Patents

Literature

48results about How to "Increase the export area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

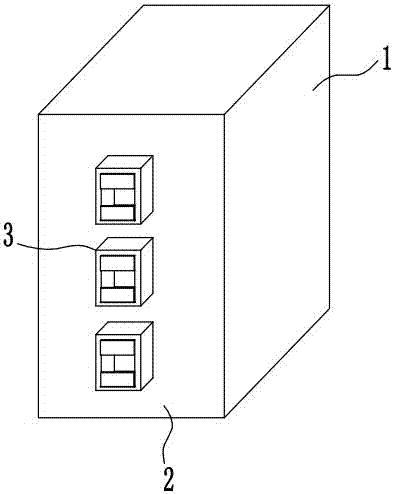

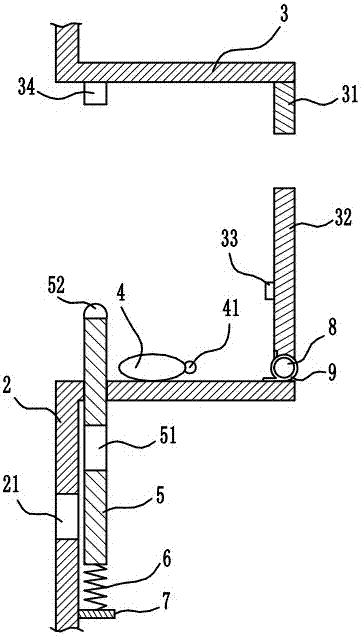

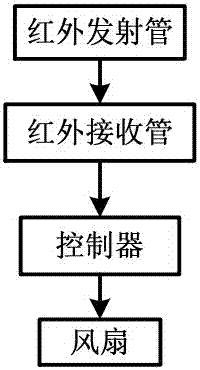

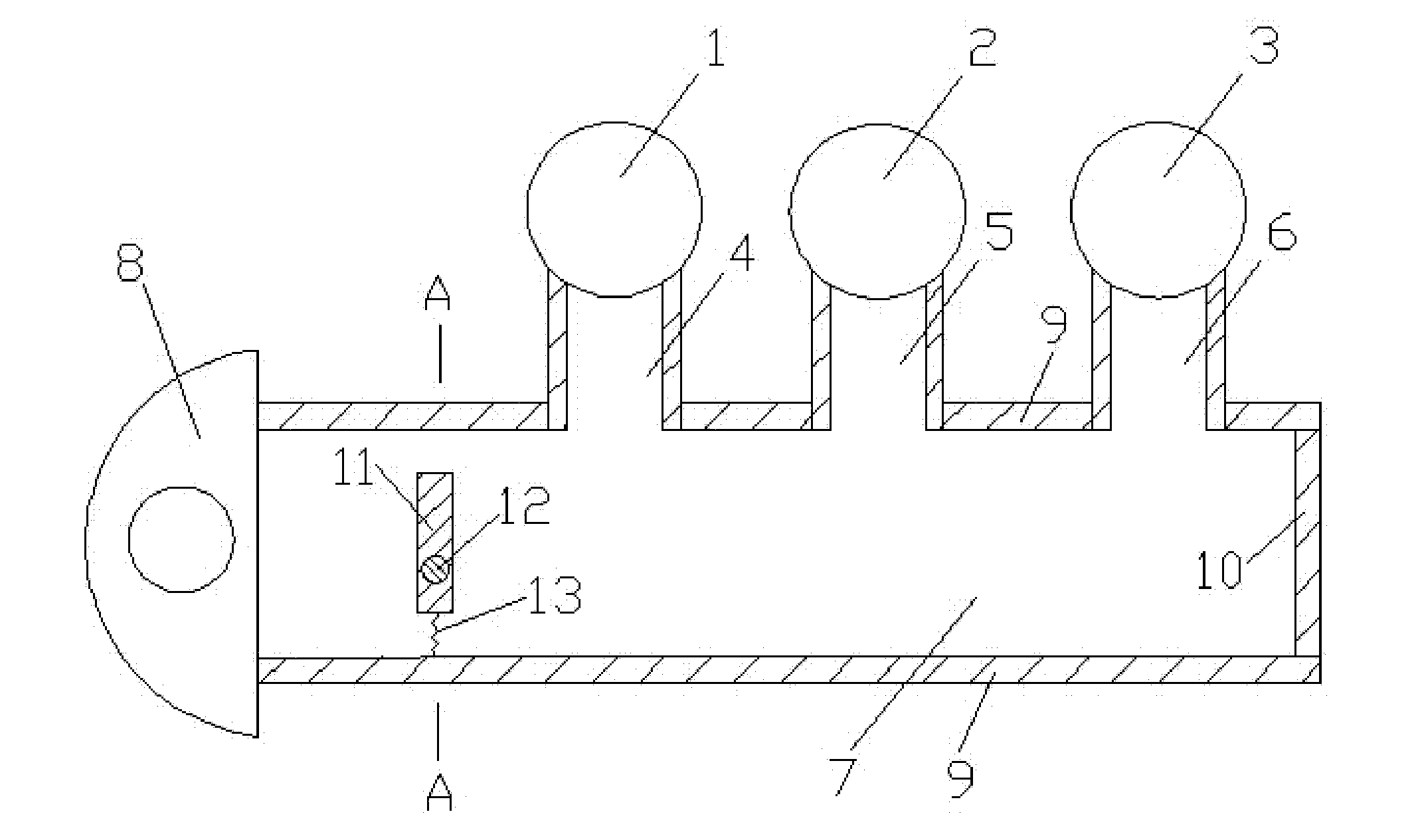

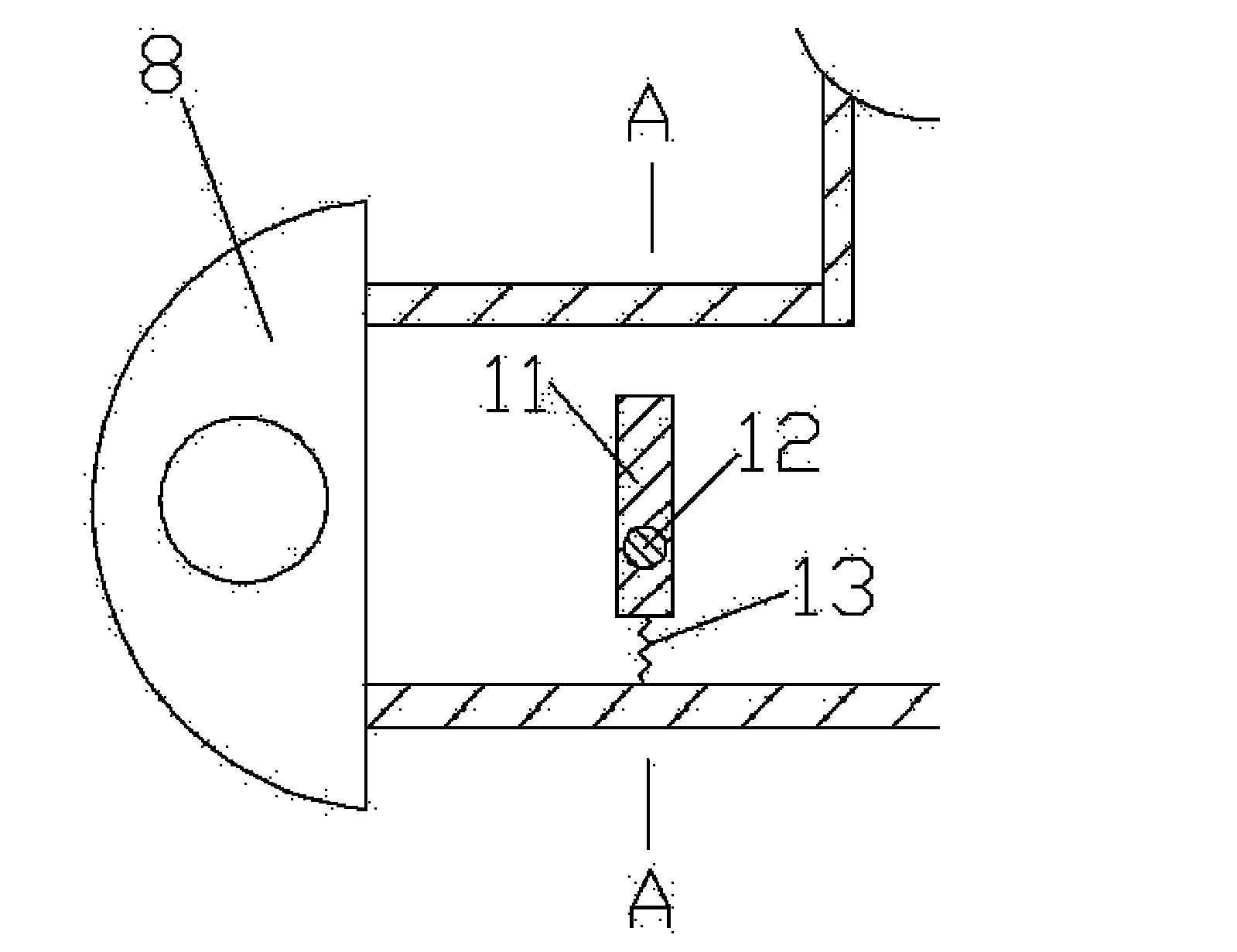

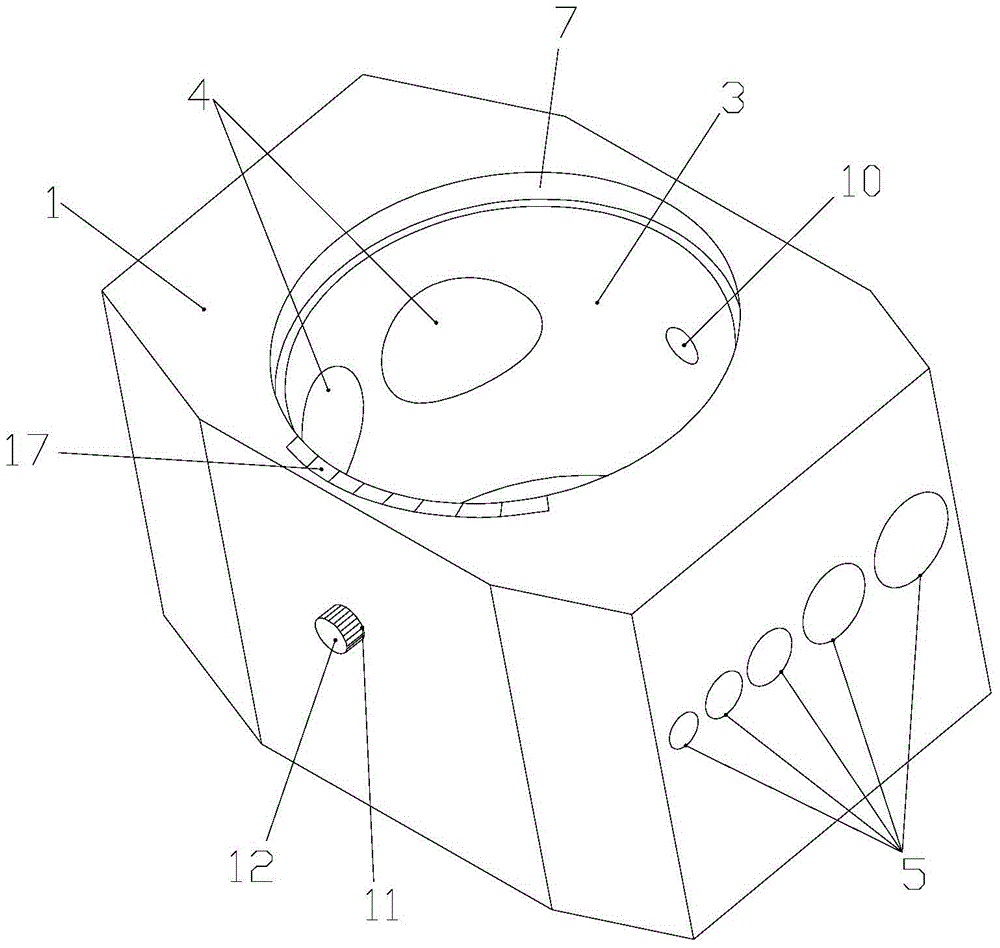

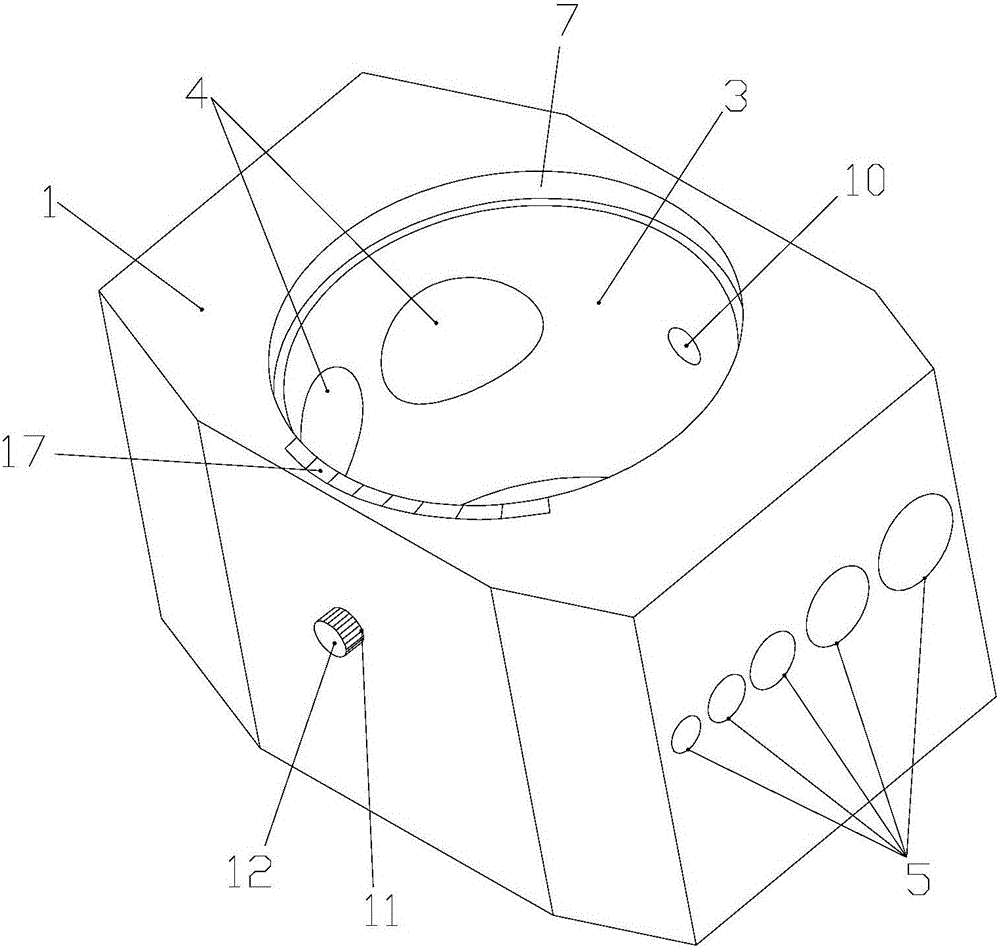

Distribution box capable of automatically dissipating heat

ActiveCN107579446APrevent suckingGuaranteed suctionSubstation/switching arrangement cooling/ventilationInfrared emitterElectromagnet

The invention relates to the technical field of electrical accessories, in particular to a distribution box capable of automatically dissipating heat. The distribution box comprises a box body and a box cover on the box body, a fan is arranged in the box body, and a plurality of heat dissipation holes protruding from the surface of the box cover are formed in the position, close to a heat source,of the box cover; each heat dissipation hole is provided with a fixing plate and a moving plate capable of automatically returning, an electromagnet is fixed to the side, toward the inner wall of thecorresponding heat dissipation hole, of each moving plate, an air bag is fixed to the inner wall of each heat dissipation hole, and an iron block attracting the corresponding electromagnet during heating expansion of the air bag is fixed to the air bag; an infrared emitter and an infrared receiver which can be covered by the corresponding moving plate are arranged on the inner wall of each heat dissipation hole, and each infrared receiver is used for receiving the infrared rays of the corresponding infrared emitter; the distribution box further comprises a controller, and the controller is used for controlling the fan to improve the rotational speed based on the signals of the infrared receivers. According to the distribution box, while the moving plates are adsorbed to the air bags to enlarge the heat dissipation holes, increase of the rotational speed of the fan is controlled to accelerate heat dissipation, and more heat is conducted out of the distribution box with the air by the enlargement of the heat dissipation holes, so that the heat dissipation effect is better.

