Design method for heat dissipation system of wind turbine generator set under severe environment and heat dissipation system

A technology for wind turbines and cooling systems, applied in wind turbine components, wind motor combinations, wind engines, etc., can solve problems such as reducing the amount of cold air entering the radiator, failing to achieve the cooling effect, and affecting the normal operation of the generator set. Achieve the effect of ensuring heat dissipation and avoiding blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

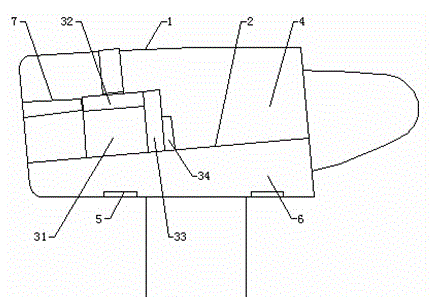

Image

Examples

Embodiment 1

[0024] A design method for the heat dissipation system of a wind power generating set in a harsh environment, comprising the following steps:

[0025] (1) Construct the outer air duct of the cooling system: the outer air duct of the cooling system is formed in the space between the wind turbine cabin shell and the radiator of each component of the wind turbine. The components of the wind turbine include a gearbox, a generator, a frequency conversion devices and control cabinets;

[0026] (2) Determine the air suction volume of the external air duct: the air suction volume Q is the sum of the cooling air volume required by each radiator to reach the rated cooling temperature, specifically: gear box radiator, generator radiator, inverter radiator and control cabinet cooling The cooling air volume required to reach the rated cooling temperature is Q1, Q2, Q3 and Q4 respectively, Q=Q1+Q2+Q3+Q4;

[0027] (3) Set the wind speed V of the air inlet of the outer air duct 0 =3.8 m / s; ...

Embodiment 2

[0033] A design method for the heat dissipation system of a wind power generating set in a harsh environment, comprising the following steps:

[0034] (1) Construct the outer air duct of the cooling system: the outer air duct of the cooling system is formed in the space between the wind turbine cabin shell and the radiator of each component of the wind turbine. The wind turbine components include generators, frequency converters and control cabinet;

[0035] (2) Determine the air suction volume of the external air duct: the air suction volume Q is the sum of the cooling air volume required by each radiator to reach the rated cooling temperature, specifically: the radiator of the generator, the radiator of the frequency converter and the radiator of the control cabinet reach the rated cooling temperature The required cooling air volumes are Q2, Q3 and Q4 respectively, Q=Q2+Q3+Q4;

[0036] (3) Set the wind speed V of the air inlet of the outer air duct 0 =3 m / s;

[0037] (4) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com