Patents

Literature

45 results about "Cold air intake" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

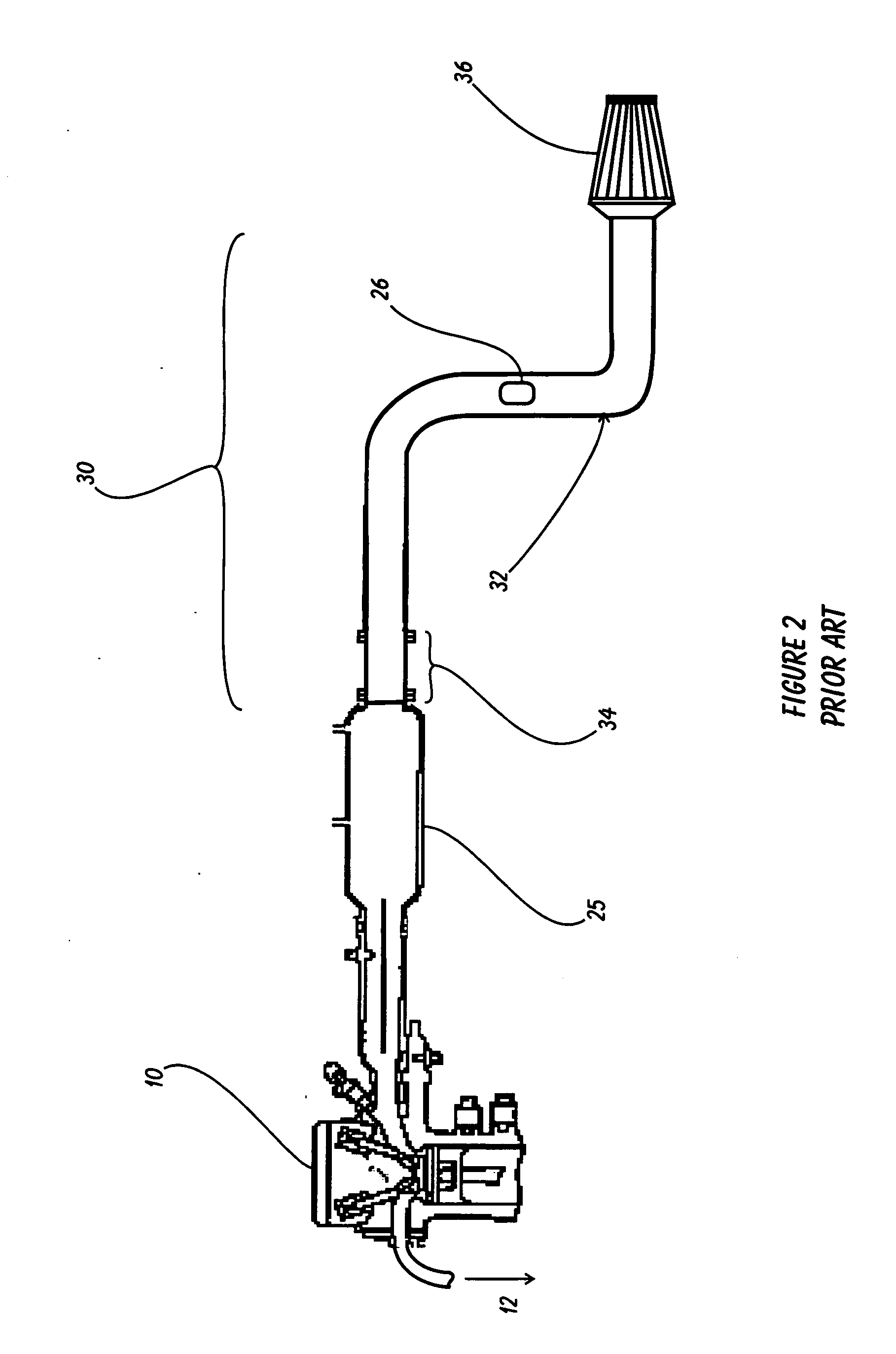

A cold air intake (CAI) is usually an aftermarket assembly of parts used to bring relatively cool air into a car's internal-combustion engine. Most vehicles manufactured from the mid-1970s until the mid-1990s have thermostatic air intake systems that regulate the temperature of the air entering the engine's intake tract, providing warm air when the engine is cold and cold air when the engine is warm to maximize performance, efficiency, and fuel economy. With the advent of advanced emission controls and more advanced fuel injection methods modern vehicles do not have a thermostatic air intake system and the factory installed air intake draws unregulated cold air. Aftermarket cold air intake systems are marketed with claims of increased engine efficiency and performance. The putative principle behind a cold air intake is that cooler air has a higher density, thus containing more oxygen per volume unit than warmer air.

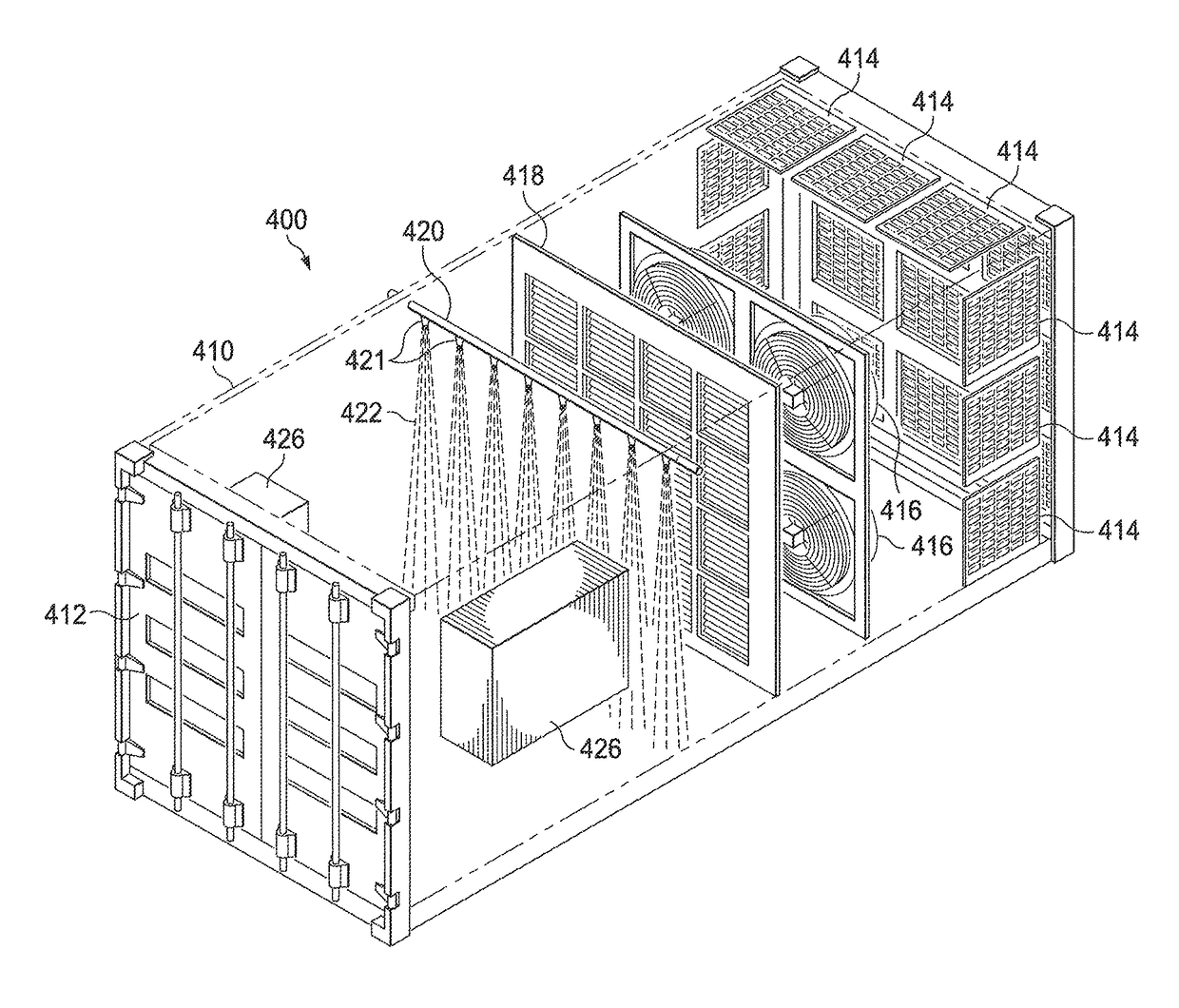

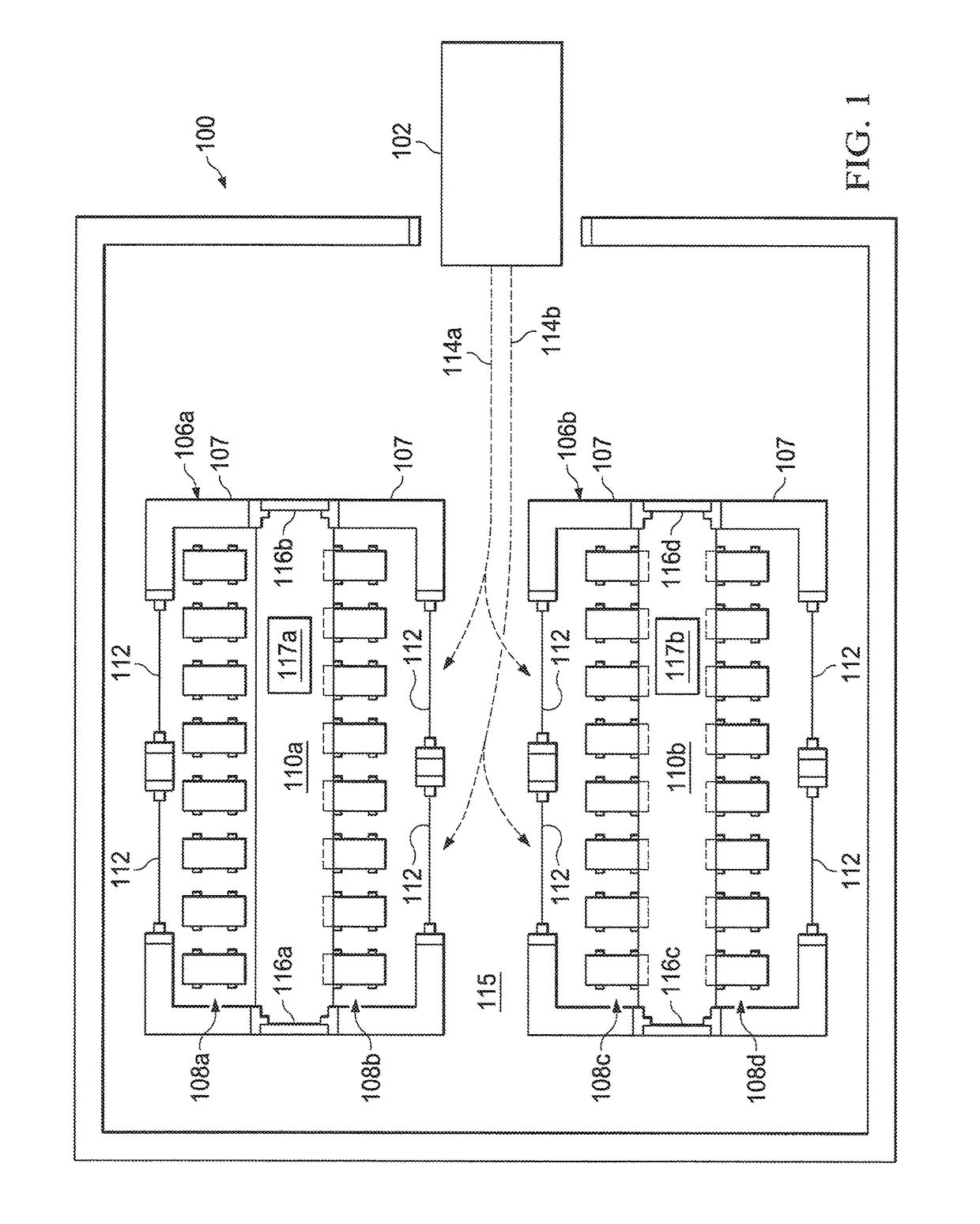

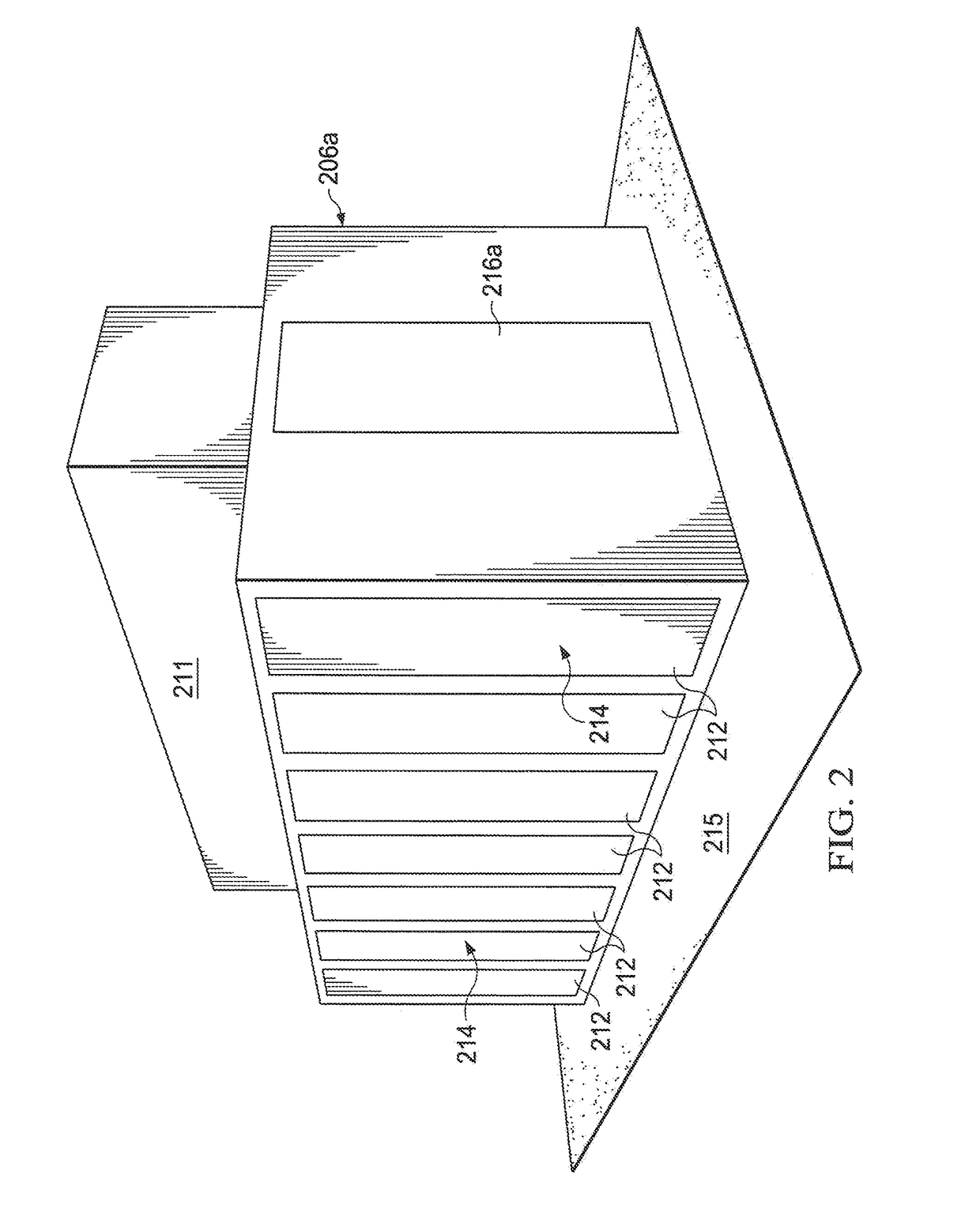

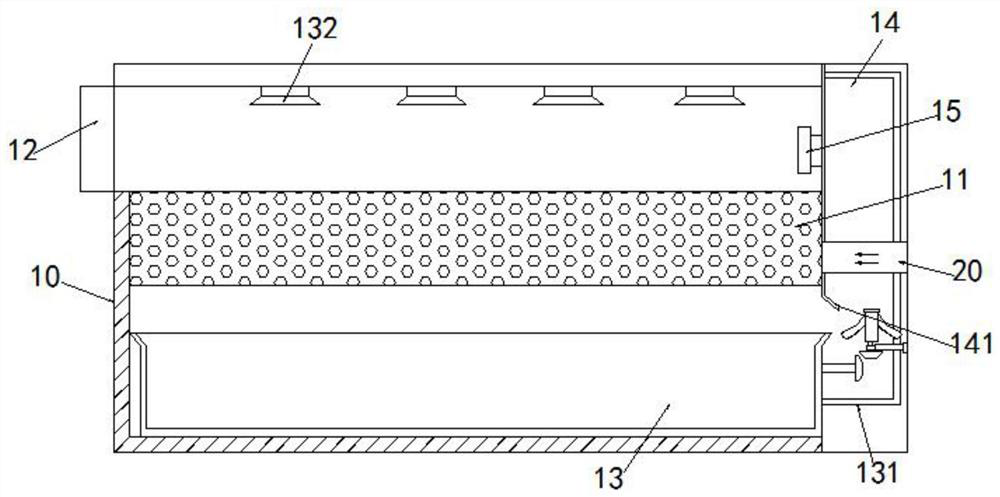

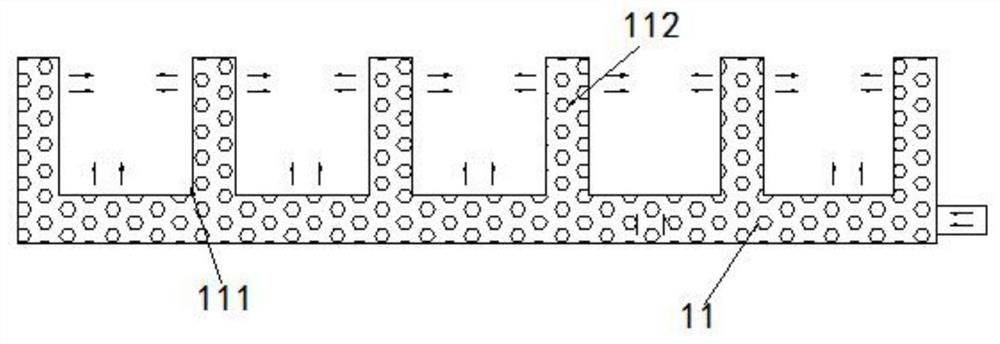

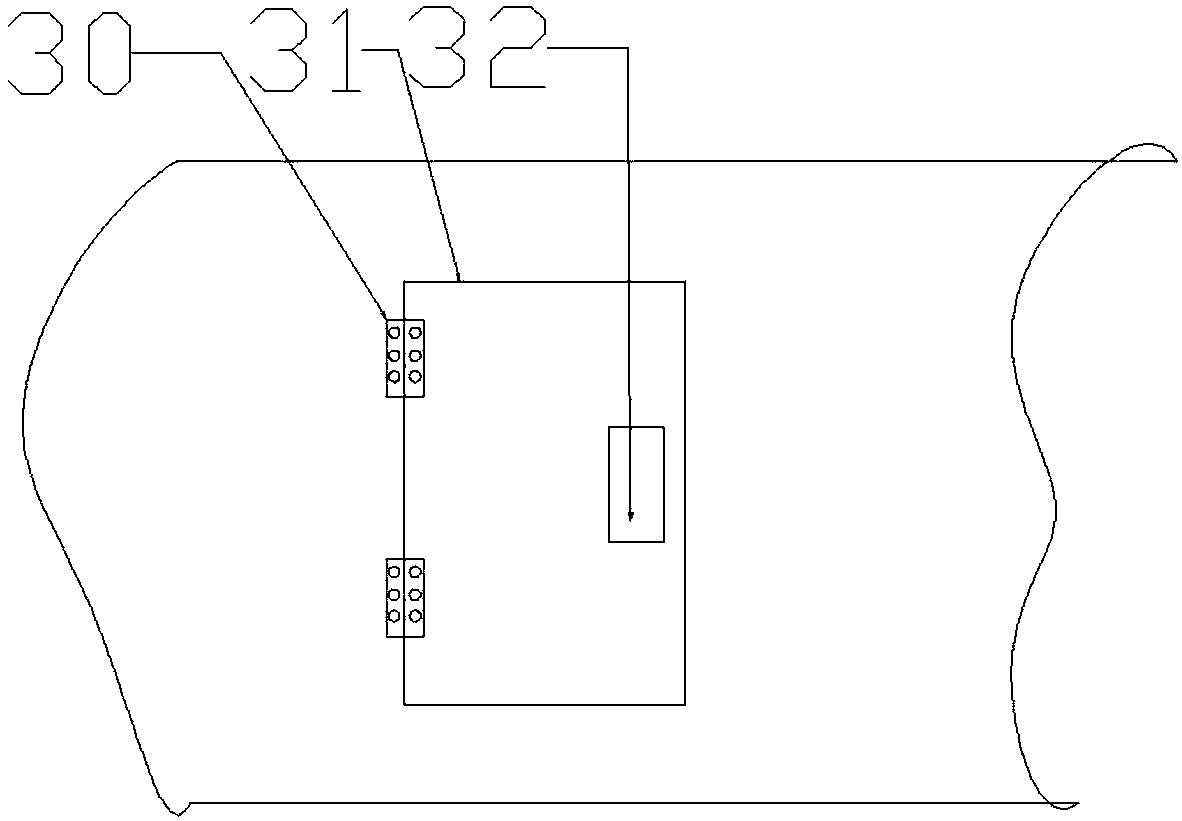

Data center heat removal systems and methods

ActiveUS20160192542A1Efficient methodMaximize air pressure differentialDigital data processing detailsOther manufacturing equipments/toolsData centerDistribution system

