Patents

Literature

53results about How to "Improve flow field structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

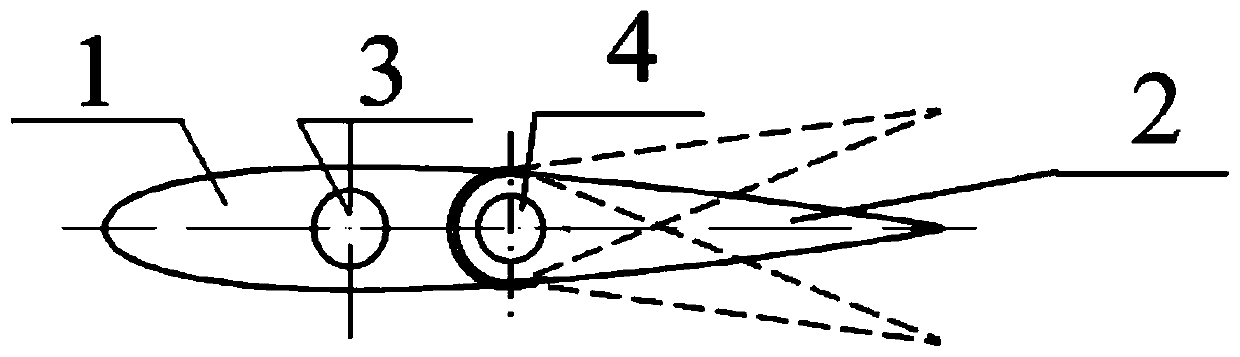

Intake and exhaust device of air breathing supersonic/hypersonic aerocraft

InactiveCN101549758APromote swellingImprove qualityPower plant exhaust arrangementsPower plant air intake arrangementsCombustion chamberEngineering

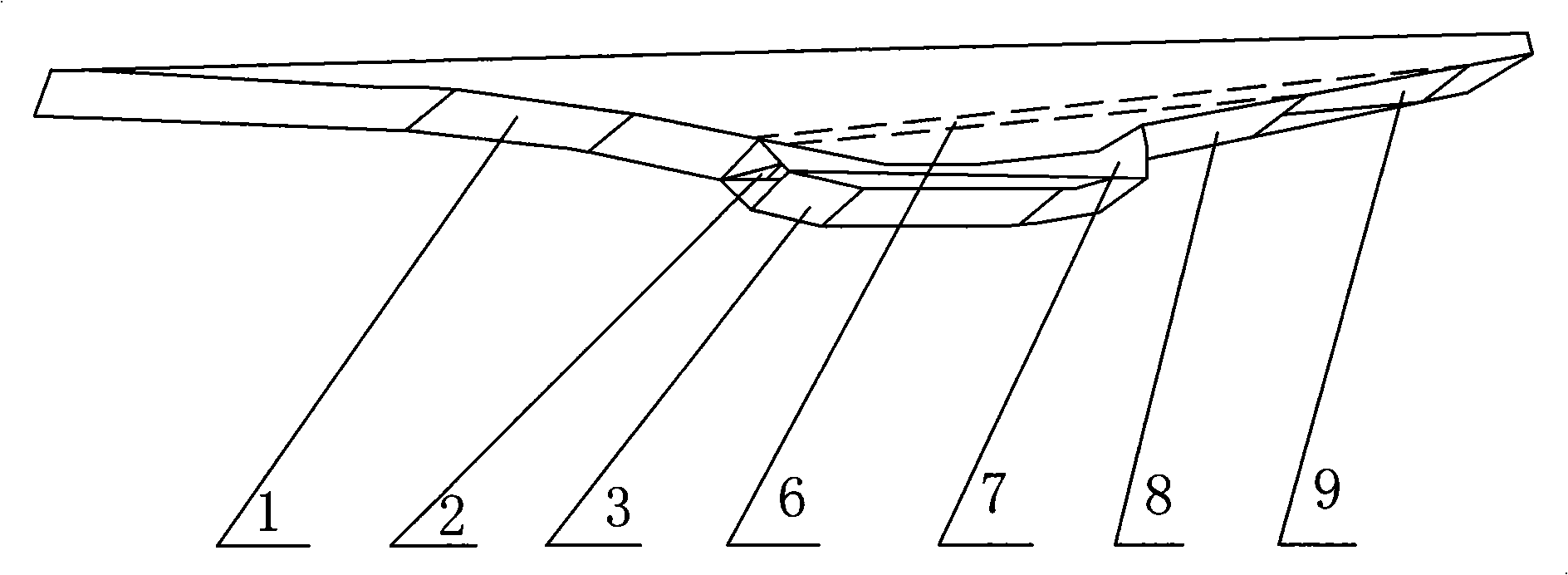

The invention relates to an intake and exhaust device of an air breathing supersonic / hypersonic aerocraft, comprising an inner flow passage arranged at the lower abdomen of the aerocraft; the inner flow passage comprises an intake passage, an isolating section, a combustion chamber and a spray pipe; the intake and exhaust device also comprises an aspirator connected between the intake passage and the spray pipe and a control device for controlling the opening or closing of the aspirator; the control device controls the suction device according to the working conditions of the aerocraft; when the air breathing supersonic aerocraft works on designed points, the control device sends an instruction to close the aspirator; when the air breathing supersonic aerocraft works on non-designed points, the control device sends instruction to open the aspirator; at the moment, an incoming flow is divided into a main flow and a secondary flow, wherein the main flow passes through the inner flow passage; and the secondary flow utilizes pressure difference between a front body and a rear body to form a suction airflow by the aspirator, thus leading the intake passage and the spray pipe to be coupled to a certain degree.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

