Kitchen automatic smoke discharging device

A fume extractor and automatic technology, applied in the fields of oil fume removal, household heating, lighting and heating equipment, etc., can solve problems such as affecting language communication, inability to discharge oil fume, noise interference, etc., achieving a wide source of materials and solving dry noise. Interference, large volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

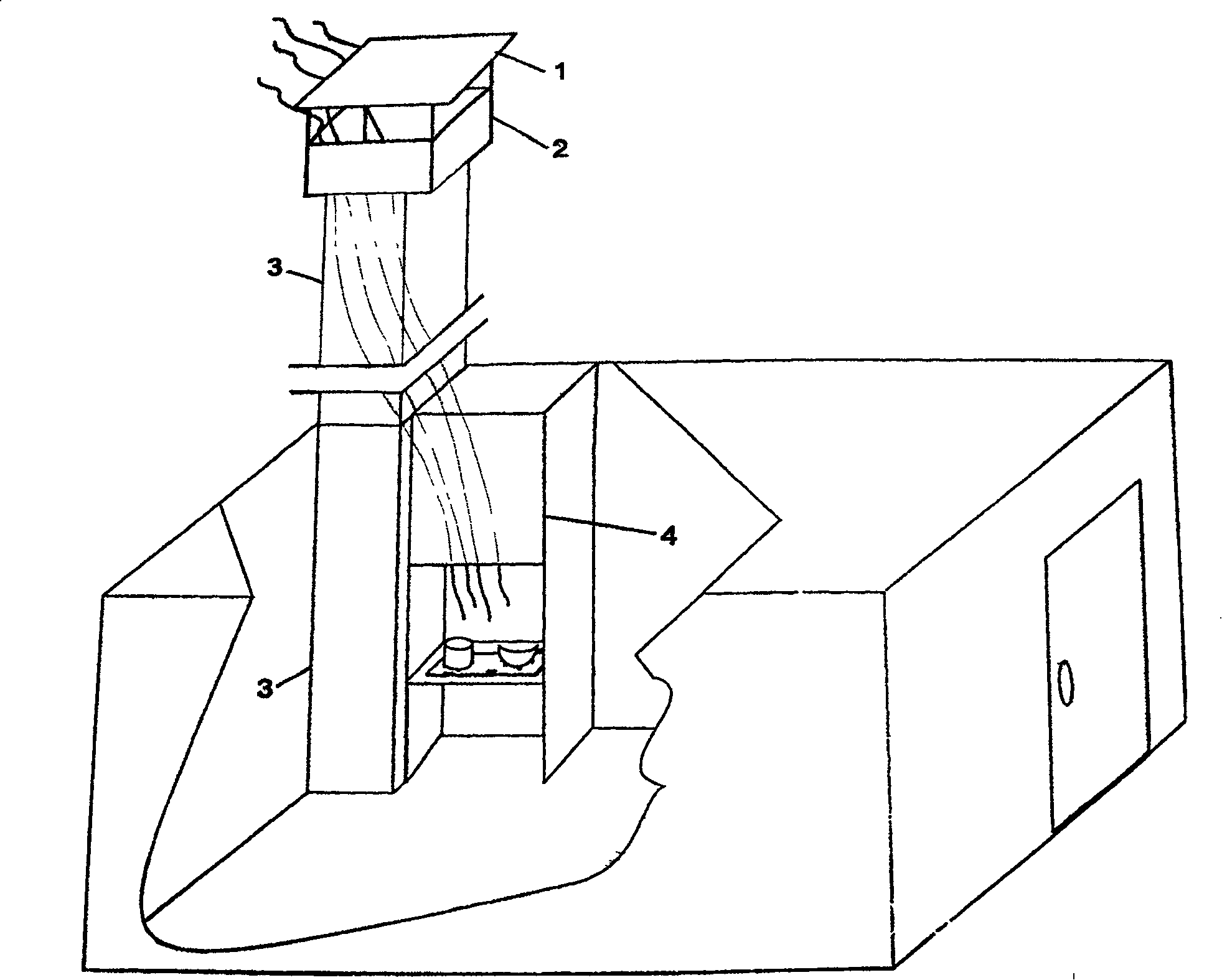

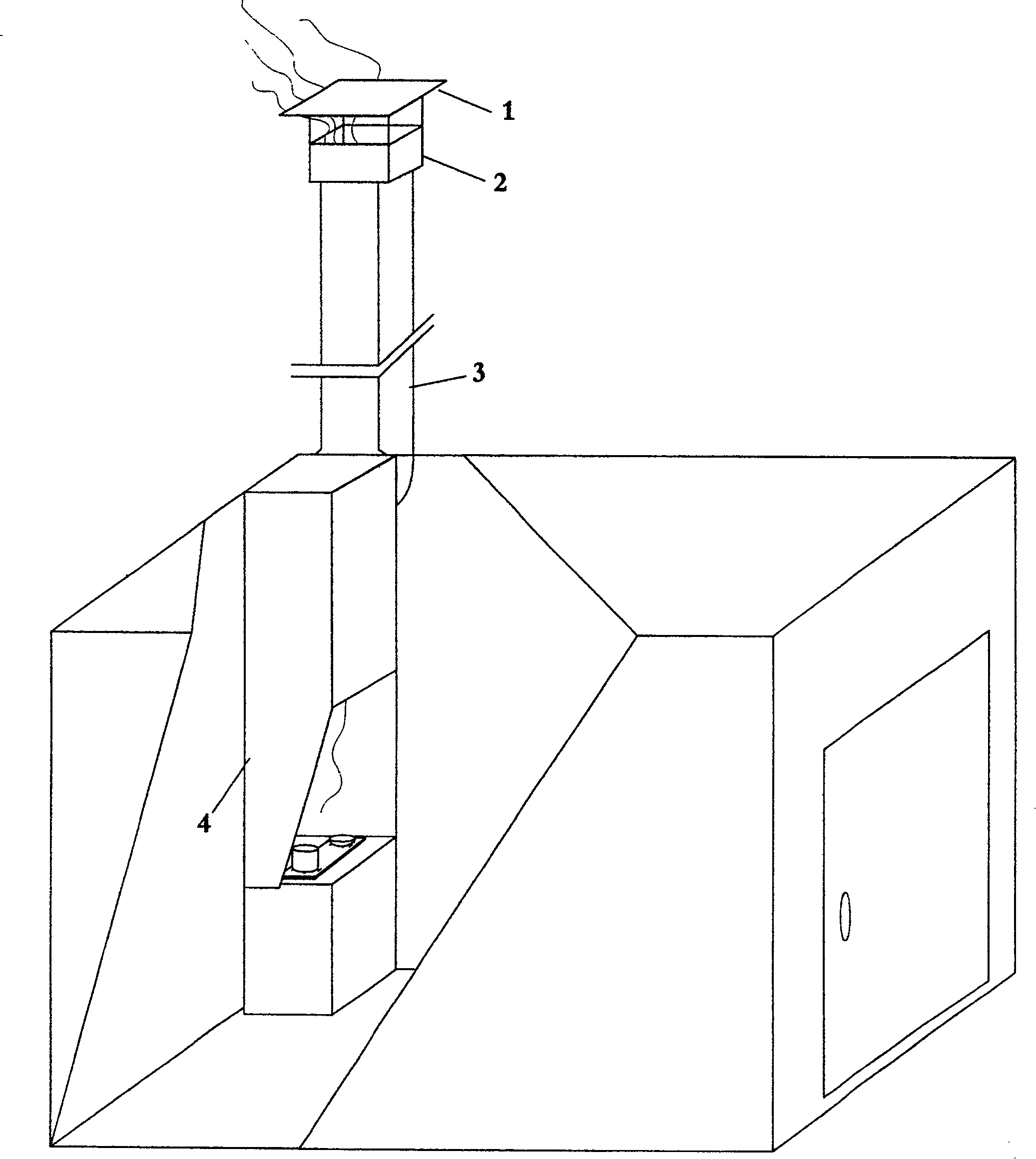

