Patents

Literature

36results about How to "Solve problems that cannot be discharged" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

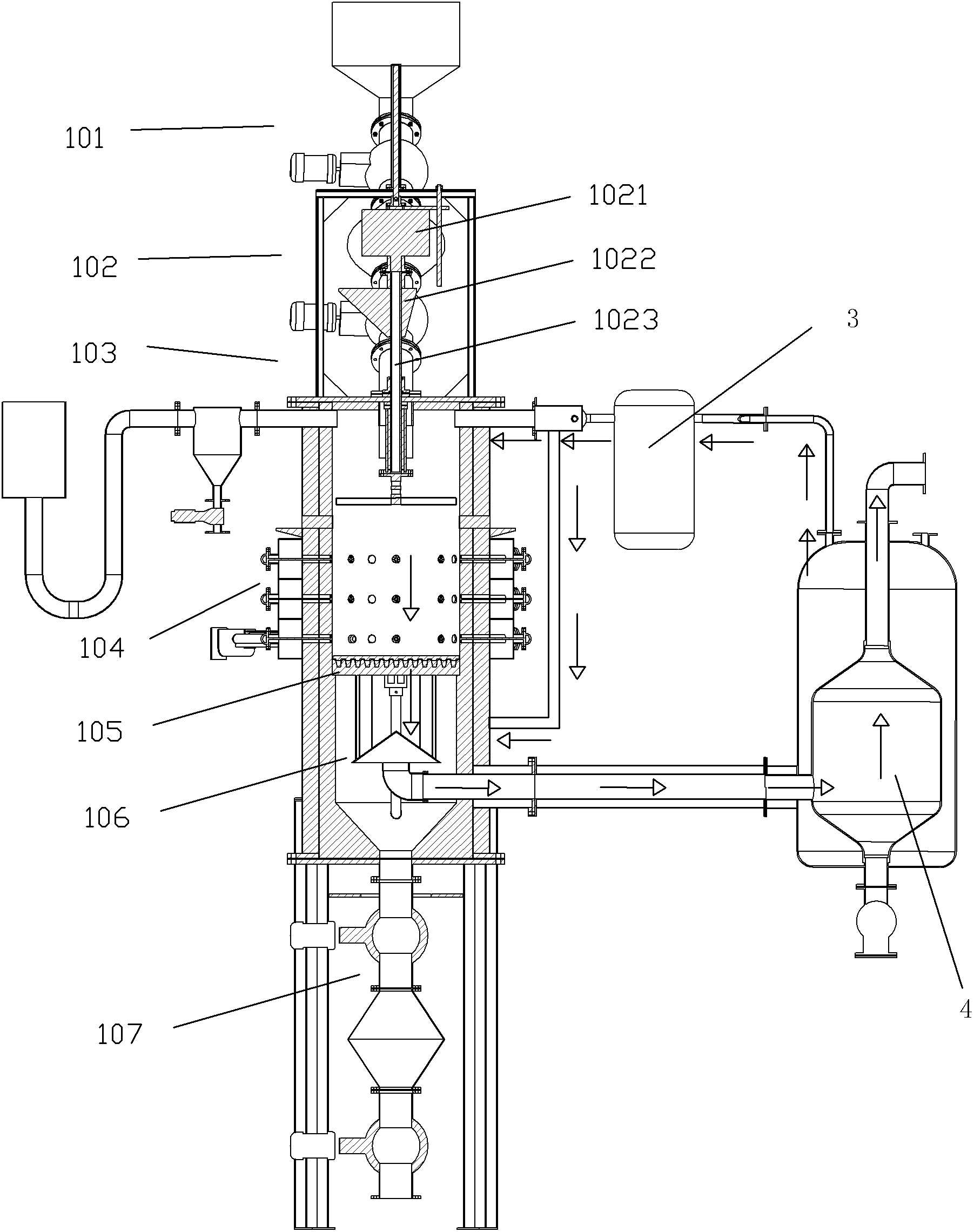

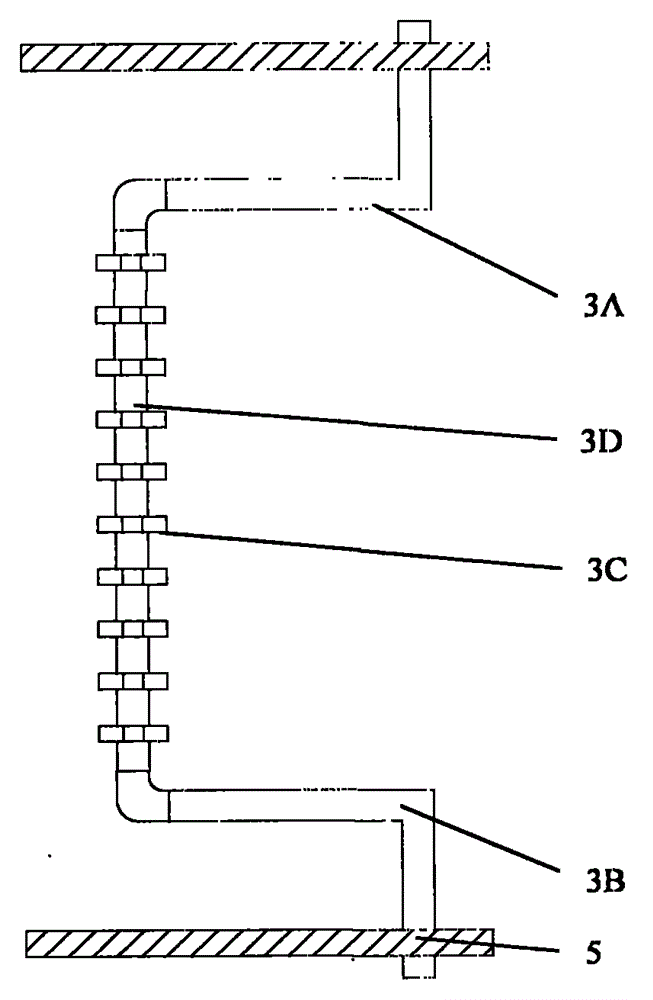

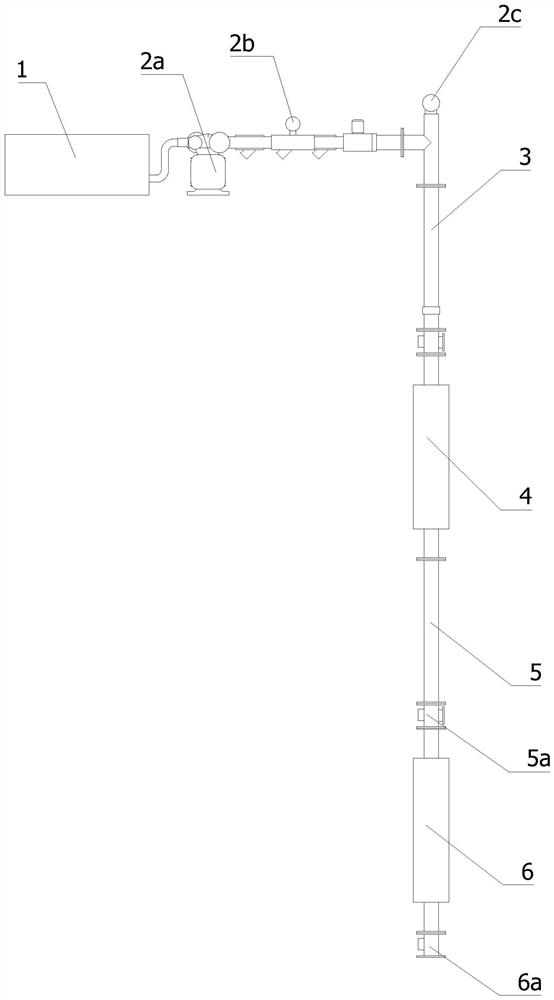

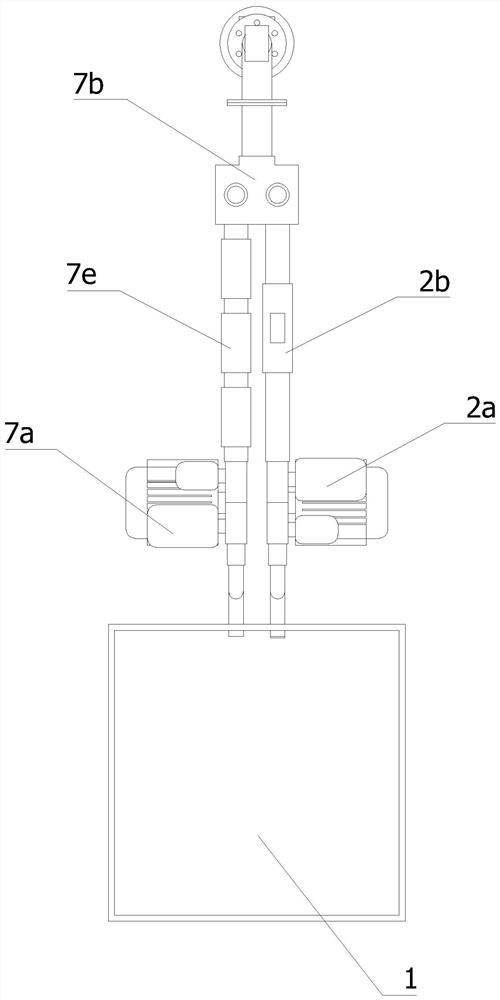

Plasma garbage gasification device and process

InactiveCN102329653AHigh operating valueReduce power consumptionChemical industryCombustible gas productionCooling towerHazardous substance

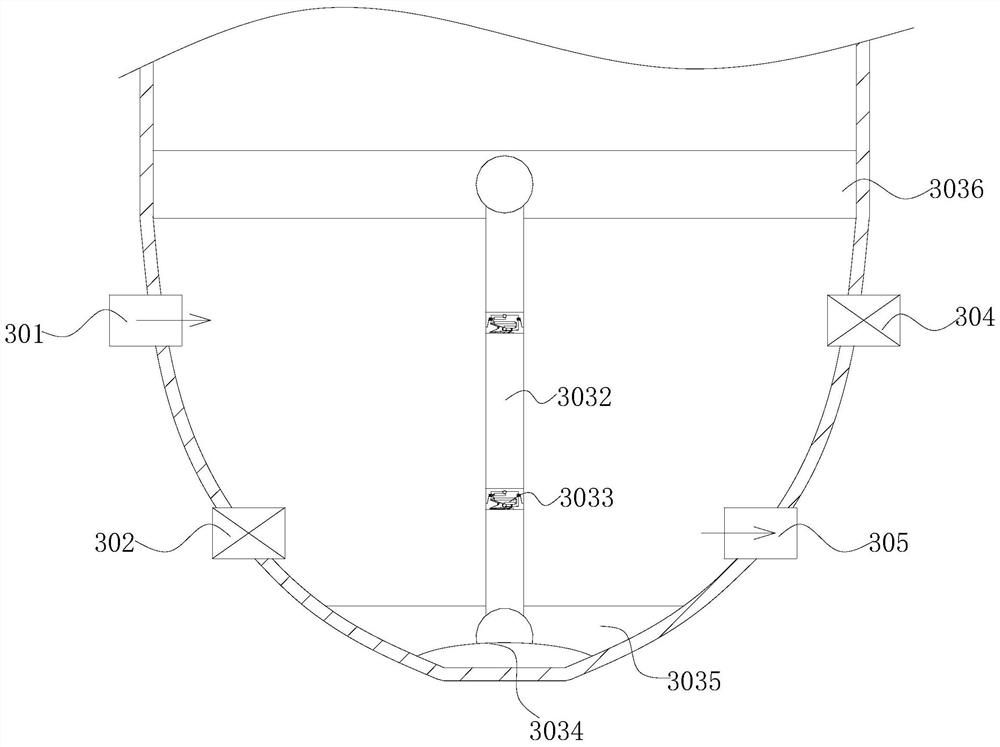

The invention relates to a plasma garbage gasification device and process. The device comprises a gasification reaction chamber, a steam heat exchanger, a steam buffer tank, an air buffer tank, an inner and outer double-cyclone heat exchanging dust collector, a cooling tower, a hydrogen sulfide removal sprayer, a water ring compressor, a gas-water separator, a gas storage tank and a control system of the device, which are connected through a gas pipeline; the gasification reaction chamber comprises an automatic feeding device, an automatic ignition device, a primary gasification zone and a plasma reaction zone; and the plasma reaction zone consists of a secondary refining zone and a gas refining zone. The process comprises the following steps of: gas generation; gasification medium preheating; gas purifying and filtering; and gas compression and storage. The invention has the characteristics of simple structural design, reasonable energy efficiency utilization, low primary input cost and low power consumption, and particularly, harmful substances such as dioxin and the like generated in the gasification process can be effectively removed, the volume reduction ratio is increased, and the waste is turned into the wealth.