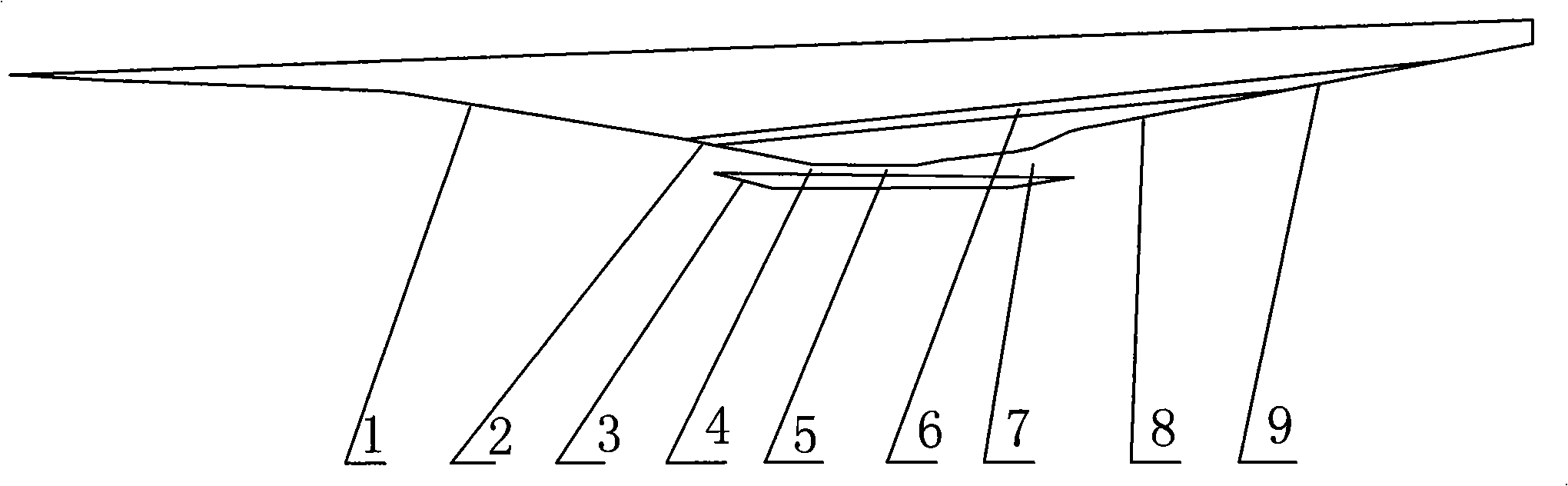

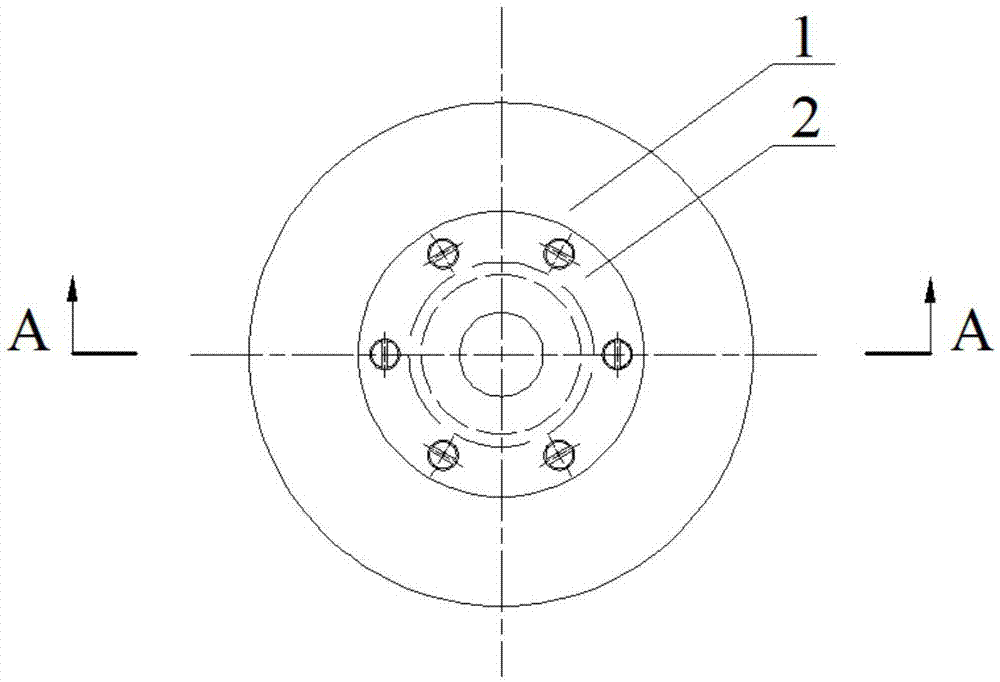

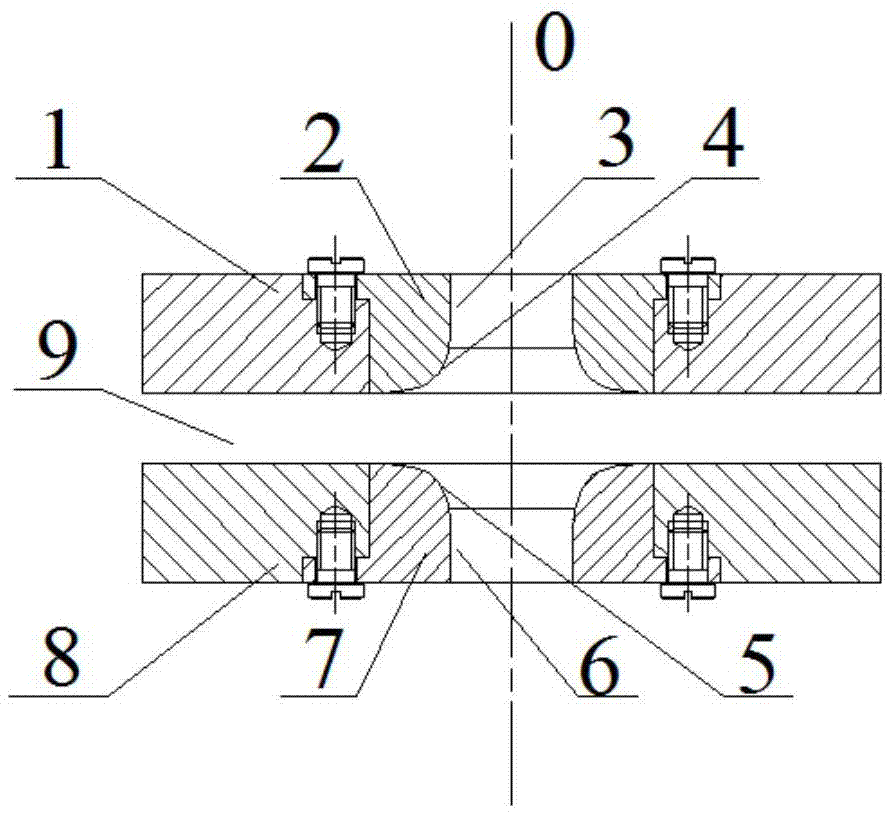

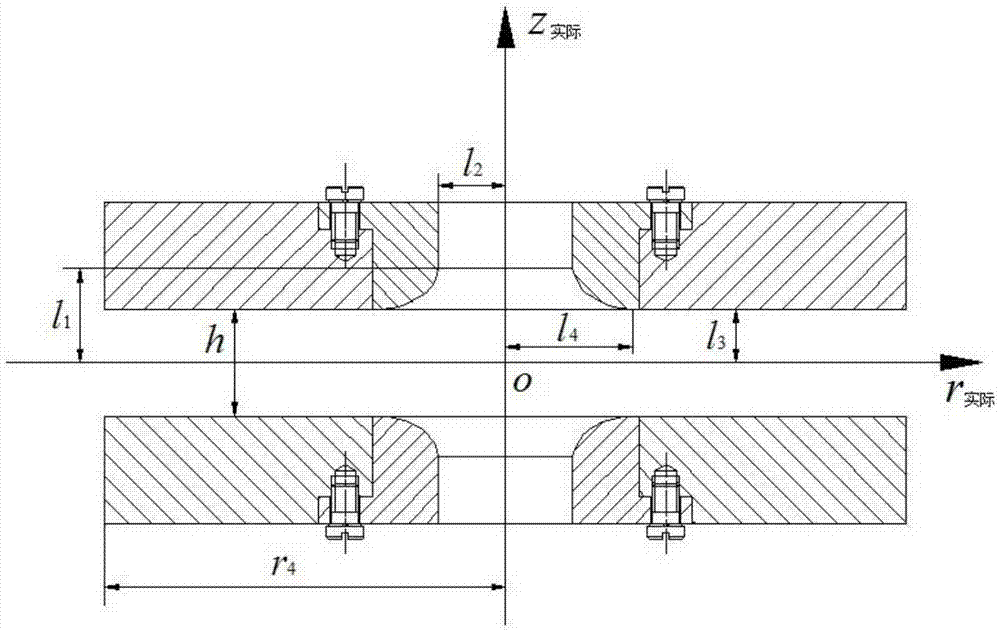

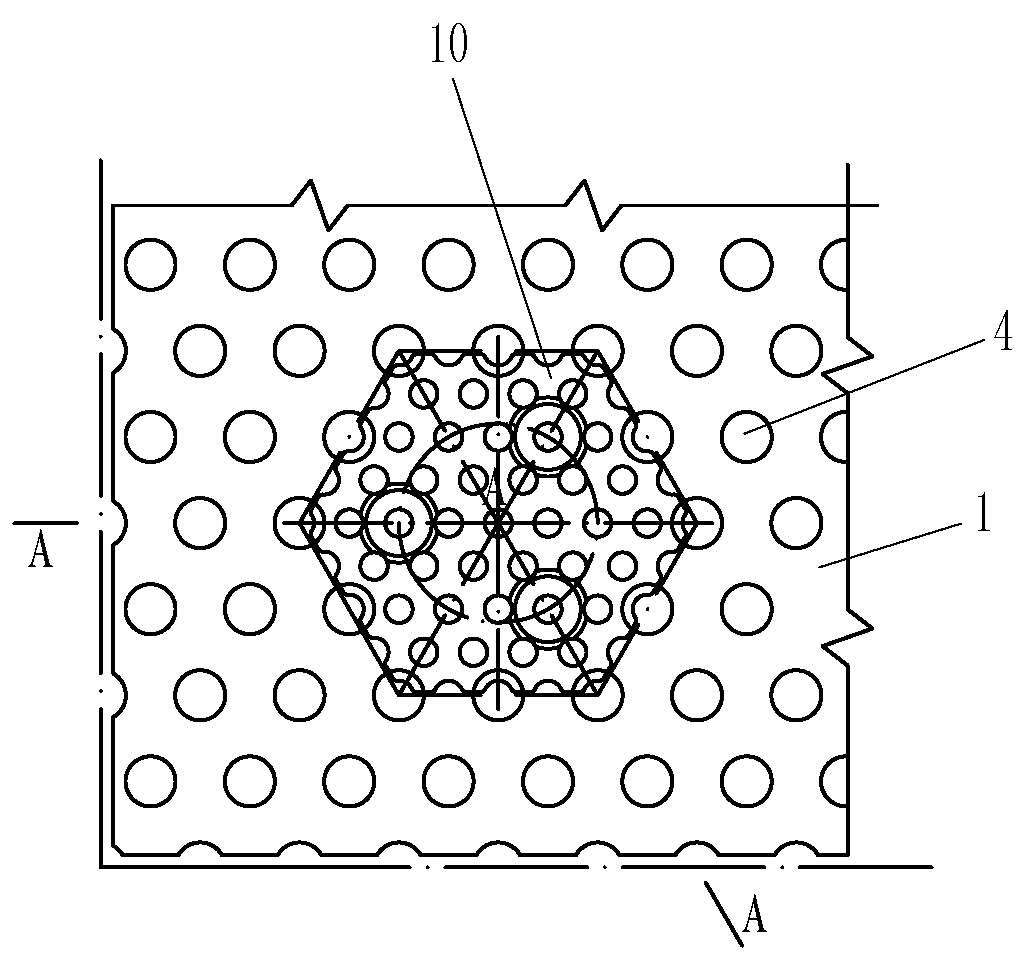

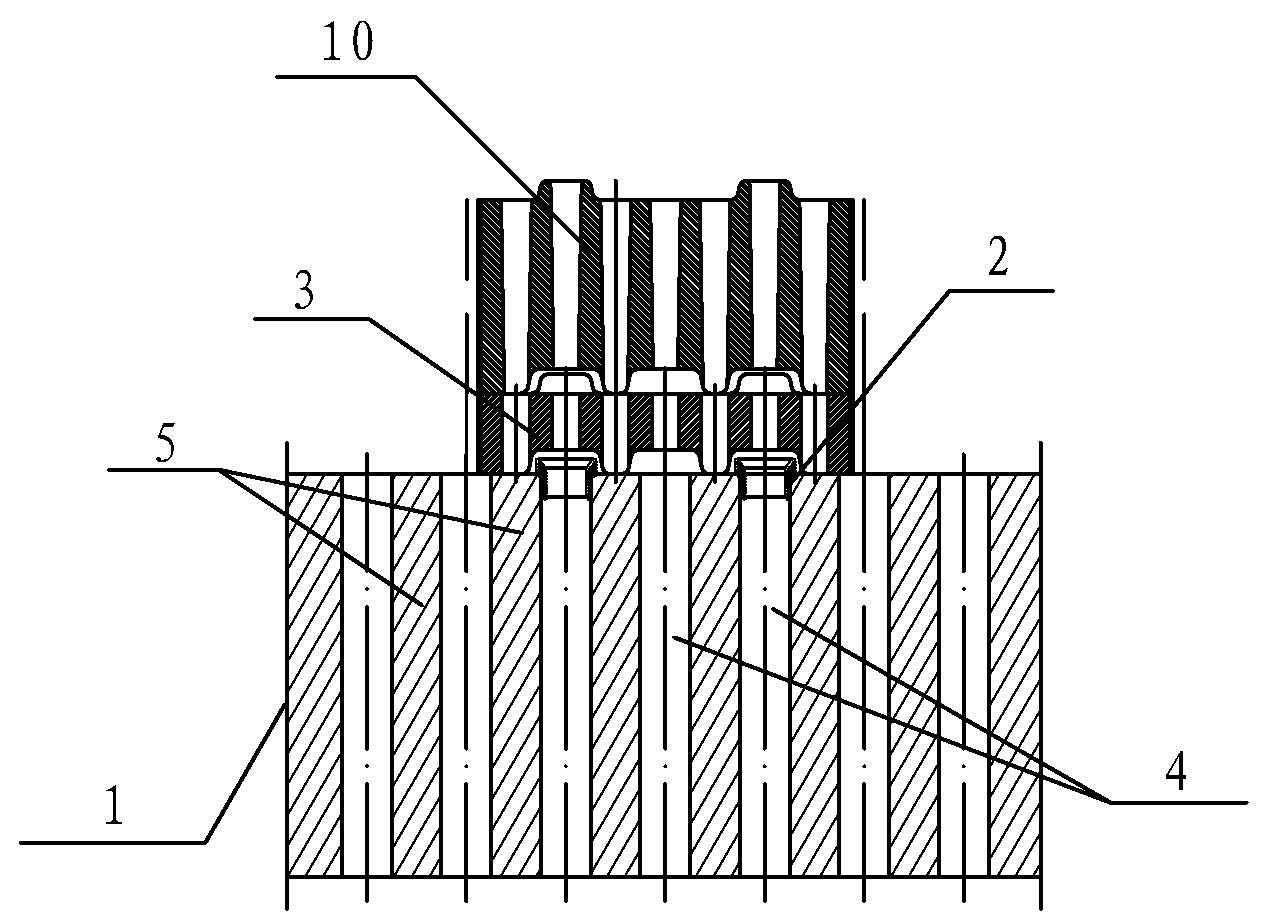

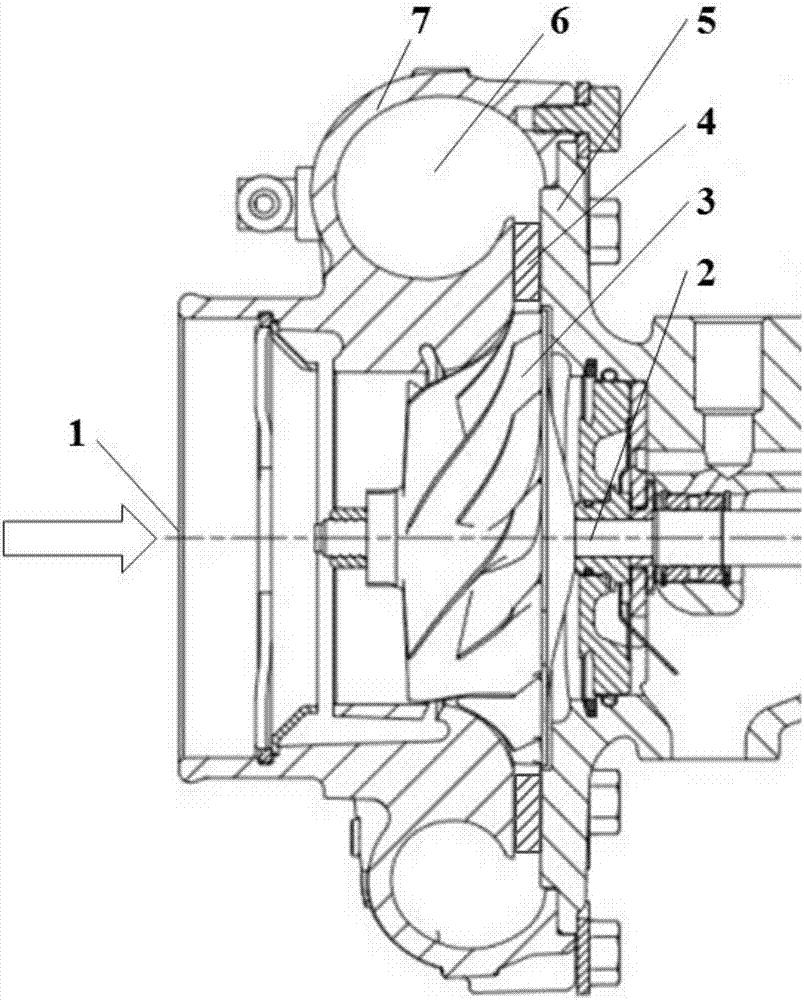

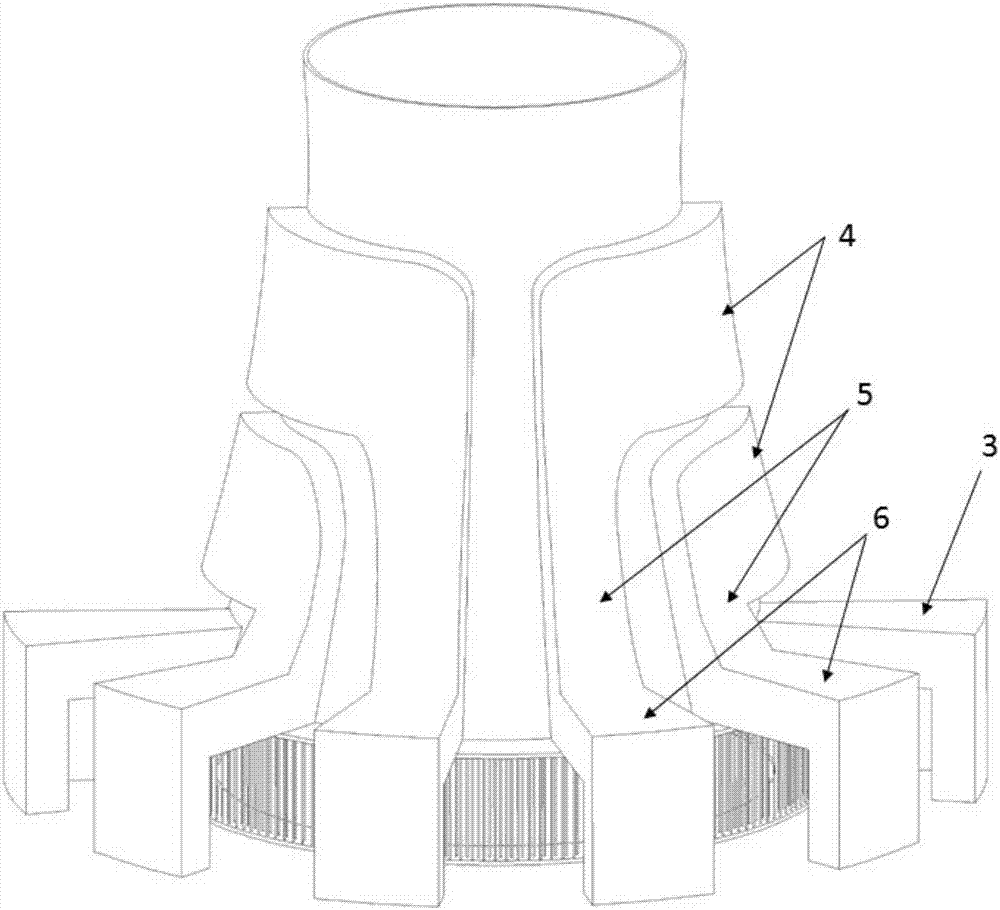

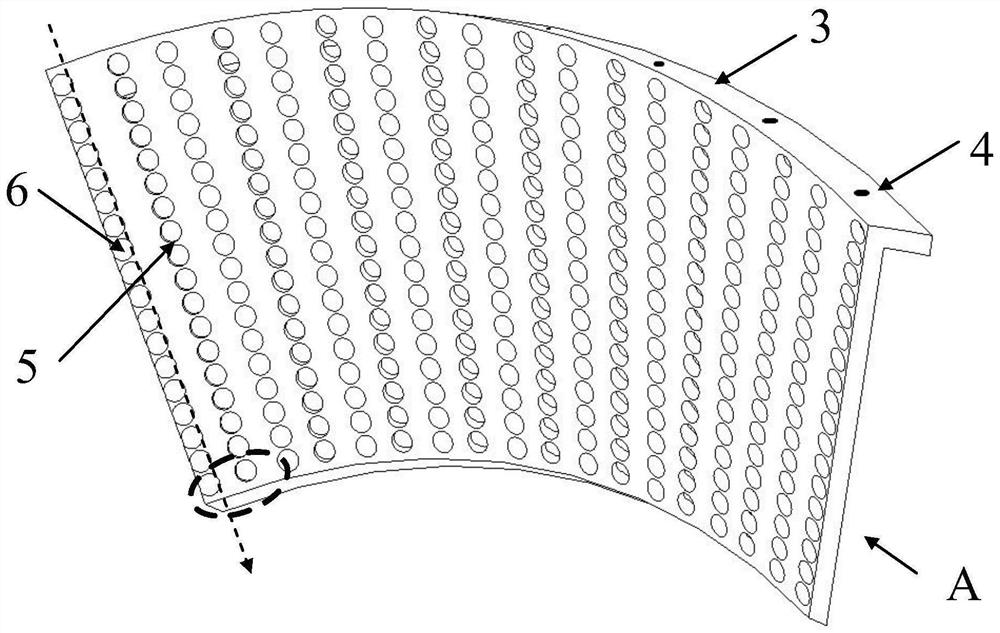