Owner:广东智信电气有限公司

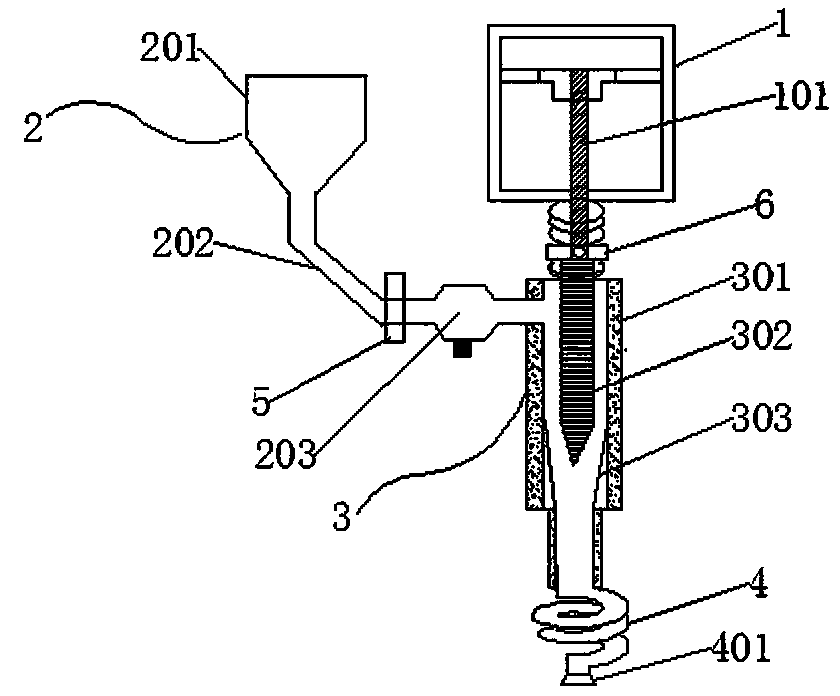

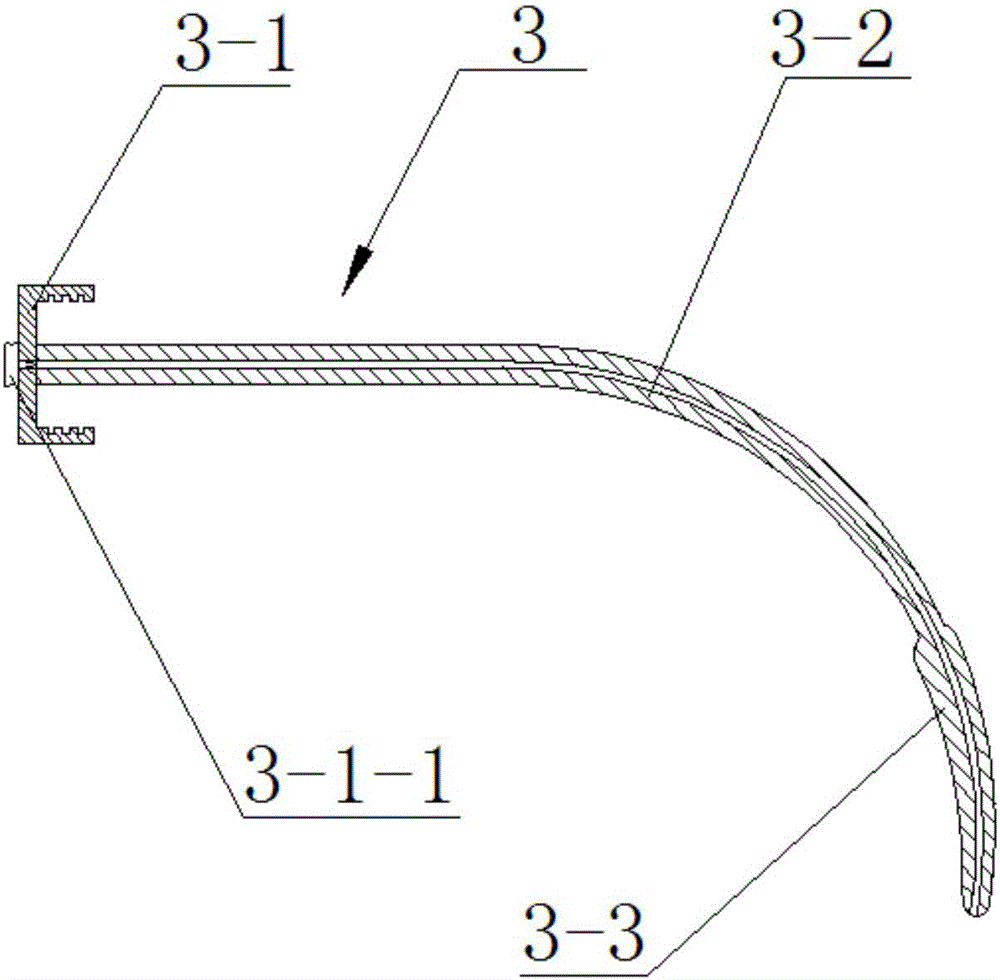

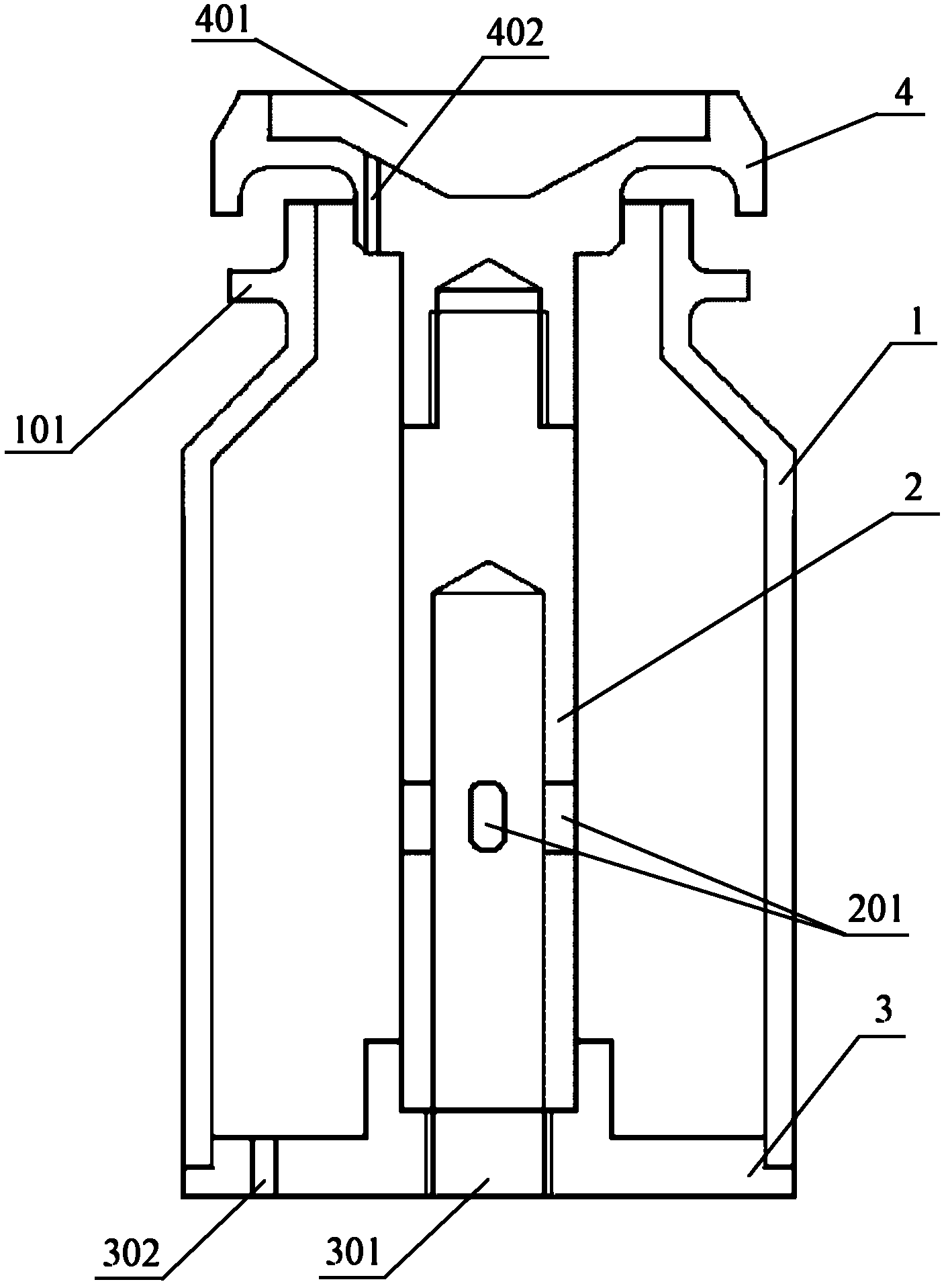

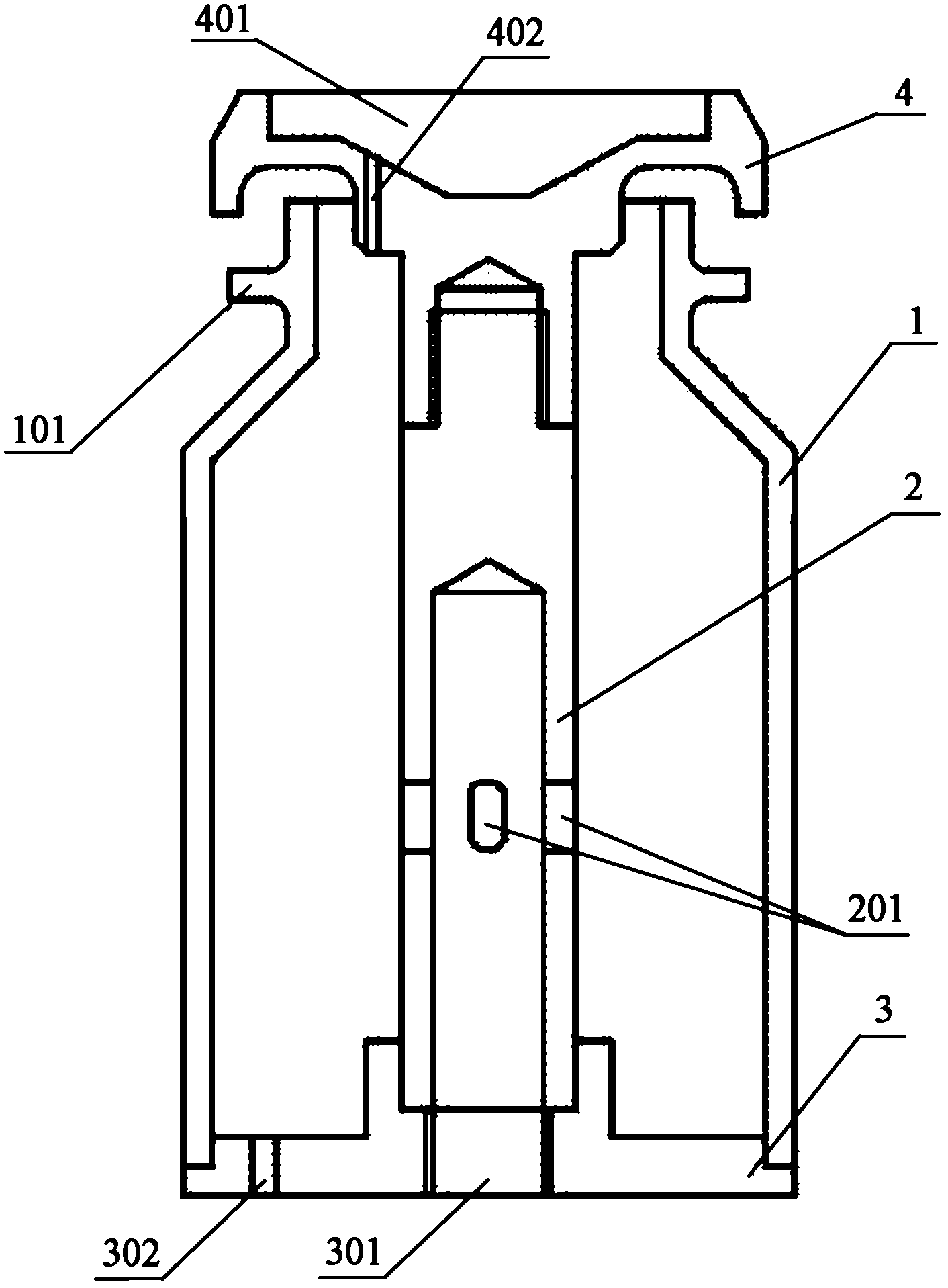

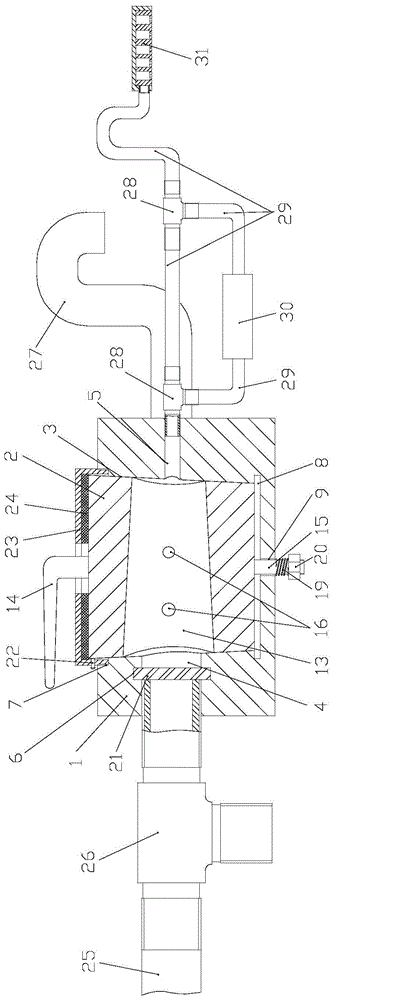

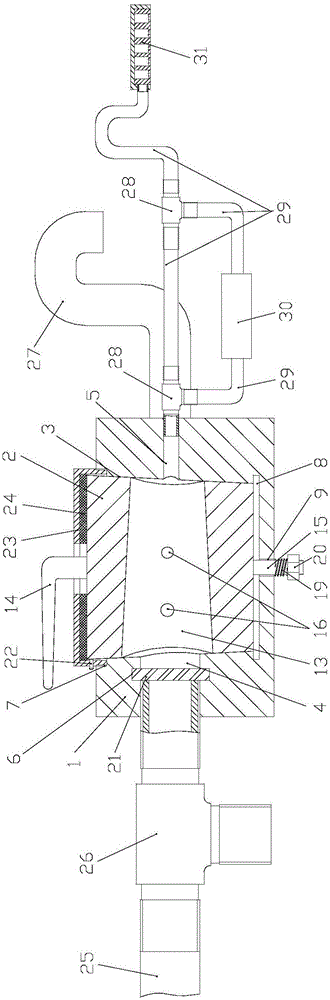

Dripping-proof low-bubble linkage-type filling structure

The invention discloses a dripping-proof low-bubble linkage type filling structure. The dripping-proof low-bubble linkage type filling structure comprises an air cylinder (1), a feeding device (2) and a filling head (3), wherein the filling head (3) comprises a material cavity (301); the material cavity (301) is internally provided with a material pushing rod (302); the top end of the material pushing rod (302) stretches out of the material cavity (301); the material pushing rod (302) is connected with a piston rod (101) of the air cylinder (1); a spiral discharging pipe (4) is arranged at the bottom end of the filling head (3); the feeding device (2) comprises a material storage bucket (201), a material pipe (202) and a material returning absorption cabin (203); the material storage bucket (201) is communicated with the material returning absorption cabin (203) through the material pipe (202); the material returning absorption cabin (203) is communicated with the material cavity (301); a solenoid valve (5) is arranged between the material storage bucket (201) and the material returning absorption cabin (203). The dripping-proof low-bubble linkage-type filling structure can sufficiently avoid dripping; dropped materials can be recycled to the material returning absorption cabin and the spiral discharging pipe is arranged at the bottom end of the filling head, so that a liquid impact force can be buffered sufficiently and bubbles are prevented from being generated in a filling process.

Owner:HUNAN XINYANG FOOD IND

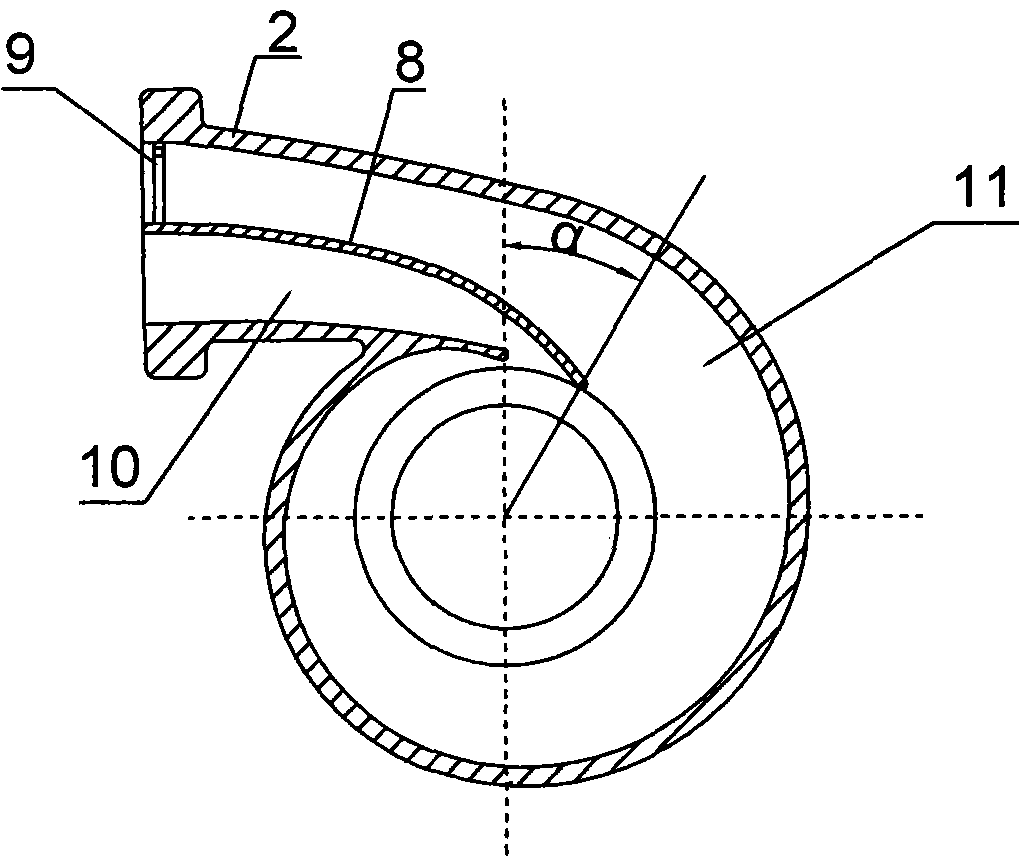

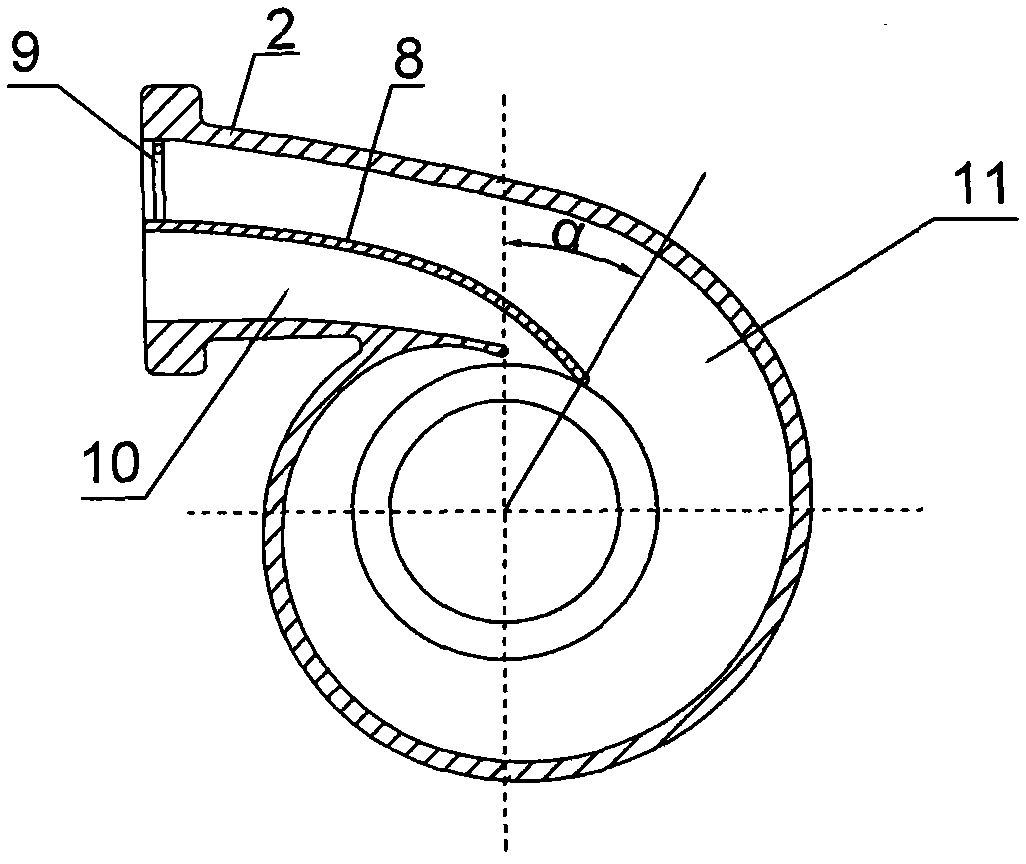

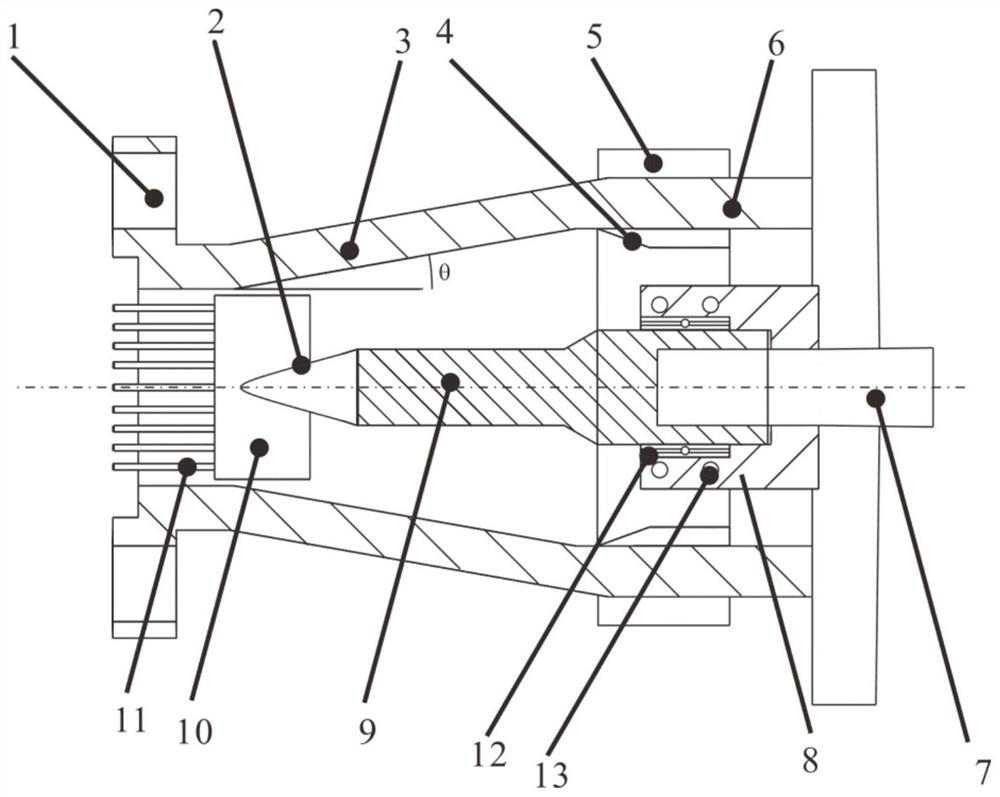

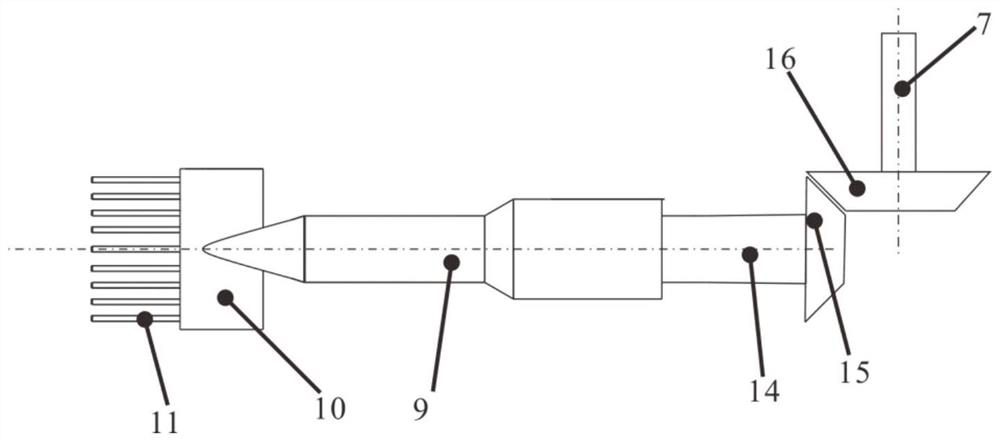

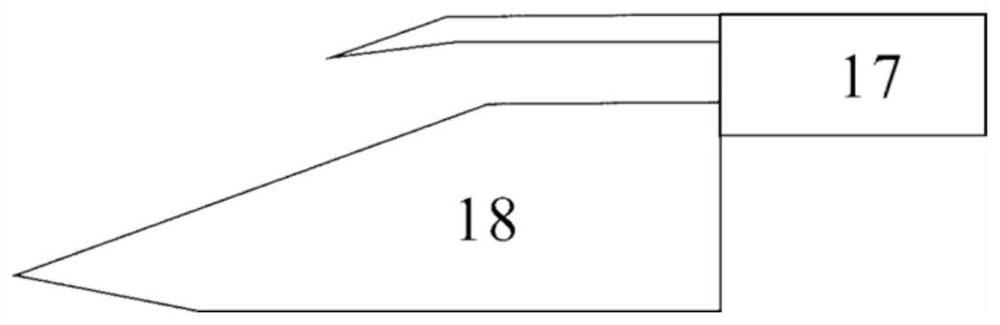

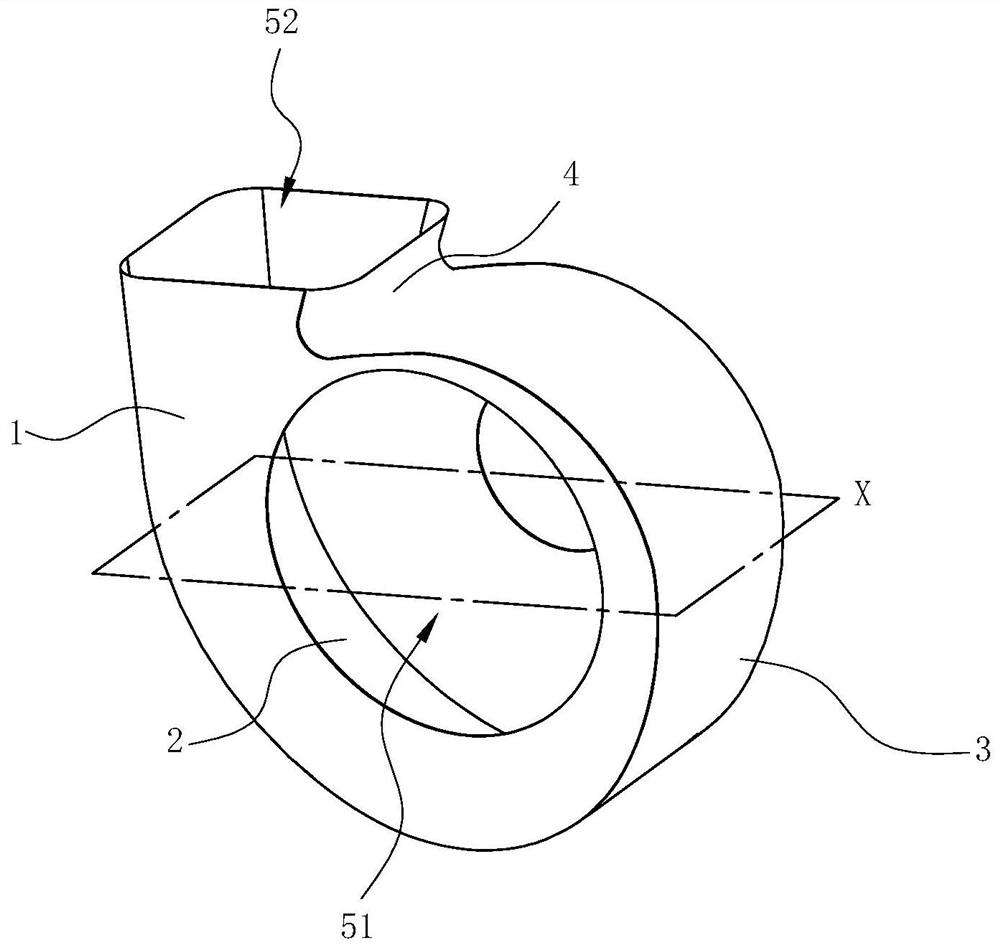

Multi-nozzle type variable flow rate supercharging device

InactiveCN102094704AMeet low speed performanceIncrease intake pressureCombustion enginesStatorsEngineeringControl mode

The invention discloses a multi-nozzle type variable flow rate supercharging device which comprises a volute casing, wherein the volute casing is internally provided with an air inlet and a volute air inlet passageway which is communicated with the air inlet, and the volute air inlet passageway is internally provided at least one intermediate baffle plate. The multi-nozzle type variable flow rate supercharging device provided by the invention has a simple air inlet regulating and controlling mechanism, the control mode is easy to realize, the reliability is high, and the problems of the existing vane type variable turbocharger in the aspects of reliability and efficiency and too low efficiency of a tongue shape baffle plate variable cross section charger are solved effectively.