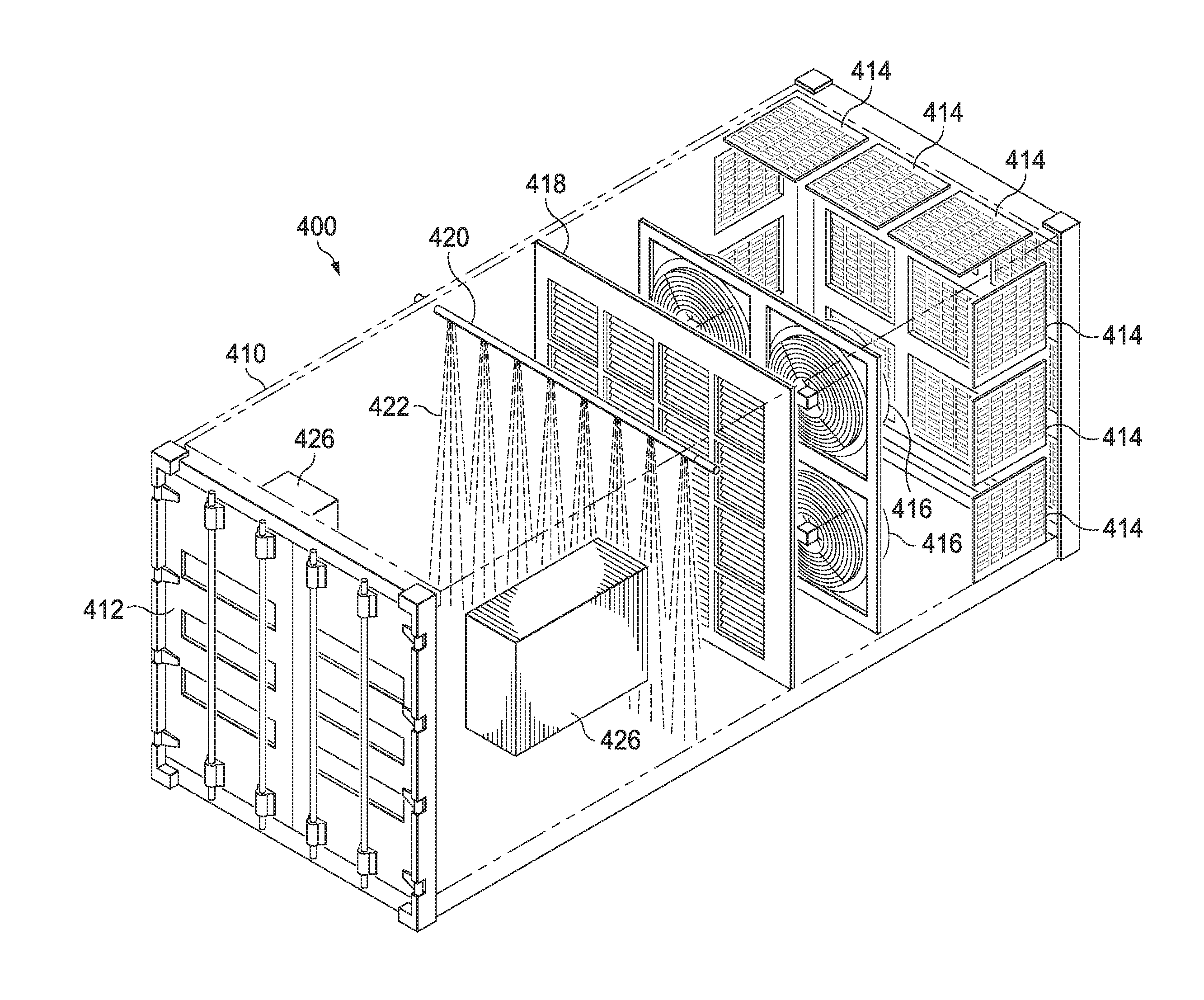

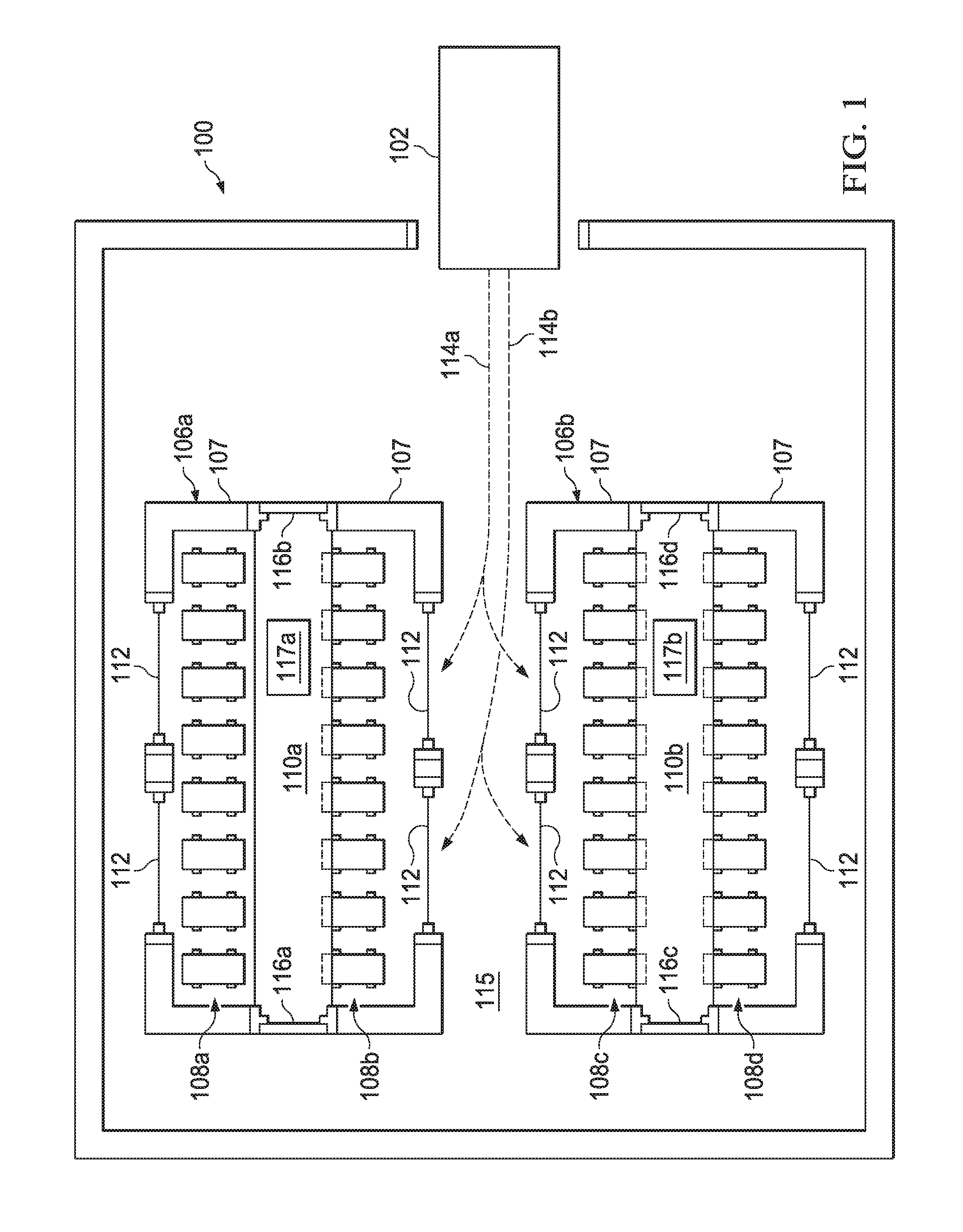

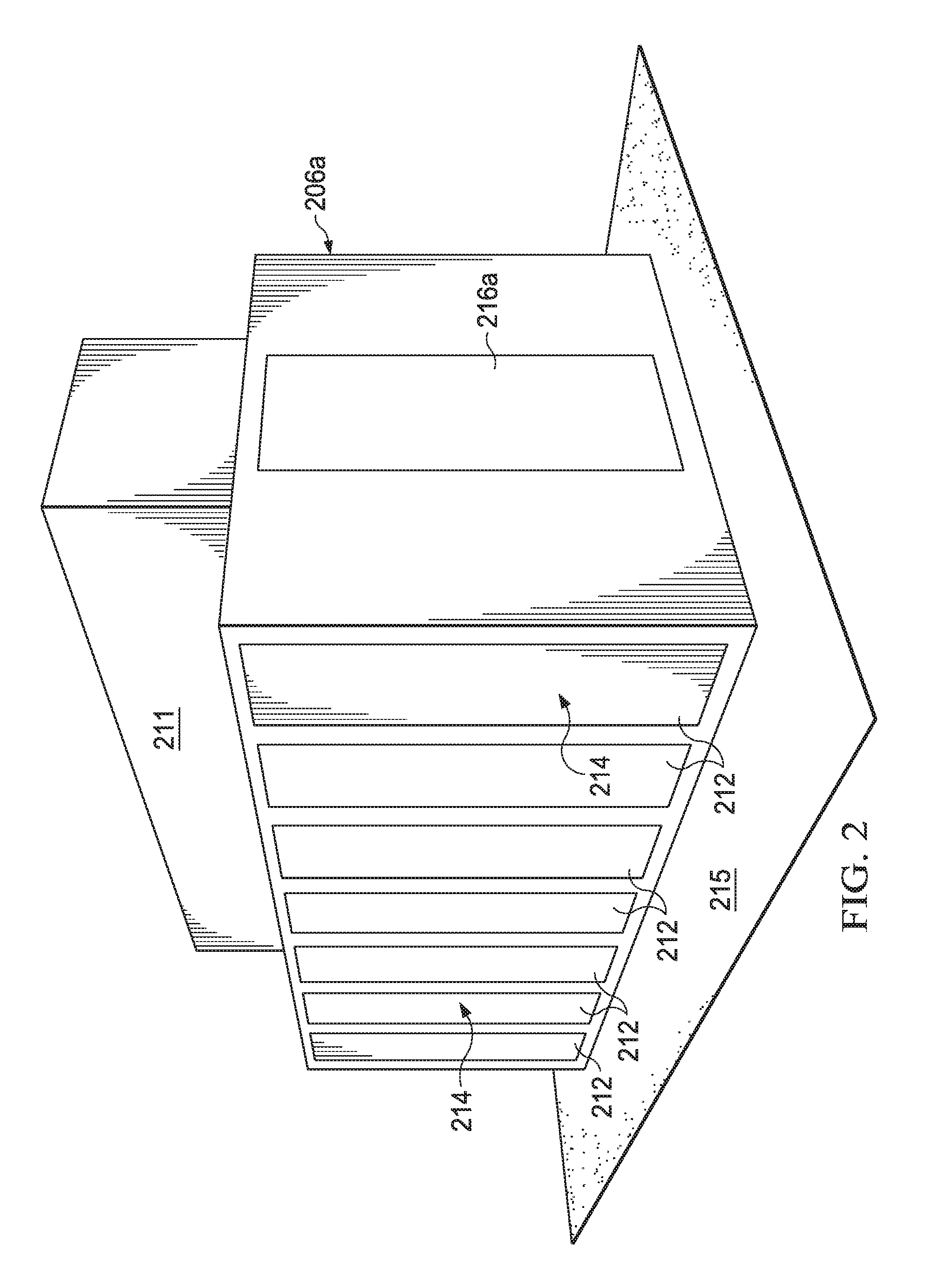

New data center heat removal systems and methods allow a combination of active and passive thermal processes for removing heat from and cooling air in data center environments. Systems and methods include a data center heat removal system including an adjustable thermal feed cold air intake system, a distribution system for cold and warm air including one or more hot aisles and one or more cold aisles, and a convection system to draw cool air through data center equipment using a naturally-occurring convection processes to expel hot air. Misters, cooling elements, and / or freezer boxes may further cool the intake of air. A controller is programmed to efficiently manage and control the climate (e.g., temperature, humidity, air flow, pressure, air quality, etc.) within a data center to minimize the use for energy for air distribution and cooling.

Owner:LEFEBVRE DALE +1

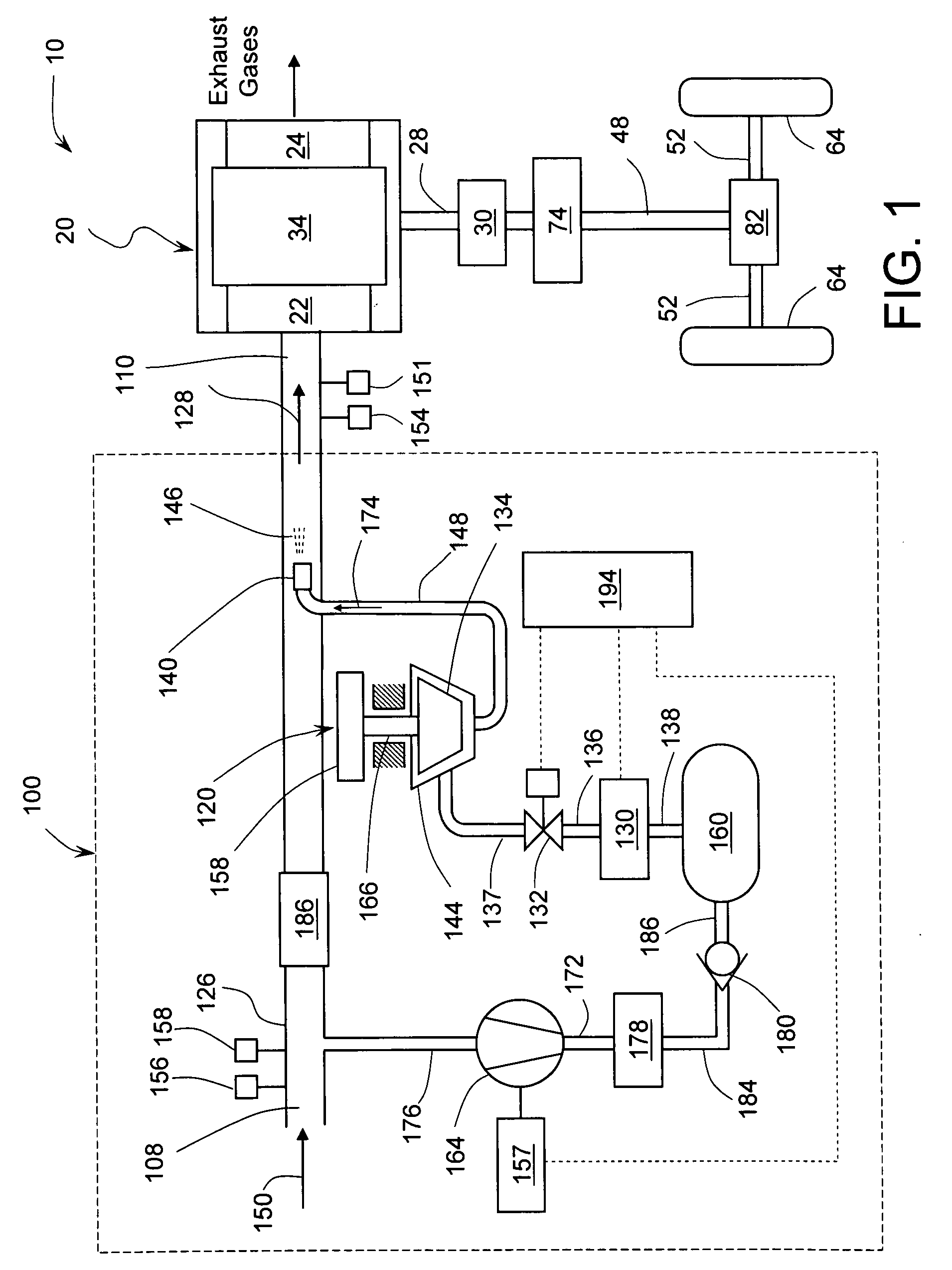

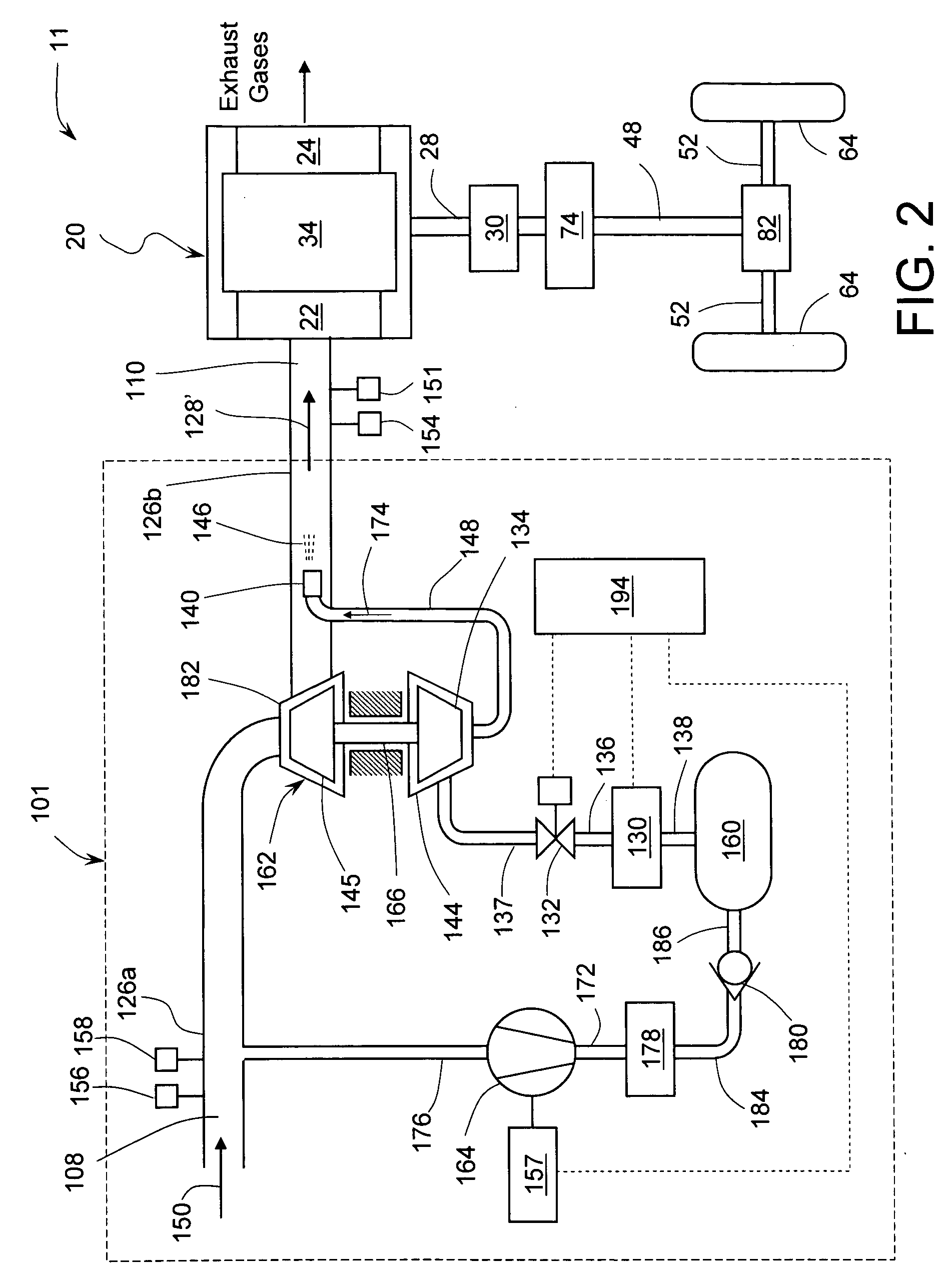

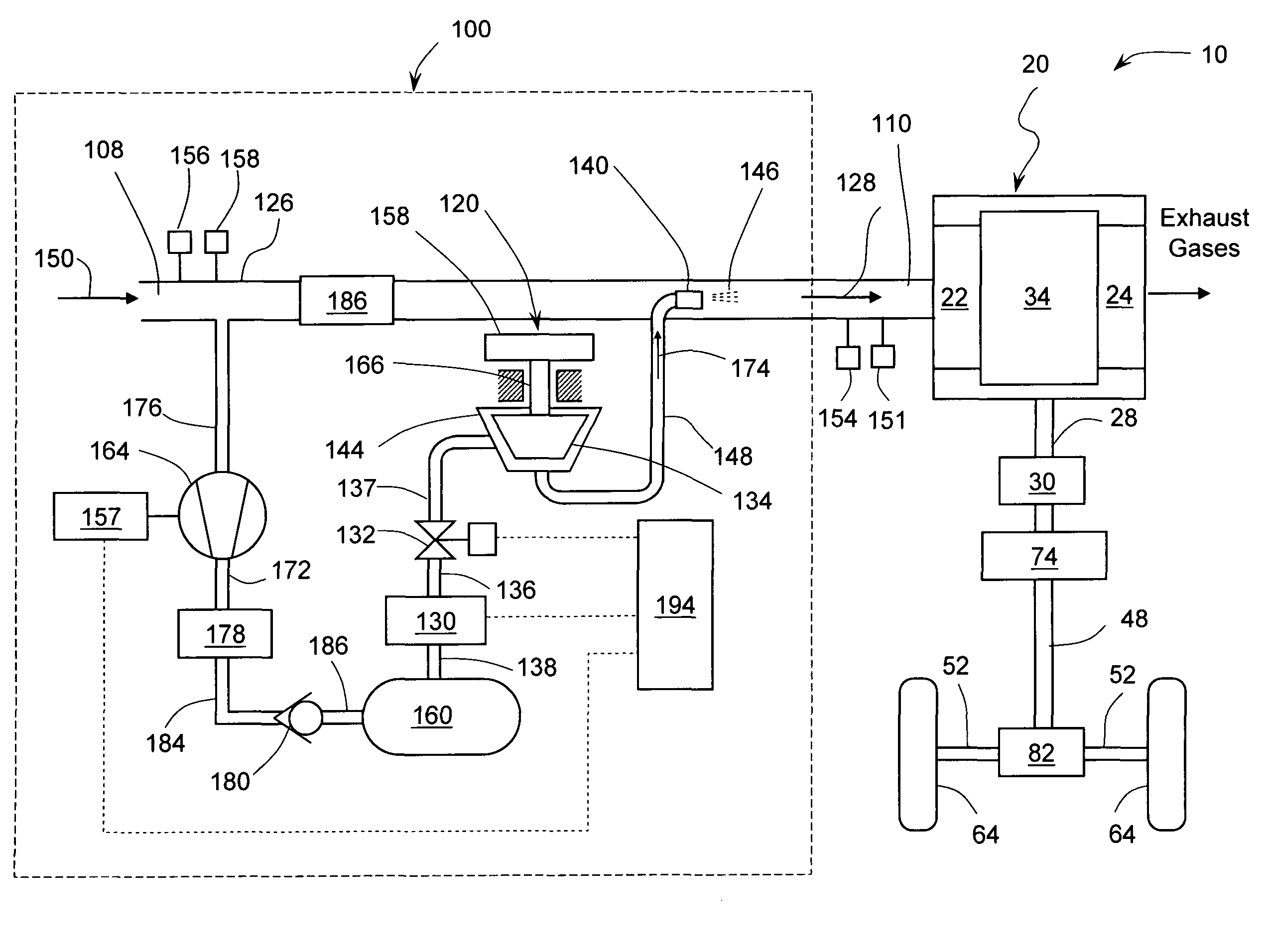

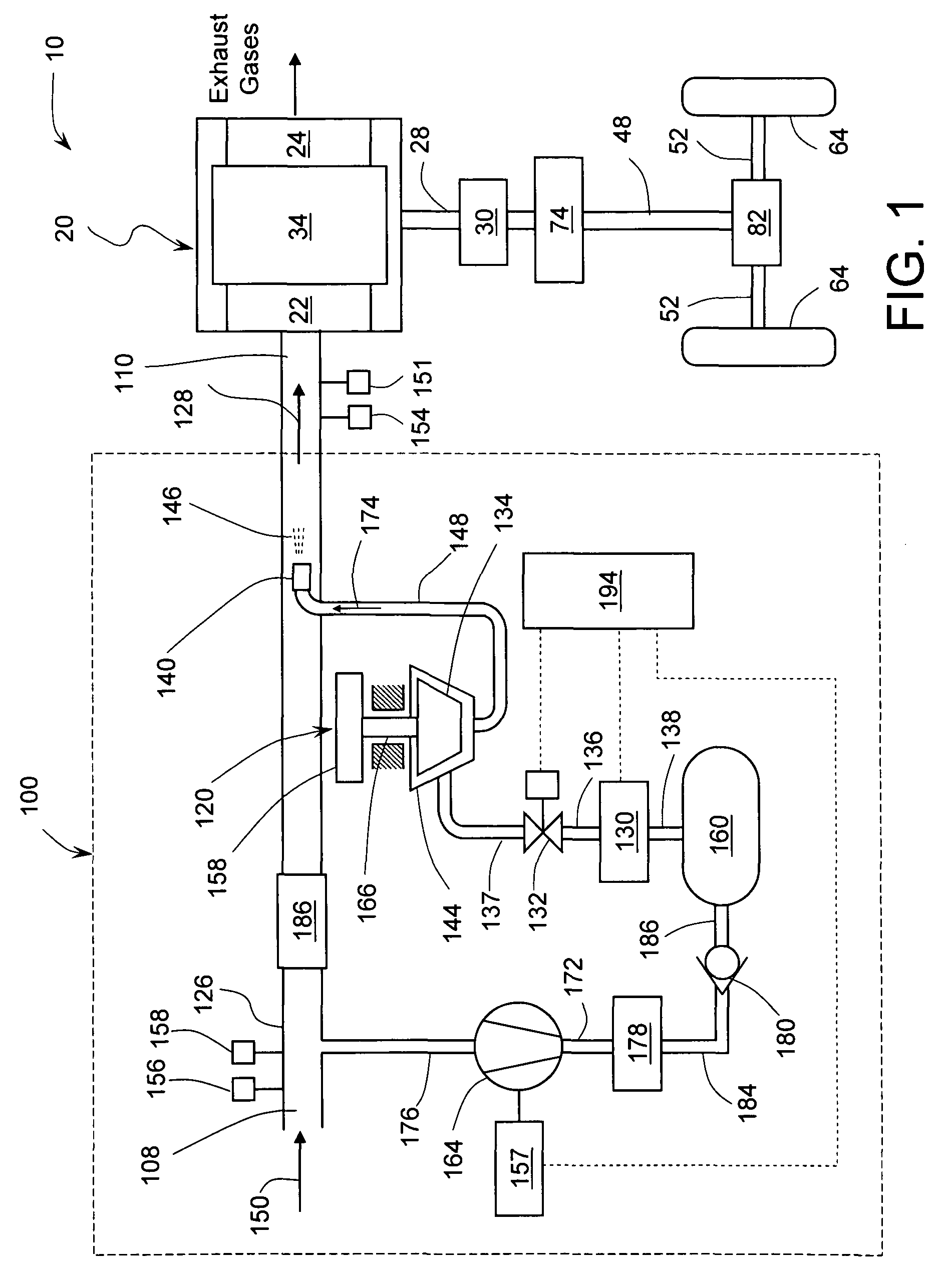

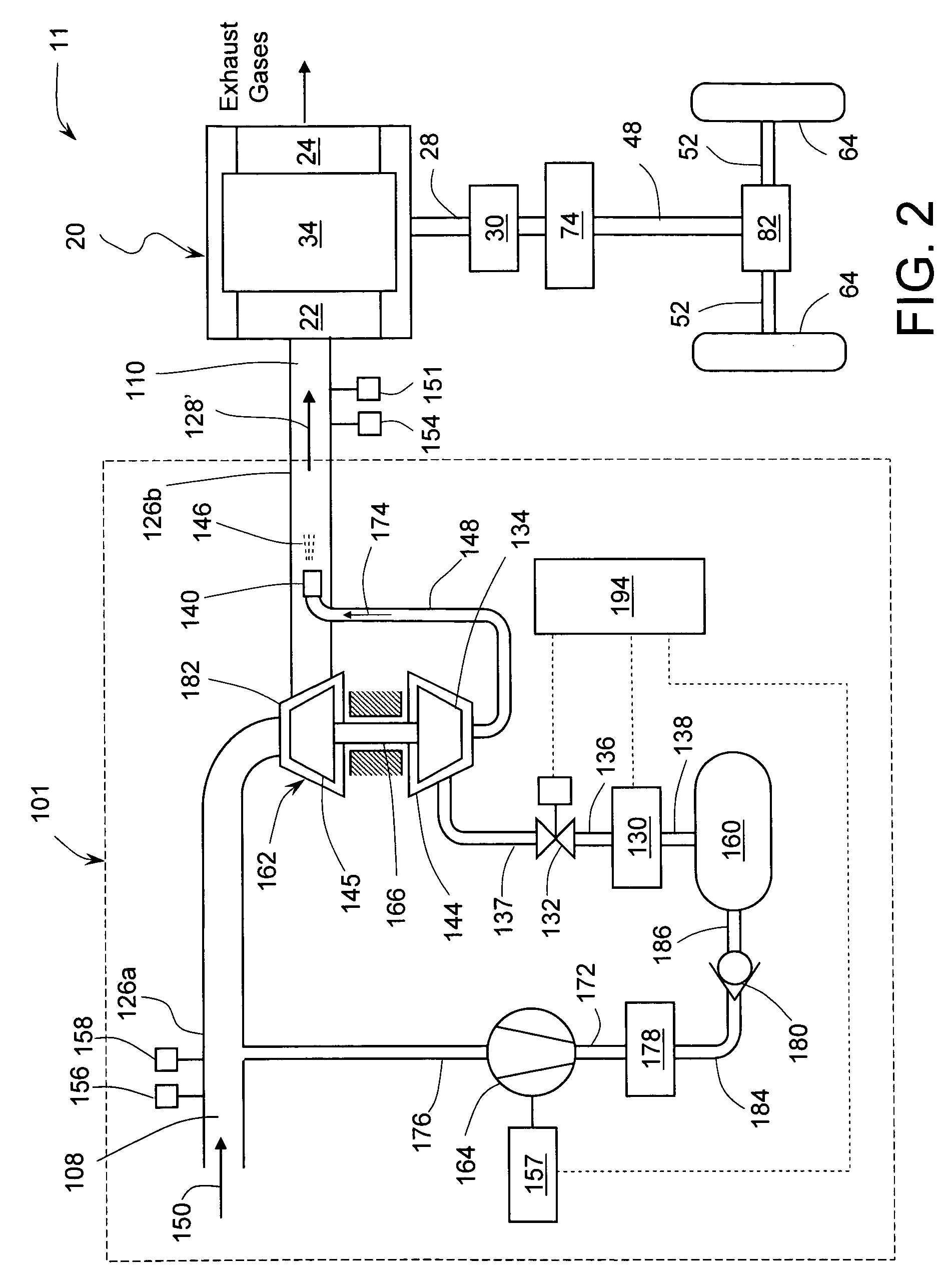

Supercharged internal combustion engine system

InactiveUS20090259388A1Weight increaseHigh densityElectrical controlInternal combustion piston enginesCombustion chamberMechanical energy

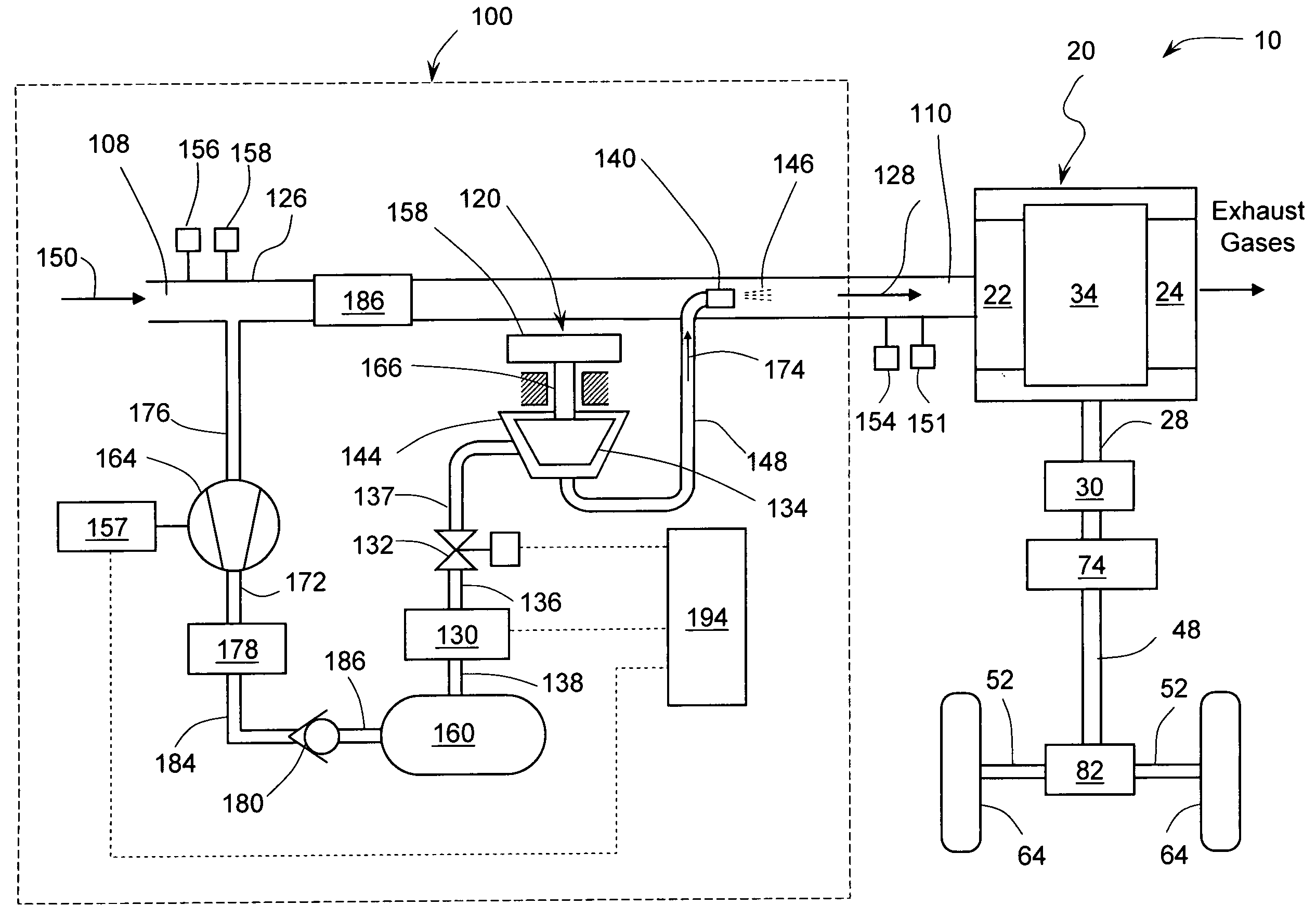

A supercharged internal combustion engine system wherein during periods of high power demand the weight of combustion chamber charge is increased by cooling a portion of intake air in a turboexpander using high-pressure air from a storage tank. In addition to increasing engine output power, cold air intake also reduces engine pre-ignition (knocking) thereby reducing emissions. Mechanical energy produced during expansion of high-pressure air may be used to operate a turbocompressor, which compresses intake air and further increases charge weight. Effective supercharging is achieved even at low engine speeds. One of the objects of the invention is to obtain more power from small displacement ICE and thus providing automotive vehicles with sufficient acceleration in addition to good fuel economy. Another object of the invention is to enhance turbocharged engines and reduce their response lag. Air storage tank may be recharged using energy recovered during vehicle deceleration.