Owner:张建超

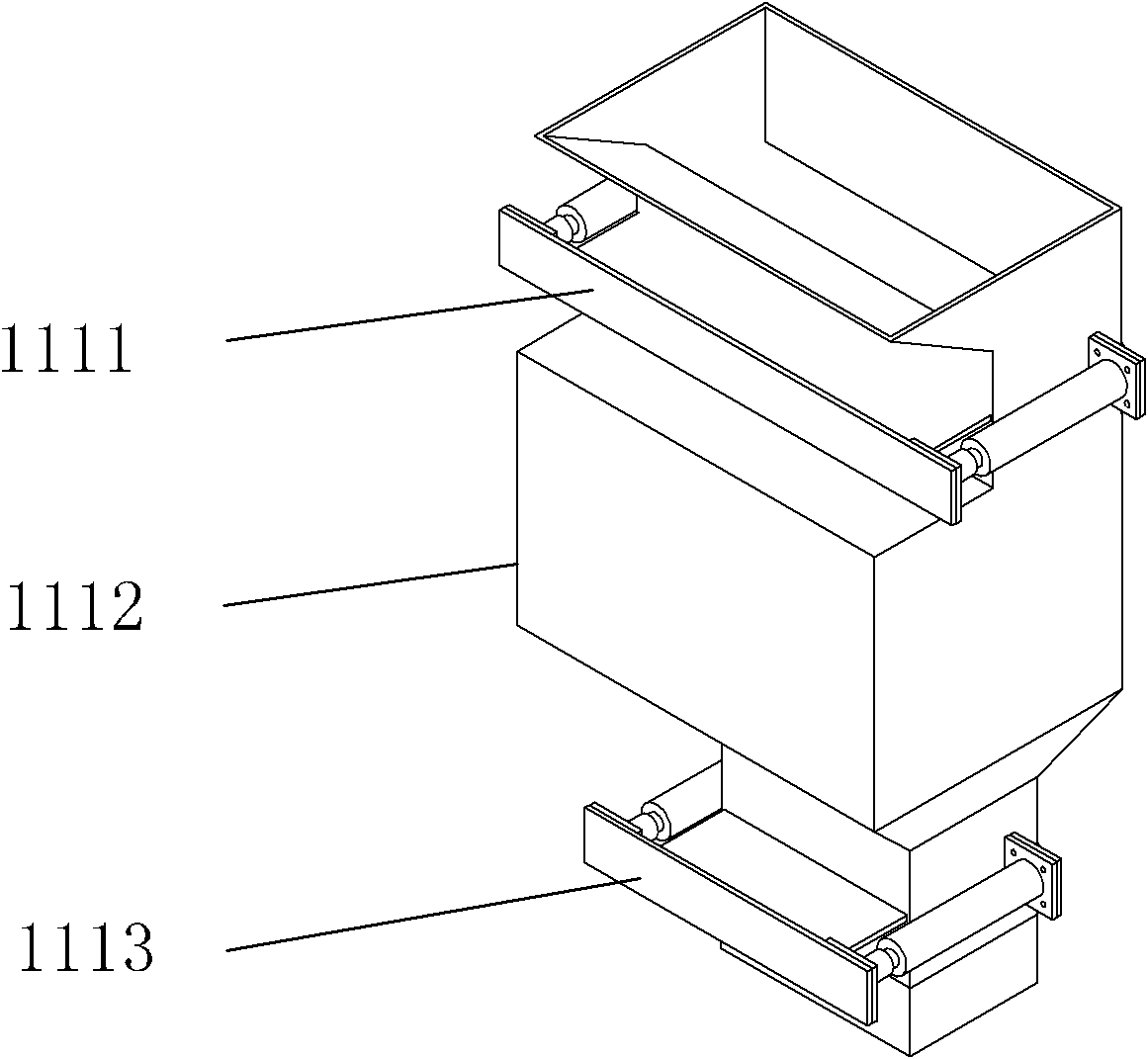

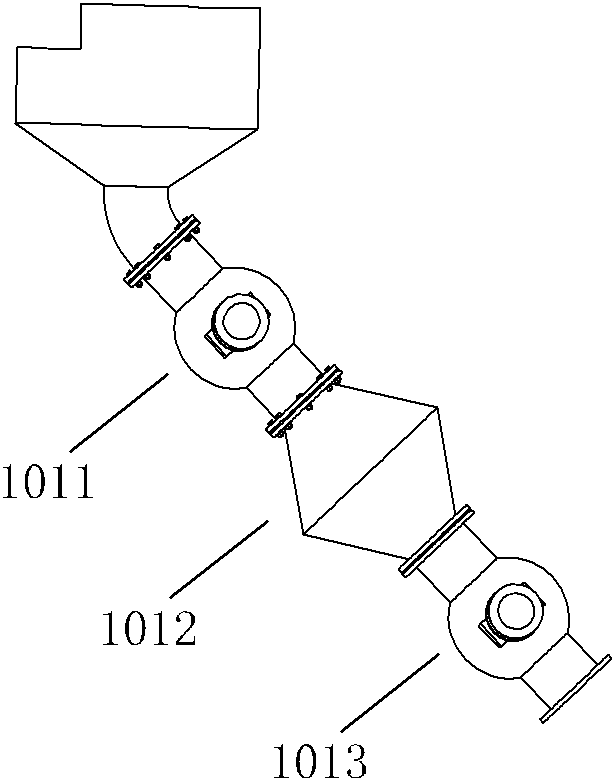

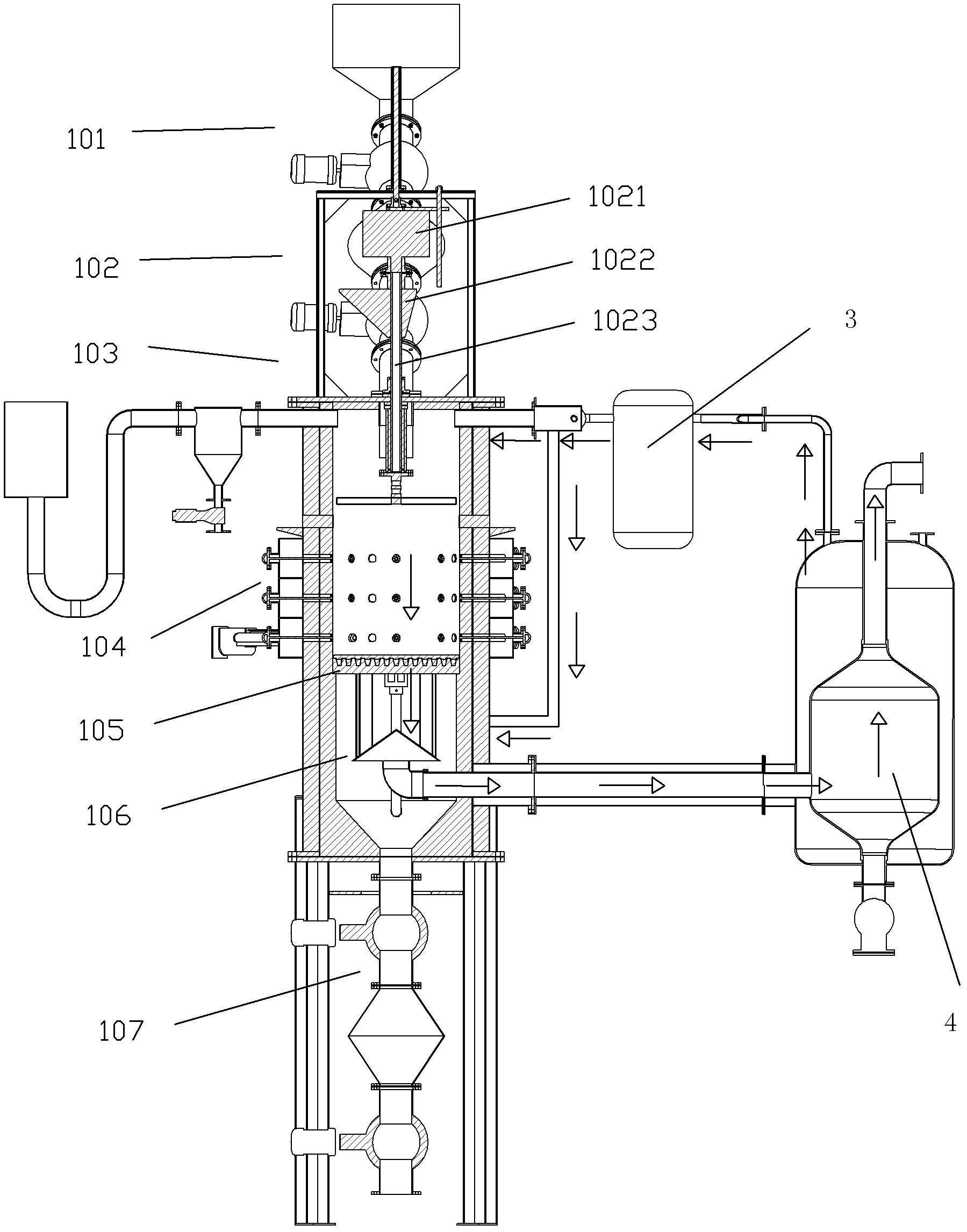

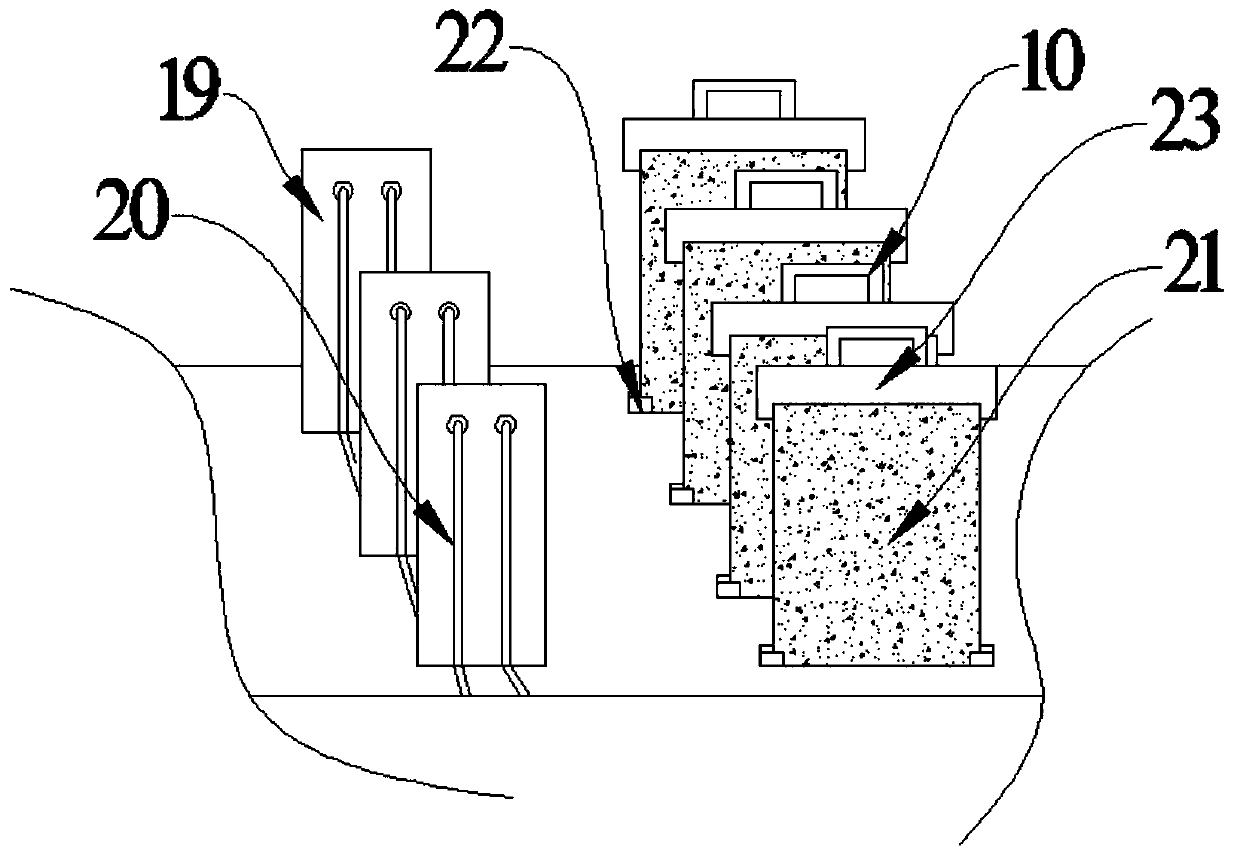

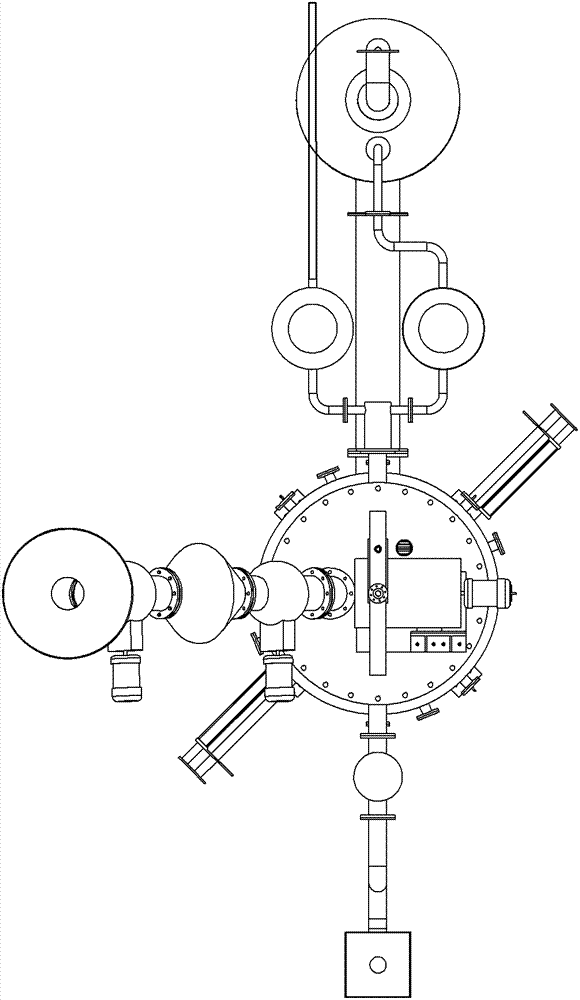

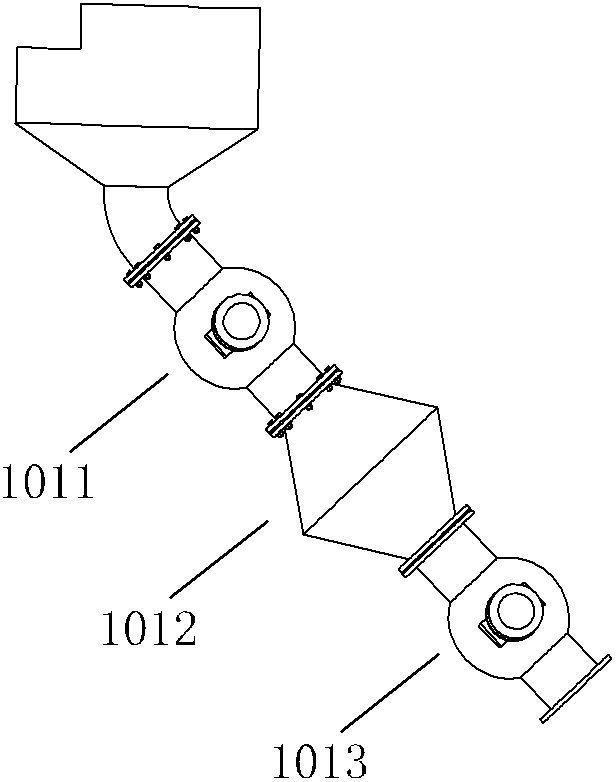

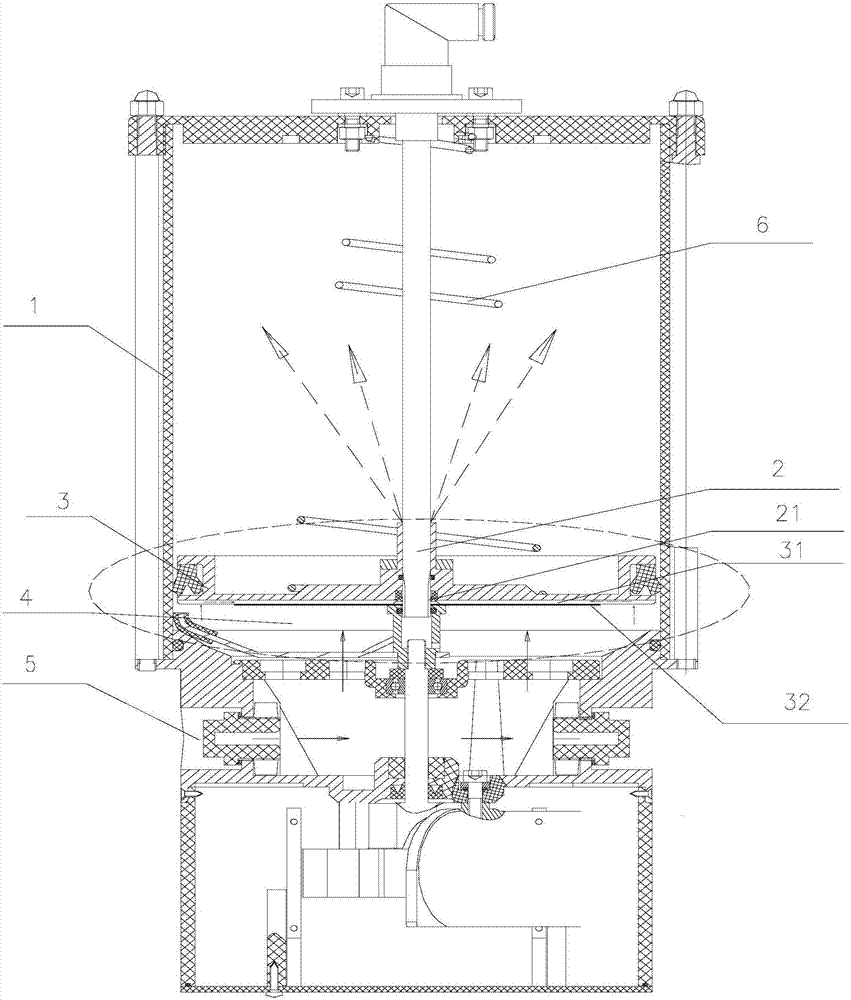

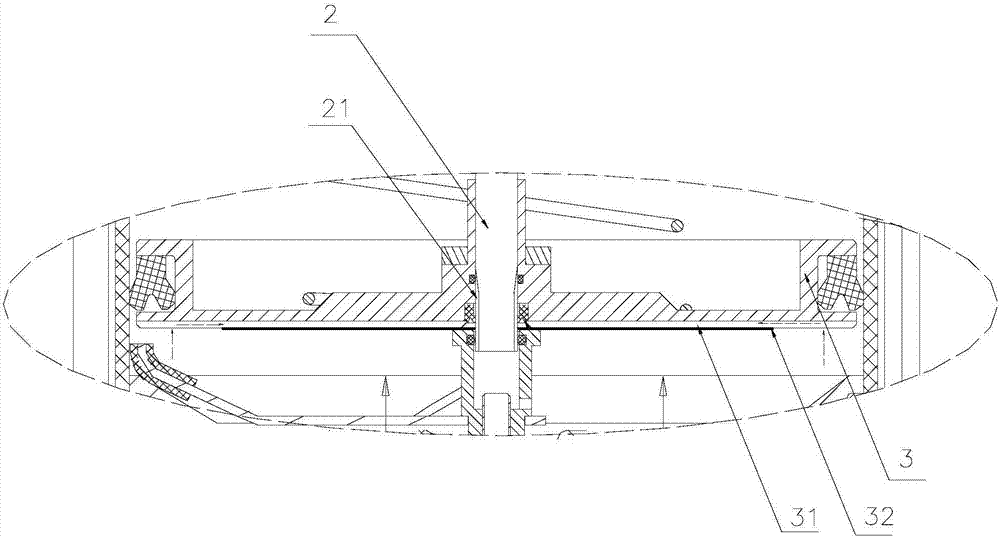

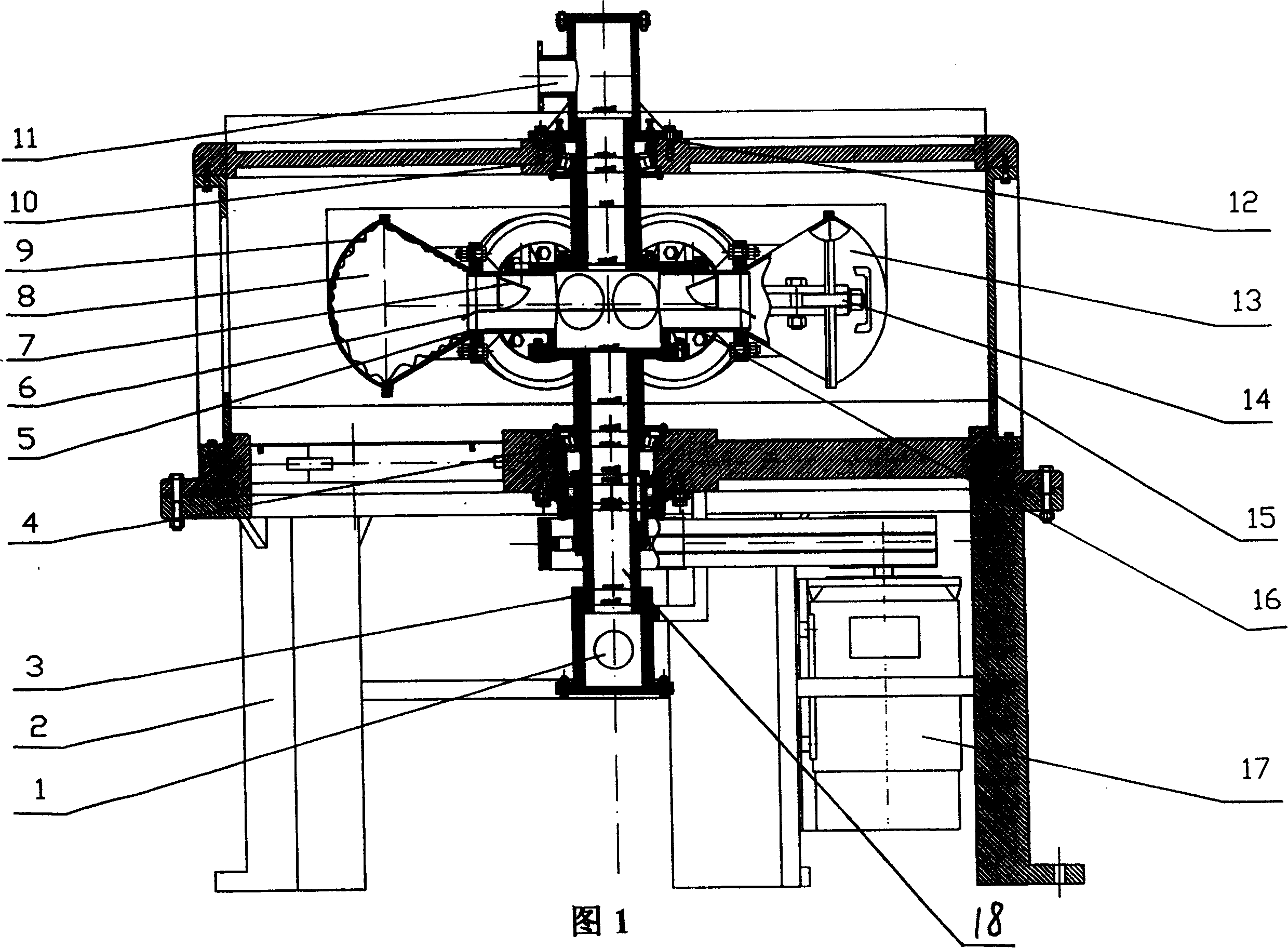

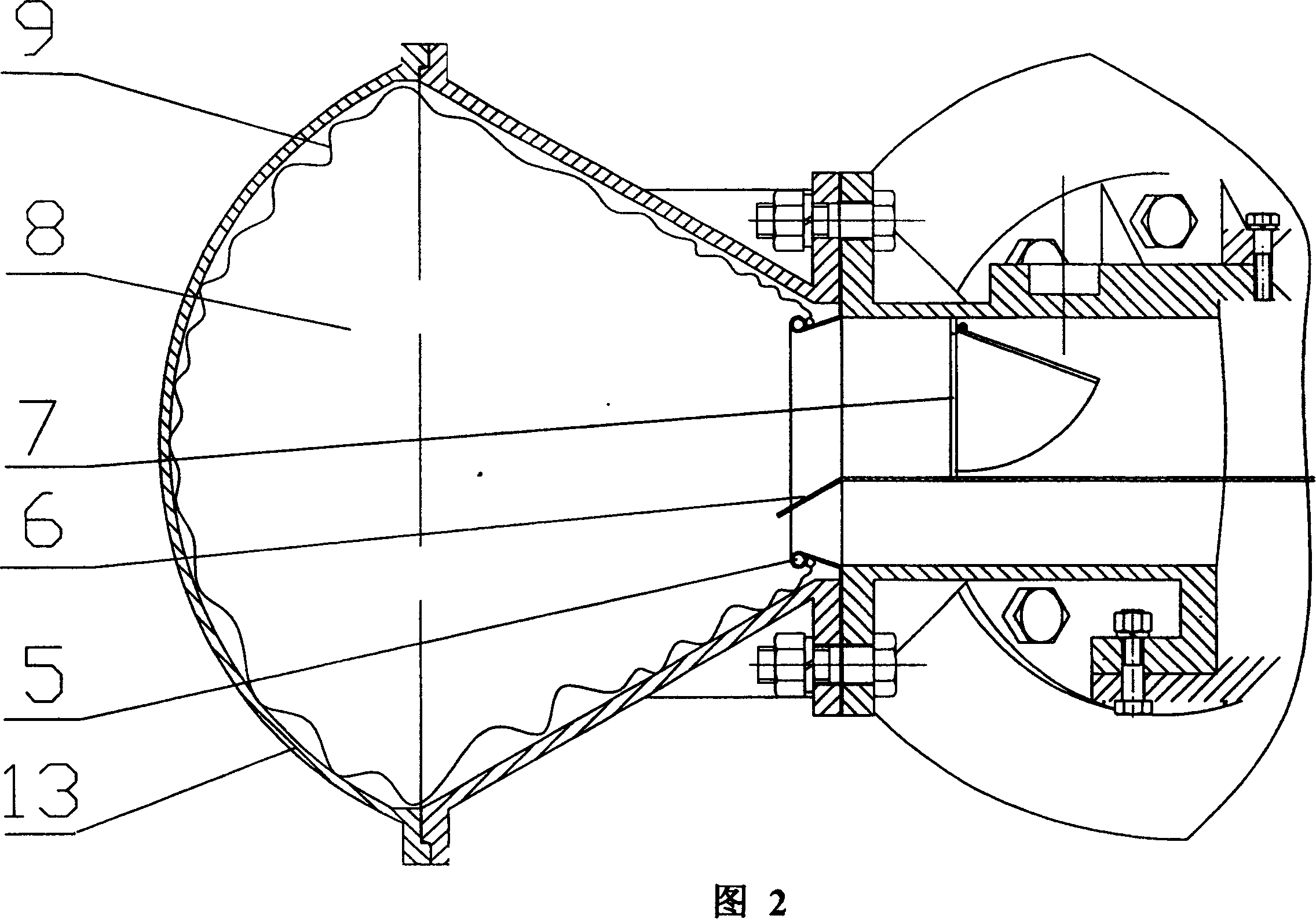

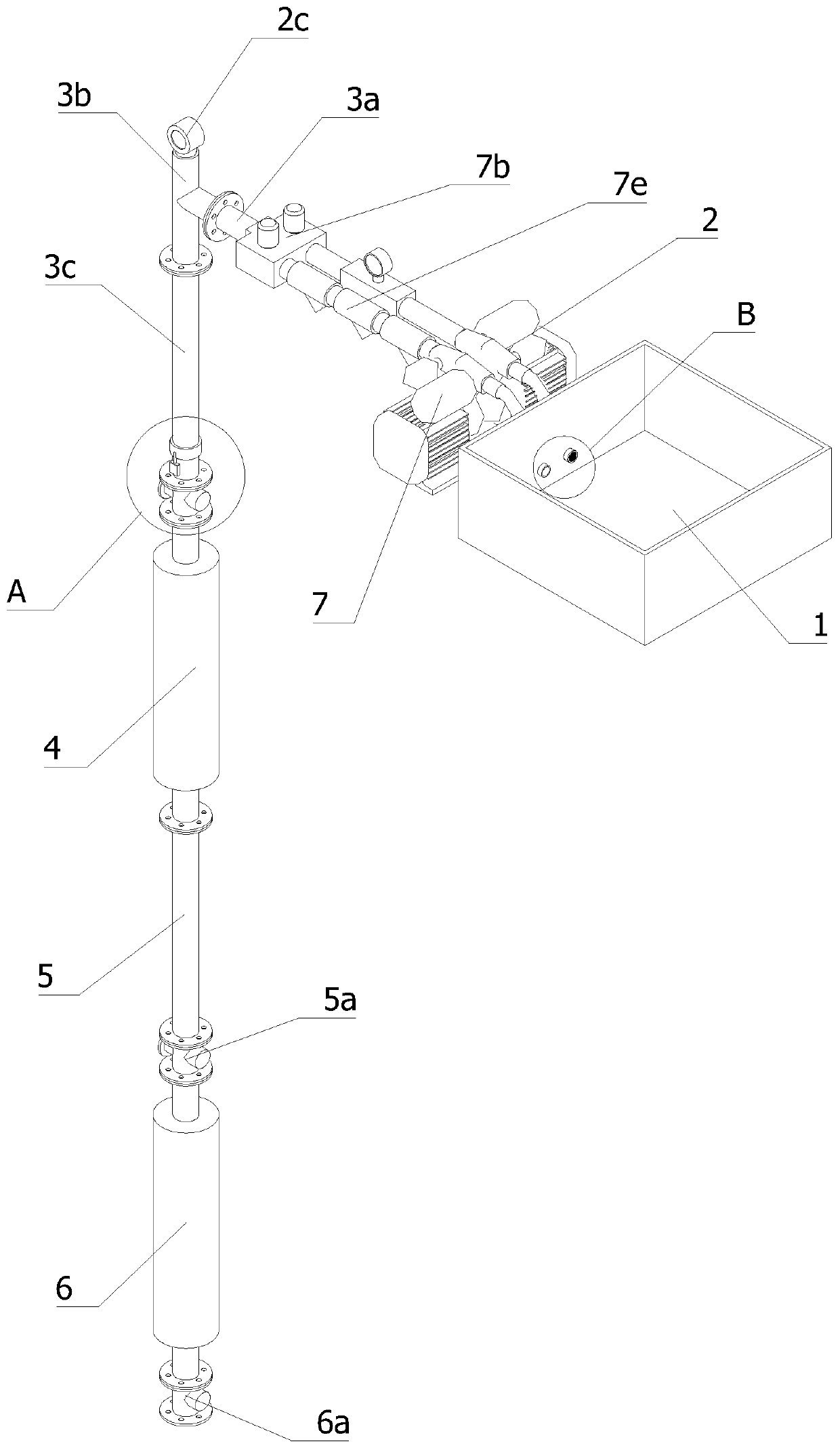

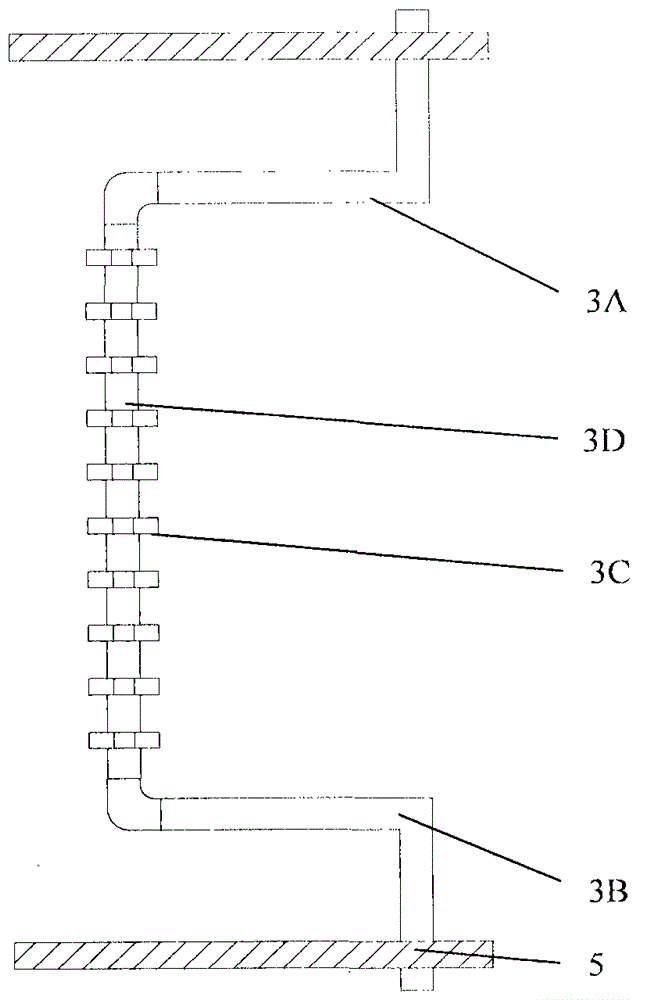

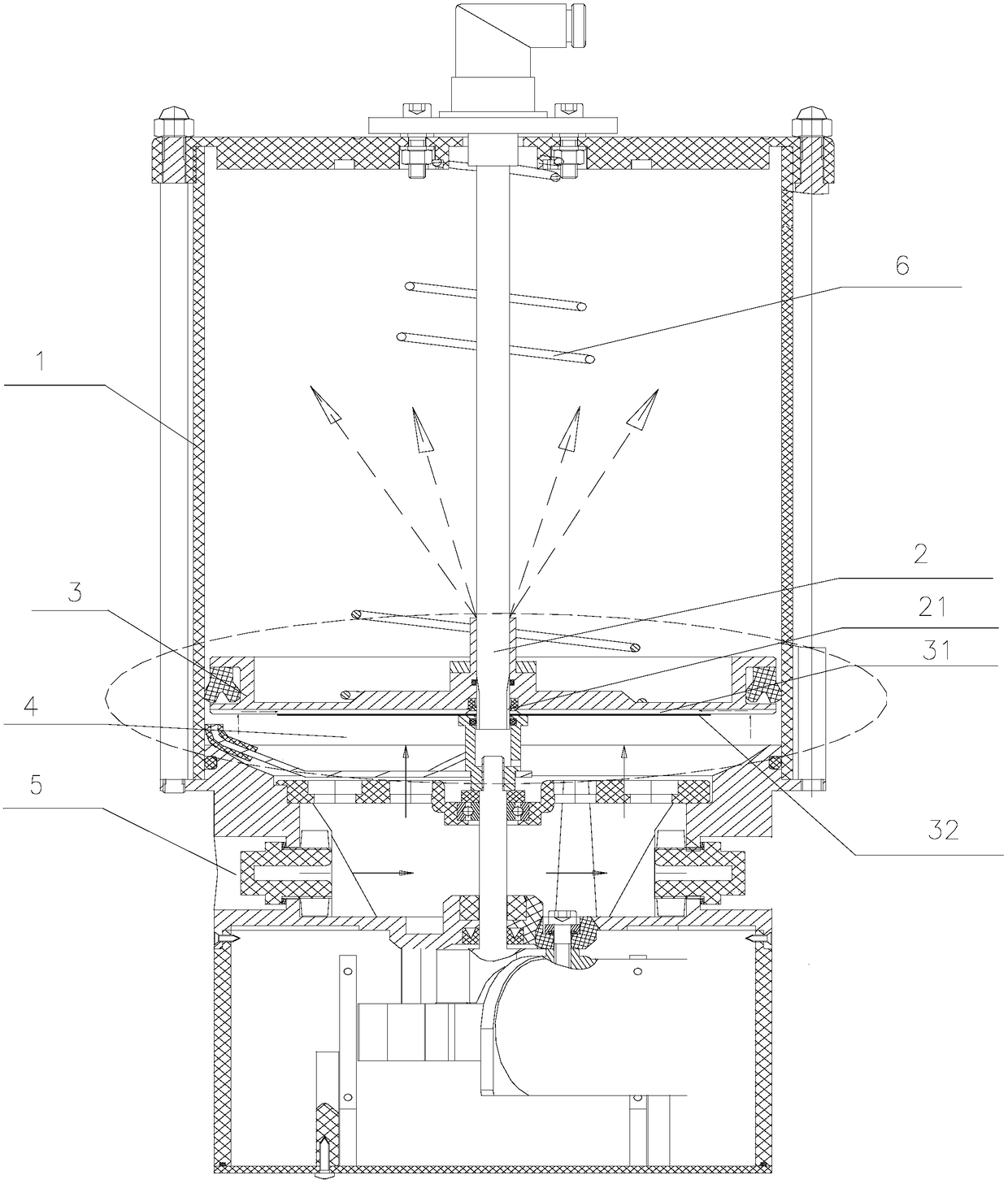

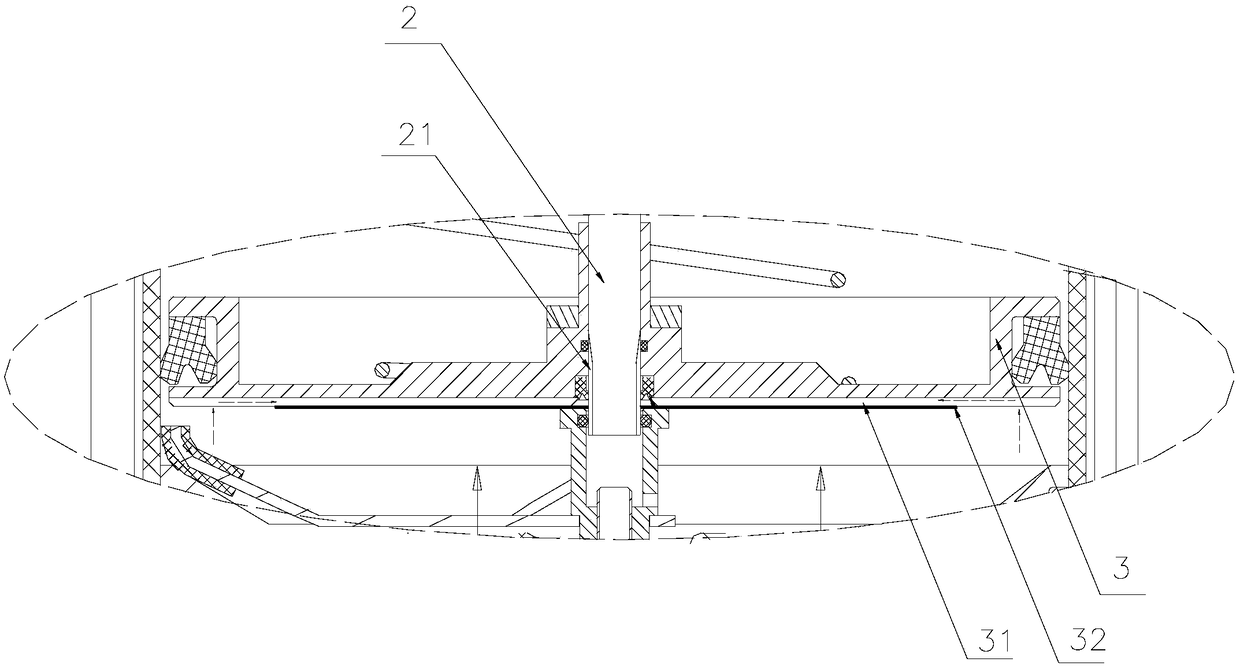

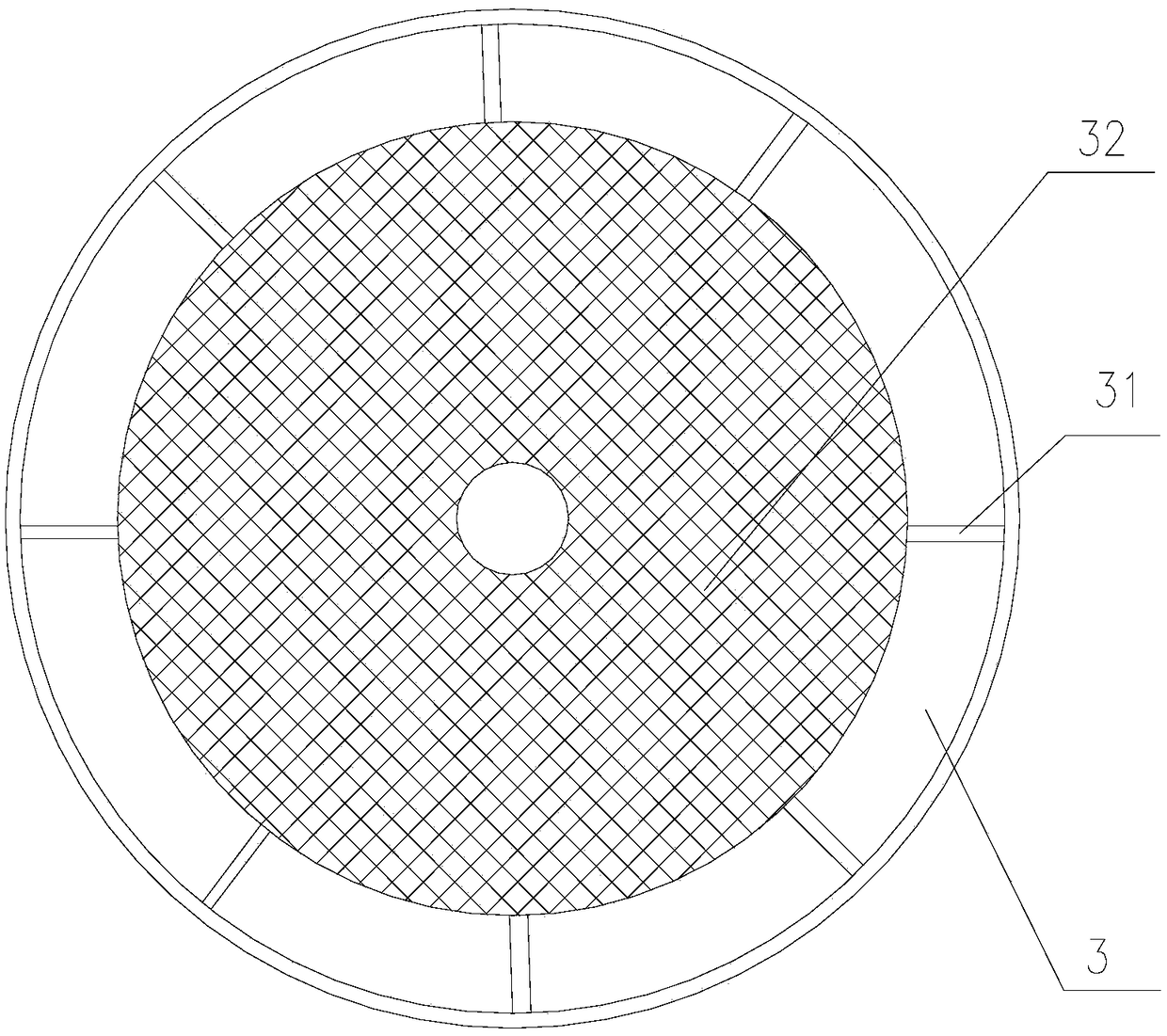

Downdraft biomass gasification reaction chamber and gasification process thereof

InactiveCN102329656AIncrease the cross-sectional areaIncrease contentEnergy inputCombustible gas productionFurnace temperatureMonitoring system

The invention relates to a downdraft biomass gasification reaction chamber and a gasification process thereof. The downdraft biomass gasification reaction chamber comprises an automatic feeding device, a gasification region consisting of a primary gasification region and a secondary gasification region which are integrated, an automatic leveling device, a vibration grate, an automatic ignition device, an automatic deslagging device, an in-furnace pressure regulating system, a furnace temperature monitoring system, an in-furnace material level monitoring system, an inlet and output gas temperature monitoring system, an inlet and outlet pressure monitoring system and a flame monitoring system. The production process comprises the following steps of: automatically feeding and introducing gas, primarily gasifying, secondarily gasifying, and automatically deslagging. The downdraft biomass gasification reaction chamber is scientific and environmentally-friendly, has the remarkable characteristics of reasonable structure design, high automation, stable and controllable gasification reaction, continuity and no interruption, has high gasification efficiency and high integral heat value, issuitable for large-area popularization, and especially can be applied to continuous and stable power generation of the existing gas generator.

