Dry spinning organic solvent recovery and air circulating use method

An organic solvent and dry spinning technology, which is applied in the field of waste gas treatment equipment containing organic solvents in dry spinning, can solve the problems of high construction investment cost, heavy pollution, complex process, etc., and achieve the effect of reducing the cost of solvent recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

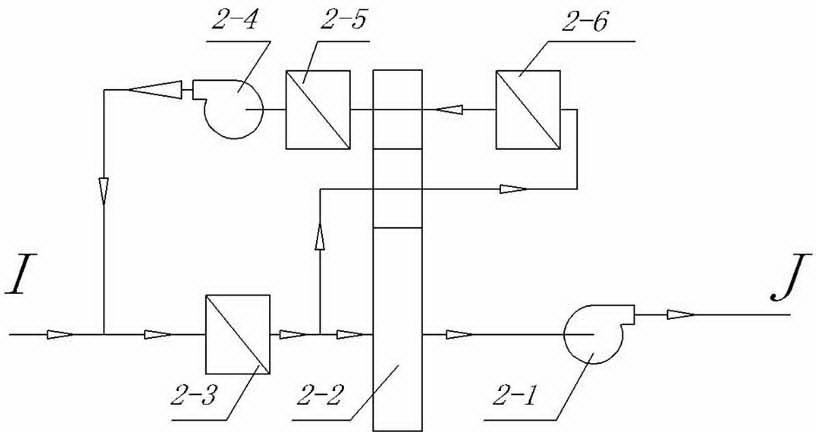

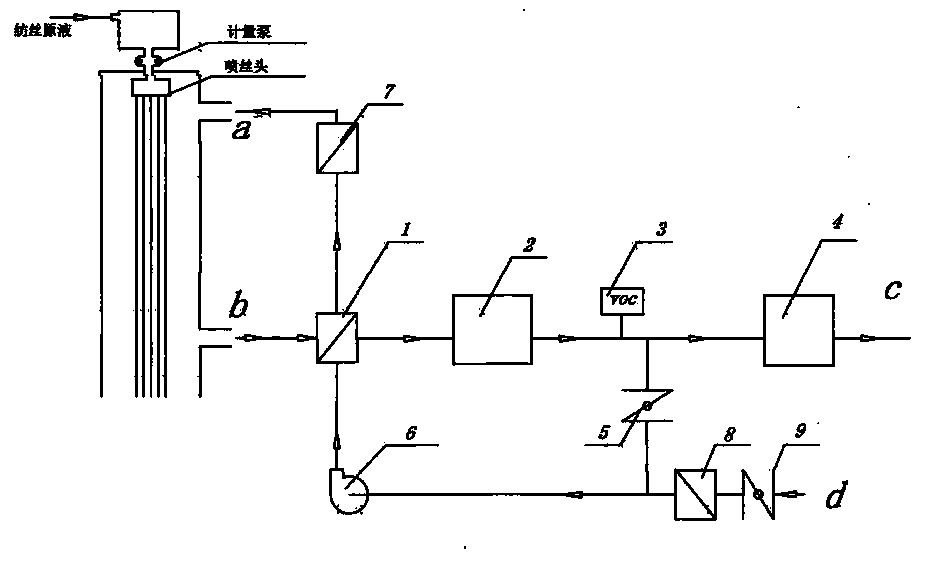

[0023] Such as figure 1 As shown, the dry spinning organic solvent recovery and air circulation utilization device of the present invention includes a spinning shaft that is respectively provided with a circulating air inlet a from top to bottom, an organic solvent-containing waste gas exhaust port b; an organic solvent-containing waste gas exhaust port Air port b is sequentially connected to heat exchanger 1 hot air inlet and outlet, circulating air high boiling point organic solvent recovery unit 2, electric damper 5, air supply fan 6, heat exchanger 1 cold air inlet and outlet, air heater 7, and circulating air intake Mouth a. The air heater 7 function is to heat the air that will be sent to the spinning shaft to the set temperature, and the air blower 6 function is to send the clean air to the spinning shaft.

[0024] One branch is connected to the gas outlet of circulating air high boiling point organic solvent recovery component 2, the external exhaust high boiling poi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com