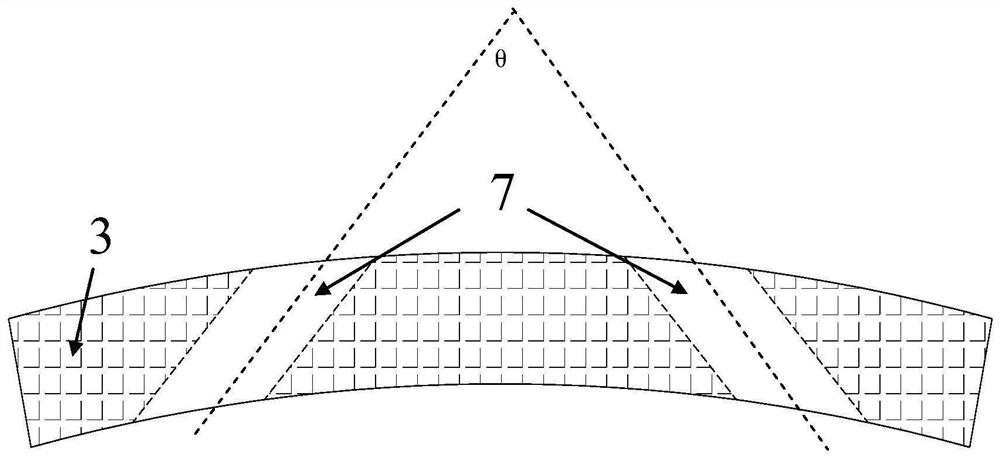

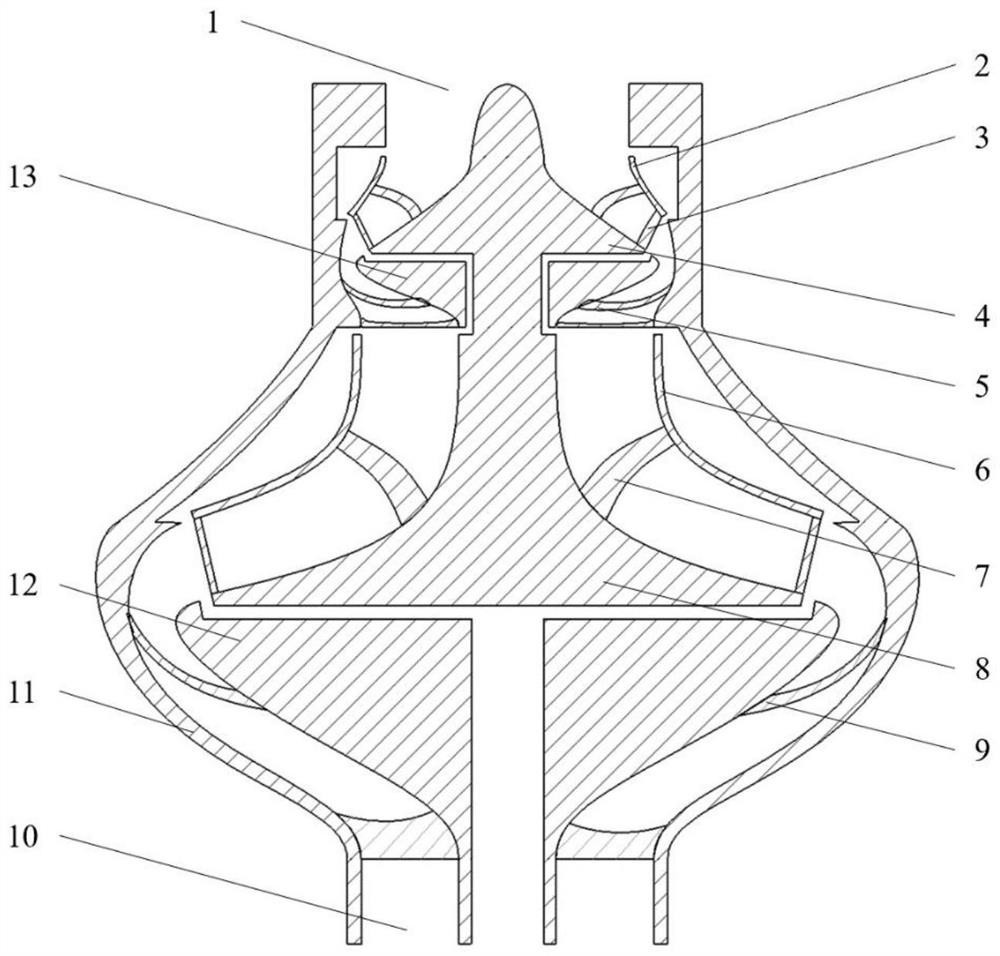

High-pressure disc thrust gas bearing adopting double symmetrical contraction sections for gas supply and design method

ActiveCN105443579AReduce distractionsImprove flow field structureGas cushion bearingsGas lubricationProcess engineering

A high-pressure disc thrust gas bearing adopting double symmetrical contraction sections for gas supply comprises an upper working disc (1) and a lower working disc (8) which are arranged in parallel, a gas lubricating film (9) is formed between the upper working disc (1) and the lower working disc (8), and a gas supply component (2) is arranged in the center of the upper working disc (1) and is further connected with an upstream pressure stabilizing cavity. A gas supply hole (3) is formed in the center of the gas supply component (2) and used for introducing gas flow. The double symmetrical contraction sections (4) in a curved surface form are arranged on the downstream of the gas supply hole (3) and are used for smoothly accelerating axial low-speed incoming flow into radial subsonic speed gas flow. According to the high-pressure disc thrust gas bearing, the axial low-speed incoming flow at inlets of the contraction sections is smoothly accelerated into the uniform radial subsonic speed gas flow at outlets of the contraction sections, serious flow separation is avoided at the same time, and the gas flow is further accelerated to the supersonic speed at a gas film outlet. After the gas supply pressure exceeds a certain specific value, the bearing capability of the bearing can be linearly increased along with the increase of the gas supply pressure, and the high-pressure disc thrust gas bearing is suitable for working under high-pressure, heavy-load and large-gap working conditions.