Owner:张建超

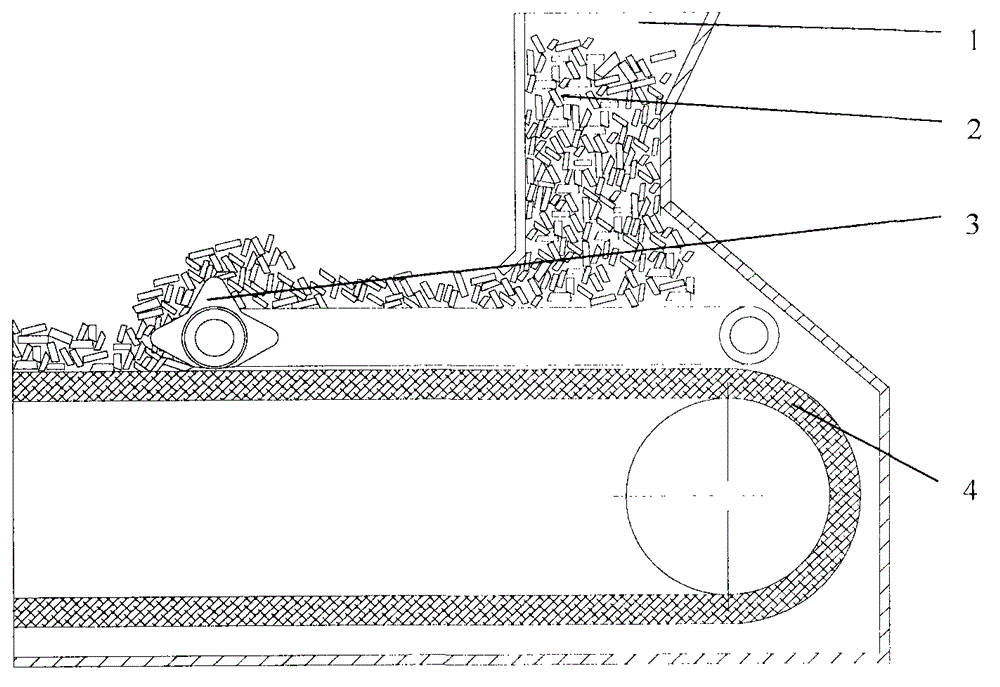

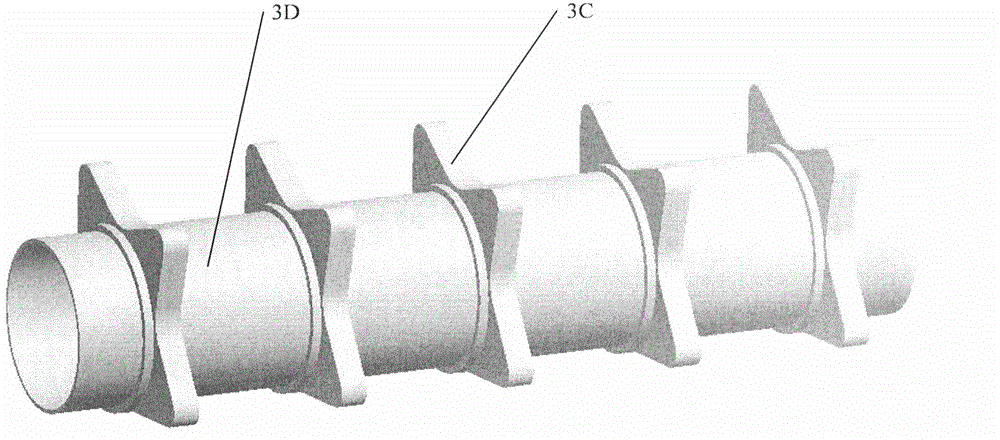

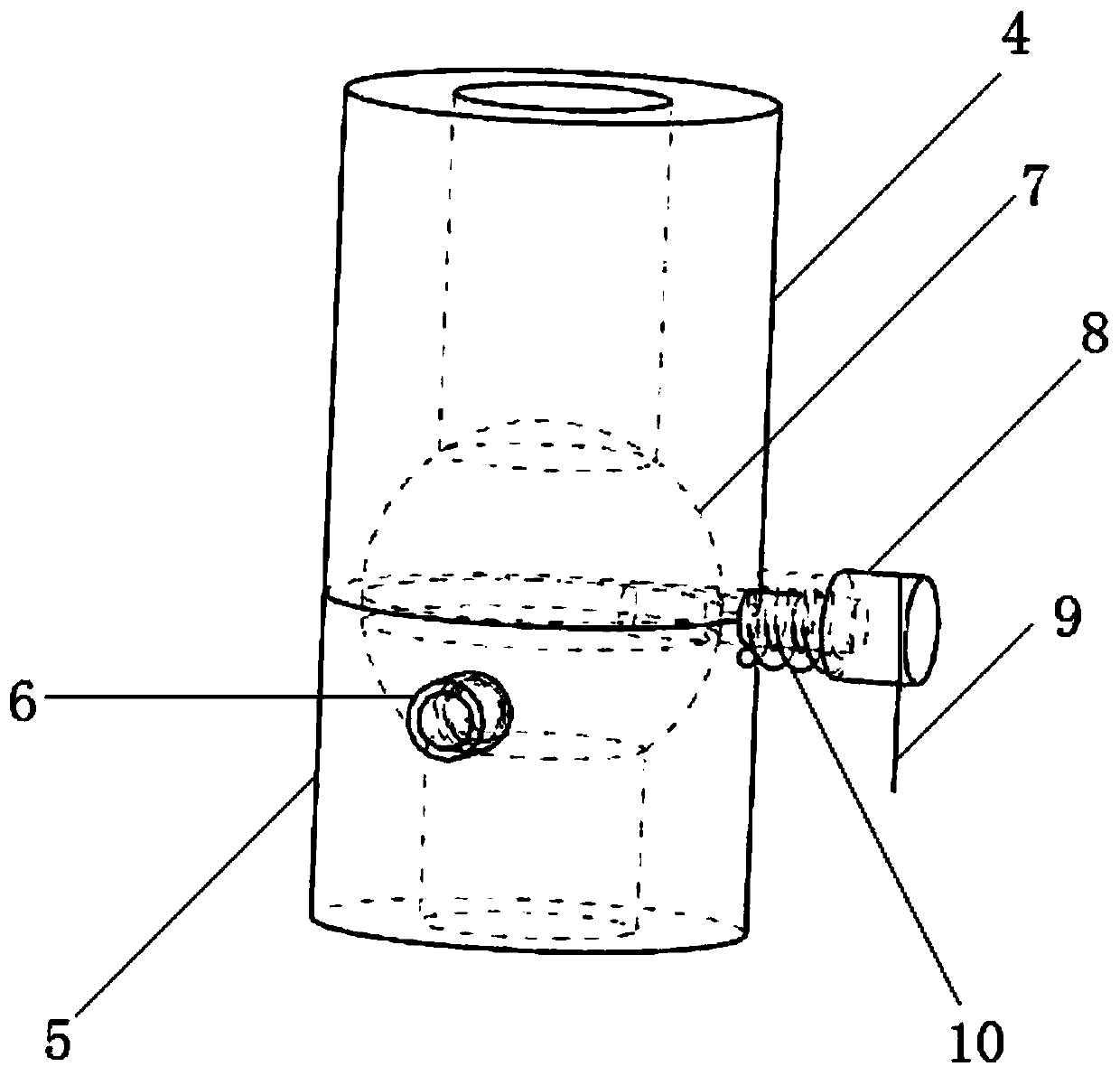

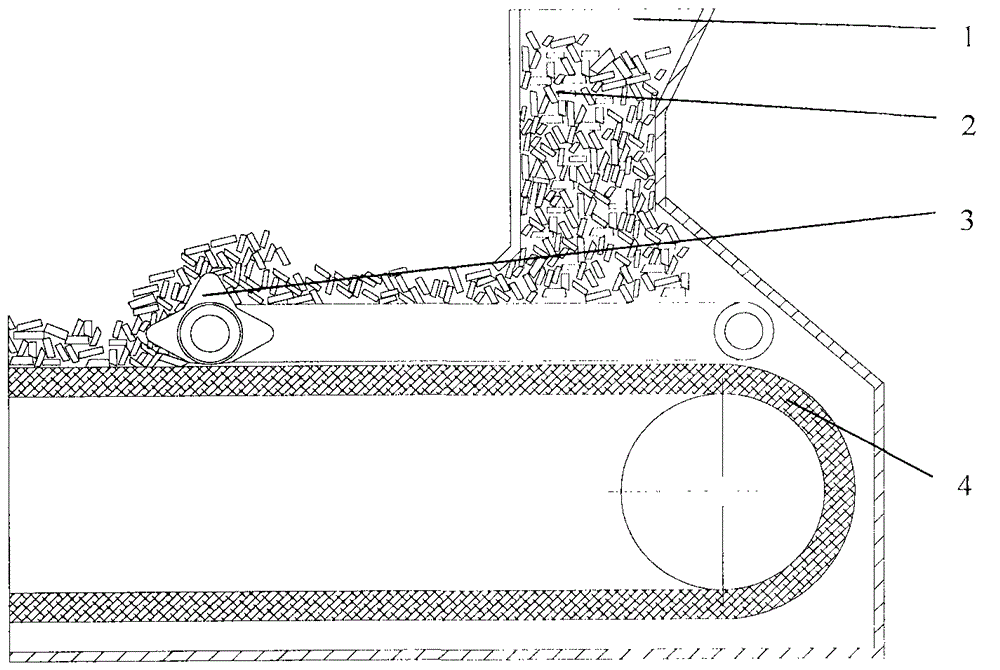

Cinder breaking device for biomass boiler

InactiveCN104344412ASolve the problem that coking cannot be cleanedSolve problems that cannot be dischargedLighting and heating apparatusSolid fuelEngineering

The invention discloses a cinder breaking device for a biomass boiler, belongs to the technical field of solid fuel burning, is applied to biomass boilers for burning of biomass granular fuel, and actively breaks and burns clinker. The device is installed in the hearth of the biomass boiler, and comprises a water inlet pipe, a water outlet pipe, cinder breaking teeth and a cooling water pipe, is horizontally placed in the hearth of the biomass boiler, and is perpendicular to a chain fire grate; the distance between the device and the fire grate is smaller than 5 mm; burning fuel and cinder move with the movement of the chain fire grate; the burnt coked cinder is broken through the cinder breaking device and then discharged. The cinder breaking device solves the problem that the cinder of biomass granular fuel is coked after being burnt, can greatly improve the efficiency and prolong the service life of the biomass boiler, and facilities promotion of the industrialization effect of straw biomass granular fuel, the coal is replaced with biomass granular fuel, and the cinder breaking device has good economic, social and environmental benefits.