Owner:AGWEST

Supercharged internal combustion engine system

InactiveUS8078385B2Weight increaseIncrease output powerElectrical controlInternal combustion piston enginesCombustion chamberMechanical energy

A supercharged internal combustion engine system wherein during periods of high power demand the weight of combustion chamber charge is increased by cooling a portion of intake air in a turboexpander using high-pressure air from a storage tank. In addition to increasing engine output power, cold air intake also reduces engine pre-ignition (knocking) thereby reducing emissions. Mechanical energy produced during expansion of high-pressure air may be used to operate a turbocompressor, which compresses intake air and further increases charge weight. Effective supercharging is achieved even at low engine speeds. One of the objects of the invention is to obtain more power from small displacement ICE and thus providing automotive vehicles with sufficient acceleration in addition to good fuel economy. Another object of the invention is to enhance turbocharged engines and reduce their response lag. Air storage tank may be recharged using energy recovered during vehicle deceleration.

Owner:AGWEST

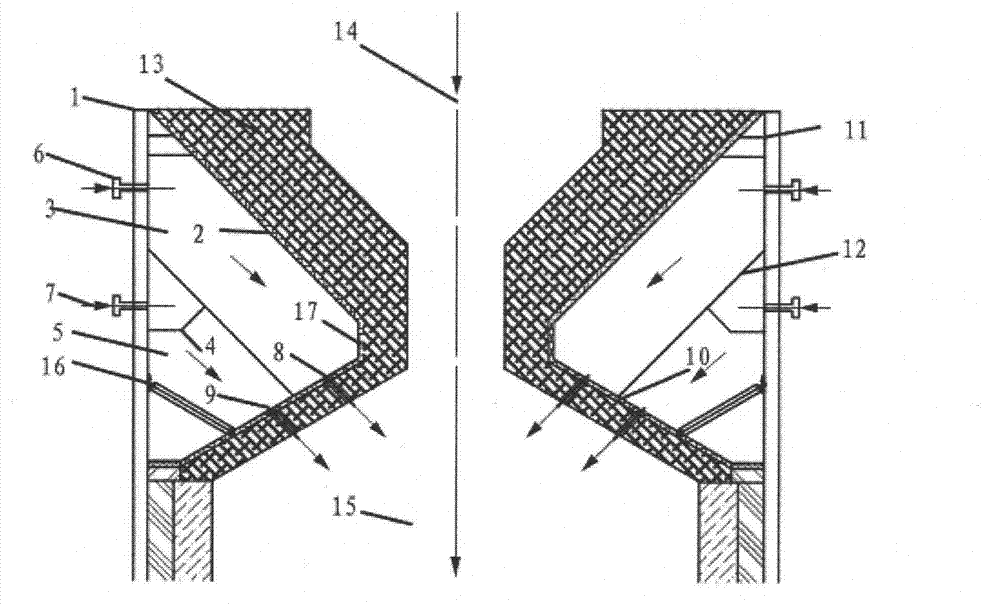

Data center heat removal systems and methods

ActiveUS9769960B2Efficient methodMaximize air pressure differentialCooling/ventilation/heating modificationsData centerDistribution system

New data center heat removal systems and methods allow a combination of active and passive thermal processes for removing heat from and cooling air in data center environments. Systems and methods include a data center heat removal system including an adjustable thermal feed cold air intake system, a distribution system for cold and warm air including one or more hot aisles and one or more cold aisles, and a convection system to draw cool air through data center equipment using a naturally-occurring convection processes to expel hot air. Misters, cooling elements, and / or freezer boxes may further cool the intake of air. A controller is programmed to efficiently manage and control the climate (e.g., temperature, humidity, air flow, pressure, air quality, etc.) within a data center to minimize the use for energy for air distribution and cooling.

Owner:LEFEBVRE DALE +1

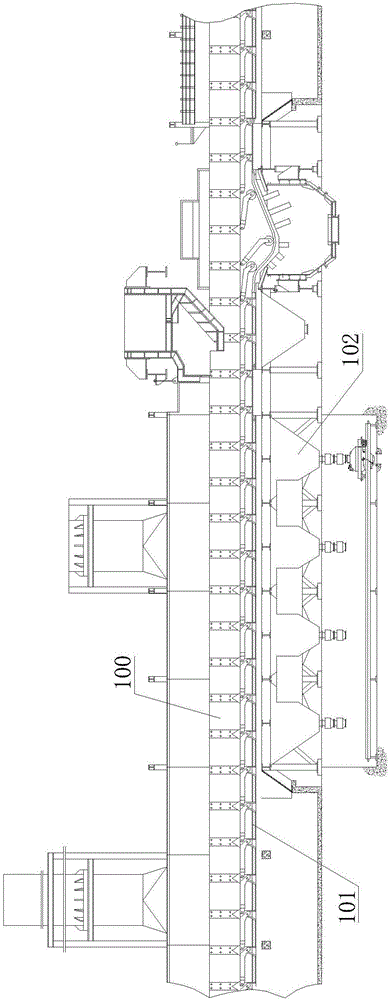

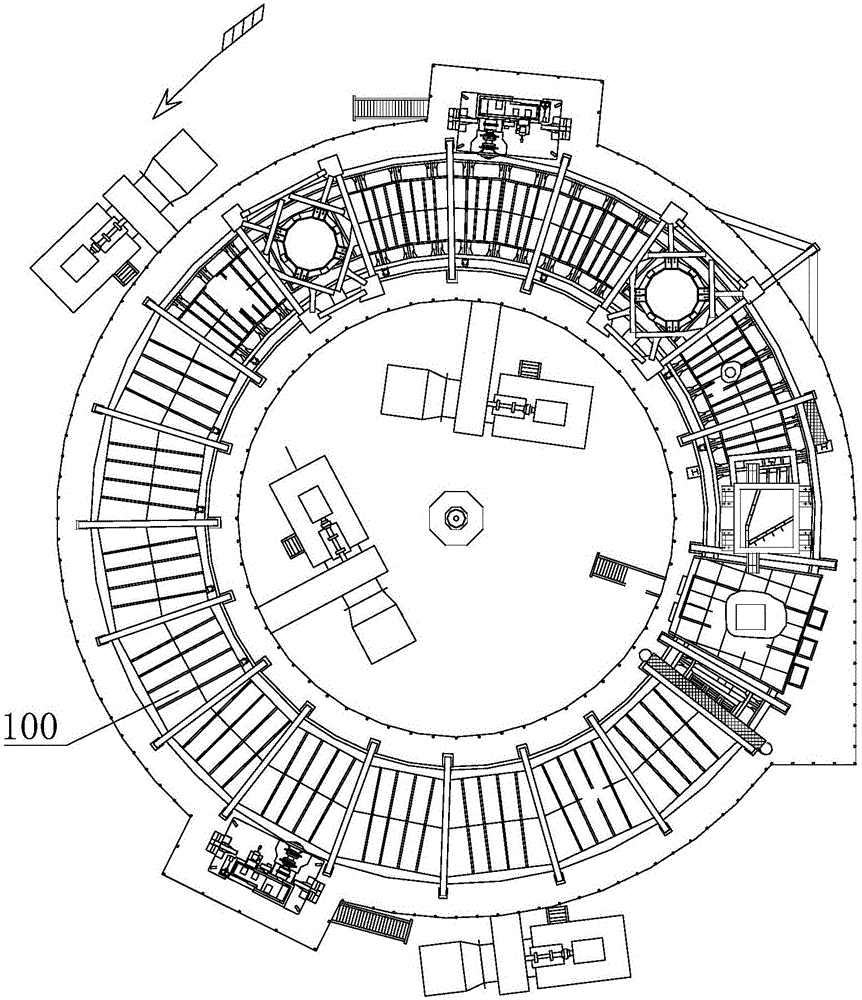

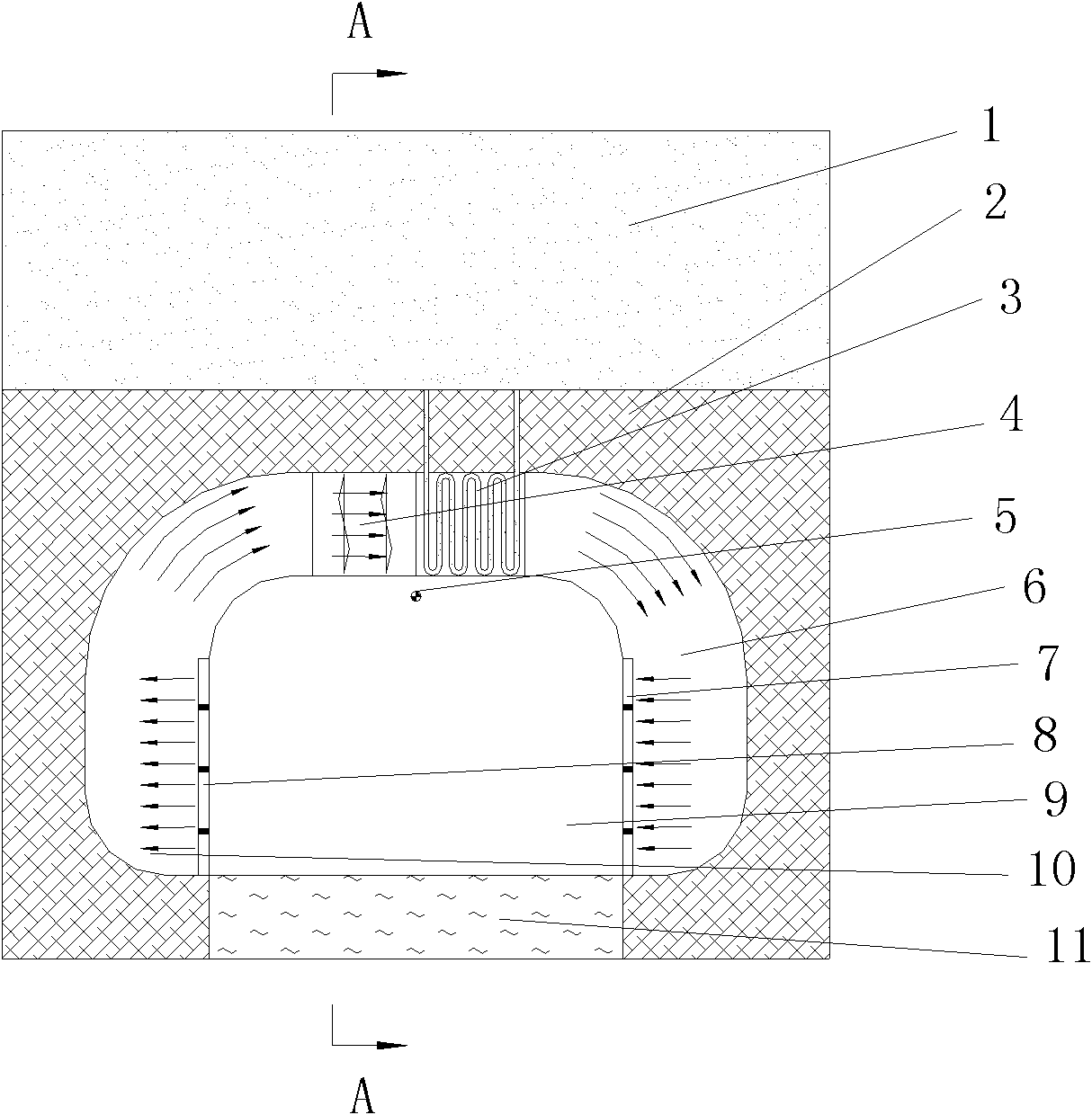

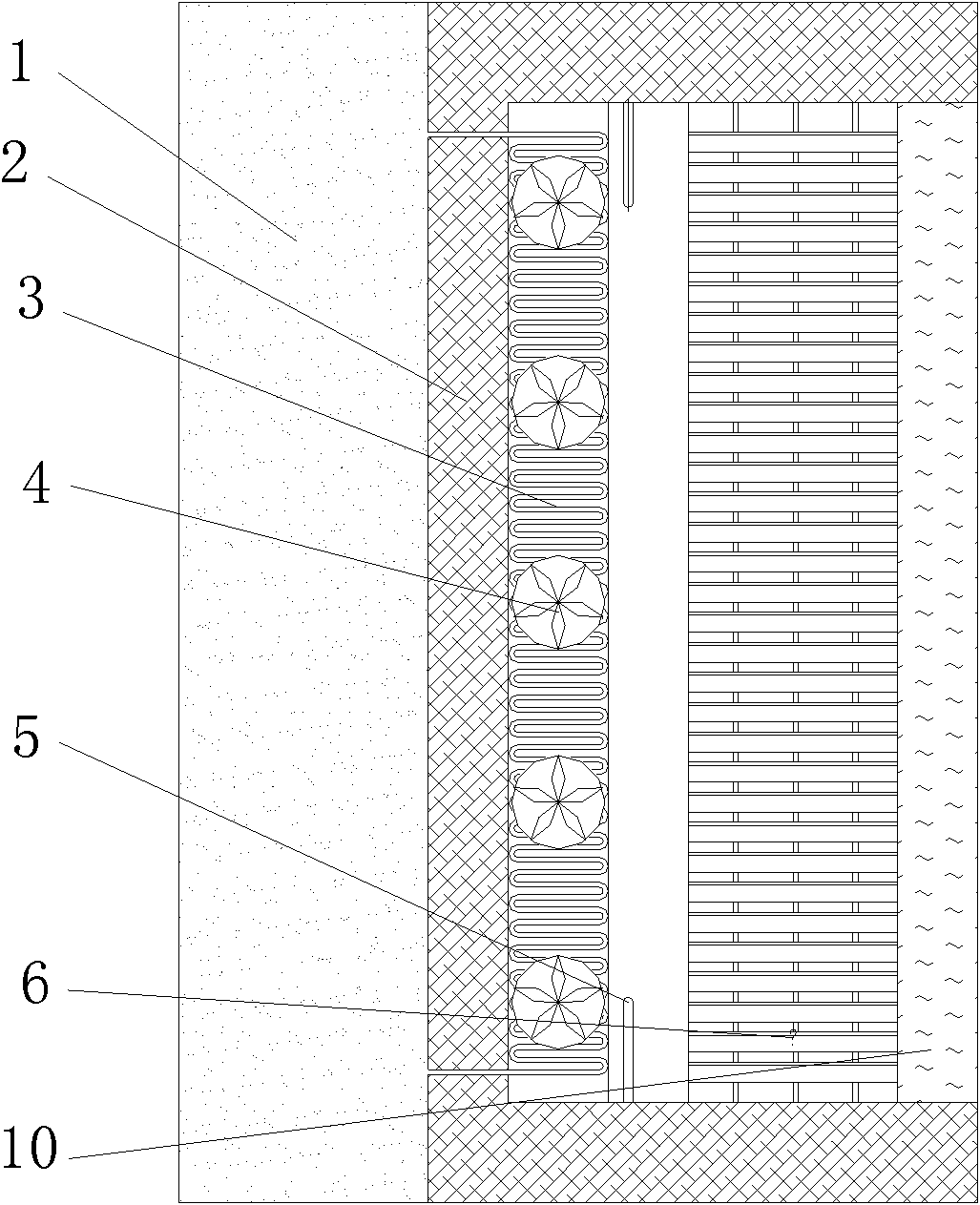

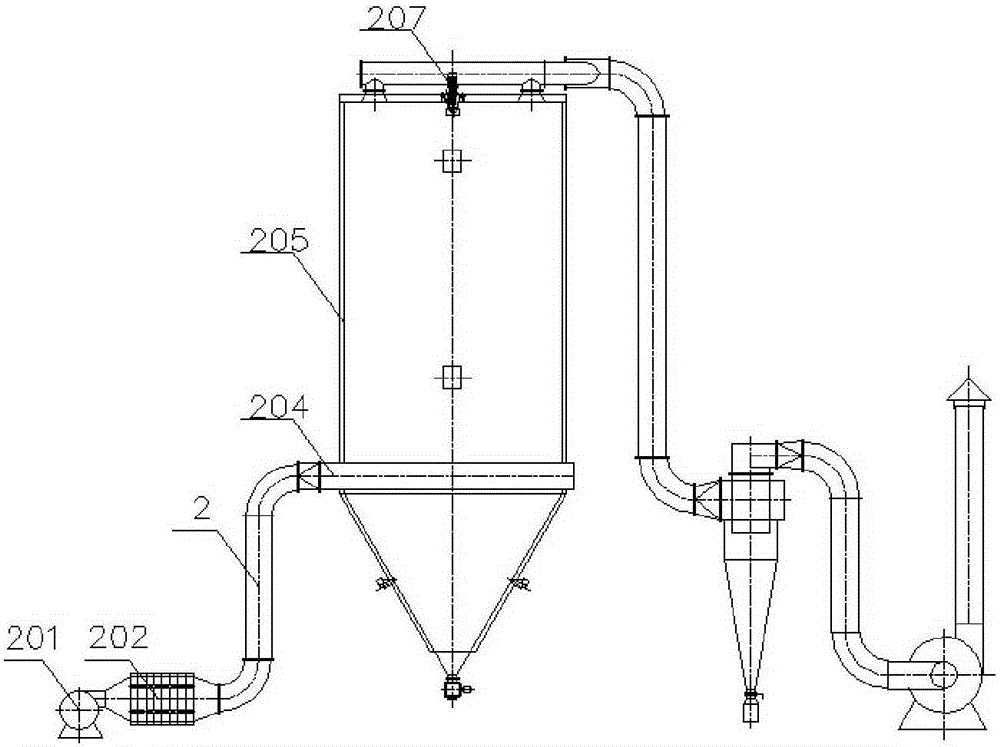

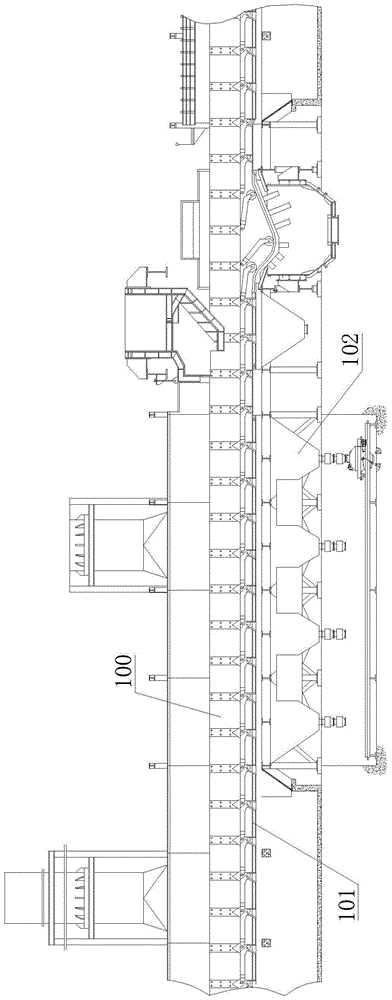

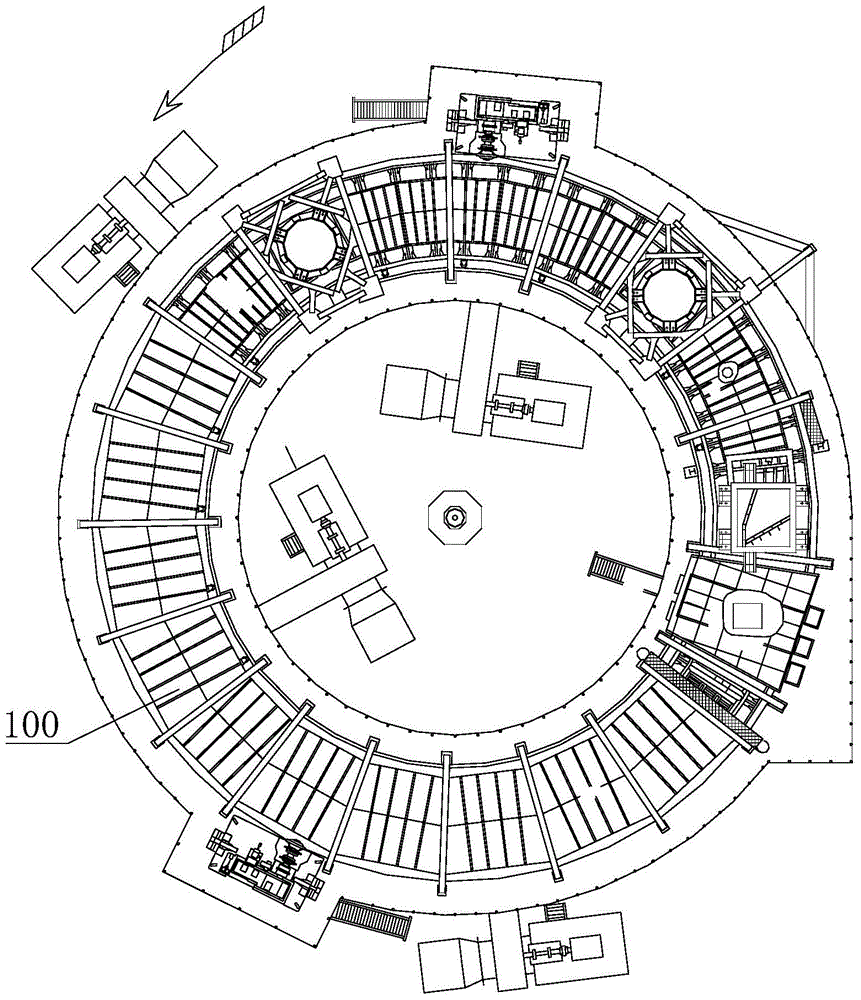

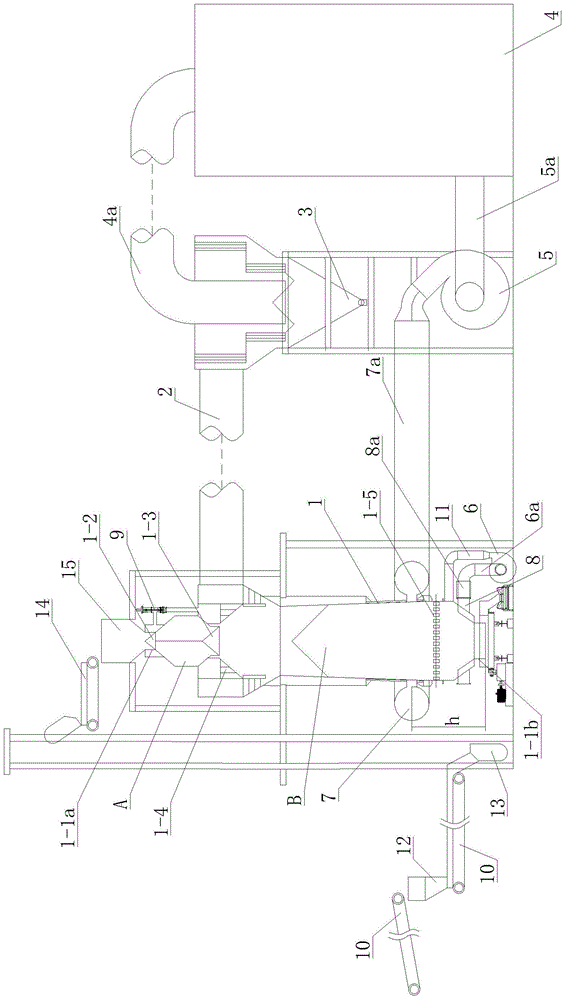

Comprehensive utilization system for sintering waste heat

ActiveCN105066718ATake advantage ofImprove sealingIncreasing energy efficiencyWaste heat treatmentCooling towerAir blower

A comprehensive utilization system for sintering waste heat comprises a cooling tower, a fine powder separator, a waste heat boiler, an induced draft fan, an air intake peripheral pipe and a cold air negative-pressure pipe. The air intake peripheral pipe is arranged on the periphery of the middle-lower part of the cooling tower, the air intake peripheral pipe is communicated with the interior of the cooling tower through air inlets arranged along the circumference at intervals, and the air intake peripheral pipe is connected with the induced draft fan through an air intake pressurization pipe. The cold air negative-pressure pipe is arranged above a discharging port of the cooling tower, the cold air negative-pressure pipe is connected with a cooling air blower through a cold air intake pipe, the cooling air blower is simultaneously connected with a cold air pressurization pipe located below the air intake peripheral pipe, and the cold air negative-pressure pipe and the cold air pressurization pipe are both communicated with the interior of the cooling tower. A material distribution area and a cooling area located below the material distribution area are formed in the cooling tower, a feeding port is formed in the top of the cooling tower, and the discharging port is formed in the bottom of the cooling tower. A material receiving seal valve is arranged in the cooling tower and located below the feeding port. A material distribution seal valve is arranged in the cooling tower and located above the opening of the material distribution area. According to the comprehensive utilization system for the sintering waste heat, secondary hot air generated in the cooling process can be recycled, energy consumption is reduced, and environmental pollution is completely eradicated.