Owner:KANGYUE TECH

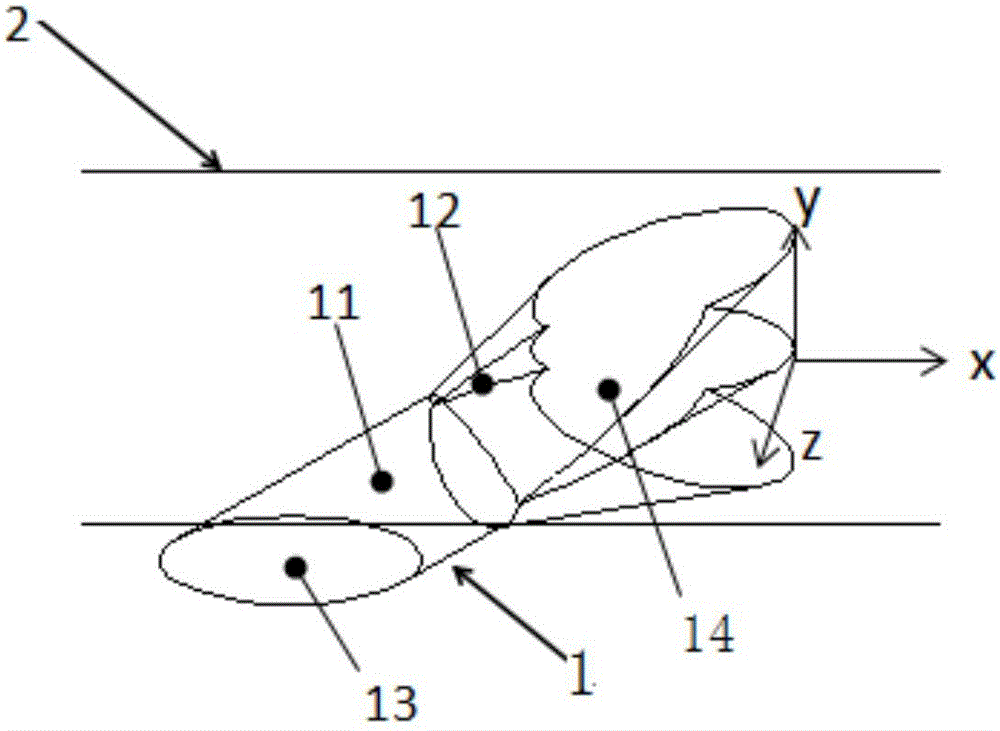

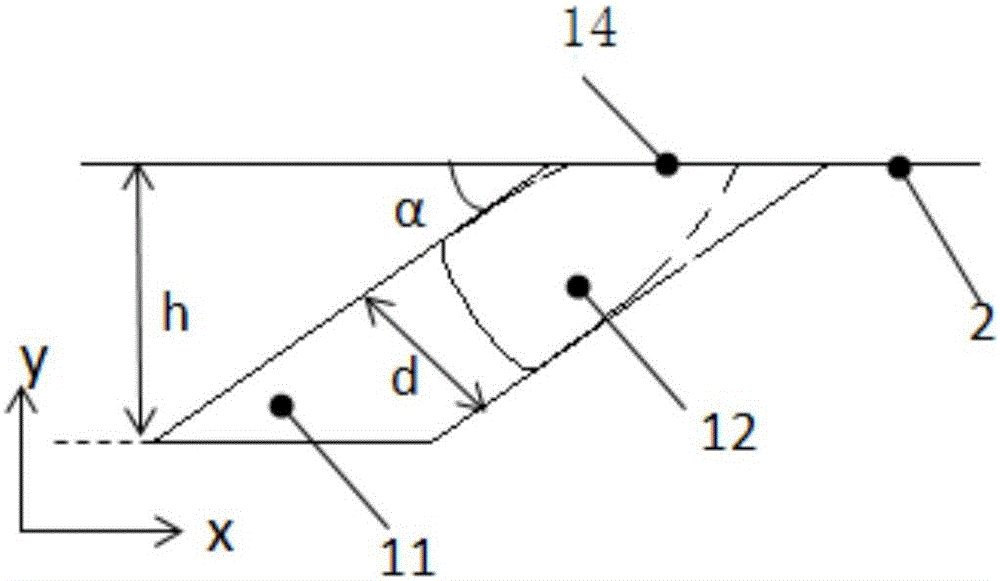

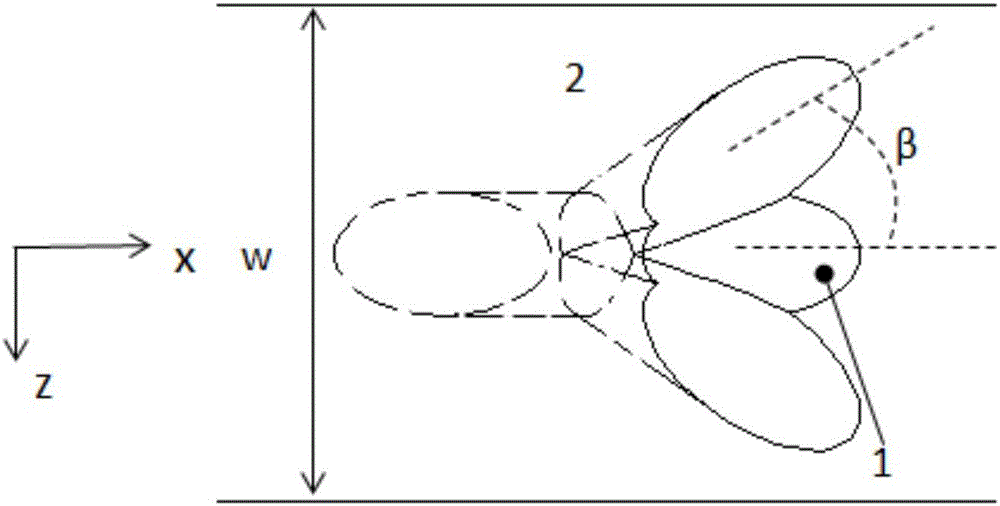

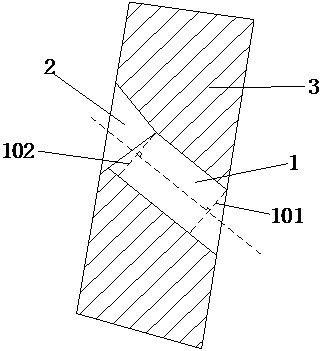

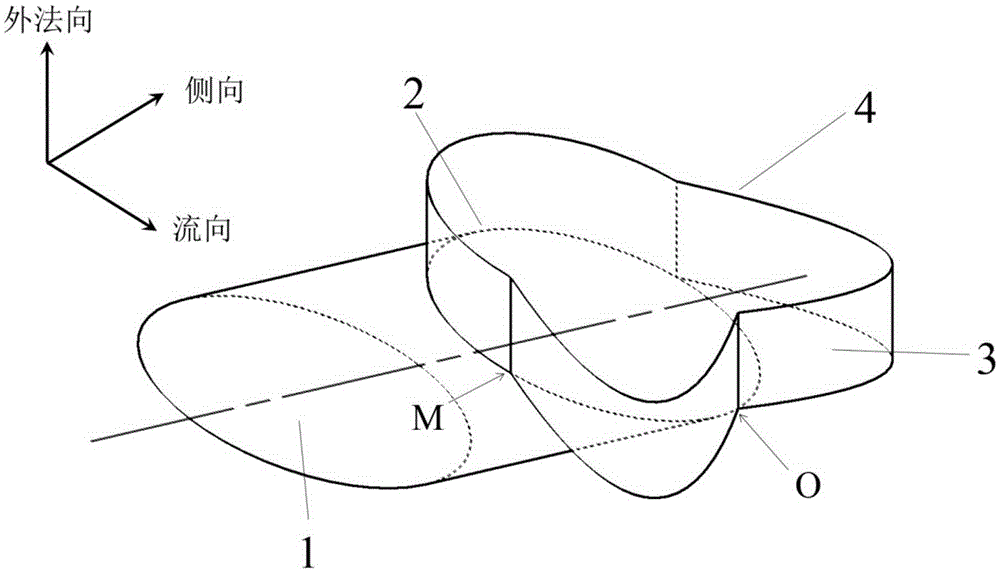

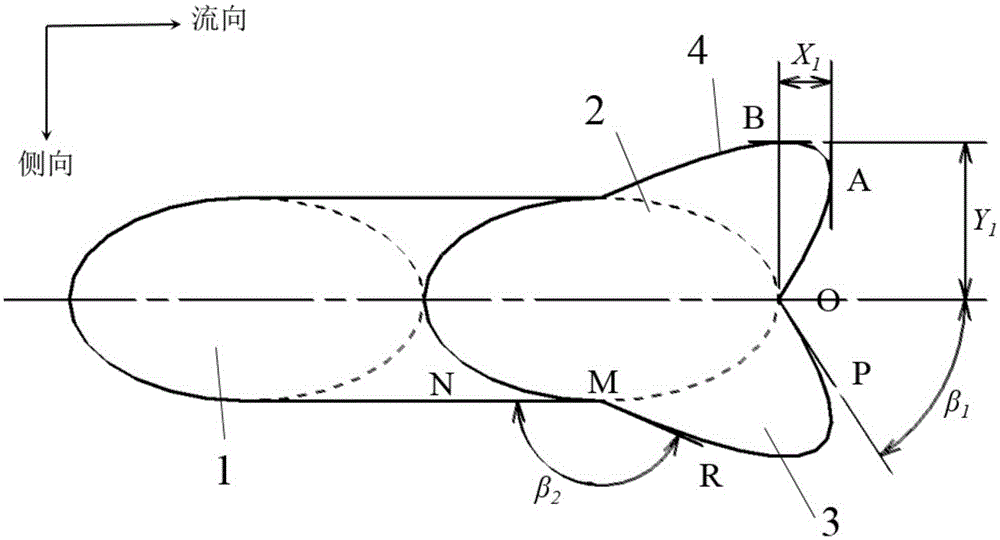

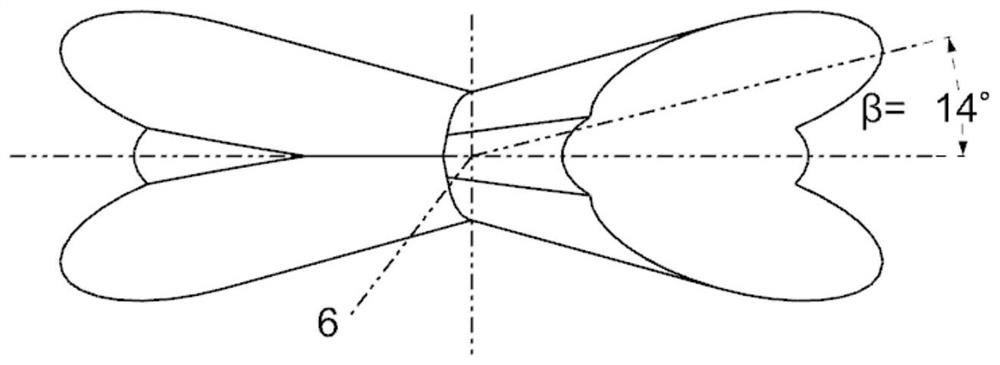

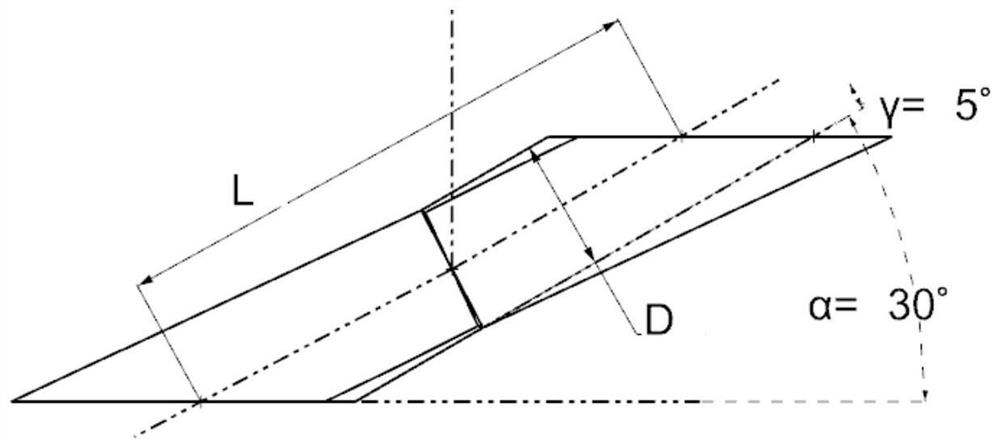

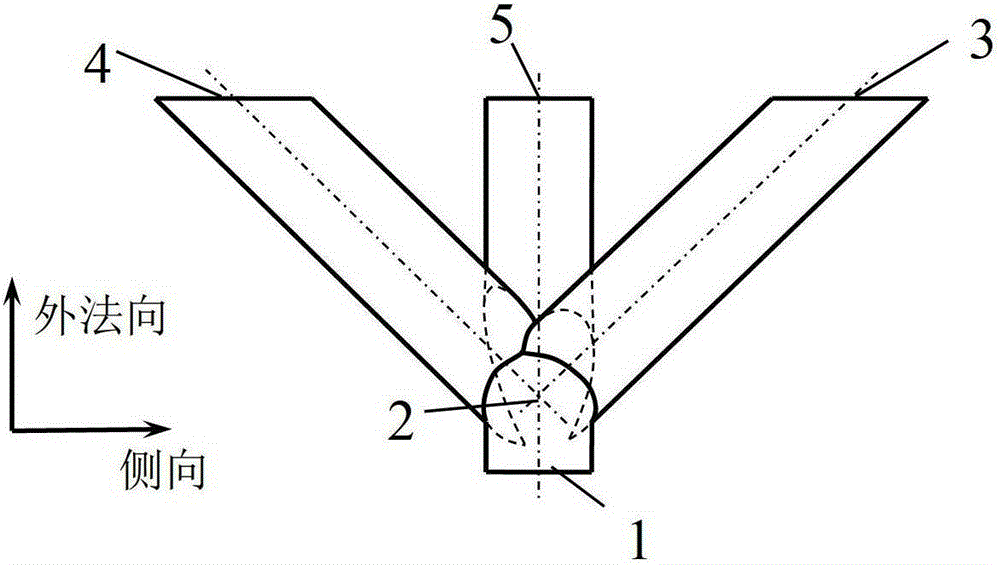

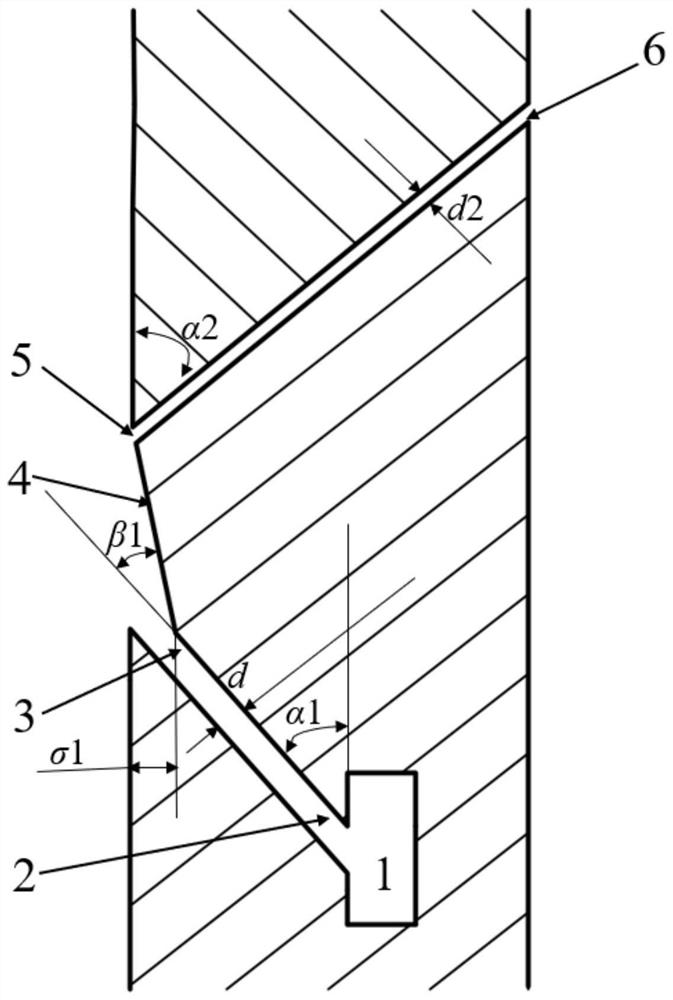

Air film cooling hole structure

ActiveCN106640216AImprove cooling efficiencyIncrease the export areaEngine fuctionsBlade accessoriesCold air intakeEngineering

The invention relates to an air film cooling hole structure. The air film cooling hole structure comprises air film holes and a wall surface; and outlets of the air film holes are positioned in the upstream region of the wall surface. The air film cooling hole structure is characterized in that each air film hole comprises a cylindrical section and an expansion section; one end of each cylindrical section is a cold air inlet; the other end of each cylindrical section is connected with one end of the corresponding expansion section; the other end of each expansion section is an outlet of the corresponding air film hole; each expansion section consists of a middle hole and two expansion holes; each middle hole communicates with each expansion hole; in the top view of the wall surface, the two expansion holes of each expansion section are axially symmetric along the corresponding middle hole; and an included angle beta between each expansion hole and the central axis of each middle hole is 10-40 degrees.

Owner:HEBEI UNIV OF TECH

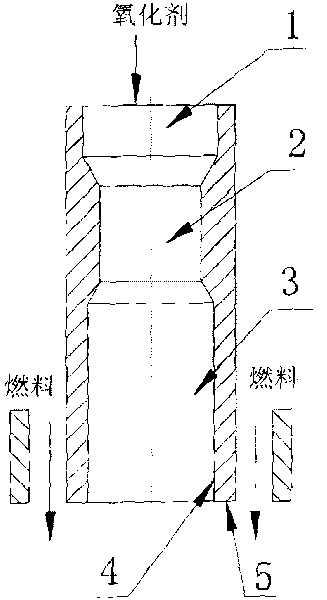

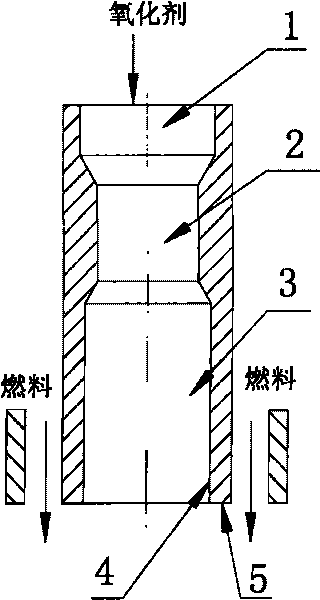

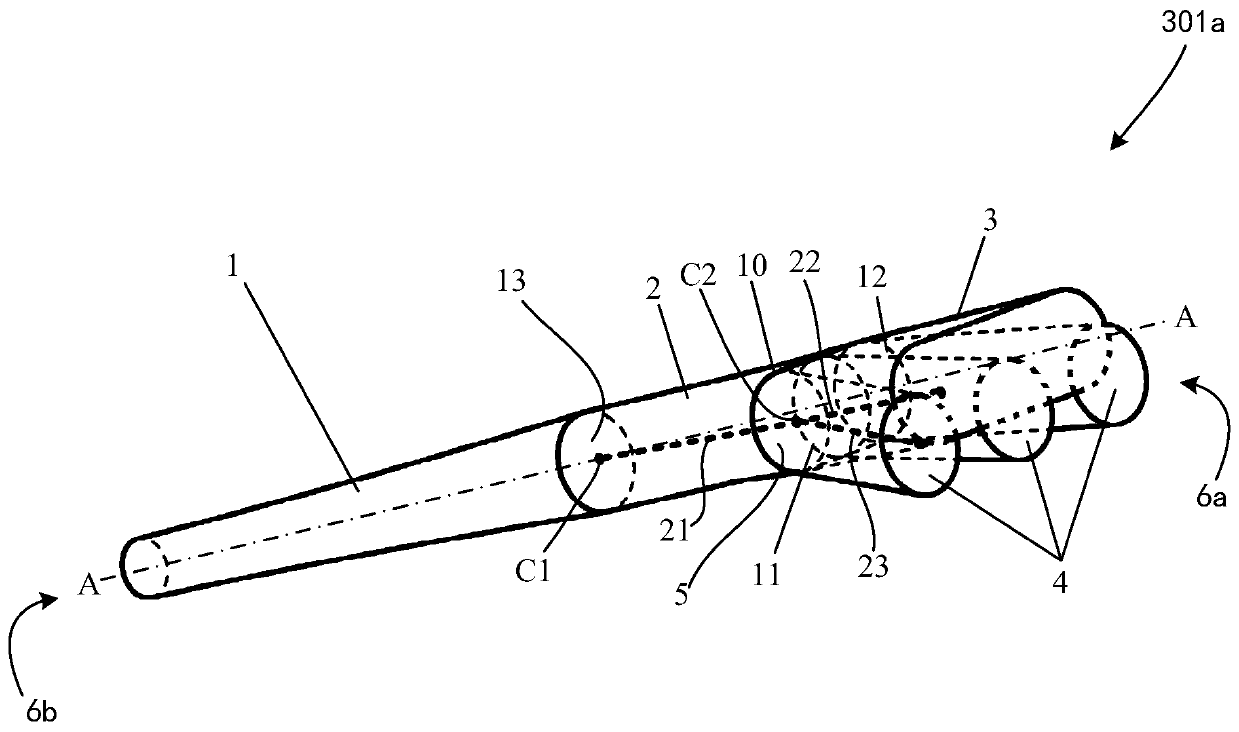

Gas-gas nozzle with constriction section

InactiveCN101737198AReduce exit speedImprove combustion efficiencyRocket engine plantsCombustion chamberEngineering

The invention relates to a gas-gas nozzle with a constriction section. A constriction section is additionally arranged in an oxidant channel. The nozzle with the constriction section comprises an inlet section (1), a constriction section (2) and a nozzle outlet section (3). A propellant is used for forming a certain inlet pressure drop at the head part of a combustion chamber to reduce the speed of an oxidant outlet and the pressure drop of a fuel nozzle. The speed of the oxidant outlet is reduced so as to be beneficial to the combustion of the propellant in the combustion chamber, the design of an engine supply system and the improvement of the combustion efficiency of the propellant.