Owner:ACADEMY OF PLANNING & DESIGNING OF THE MINIST OF AGRI

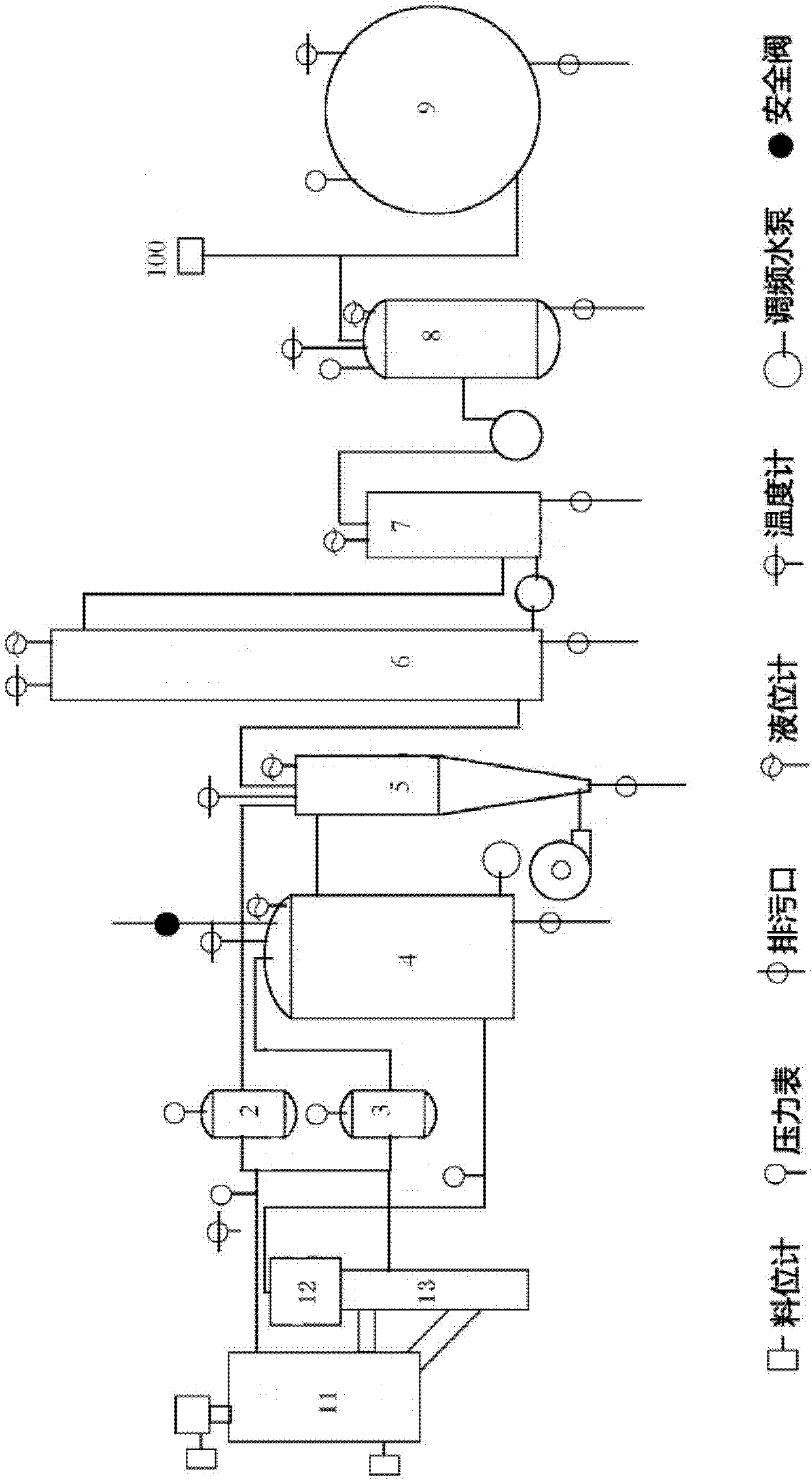

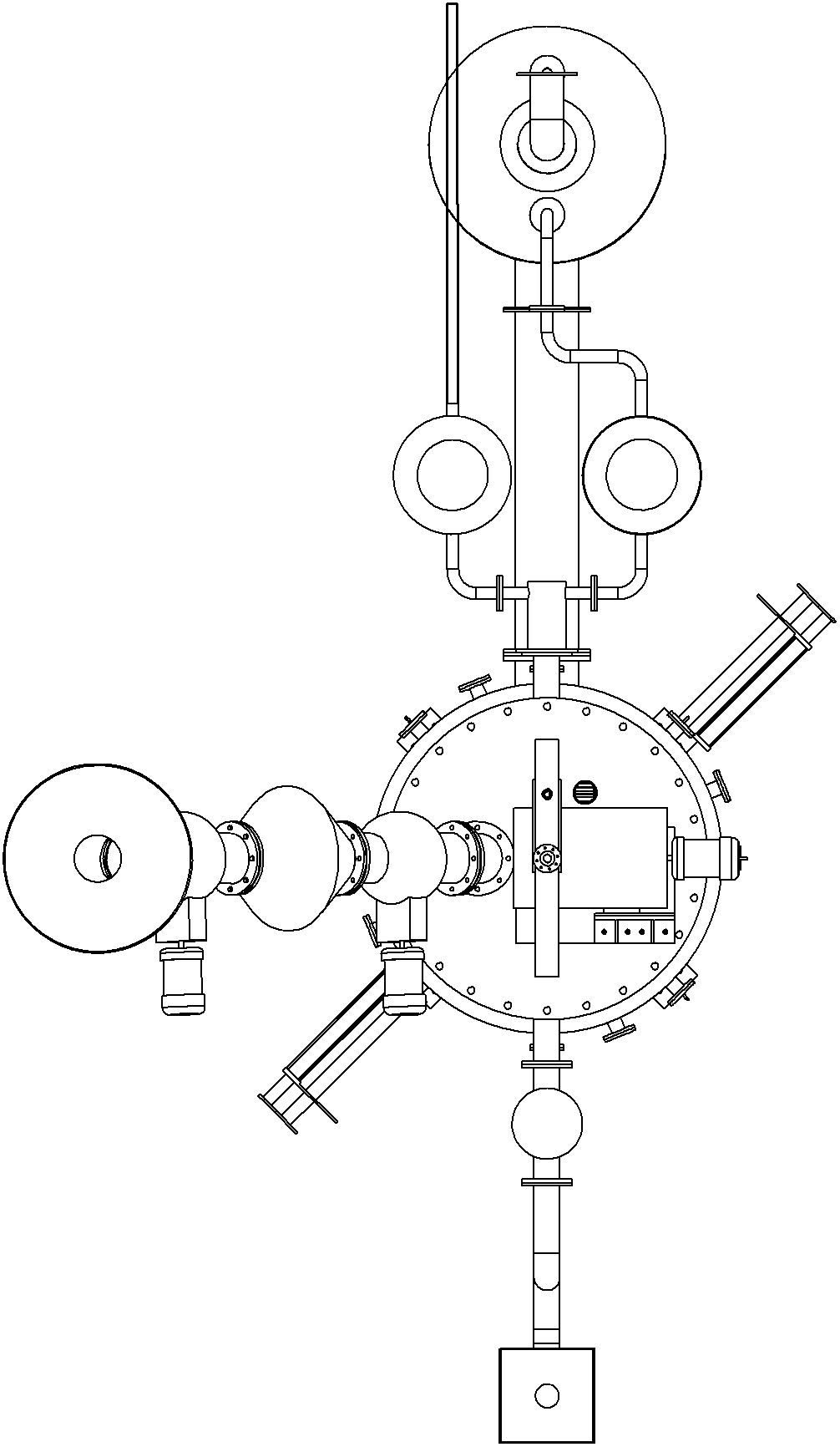

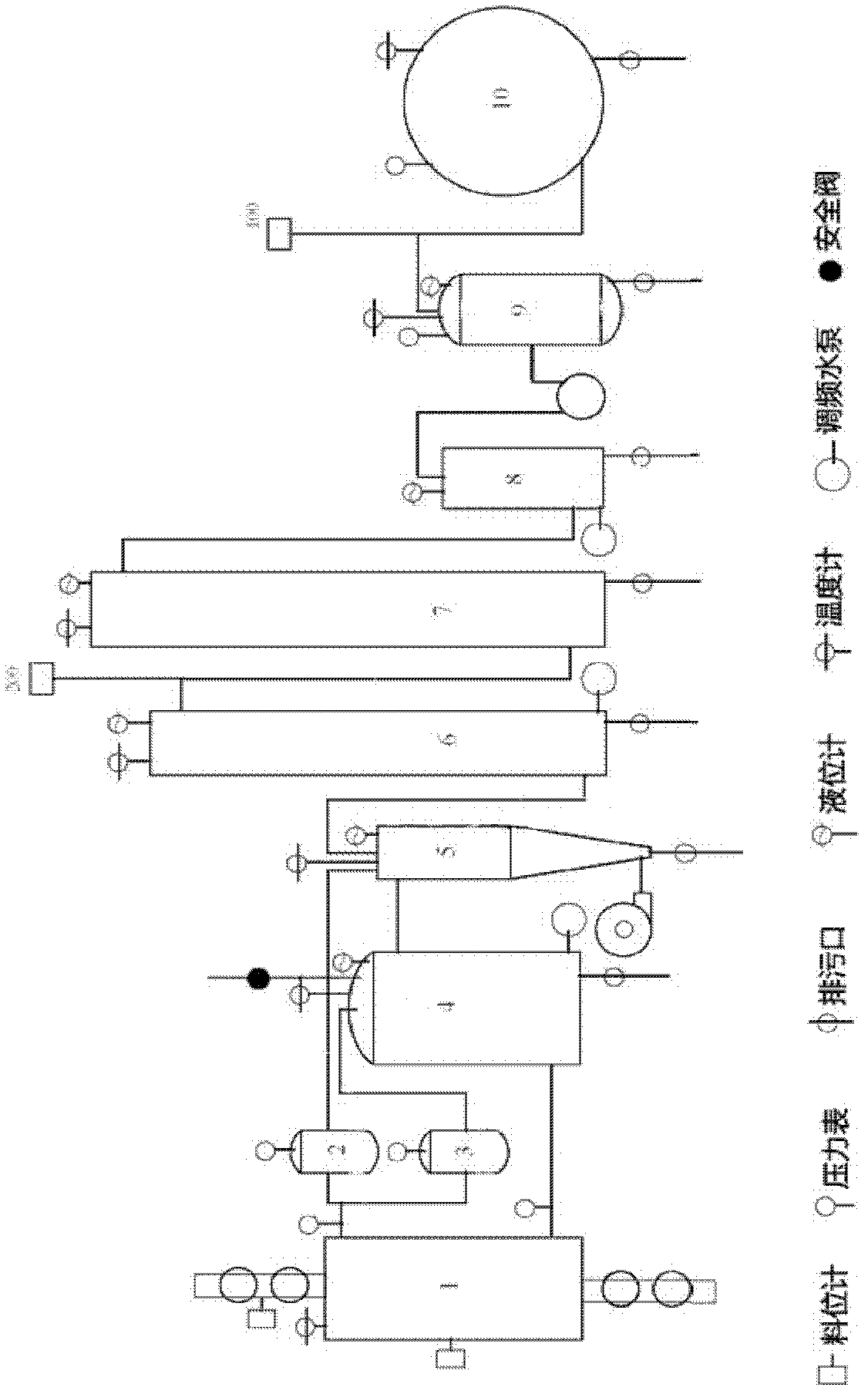

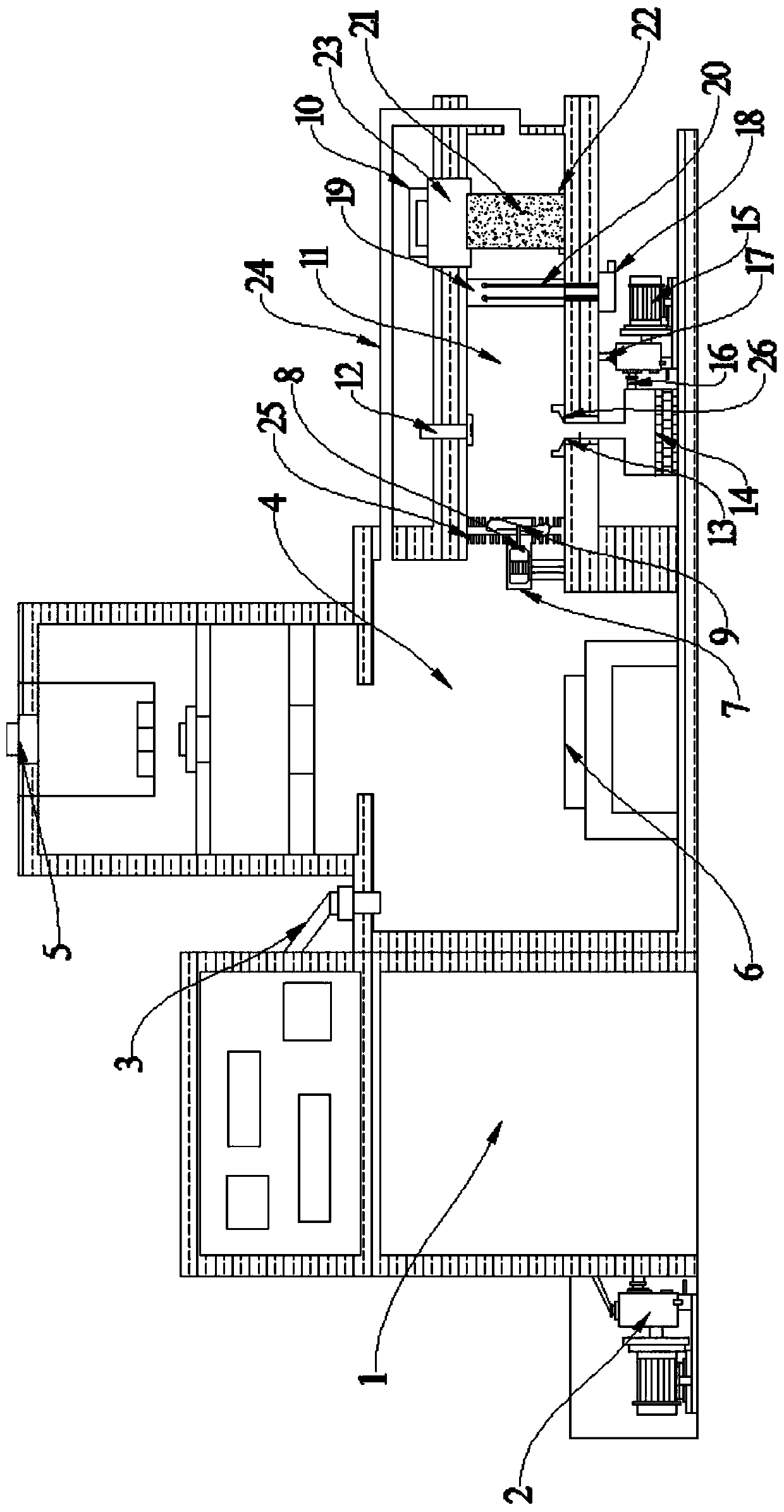

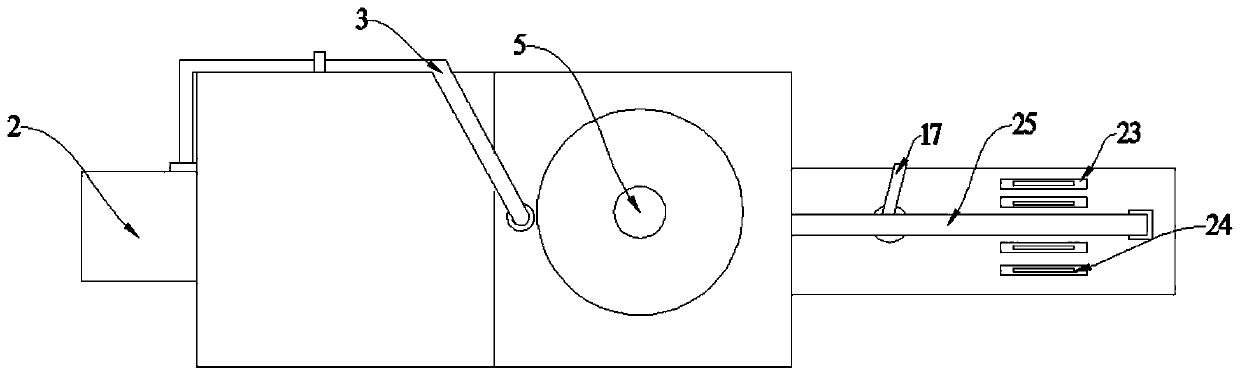

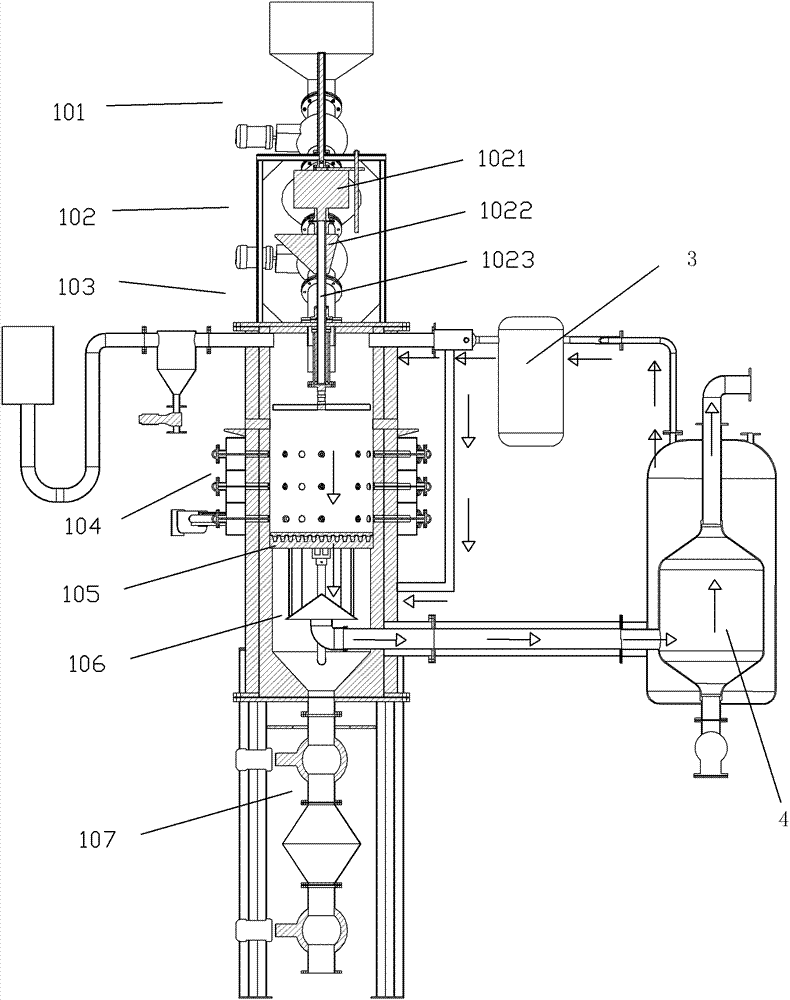

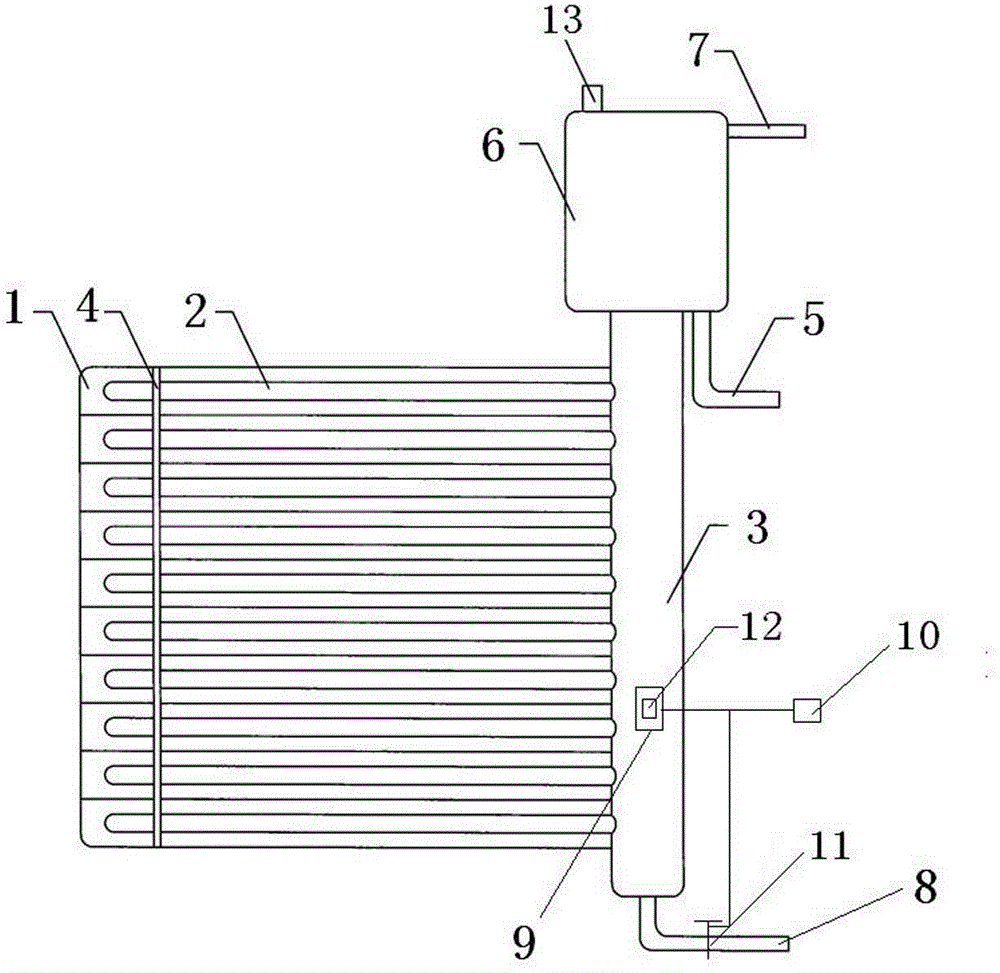

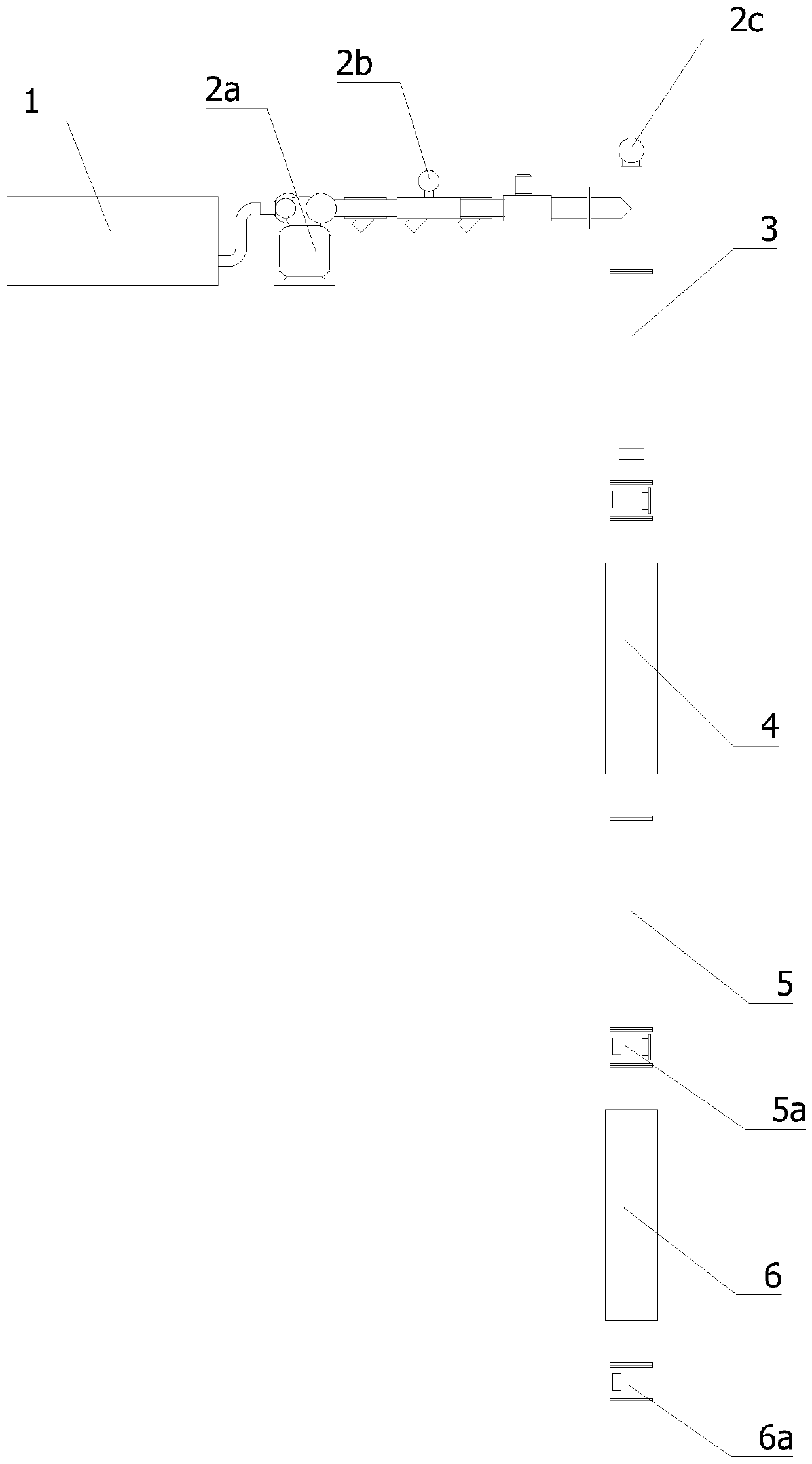

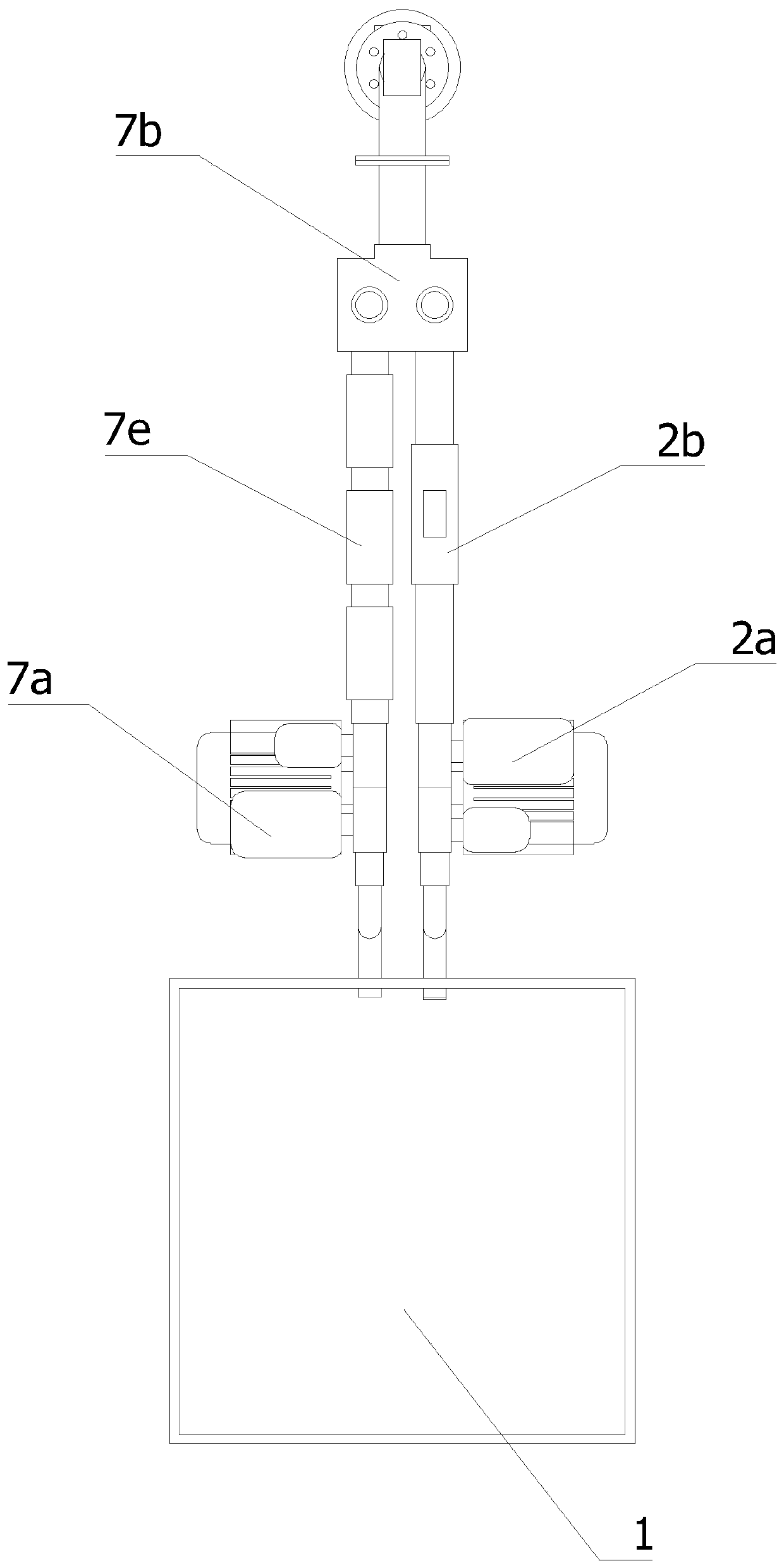

Biomass gasification device and process

InactiveCN102329654AImprove gasification efficiencySafe and controllable operationCombustible gas productionCooling towerSprayer

The invention relates to a biomass gasification device and process. The device comprises a gasification reaction chamber, a steam heat exchanger, a steam buffer tank, an air buffer tank, an inner and outer double-cyclone heat exchanging dust collector, a cooling tower, an electro tar precipitator, a hydrogen sulfide removal sprayer, a water ring compressor, a gas-water separator, a gas storage tank and a control system of the device, which are connected through a gas pipeline; the gasification reaction chamber comprises an automatic feeding device, a two-stage gasification zone, a vibrating grate, an automatic ignition device, an automatic slagging device and an automatic leveling device. The gasification process comprises the following steps of: gas generation; gasification medium preheating; gas purifying and filtering; and gas compression and storage. The biomass gasification device and process are scientific and environment friendly, have the remarkable characteristics of simple structural design, high degree of automation as well as stable, controllable and continuous gasification reaction, have high gasification efficiency and entire caloricity, are suitable for popularization and application on a large scale, and are particularly applicable to continuous and stable generation of the traditional gas generating set.

Owner:张建超

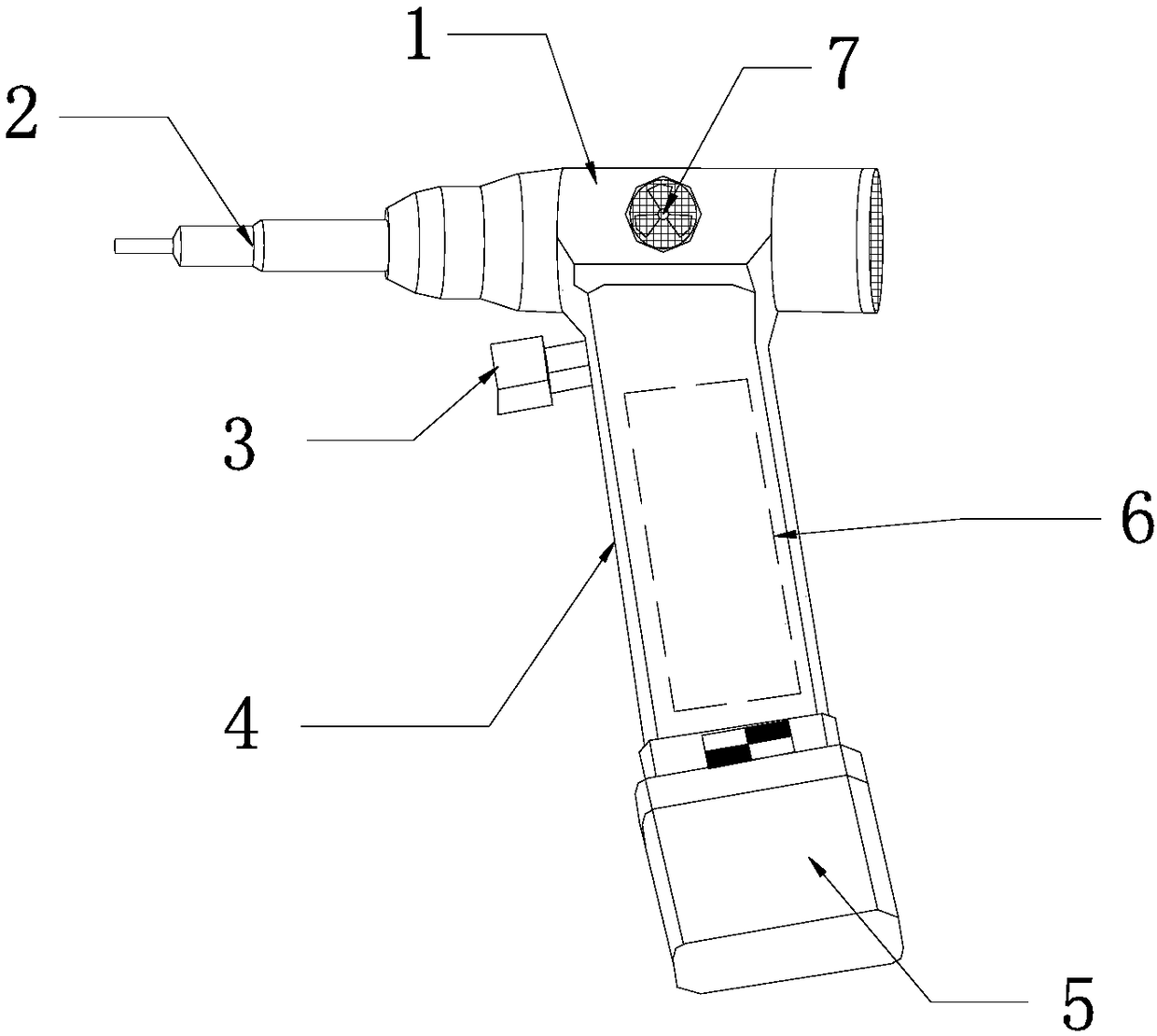

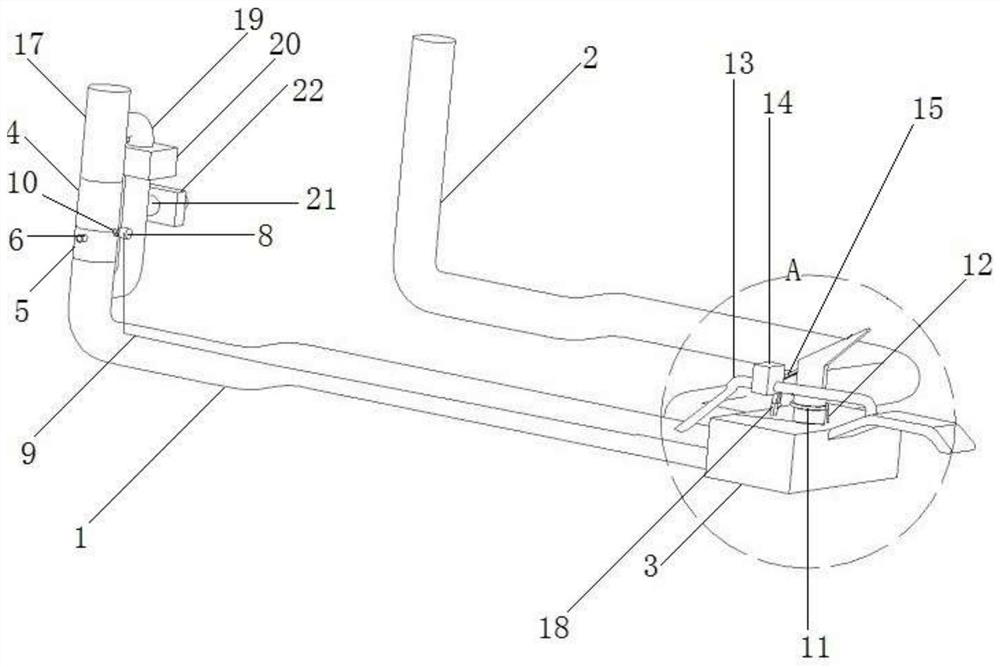

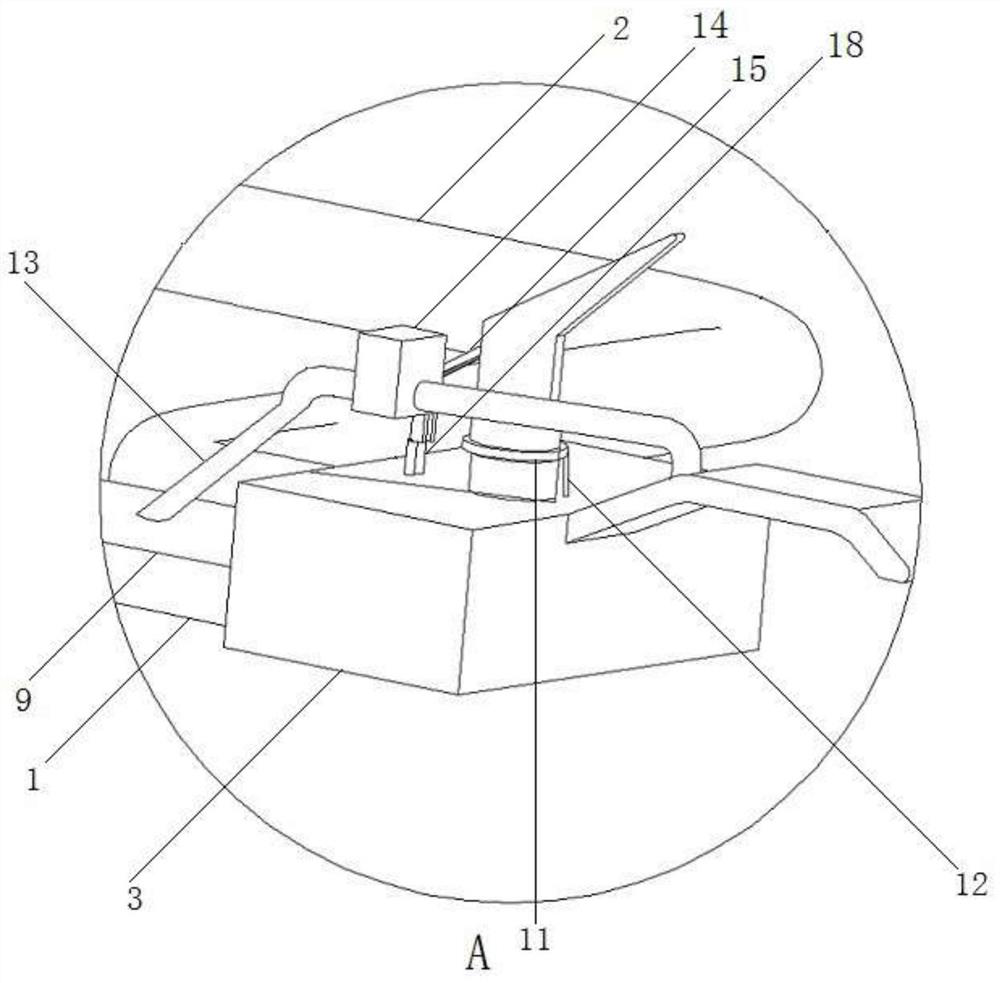

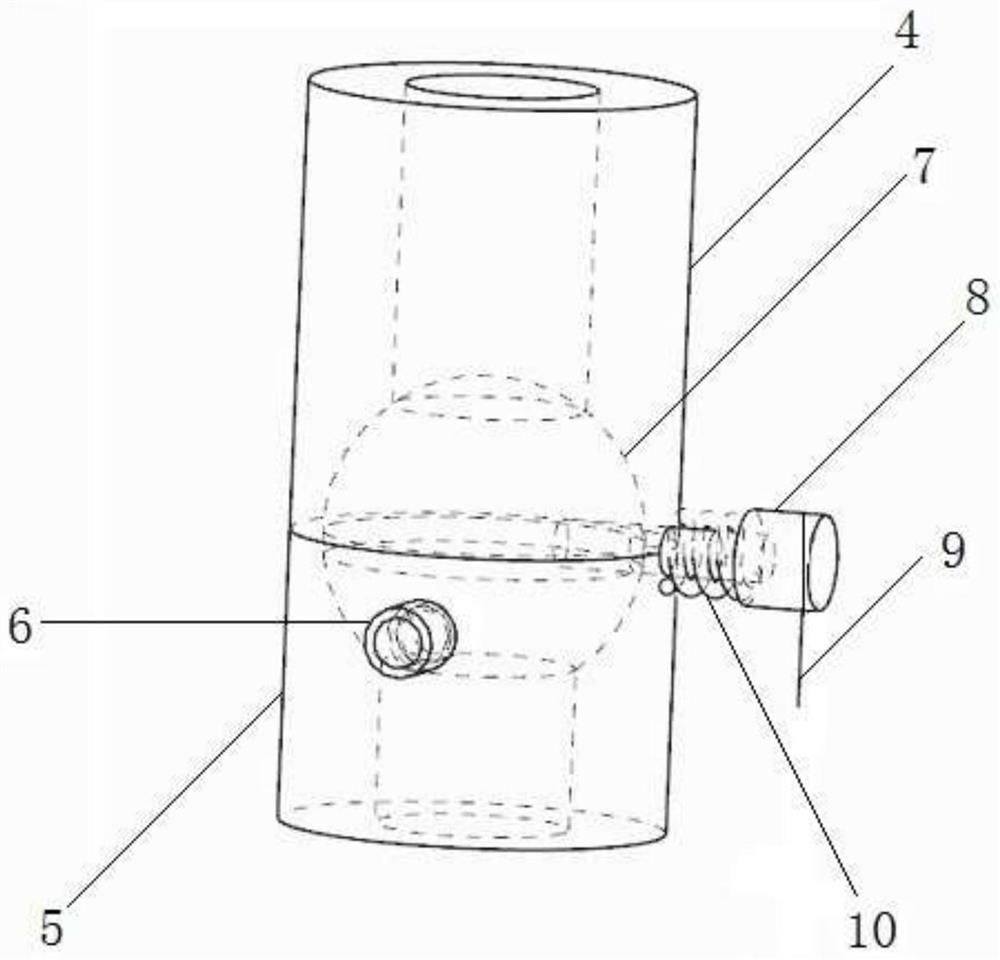

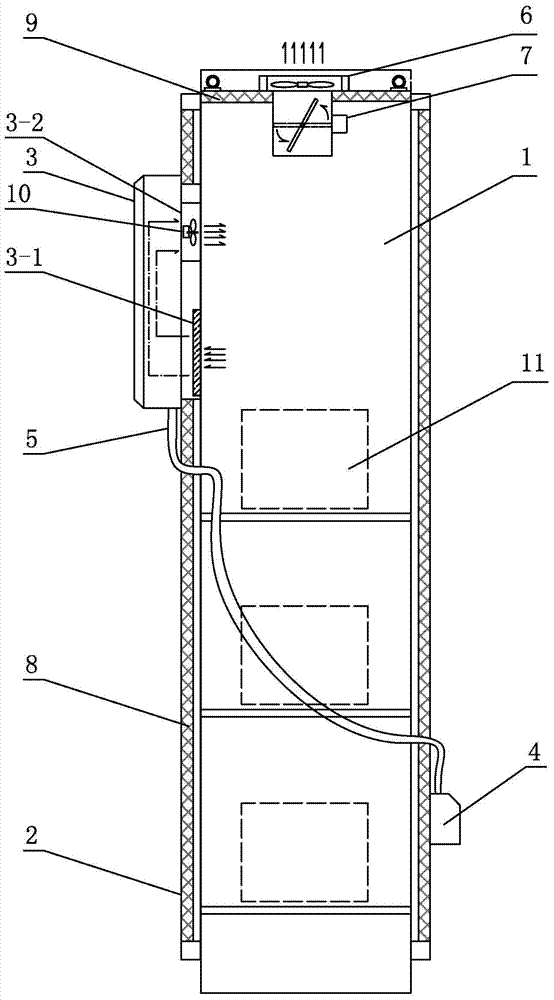

Craniotomy milling cutter with built-in cooling water channel

InactiveCN108338820ASolve the problem of not being able to cool down internallyImprove work efficiencySurgeryWater channelMilling cutter

The invention provides a craniotomy milling cutter with a built-in cooling water channel. The craniotomy milling cutter comprises a heat conduction pipe, a micro water pump, a water tank, a refrigerator, an air inlet fan and an exhaust fan, wherein the rear end of the heat conduction pipe is installed in the water tank, the micro water pump is installed in the water tank, the upper end of the water tank is connected with the lower end of a handle, and the refrigerator is installed in the water tank, the air inlet fan is installed in a fan groove, and the exhaust fan is fixed in the rear end ofa machine body through a fixing support. A motor is cooled according to the principle of water circulation, and the working efficiency of the motor is improved; the operation time is shortened by increasing the rotating speed; the air circulation principle is used, so that hot air generated when the motor works is discharged through air convection formed by the air inlet fan and the exhaust fan,air circulation and air exchange inside the machine body are accelerated, and the effect of cooling the motor is achieved.