Owner:宝鸡市晋旺达机械设备有限公司

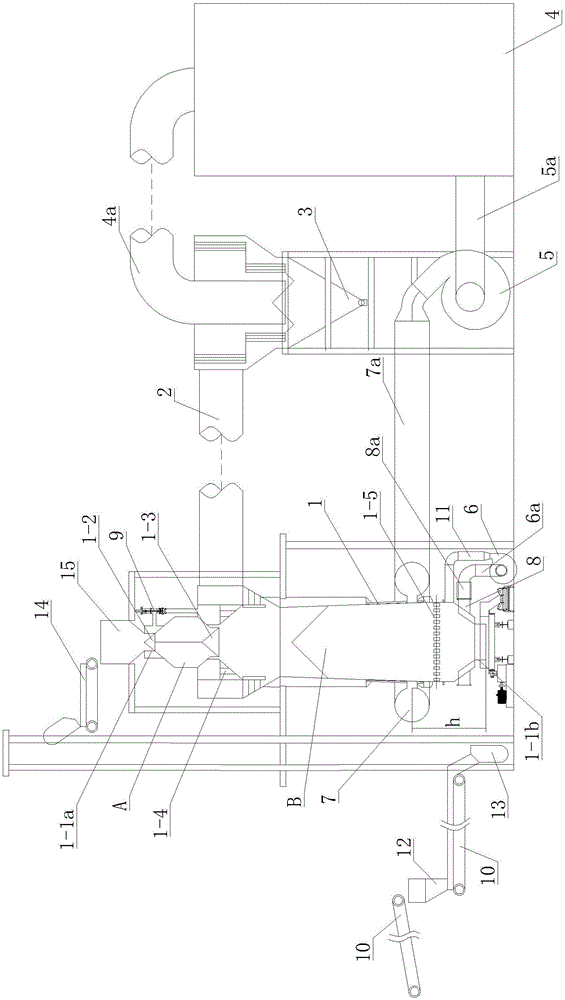

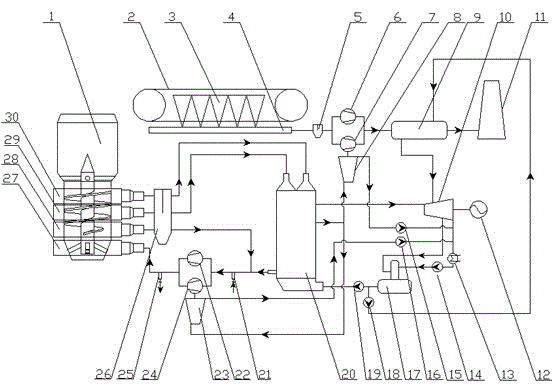

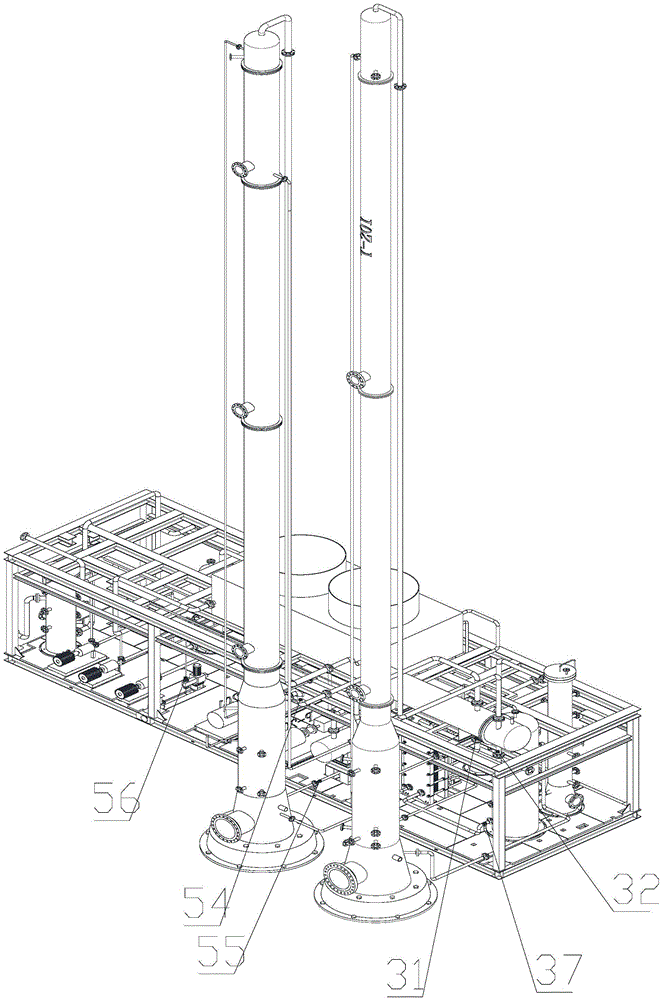

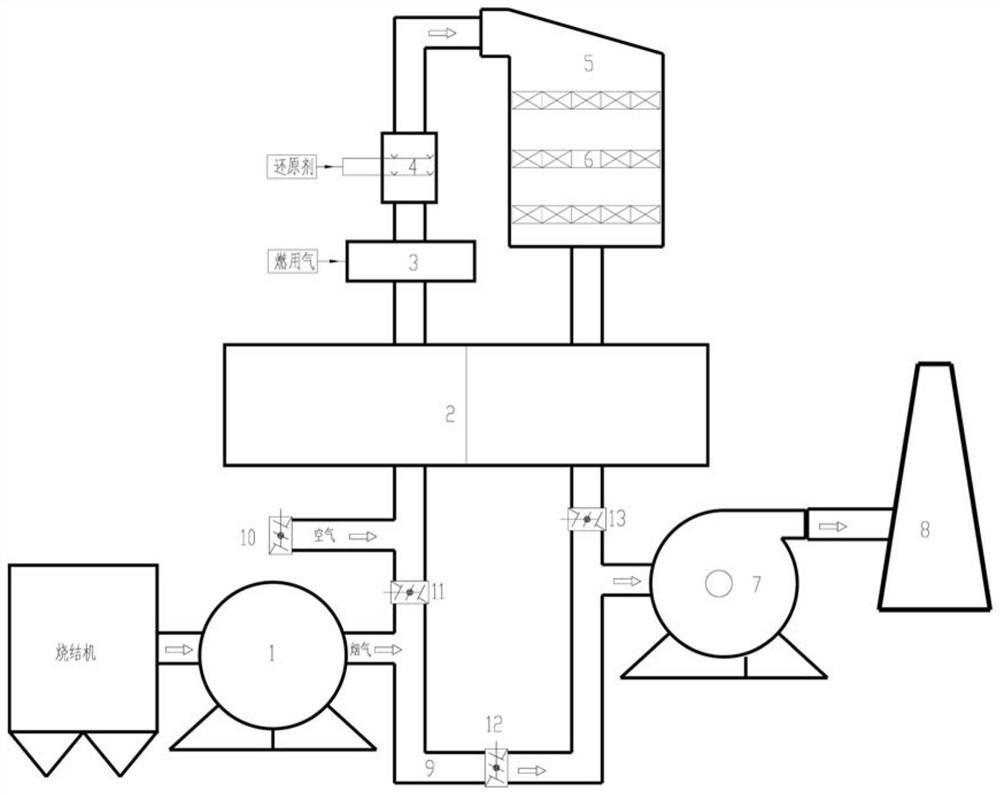

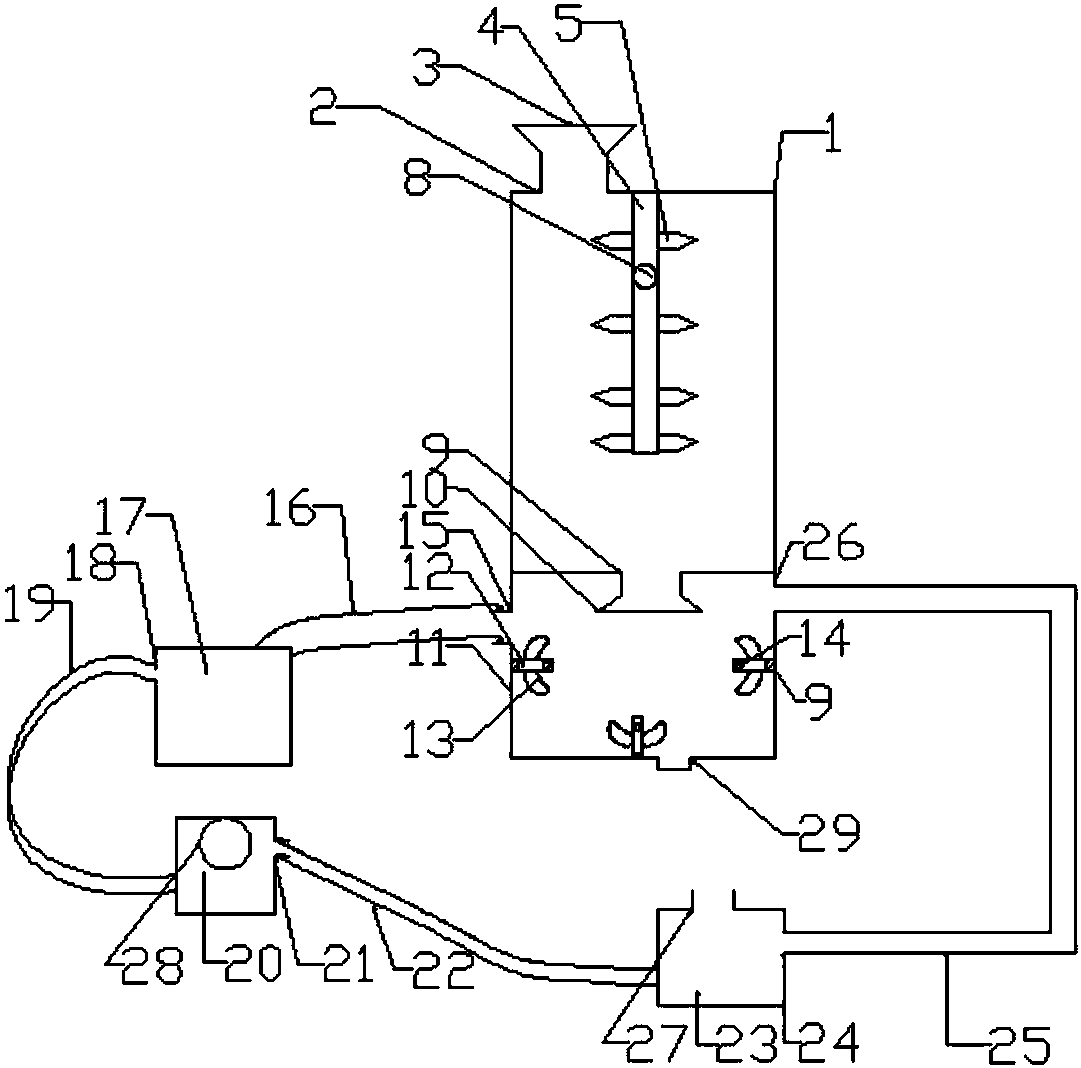

Screw expander dragged sintering wast heat power generation system and method

InactiveCN104457299AImproving the Recovery and Utilization Rate of Sintering Waste HeatSave electricityIncreasing energy efficiencySteam engine plantsHeat powerHeating power

The invention discloses a screw expander dragged sintering wast heat power generation system and method. The system comprises a vertical sinter cooling device, a sintering machine, a bellows, a main flue, a dust collector, a first electric fan, a first fan, a first screw expander, a heat pipe waste heat boiler, a steam supplementing and condensing type steam turbine, a chimney, a generator, a condenser, a first water pump, a second water pump, a third water pump, a deaerator, a fourth water pump, a fifth water pump, a dual-intake dual-pressure waste heat boiler, a cold air intake valve, a second electric fan, a second screw expander, a second fan, a blow off valve, another dust collector, a vertical sinter cooling device intake chamber, a vertical sinter cooling device low-temperature air outtake chamber, a vertical sinter cooling device medium-temperature air outtake chamber and a vertical sinter cooling device high-temperature air outtake chamber. By the system and method, sintering waste heat and energy can be recovered efficiently, power generation efficiency is improved, consumed energy needed for equipment operation is saved greatly, and the system and method is of great significance to energy conservation and emission reduction of iron and steel enterprises.

Owner:ZHEJIANG UNIV

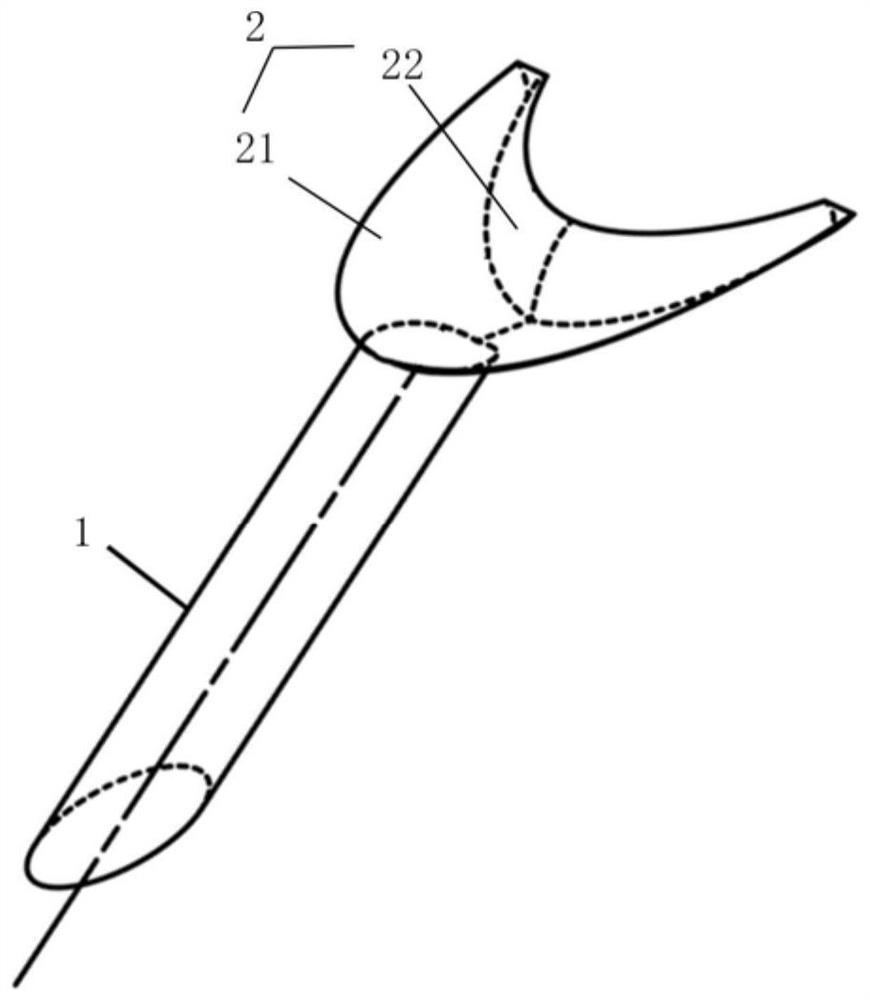

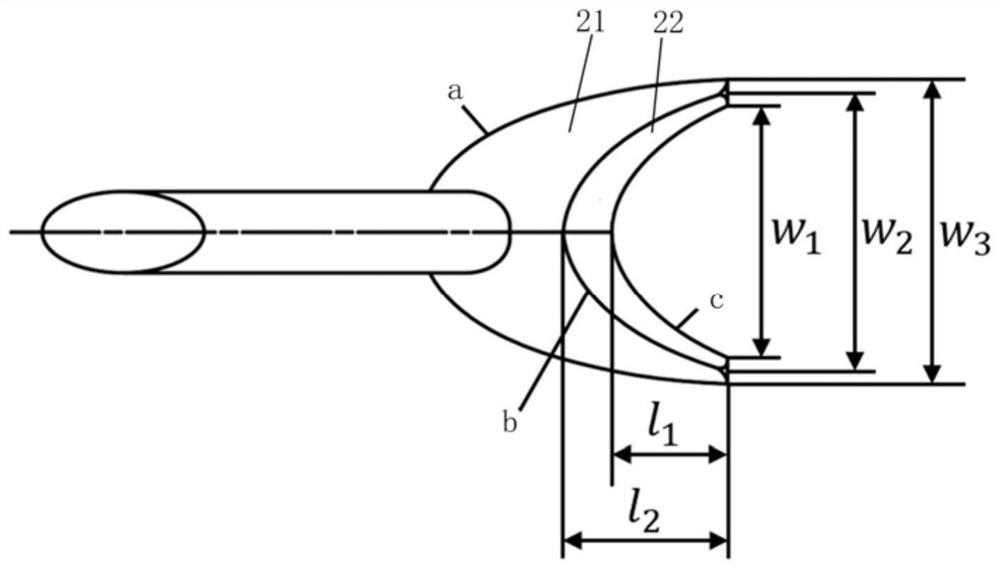

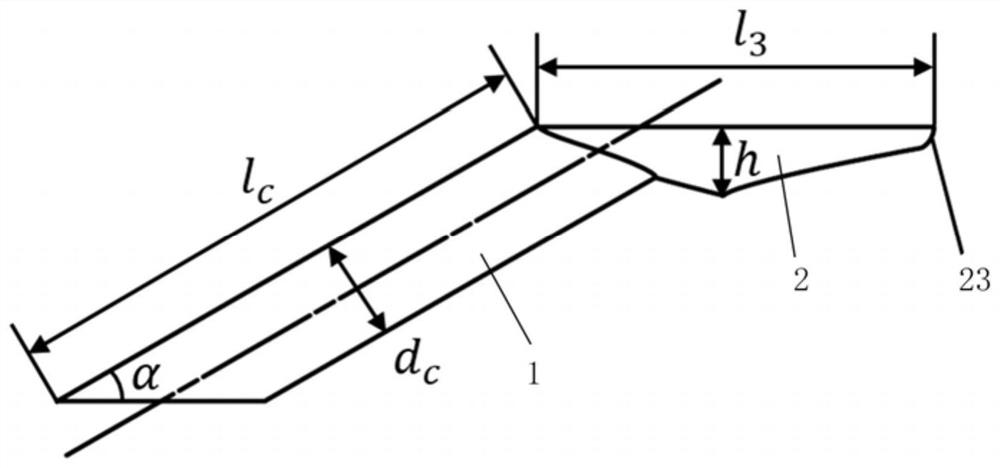

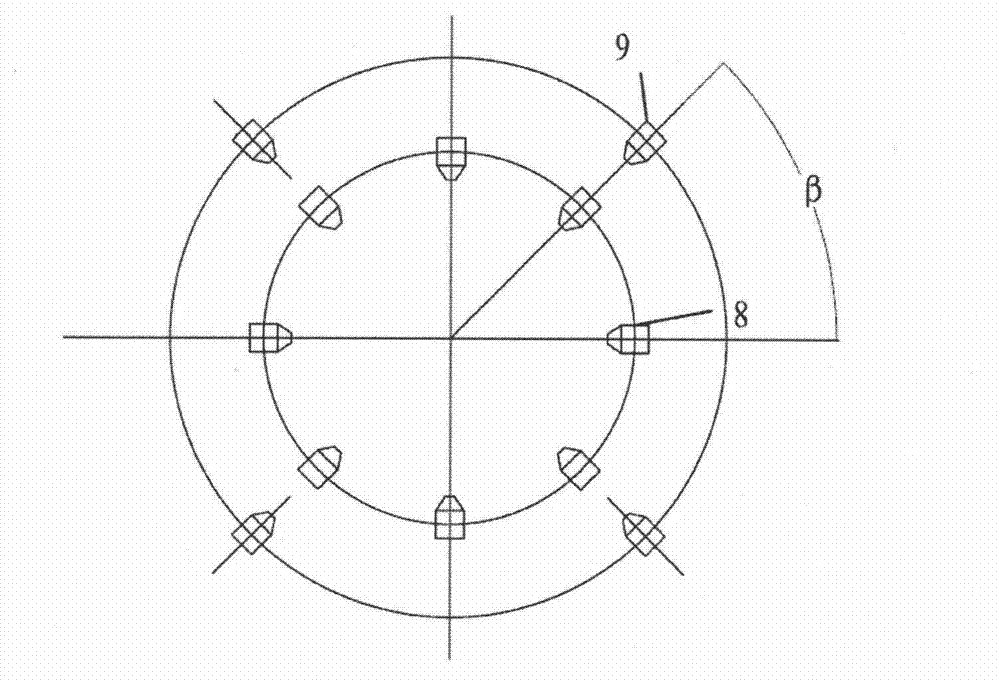

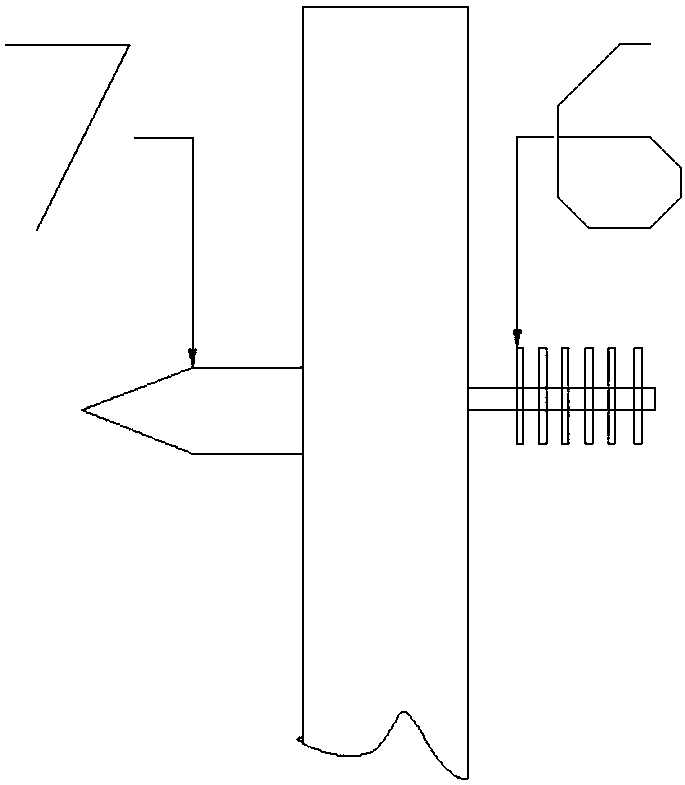

Air film cooling hole pattern structure

ActiveCN112282857AGood adhesionIncrease the lateral spread areaEngine fuctionsBlade accessoriesThermodynamicsEngineering

The invention relates to an air film cooling hole pattern structure which comprises an air film hole and a wall face, wherein an outlet of the air film hole is located in the upstream area of the wallface, the air film hole comprises a cylindrical section and an expansion section, one end of the cylindrical section is a cold air inlet, the other end of the cylindrical section is connected with the expansion section, and an opening is formed in the top face of the expansion section, namely the outlet of the air film hole. The bottom surface of the expansion section is a crescent concave curvedsurface with a sharp corner end, and the crescent concave curved surface is communicated with the cylindrical section. Compared with the prior art, the air film cooling hole pattern structure has thebeneficial effects that on one hand, due to the coanda effect, cold air can expand towards the two sides after reaching the position of the crescent concave curved surface expansion outlet with the sharp corner end, and the transverse spreading area of the cold air film is increased; and on the other hand, the expansion type outlet can effectively reduce the momentum of cold air jet flow, cold air can be well attached to the wall face, and therefore the air film cooling efficiency is improved.

Owner:SHANGHAI JIAO TONG UNIV

High-temperature synthetic gas graded chilling device and method

ActiveCN103113926AUniform flow fieldAvoid stickingCombined combustion mitigationCombustible gas productionSyngasSprayer

The invention provides a high-temperature synthetic gas graded chilling device which comprises a shell, wherein the inner wall of the shell is provided with a primary chilling chamber formed by the shell, an upper support plate, the upper part of a lower support plate, and a partition plate; a secondary chilling chamber formed by the shell, the lower part of the lower support plate and the partition plate is arranged below the primary chilling chamber; the upper support plate is connected with a vaporizing chamber; and a high-temperature synthetic gas circulating channel is formed at the center in the shell. The invention also provides an application method of the high-temperature synthetic gas graded chilling device, which is implemented in a way that: part of chilling gas enters the primary chilling chamber through a primary chilling gas inlet, the rest of chilling gas enters the secondary chilling chamber through a secondary chilling gas inlet, and the two parts of chilling gas are respectively sprayed out by a primary sprayer and a secondary sprayer and mixed with high-temperature synthetic gas. The device provided by the invention can quickly, uniformly and efficiently lower the high-temperature synthetic gas to the temperature range required by the technique through graded chilling, has the characteristics of simple structure and low operating cost, and is convenient for maintenance.