Owner:BEIHANG UNIV

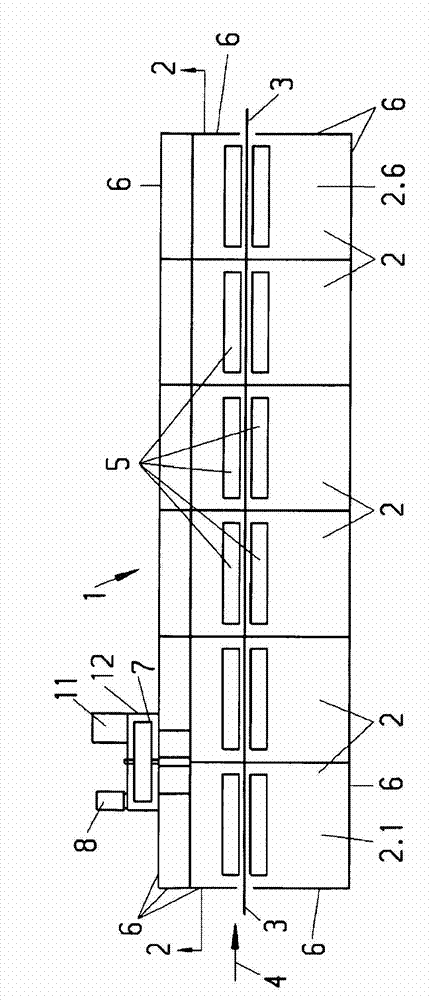

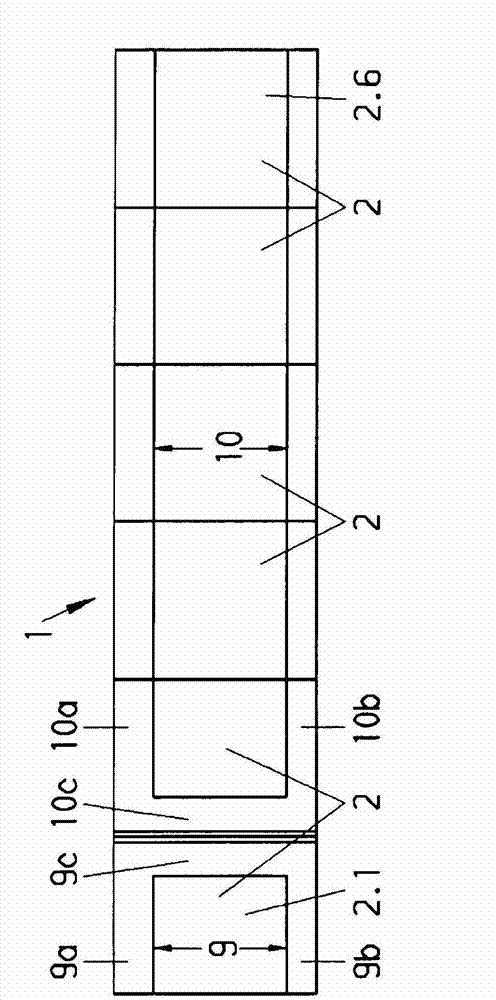

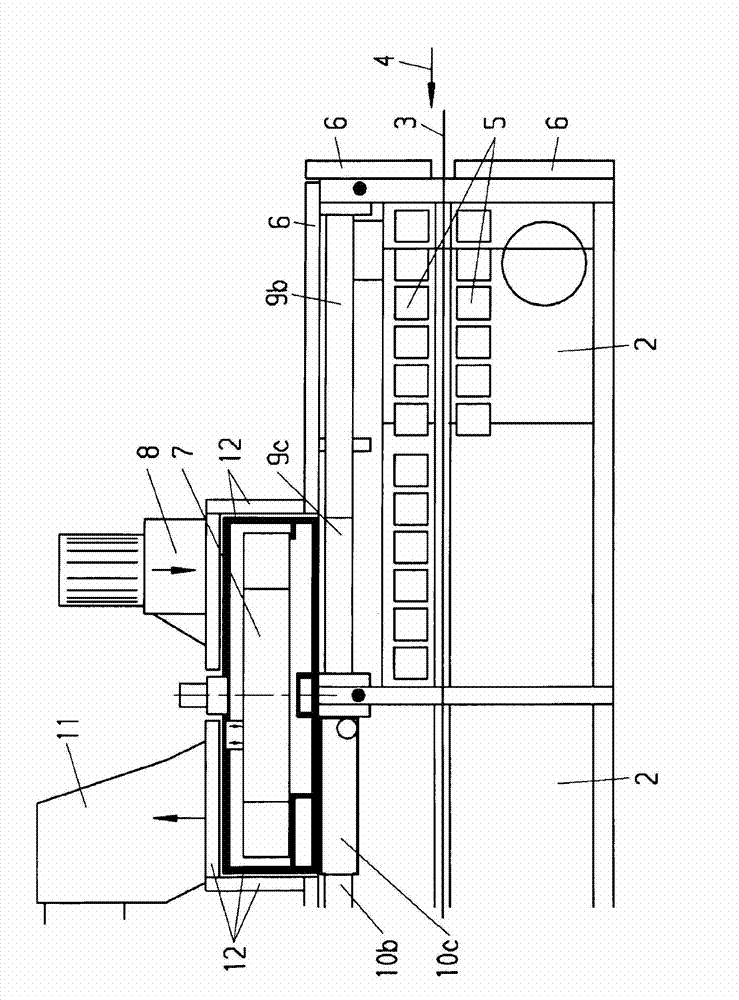

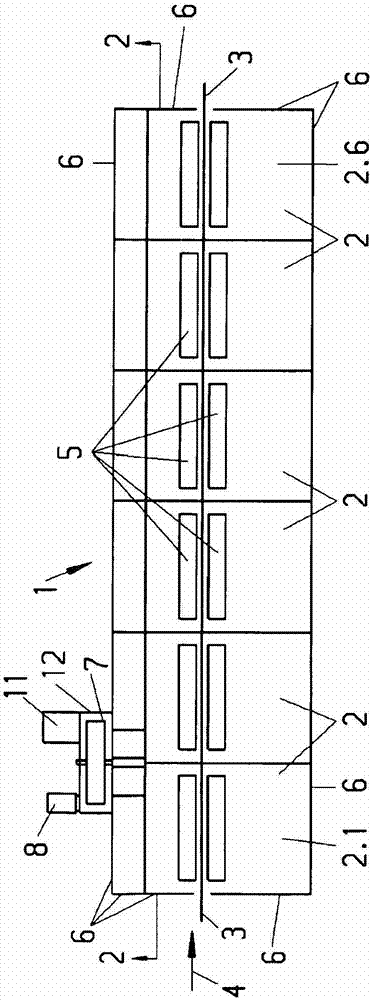

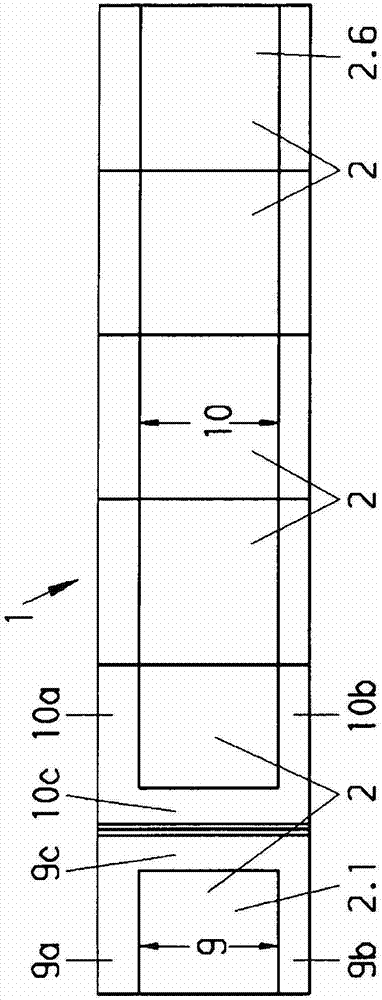

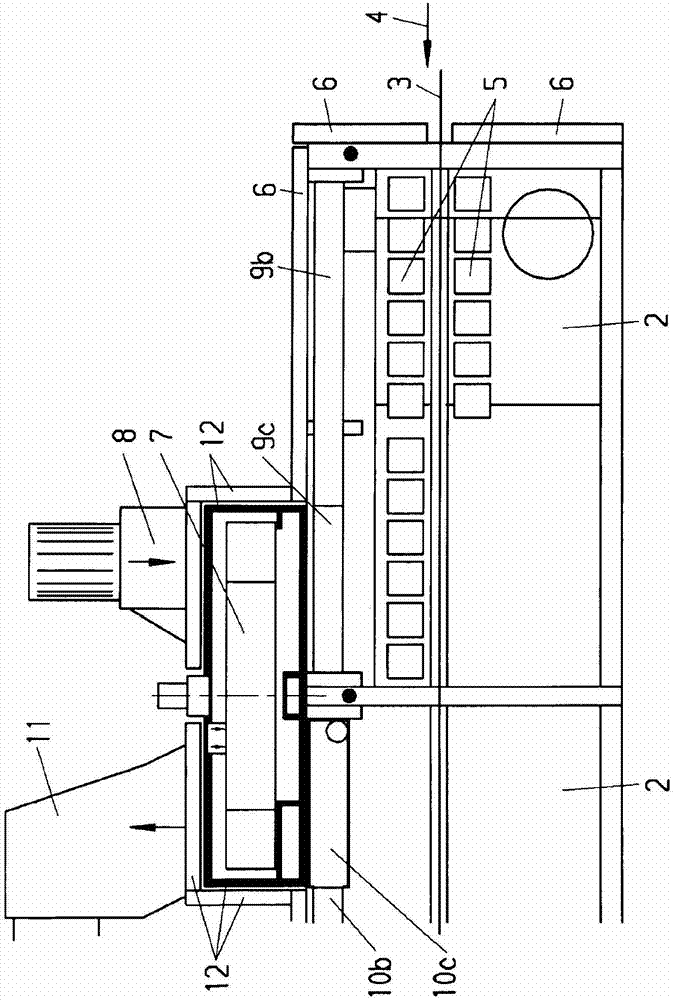

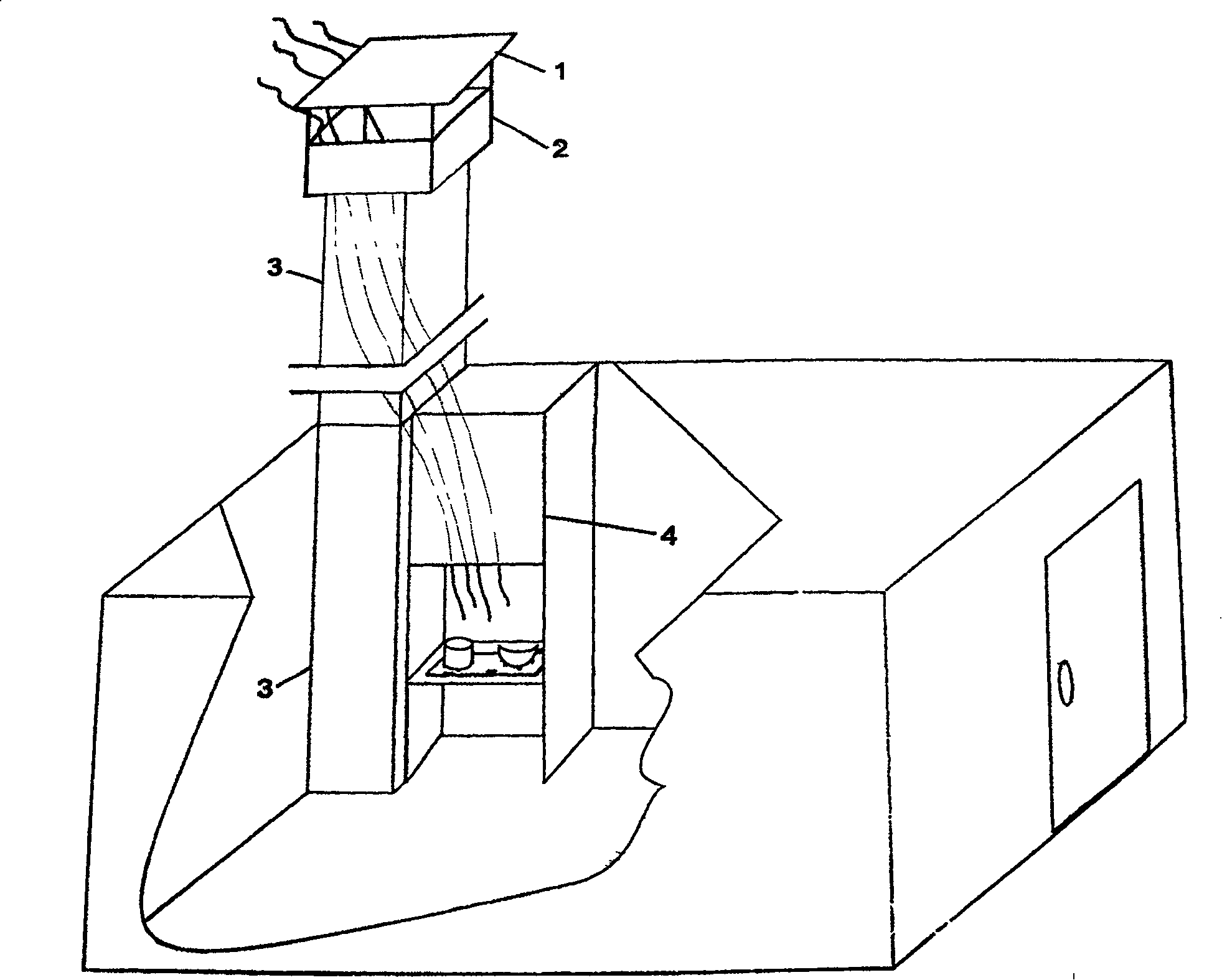

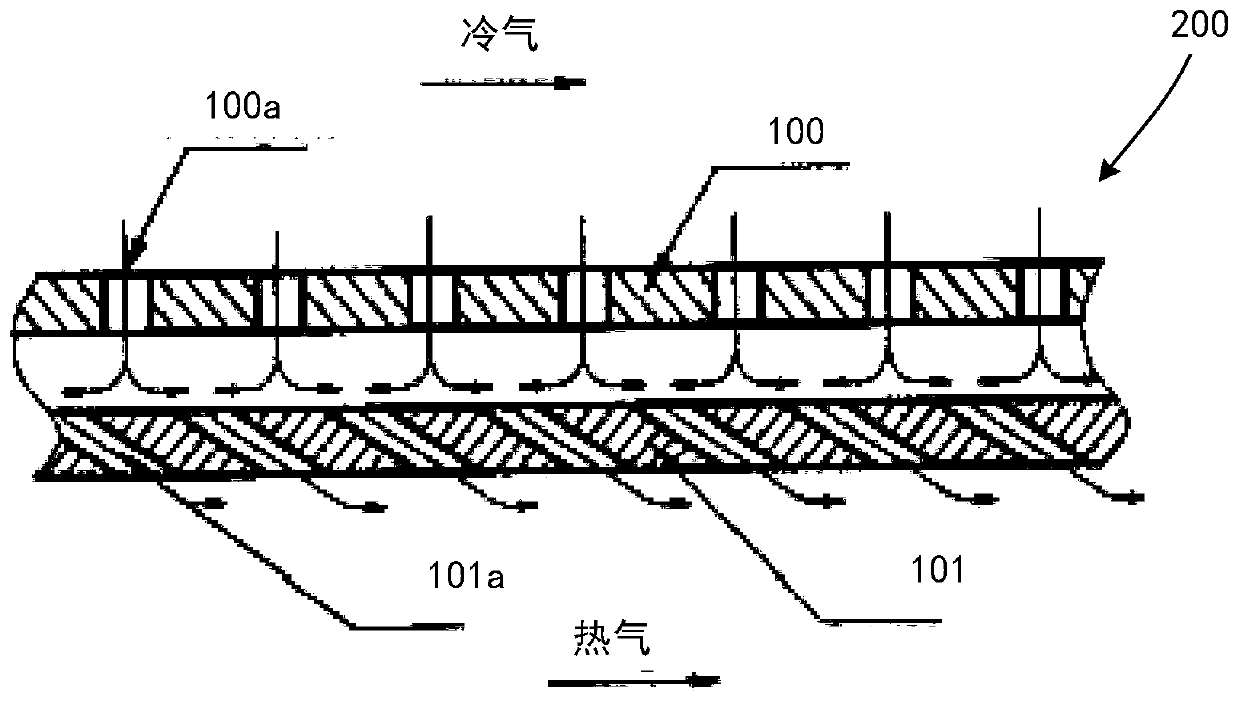

Apparatus for the heat treatment of a web of textile material

InactiveCN102971598APlay a role in heat insulationAbsorb moreDrying machines with progressive movementsHeating arrangementHeat treatingExhaust gas

The invention relates to an apparatus for the heat treatment of a web of textile material (3) comprising a housing (6), means for guiding the web of material (3) in the housing (6), means for blowing heated treatment gas (5) onto the web of material (3), at least part of the treatment gas being supplied as fresh air and exhaust gas being carried away, and a heat wheel (7) for preheating the fresh air by means of the exhaust gas. It is intended to improve the apparatus in such a way as to create lines for indirectly preheating fresh air by means of exhaust air without any significant additional expenditure and without the height of the apparatus being any greater, or significantly greater, than in the case of apparatuses without preheating. This is achieved by the heat wheel (7) being connected directly to warm sides of the ducts (9, 10) for the fresh air and for the exhaust air, the warm sides of the ducts (9, 10) being routed exclusively inside the housing (6).

Owner:A MONFORTS TEXTILMASCHINEN GMBH & CO KG

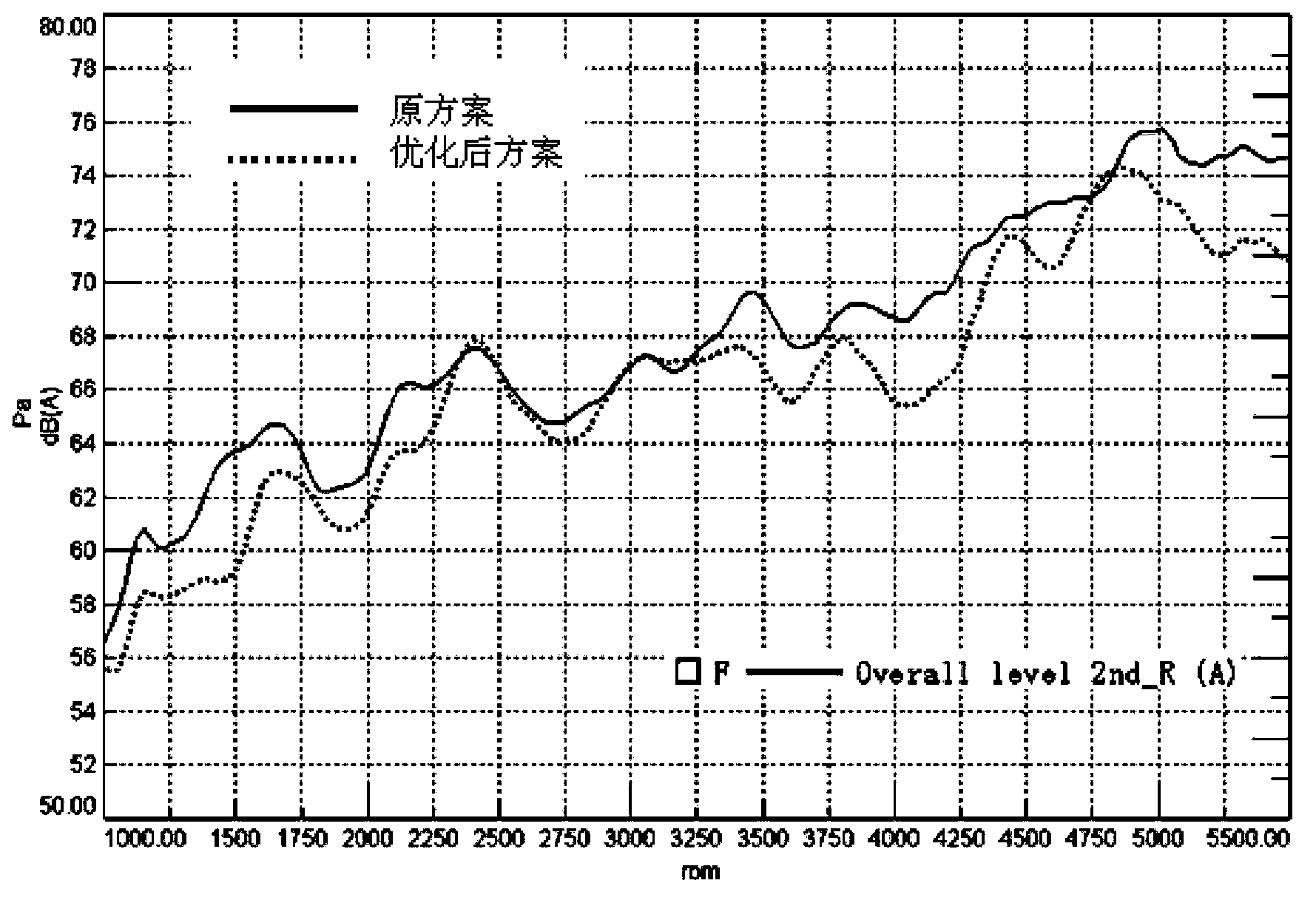

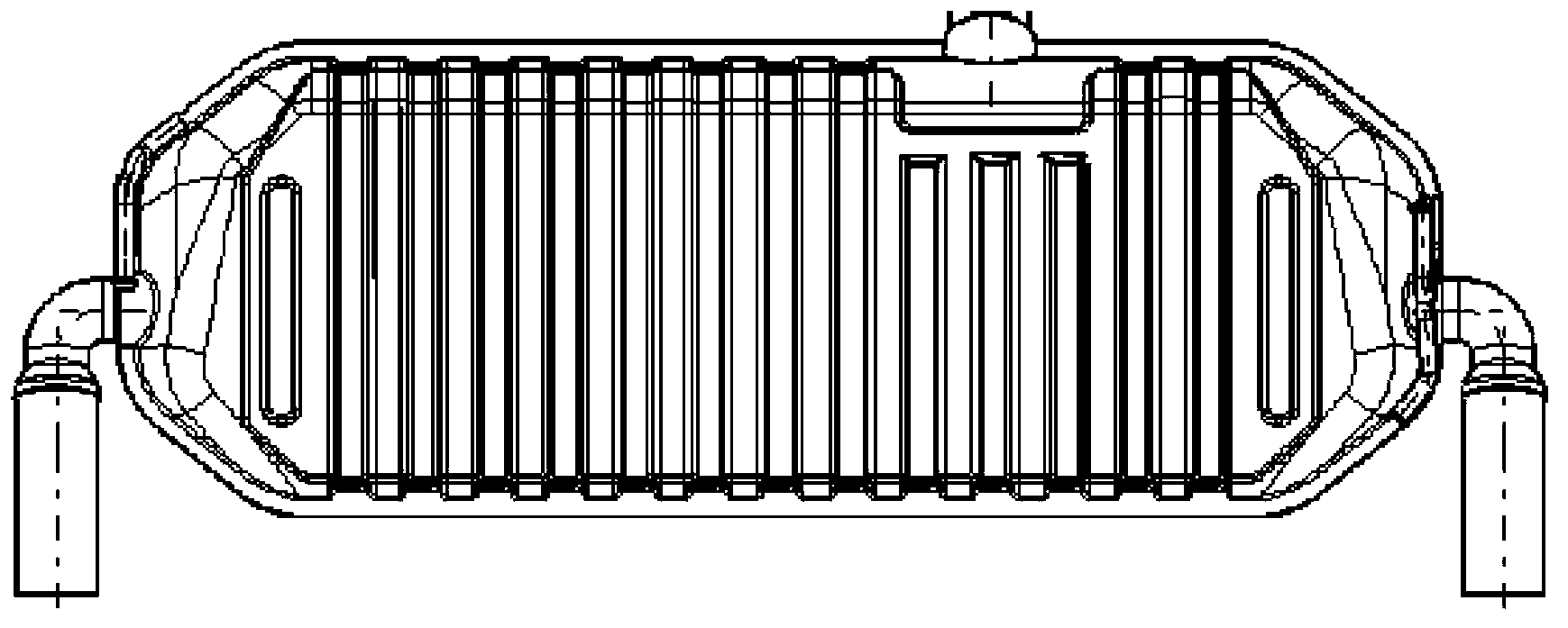

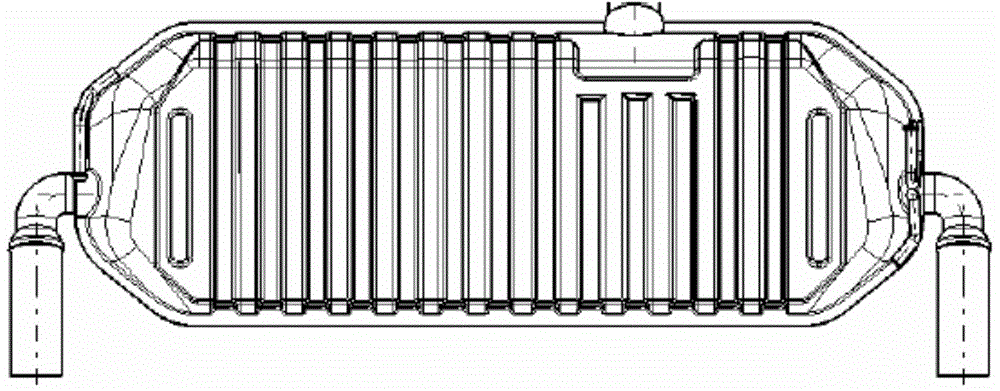

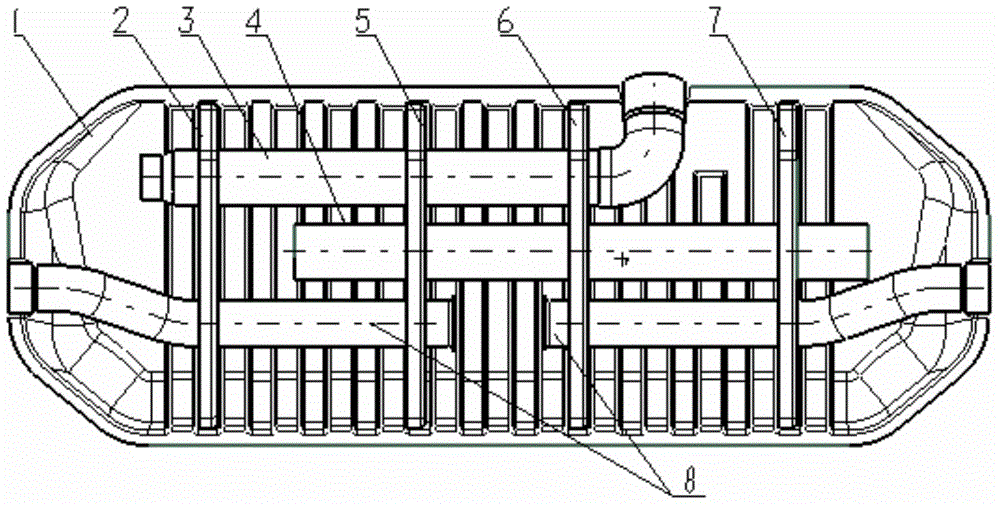

Multifunctional muffler structure

ActiveCN103410586AStationary Noise ReductionGood exhaust noiseExhaust apparatusSilencing apparatusSiphonEngineering

The invention relates to a multifunctional muffler structure. The multifunctional muffler structure comprises a barrel body, an inner partition plate A, an inner partition plate B, an inner partition plate C and an inner partition plate D are arranged in the barrel body, and an air inlet muffler pipe, a middle muffler pipe and two air outlet muffler pipes are fixed in the barrel body; the four inner partition plates divide the barrel body into five muffler cavities. The air outlet muffler pipes are arranged symmetrically, so that exhaust back pressure is favorable for being reduced, and then the work efficiency of an engine is ensured; because siphons are arranged on the air outlet muffler pipes, water accumulating in a muffler can be eliminated by the utilization of the pressure difference between an inlet and an outlet of the muffler and on the basis of the siphon principle, the muffler is prevented from rusting, and the service life and the using reliability of the muffler are ensured; due to the combination of the multiple muffler cavities and the muffler components, exhaust noise is reduced substantially, and the riding comfort of a whole vehicle is improved; the application of a stamped shell makes the muffler be more beautiful and more elegant and fully show the feel of modern science and technology.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

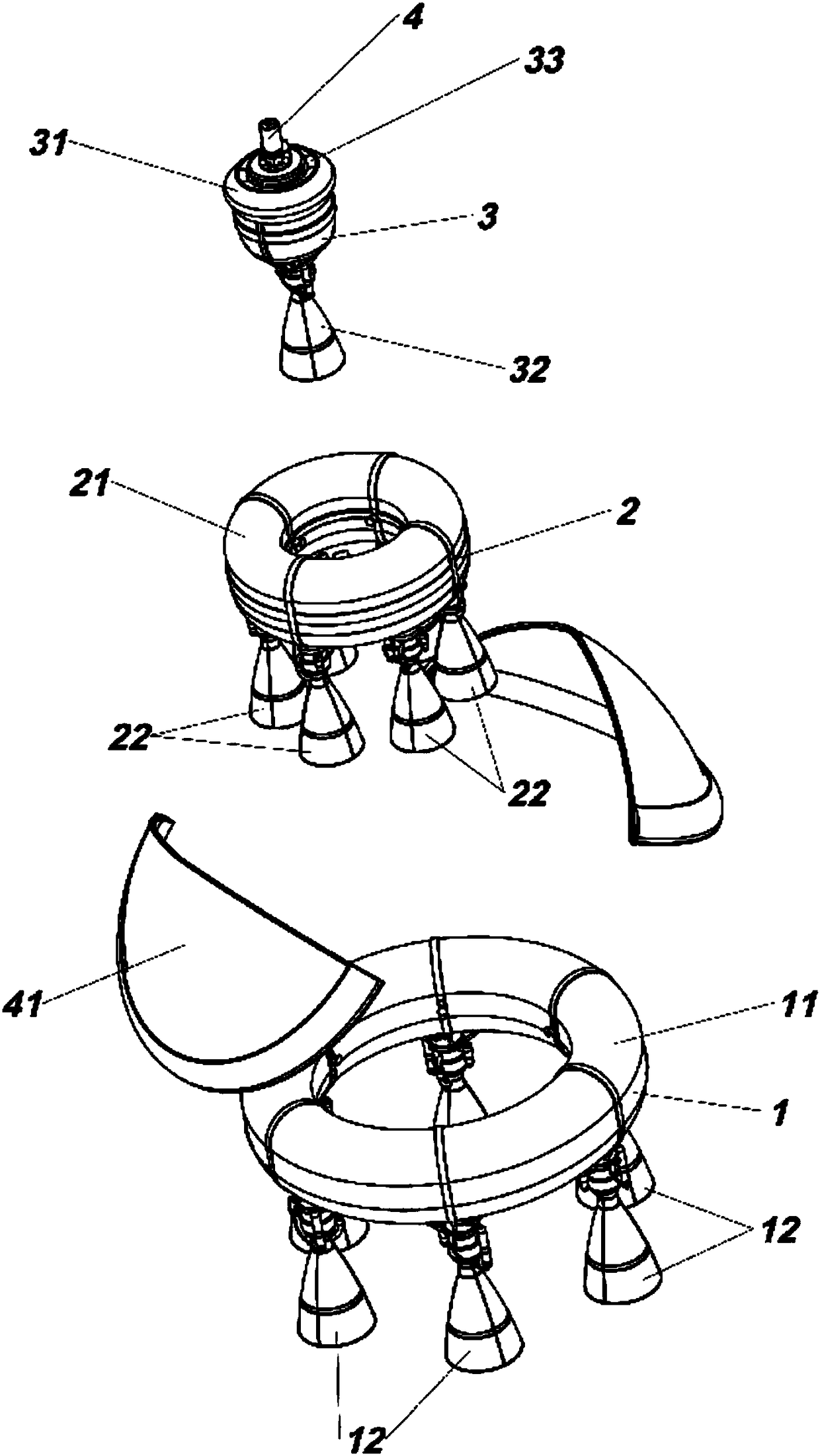

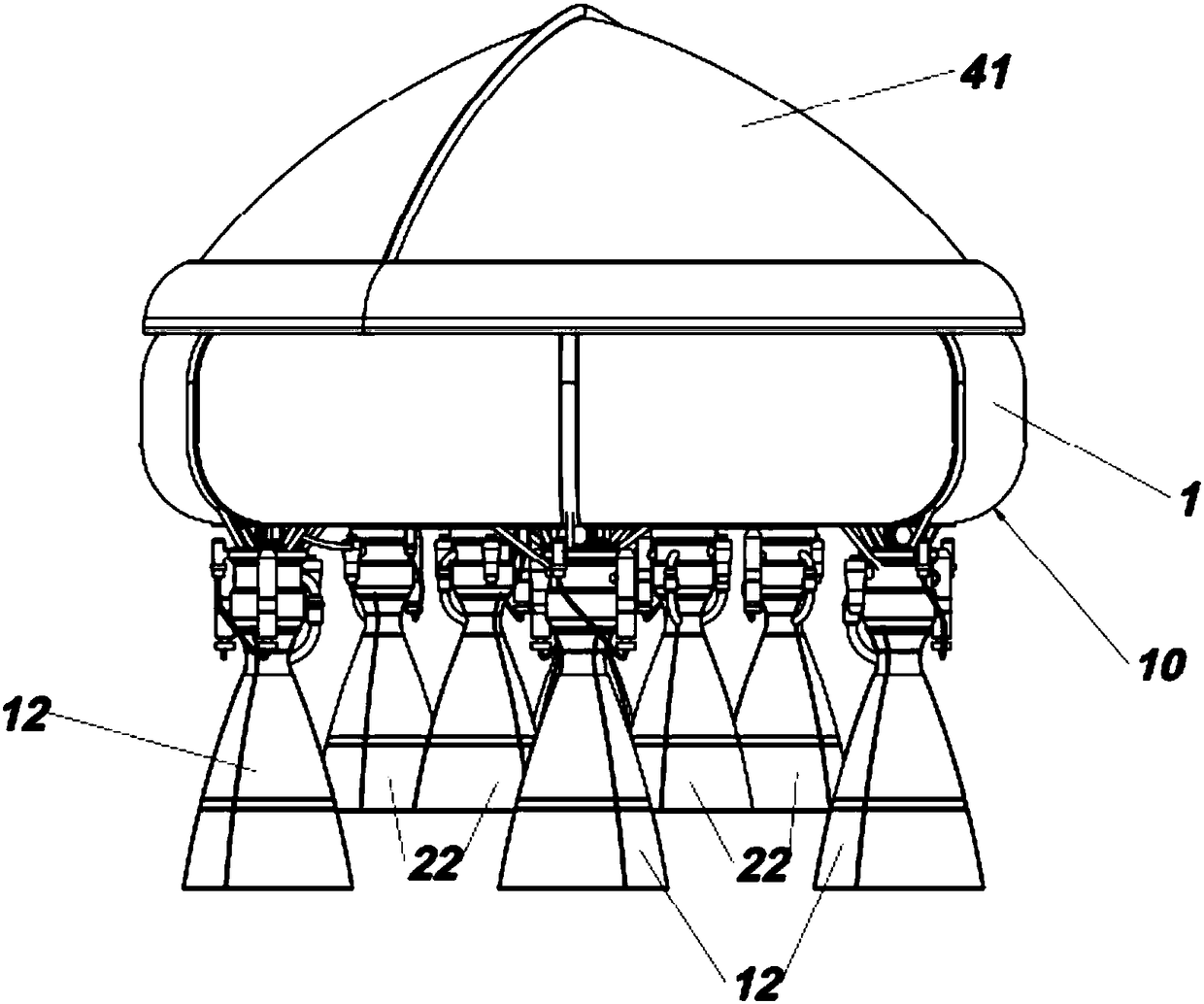

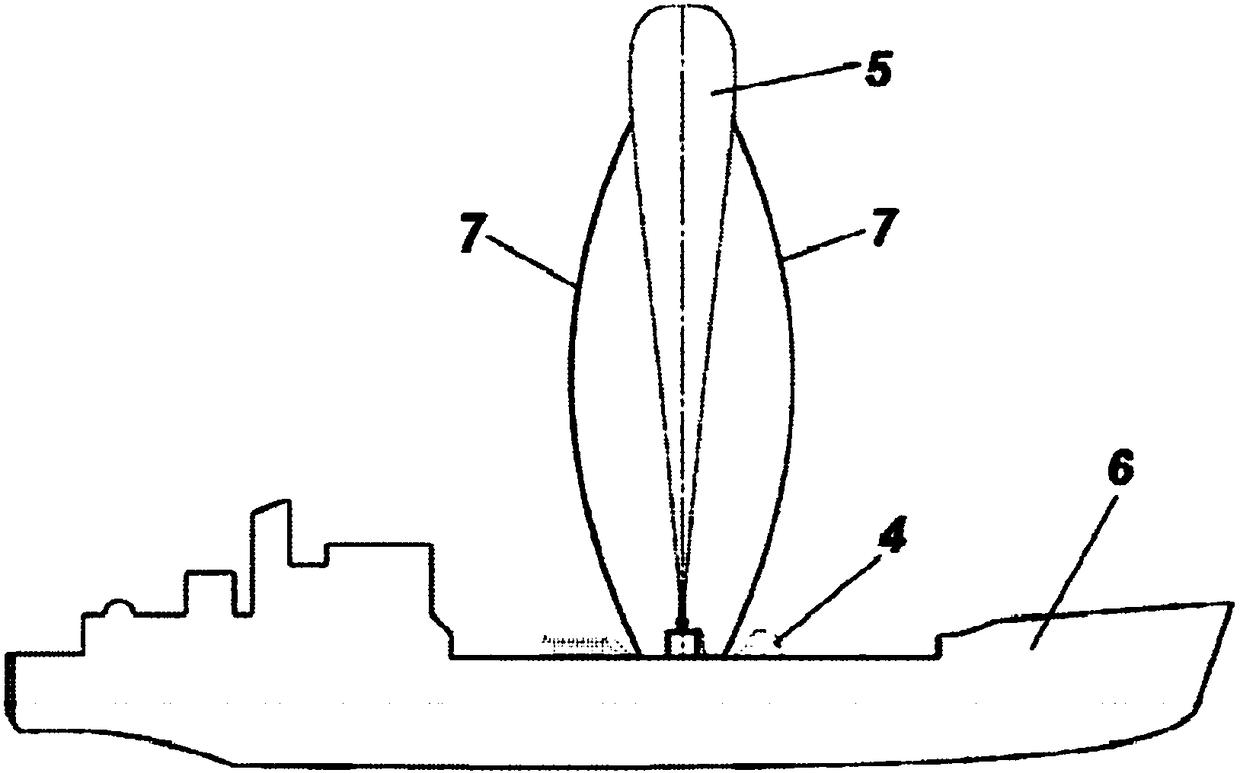

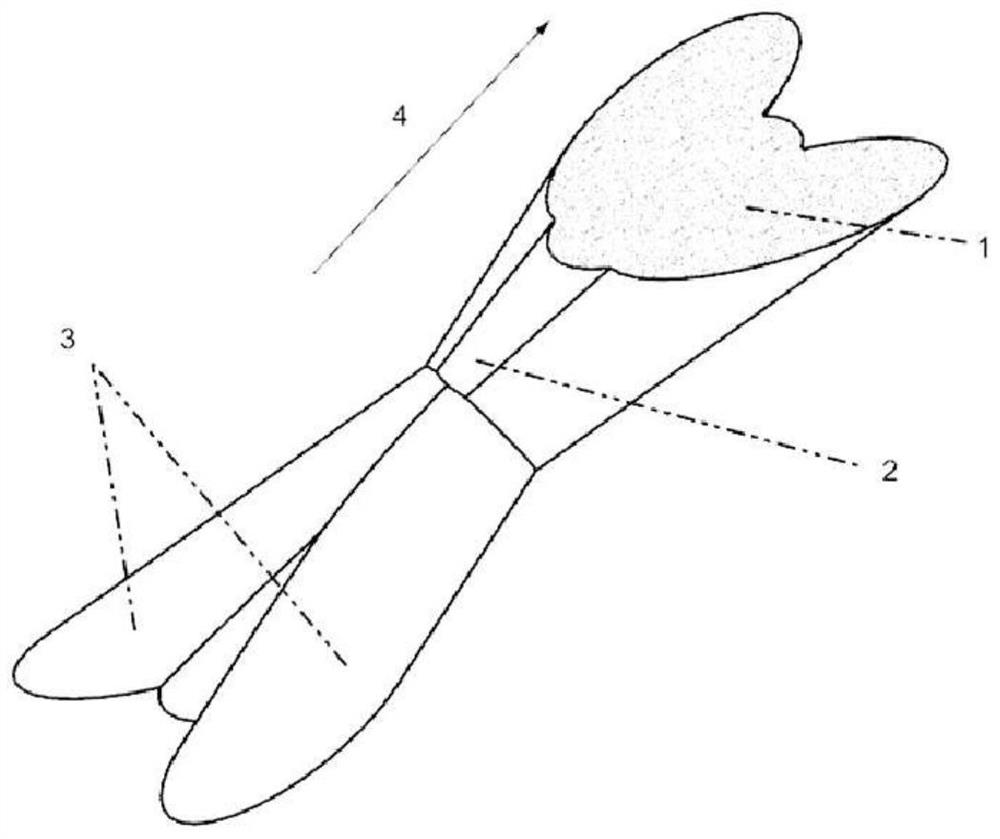

Satellite launcher and method for putting satellites into orbit using said satellite launcher

InactiveCN108290642AEasy to integrateEasy levels and payloadsCosmonautic ground equipmentsLaunch systemsSatellite transmitterNatural satellite

The satellite launcher comprises a plurality of stages detachable from each other, at least one stage including at least one engine, and at least one of said stages carrying a payload, and said stagesare placed one beside or around the other, so that the width of the vehicle is at least one third of its length. The method comprises the following phases: a) ascent of the vehicle with a balloon from a ship; and b) ignition of engines of the vehicle to put a satellite placed in the vehicle into orbit.