Owner:山东品优工程材料有限公司

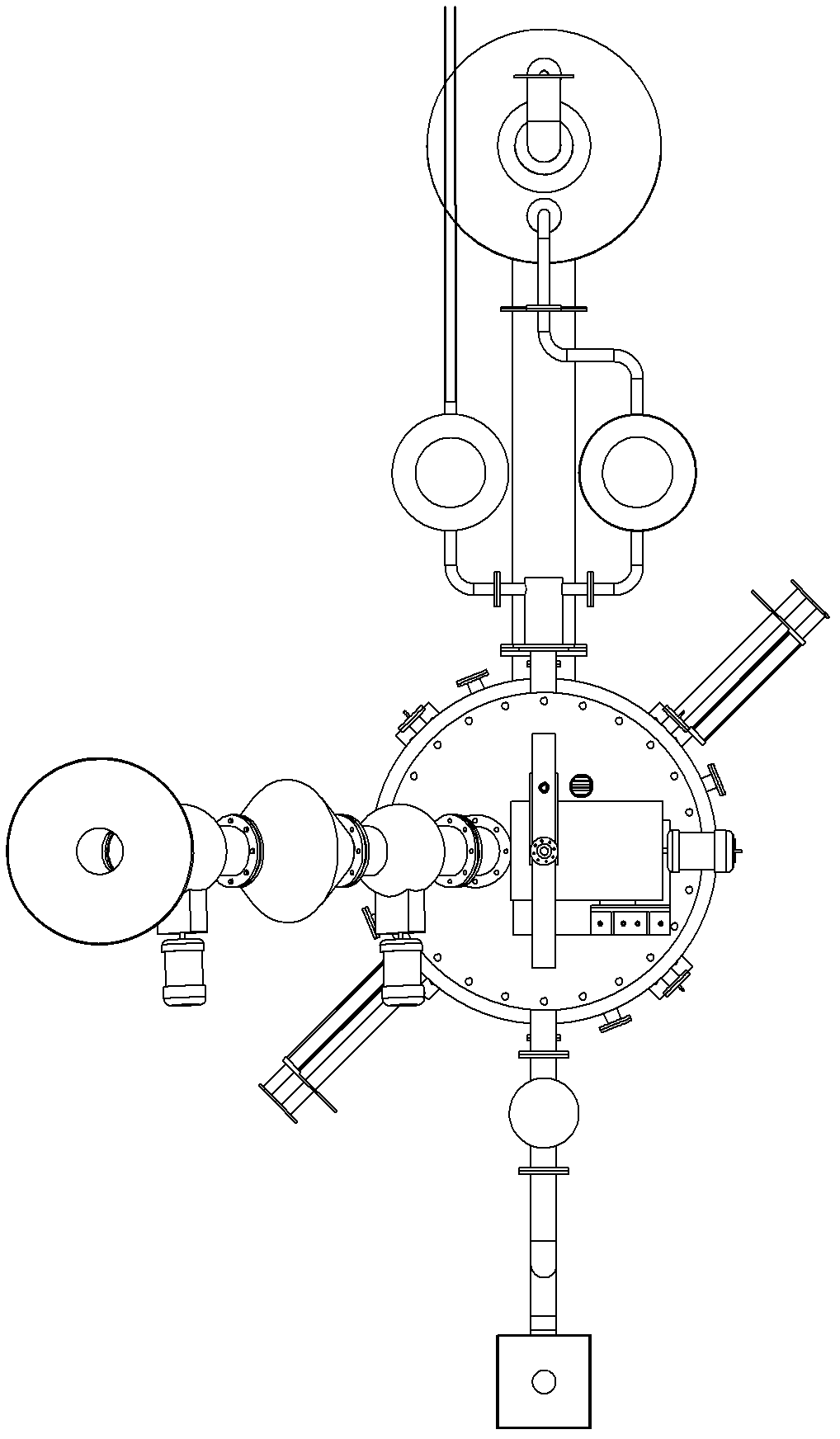

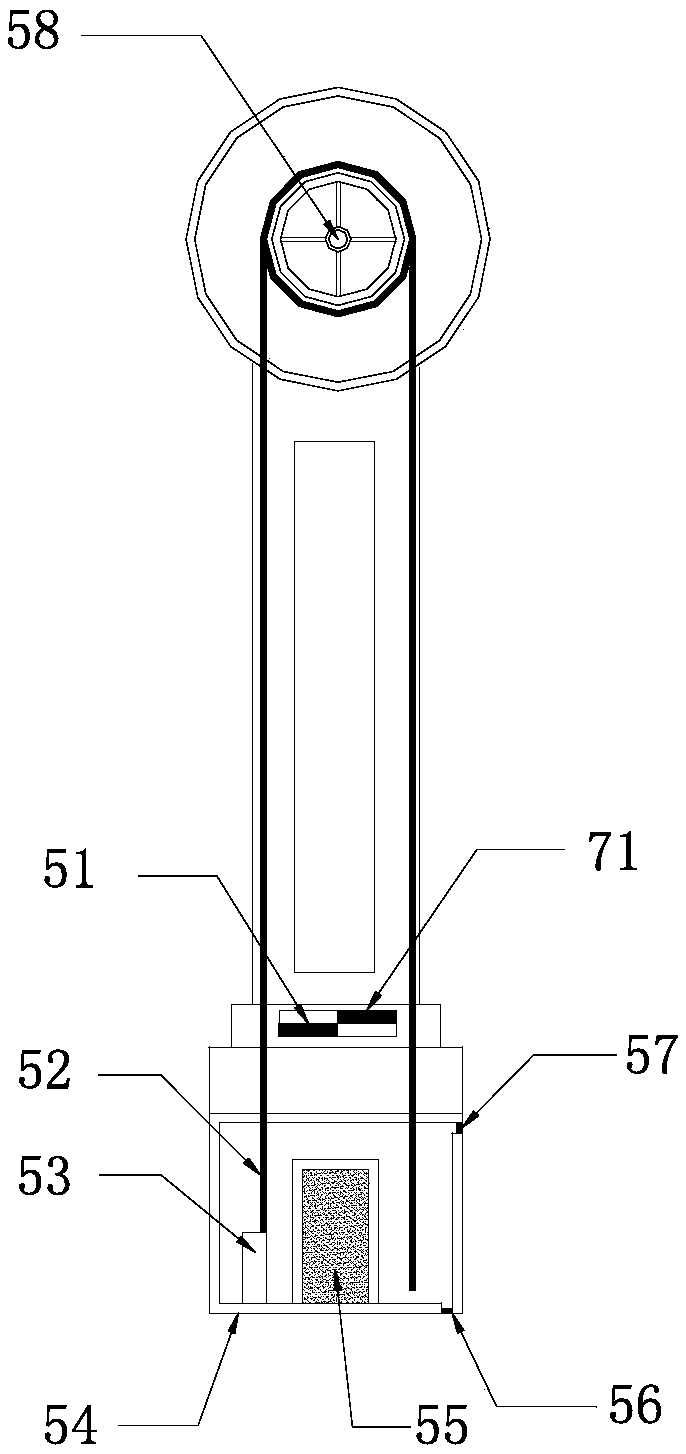

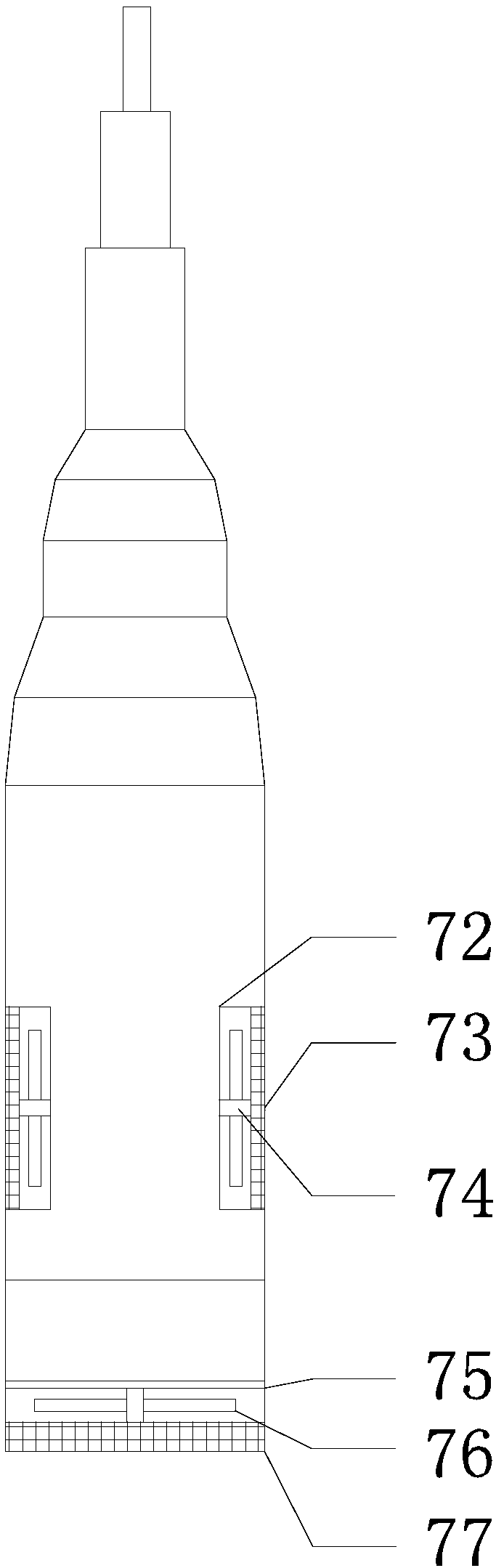

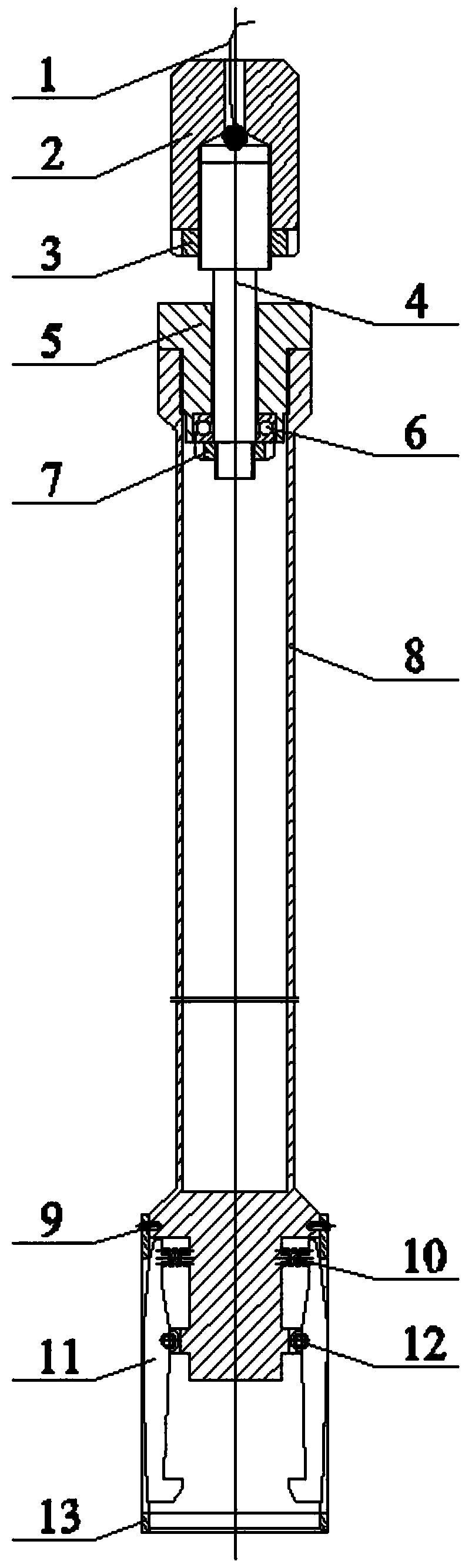

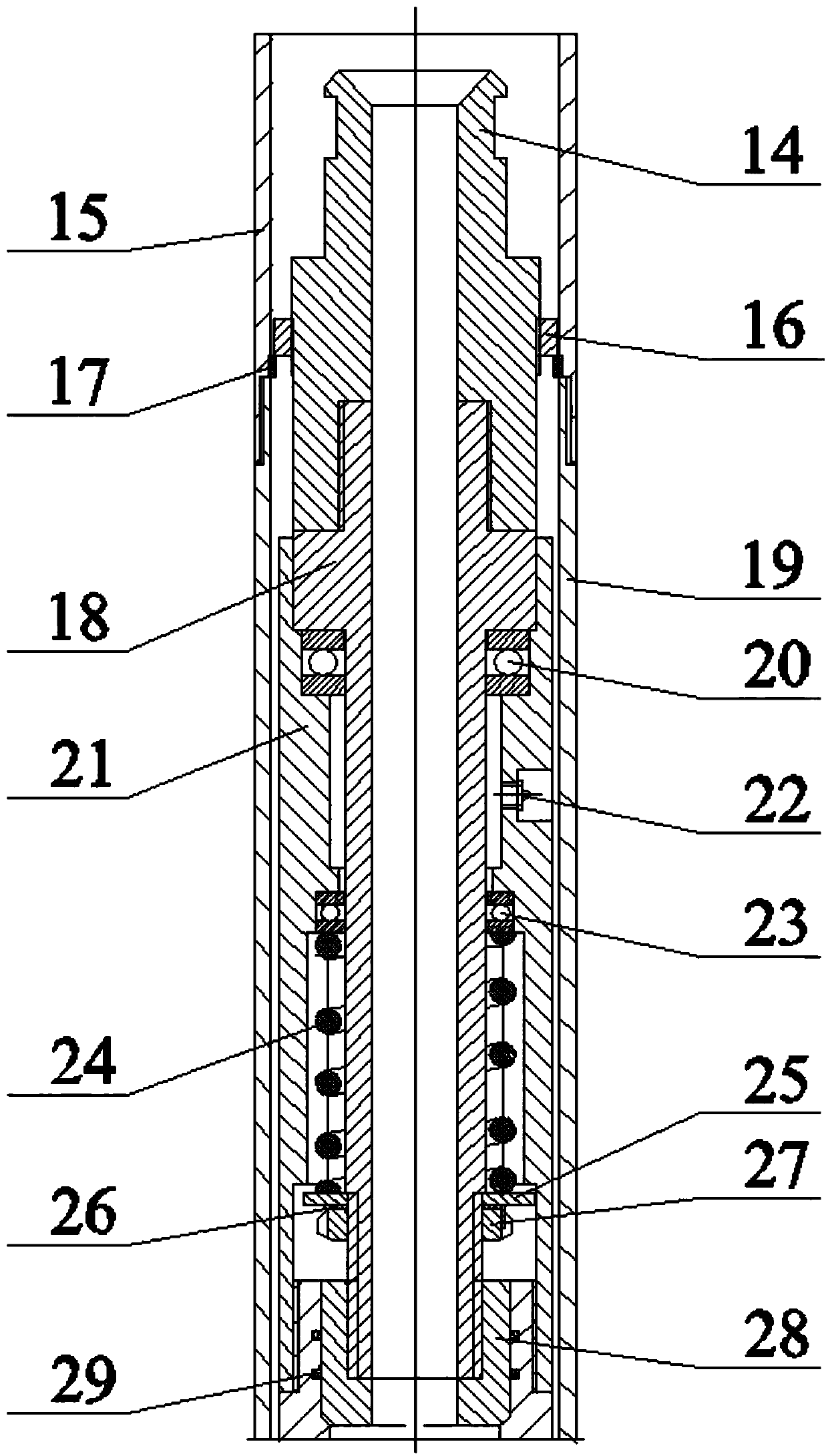

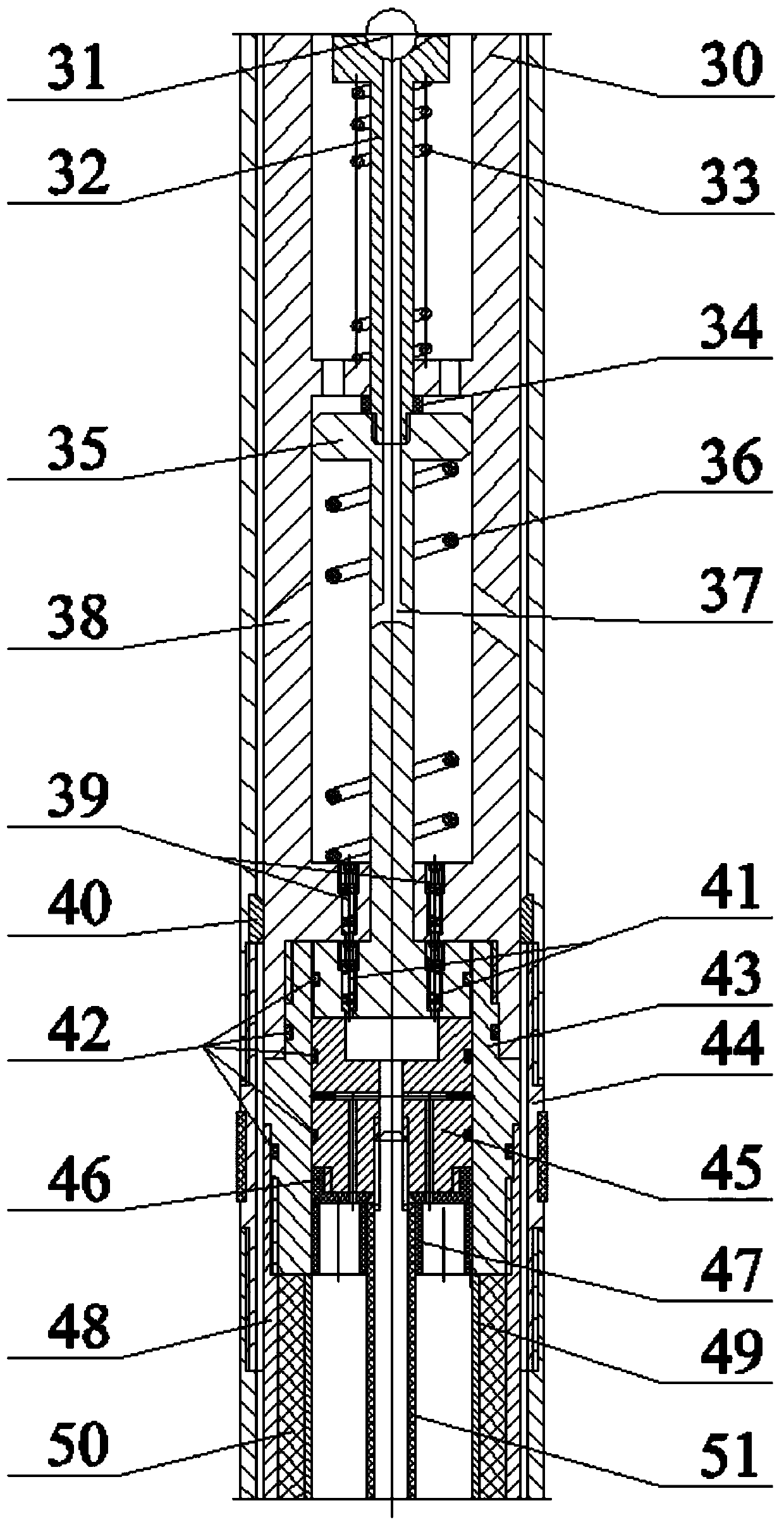

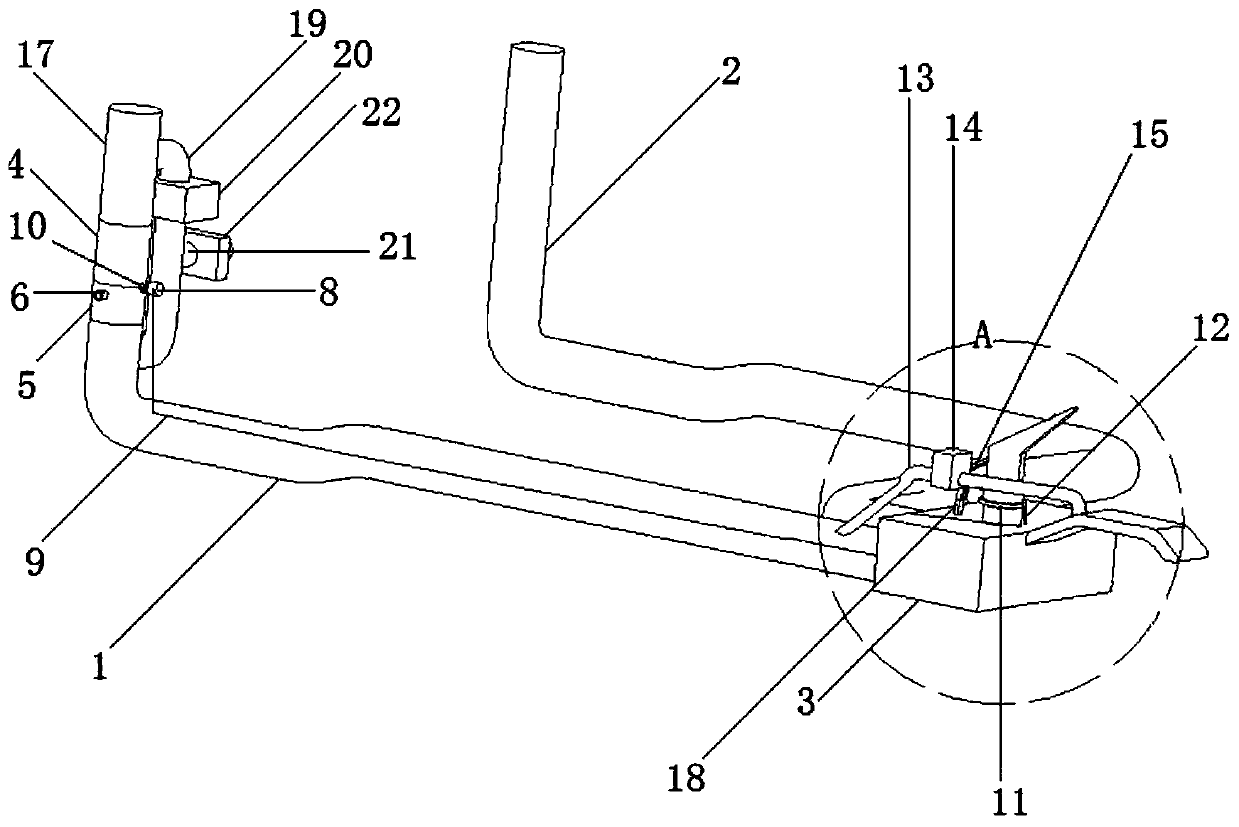

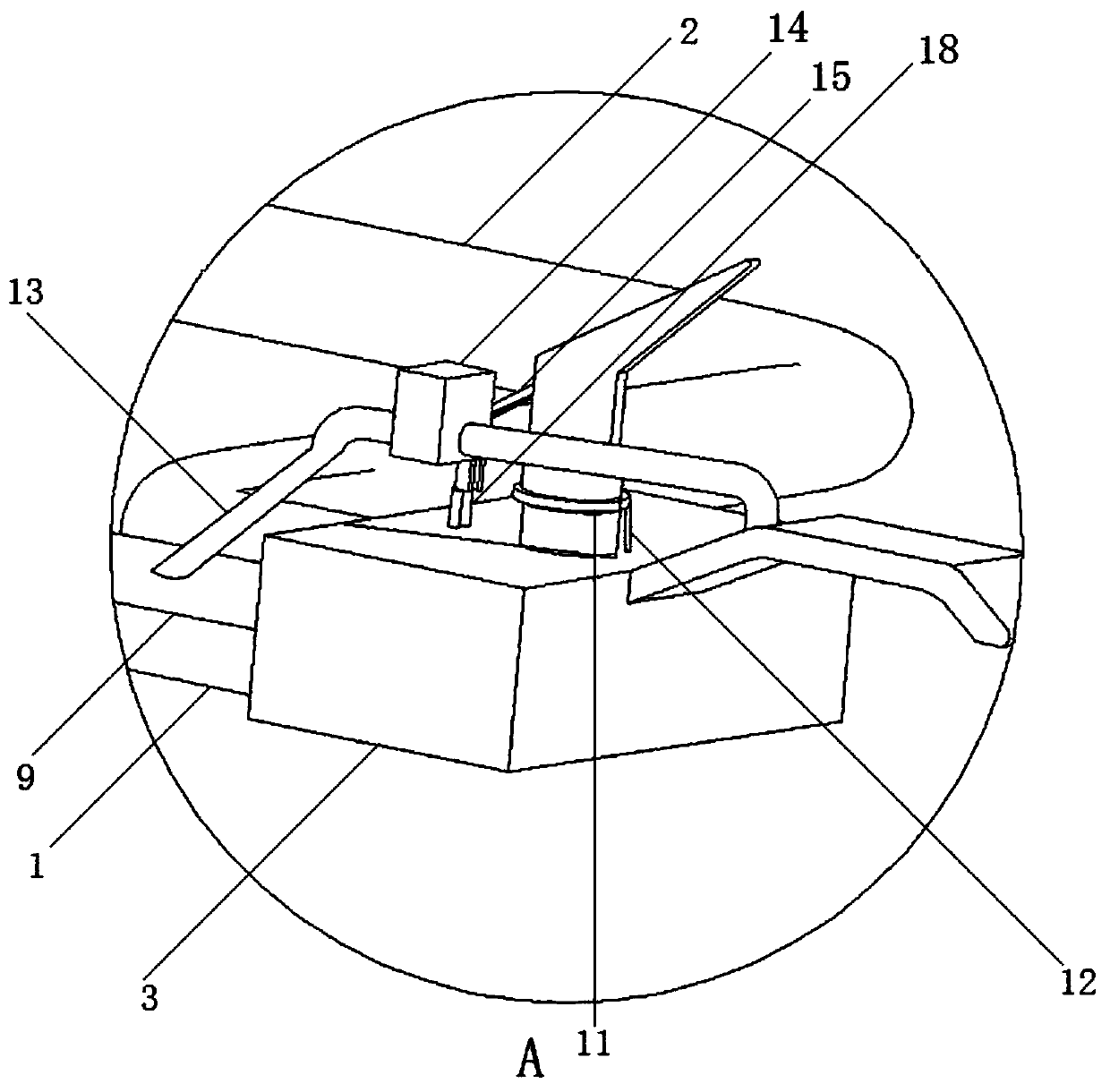

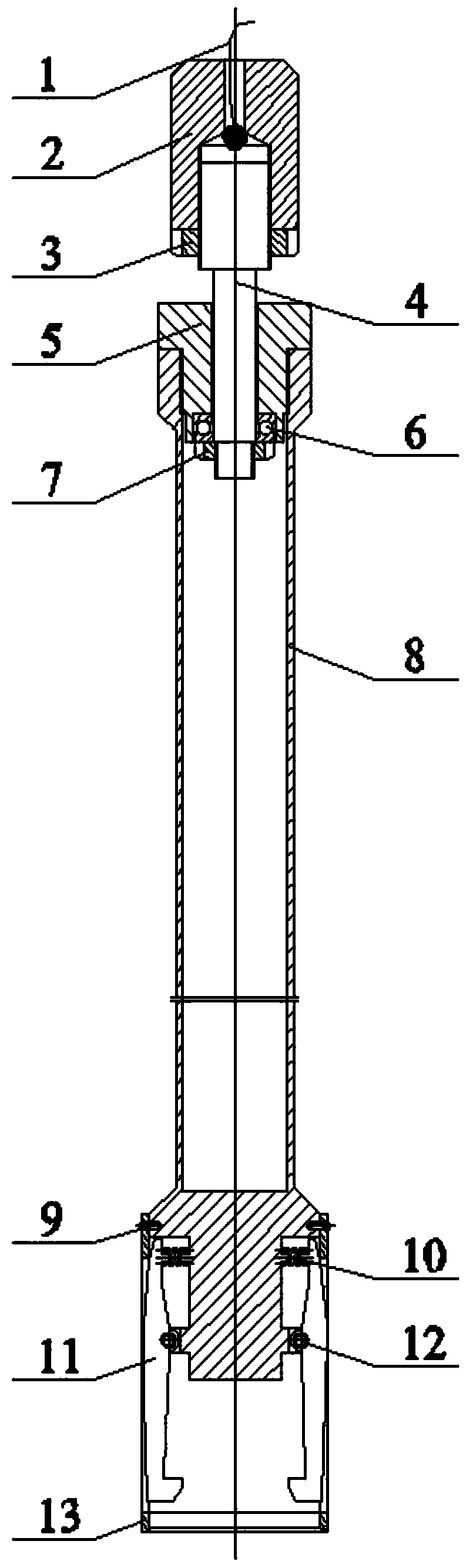

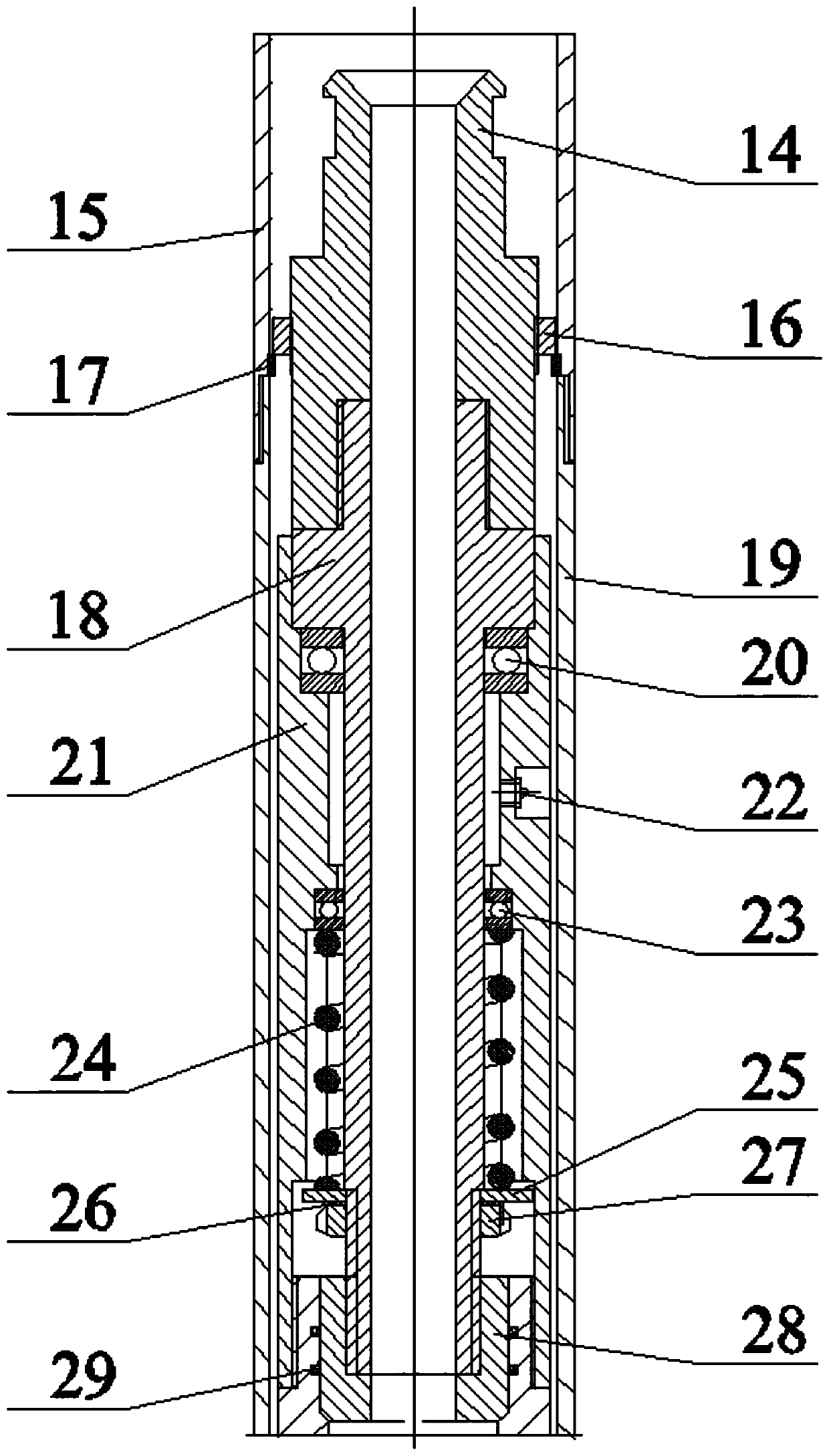

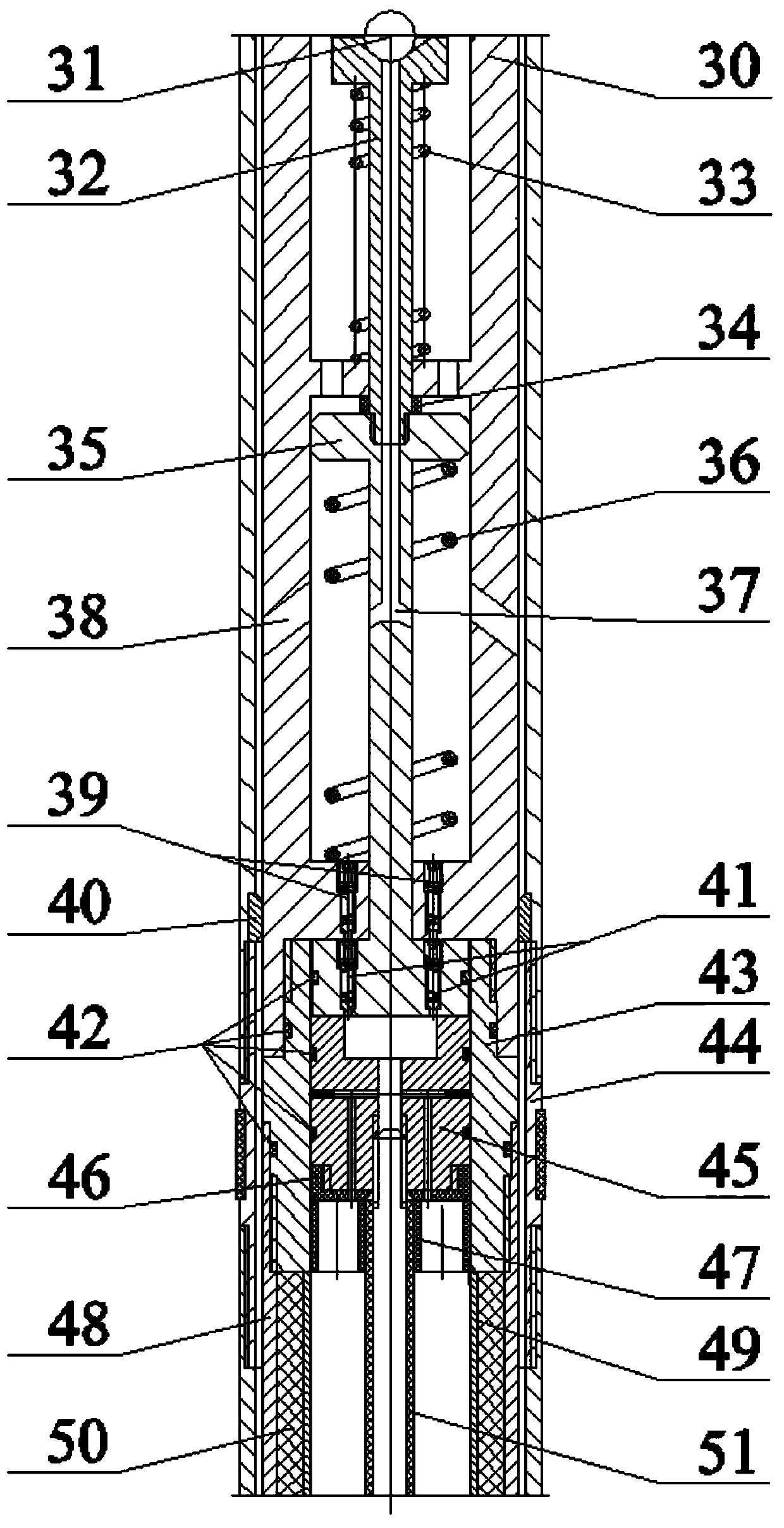

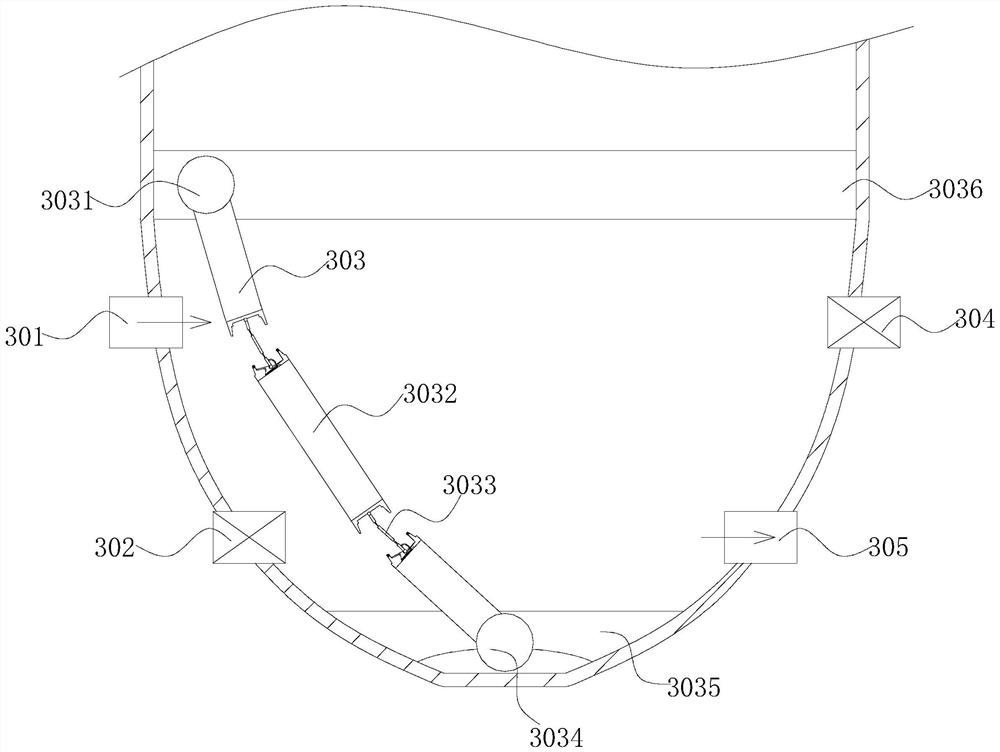

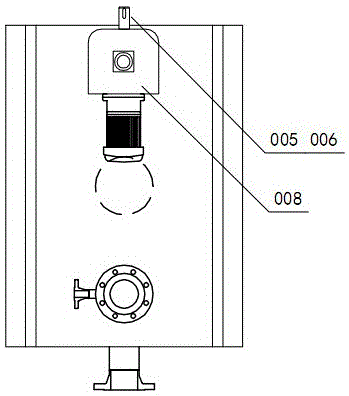

Marine natural gas hydrate phase change refrigeration rope coring drilling tool and coring method

ActiveCN109098679ANo decompositionSolve problems that cannot be dischargedConstructionsFluid removalSteel ballEngineering

The invention discloses a marine natural gas hydrate phase change refrigeration rope coring drilling tool and a coring method. The invention adopts phase change fluid as a refrigerant to exhaust gas generated by gasification of the phase change fluid from the interior of the drilling tool through a rapid gas exhaust mechanism, and solves the problem that the refrigeration capacity of the drillingtool is insufficient caused by the fact that the pressure in the cavity is too high, the critical point of the phase change pressure of the fluid is reached, and the fluid is not subjected to phase change heat absorption because the gas generated by phase change of the refrigerant cannot be exhausted under the action of deep sea hydrostatic pressure. The coring method includes the following steps:after coring is completed, putting a steel ball into the drilling tool to block a drilling fluid circulation channel; providing power to the rapid gas exhaust mechanism through the drilling fluid pressure; and injecting the refrigerant into a hole bottom freezing mechanism. The rope coring is combined with the freezing of the hole bottom to realize rapid coring without drilling; during drilling,the inner pipe assembly does not rotate, so that the damage to the natural gas hydrate core caused by the mechanical force generated by the rotation of the drilling tool is avoided to a greater extent, and the core recovery rate, integrity and representativeness are more effectively improved.

