reel 1, and the deceleration motor 4 is fixed on the frame 2; the robot 6 is fixed on On the mobil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com