Owner:ZERO 2 INFINITY SL

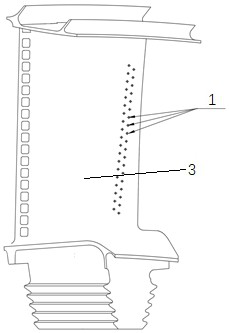

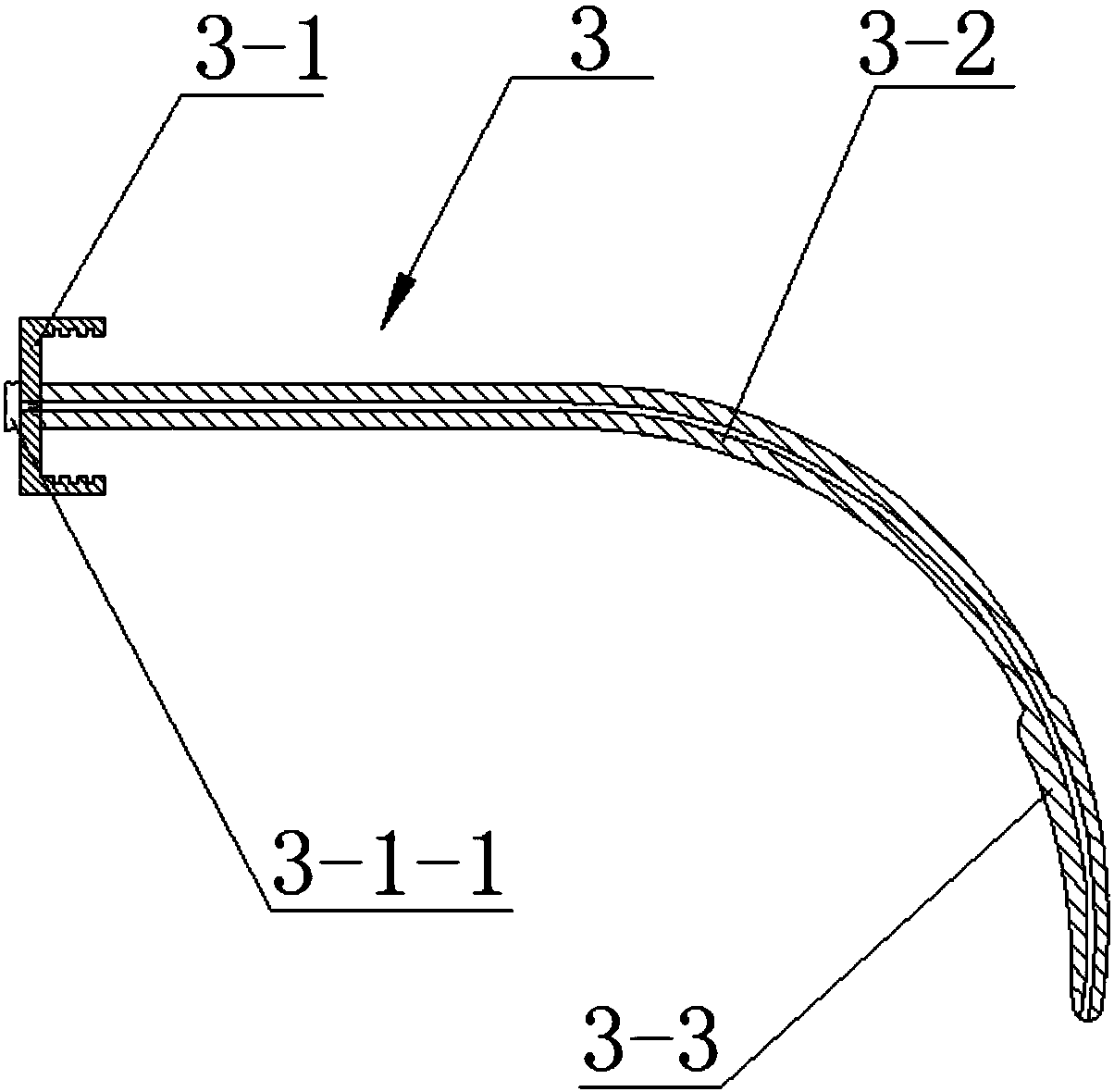

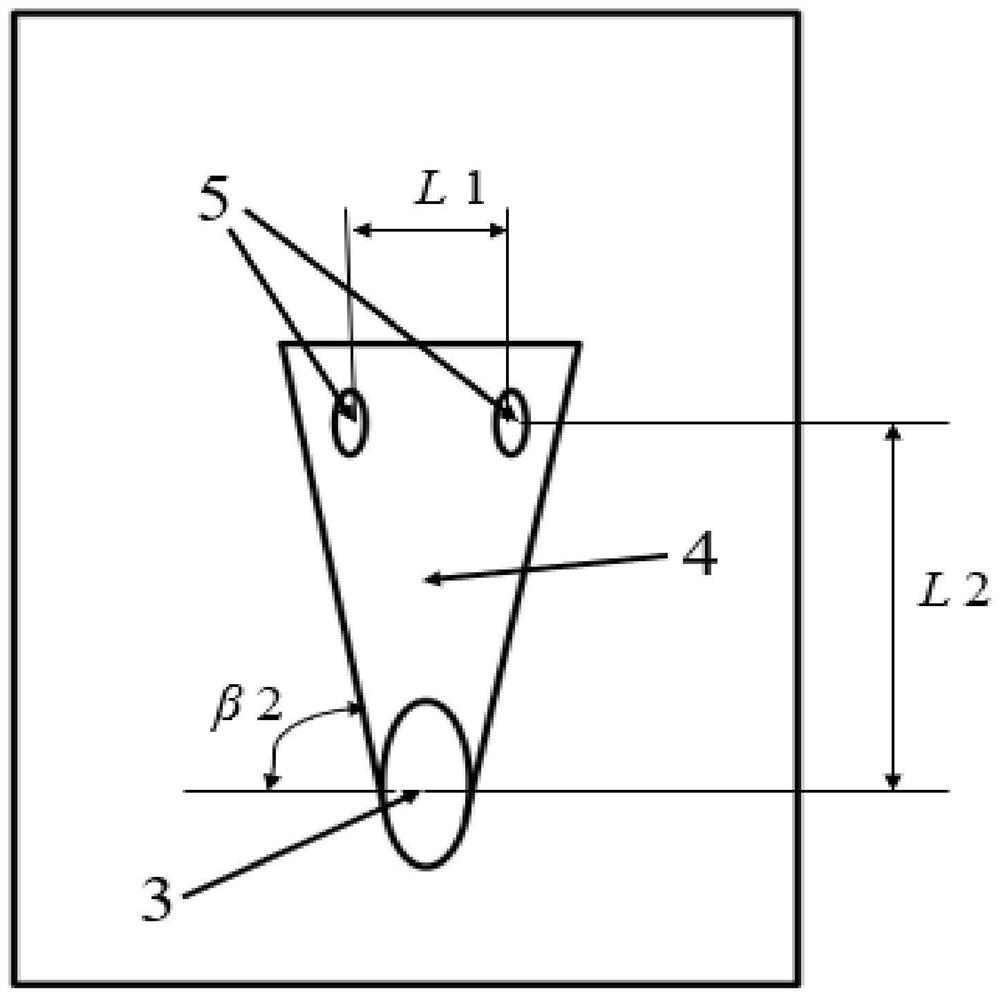

Combined structure air film hole for cooling front edge of turbine blade

InactiveCN112922677AIncrease the export areaImprove cooling effectBlade accessoriesMachines/enginesTurbine bladeEngineering

The invention discloses a combined structure air film hole for cooling the front edge of a turbine blade. The air film hole comprises a first through hole and a conical hole which are communicated in sequence from the inlet direction to the outlet direction, the first through hole and the conical hole are arranged in a non-coaxial manner, and the cross section area of an outlet of the conical hole is larger than the area of the cross section of the first through hole; the axis of the first through hole is a straight line; and the inner wall surface of the first through hole and the inner wall surface of the conical hole have no corner angles. According to the combined structure air film hole, a well cooling air film can be formed at the front edge of the blade, the first through hole controls the flow of cooling air, the conical hole increases the outlet area of the air film hole, the speed of cooling air at the outlet of the air film hole is reduced, the covering effect of cooling air flow is improved, the cooling effect of the blade is remarkably improved, and the wall surface temperature of the front edge of the blade is reduced; and the sharp edge of the outlet edge of the air film hole is passivated, a stress concentration coefficient of the outlet edge of the air film hole is improved, the stress of the outlet edge of the air film hole is reduced, the wall surface temperature of the blade is reduced, the reliability of the blade is improved and the service life of the blade is prolonged.

Owner:成都中科翼能科技有限公司

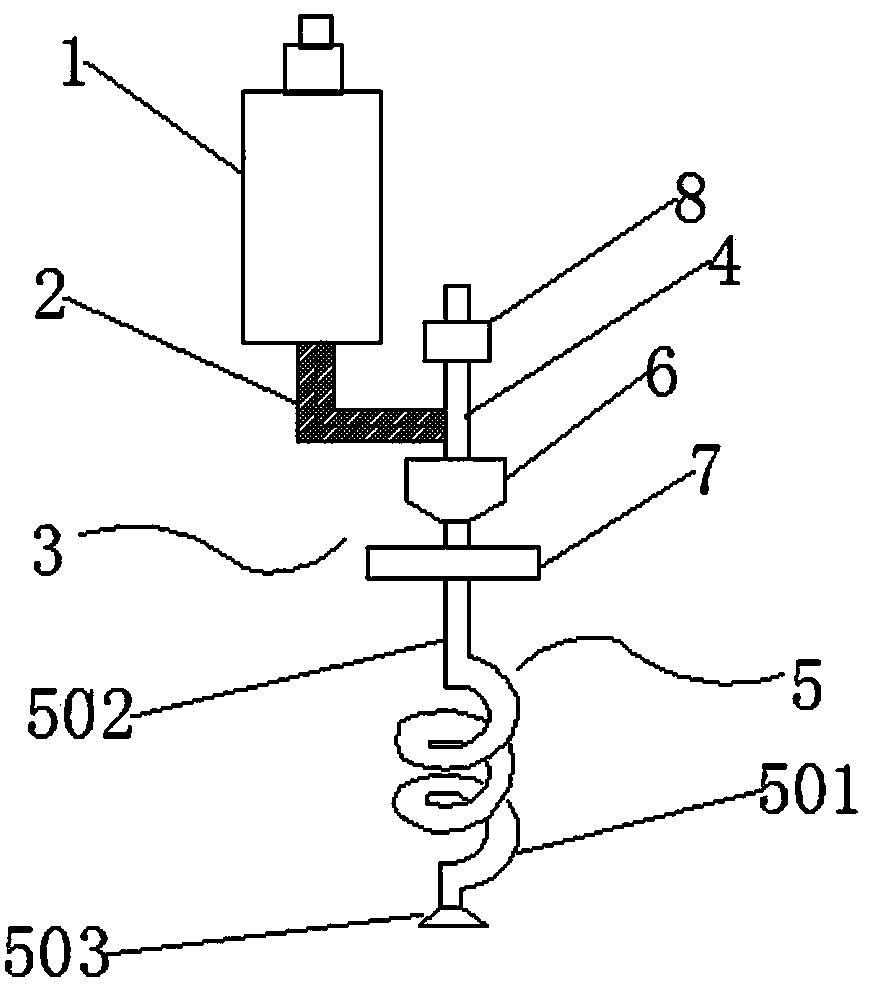

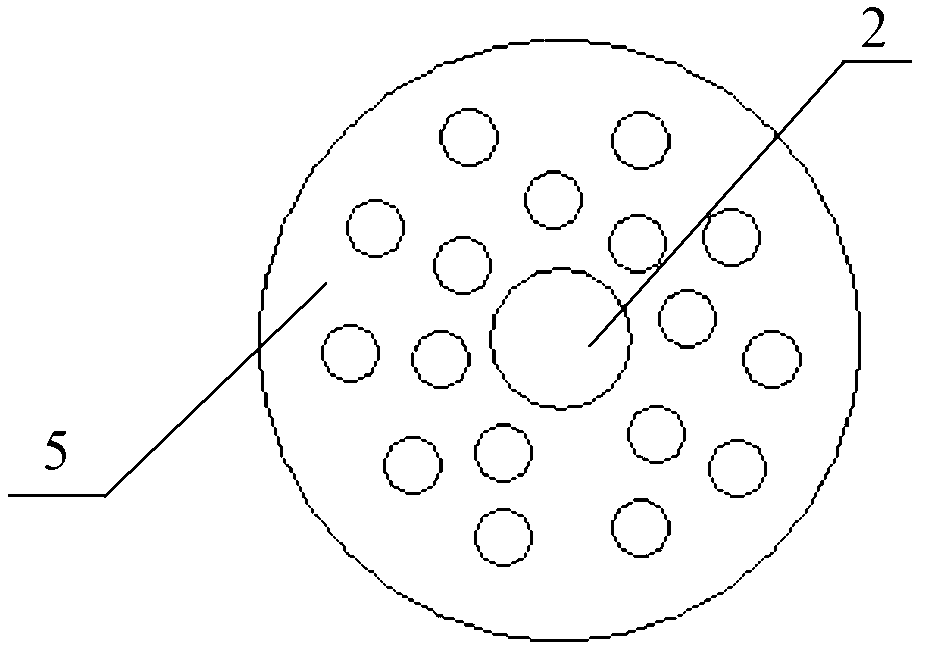

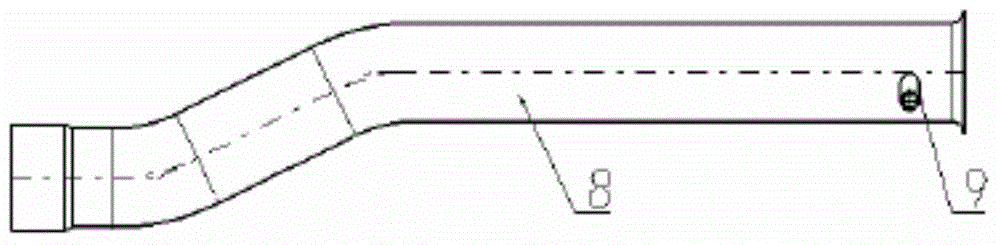

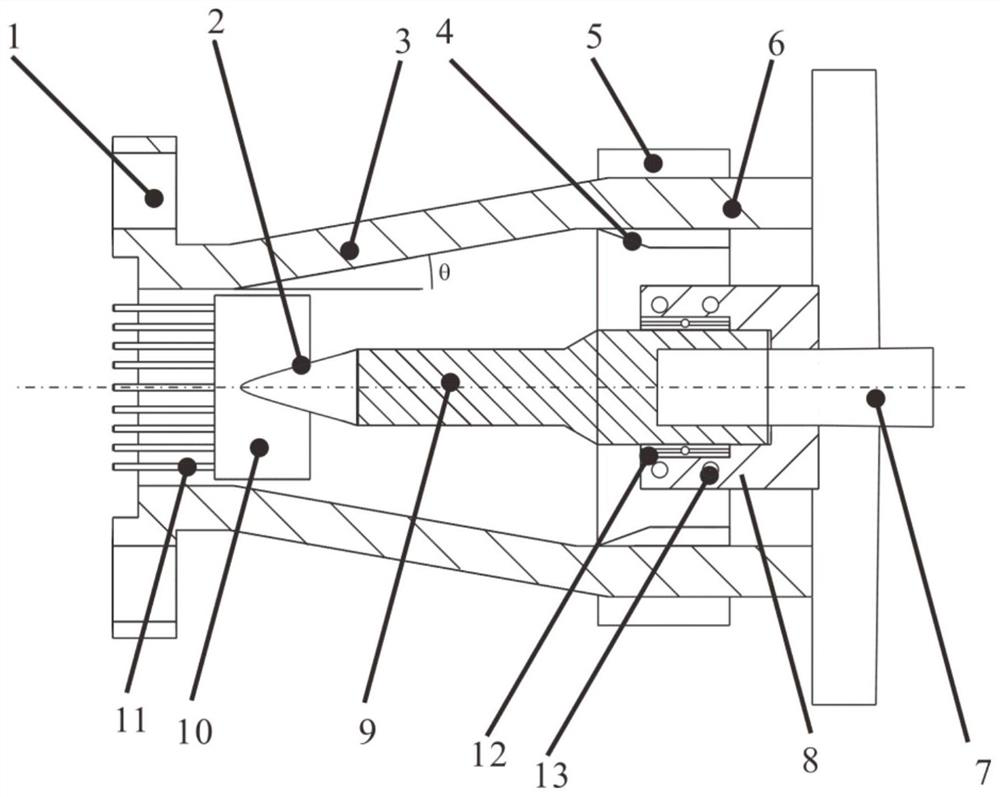

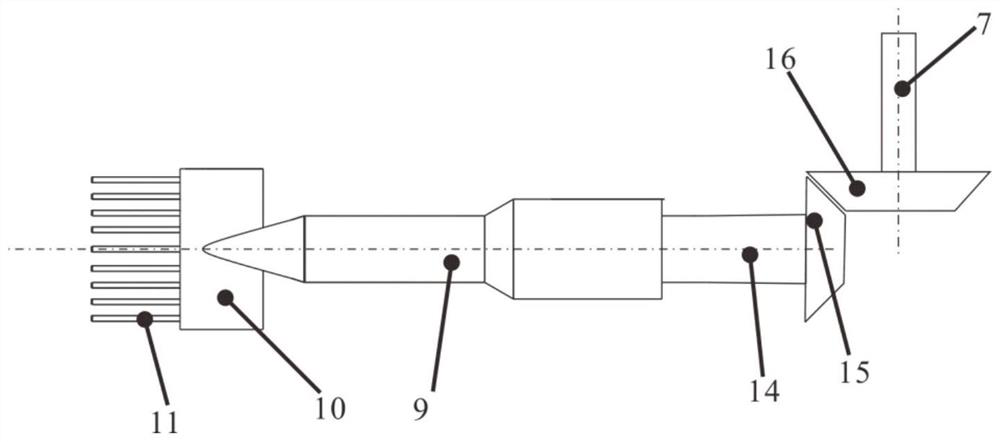

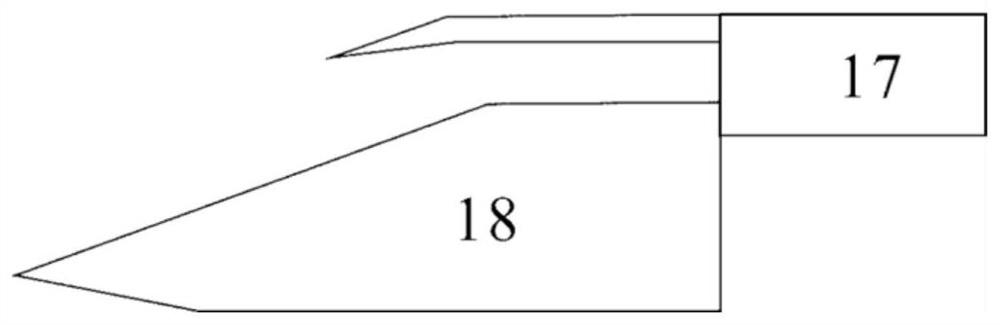

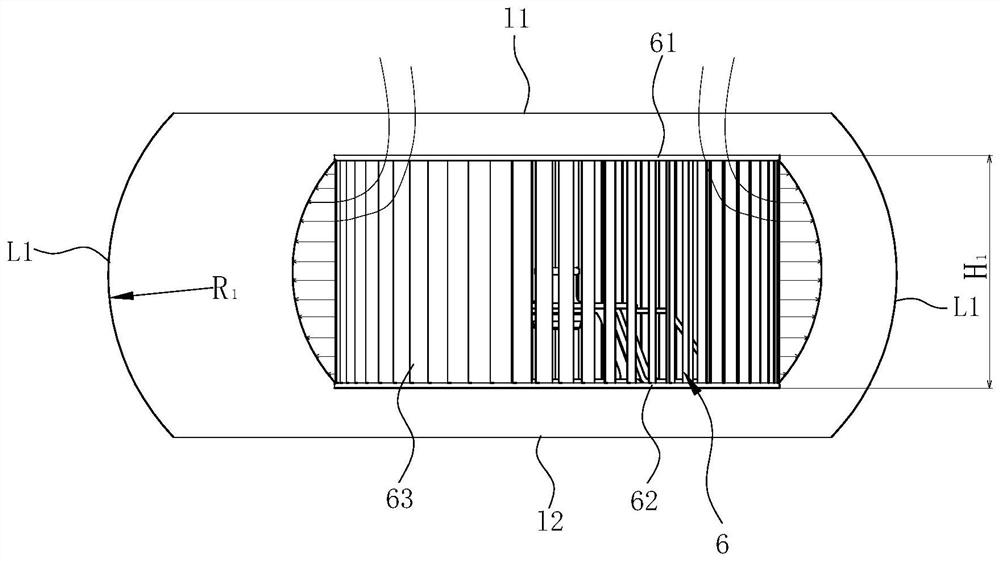

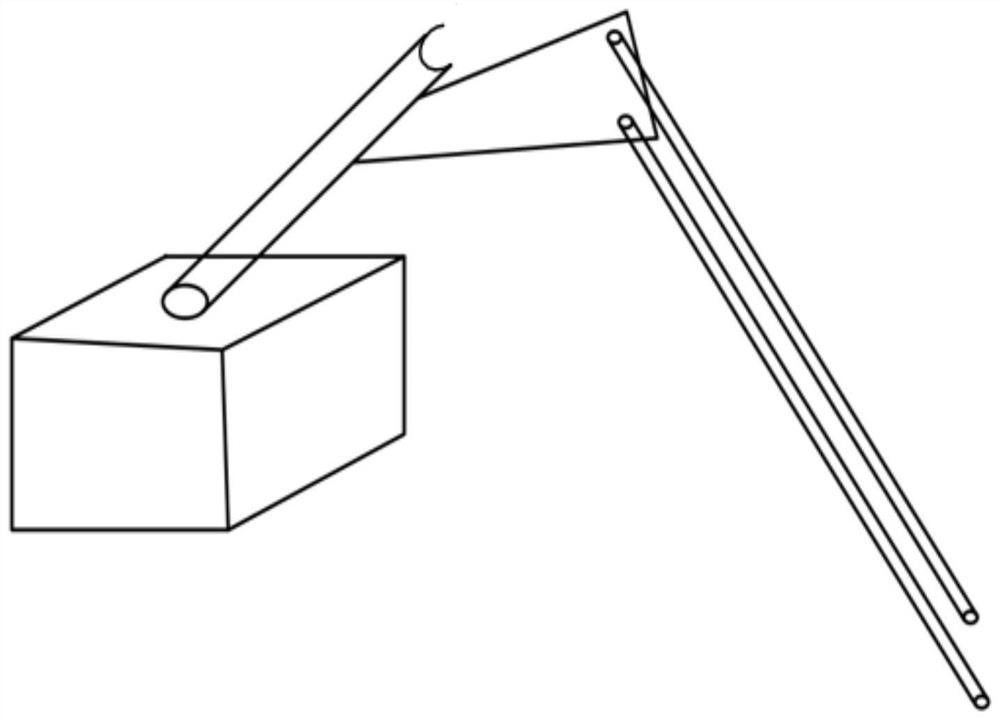

Rotary harrow total pressure test system and test method suitable for aircraft air inlet channel

ActiveCN112729756AReduce in quantityIncreased total pressure test rangeAerodynamic testingFluid pressure measurementInlet channelFlight vehicle

The invention discloses a rotary harrow total pressure test system and test method suitable for an aircraft air inlet channel. The test system comprises a total pressure harrow module, a rotating module and a driving device. The total pressure harrow module is driven by a driving device to rotate so that the pressure probe on the total pressure harrow can test the total pressure at different positions in the outlet of the air inlet channel in a pneumatic operation process. The system is simple in structure, small in size, wide in test range, high in quantization precision and rich in obtained data, avoids additional blockage of a test flow channel by traditional total pressure test systems such as a *-shaped harrow, a water-shaped harrow and the like and even adverse effects that the air inlet channel is not started, and solves the problems that the traditional total pressure harrow is fixed in structure position, single in data and the like. The test precision is greatly improved, the test cost is reduced, the influence on a test flow field is small, and the system is particularly suitable for a total pressure test with a small scaling model and a small flow channel area.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