Owner:JILIN UNIV

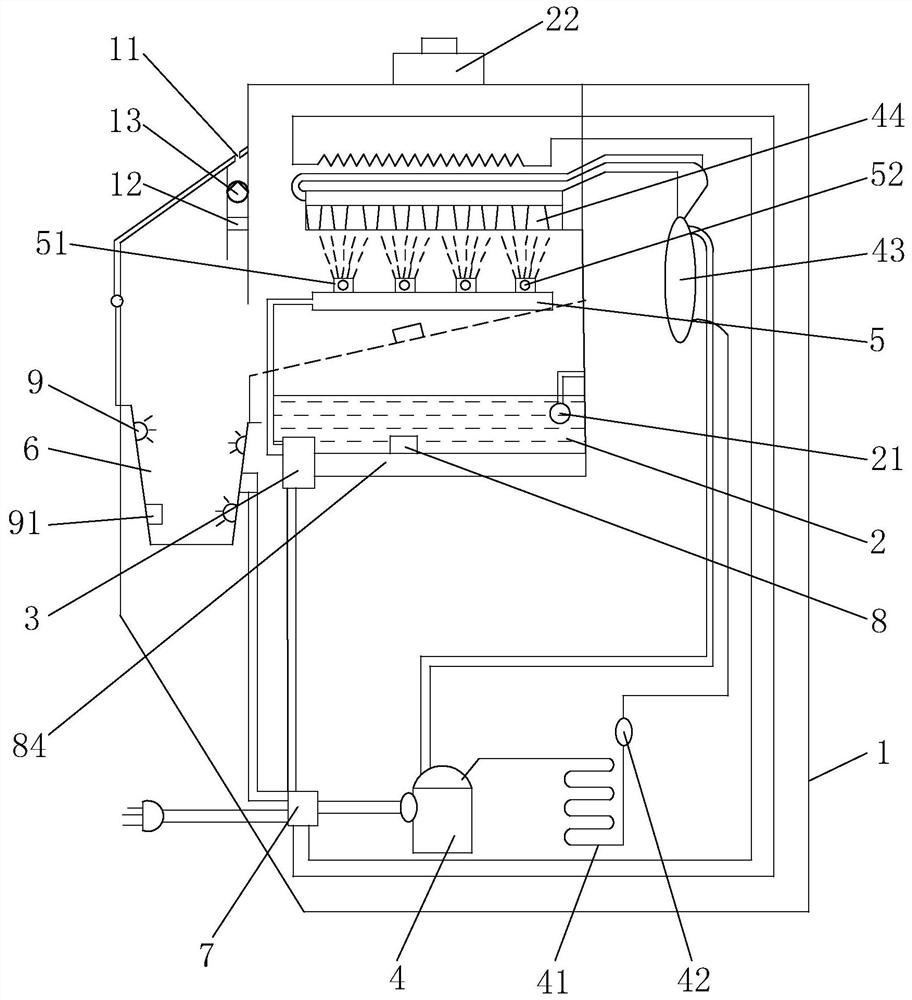

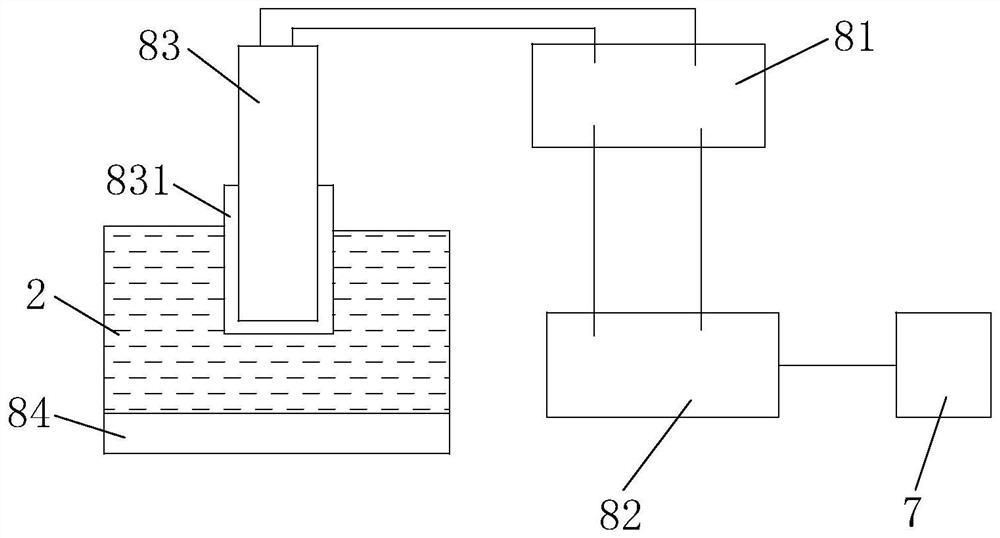

Novel ice maker

PendingCN112432407AReduce pollutionImprove securityWater/sewage treatment by irradiationLighting and heating apparatusProcess engineeringIce storage

The invention relates to a novel ice maker. The novel ice maker comprises a box body, wherein an ice making system and a microorganism detection and sterilization system are arranged in the box body,the ice making system comprises a water storage tank, a water pump and an ice maker, one end of the water pump is connected with the water storage tank, and the other end of the water pump is connected with a flow dividing head. The water pump sends water in the water storage tank to the flow dividing head and evenly sprays the water to the surface of the ice maker for ice making, the ice maker isconnected with a deicing module, and the deicing module is used for separating ice on the ice maker into an ice storage barrel. The microbiological detection and sterilization system comprises a single-chip microcomputer, a microbiological detection device and ultraviolet sterilization lamps, the single-chip microcomputer is in control connection with the microbiological detection device and theultraviolet sterilization lamps, the microbiological detection device is installed in the water storage tank, the ultraviolet sterilization lamps are installed in the ice storage barrel, and the single-chip microcomputer is connected with the water pump and the ice maker. The ultraviolet germicidal lamps are arranged in the ice storage barrel of the ice maker, so that microorganisms are killed byradiation damage to the microorganisms and the function of destroying nucleic acid, and the purpose of disinfection is achieved.

Owner:上海典梵品牌管理有限公司

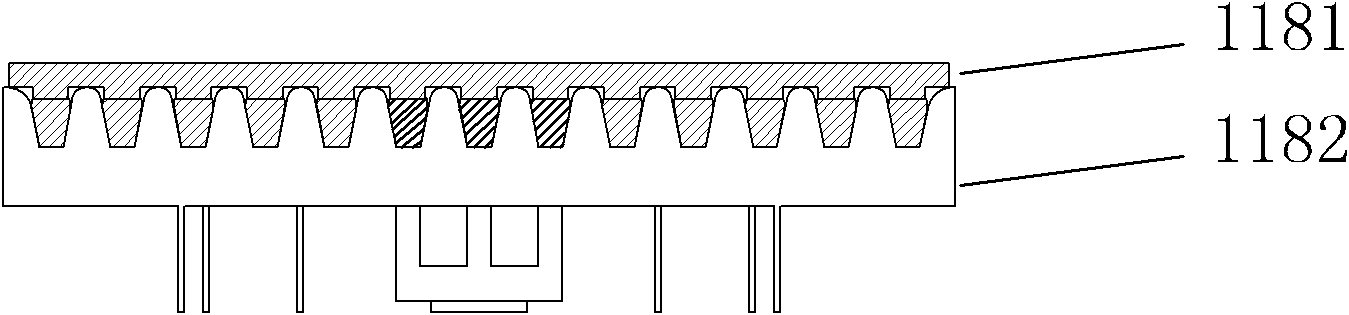

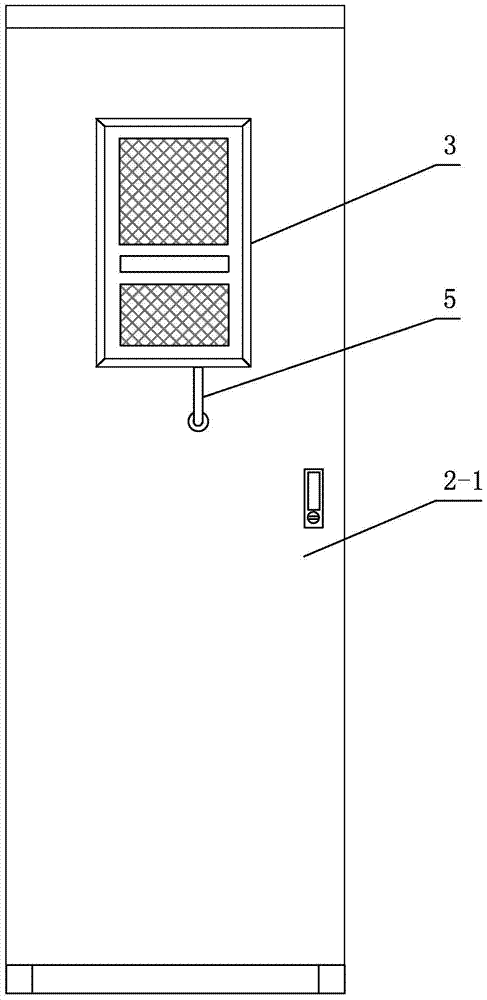

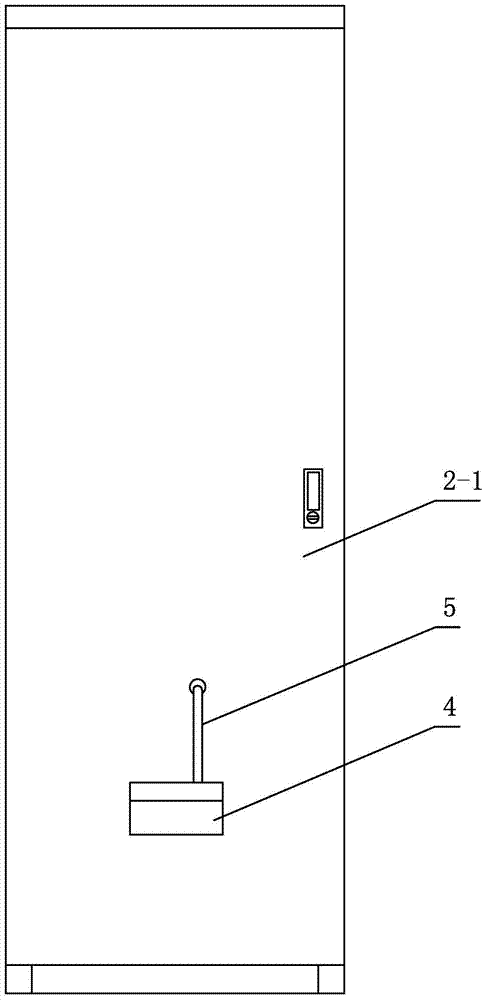

Combined power distribution cabinet with moisture-proof function

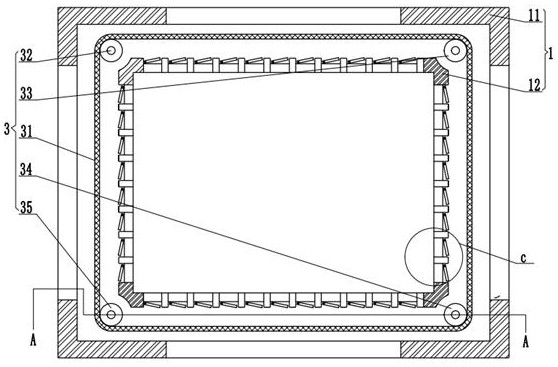

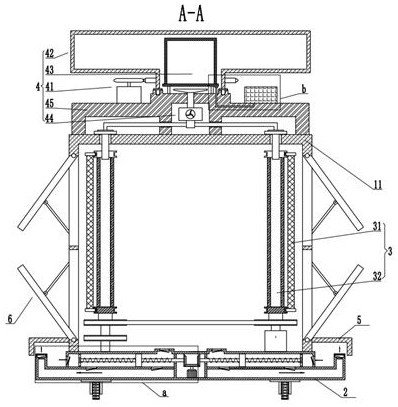

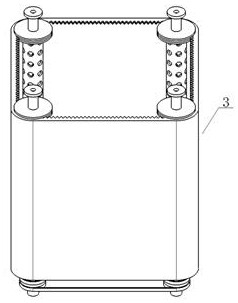

ActiveCN114069448AGood moisture-proof effectAvoid wasting time and effortSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsDamp proofingElectrical and Electronics engineering

The invention relates to the technical field of power distribution cabinets, and provides a combined power distribution cabinet with a moisture-proof function. The cabinet comprises a power distribution cabinet frame and a dehumidification mechanism, and is characterized in that the power distribution cabinet frame comprises an outer side frame, an inner side frame and a base, the bottoms of the outer side frame and the inner side frame are both mounted on the base, cavity is formed between the outer side frame and the inner side frame, a dehumidification mechanism is installed in the cavity and comprises a water absorption cotton net, a first rotating pipe, a second rotating pipe, a third rotating pipe and a fourth rotating pipe, rotating discs are installed at the two ends of the first rotating pipe, the two ends of the second rotating pipe, the two ends of the third rotating pipe and the two ends of the fourth rotating pipe correspondingly, the water absorption cotton net is installed on the rotating discs, an annular batten is installed on the water absorption cotton net, a plurality of first gear teeth are evenly arranged on the annular batten, a first circular guide rail is arranged on the rotating disc, second gear teeth are evenly arranged in the first circular guide rail, the annular batten is located in the first circular guide rail, and the first gear teeth are connected with the second gear teeth in a meshed mode.

Owner:常州东皓电气有限公司

Smoke removing device for vacuum beam welder

PendingCN110624354ASolve problems that cannot be dischargedReduce economic costsCombination devicesElectron beam welding apparatusEngineeringVacuum pump

The invention discloses a smoke removing device for a vacuum beam welder, relates to the technical field of smoke removing of the vacuum beam welder, and aims to solve the problem that smoke generatedin a welding process cannot be discharged. A vacuum pump is arranged on one side of an operation table; an electric welding operation chamber is arranged on the other side of the operation table; a holding platform is arranged in the middle inside the electric welding working chamber; an emission hole is formed above the holding platform; a smoke removing chamber is arranged at one end of the electric welding working chamber; a high temperature resistant tank is arranged on one side of the smoke removing chamber; the high temperature resistant tank is fixedly connected with the smoke removingchamber; a motor is arranged on one side of the high temperature resistant tank; one end of the motor extends into the high temperature resistant tank; and an air sucking fan is arranged at one end of the motor.

Owner:太仓束捍机电科技有限公司

On-site penetration test device and test method for building foundation

ActiveCN110018103BTroubleshoot issues affecting test resultsSolve the problem of working lifePermeability/surface area analysisSolenoid valveWorking life

The present invention relates to the field of foundation penetration test, in particular to a building foundation site penetration test device and a test method thereof, comprising a water tank, a water pressure mechanism, a first water pipe, a first hydraulic plug, a second water pipe, and a second hydraulic pressure plug. The water pressure mechanism includes a pressure regulating water pump, a flow meter and a pressure gauge. The input port of the pressure regulating water pump is connected with the water tank. The output port of the pressure regulating water pump is equipped with a flow meter. The bottom end of the second water pipe is installed with The first electromagnetic three-way valve, the bottom end of the second hydraulic plug is equipped with a solenoid valve, the first water pipe, the first hydraulic plug, the second water pipe, the first electromagnetic three-way valve, the second hydraulic plug, The solenoid valves are connected sequentially from top to bottom; the test device and its test method solve the problem that the residual debris in the hole affects the test results, and at the same time solve the problem that the air in the test area cannot be discharged, and also solve the problem of the air above the test area. The water pressure generated by the water column reduces the working life of the hydraulic plug.

Owner:JIANGXI UNIV OF SCI & TECH

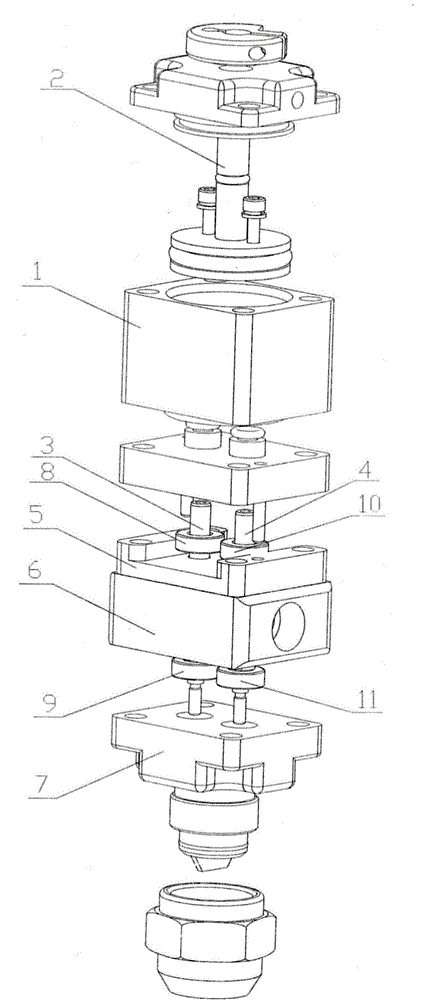

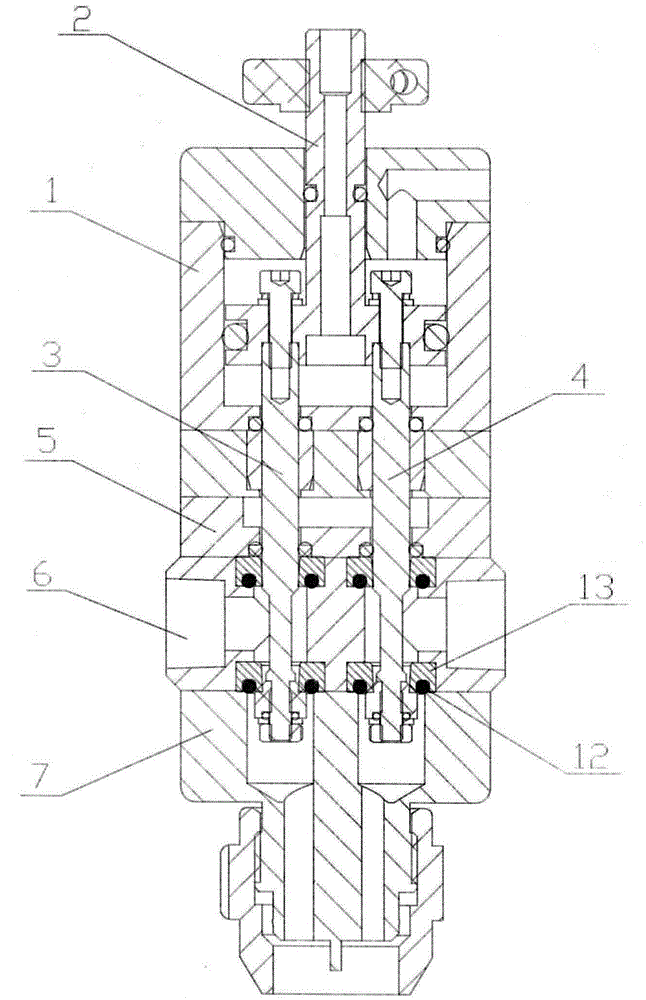

Double-component dispensing valve

InactiveCN104415886AAvoid containing air bubblesAvoid enteringLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention provides a double-component dispensing valve, sequentially composed of a cylinder shell, a piston rod, a valve core, a U-shaped block, a glue feed valve body and a glue discharge valve body which are connected; the piston rod vertically penetrates through the upper half part of the cylinder shell; the valve core comprises a first valve core and a second valve core the same as the first valve core, wherein the first valve core and the second valve core are connected to the lower end of the piston rod and are eudipleural along the piston rod, and the first valve core and the second valve core respectively penetrate through the U-shaped block, the glue feed valve body and the glue discharge valve body in sequence; a groove is formed in a connecting site of the U-shaped block and the cylinder shell. The double-component dispensing valve provided by the invention has the beneficial effects of effectively discharging gas leaked from the cylinder to prevent the gas from entering the glue feed valve body; in addition, the gas in glue in the glue feed valve body can be discharged from the groove of the U-shaped block by extrusion when the valve cores move downwards, so that a cylinder is protected and the phenomenon that the glue contains bubbles in a glue discharge process of the dispensing valve is eliminated.

Owner:孙小跃

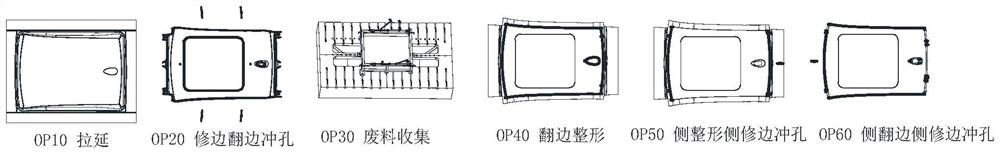

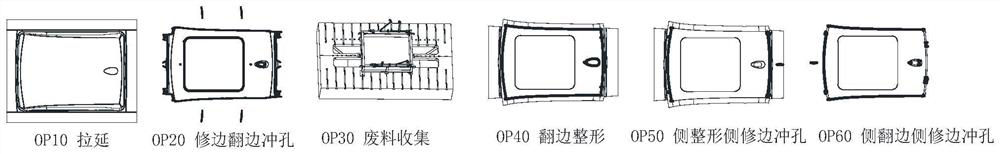

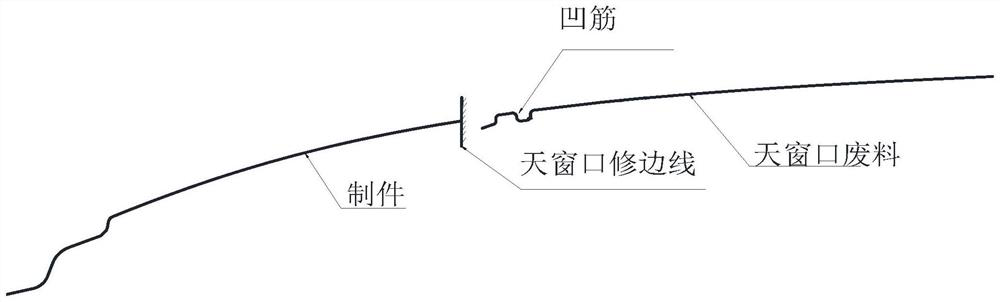

Manufacturing method of top cover skylight

PendingCN114192640ALow costGuaranteed dimensional accuracyShaping toolsPerforating toolsPunchingManipulator

The invention relates to the technical field of automobiles, in particular to a manufacturing method of a roof skylight. Comprising the following steps: OP10, drawing; oP20, trimming, flanging and punching are conducted through a trimming and shaping die; oP30, an idle station; the manipulator grabs the waste materials to an idle station, and the waste materials fall into a collecting box after the suction cup is deflated; oP40, flanging and shaping are carried out; straight flanging is conducted on the periphery of the top cover, the front air window is flanged to the depth of the flange edge, the rear air window is shaped in place, and straight flanging is completed on the side wall tailor-welded edge; oP50, side trimming, punching and side shaping are carried out; flanging and shaping the front air window clamping wedge in place, and trimming and punching the rear air window wedge; oP60, side flanging, side trimming and punching are carried out; and flanging the wedge of the side body tailor-welded edge, trimming the front windshield wedge, punching the rear windshield wedge, and punching shark fin mounting holes in the wedge. According to the manufacturing method, the workpiece manufacturing procedure is shortened, the production efficiency is improved, the workpiece material utilization rate is greatly improved, and the problems that the manufacturing cost is increased and the effective use area of material sheets is reduced in a traditional process are solved.

Owner:CHINA FIRST AUTOMOBILE

Drainage system of water heater

ActiveCN110895046ASolve problems that cannot be dischargedAvoid wasted situationsFluid heatersEngineeringHydrology

The invention discloses a drainage system of a heat water. The drainage system comprises a hot water pipe A, a cold water pipe and a water mixing valve and one end of the hot water pipe A and one endof the cold water pipe are fixedly communicated with a hot water port and a cold water port of the water mixing valve respectively; the system further comprises a connector pipe A, a connector pipe B,a hot water pipe B, an air inlet pipe, a reversing ball block, a rotating column inhaul cable, a torsional spring, a bearing and a water distribution pipe; an inner line, connected with an adjustinghandle of the water mixing valve, of the inhaul cable retracts, the inner line end, connected with a rotating column, of the inhaul cable rotates together with the rotating column to reset under effect of the torsional spring; and at the moment, the reversing ball block rotates from the position of blocking the air inlet pipe to the position of blocking the hot water pipe A, hot water in an electric heating water tank cannot enter the hot water pipe A again, external air enters the air inlet pipe to continuously press down the hot water in the hot water pipe A, and the hot water in the hot water pipe A is discharged from the water distribution pipe. Thus, the problem that the hot water in the hot water pipe cannot be discharged after the water mixing valve is closed in winter at present issolved.

Owner:ZHENJIANG BODE ELECTRIC EQUIP CO LTD

Marine natural gas hydrate phase change refrigeration wireline coring tool and coring method

ActiveCN109098679BNo decompositionSolve problems that cannot be dischargedConstructionsFluid removalRock coreSteel ball

The invention discloses a marine natural gas hydrate phase change refrigeration rope coring drilling tool and a coring method. The invention adopts phase change fluid as a refrigerant to exhaust gas generated by gasification of the phase change fluid from the interior of the drilling tool through a rapid gas exhaust mechanism, and solves the problem that the refrigeration capacity of the drillingtool is insufficient caused by the fact that the pressure in the cavity is too high, the critical point of the phase change pressure of the fluid is reached, and the fluid is not subjected to phase change heat absorption because the gas generated by phase change of the refrigerant cannot be exhausted under the action of deep sea hydrostatic pressure. The coring method includes the following steps:after coring is completed, putting a steel ball into the drilling tool to block a drilling fluid circulation channel; providing power to the rapid gas exhaust mechanism through the drilling fluid pressure; and injecting the refrigerant into a hole bottom freezing mechanism. The rope coring is combined with the freezing of the hole bottom to realize rapid coring without drilling; during drilling,the inner pipe assembly does not rotate, so that the damage to the natural gas hydrate core caused by the mechanical force generated by the rotation of the drilling tool is avoided to a greater extent, and the core recovery rate, integrity and representativeness are more effectively improved.