Owner:SHANGHAI BOILER WORKS

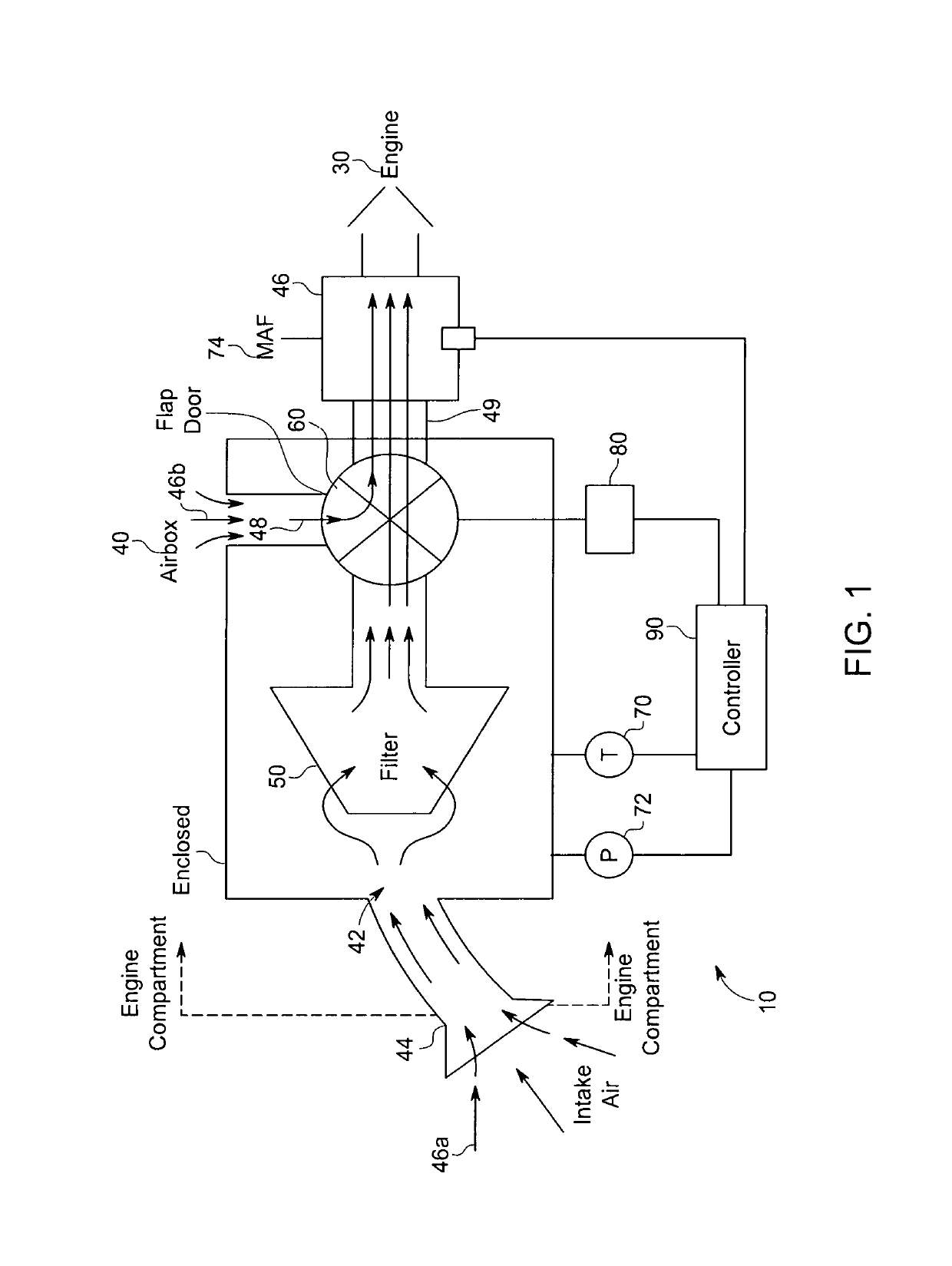

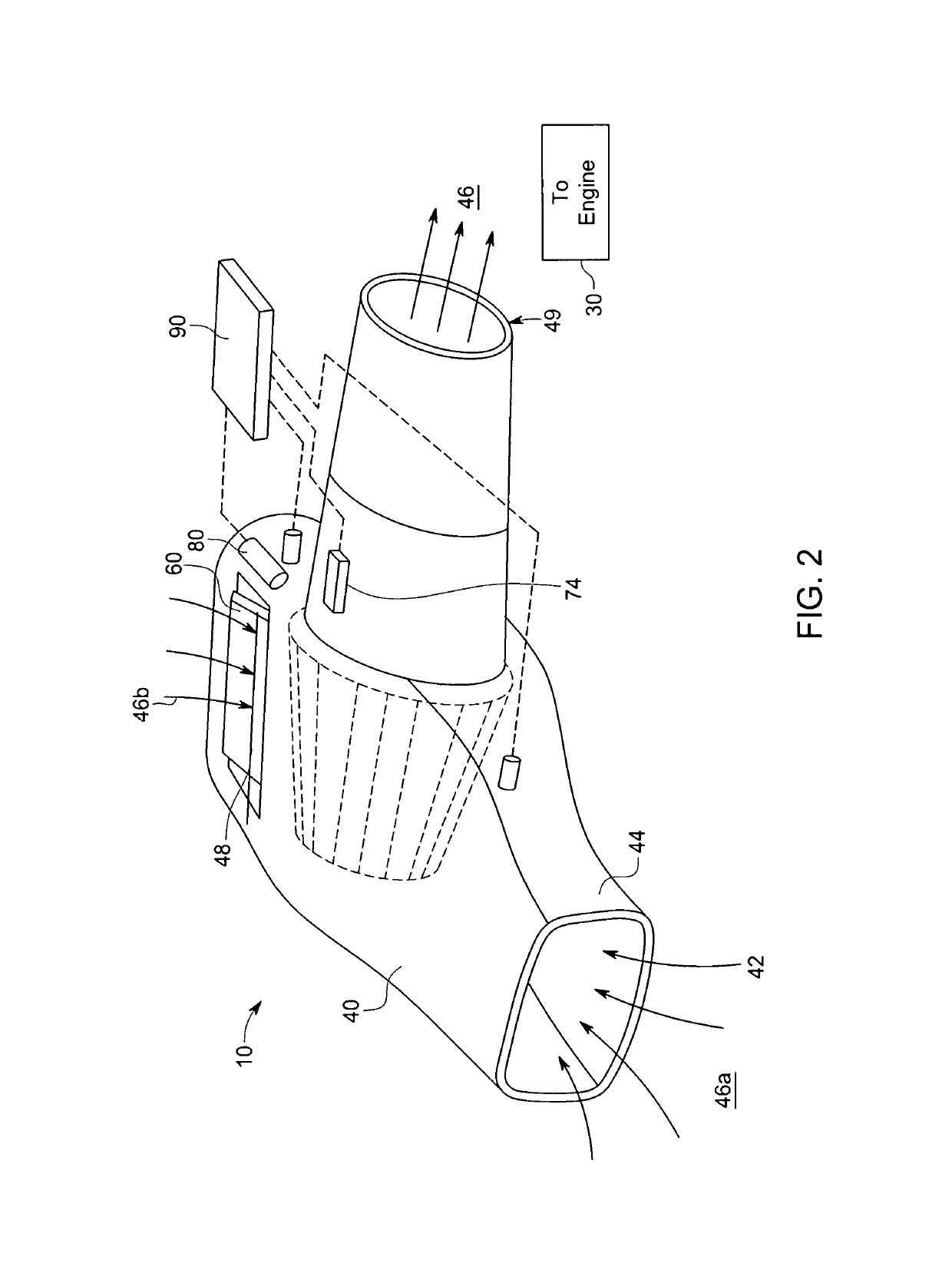

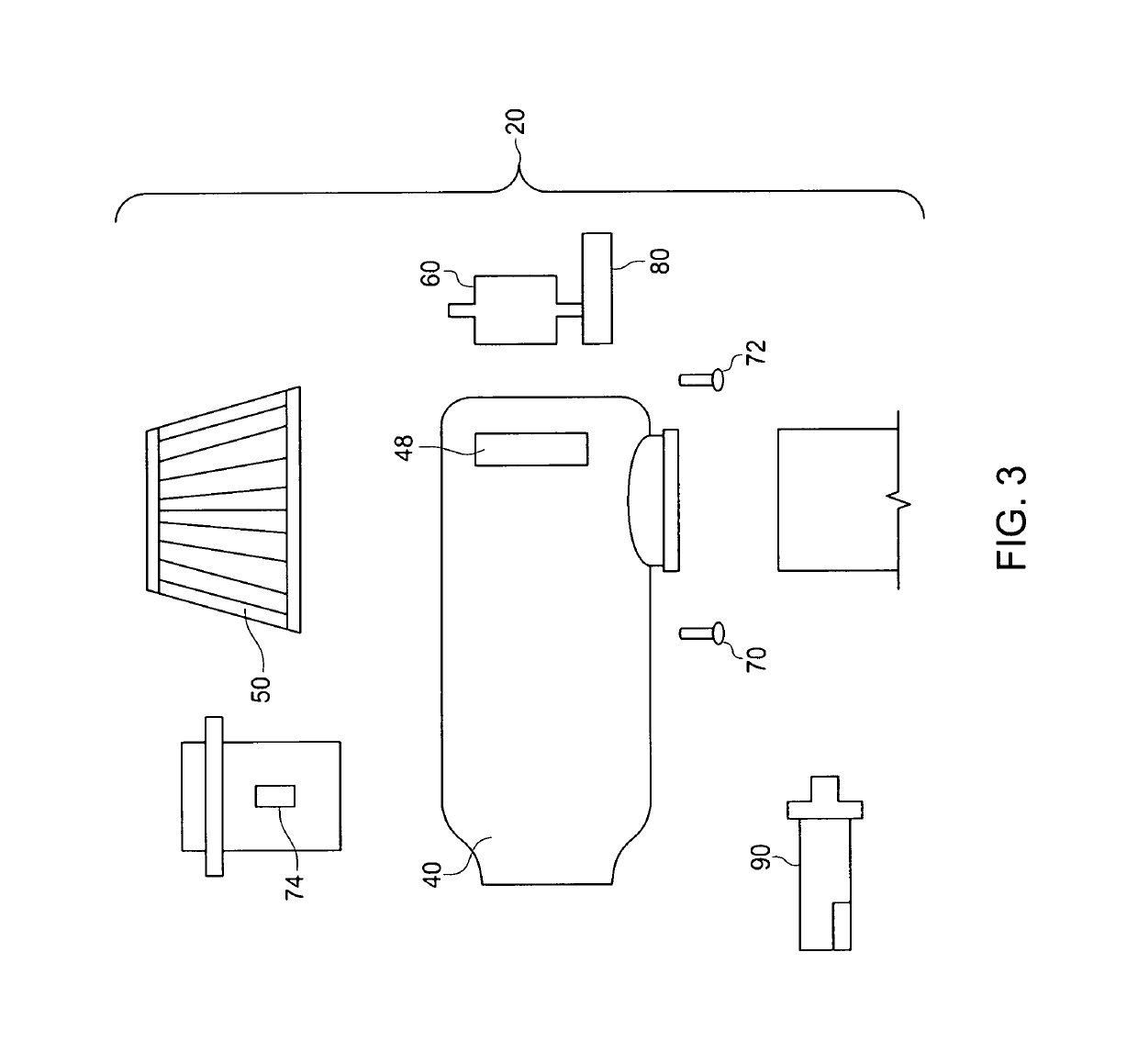

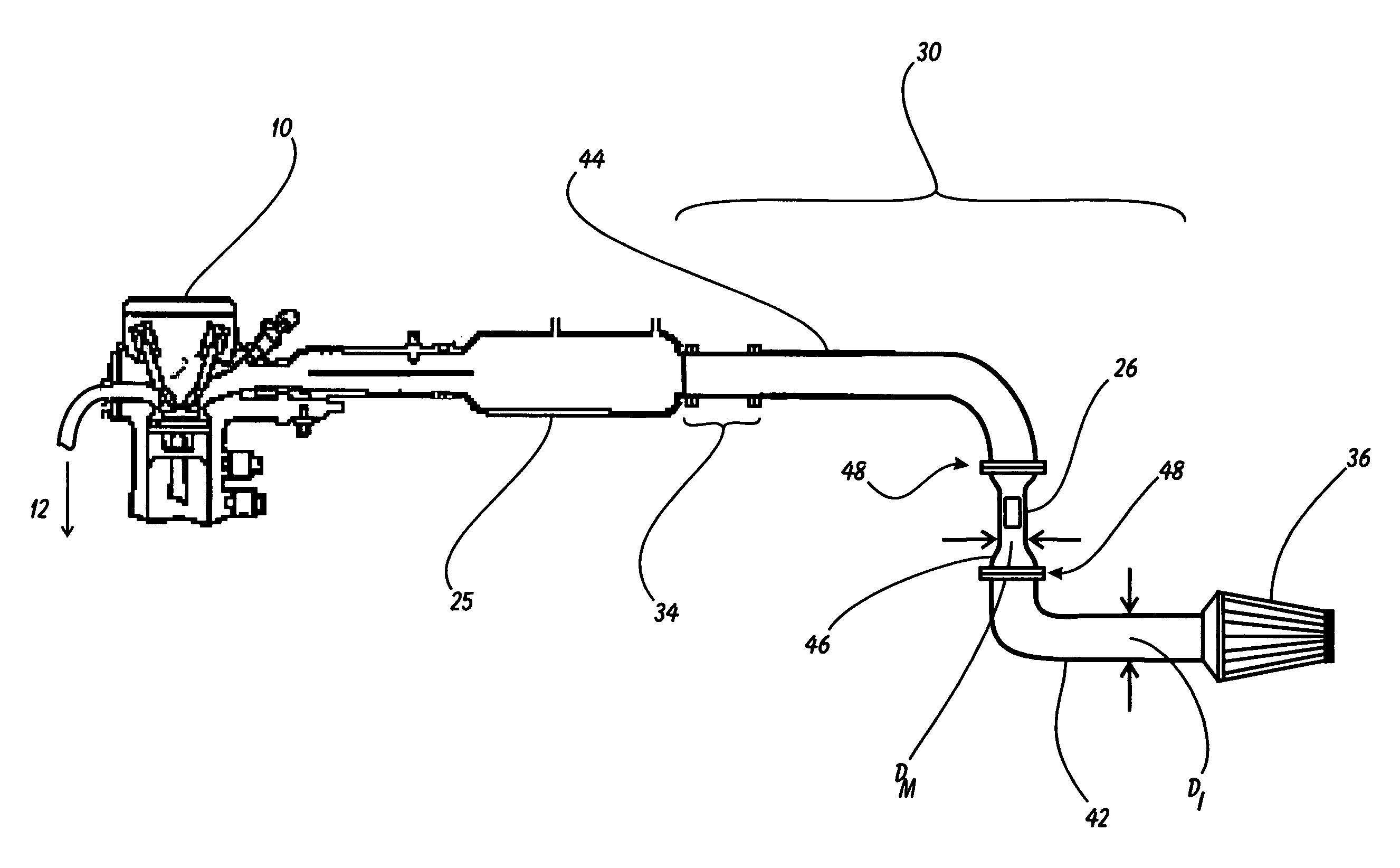

Active cold air intake system

ActiveUS10465640B1Improve efficiencyImprove performanceElectrical controlInternal combustion piston enginesPressure decreaseUser input

A cold air intake system is provided for actively controlling airflow based upon user input and / or demand conditions. Two air inlets are provided into a sealed air box with the secondary air intake including an air control valve for modulating intrusion of intake air. The valve has a valve seat formed the housing sidewall and a flap door valve member actively actuated via a controller. The mass air flow sensor indicates total demand. A pressure sensor and a temperature sensor provide additional input from the airbox. The controller modifies the valve position based upon pressure, temperature and mass air flow. Control is biased to increase secondary air intake when airbox pressure decreases and biased to decrease secondary air intake when airbox temperature increases. Controller biasing occurs between 30° F. to 160° F. and over pressure ranges between 0.01″ H2O to 5″ H2O.

Owner:SUPERTRAP IND INC

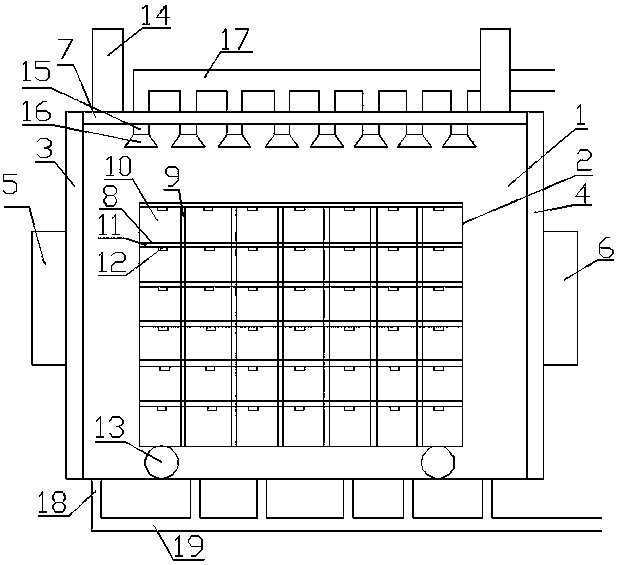

LED lighting lamp aging test box

InactiveCN104166029AConvenient control simulationEffective flame retardantMeasurement instrument housingLamps testingEffect lightEngineering

The invention provides an LED lighting lamp aging test box. A box body provided with a left box door and a right box door is arranged, the left box door and the right box door are provided with a hot air port and a cold air port for hot air intake and cold air intake respectively, the tops of the two doors and the top of the box body are respectively provided with a heat preservation layer, the two sides of each top are respectively provided with a circulation air opening, the middle of each top is provided with an atomization water pipe, and therefore control simulation can be carried out on the environment needed in the box body conveniently. An aging rack is placed in the box body and divided into a plurality of test cells. The top of each cell is provided with a flame retardant liner with the wiring end. Due to the fact that supporting boards and partition boards are adjustable in position, the size of the test cells can be adjusted, lamps can be placed according to actual sizes, effective flame retardance can be achieved, and due to the fact that a collection water pipe is arranged to collect water of the atomization water pipe, waste is avoided. The whole LED lighting lamp aging test box is simple in structure, easy to operate, capable of carrying out simulation testing on the aging environment of LED lighting lamps, and suitable for production.

Owner:SUZHOU CHENGTENG ELECTRONICS TECH

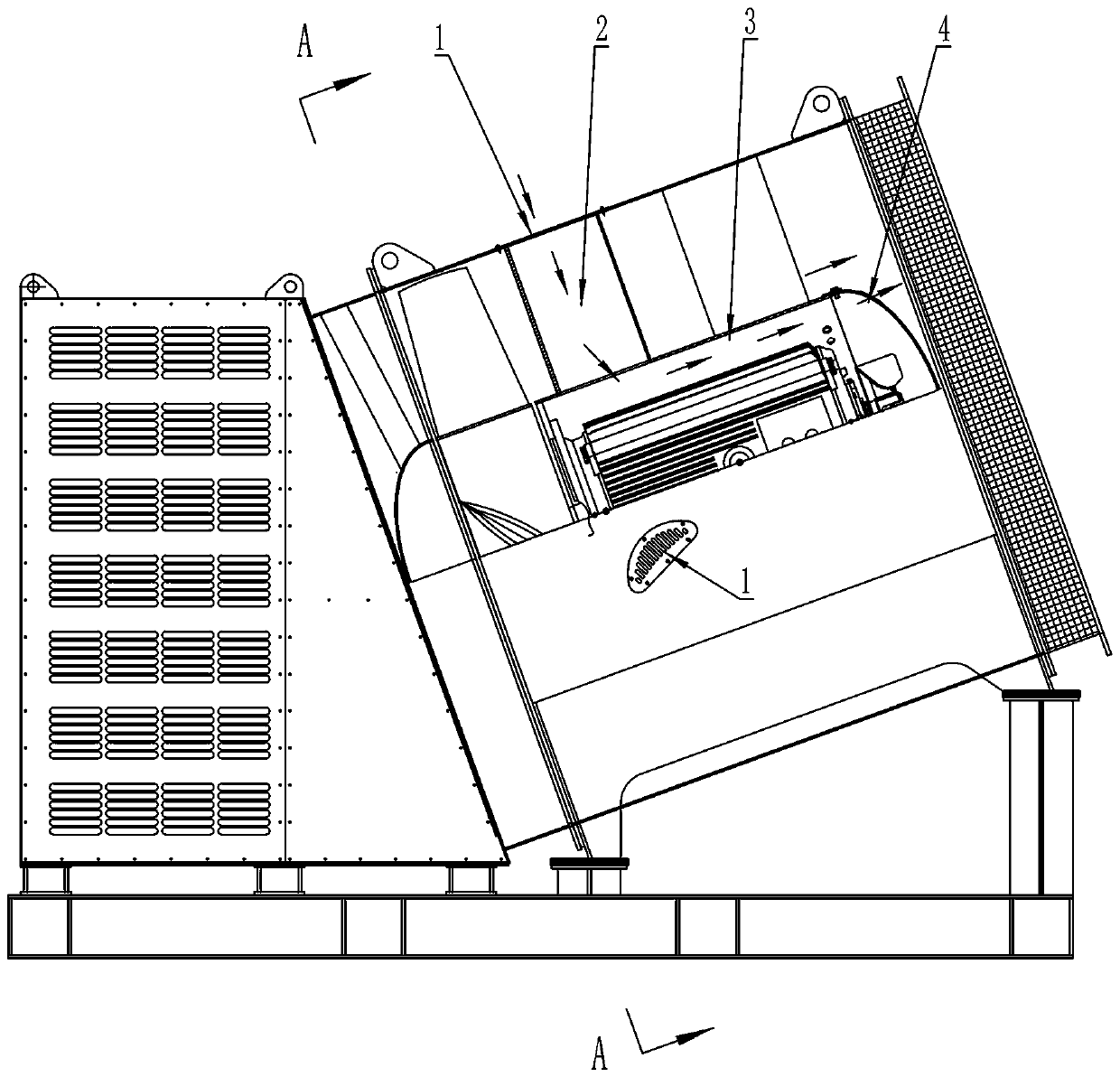

Design method for heat dissipation system of wind turbine generator set under severe environment and heat dissipation system

ActiveCN104791197AWon't clogAdapt to the needs of useEngine fuctionsEfficient propulsion technologiesCold air intakeAir volume

The invention discloses a design method for a heat dissipation system of a wind turbine generator set under a severe environment and the heat dissipation system. An outer air duct is added to a heat dissipation system of an original wind turbine generator set through the five steps of constructing the outer air duct of the heat dissipation system, determining the air volume of the outer air duct, determining the air speed of an air inlet of the outer air duct, determining the area of the air inlet of the outer air duct and forming the air inlet. The air speed of the air inlet is made to be 3 m / s-4 m / s by controlling the area of the air inlet, so that little or no suspended matter is sucked into the outer air duct. Radiators of the original heat dissipation system suck cold air through the outer air duct, and therefore exhaust inlets of the radiators cannot be blocked, the cold air intake volume and the heat dissipation effect are guaranteed, and the wind turbine generator set can meet use requirements under the severe environment.

Owner:CSIC CHONGQING HAIZHUANG WINDPOWER EQUIP

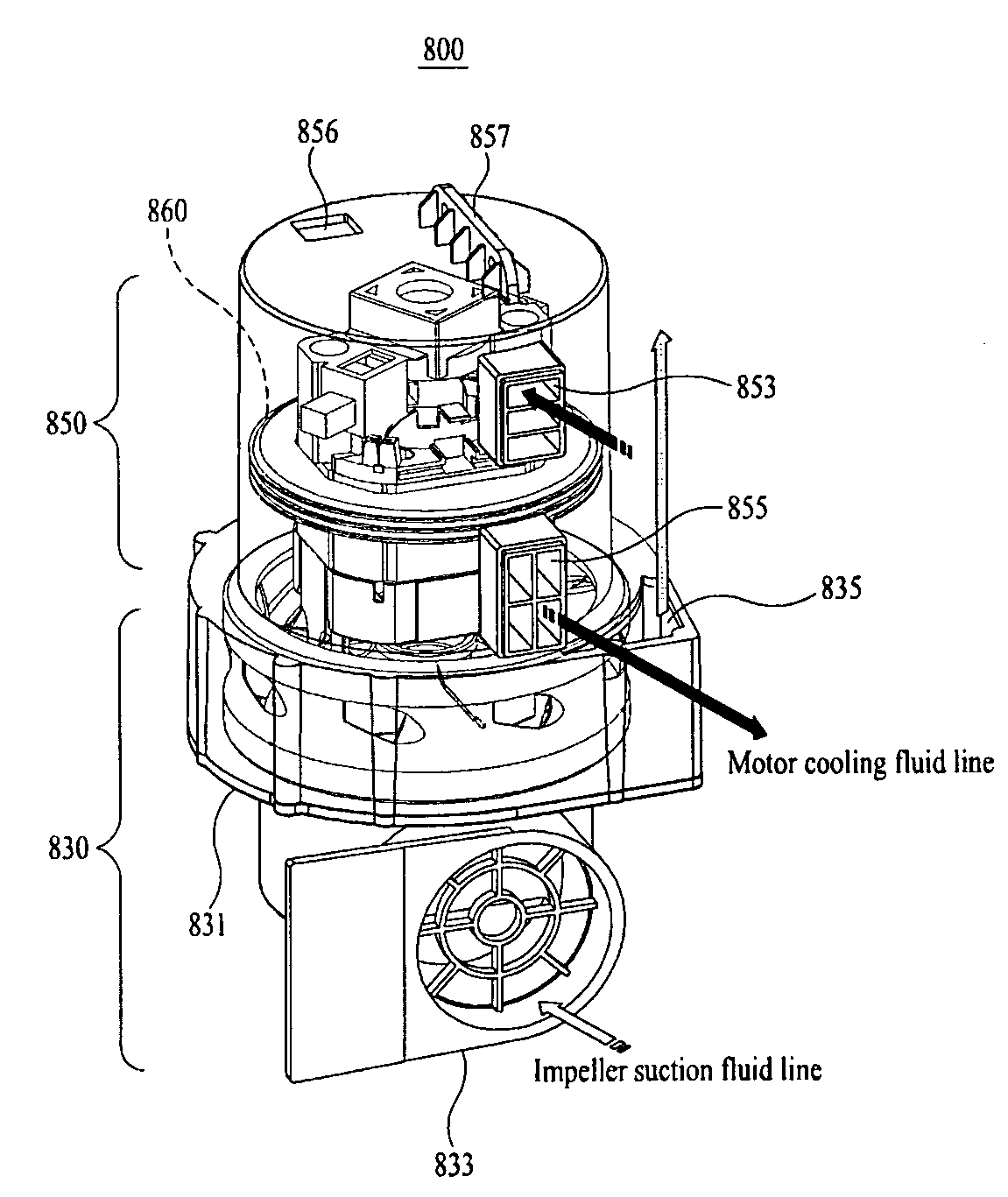

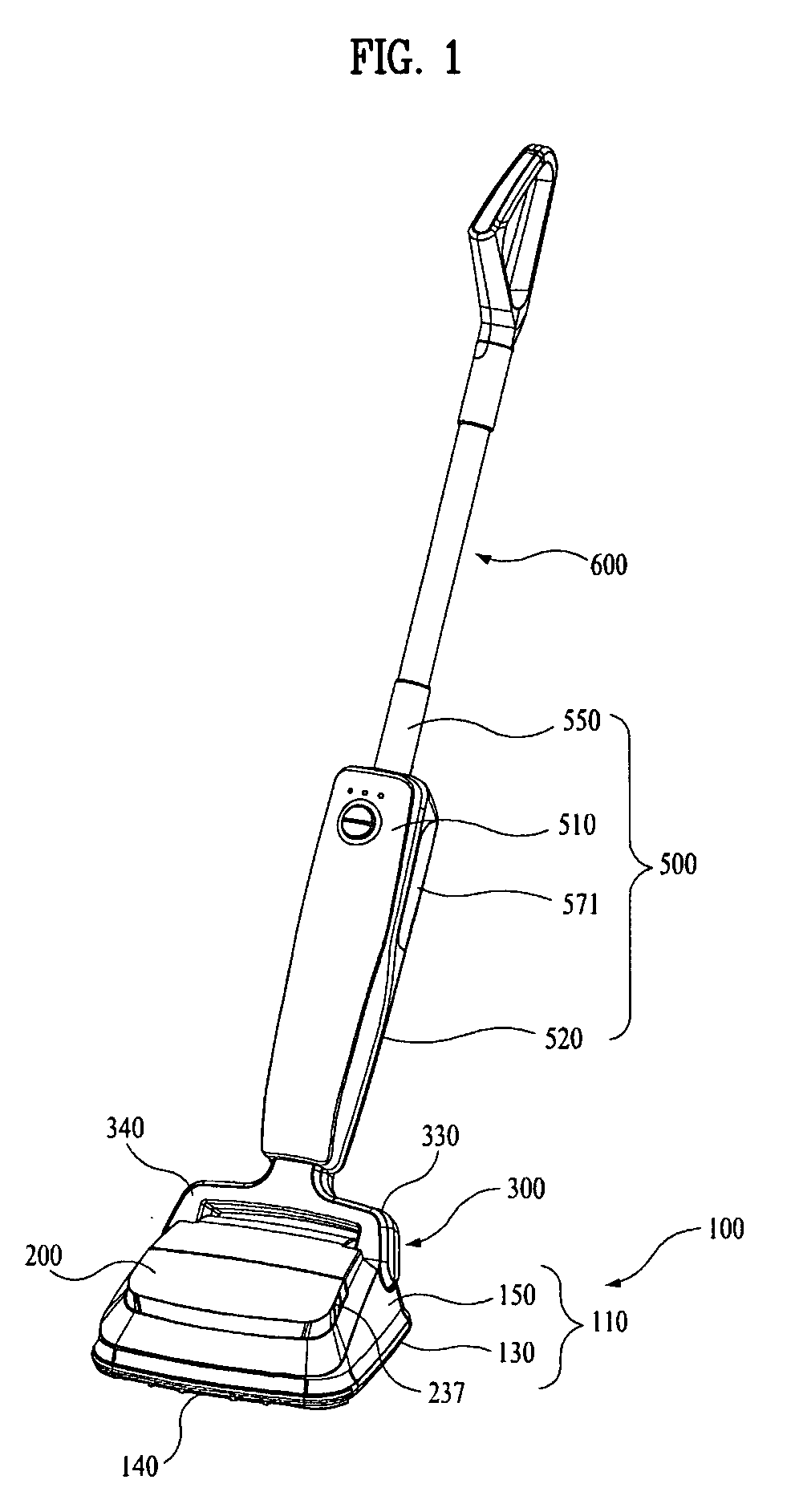

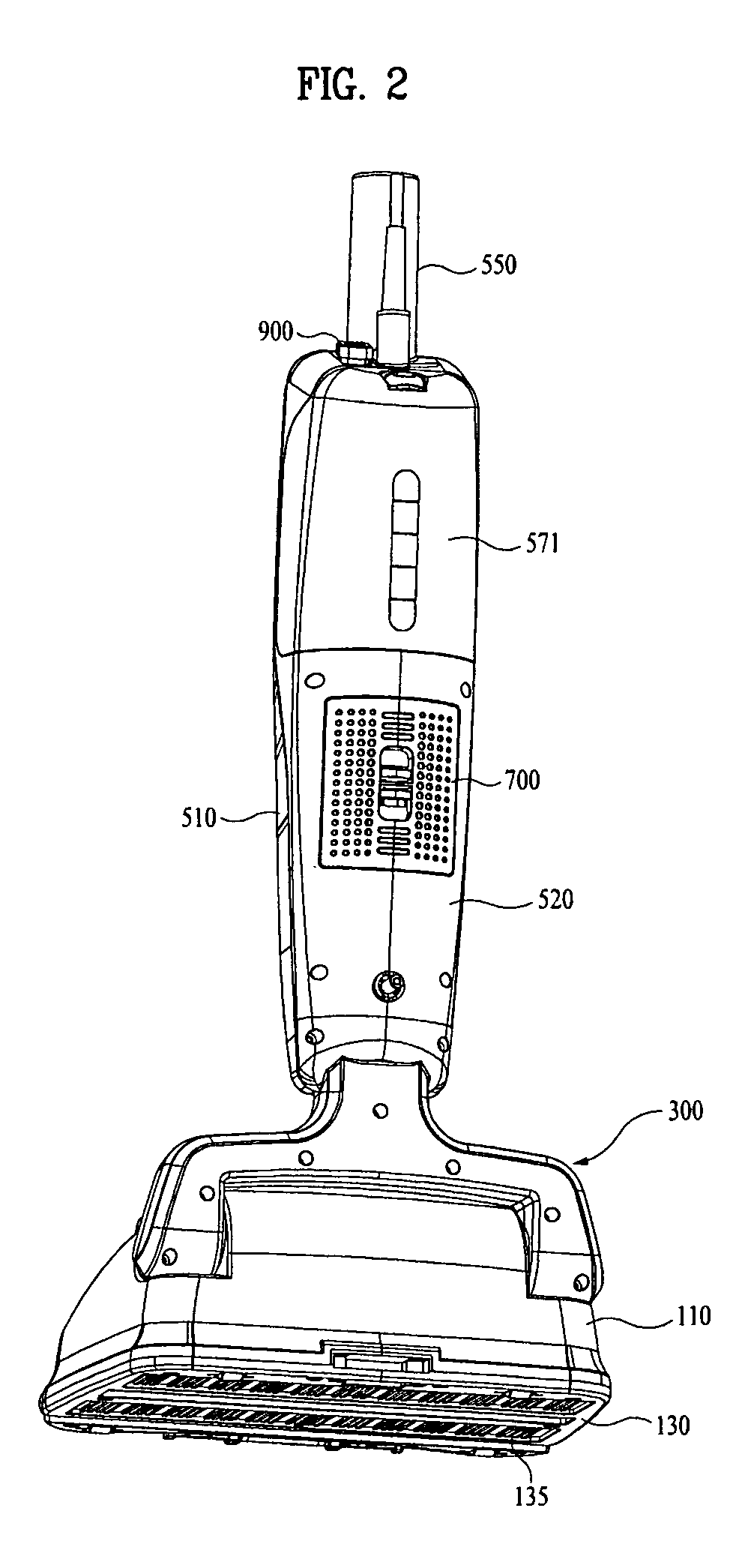

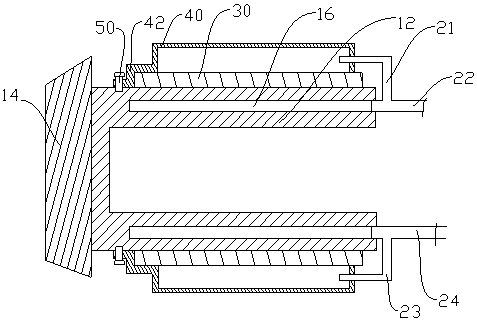

Motor assembly for steam vacuum cleaner

InactiveUS20080235898A1Maximizing efficiency of wetMaximize efficiencyPump componentsMachine detailsEngineeringVacuum cleaner

A motor assembly for a steam vacuum cleaner comprises a flow separation packing which is coupled within a motor cooling casing between a cold air intake duct and an air exhaust duct, so as to maximize cooling efficiency of a wet type motor by separating the sucked cold air from the hot air having undergone a cooling operation.