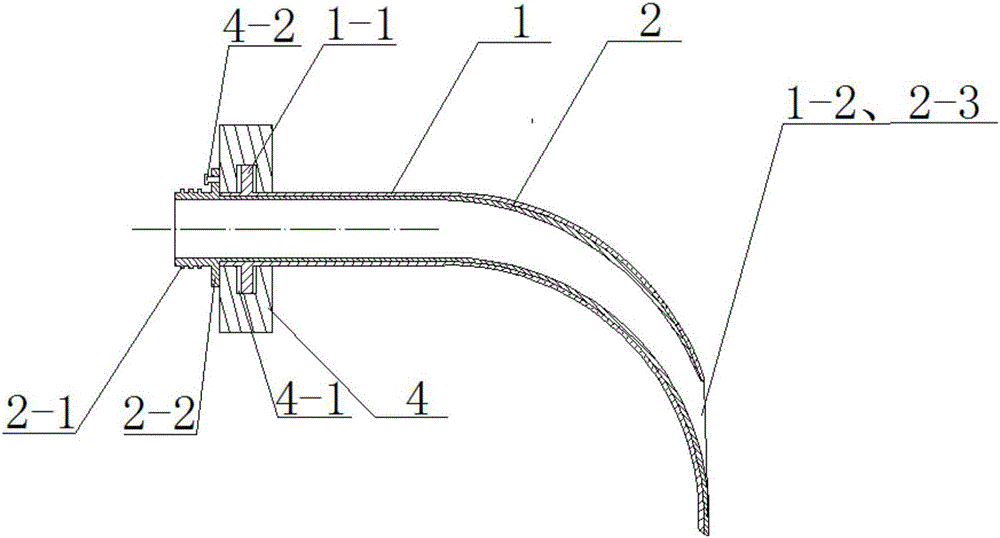

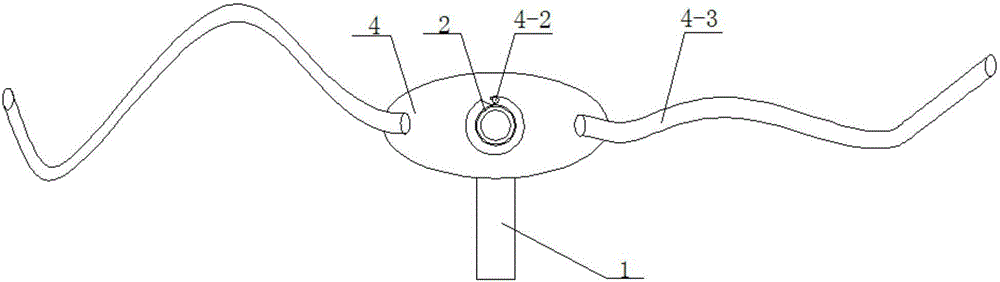

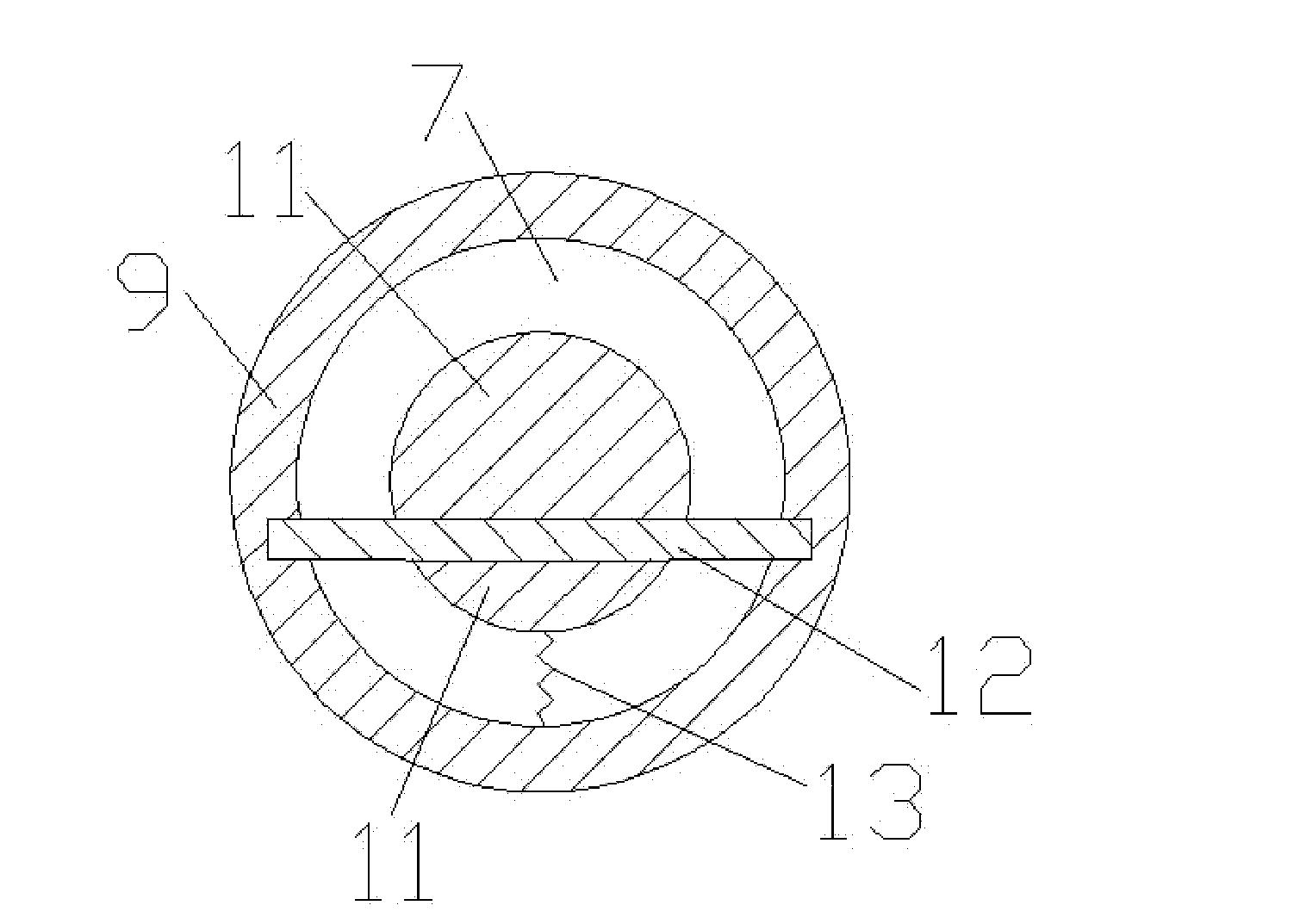

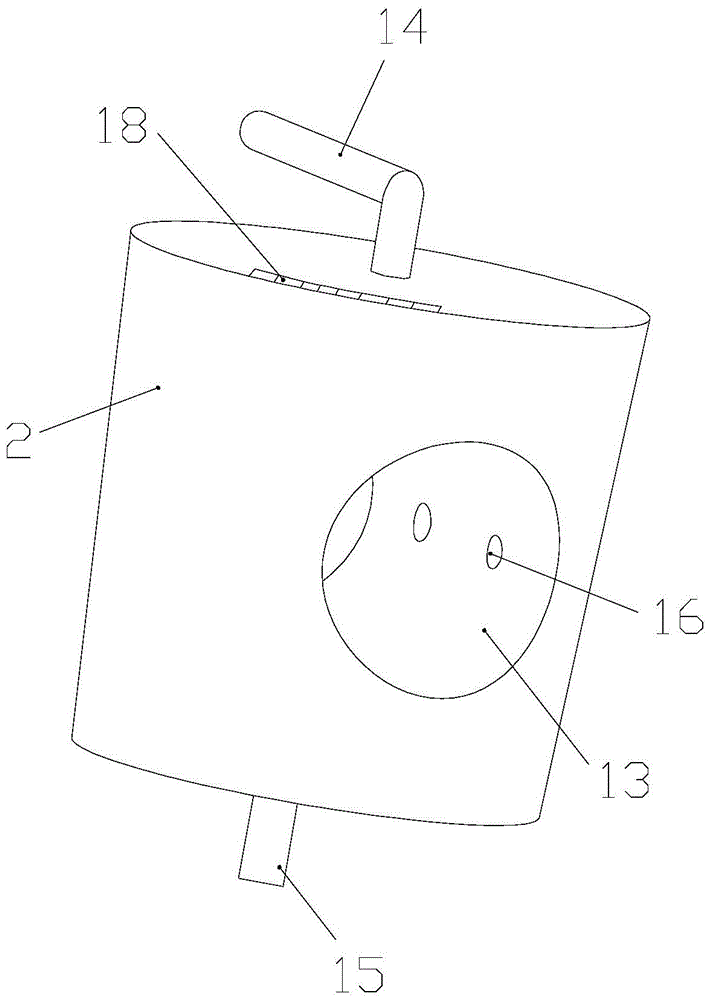

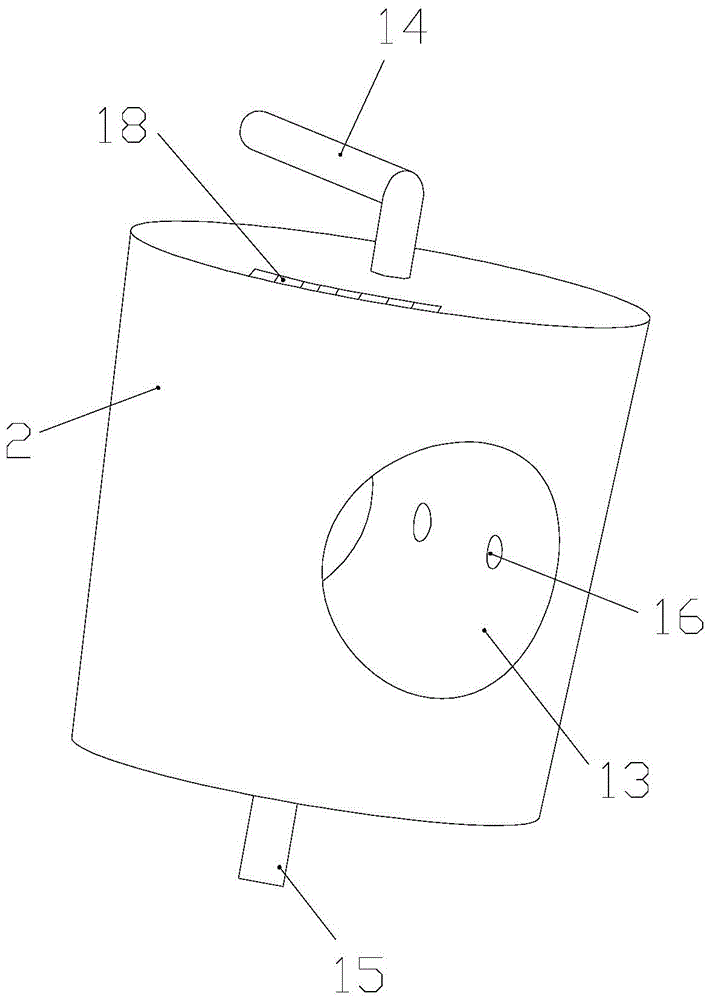

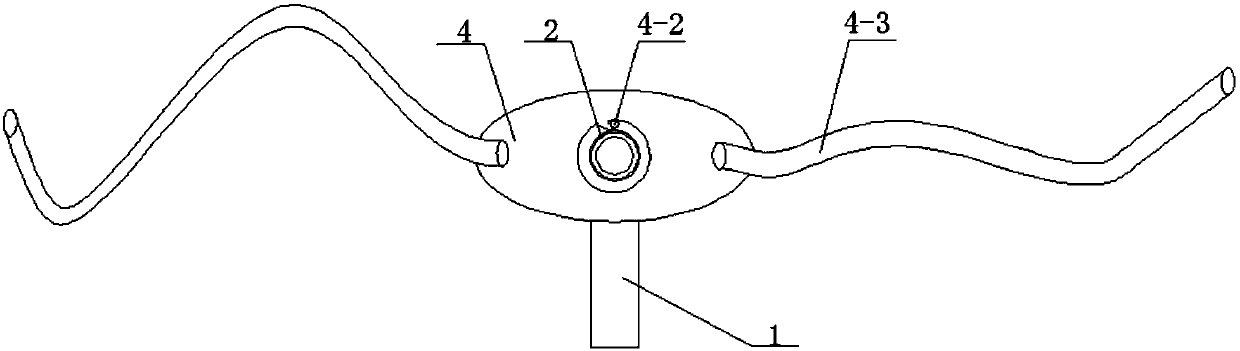

Sleeve used for tracheotomy

ActiveCN105944206AWon't come outIncrease the export areaTracheal tubesMedical devicesTracheotomyBiochemical engineering

The invention provides a sleeve used for the tracheotomy, relating to medical apparatus and instruments, aiming at solving the technical problem that the existing sleeve enables a patient to have the sensation of asphyxia, ventilation difficulty and sound production difficulty. An outer sleeve body of the sleeve is an arc-shaped tube, one end of the outer sleeve body is provided with an annular flange, the other end of the outer sleeve body is provided with a tapered cut; a fixing wing is arranged on the outer sleeve body, and fixing belts are arranged in through holes in the two ends of the fixing wing; an inner sleeve body is sleeved by the outer sleeve body and is an arc-shaped tube, one end of the inner sleeve body is provided with a flange, a clamp groove is formed in the flange and matched with a clamp pin of the fixing wing, external threads are arranged in front of the flange, and the external-cambered-surface side wall of the other end of the inner sleeve body is provided with a tapered cut; a tube core penetrates through the cavity of the inner sleeve body, and is composed of a plugging cap, a connecting rod and a guide head, and the inner wall of the plugging cap is provided with internal threads matched with the external threads of the inner sleeve body; and a hollow channel is formed in the tube core. The sleeve is used for the clinical tracheotomy, and has the advantages that the sensation of asphyxia of the patient can be alleviated, the separating seldom occurs, the sound production is easy during the sound production training, the design is reasonable, the connection is reliable, and the operation is convenient.

Owner:山西东景森贸易有限公司

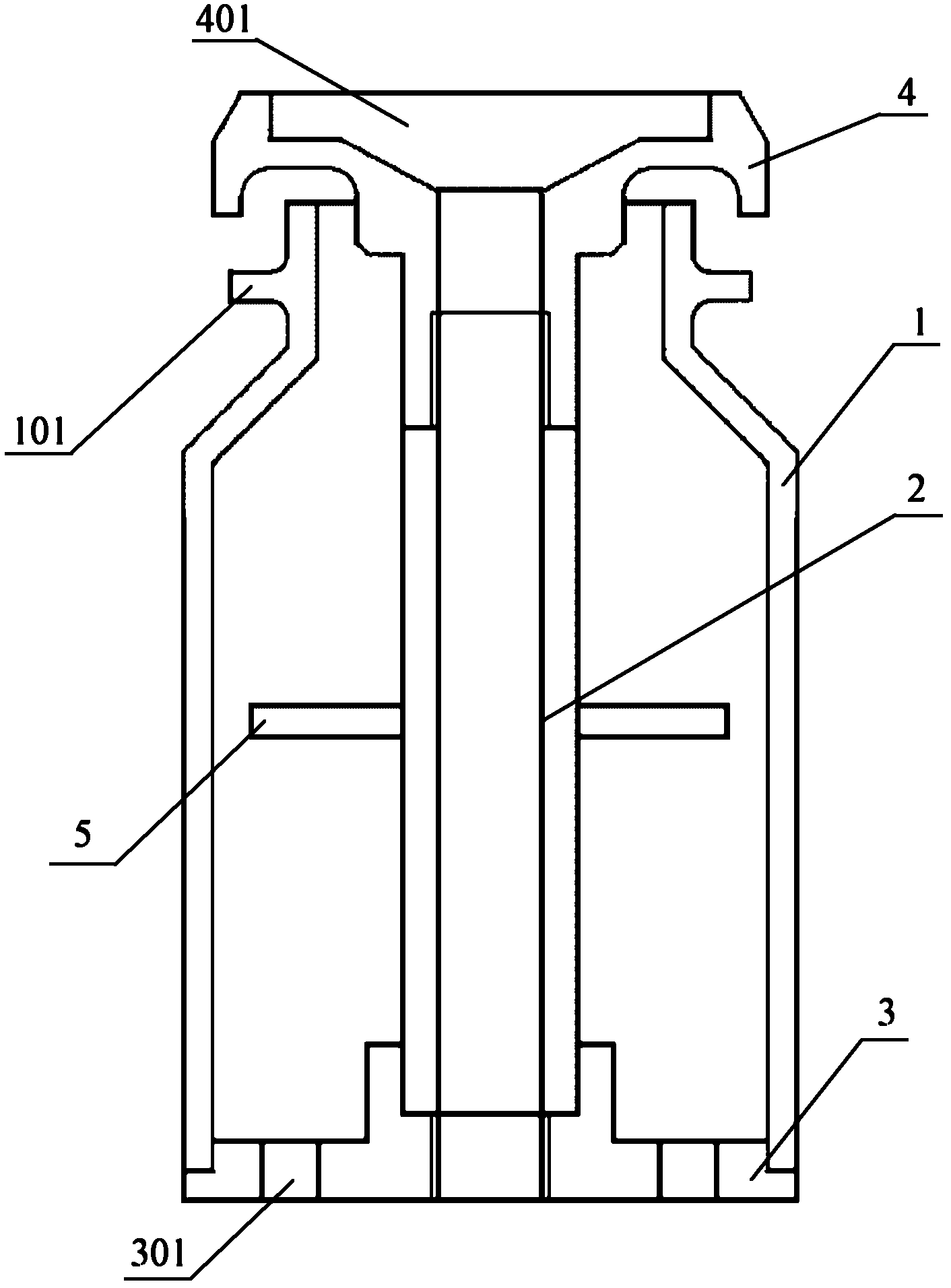

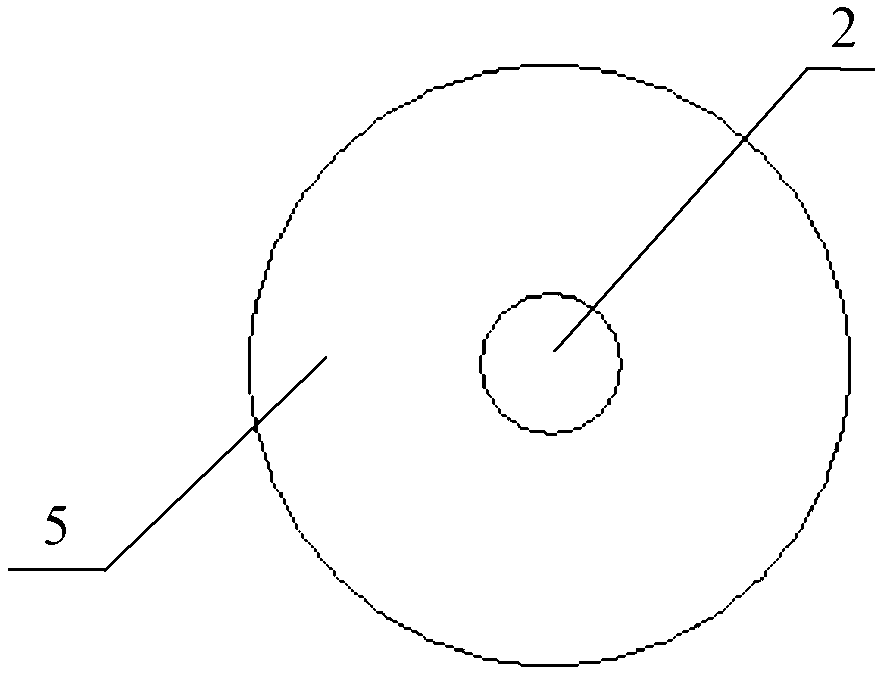

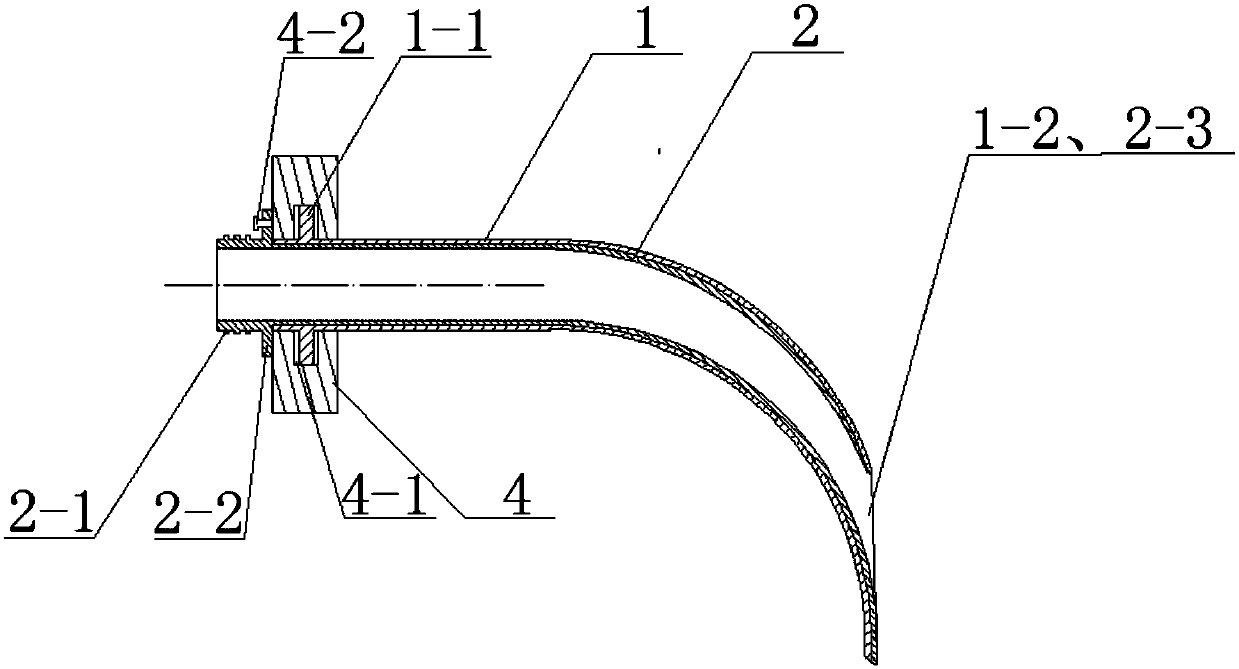

Anti-bubble rotary liquid filling mechanism

InactiveCN104015946AReduce impactAvoid it happening againLiquid materialLiquid bottlingVapor–liquid separatorEngineering

The invention discloses an anti-bubble rotary liquid filling mechanism which comprises an air cylinder (1), a connecting rod (2) and a filling head (3). The filling head (3) comprises a feeding pipe (4) and a discharge pipe (5). A buffer material bin (6) is arranged between the feeding pipe (4) and the discharge pipe (5), the feeding pipe (4), the buffer material bin (6) and the discharge pipe (5) are communicated, the lower end of the discharge pipe (5) is a spiral pipe body (501), the upper end of the discharge pipe (5) is a vertical pipe body (502), a baffle (7) is arranged outside the vertical pipe body (502) in a sleeved mode, a sensor is arranged on the lower surface of the baffle (7), and the sensor is connected with a control unit for controlling a piston rod of the air cylinder (1) to move. The liquid inlet end of the feeding pipe (4) is connected with a gas-liquid separator (8). The anti-bubble rotary liquid filling mechanism can disperse the vertical downward impact force of the liquid, so that when the liquid is injected into a bottle body or a box body, the impact force is small, and bubbles can be prevented from generation.

Owner:SUZHOU BODENA TECH

Gas film cooling hole structure used for thin-walled hot end part of gas turbine engine

ActiveCN105298649AReduce processing costsIncrease the export areaTurbine/propulsion engine coolingBody shapeDemarcation point

The invention discloses a gas film cooling hole structure used for a thin-walled hot end part of a gas turbine engine and belongs to the technical field of gas turbine engines. The gas film cooling hole comprises an inlet segment and a pit segment; the inlet segment is a cylindrical hole; the pit segment is formed by connecting a pit segment body shaped like a Chinese character 'xin' and located on the hole leeward with a semi-cylindrical pit segment body located on the hole windward face; starting from the tail end circle center, serving as an original point, of the inlet segment, the pit segment starts to expand to the hole windward face to form the semi-cylindrical pit segment body, and expand to the hole leeward to form the pit segment body shaped like the Chinese character 'xin'; and the pit segment body shaped like the Chinese character 'xin' and the semi-cylindrical pit segment body use an outlet cross section center point of the cylindrical hole as a demarcation point. The gas film cooling hole has the beneficial effects that the outlet area of the gas film cooling hole can be increased, the cold gas outlet momentum is reduced, and the cold gas covering effect is enhanced; and inverted-kidney-shaped vortexes are generated through the pit segment body shaped like the Chinese character 'xin' and located on the leeward of the pit segment, a flow field structure favorable for gas film cooling coverage is constructed, and the wall face can be better covered with cooling fluid.

