High-temperature synthetic gas graded chilling device and method

A synthesis gas, high temperature technology, which is applied in the joint combustion mitigation, the manufacture of combustible gas, the petroleum industry, etc. Simple, efficient reduction, uniform flow field effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

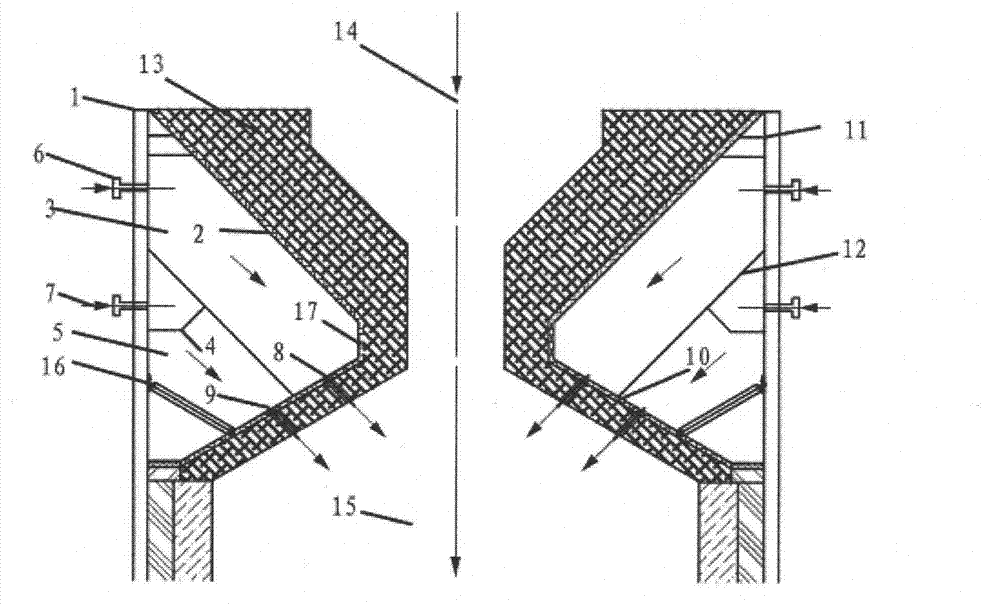

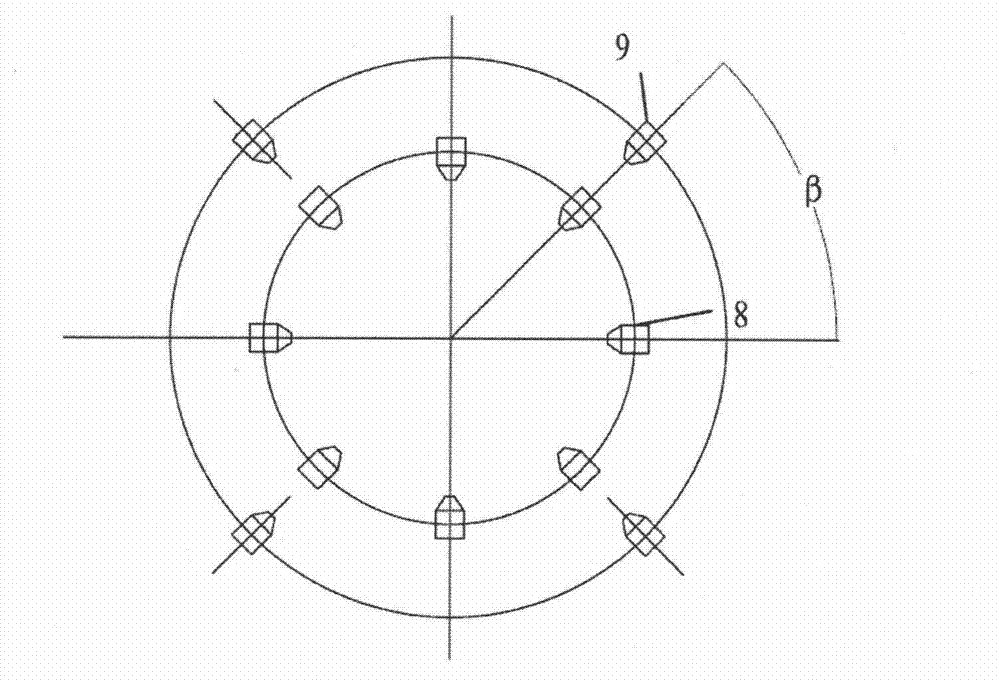

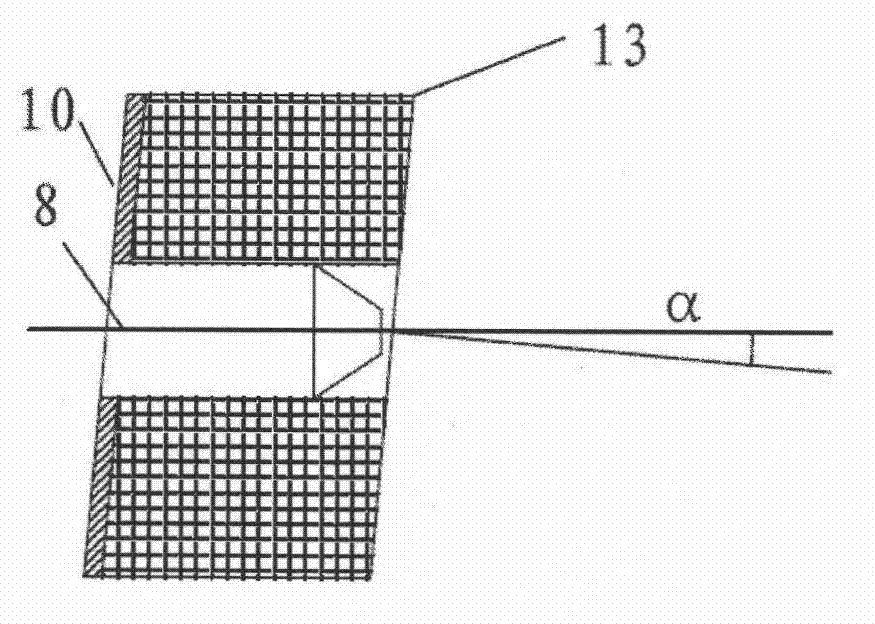

[0040]A dry powder gasifier with a daily processing capacity of 3,000 tons of coal has a gasification pressure of 4.0 MPa, the temperature at the inlet of the slagging chamber after gasification of the syngas is 1300°C, and the total gas flow out of the gasification chamber is 26,706 Nm3 / h. The total amount of chilled air is 31513Nm 3 / h, the chilling gas distribution ratio of the primary and secondary chilling chambers is 0.85:0.15, the primary chilling chamber is arranged with two layers of primary nozzles, each layer has 64 primary nozzles, and the axial and The included angle α=0° between the normal direction of the lower support plate, the included angle α=3° between the axial direction of the first-stage nozzle on the lower layer and the normal direction of the lower support plate, and a layer of second-stage nozzles arranged in the second-stage chilling chamber, and the second-stage The number of nozzles is 16, and the included angle between the axial direction of the s...

Embodiment 2

[0044] A dry powder gasifier with a daily processing capacity of 3,000 tons of coal, the gasification pressure is 4.0MPa, the inlet temperature of the slag collection chamber after gasification and synthesis gas is 1100°C, and the total amount of gasification synthesis gas is 27402Nm 3 / h. The total amount of chilled air is 28700Nm 3 / h, the distribution ratio of the primary and secondary cooling chambers is 0.8:0.2, the primary cooling chamber is arranged with two layers of primary nozzles, each layer has 48 primary nozzles, and the axial and lower support of the upper layer of primary nozzles The angle between the normal direction of the plate is α=0°, the angle between the axial direction of the first-stage nozzle on the lower layer and the normal direction of the lower support plate is α=3°, the second-stage quenching chamber is arranged with a layer of second-stage nozzles, and the number of second-stage nozzles is 16, and the included angle β between the axial direction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com