Owner:HAAN

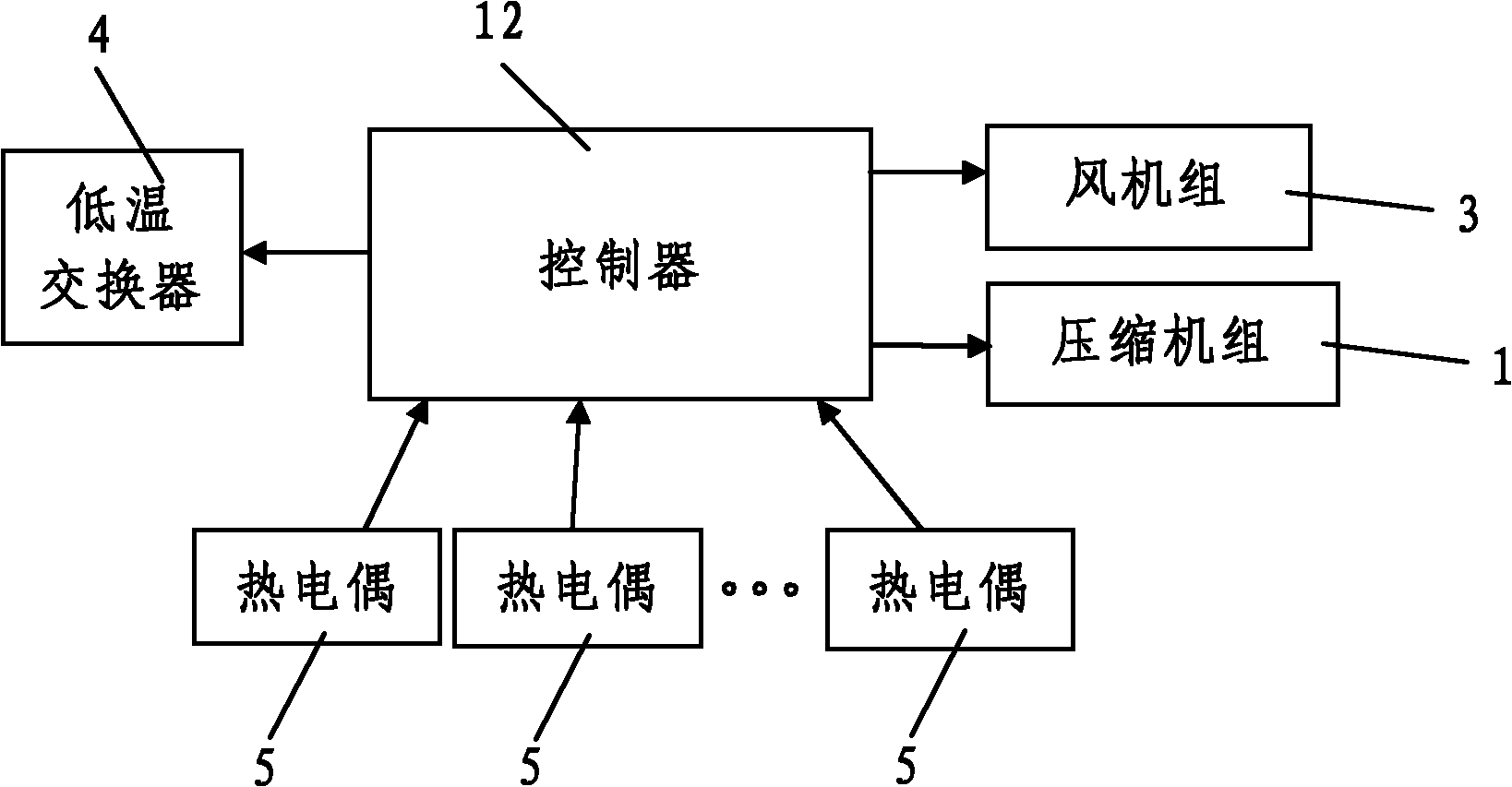

Low temperature environment testing apparatus

InactiveCN102486453AEasy to installSimple structureWeather/light/corrosion resistanceEngineeringReturn channel

The invention discloses a low temperature environment testing apparatus. The apparatus comprises a low temperature working bin, a controller, a cold air intake window, an airflow returning window, a cold air circulation channel and temperature-detecting devices; the cold air circulation channel comprises a cold airflow intake channel and an airflow returning channel, a low temperature exchanger is arranged at a position where the cold airflow intake channel and the airflow returning channel joint, a fan set is installed on the cold airflow intake channel or on the airflow returning channel, and the fan set continuously sends cold airflow obtained after the low temperature exchanger carries out low temperature exchange to the low temperature working bin through the cold airflow intake channel and synchronously continuously pumps air in the low temperature working bin to the position where the low temperature exchanger is installed through the airflow returning channel for low temperature exchange, thereby realizing continuous circular flowing of air in the cold air circulation channel. The low temperature environment testing apparatus provided in the invention has the advantages of a simple structure, compact installation, convenient arrangement, simple usage and operation, a good application effect, a fast cooling speed, a good constant temperature effect and low energy consumption and can effectively overcome a plurality of practical problems of conventional low temperature environment testing apparatuses.

Owner:XIAN DAYU PHOTOELECTRIC TECH

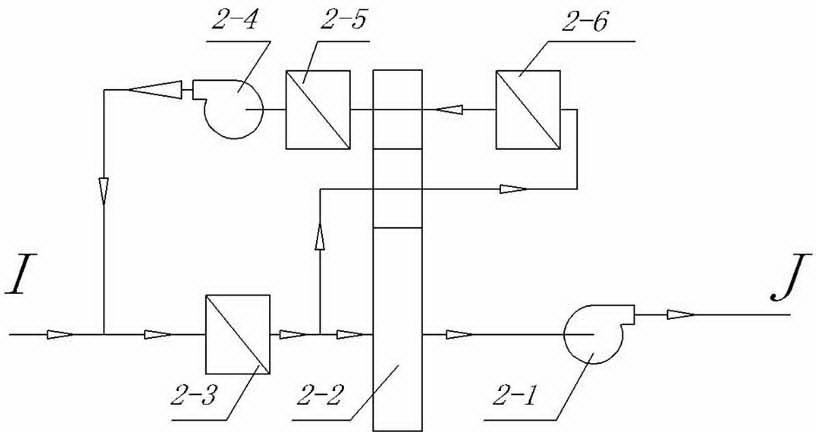

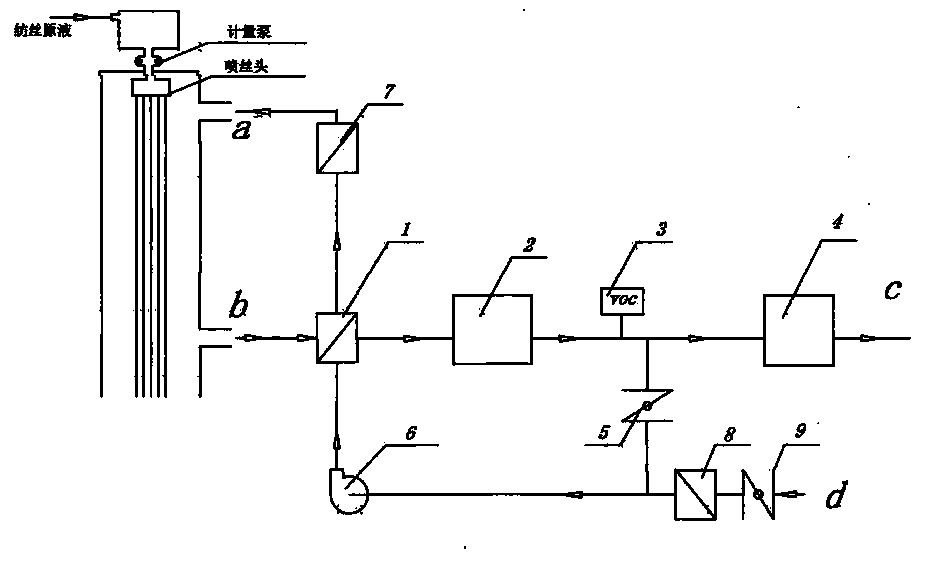

Dry spinning organic solvent recovery and air circulating use method

InactiveCN104342785AReduce recycling costsReduce power consumptionArtificial filament recoveryDispersed particle separationAir cycleSpinning

The invention relates to a dry spinning organic solvent recovery and air circulating use method. A spinning shaft is respectively provided with a circulating air intake opening and an organic solvent-containing waste air exhaust opening from top to bottom, wherein the organic solvent-containing waste air exhaust opening is sequentially connected with a hot air intake and exhaust opening of a heat exchanger, a circulating air high boiling organic solvent recovery assembly, an electric air valve, an air delivery fan, a cold air intake and exhaust opening of the heat exchanger, an air heater and the circulating air intake opening, a branch pipeline is connected with an air exhaust opening of the circulating air high boiling organic solvent recovery assembly and an exhaust air high boiling organic solvent recovery assembly, a branch pipeline is connected with a fresh air supplementing opening, the electric air valve for controlling fresh air, a fresh air cooler, and an air intake opening of the air delivery fan, and an organic solvent concentration detection instrument is arranged on a pipeline of the air exhaust opening of the circulating air high boiling organic solvent recovery assembly. The dry spinning organic solvent recovery and air circulating use method has the advantages that the solvent recovery cost is low, the running is safe and continuous, one part of air is exhausted to the outside, the negative pressure in the spinning shaft is formed, and other spinning devices are not needed by the spinning shaft.

Owner:马军

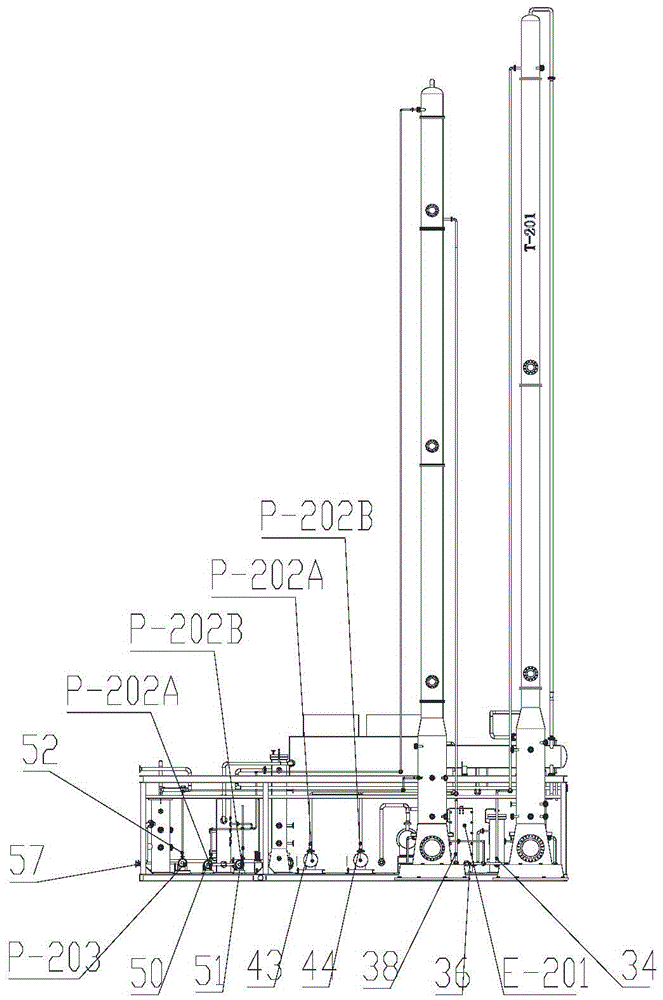

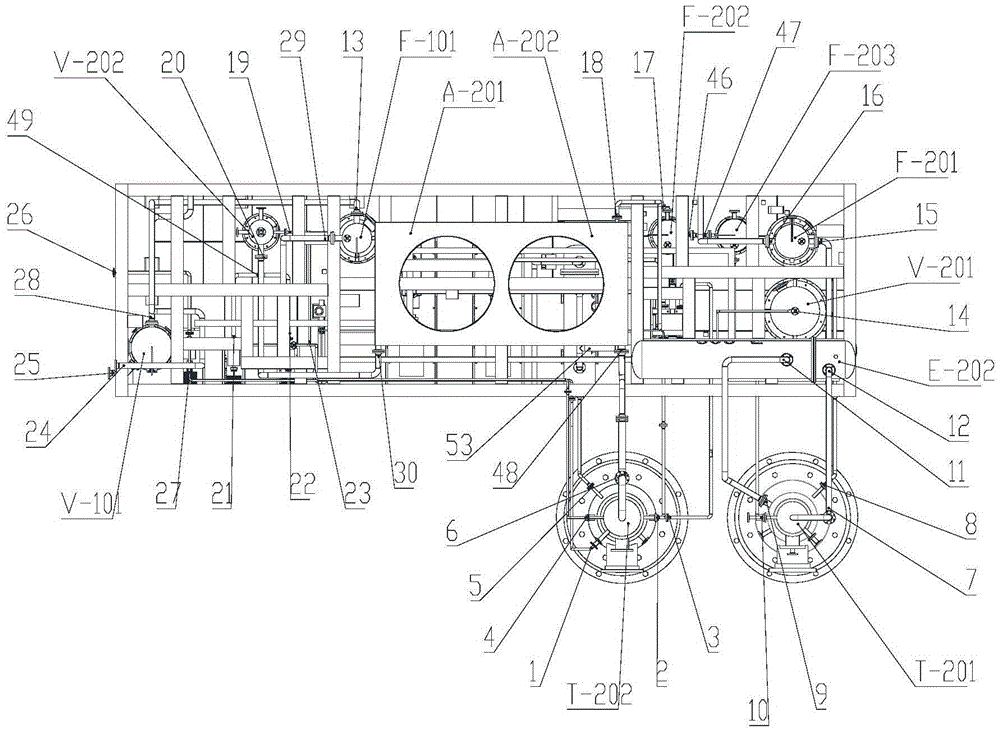

Small mobile skid-mounted natural gas purification device

InactiveCN105462641ASmall footprintQuick installationGaseous fuelsActivated carbon filtrationFiltration

The invention relates to a small mobile skid-mounted natural gas purification device which comprises a feed gas filtration and measurement unit and a deacidification and decarburization unit. The filtration and measurement unit comprises an inlet separator and an inlet filter; an air outlet pipeline of the inlet separator is connected with an air inlet of the inlet filter, and an air outlet pipeline of the inlet filter is connected with a cool air inlet of a deacidification gas heat exchanger. Condensed liquid and solid impurities are removed respectively by wellhead gas through the filtration and measurement unit, the separated and purified natural gas enters the deacidification and decarburization unit, acid gas is removed, and natural gas of which the acid gas is removed enters an activated carbon filter and a lean amine filter to remove the solid impurities to become purified gas. According to the small mobile skid-mounted natural gas purification device, the occupied area is much smaller than that of a fixing technology device with the same treatment capacity; equipment installation is completed in a factory, and on-site installation is easy, convenient and rapid; type selection of equipment for all parts is fixed, standardization production is achieved, and products are stable; the small mobile skid-mounted natural gas purification device can work by moving from one gas source to another gas source; moving and transferring are easier.

Owner:天津市振津石油天然气工程有限公司

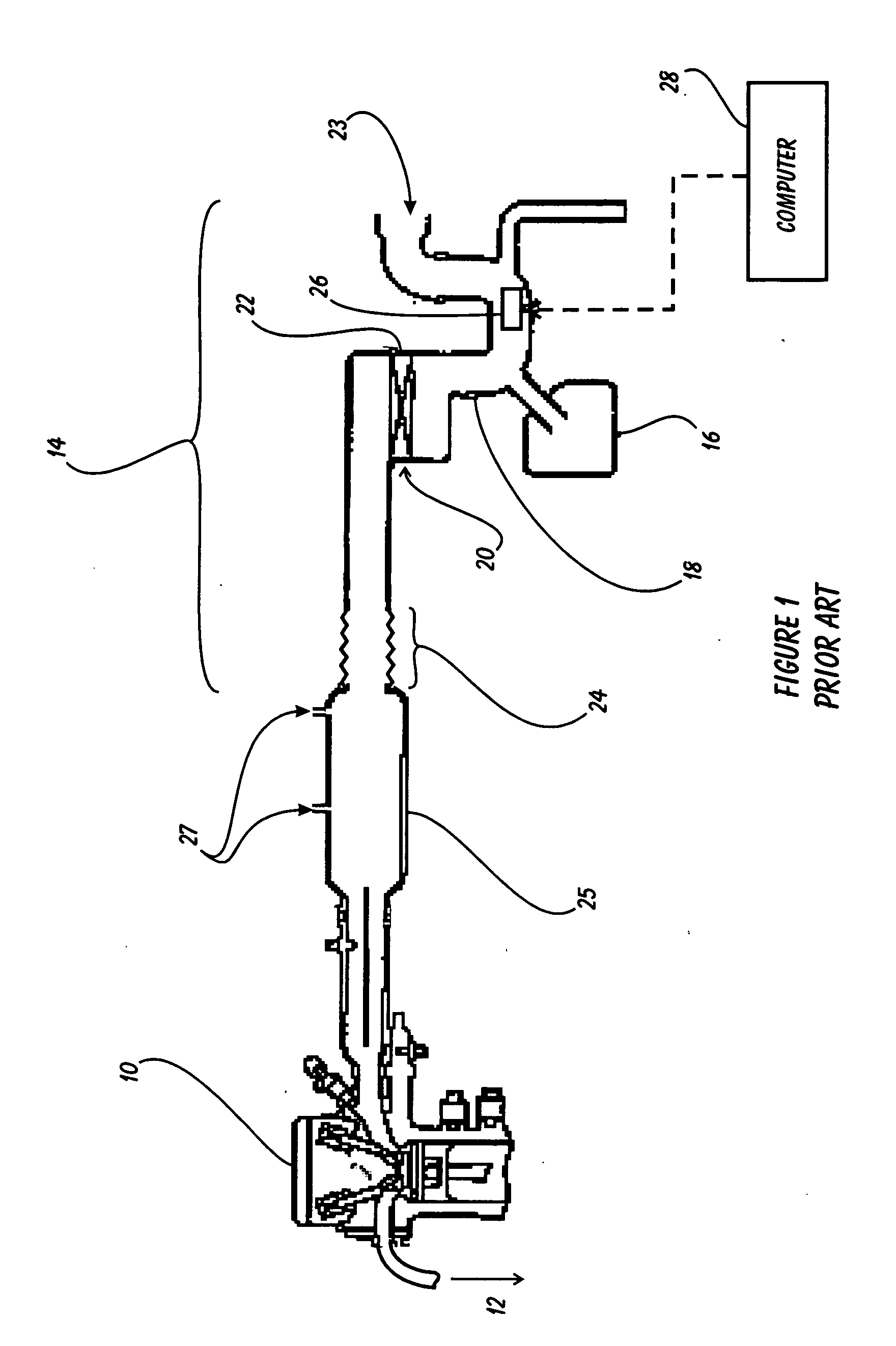

Calibration method for air intake tracts for internal combustion engines

A Calibration Method for Air Intake Tracts for Internal Combustion Engines is disclosed. The method tunes the replacement cold air intake so that the Original Equipment Mass Airflow Sensor will function with the emissions control system without check engine light illumination. The method uses the exhaust effluent composition to benchmark the OEM intake system and then to match the cold air intake to that benchmark test result. The method could use the exhaust effluent composition for calibration as well as verification, or the method could use Sensor signal output for calibration and then exhaust effluent composition for verification of the design specification.