Owner:JILIN UNIV

Downdraft biomass gasification reaction chamber and gasification process thereof

InactiveCN102329656BImprove gasification efficiencySafe and controllable operationEnergy inputCombustible gas productionFurnace temperatureMonitoring system

The invention relates to a downdraft biomass gasification reaction chamber and a gasification process thereof. The downdraft biomass gasification reaction chamber comprises an automatic feeding device, a gasification region consisting of a primary gasification region and a secondary gasification region which are integrated, an automatic leveling device, a vibration grate, an automatic ignition device, an automatic deslagging device, an in-furnace pressure regulating system, a furnace temperature monitoring system, an in-furnace material level monitoring system, an inlet and output gas temperature monitoring system, an inlet and outlet pressure monitoring system and a flame monitoring system. The production process comprises the following steps of: automatically feeding and introducing gas, primarily gasifying, secondarily gasifying, and automatically deslagging. The downdraft biomass gasification reaction chamber is scientific and environmentally-friendly, has the remarkable characteristics of reasonable structure design, high automation, stable and controllable gasification reaction, continuity and no interruption, has high gasification efficiency and high integral heat value, issuitable for large-area popularization, and especially can be applied to continuous and stable power generation of the existing gas generator.

Owner:张建超

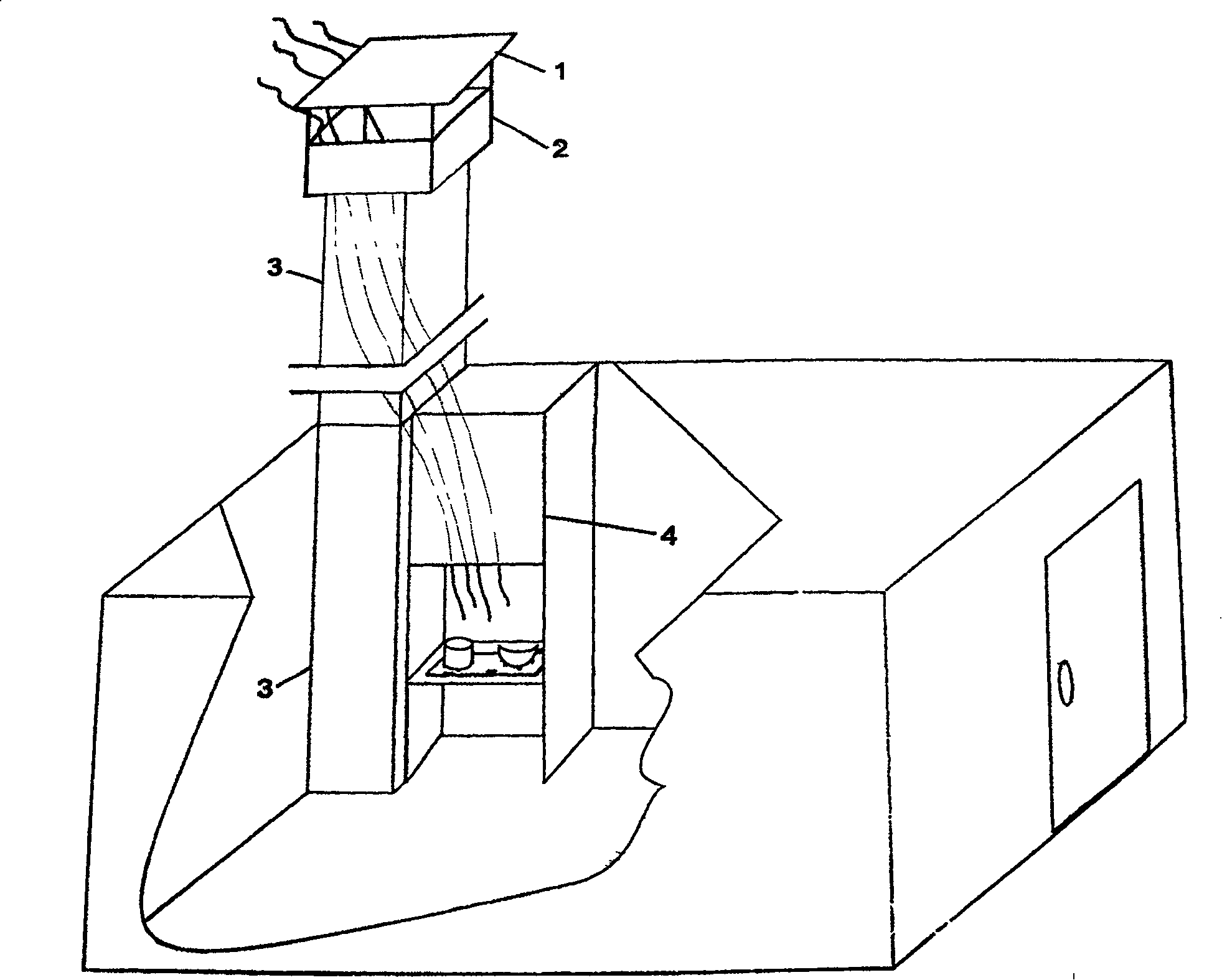

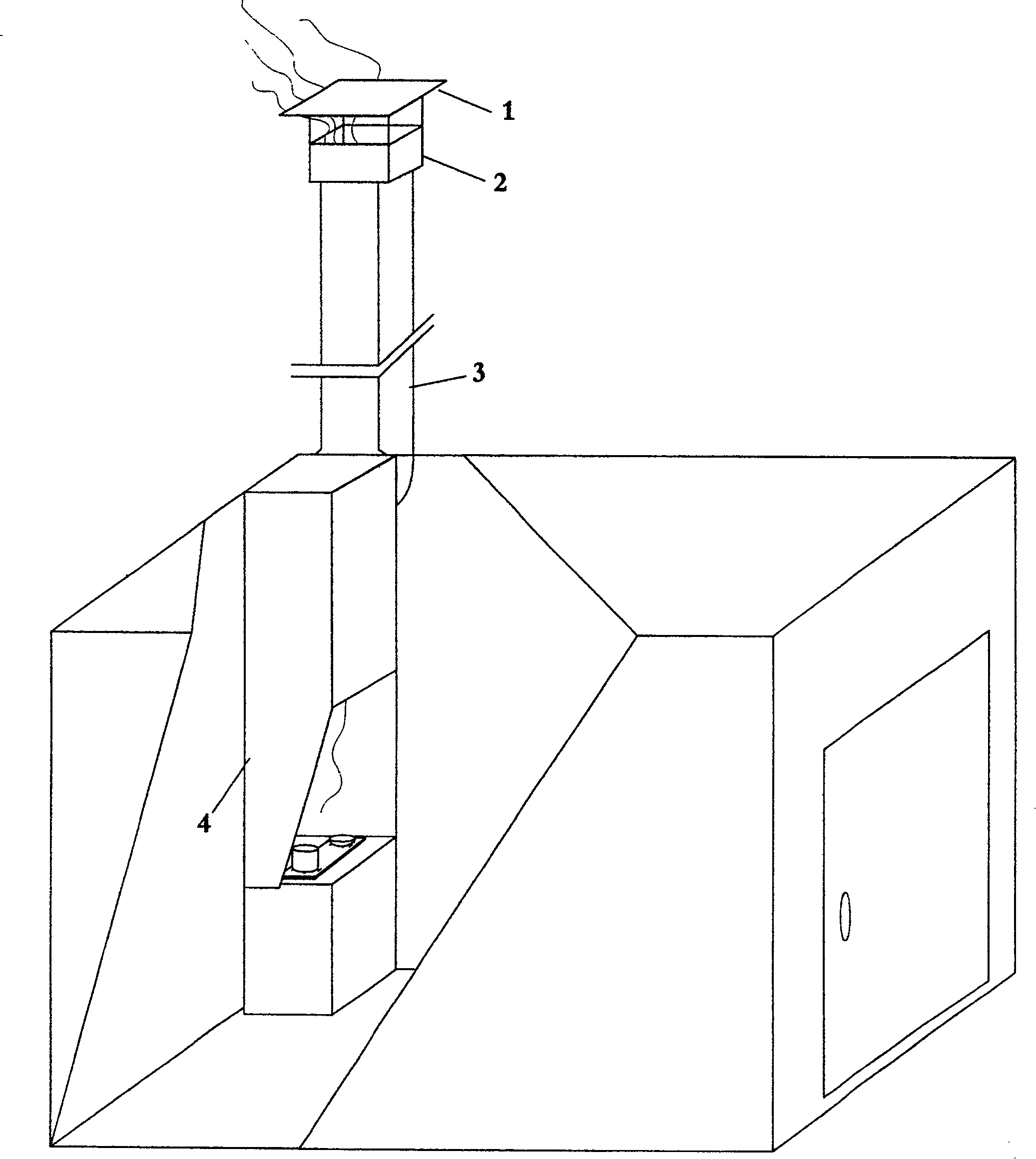

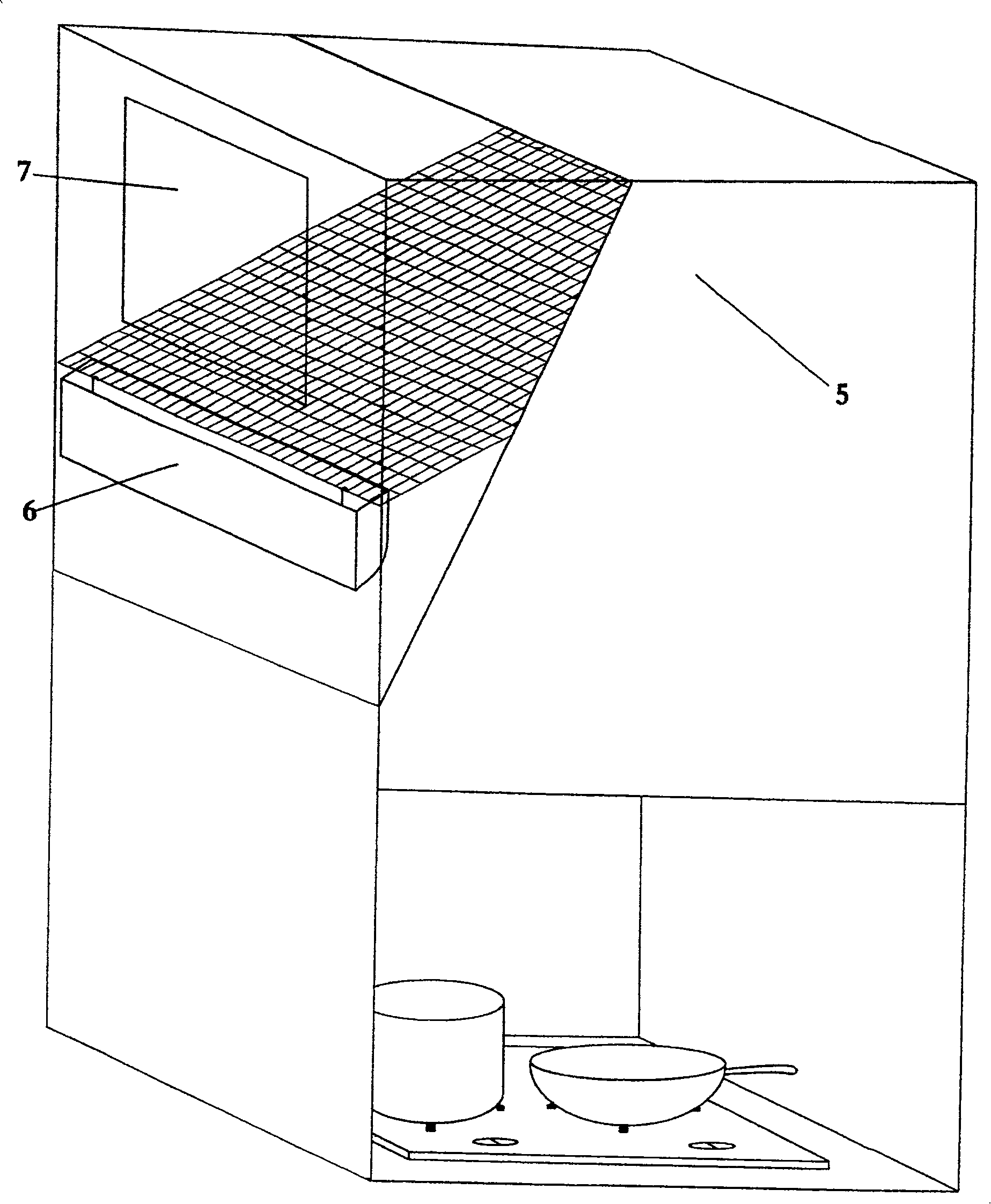

Kitchen automatic smoke discharging device

InactiveCN100404961CLarge volumeSufficient depthDomestic stoves or rangesLighting and heating apparatusThermal energyMechanical abrasion

This invention provides kitchen auto smoke evacuation device. It includes suction flue, breakwind deck, flashing, smoke collection cavity, oil guide net and oil sump. Its feature is that smoke evacuation is big, using is convenient, no needs of electrical energy and mechanism equipment, no economic consumption in smoke evacuation, no noise disturbing talk inside and outside house, no mechanical friction, no operation program, no unpick and wash program, no rest working capability, natural protection of cavity inner wall in the process of sucking oil smoke. It can full discharge oil smoke and discharging time is free, and the oil smoke discharged will not pollute house. Existing problem and defect of oil smoke discharging is fully solved, and its structure is simple, manufacturing is convenient, material source is wide, price is cheap, and product fabrication cost is low.

Owner:张俊岭

A bridge abutment seepage material sandless concrete block and its manufacturing process

ActiveCN103242009BSolve problems that cannot be dischargedImprove efficiencyAbutmentMaterials science

The invention discloses a water permeable material non-fine concrete block for a bridge abutment. The non-fine concrete block is characterized in that the non-fine concrete block is manufactured by mixing the following components in part by weight: 1 part of concrete, 0.32 to 0.33 part of water and 5.33 to 5.55 parts of stone. The manufacturing process comprises the following steps of: uniformly stirring the concrete, the water and the stones by using a forced stirrer; injecting a mixture into a standard template; sequentially performing vibration, forming and maintenance in the template; and removing the template. The non-fine concrete block and the manufacturing process have the advantages that the non-fine concrete block is an excellent water permeable material, and the problem of incapability of draining osmotic water during the conventional bridge abutment construction can be effectively solved; the non-fine concrete block is lower in volume to weight ratio, so that convenience is brought to transportation and construction; and waste non-fine concrete blocks can be crushed to form good coarse aggregate which can be recycled.

Owner:CHINA RAILWAY SHANGHAI ENGINEERING BUREAU GROUP CO LTD

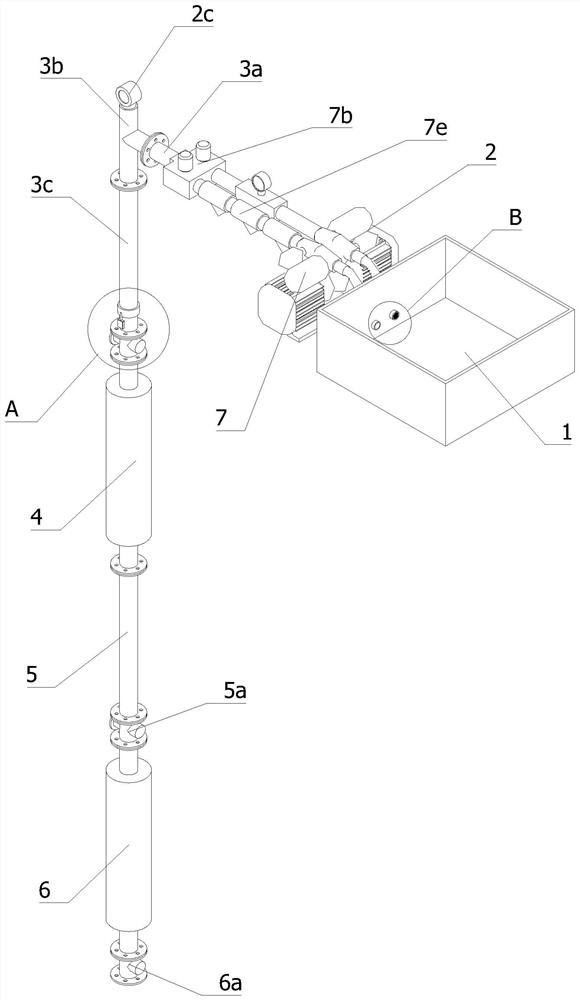

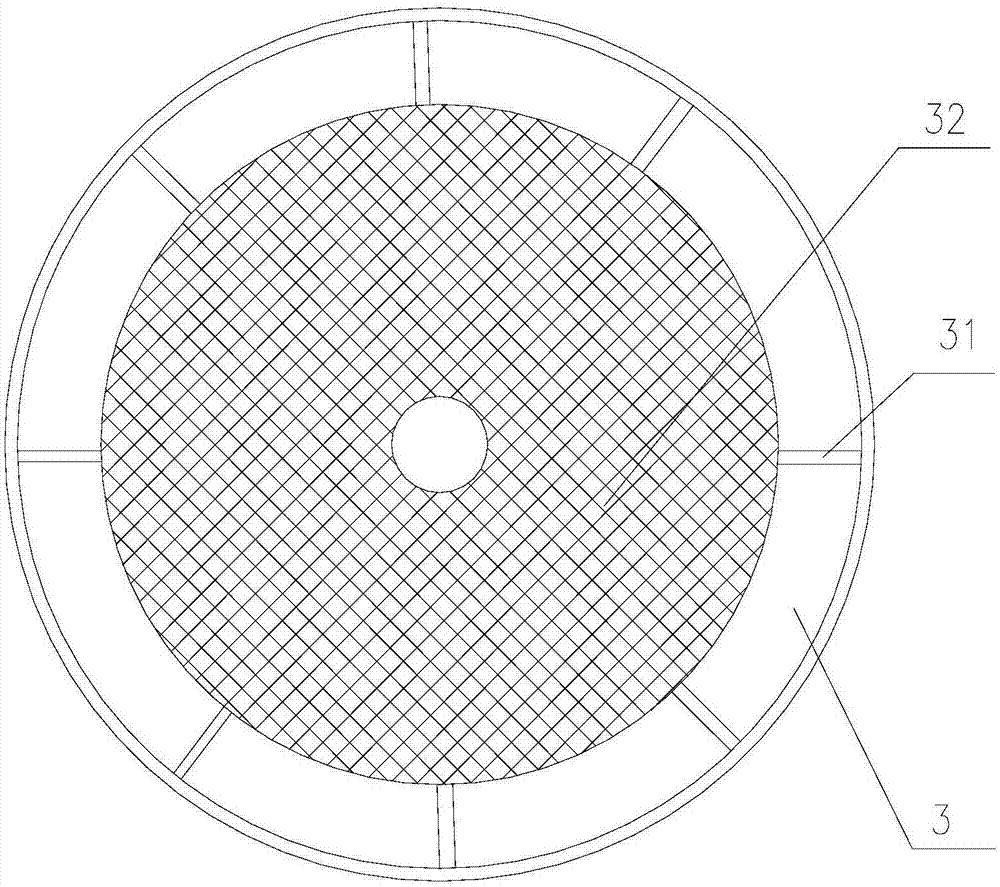

Pressure plate type lubrication pump convenient to exhaust

ActiveCN107035954AEasy dischargeSolve problems that cannot be dischargedLubricating pumpsConduits/junctionsProduct gasLubrication

The invention provides a pressure plate type lubrication pump convenient to exhaust. The pressure plate type lubrication pump comprises an oil bucket and an oil pumping assembly. The oil bucket is internally provided with a guide rod and is in sliding fit with a pressure plate along the guide rod. The edge of the pressure plate and the inner wall of the oil bucket are slidably sealed. An oil storage space of the lubrication pump is provided with an exhaust channel. Air inlets of the exhaust channel are located in the edge of the pressure plate. The exhaust channel extends towards the center of the pressure plate in the radial direction. According to the lubrication pump, the structures of the pressure plate and the guide rod are subjected to innovative design, the air inlets are formed in the edge of the pressure plate, thus, air in the oil storage space of the lubrication pump can be exhausted out only from the air inlets in the edge of the pressure plate so as to be exhausted completely, and the situation that oil is overflowed the pressure plate can be effectively avoided through the structure that the exhaust channel extends towards the center of the pressure plate in the radial direction. Through the lubrication pump, the problems that gas in an existing lubrication pump cannot be exhausted completely, and oil is discharged are solved, air is automatically exhausted while the oil is injected, and the exhaust effect is good.

Owner:重庆安特瑞润滑设备有限公司

Simple solar water heater

PendingCN106066099ANo wasteSolve problems that cannot be dischargedSolar heat devicesFailure rateSolar water

The invention discloses a simple solar water heater, which comprises a reflector, a heat collecting tube and a header. A reflector is installed under a horizontally arranged heat collecting tube. The side end is installed together with the heat collecting tube bracket arranged on the reflector, the bottom of the header is provided with the outlet pipe 2, the top of the header is provided with the water tank, the upper part of the water tank is provided with the water inlet pipe, and the lower part of the water tank is provided with the outlet pipe 1 , the header is also provided with a temperature sensor, the temperature sensor is connected to a controller, the outlet pipe is provided with a regulating valve, and the regulating valve is connected to the controller. The present invention has the advantages of reasonable design and simple structure. , Easy to process, small size, easy to use, low production cost, low failure rate, safe and reliable operation, etc., the water quality is good, non-toxic and tasteless, and the temperature sensor is used to control the temperature of the water in the box to ensure the temperature without causing energy waste. The water that has reached the water temperature is discharged to other places that need hot water through the controller, and at the same time, the problem that the scale cannot be discharged is solved.

Owner:陆远

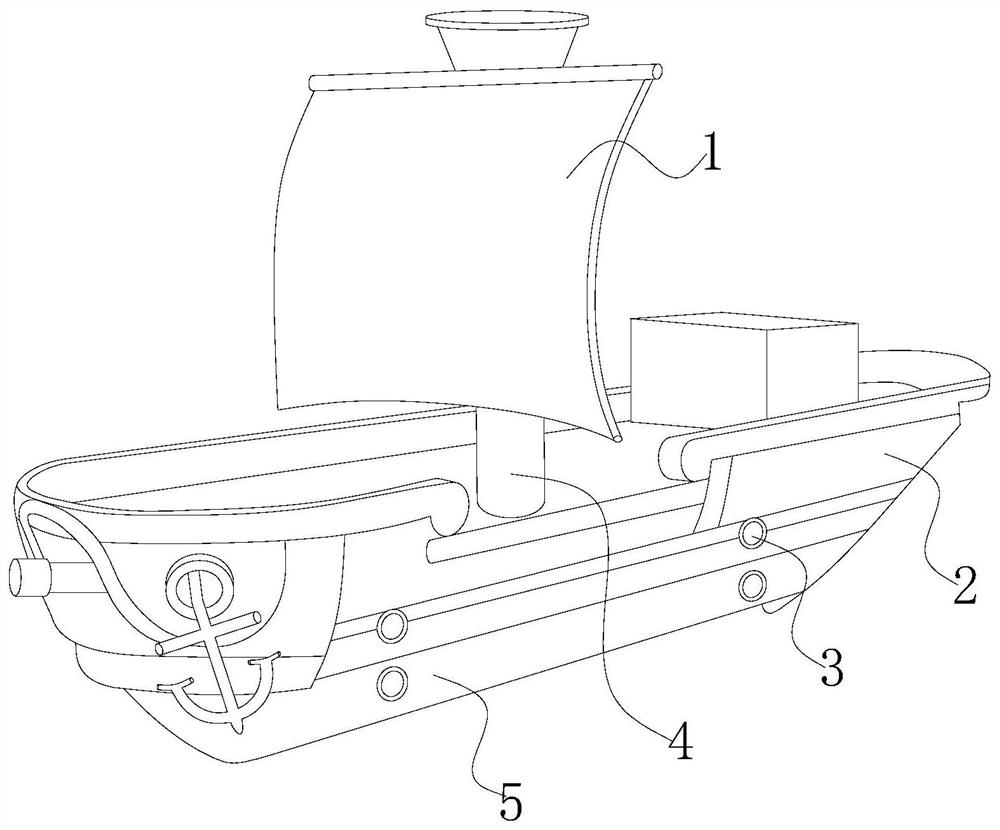

Ship ballast water exchange device with mobile and telescopic snap-in barrier airbag

ActiveCN109436281BSolve problems that cannot be dischargedAvoid mixingAuxillariesWater treatment installationsStructural waterHull

The invention discloses a ship ballast water exchange device with clamping type preventing an air bag from moving and stretching function, which comprises a sail, a hull, a water treatment device, a sail fixed column, a water carrying chamber; the sail fixed column is fixed to the hull; the sail fixed column is provided with the sail; the sail fixed column is fixed to the sail; the water carryingchamber is formed in the bottom of the hull and is integrated with the hull; the water treatment device is installed in the water carrying chamber. The device has the advantages of separating the newballast water from the original ballast water through the air bag plate, thus effectively avoiding the mixing of the new ballast water and the original ballast water; using the amount of the new ballast water to push the air bag plate to the direction of discharge so as to achieve the gradual replacement of the ballast water, thereby solving the problem that the original ballast water and the newballast water mix so as to result in some of the original ballast water cannot be discharged.

Owner:徐州天顾科技有限公司

Oil-sand separator and method for removing sand and sealing

InactiveCN100362208CSolve problems that cannot be dischargedNo pollution in the processFluid removalDrive motorCheck valve

The present invention relates to oil and sand separating machine and sand discharge and sealing method. Said separating machine includes base seat, oil inlet, oil outlet, drive motor, supporting frame, drum tumbler and drum tumbler shaft, several sand cavities, hanging ring, sealing bag, sand-discharging gate, flow deflector and check valve, etc. Said invention also provides their connection mode and mounting method. Besides, said invention also provides its working principle.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Building foundation field penetration test device and test method thereof

ActiveCN110018103ASolve the problem of working lifeSolve problems that cannot be dischargedPermeability/surface area analysisPore water pressureEngineering

The invention relates to the field of foundation penetration tests, and particularly relates to a building foundation field penetration test device and a test method thereof. The device comprises a water tank, a water pressing mechanism, a first water pipe, a first hydraulic plug, a second water pipe, a second hydraulic plug and a controller, wherein the water pressing mechanism comprises a pressure regulating water pump, a flow meter and a pressure gauge, the input port of the pressure regulating water pump is communicated with the water tank, the output port of the pressure regulating waterpump is installed with the flow meter, a first electromagnetic three-way valve is installed at the bottom end of the second water pipe, an electromagnetic valve is installed at the bottom end of the second hydraulic plug, and the first water pipe, the first hydraulic plug, the second water pipe, the first electromagnetic three-way valve, the second hydraulic plug and the electromagnetic valve aresequentially connected from top to bottom. By adopting the test device and the test method thereof, the problem that the residual debris in the hole affects test results can be solved, and meanwhile,the problem that air in a test area cannot be discharged can be solved, and the problem that the water pressure produced by a water column above the test area reduces the operating life of the hydraulic plugs can also be solved.

Owner:JIANGXI UNIV OF SCI & TECH

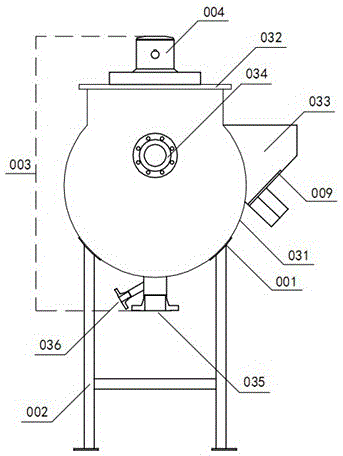

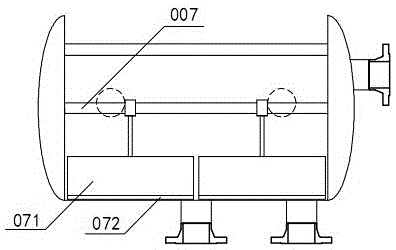

A horizontal heavy sludge flocculation reaction device

ActiveCN104276741BOvercome the situation of not being able to get out of the mudSmall footprintSludge treatment by de-watering/drying/thickeningWater/sewage treatment apparatusFlocculationSludge

The invention discloses a horizontal heavy sludge flocculation reaction device comprising a chassis support and a reaction device arranged on the support, wherein the reaction device comprises a U-shaped groove-like shell horizontally arranged on the support; the upper end inside the shell is provided with a cover body on which a reaction motor is arranged; the reaction motor is in transmission connection with one end of a main transmission shaft through a speed reducer and a chain wheel-chain group; the main transmission shaft is horizontally arranged in the shell; two ends of the main transmission shaft extend out of two ends of the shell and are fixed by using bearing blocks; at least one connecting plate arranged in the vertical direction is welded on the main transmission shaft; the tail end of the connecting plate is connected with a flow pushing paddle board; the side of the shell is provided with an inclined flocculate discharging chute which is welded on the shell and is internally provided with a mud cut-off plate; an overflow opening is formed in the end face of the shell; and a sewage inlet and a flushing water inlet are formed in the bottom of the shell. The horizontal heavy sludge flocculation reaction device is novel in structure, simple and convenient to maintain and capable of avoiding the condition that sludge is deposited and accumulated at the bottom after being flocculated.

Owner:JIANGSU SAIOU ENVIRONMENTAL PROTECTION EQUIP

water heater drainage system

ActiveCN110895046BSolve problems that cannot be dischargedAvoid wasted situationsFluid heatersHydrologyThermal water

The invention discloses a drainage system for a water heater, which comprises a hot water pipe A, a cold water pipe, and a water mixing valve. The ends of the hot water pipe A and the cold water pipe respectively correspond to the hot water port and the cold water port of the water mixing valve in airtight and fixed communication; Including: joint pipe A, joint pipe B, hot water pipe B, air intake pipe, reversing ball block, rotating column cable, torsion spring, bearing, water distribution pipe; the inner cable connecting the cable to the mixing valve adjustment handle retracts, The inner line end connected by the cable and the rotating column is rotated and reset together with the rotating column under the action of the torsion spring. At this time, the reversing ball rotates from the position blocking the intake pipe to the position blocking the hot water pipe A. At this time, the electric water tank Hot water can no longer enter the hot water pipe A, and the outside air enters the air intake pipe to continue to press down the hot water inside the hot water pipe A, and the hot water inside the hot water pipe A is discharged from the water distribution pipe, which solves the current problem of hot water in winter. The hot water in the water pipe cannot be discharged after the water mixing valve is closed.

