Leachate system based on domestic sewage and treatment process of system

A domestic sewage and leachate technology, applied in the direction of contaminated groundwater/leachate treatment, water/sewage treatment, adsorption water/sewage treatment, etc., can solve the problem of large fluctuations in effluent water quality, many supporting civil engineering facilities, hydraulic retention time long wait question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

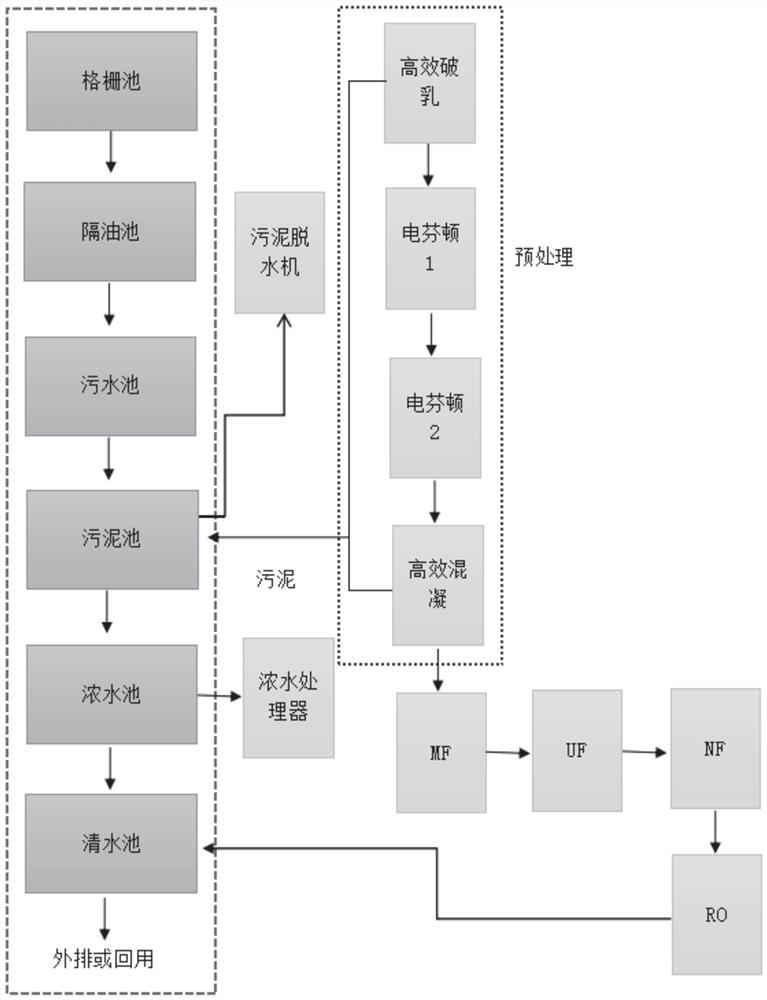

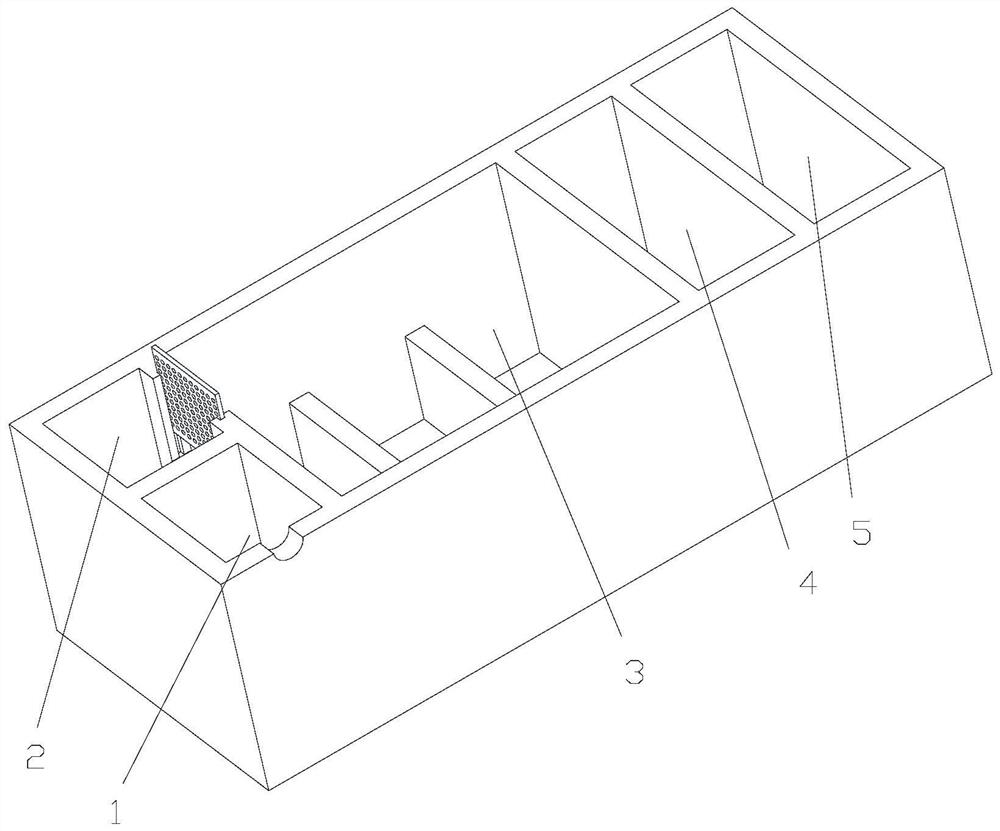

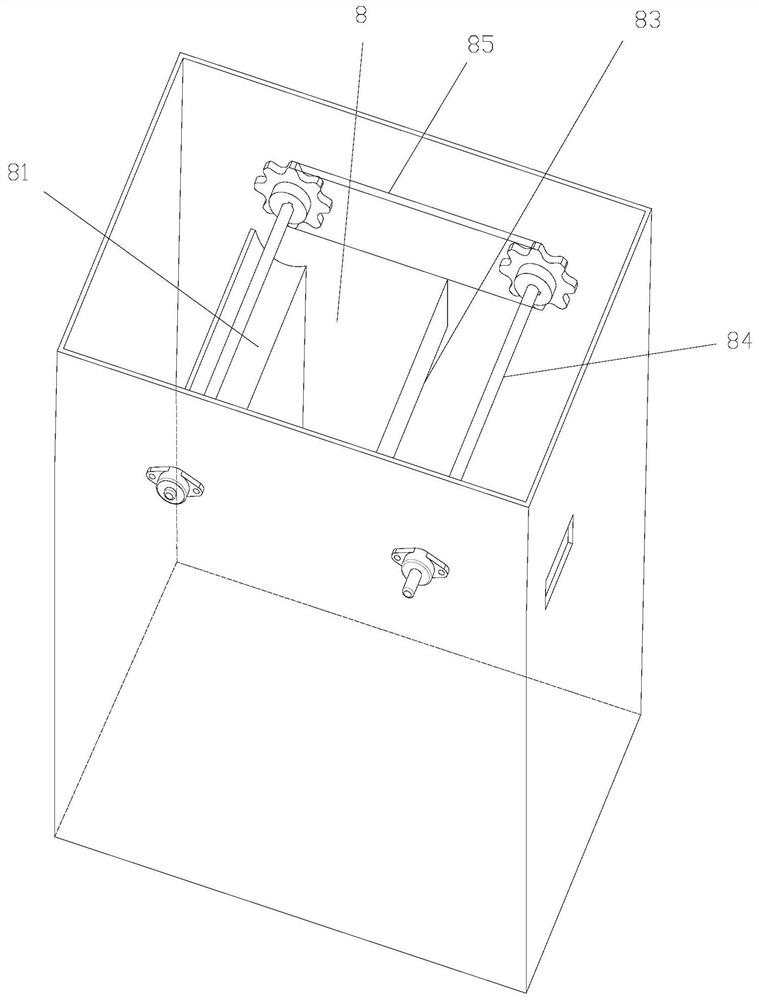

[0027] refer to Figure 1-6 , a leachate system based on domestic sewage, including a pretreatment area, a pretreatment tank and a sludge treatment device, the pretreatment tank includes a grid grit chamber 1, a grease trap 2, and a sewage tank 3 connected in sequence , sludge pond 4 and clear water pond 5, described pretreatment area comprises demulsification reactor 6, electric Fenton reactor 7, coagulation reactor and sewage filter, and described demulsification reactor comprises agitator 61 and Shearing dispersing disk, the shearing dispersing disk is connected with the agitator 61 through the stirring shaft 63, and is driven to rotate by the agitator; the electric Fenton reactor 7 includes an anode iron plate 71 and a cathode graphite plate 72 arranged oppositely. Sewage enters the anode iron plate and cathode graphite plate in the ionization zone, which form an electric Fenton reaction, which can oxidize and degrade impurities in the sewage to remove pollutants.

[0028...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com