Owner:INJEN TECH CO LTD

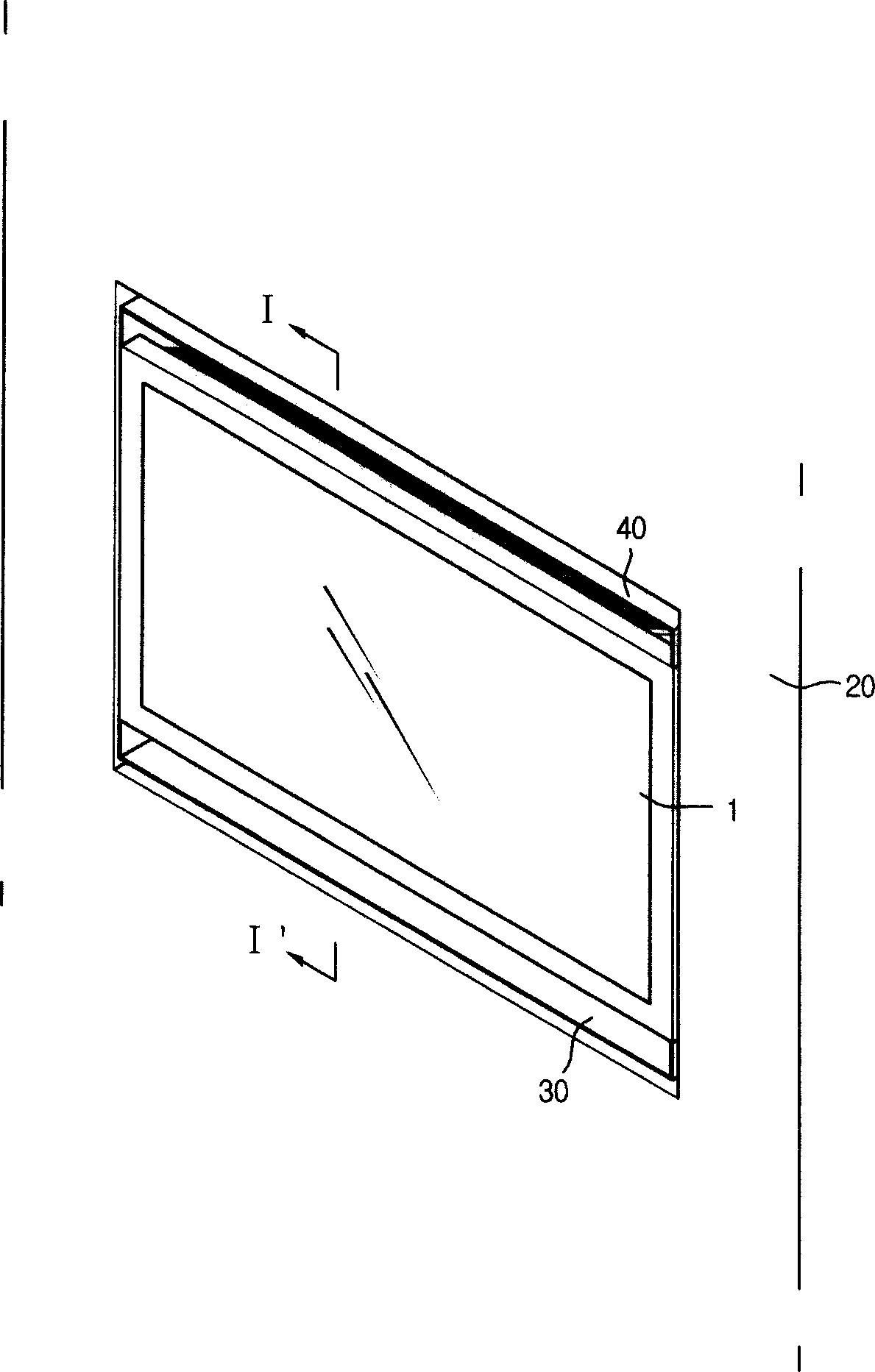

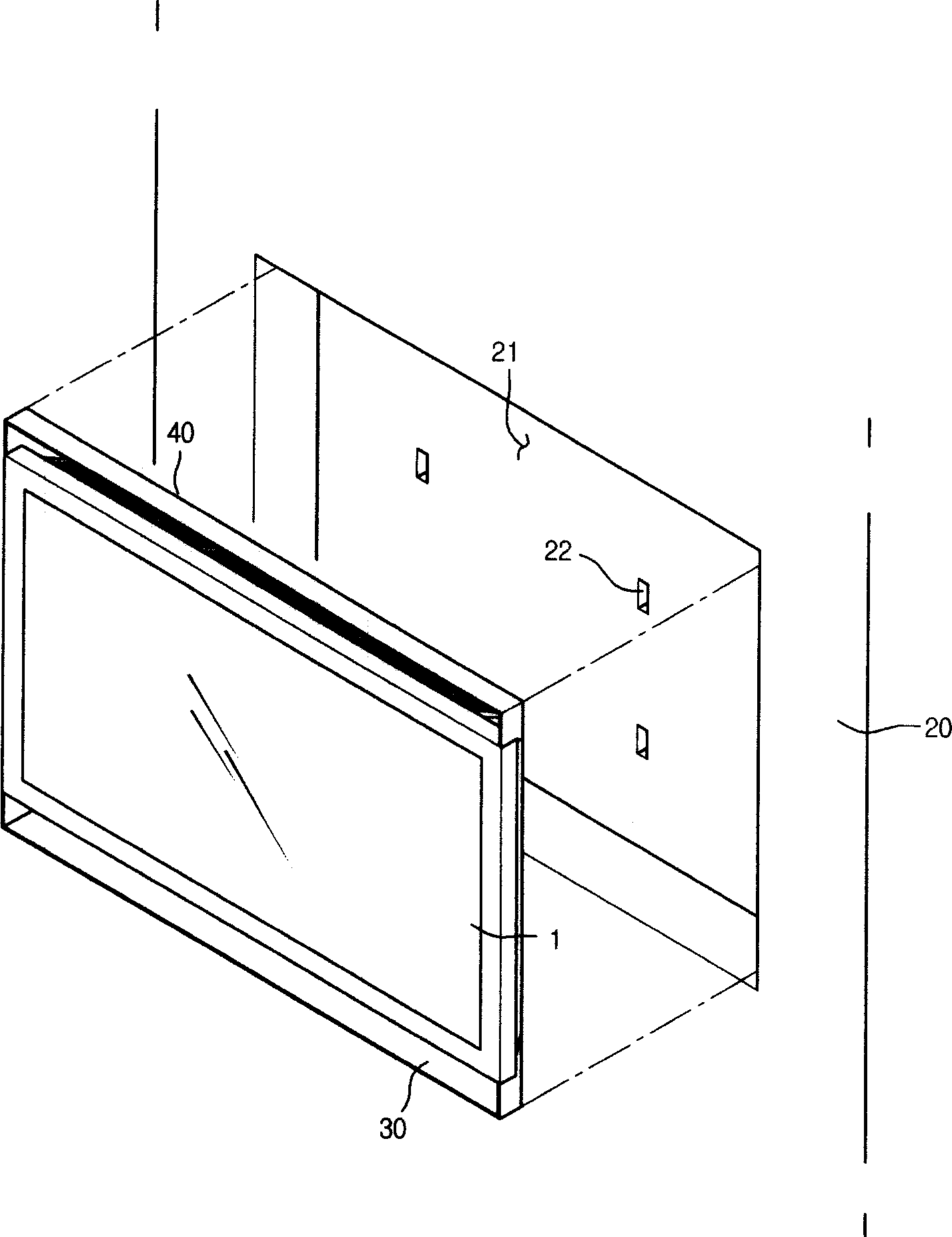

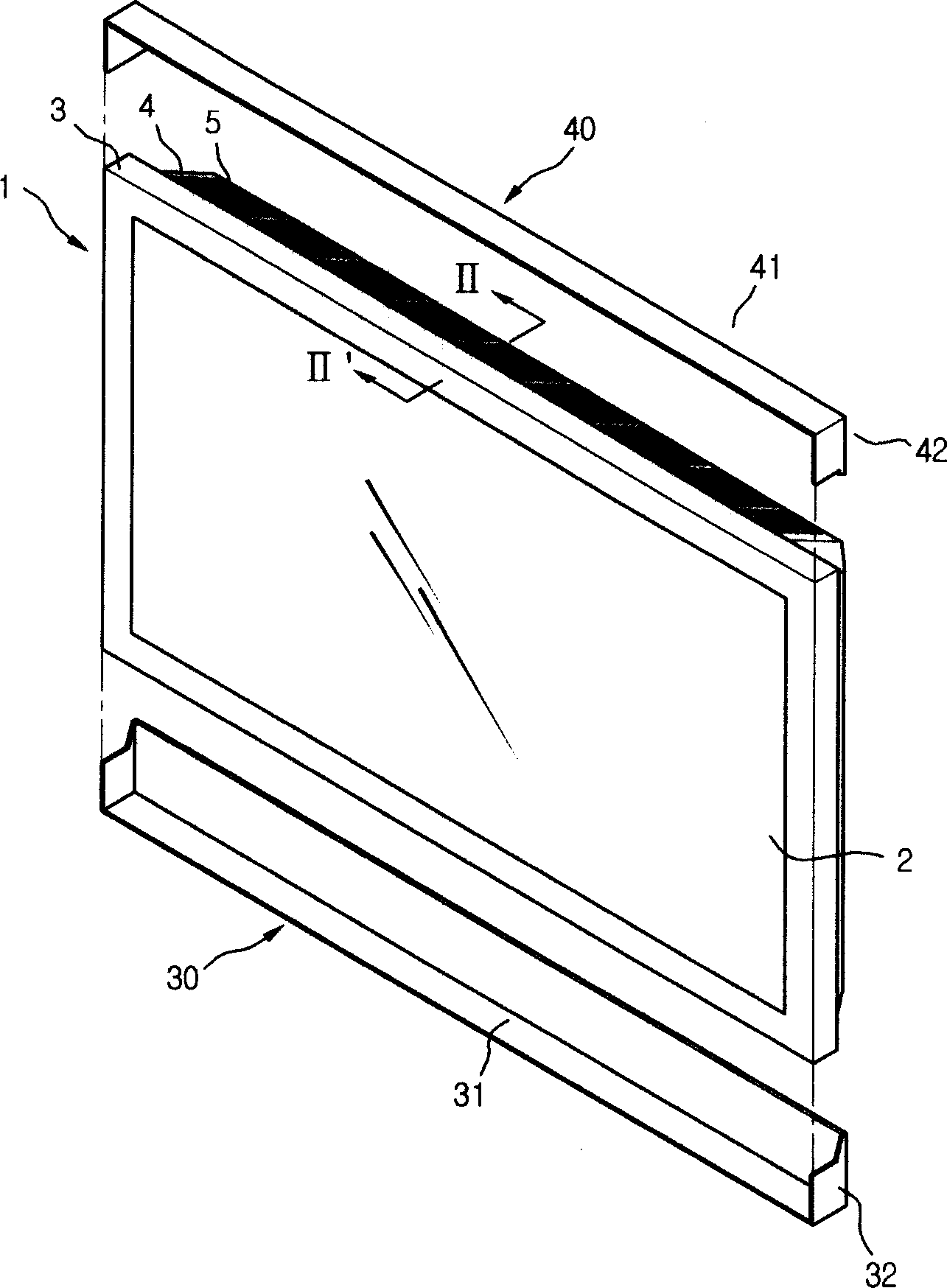

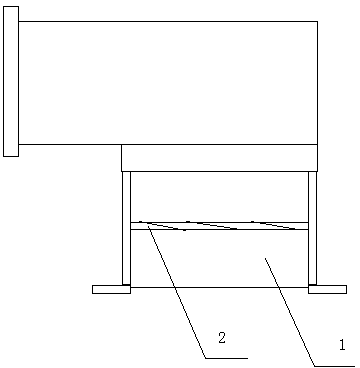

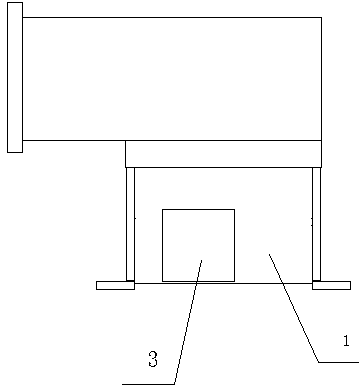

Panel display device and panel display device setting device

InactiveCN1901788ASet compactSolve the cooling problemTelevision system detailsRack/frame constructionConfined spaceDisplay device

The present invention relates to a panel display device, including a panel display module; a casing for protecting the outside of said panel display module; a cold air intake positioned on one side of said casing; a hot air outlet positioned on the other side of the casing; a blower installed on said hot air outlet; an inflow guiding groove for guiding the air inflowing through the cold air intake; an outflowing guiding groove for guiding the air outflowing through the hot air outler. The panel display device has the advantage of solving the problem of heat dissipation by setting the panel display device closely in a confined space. As a result, the panel display device can be positioned closely in a confined space in a best mode, and the positioning of the panel display is easiest and the reliability of the operating of the panel display device is improved.

