Motor assembly for steam vacuum cleaner

a technology of motor assembly and vacuum cleaner, which is applied in the direction of carpet cleaners, liquid fuel engines, bowling games, etc., can solve the problems of less user-friendly type of vacuum, large contact area with the floor, and difficulty in maneuvering the vacuum in order to clean under and/or around certain objects such as beds or couches, etc., to maximize the cooling efficiency of wet type motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

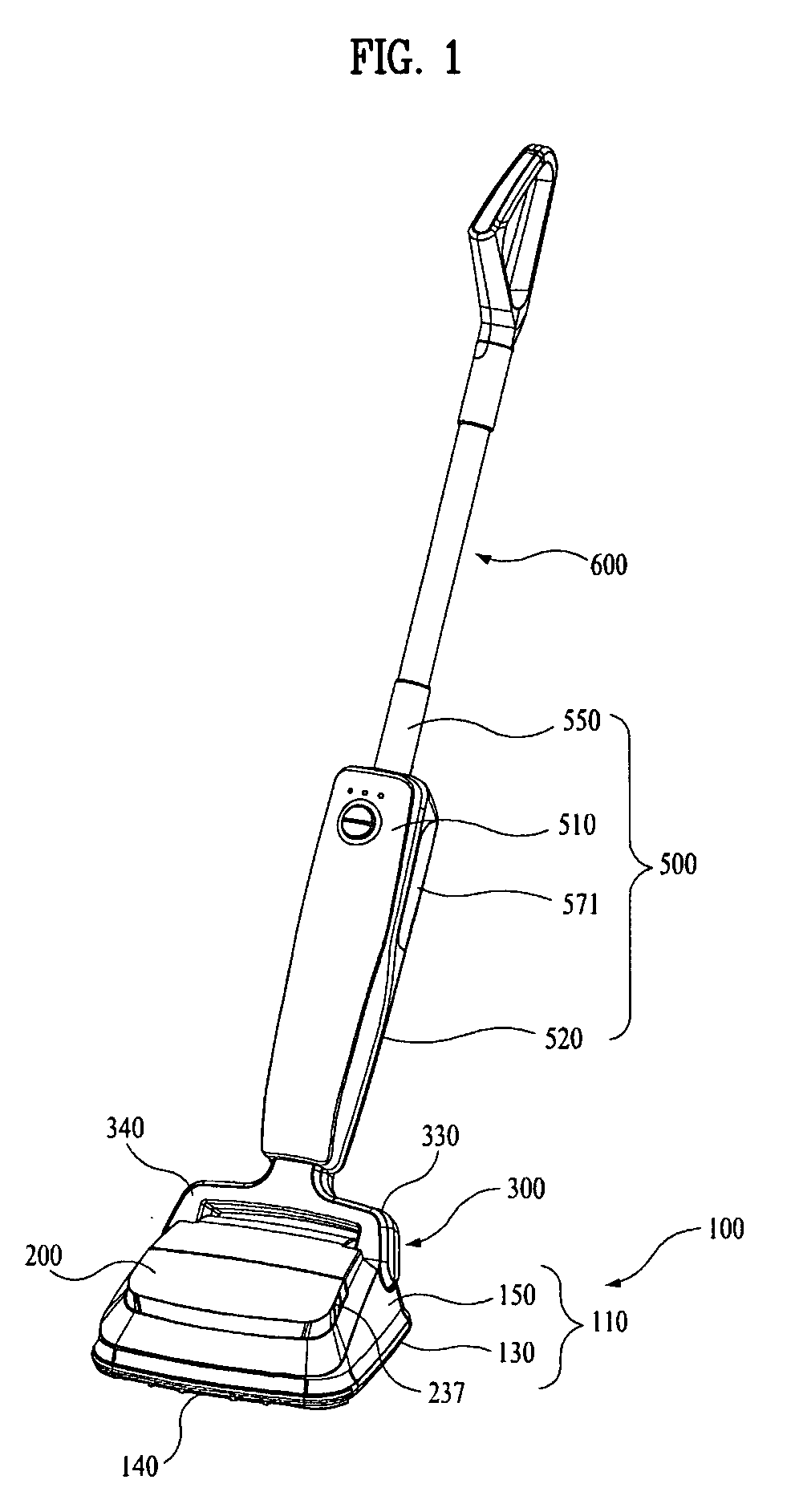

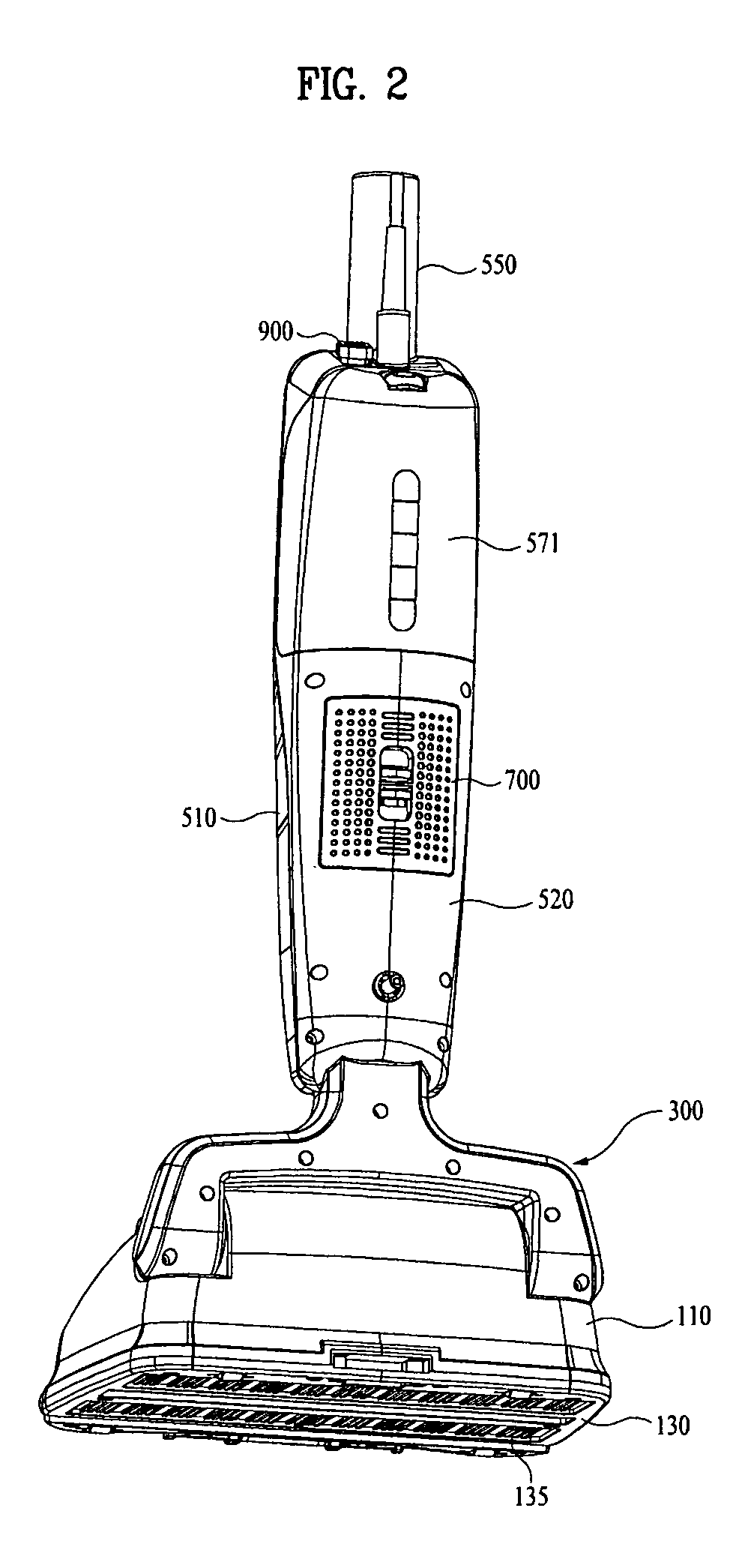

[0029]Hereinafter, preferred embodiments of the present invention will be set forth in detail with reference to the accompanying drawings so that those skilled in the art can easily carry out the invention. Referring to FIG. 1, there is shown a front perspective view of a steam vacuum cleaner according to a preferred embodiment of the present invention. FIG. 2 is a rear perspective view of the steam vacuum cleaner of FIG. 1. Referring to these figures (FIGS. 1 and 2), the steam vacuum cleaner is largely constituted by a base assembly 100, a main assembly 500, and a neck assembly 300 which is connected between the base assembly 100 and the main assembly 500.

[0030]The main assembly 500 has a pipe 550 extending therefrom and to which a length-adjustable mop handle 600 is connected in a detachable manner. The mop handle 600 is preferably comprised of a telescopic stick and a handle.

[0031]Referring still to FIG. 1 and FIG. 2, the base assembly 100 is comprised of a main body 110 which pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com