Owner:TSINGHUA UNIV

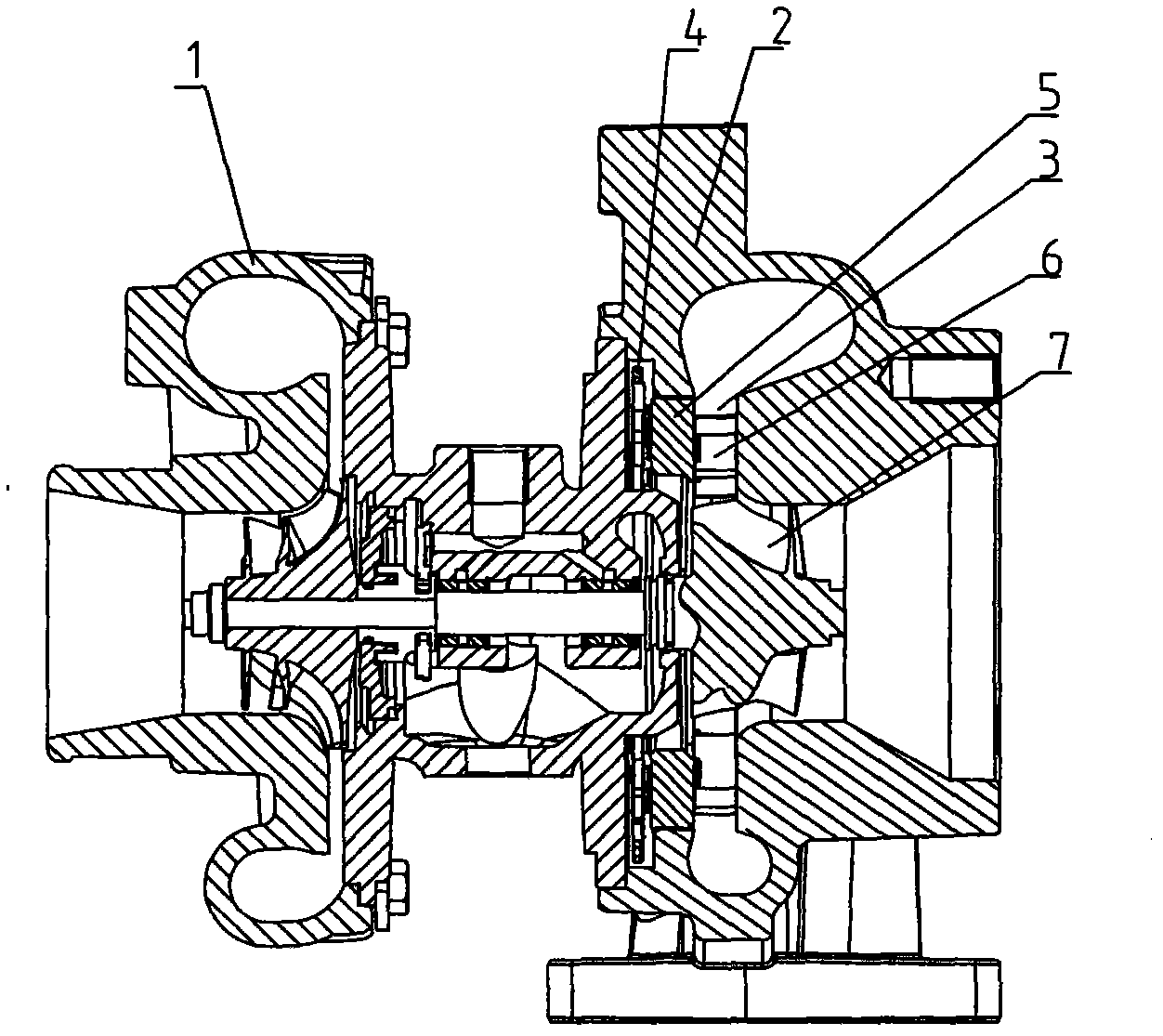

Turbocharging system with adjustable exhaust pipe outlet area

InactiveCN102425489AIncrease the export areaImprove machine performanceInternal combustion piston enginesLow speedCombustion

The invention provides a turbocharging system with adjustable exhaust pipe outlet area, belonging to the technical field of internal combustion engines. The system comprises cylinders, an exhaust pipe, a turbine, a rotating plate, a rotating shaft and an elastic part, wherein the rotating shaft passes through the rotating plate and is fixedly connected with the rotating plate; the rotating plate is asymmetrically distributed at the upper and lower sides of the rotating shaft; the two ends of the rotating shaft are installed on the side walls of the exhaust pipe; and the rotating plate is connected with one side wall of the exhaust pipe by the elastic part. In the working process of the system, when the engine is in the high speed working condition, the rotating plate drives the rotating shaft to rotate counterclockwise, the exhaust pipe outlet area is relatively large, the pumping loss is lower and the overall performance of the engine is better; and when the engine is in the low speed working condition, the rotating plate drives the rotating shaft to rotate clockwise, the exhaust pipe outlet area is relatively small, more available energy exists in front of the turbine, the inlet pressure of the engine is higher and the overall performance of the engine is better. The system has reasonable design and simple structure and is suitable to be provided with one turbine inlet and the side turbine.

Owner:SHANGHAI JIAO TONG UNIV

Corrugated film hole with branch holes

ActiveCN111706409AIncrease the export areaReduce momentumEngine fuctionsBlade accessoriesPhysicsEngineering

The invention discloses a corrugated film hole with branch holes. The corrugated film hole is divided into double-corrugated hole and single-corrugated hole; the double-corrugated hole comprises a main hole and two branch holes; each branch hole is composed of a branch hole front half section and a branch hole rear half section; and the single-corrugated hole comprises a main hole and two branch hole rear half sections. Compared with a cylindrical hole, the corrugated film hole with the branch holes provided by the invention has the advantages that the film cooling performance can be greatly improved, the cooling effect is better and more stable under the low air blowing ratio compared with an international advanced nekomimi hole, and the cooling effect is greatly improved under the high air blowing ratio, so that the film coverage is more balanced and effective; the hole pattern structure complexity is greatly simplified, the machining difficulty is reduced, the machining fault tolerance degree is increased, and a contribution is made to landing of the advanced cooling technology in China.

Owner:CIVIL AVIATION UNIV OF CHINA

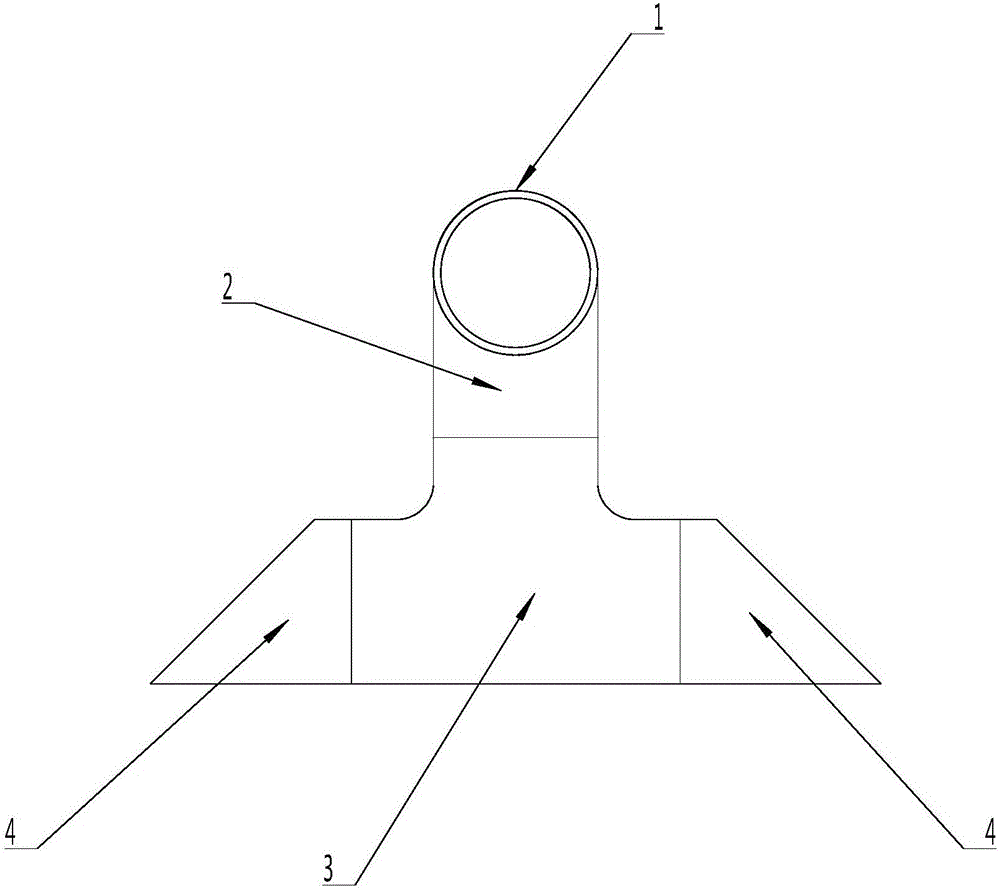

Outdoor weather-proof pilot flame combustion device

ActiveCN102330981AIncrease the export areaAvoid hypoxic extinguishingGaseous fuel burnerBad weatherSevere weather

The invention provides an outdoor weather-proof pilot flame combustion device, which comprises a shell, a central gas inlet pipe and a pedestal, and is characterized by also comprising an upper cover, wherein the upper part of the upper cover is provided with a concave body; the lower end of the shell is connected with the pedestal; the near end part of the upper end of the shell is provided witha ring body; the middle part of the pedestal is provided with a fuel gas inlet; the fuel gas inlet is joined to the lower end of the central gas inlet pipe; the middle part of the central gas inlet pipe is radially provided with a fuel gas outlet; the upper end of the central gas inlet pipe is joined to the upper cover; the outer edge of the upper cover protrudes downwards; and the protrusion andthe ring body form an inverted U-shaped fuel gas passage. The combustion device provided by the invention can keep flame combusting outdoors under bad weather conditions such as strong wind, rainstorm and the like, and the fuel gas consumption is reduced.

Owner:上海集焰节能科技有限公司

Outdoor natural gas burner

ActiveCN102330977AIncrease the export areaAvoid hypoxic extinguishingGaseous fuel burnerCombustorEngineering

The invention provides an outdoor natural gas burner. The burner comprises a shell, a pedestal and a fuel gas inlet, a centre drainpipe and an upper cover, wherein the lower end of shell is connected with the pedestal, and the position close to the end part of the upper end of shell is provided with a ring body; the external edge of the upper cover is provided with a downward bulge, the bulge andthe ring body form an inverted U-shaped fuel channel, and the upper part of the upper cover is provided with a concave part; and the upper end of the centre drainpipe is communicated with the bottom of the concave part, the lower end of the centre drainpipe is communicated with the pedestal, the fuel gas inlet is arranged on the pedestal and positioned between the shell and the centre drainpipe. The burner provided by the invention has the advantages of keeping flame burning under the outdoor server weather environment, and reducing the loss of the fuel gas.

Owner:上海集焰节能科技有限公司

Multi-purpose valve device

InactiveCN104565450ADosage controlEffective traffic controlValve members for heating/coolingMultiple way valvesEngineeringMechanical engineering

The invention provides a multi-purpose valve device. The device comprises a valve body and a valve element; a spigot is formed in the valve body and is closely clung to the outer tapered surface of the valve element; the valve element is compressed into the spigot through a valve element core and a sealing pad; a rod arranged at the bottom part of the valve element passes through a hole in the bottom part of the valve rod and then extends out from the valve body; a spring is arranged on the rod; a nut is screwed to threads in the rod to compress the spring; a plurality of inlets are formed in one end of the valve body, and while a plurality of outlets are formed in the other end of the valve body; filters are arranged in the inlets; each inlet is connected with a solution source or an air source through a pipe joint or a connecting pipe; each outlet is connected with a water faucet or a spiral groove injection head through the pipe joint and the connecting pipe. According to the multi-purpose valve device, the valve element communicates with one or a plurality of inlets and one or a plurality of outlets of different specifications in the valve body to control solution flow rate as requirement; the device has the advantages of being simple in structure and convenient to operate; people can accurately control the dosage and save the resource.

Owner:黄卫科

Apparatus for the heat treatment of a web of textile material

InactiveCN102971598BPlay a role in heat insulationAbsorb moreDrying machines with progressive movementsHeating arrangementHeat treatingExhaust gas

The invention relates to an apparatus for the heat treatment of a web of textile material (3) comprising a housing (6), means for guiding the web of material (3) in the housing (6), means for blowing heated treatment gas (5) onto the web of material (3), at least part of the treatment gas being supplied as fresh air and exhaust gas being carried away, and a heat wheel (7) for preheating the fresh air by means of the exhaust gas. It is intended to improve the apparatus in such a way as to create lines for indirectly preheating fresh air by means of exhaust air without any significant additional expenditure and without the height of the apparatus being any greater, or significantly greater, than in the case of apparatuses without preheating. This is achieved by the heat wheel (7) being connected directly to warm sides of the ducts (9, 10) for the fresh air and for the exhaust air, the warm sides of the ducts (9, 10) being routed exclusively inside the housing (6).

Owner:A MONFORTS TEXTILMASCHINEN GMBH & CO KG

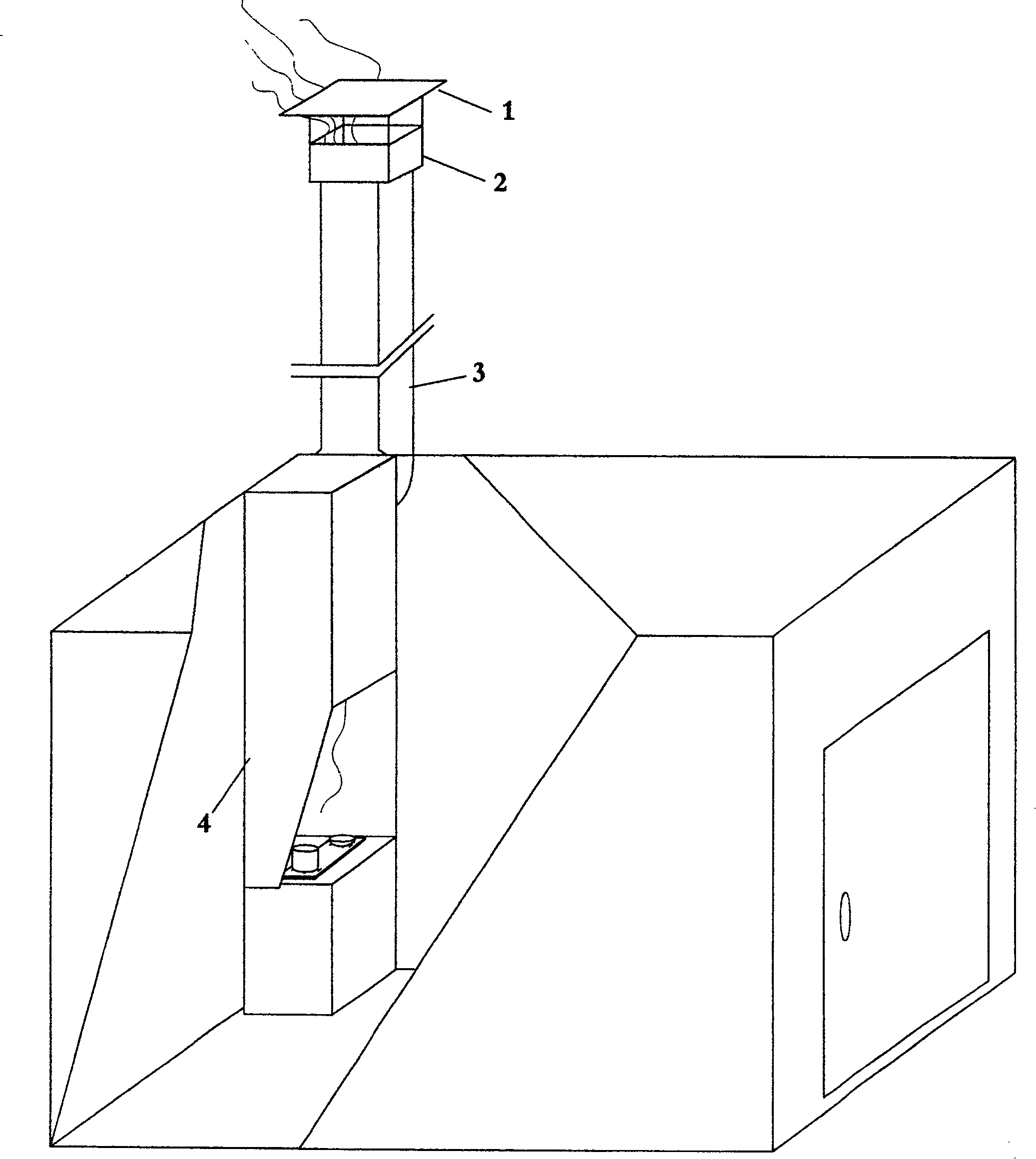

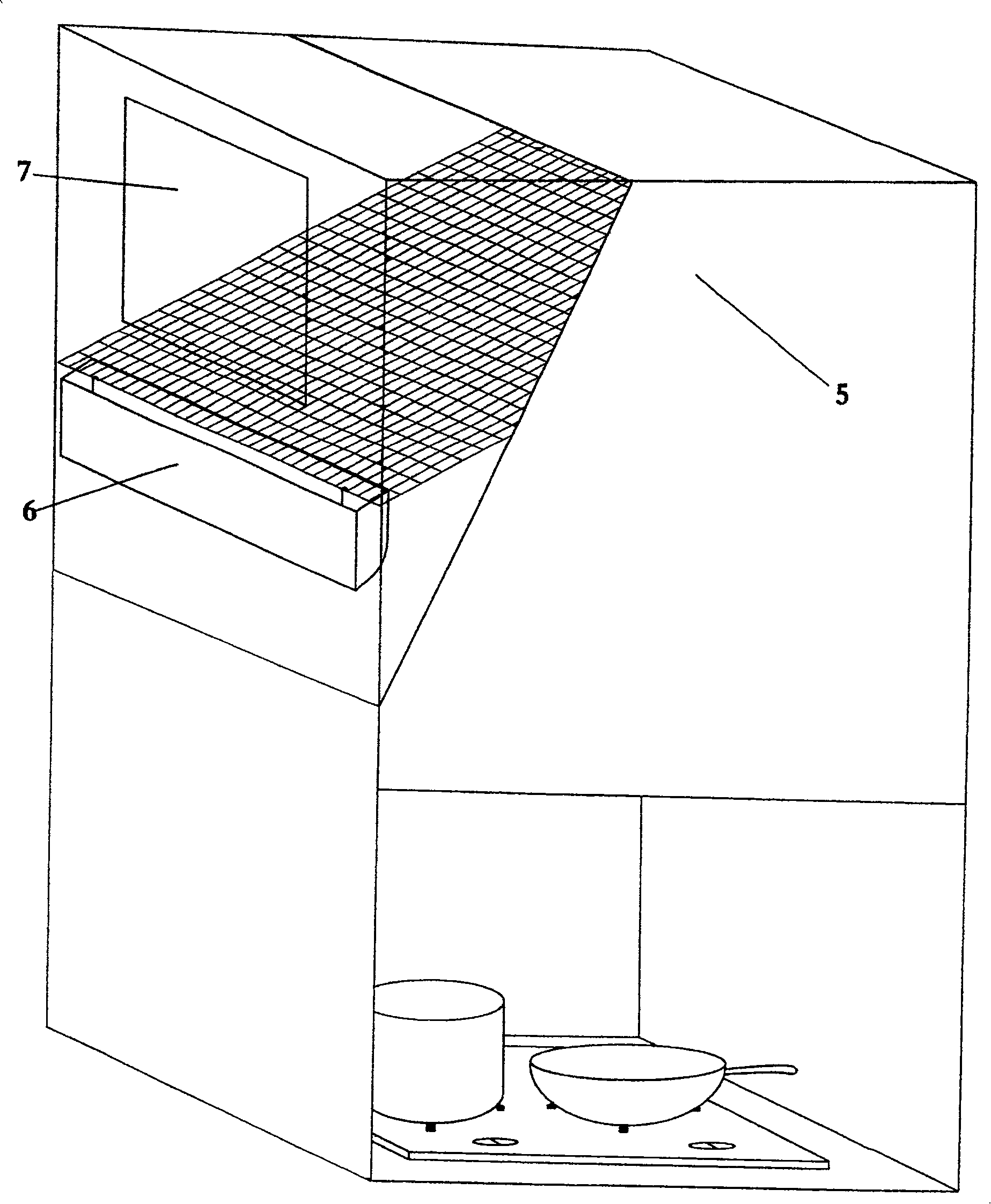

Kitchen automatic smoke discharging device

InactiveCN100404961CLarge volumeSufficient depthDomestic stoves or rangesLighting and heating apparatusThermal energyMechanical abrasion

This invention provides kitchen auto smoke evacuation device. It includes suction flue, breakwind deck, flashing, smoke collection cavity, oil guide net and oil sump. Its feature is that smoke evacuation is big, using is convenient, no needs of electrical energy and mechanism equipment, no economic consumption in smoke evacuation, no noise disturbing talk inside and outside house, no mechanical friction, no operation program, no unpick and wash program, no rest working capability, natural protection of cavity inner wall in the process of sucking oil smoke. It can full discharge oil smoke and discharging time is free, and the oil smoke discharged will not pollute house. Existing problem and defect of oil smoke discharging is fully solved, and its structure is simple, manufacturing is convenient, material source is wide, price is cheap, and product fabrication cost is low.

Owner:张俊岭

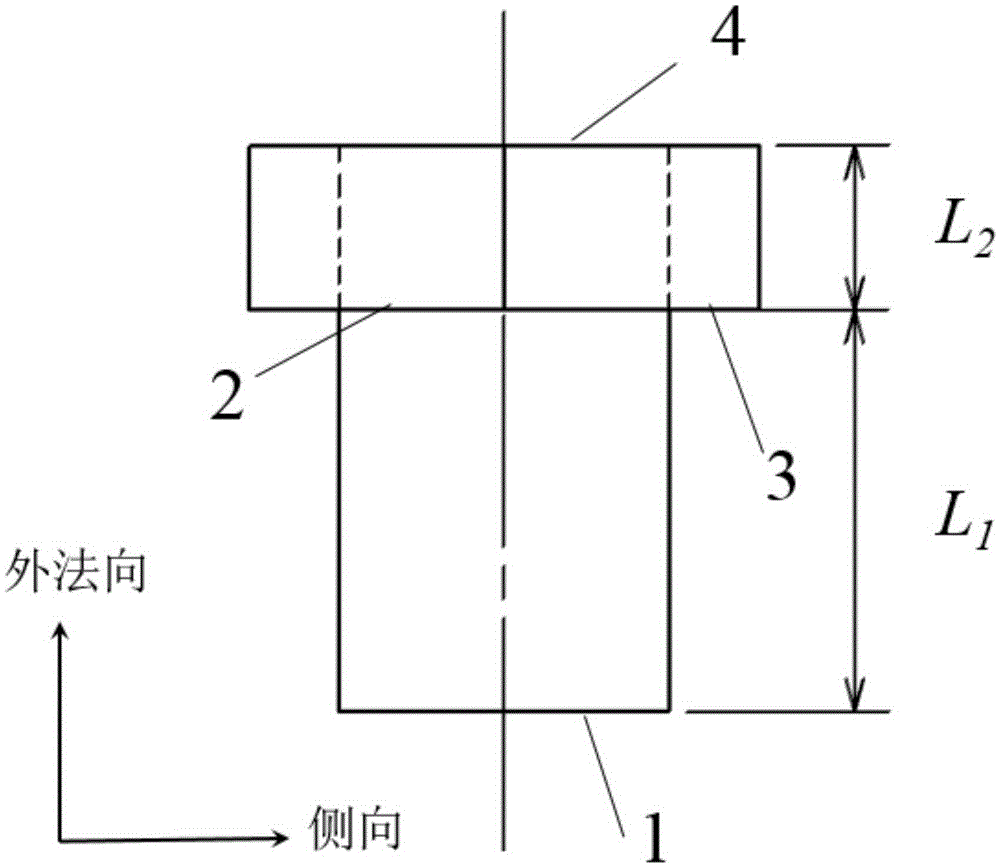

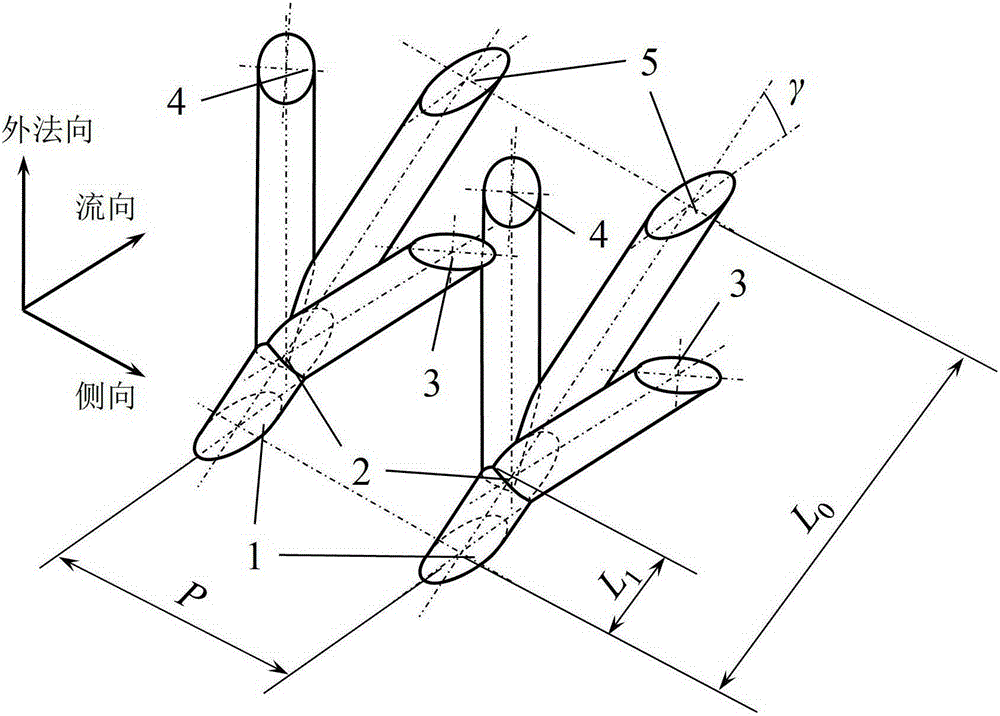

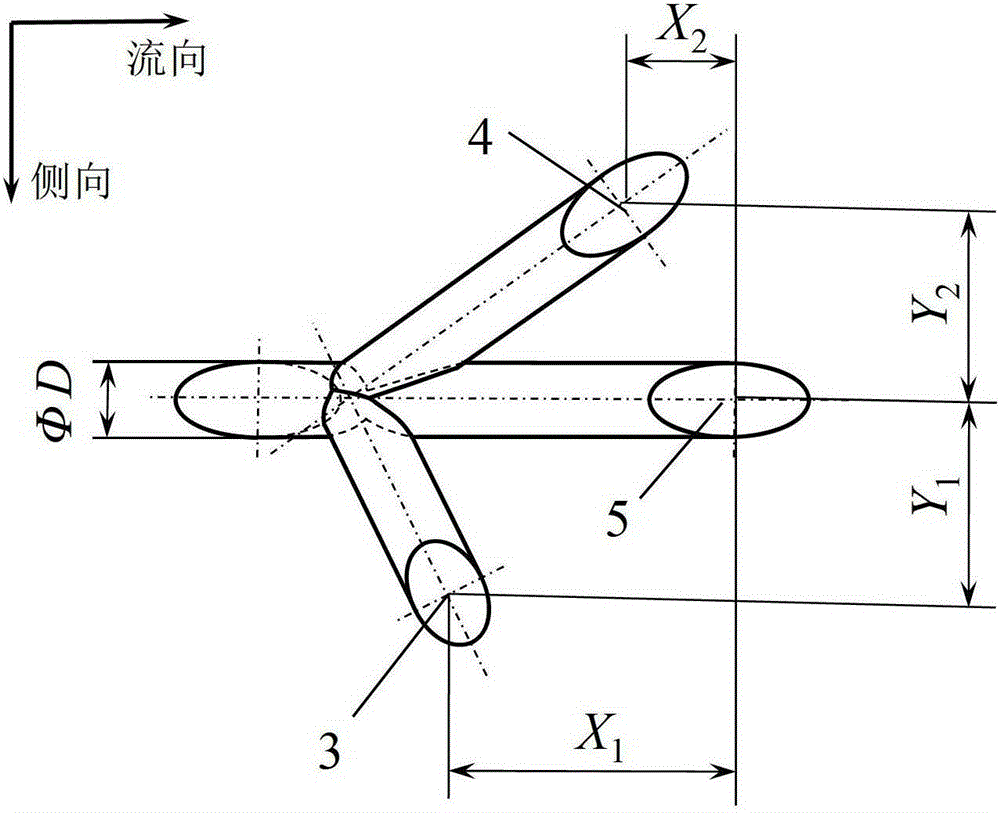

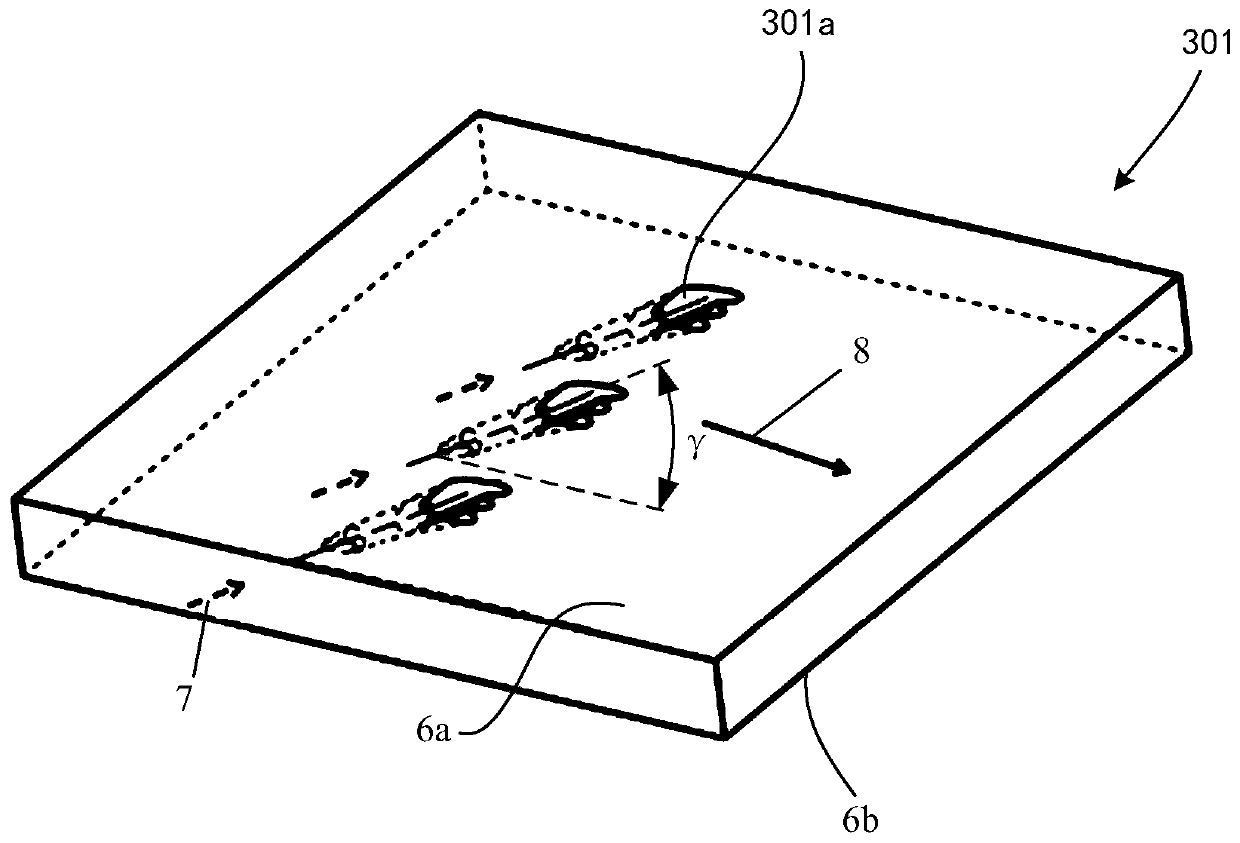

A Branched Film Hole Structure for Gas Turbine Engine Cooling

ActiveCN103437889BGood for flow field structureReduce processing costsContinuous combustion chamberTurbine/propulsion engine coolingCombustion chamberEngineering