Owner:NANJING LG TONGCHUANG COLOR DISPLAYS SYST CO LTD

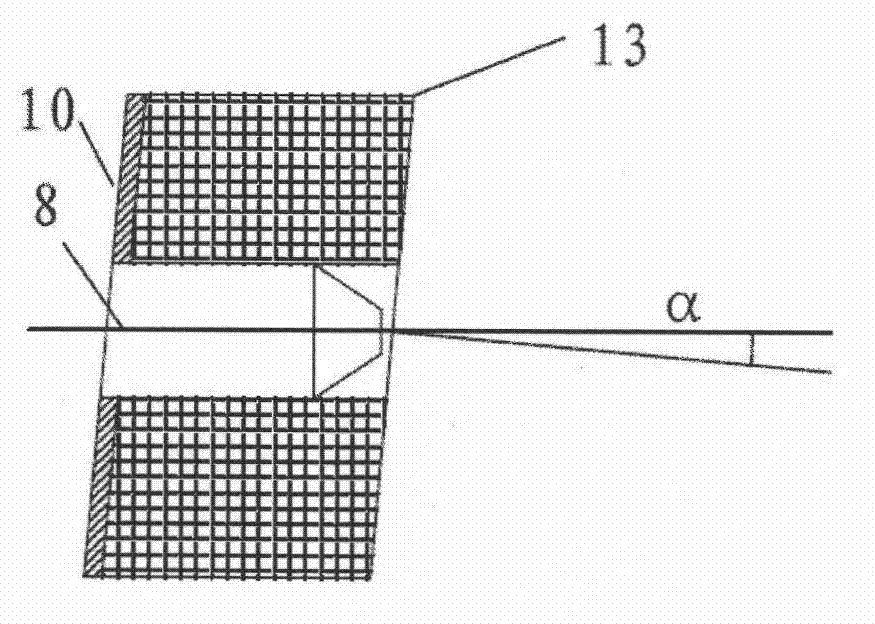

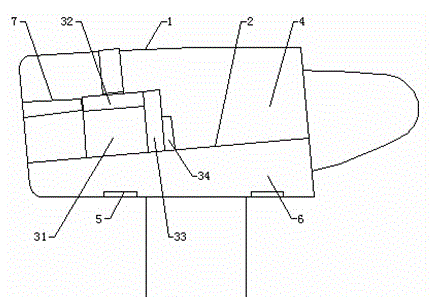

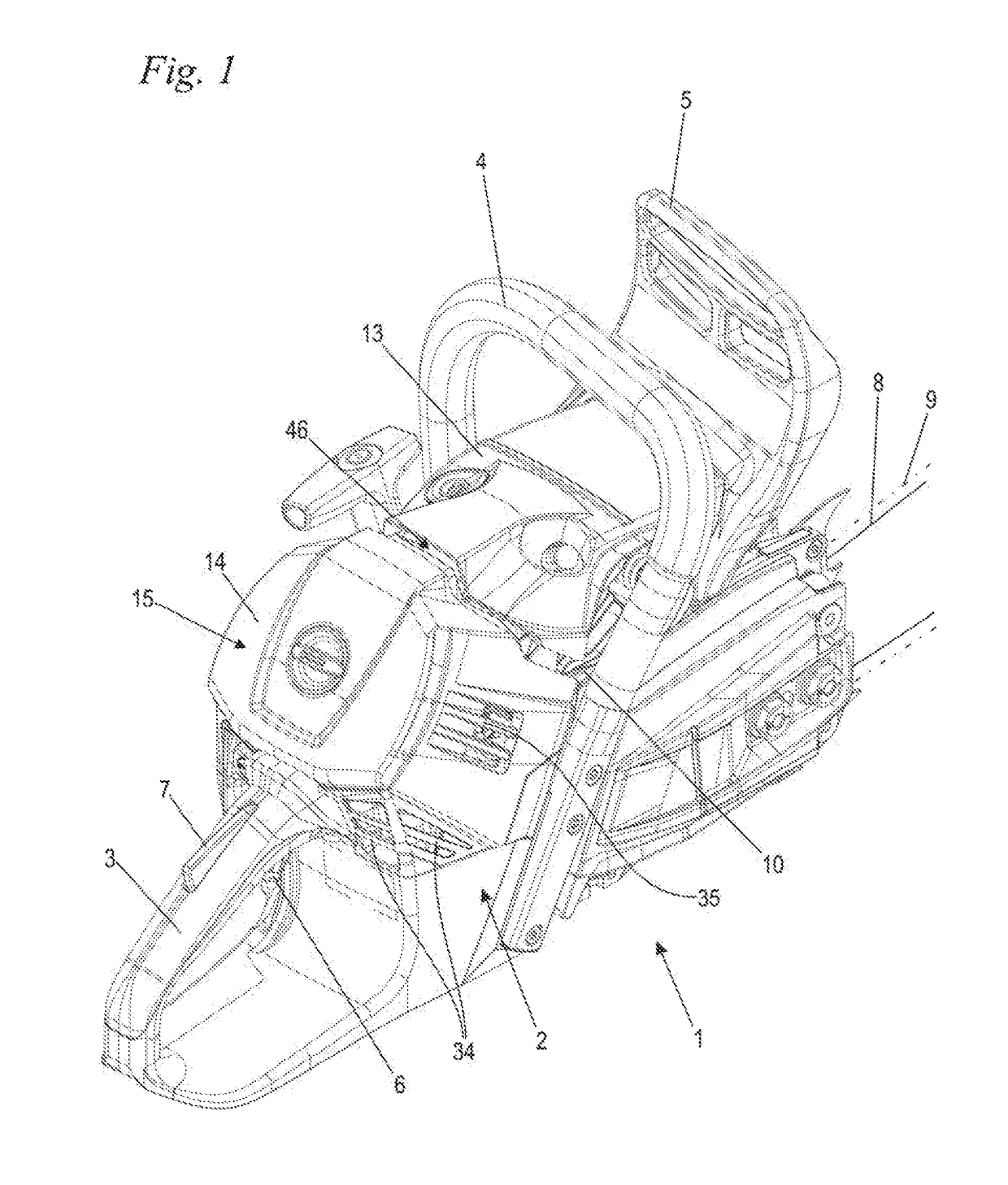

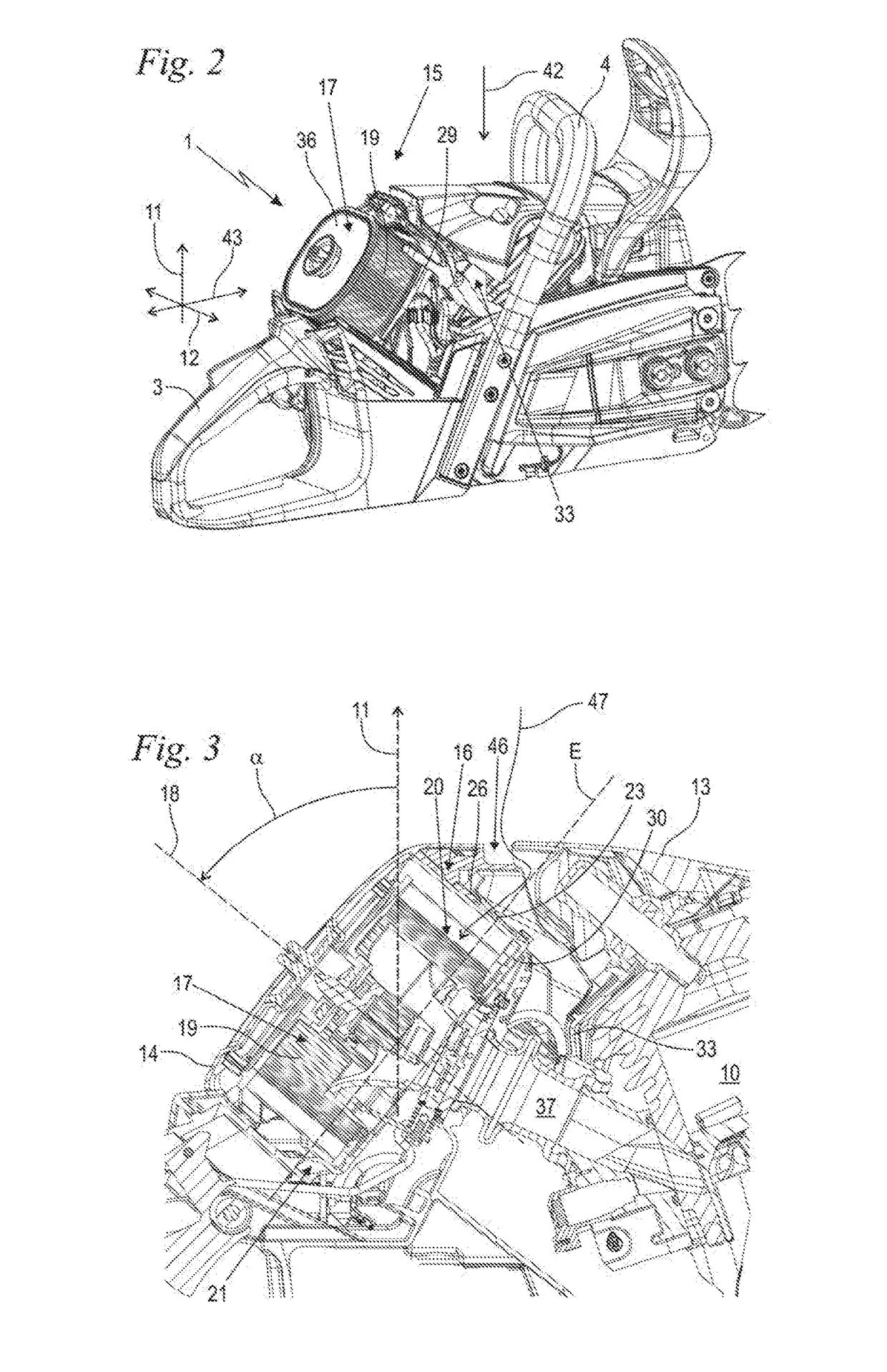

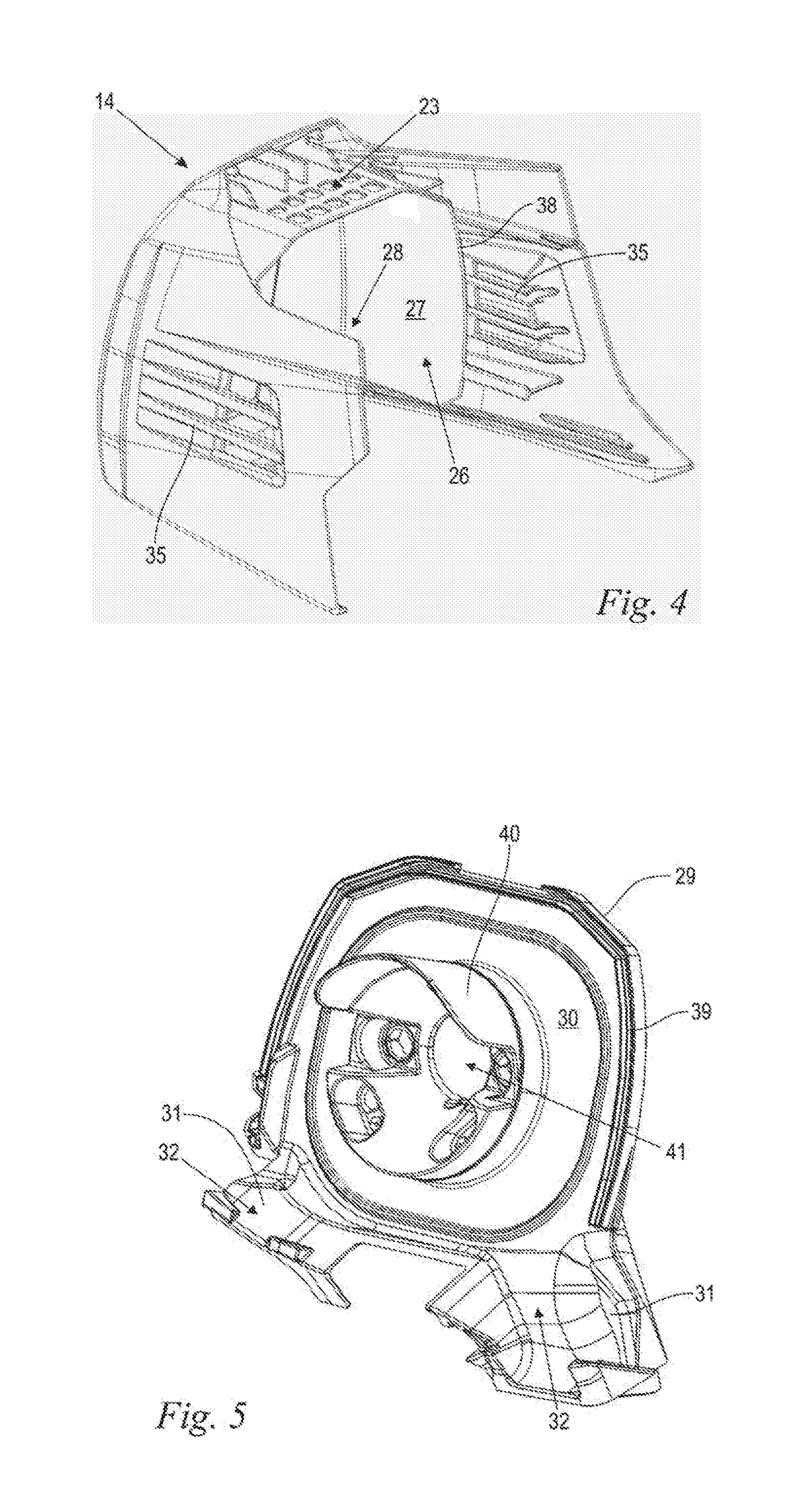

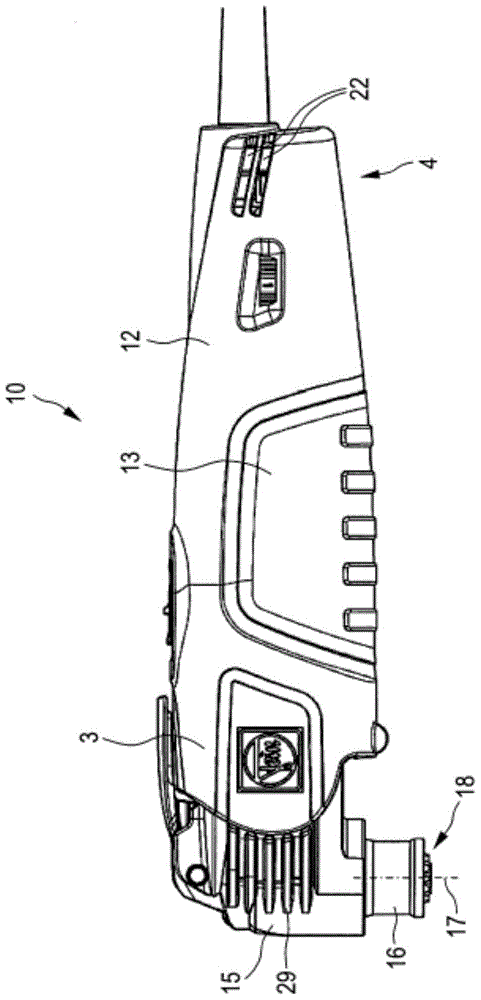

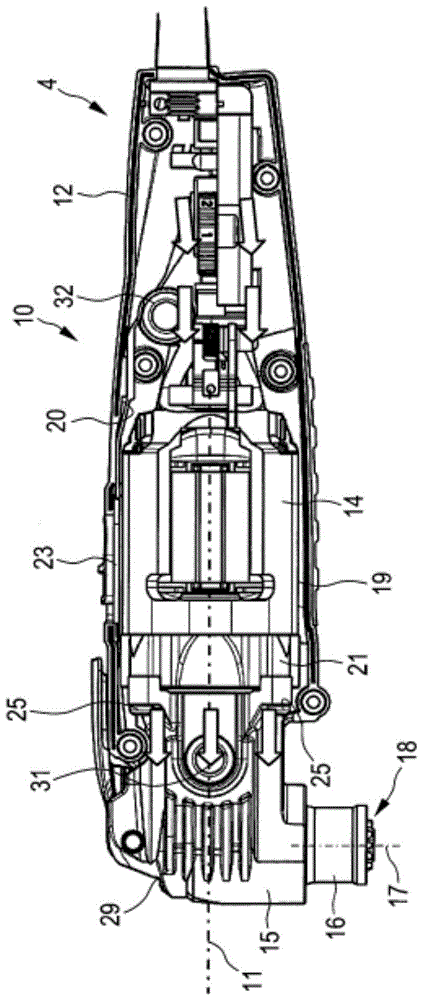

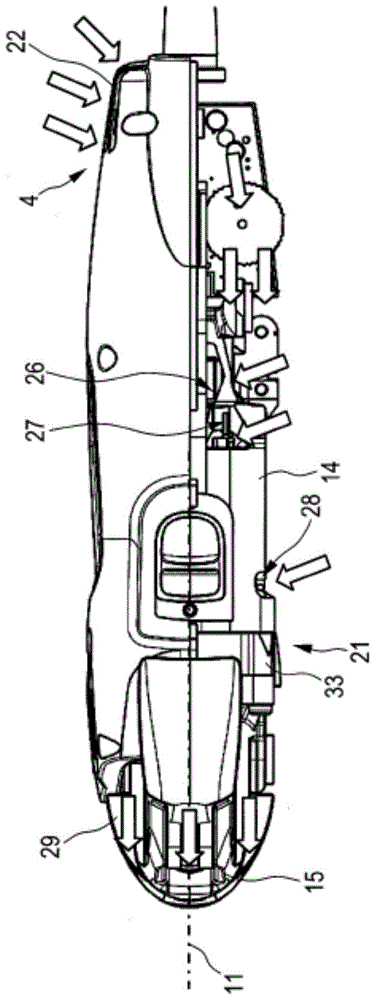

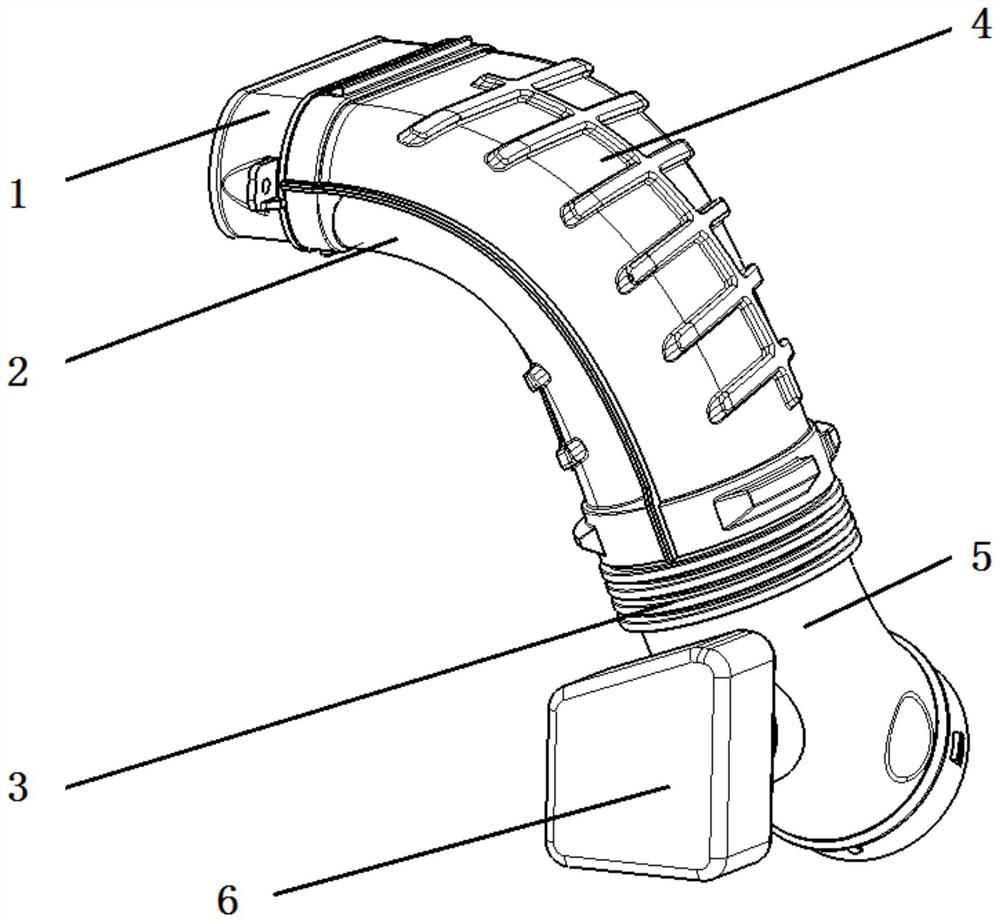

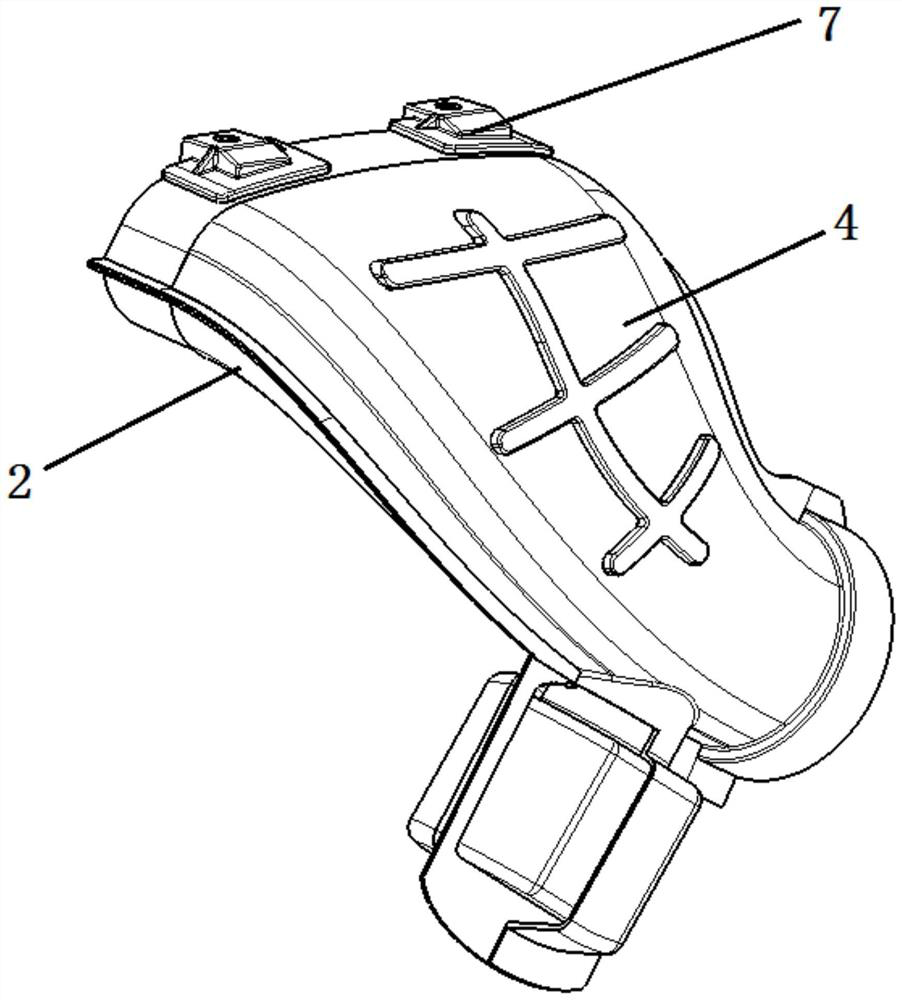

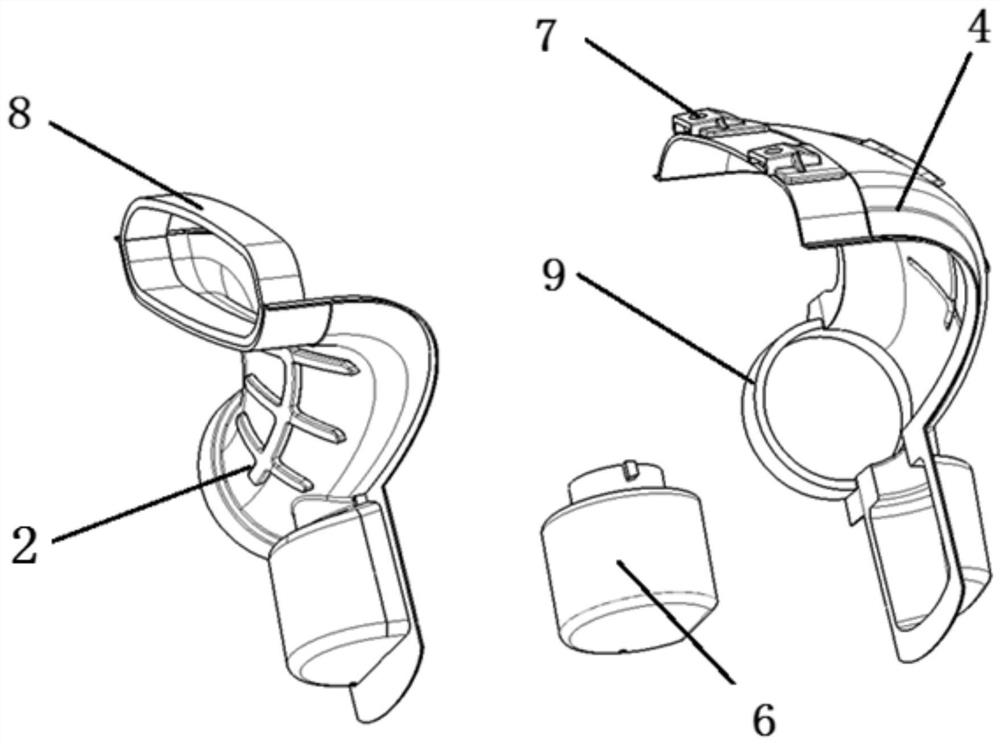

Handheld work apparatus

ActiveUS20190085797A1Reliable screeningHigh power transmissionGas treatmentDispersed particle filtrationCold air intakeInternal combustion engine

A handheld work apparatus has a combustion engine for driving a tool of the work apparatus and further has an air filter unit for filtering the intake air of the combustion engine. The work apparatus defines a vertical direction. The air filter unit includes an air filter and a filter housing enclosing the air filter. The air filter extends along a filter axis and has a filter element disposed peripherally around the filter axis, wherein the filter axis forms an angle of inclination (α) with the vertical direction. The filter element has an upper filter section in relation to the vertical direction. The filter housing has, remotely from the upper filter section, at least one air intake window and, in addition thereto, a further upper, permanently open cold air intake window in the region of the upper filter section.

Owner:ANDREAS STIHL AG & CO KG

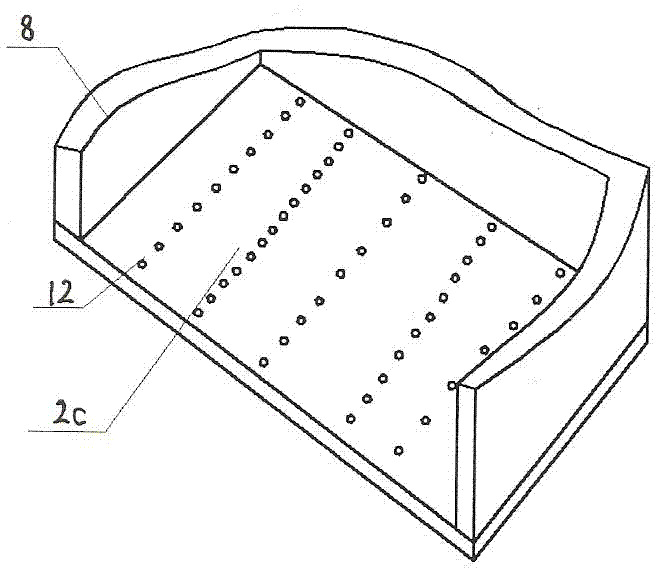

Cooling granulating tower for melts

InactiveCN105214558ALower the altitudeReduce heat exchange timeGranulation by liquid drop formationPore diameterEngineering

The invention discloses a cooling granulating tower for melts comprising a main tower, an atomizer fixed on the top of the main tower, and a cold air intake system. The air intake system comprises a blower, a condenser and a volute casing connected in series, and the volute casing is disposed on the bottom of the main tower. The atomizer is a centrifugal atomizer. By using the air intake volute casing, a counter-current operation relation is shown between the product and the cold air in the tower, the heat exchange time between the product and the cold air in the tower is greatly reduced, so that the height of the cooling granulating tower is reduced. By using the centrifugal atomizer, the cooling granulating tower has large throughput and is easy to adjust, the product has good particle roundness, and the particle size of the product can be changed by adjusting a frequency converter, the pore diameter of a meshed disc and so on.

Axial flow fan with independent air cooling channel

PendingCN109899308AExtended service lifeImprove cooling effectPump componentsCooling/ventillation arrangementCooling channelCold air intake

The invention discloses an axial flow fan with an independent air cooling channel, and belongs to the field of fans; the axial flow fan is used for cooling a fan motor and provided with cold air intake windows on the outer wall of the cylinder body of the axial flow fan; the cold air intake windows penetrate through hollow wing type guide vanes to form an air flow channel; the air flow channel penetrates with a motor installation chamber; and an air exhaust window is arranged at the tail of the motor installation chamber. In view of the above technical scheme, the axial flow fan provided by the invention can radiate the motor of a large-sized motor direct-connected axial flow fan effectively without adding other power.

Owner:LINYI YUANTONG FAN CO LTD

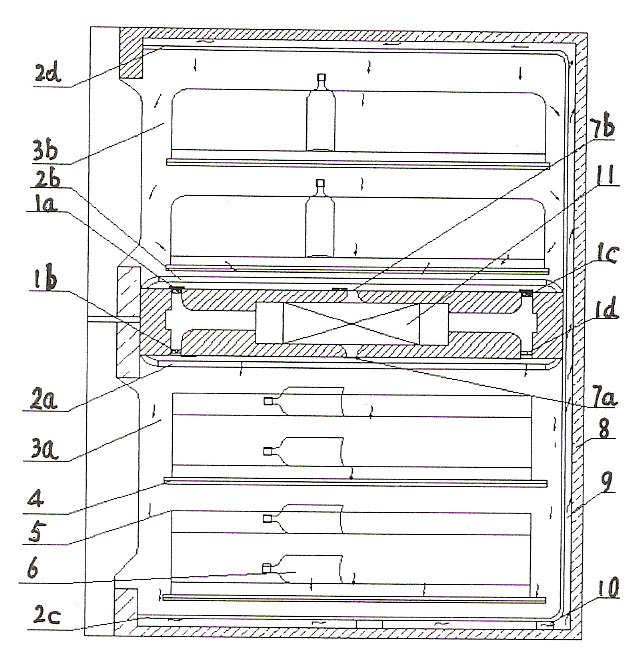

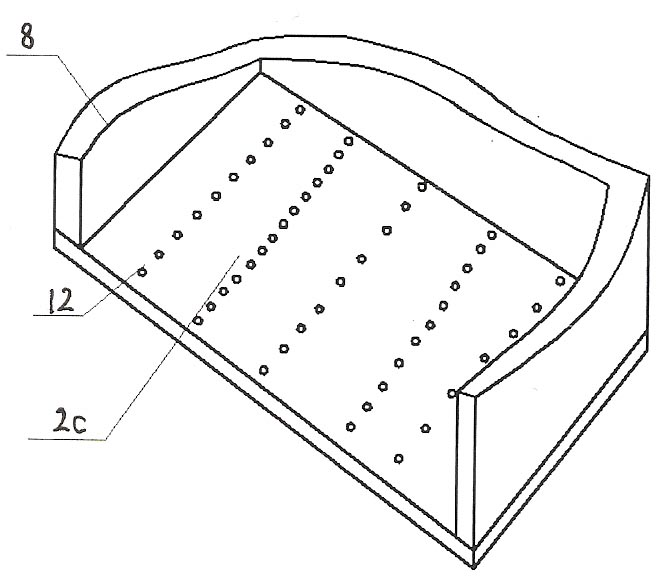

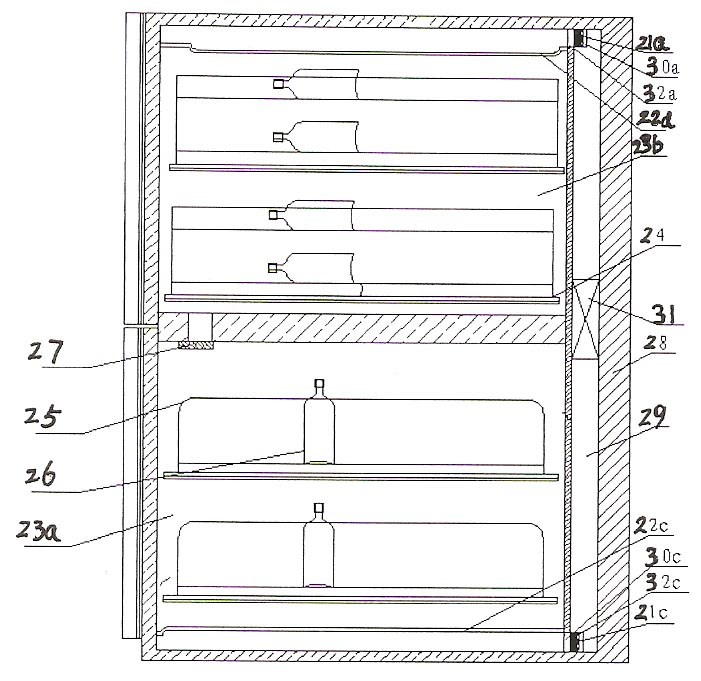

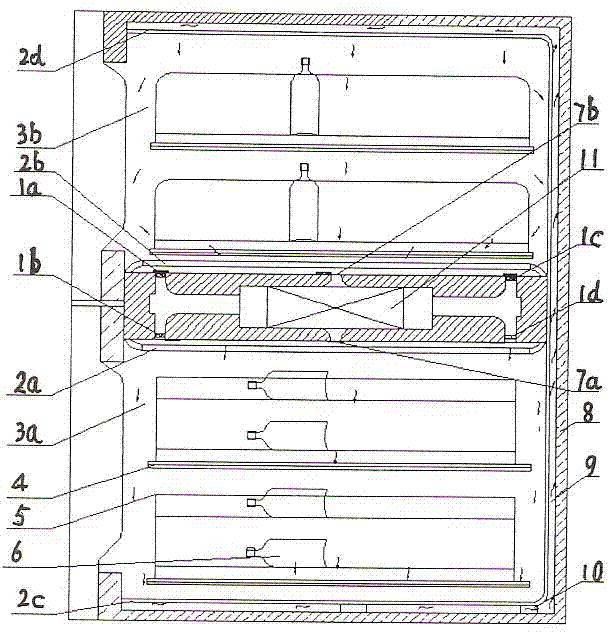

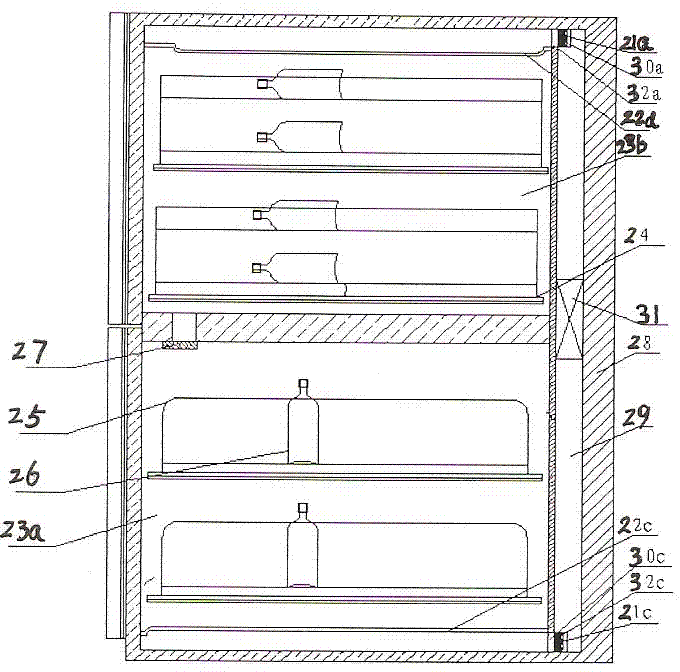

Refrigerator for manufacturing overcooled liquid

InactiveCN102519197ARealize rotation coolingReasonable structureLighting and heating apparatusDomestic refrigeratorsEngineeringRefrigeration

The invention discloses a refrigerator for manufacturing overcooled liquid. The refrigerator comprises two storage chambers for forming undercooling chambers in turn, wherein a blowing fan for circulating flow of cool air is arranged inside each storage chamber or at a cool air inlet; in addition, an electromagnetic switch for controlling two storage chambers to respectively become overcooling chambers and a controller for controlling the volume of the cool air entering in each storage chamber and keeping the temperature of each storage chamber to be between the overcooling temperatures are arranged. The refrigerator for manufacturing the overcooled liquid is reasonable in structure, and is capable of realizing alternating refrigeration of two storage chambers, wherein the other storage chamber is in a pre-cooling state when one storage chamber is in a refrigerating state, and meets the conditions for manufacturing the overcooled liquid. In short, the other storage chamber is in a pre-cooling state when one storage chamber is in an overcooling chamber state.

Owner:NANTONG UNIVERSITY

Cold head for medical laser equipment

InactiveCN108498168AAdjustable temperatureSurgical instrument detailsLight therapyMedical equipmentEngineering

The invention relates to a cold finger for a medical laser device, which comprises a working part, a main body part, a cold air supply device, a semiconductor refrigeration piece and a cold air sleeve. An annular air cavity is arranged in the main body part. The main body part is far away from the working part end face and is provided with a main body air inlet and outlet which are communicated with the air cavity. The cold air supply device is provided with a temperature adjusting button. One end of the main air inlet pipe is connected with the air inlet of the main body, and the other end ofthe main air inlet pipe is connected with the cold air supply device. One end of the main air outlet pipe is connected with the air outlet of the main body and the other end is communicated with theoutside. The semi-conductor refrigeration piece is arranged on the outer surface of the main body part. The cold air sleeve is sleeved outside the semiconductor refrigeration piece, and a cold air inlet and outlet are arranged on the cold air sleeve. One end of the air inlet pipe branch is connected with the cold air inlet, and the other end of the air inlet pipe branch is connected with the mainair inlet pipe. One end of the air outlet pipe branch is connected with the air outlet of the cold air, and the other end of the air outlet pipe branch is connected with the main air outlet pipe. Thetemperature of the cold head for the medical laser device of the present invention is adjustable.

Owner:SUZHOU DANENG LASER TECH CO LTD

System and method for sintering flue gas SCR denitration catalyst preheating

ActiveCN112275137BAvoid cloggingExtended service lifeDispersed particle separationThermodynamicsPtru catalyst

The invention discloses a system and a method for preheating a SCR denitration catalyst for sintering flue gas. The system includes: an original sintering flue gas SCR denitration line, including a flue gas introduction unit, a supplementary combustion unit, an SCR unit connected in sequence through a flue A denitration unit and a flue gas discharge unit, and a flue gas heat exchange unit arranged between the inlet flue and the outlet flue of the SCR denitration unit; the cold air intake unit is arranged on the flue gas inlet side of the flue gas heat exchange unit And it is used to introduce cold air; the bypass unit can control the sintering flue gas to be directly sent from the flue gas introduction unit to the flue gas discharge unit. The method utilizes the above-mentioned system for preheating the SCR denitration catalyst for sintering flue gas to preheat the SCR denitration catalyst. The invention can avoid the influence of excessive dust and excessive moisture in the initial stage of the sintering machine to the greatest extent, avoid the blockage of the catalyst caused by high dust and high moisture, and prolong the service life of the catalyst.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

Refrigerator for manufacturing overcooled liquid

InactiveCN102519197BRealize rotation coolingReasonable structureLighting and heating apparatusDomestic refrigeratorsRefrigerationPre cooling

The invention discloses a refrigerator for manufacturing overcooled liquid. The refrigerator comprises two storage chambers for forming undercooling chambers in turn, wherein a blowing fan for circulating flow of cool air is arranged inside each storage chamber or at a cool air inlet; in addition, an electromagnetic switch for controlling two storage chambers to respectively become overcooling chambers and a controller for controlling the volume of the cool air entering in each storage chamber and keeping the temperature of each storage chamber to be between the overcooling temperatures are arranged. The refrigerator for manufacturing the overcooled liquid is reasonable in structure, and is capable of realizing alternating refrigeration of two storage chambers, wherein the other storage chamber is in a pre-cooling state when one storage chamber is in a refrigerating state, and meets the conditions for manufacturing the overcooled liquid. In short, the other storage chamber is in a pre-cooling state when one storage chamber is in an overcooling chamber state.

Owner:NANTONG UNIVERSITY

Aluminum profile heat treatment device

The invention relates to an aluminum profile heat treatment device. The aluminum profile heat treatment device comprises a placing frame for placement of an aluminum profile; the placing frame is a placing frame with a U-shaped structure; a cavity is formed in the placing frame; one side edge of the external of the placing frame is connected with a cold air intake pipe; a plurality of air outlets for throttling and expanding air in the cold air intake pipe to cool the air are uniformly formed in the surface and two sides of the placing frame; support pads for reducing the direct contact area with the aluminum profile are arranged at the ends, which are away from the placing frame, of the air outlets; and a fan for upwards blowing to increase air convection is arranged at the bottom of the placing frame. The aluminum profile heat treatment device has the beneficial effects that the aluminum profile can be preferably cooled through the air outlets in the bottom end; and the fan arranged at the bottom end of the placing frame can upwards blow from the bottom, so that the air convection can be accelerated, the aluminum profile is preferably cooled, and meanwhile, cold air in the cold air intake pipe can be upwards blown to the surface of the aluminum profile for exchange of the cold air and hot air to accelerate cooling of the aluminum profile.

Owner:马鞍山市华冶铝业有限责任公司

Hand tools with ventilation

The invention relates to a hand-held power tool (10) having a housing (12) extending substantially along a longitudinal axis; an electric drive unit (14) housed in the housing; Tool Equipment (15). The housing of the power tool has a defined inner contour (20), and the electric drive unit and the tool device have a defined outer contour (19). The outer contour and the inner contour of the housing have a predetermined minimum distance from each other. At least one cooling air intake hole (22) is provided in the end region of the housing. The ventilation device (21) is driven by the electric drive unit, the ventilation device draws in cool air through at least one air intake opening, the cool air flows through the machine tool along the axis of rotation (11) approximately parallel to the electric drive unit, and is distributed in the machine tool Outflow from the shell on the outer contour.

Owner:C.& E.泛音有限公司

A comprehensive utilization system of sintering waste heat

ActiveCN105066718BTake advantage ofImprove sealingIncreasing energy efficiencyWaste heat treatmentCooling towerAir blower

A comprehensive utilization system for sintering waste heat comprises a cooling tower, a fine powder separator, a waste heat boiler, an induced draft fan, an air intake peripheral pipe and a cold air negative-pressure pipe. The air intake peripheral pipe is arranged on the periphery of the middle-lower part of the cooling tower, the air intake peripheral pipe is communicated with the interior of the cooling tower through air inlets arranged along the circumference at intervals, and the air intake peripheral pipe is connected with the induced draft fan through an air intake pressurization pipe. The cold air negative-pressure pipe is arranged above a discharging port of the cooling tower, the cold air negative-pressure pipe is connected with a cooling air blower through a cold air intake pipe, the cooling air blower is simultaneously connected with a cold air pressurization pipe located below the air intake peripheral pipe, and the cold air negative-pressure pipe and the cold air pressurization pipe are both communicated with the interior of the cooling tower. A material distribution area and a cooling area located below the material distribution area are formed in the cooling tower, a feeding port is formed in the top of the cooling tower, and the discharging port is formed in the bottom of the cooling tower. A material receiving seal valve is arranged in the cooling tower and located below the feeding port. A material distribution seal valve is arranged in the cooling tower and located above the opening of the material distribution area. According to the comprehensive utilization system for the sintering waste heat, secondary hot air generated in the cooling process can be recycled, energy consumption is reduced, and environmental pollution is completely eradicated.

Owner:宝鸡市晋旺达机械设备有限公司

Quick rubber producing and processing equipment

The invention discloses a rubber rapid production and processing equipment, which comprises a feeding barrel, a feeding funnel is arranged on the upper part of the feeding barrel, a rubber crushing device is arranged inside, and a discharge port is opened in the middle of the bottom end. There is a discharge funnel on the mouth, and a filter is connected to the bottom of the feeding barrel. There is a stirring device inside the filter, and an air storage port is opened in the middle of the left side of the filter. The bottom of the front surface of the lower part of the filter is opened There is a rubber discharge port, and a cold air inlet is opened on the right side of the filter, and a hot gas storage tank is connected to the gas storage port, and the left side of the hot gas storage tank is connected to the cold and heat exchanger , the cold and heat exchanger is connected with the cold air storage chamber, the top of the cold air storage chamber is provided with an exchange air outlet, and the middle position of the front surface of the feeding barrel is provided with a controller. The invention has the advantages of simple structure and strong practicability.

Owner:徐杨杰

Air intake

InactiveCN102889610APrecise and sensitive controlEasy maintenanceAir supply regulationAir/fuel supply for combustionControl theoryFrequency modulation

The invention discloses an air intake, wherein a frequency modulation motor is arranged on the air intake. The air intake has the advantages of simple structure, convenience in operation, flexibility and accuracy in control and easiness in maintenance.

Owner:JIANGSU OUBIAO

A pet cold air intake with resonant cavity

The invention discloses a PET cold air inlet with a resonant cavity. The main pipeline of the air inlet is all made of PET material, including a PET upper part and a PET lower part, and a cavity shell wrapping the resonant cavity is arranged between the PET upper part and the PET lower part. , PET upper part and PET lower part are welded and fixed, and the resonant cavity is covered in the cavity shell, and the resonant cavity and the cavity shell are closely matched, so that the resonant cavity cannot move in the pipeline. The front end of the air inlet pipeline is preset with a fixed structure and the fixing nut is pre-embedded on the fixed structure, and the air inlet pipeline is fixed on the front frame by bolts, and the rear end of the air inlet pipeline is fastened to the air filter.

Owner:CHINA FIRST AUTOMOBILE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com