Refrigerator for manufacturing overcooled liquid

A refrigerator and supercooling technology, which is applied to household refrigerators, household refrigeration devices, cooling fluid circulation devices, etc., can solve the problems of unfavorable obtaining of supercooled beverages in large quantities, unfavorable production of supercooled beverages, etc., and achieve the effect of reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

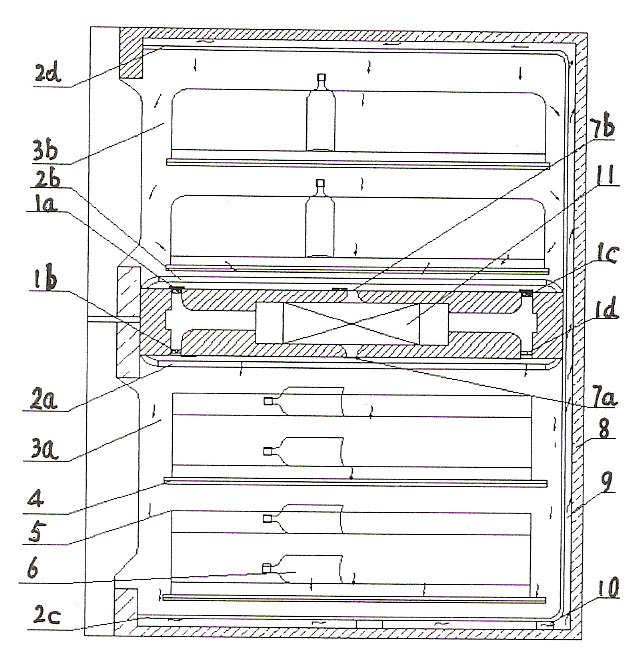

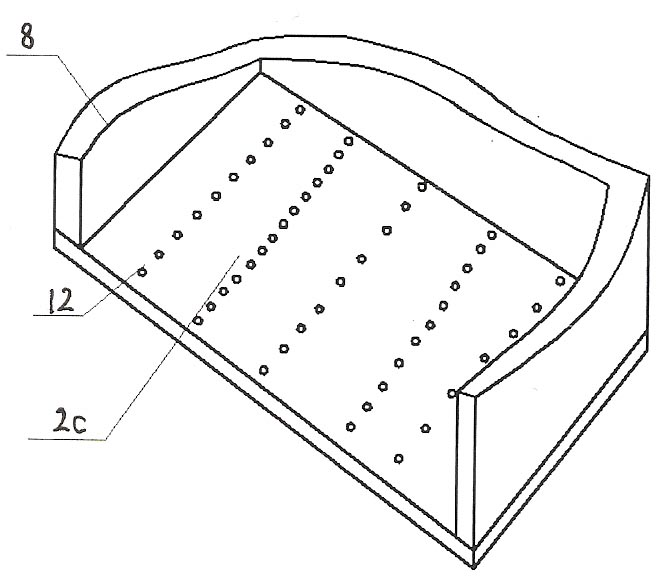

[0030] Such as figure 1 As shown, the refrigerator according to the first embodiment of the present invention includes upper air intake blowing fans 1a, 1c and lower air intake blowing fans 1b, 1d, lower air distribution plates 2a, 2c and upper air distribution plates 2b, 2d, storage room 3 ( Including 3a, 3b two rooms), 4 is the storage room shelf frame, 5 is the iron frame, 6 is the beverage bottle placed in the storage room, 7 is the suction port (including 7a, 7b), 8 is the refrigerator box, 9 is a cold air return channel, 10 is a cold air return channel switch, and 11 is an evaporator. The evaporator is placed between the two storage compartments.

[0031] As shown in the figure, when the lower box is cooling, the blowing fans 1b and 1d and the suction port 7b are turned on at the same time, and the blowing fans 1b and 1d pump the air from the upper box, and the air flow enters the lower box through the suction port 7b through the evaporator.

[0032] The lower air dis...

Embodiment 2

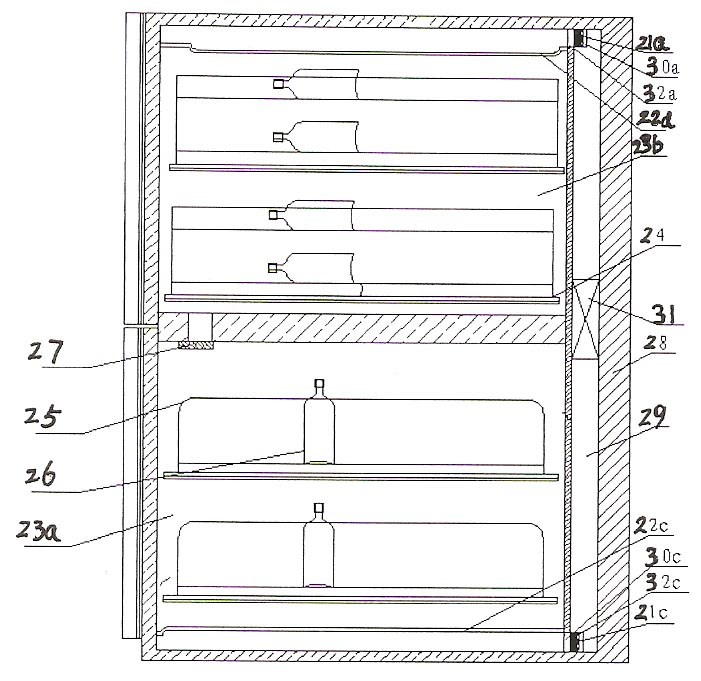

[0036] Such as image 3 As shown, among the figure, there are upper air intake blower fans 21a, 21c and lower air intake blower fans 21b, 21d, lower air distribution plate 22c and upper air distribution plate 22d, storage room 23 (comprising two chambers of 23a and 23b), and 24 is storage 25 is an iron frame, 26 is a beverage bottle placed in the storage room, 27 is an air inlet and outlet, 28 is a refrigerator casing, 9 is a cold air return passage, and 31 is an evaporator.

[0037] The evaporator 31 is placed behind the refrigerator, and the blower fans are placed on the top and bottom of the refrigerator, and the cold air is directly blown into the air distribution plates 2d and 2c. 30 among the figure is cold air inlet and outlet (comprising 30a, 30b, 30c, 30d). 32 is a sheet baffle (including 32a, 32c).

[0038] When the upper storage room is a supercooling room, the blowing fans 21a and 21b are turned on, and the 21c and 21d are closed; the sheet baffle 32a is closed, ...

Embodiment 3

[0041] Such as Figure 5 As shown, the evaporator 51 and the evaporator 52 are connected in parallel through the three-way valve 53, so it is impossible for refrigerant to flow through at the same time. Such as Figure 6 As shown, the two evaporators are connected in parallel through a three-way valve, the heat exchange tubes of each evaporator are wound around one storage room, and the copper tubes connecting the outlet of each evaporator to the compressor are wound around the other storage room. The two evaporators are respectively wound around different storage rooms for direct cooling. Through the switching of the three-way valve, the two storage rooms are refrigerated in turn. This type of refrigerator is a direct-cooling refrigerator. Through the switching of the three-way valve, the upper and lower storage chambers are rapidly refrigerated in turn, thereby shortening the time for the storage chamber to reach the required supercooling temperature. There are also capill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com