Owner:ZHENJIANG BODE ELECTRIC EQUIP CO LTD

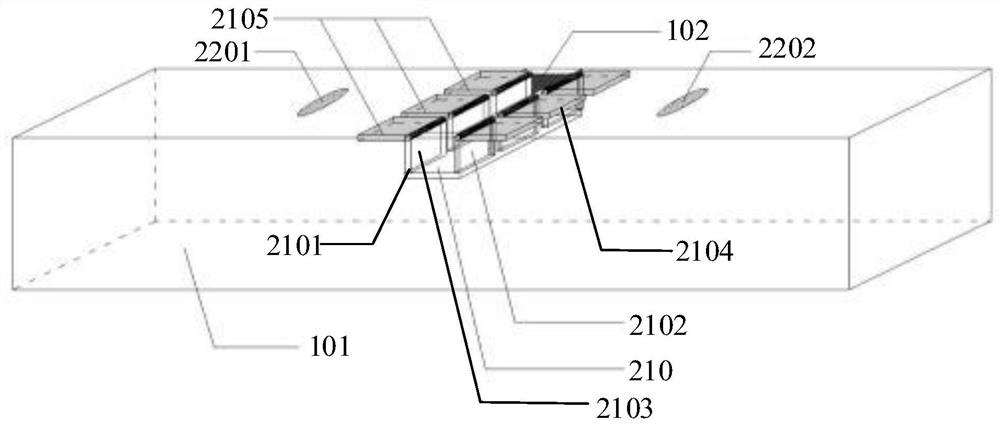

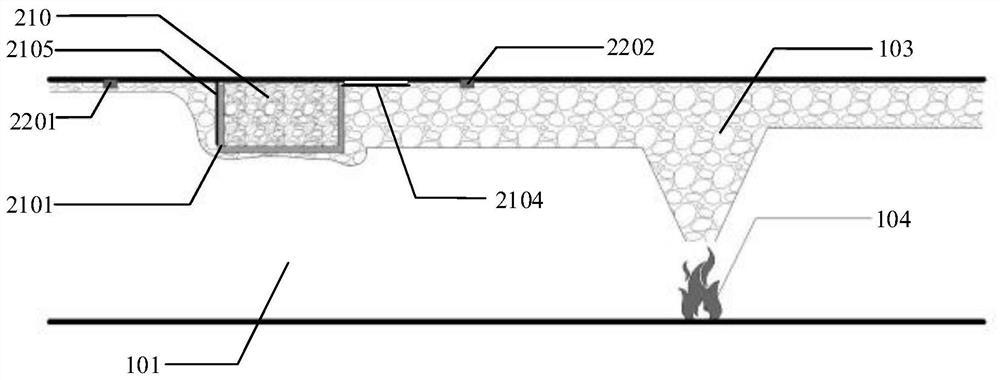

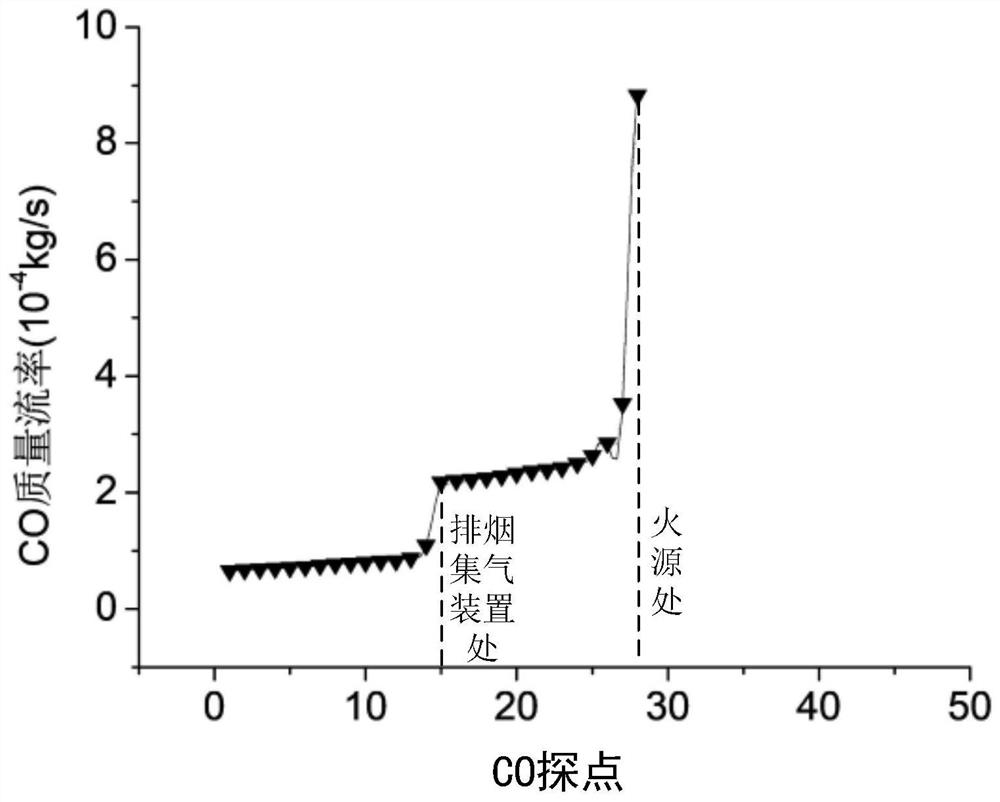

Lateral smoke discharging and gas collecting device

ActiveCN113503182ASolve problems that cannot be dischargedAvoid spreadingMining devicesTunnel/mines ventillationThermodynamicsEngineering

The invention discloses a lateral smoke discharging and gas collecting device. The lateral smoke discharging and gas collecting device comprises a gas collecting pipe and a detector set, wherein the gas collecting pipe is arranged in the transverse direction of a tunnel, fixed to the top of the tunnel and connected with a side wall smoke discharging opening of the tunnel; the gas collecting pipe is used for collecting hot smoke and conveying the hot smoke to the side wall smoke discharging opening when a fire disaster occurs; and the detector set is arranged at the top of the tunnel, connected with the gas collecting pipe and used for detecting the hot smoke so as to control opening and closing of the gas collecting pipe. According to the lateral smoke discharging and gas collecting device, the hot smoke with the whole cross section width at the top of the tunnel can be sucked through the gas collecting pipe and conveyed to the side wall smoke discharging opening so as to be discharged out of the tunnel, and thus the problem that in the prior art, a large amount of hot smoke on the side away from the side wall smoke discharging opening cannot be discharged is solved.

Owner:SHANGHAI MARITIME UNIVERSITY

A battery cabinet of a substation and distribution station using a constant temperature and temperature adjustment device

ActiveCN104752792BDoes not affect the basic structureEasy to transformSecondary cellsTemperature controlElectricity

The invention relates to a storage battery cabinet with a constant-temperature adjusting device for a power transformer and distribution station, belonging to the field of direct-current power supplies of power transformer and distribution stations, wherein a cabinet type air conditioning device is arranged outside the upper part of a front opening door or a rear opening door of the cabinet body; an air inlet and an air outlet of the cabinet type air conditioning device are arranged to pass through the front opening door or the rear opening door towards the interior of the cabinet body of the storage battery cabinet; an electric heating gas atomization device is arranged outside the lower part of the front opening door or the rear opening door; a condensate water discharging pipe of the cabinet type air conditioning device is connected with the electric heating gas atomization device; an air exchange fan is arranged on the top of the cabinet body; a turnover electric air exchange valve is arranged at the air inlet end of the air exchange fan; and the air inlet end of the air exchange fan is communicated with the interior of the cabinet body of the storage battery cabinet through the turnover electric air exchange valve. According to the invention, constant temperature and ventilation of the storage battery cabinet can be kept; the problem that condensate water generated by the constant-temperature storage battery cabinet in the operation process cannot be discharged can also be solved; the operation service life of a storage battery can be greatly prolonged; simultaneously, the capacity of the storage battery can also be ensured; and operation safety and reliability of a power grid can be easily ensured.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO

A biomass boiler slag breaking device

InactiveCN104344412BSolve the problem that coking cannot be cleanedSolve problems that cannot be dischargedLighting and heating apparatusSolid fuelBoiler slag

The invention discloses a cinder breaking device for a biomass boiler, belongs to the technical field of solid fuel burning, is applied to biomass boilers for burning of biomass granular fuel, and actively breaks and burns clinker. The device is installed in the hearth of the biomass boiler, and comprises a water inlet pipe, a water outlet pipe, cinder breaking teeth and a cooling water pipe, is horizontally placed in the hearth of the biomass boiler, and is perpendicular to a chain fire grate; the distance between the device and the fire grate is smaller than 5 mm; burning fuel and cinder move with the movement of the chain fire grate; the burnt coked cinder is broken through the cinder breaking device and then discharged. The cinder breaking device solves the problem that the cinder of biomass granular fuel is coked after being burnt, can greatly improve the efficiency and prolong the service life of the biomass boiler, and facilities promotion of the industrialization effect of straw biomass granular fuel, the coal is replaced with biomass granular fuel, and the cinder breaking device has good economic, social and environmental benefits.

Owner:ACADEMY OF PLANNING & DESIGNING OF THE MINIST OF AGRI

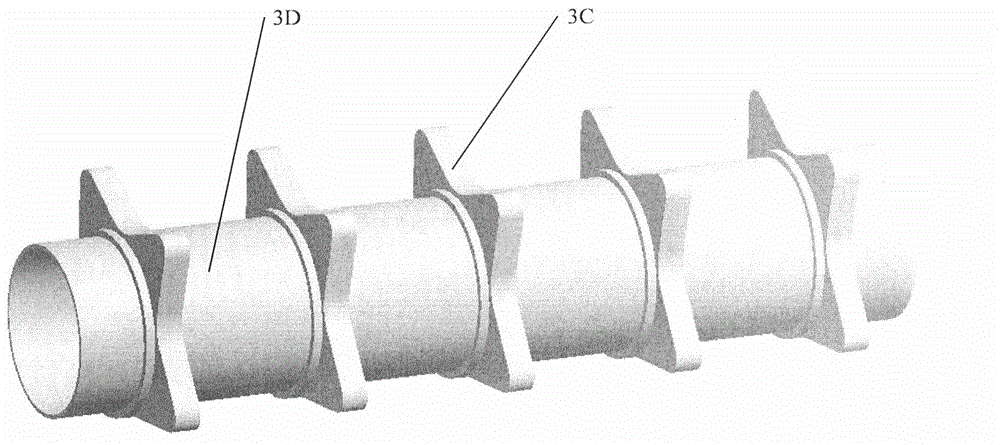

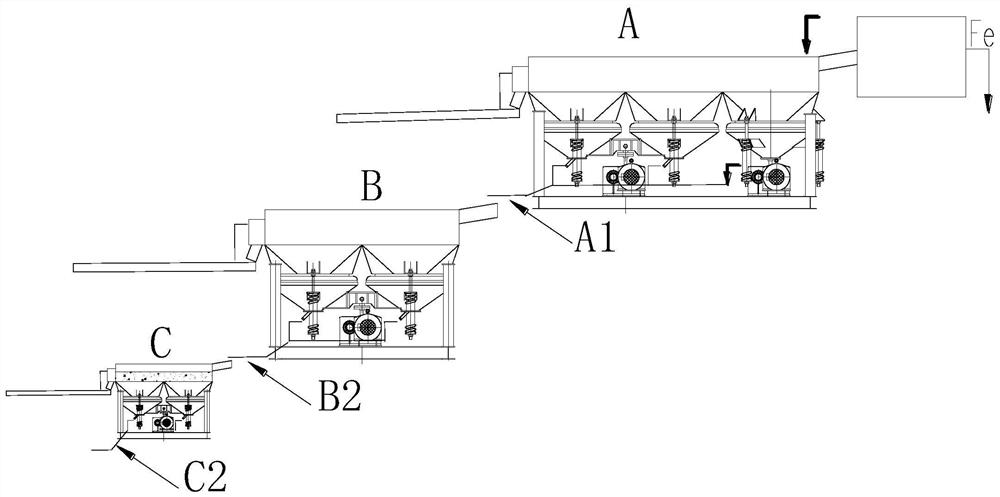

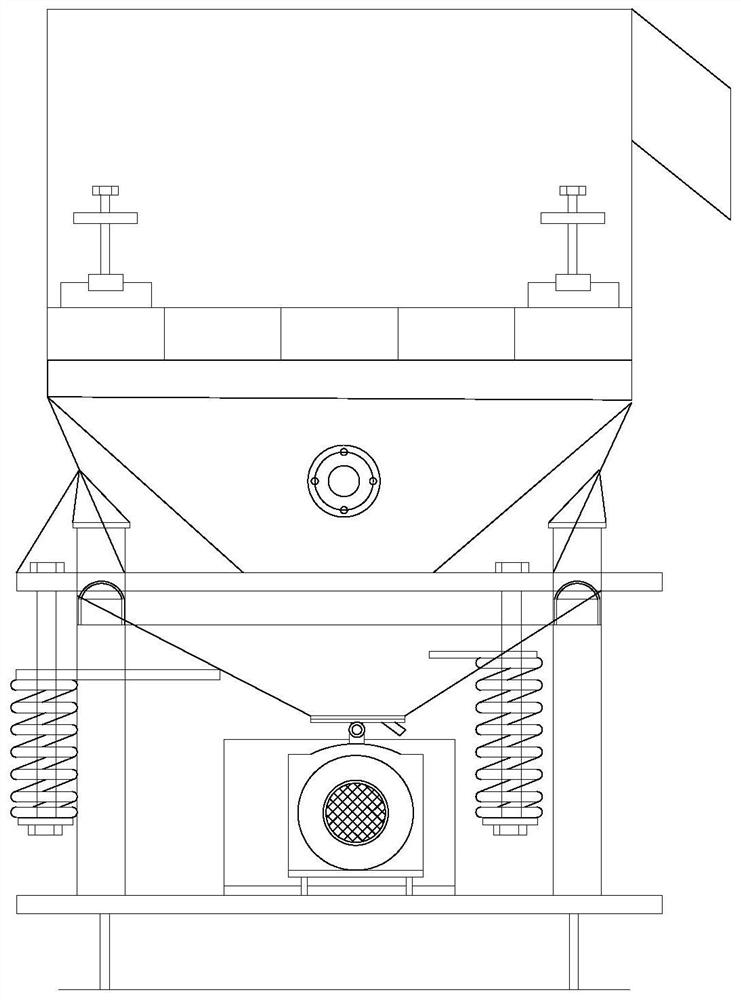

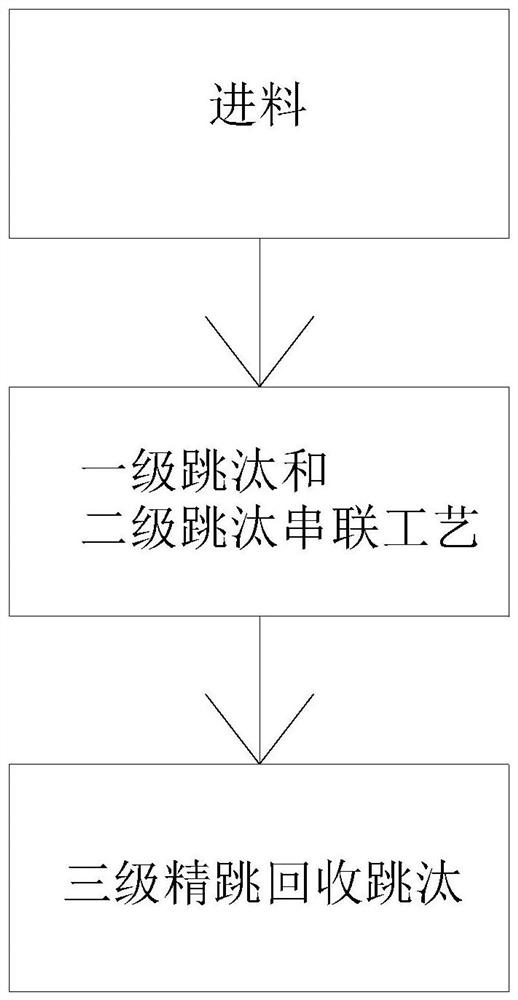

Tandem type jigger system capable of improving sorting efficiency of household garbage incinerator slag

The invention discloses a tandem type jigger system capable of improving sorting efficiency of household garbage incineration slag, and relates to the technical field of jiggers. The system comprises the following steps: 1, feeding material into the tandem type jigger system, 2, carrying out a first-stage jigging A and second-stage jigging tandem process on the fed material, 3, carrying out third-stage concentrate recovery jigging, sawtooth waves firstly rise in a straight line, then steeply fall, then rise and then steeply fall, and the process is repeated, so that water is used as a mineral separation medium, and separation is carried out according to the specific gravity (density) difference of useful minerals and gangue. According to the system, a third stage uses two special one-square-meter jiggers which are cascaded into a two-square-meter jigger with a bed, a special iron ore cushion layer is laid on the screen surface, tailings are directly discharged to enter closed-loop beneficiation, water is directly discharged after a concentrate is separated through a three-stage desilting sand water hopper, and copper sand is directly recycled from a concentrate in a sedimentation hopper, the separation efficiency of the jigger in gravity separation is improved, and the working efficiency of the equipment process is improved.

Owner:广东绿富域资源再生科技有限公司

Pressure plate type lubrication pump for easy exhaust

ActiveCN107035954BEasy dischargeSolve problems that cannot be dischargedLubricating pumpsConduits/junctionsProduct gasLubrication

The invention provides a pressure plate type lubrication pump convenient to exhaust. The pressure plate type lubrication pump comprises an oil bucket and an oil pumping assembly. The oil bucket is internally provided with a guide rod and is in sliding fit with a pressure plate along the guide rod. The edge of the pressure plate and the inner wall of the oil bucket are slidably sealed. An oil storage space of the lubrication pump is provided with an exhaust channel. Air inlets of the exhaust channel are located in the edge of the pressure plate. The exhaust channel extends towards the center of the pressure plate in the radial direction. According to the lubrication pump, the structures of the pressure plate and the guide rod are subjected to innovative design, the air inlets are formed in the edge of the pressure plate, thus, air in the oil storage space of the lubrication pump can be exhausted out only from the air inlets in the edge of the pressure plate so as to be exhausted completely, and the situation that oil is overflowed the pressure plate can be effectively avoided through the structure that the exhaust channel extends towards the center of the pressure plate in the radial direction. Through the lubrication pump, the problems that gas in an existing lubrication pump cannot be exhausted completely, and oil is discharged are solved, air is automatically exhausted while the oil is injected, and the exhaust effect is good.

Owner:重庆安特瑞润滑设备有限公司

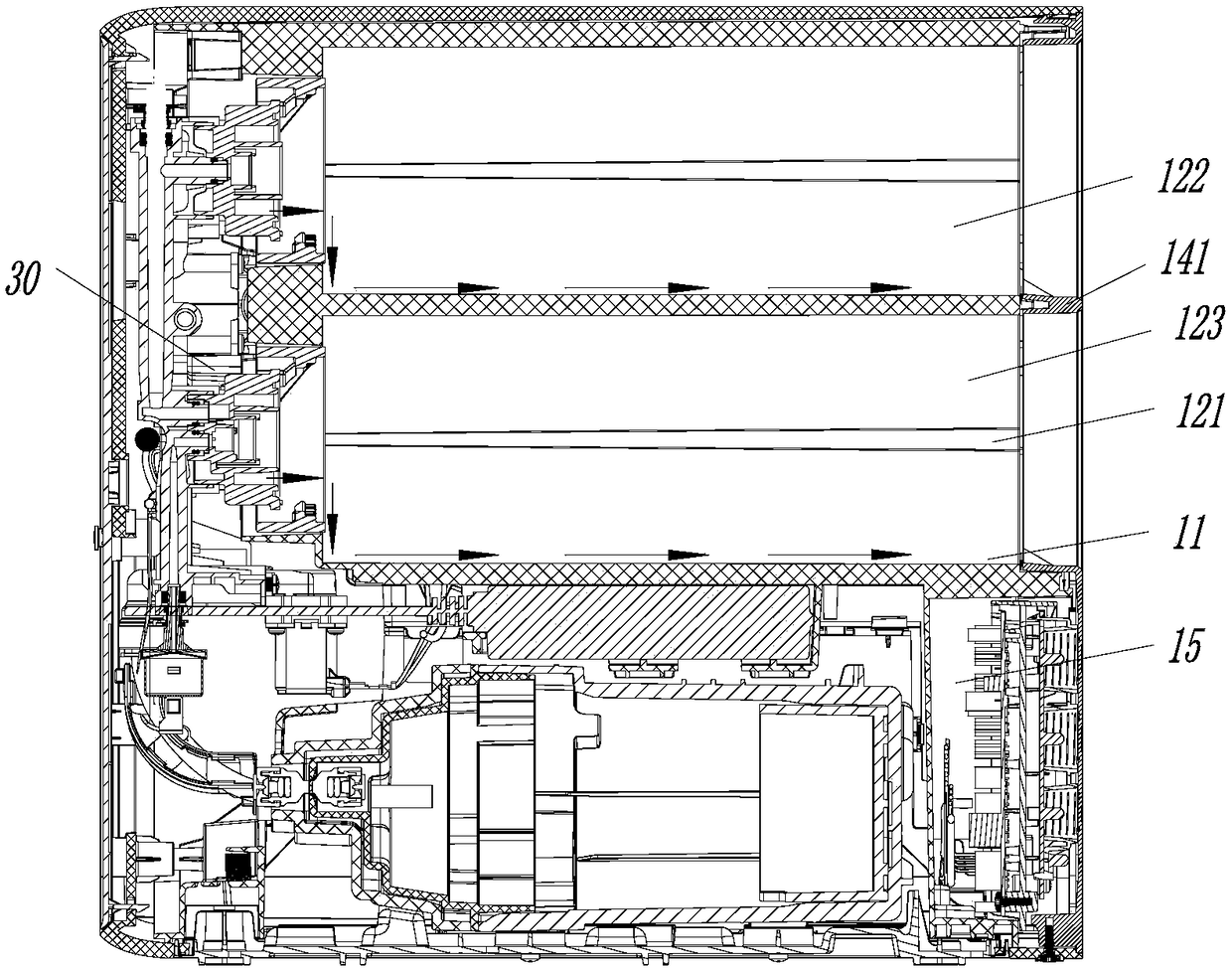

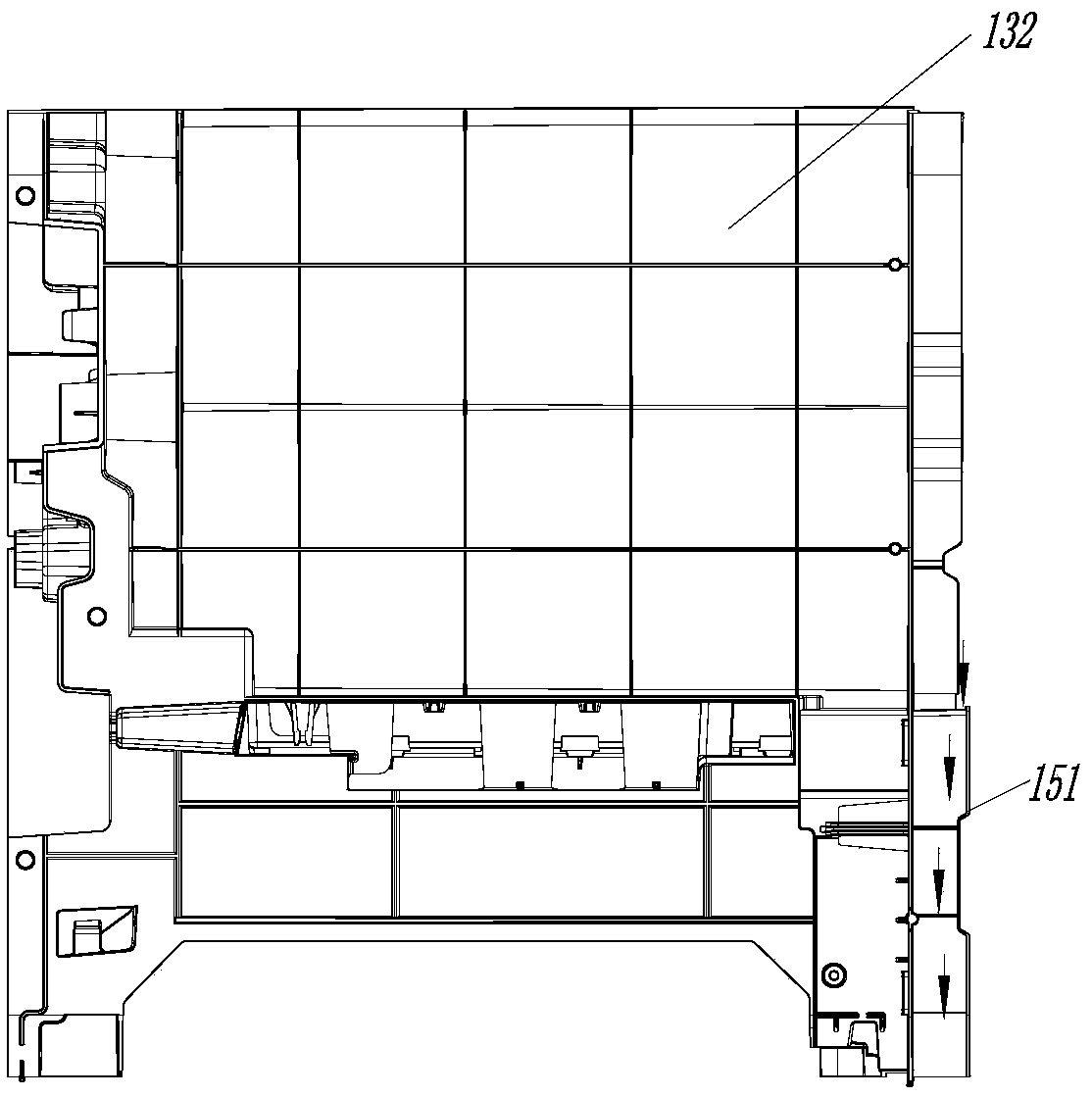

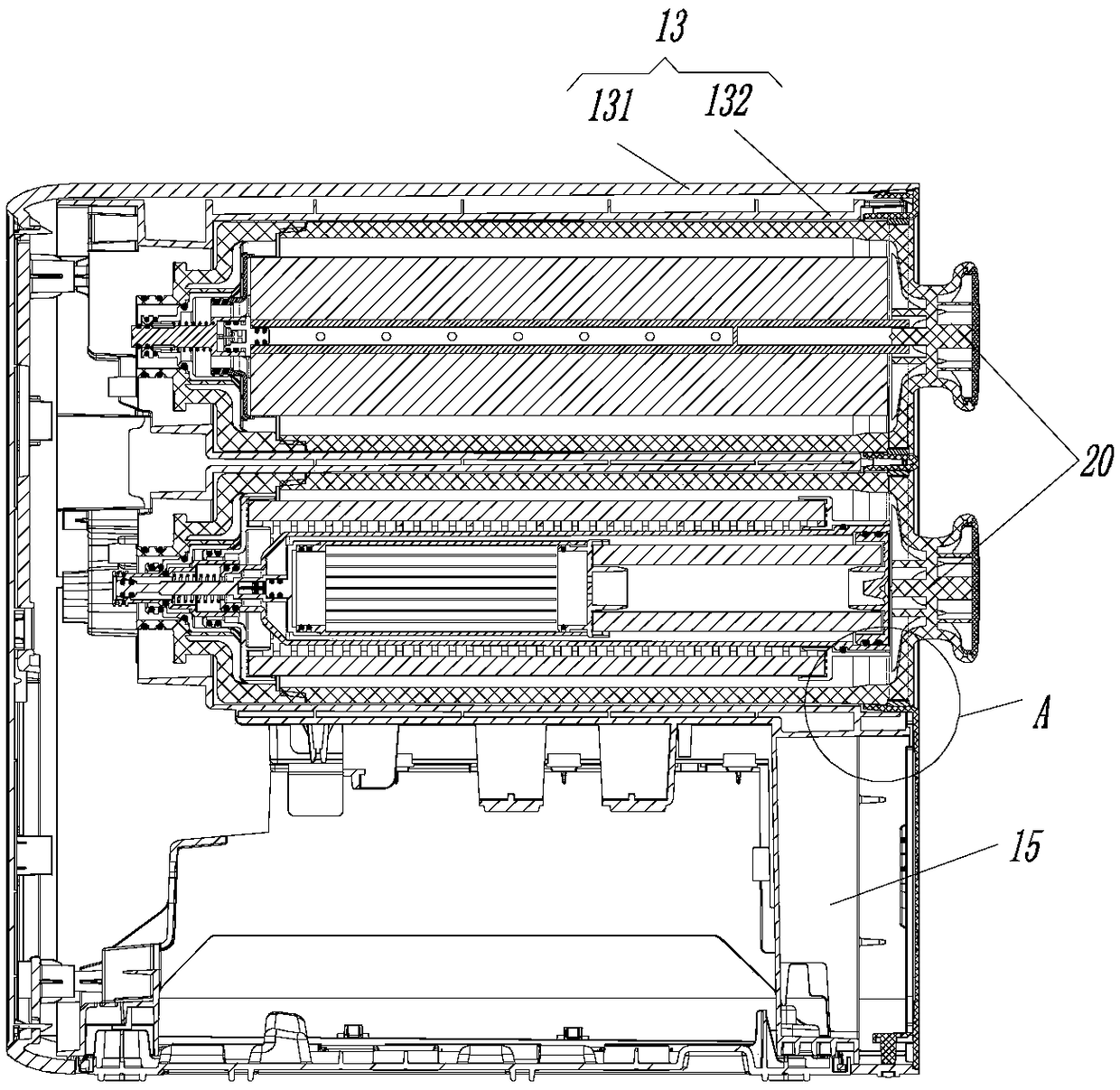

Horizontal water purifier shell and horizontal water purifier comprising the same

ActiveCN109011814ASolve problems that cannot be dischargedAvoid breedingFiltration separationEnvironmental engineeringEngineering

Owner:GREE ELECTRIC APPLIANCES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com