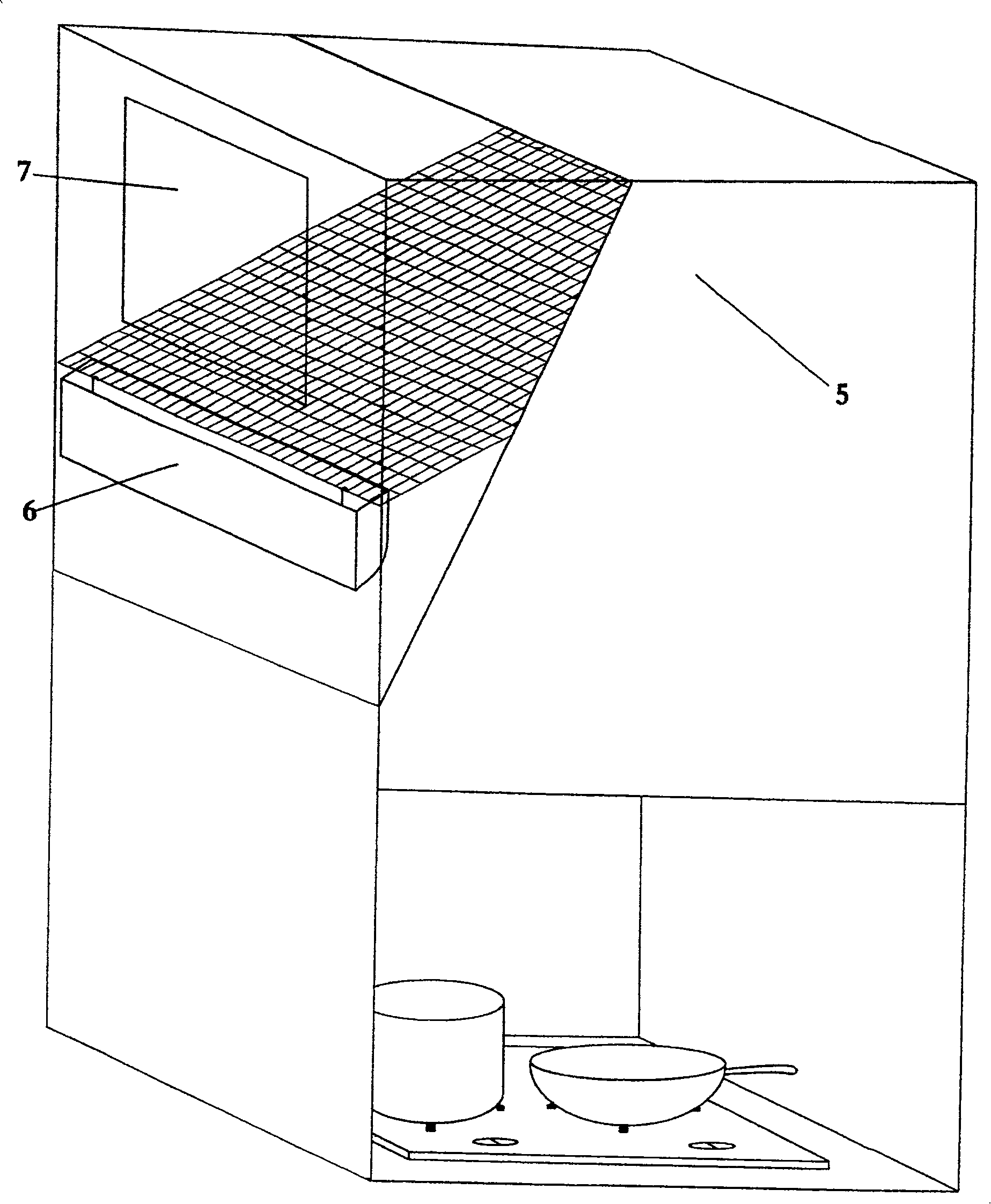

[0008] figure 1 and figure 2 As shown, the smoke collecting chamber 4 is made of thin materials such as glass plastic board or aluminum iron sheet; the material of the smoke collecting chamber on the back and side of the stove can be directly replaced by a wall, and the other two sides are made of glass plastic board or aluminum sheet. After the material such as iron sheet is formed, it is installed vertically above the stove and connected to the side wall as a whole, and the surrounding gaps are sealed; the bottom edge of the cooking operation port of the smoke collection chamber starts from the stove top and ends at the top edge so as not to hinder the cooking operation The position of the oil fume is based on the position in the entrance of the smoke collection cavity obtained by its own power (the lower the height of the cooking operation port, the stronger the smoke collection and smoking function), the height of the smoke collection cavity is from the stove top to the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com