The invention provides a branch gas film hole structure for cooling a gas turbine engine, which is applicable to cooling high-temperature components such as a combustion chamber and a turbine of the gas turbine engine. Branch gas film holes are formed equidistantly in rows; each branch gas film hole comprises a main hole, a first branch hole and a second branch hole; the holes are straight holes with circular sections; the two branch holes are connected with the main hole in the same position in each branch gas film hole; and positions of flow directions of the first branch holes and the second branch holes are in tandem, so that the first branch hole of each branch gas film hole and the second branch hole of the adjacent branch gas film hole form mutual interference. According to the branch gas film hole structure, an outlet area is increased by the branch holes; a gas film cooling coverage area is increased; a flow field structure facilitating gas film cooling coverage is constructed due to the mutual interference among the branch holes of the adjacent branch gas film holes; and a cooling fluid has a better coverage effect on a wall surface.

Owner:TSINGHUA UNIV

Multifunctional muffler structure

ActiveCN103410586BStationary Noise ReductionGood exhaust noiseExhaust apparatusSilencing apparatusSiphonEngineering

The invention relates to a multifunctional muffler structure. The multifunctional muffler structure comprises a barrel body, an inner partition plate A, an inner partition plate B, an inner partition plate C and an inner partition plate D are arranged in the barrel body, and an air inlet muffler pipe, a middle muffler pipe and two air outlet muffler pipes are fixed in the barrel body; the four inner partition plates divide the barrel body into five muffler cavities. The air outlet muffler pipes are arranged symmetrically, so that exhaust back pressure is favorable for being reduced, and then the work efficiency of an engine is ensured; because siphons are arranged on the air outlet muffler pipes, water accumulating in a muffler can be eliminated by the utilization of the pressure difference between an inlet and an outlet of the muffler and on the basis of the siphon principle, the muffler is prevented from rusting, and the service life and the using reliability of the muffler are ensured; due to the combination of the multiple muffler cavities and the muffler components, exhaust noise is reduced substantially, and the riding comfort of a whole vehicle is improved; the application of a stamped shell makes the muffler be more beautiful and more elegant and fully show the feel of modern science and technology.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Cooling hole, engine combustion chamber and cooling hole processing method

ActiveCN109519969BImprove cooling effectIncrease the export areaContinuous combustion chamberThermodynamicsLaser processing

Owner:AECC COMML AIRCRAFT ENGINE CO LTD

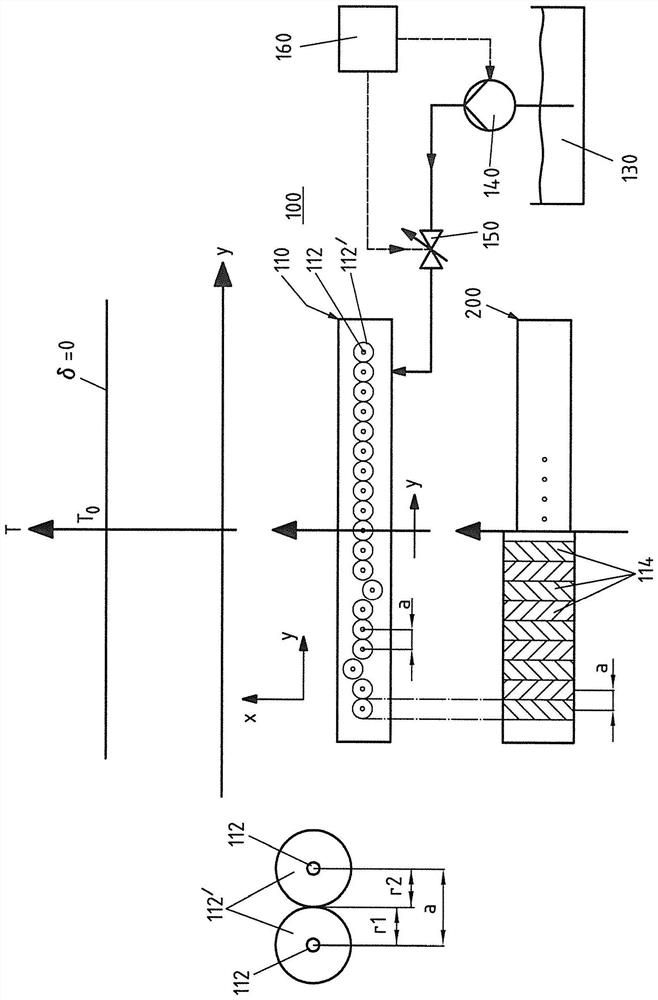

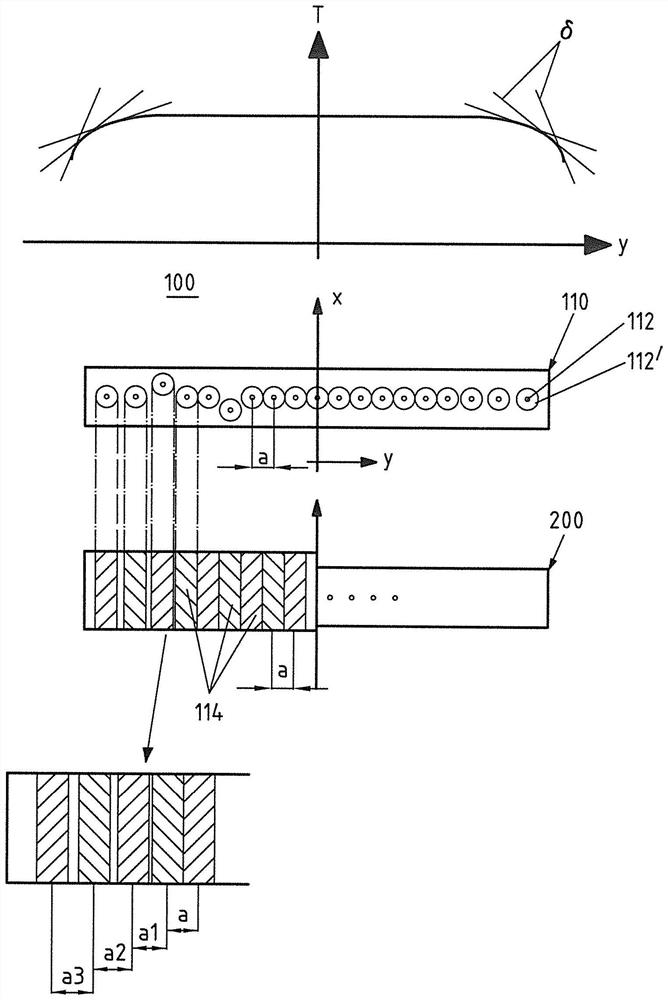

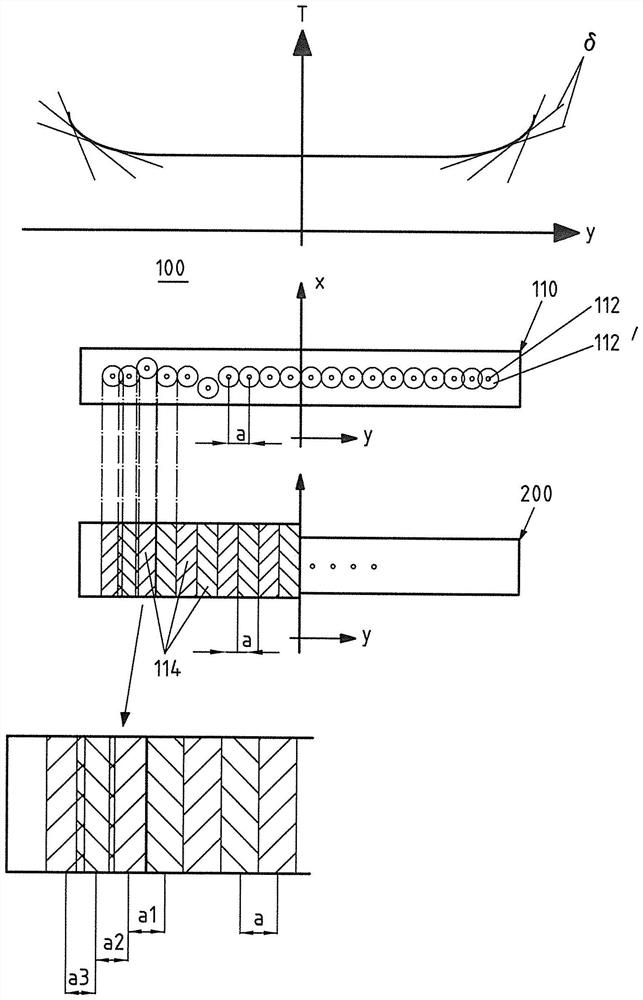

Cooling apparatus for cooling a metal material and method for the production and use thereof

ActiveCN112041098ALow densityIncrease the export areaTemperature control deviceFurnace typesEngineeringMaterials science

The invention relates to a cooling apparatus (100) for cooling a metal material and to methods for operating and producing the cooling apparatus. The cooling apparatus has at least one cooling beam (110) having a plurality of coolant application elements (112) for applying a coolant to the metal material, wherein each coolant application element (112) has an outlet opening having a cross-sectionalarea (112') for the outlet of the coolant. In order to be able to adapt such known cooling apparatuses more precisely to different temperature distributions over the width of the metal material to becooled, according to the invention the density of the cross-sectional areas (112') of the outlet openings of the coolant application elements (112) in the width direction y of the cooling beam (110)is adapted and dimensioned in accordance with the magnitude of the slope of the distribution of the temperature T(y) of the metal material over the width of the latter before running in under the cooling beam (110).

Owner:SMS GRP GMBH

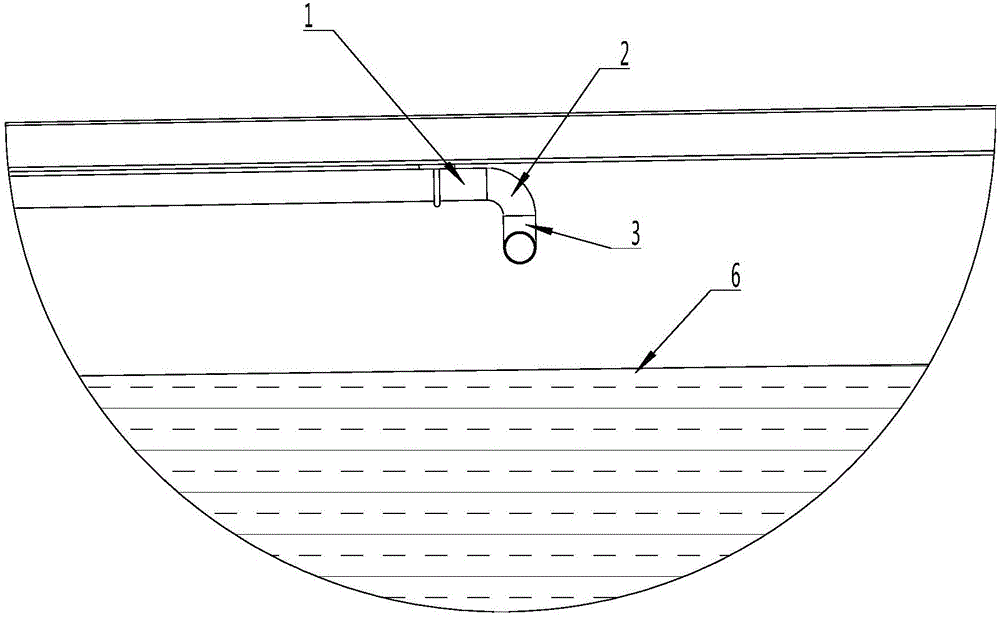

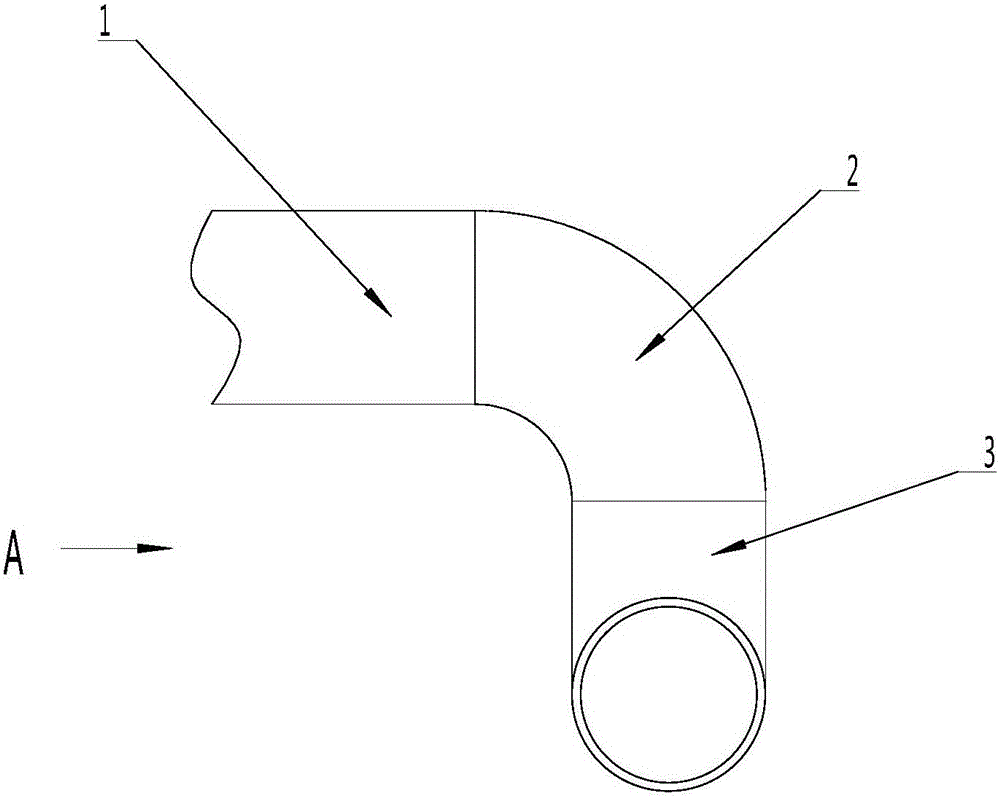

Gas phase opening liquid-inlet-prevention device

ActiveCN105782714AIncrease the export areaReduced air speedVessel geometry/arrangement/sizeContainer filling methodsAirflowEngineering

The invention discloses a gas phase opening liquid-inlet-prevention device. The gas phase opening liquid-inlet-prevention device comprises a main pipe and a branch pipe, wherein the main pipe is connected with a gas phase pipe and points to the liquid level, and the branch pipe is used for carrying out separated guiding on gas; the main pipe is connected with the middle segment of the branch pipe, and the total radial cross-sectional area of an outlet of the branch pipe is not smaller than that of the gas phase pipe; and according to the gas phase opening liquid-inlet-prevention device, the effect on blocking liquid can be achieved, splashed liquid falls back into a tank, a gas path is separated through the branch pipe, the pipe area is increased, and the gas flow speed is reduced. According to the structure, resistance to the air flow can be further reduced, the noise in the use is reduced, it is ensured that gas can smoothly enter the device from the gas phase pipe, and therefore a pipeline outside the tank can be protected against being affected, and the service life of a tank car is prolonged.

Owner:广东建成机械设备有限公司

A rotary rake total pressure test system and test method suitable for aircraft air intakes

ActiveCN112729756BReduce in quantityIncreased total pressure test rangeAerodynamic testingFluid pressure measurementFlight vehicleClassical mechanics

The invention discloses a rotary rake total pressure testing system and a testing method suitable for an aircraft air inlet. The test system includes a total pressure rake module, a rotating module and a driving device. The total pressure rake module is driven to rotate by the driving device, so that the pressure probe on the total pressure rake can test the total pressure at different positions in the outlet of the air inlet during pneumatic operation. The invention has the advantages of simple structure, small size, wide testing range, high quantification accuracy, and abundant data, which avoids the additional blockage of the test flow channel by the traditional total pressure test system such as the rice rake and the water rake, and even causes the air inlet channel to be unsightly. It solves the problems of fixed location and single data of the traditional total pressure rake structure, greatly improves the test accuracy, reduces the test cost, and has little influence on the test flow field, especially suitable for small scale models and flow Total pressure test with small channel area.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

A multi-purpose valve device

InactiveCN104565450BDosage controlEffective traffic controlValve members for heating/coolingMultiple way valvesEngineeringMechanical engineering

The invention provides a multi-purpose valve device. The device comprises a valve body and a valve element; a spigot is formed in the valve body and is closely clung to the outer tapered surface of the valve element; the valve element is compressed into the spigot through a valve element core and a sealing pad; a rod arranged at the bottom part of the valve element passes through a hole in the bottom part of the valve rod and then extends out from the valve body; a spring is arranged on the rod; a nut is screwed to threads in the rod to compress the spring; a plurality of inlets are formed in one end of the valve body, and while a plurality of outlets are formed in the other end of the valve body; filters are arranged in the inlets; each inlet is connected with a solution source or an air source through a pipe joint or a connecting pipe; each outlet is connected with a water faucet or a spiral groove injection head through the pipe joint and the connecting pipe. According to the multi-purpose valve device, the valve element communicates with one or a plurality of inlets and one or a plurality of outlets of different specifications in the valve body to control solution flow rate as requirement; the device has the advantages of being simple in structure and convenient to operate; people can accurately control the dosage and save the resource.

Owner:黄卫科

A kind of cannula for tracheotomy

ActiveCN105944206BWon't come outIncrease the export areaTracheal tubesMedical devicesTracheotomyBiochemical engineering

The invention provides a sleeve used for the tracheotomy, relating to medical apparatus and instruments, aiming at solving the technical problem that the existing sleeve enables a patient to have the sensation of asphyxia, ventilation difficulty and sound production difficulty. An outer sleeve body of the sleeve is an arc-shaped tube, one end of the outer sleeve body is provided with an annular flange, the other end of the outer sleeve body is provided with a tapered cut; a fixing wing is arranged on the outer sleeve body, and fixing belts are arranged in through holes in the two ends of the fixing wing; an inner sleeve body is sleeved by the outer sleeve body and is an arc-shaped tube, one end of the inner sleeve body is provided with a flange, a clamp groove is formed in the flange and matched with a clamp pin of the fixing wing, external threads are arranged in front of the flange, and the external-cambered-surface side wall of the other end of the inner sleeve body is provided with a tapered cut; a tube core penetrates through the cavity of the inner sleeve body, and is composed of a plugging cap, a connecting rod and a guide head, and the inner wall of the plugging cap is provided with internal threads matched with the external threads of the inner sleeve body; and a hollow channel is formed in the tube core. The sleeve is used for the clinical tracheotomy, and has the advantages that the sensation of asphyxia of the patient can be alleviated, the separating seldom occurs, the sound production is easy during the sound production training, the design is reasonable, the connection is reliable, and the operation is convenient.

Owner:山西东景森贸易有限公司

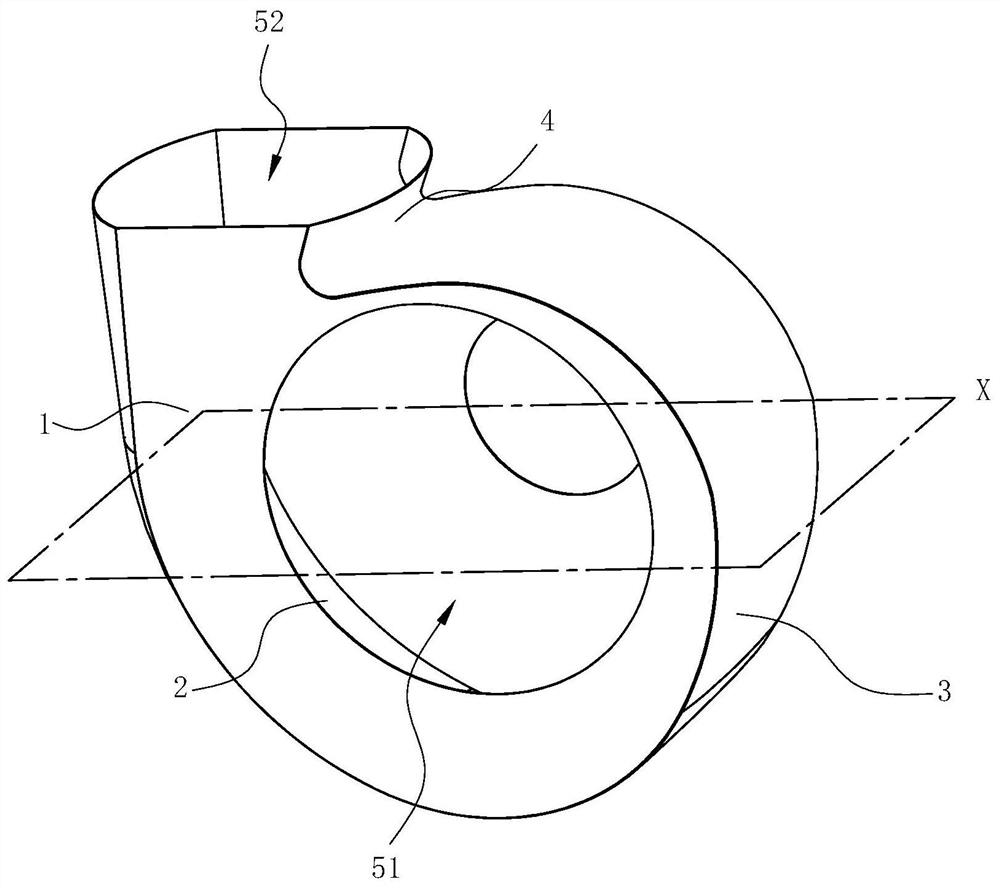

a centrifugal fan

ActiveCN110259724BReduce flow dead zoneEliminate flow dead zonesPump componentsPumpsCentrifugal fanPhysics

The invention discloses a volute for a centrifugal fan. The volute comprises a front cover and a rear cover which are parallel to each other, and a ring wall connected between the front cover and the rear cover, wherein an air outlet is formed among the front cover, the rear cover and an annular wall, a plane which is perpendicular to the front cover and the rear cover, penetrates through the annular wall, and is parallel to the air outlet is used as a section, on the section, a molded line of the annular wall comprises two line segments connecting the corresponding end portions of a front cover type line and a rear cover type line, and the middles of the line segments are more protruded out of the volute relative to the two ends. The invention further discloses a centrifugal fan using the volute. Compared with the prior art, the volute has the advantages that the annular wall can meet the characteristics that the flow speed of an outlet of an impeller is large in the middle, and small on the two sides, the non-uniform impact of the outlet air flow to the annular wall is weakened, airflow turbulence caused by mutual interference among air flow is reduced, circulation flowing caused by mutual interference among the air flow is eliminated, vortexes are eliminated, the performance of the fan can be effectively improved, and pneumatic noise is reduced.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Air film cooling structure applied to turbine stationary blade

PendingCN114151140AIncrease the export areaIncrease widthStatorsMachines/enginesCold airSuction force

The invention provides an air film cooling structure applied to a turbine stationary blade. The air film cooling structure comprises a cold air cavity, a first group of air film hole inlets, a first group of air film hole outlets, a blade surface groove, a second group of air film hole inlets and a second group of air film hole outlets. Inlets of the first set of cylindrical air film cooling holes are connected with a cold air cavity, outlets of the first set of cylindrical air film cooling holes are fixed to a blade surface groove, the blade surface groove is fixed to a blade pressure face, inlets of the second set of cylindrical air film cooling holes are fixed to the other end of the blade surface groove, and the second set of cylindrical air film cooling holes penetrate through the whole blade. And outlets of the second group of air film holes are fixed on the suction surface of the turbine stationary blade. The grooves are formed in the outlets of the first group of air film holes, the area of the outlets of the air film holes is increased, the cold air ejection speed is reduced, the second group of air film holes are adopted, air flow forms an air film after being ejected from the outlets of the second group of air film holes, cold air is reutilized, cold air consumption is reduced, and therefore the efficiency of the whole machine is improved.

Owner:HARBIN ENG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com