Owner:WUHAN UNIV OF SCI & TECH

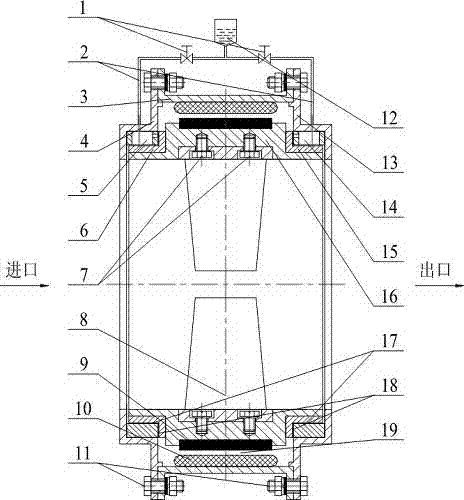

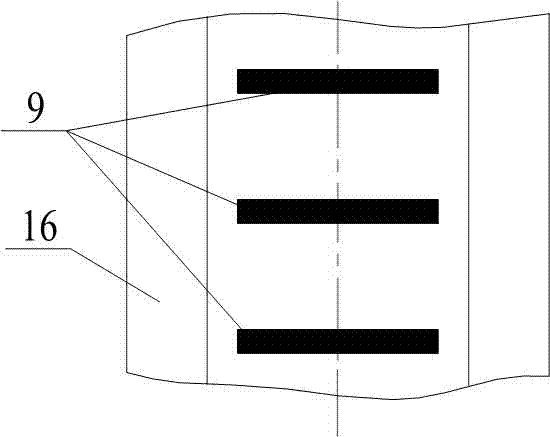

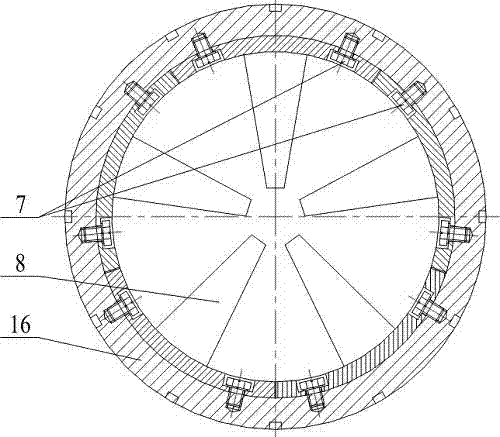

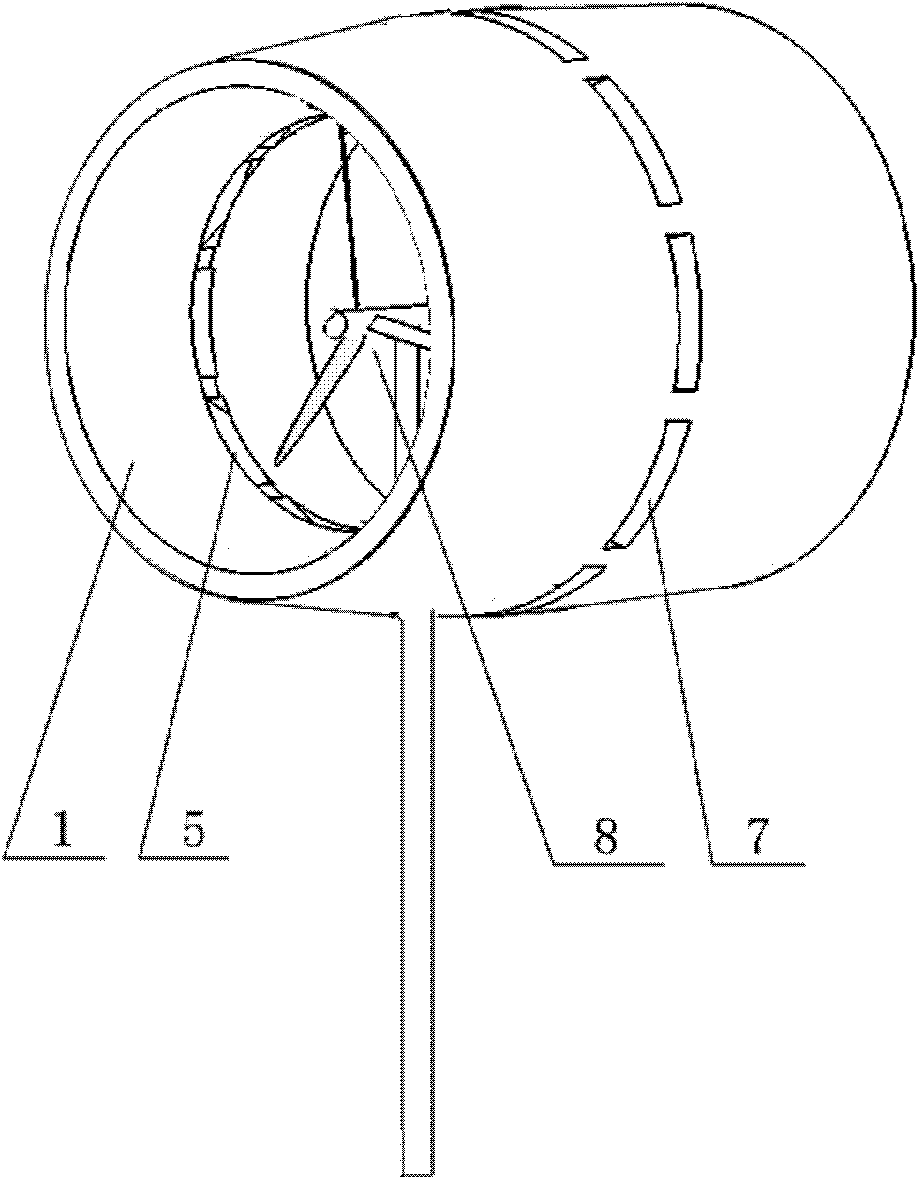

Wheel rim-driven shaftless fan

InactiveCN107461354ASave flow spaceSave materialPump componentsPump installationsInterference fitEngineering

The invention specifically relates to a wheel rim-driven shaftless fan. The wheel rim-driven shaftless fan comprises a stator component, a rotor component and a lubrication device, wherein the stator component comprises a front end cover 4, an inlet-side slide bearing 5, an air barrel 3, an armature 10, an outlet-side slide bearing 14 and a rear end cover 13, wherein the rotor component comprises an inlet-side shaft neck 6, a wheel hub 16, permanent magnets 9, blades 8 and an outlet-side shaft neck 15, the inlet-side shaft neck 6 and the outlet-side shaft neck 15 are both L-shaped and both installed on the wheel hub 16 in a manner of interference fit, a plurality of grooves are uniformly formed in the excircle surface of the wheel hub 16, and the permanent magnets 9 are inlaid in the grooves in the excircle surface of the wheel hub 16; a blade handle is arranged at the blade tip of each blade 8, each blade handle is an incurved tile, and all the tiles are spliced to just form the inner diameter of the wheel hub; and the lubrication device comprises an oil cup 12, a guide pipe 2 and an adjustment valve 1, one end of the guide pipe 2 is connected to the oil cup 12, and two outlets are formed in the other end of the guide pipe 2. According to the wheel rim-driven shaftless fan disclosed by the invention, a wheel hub needed for driving the central shaft of a traditional fan is avoided, the separation of secondary flow and a boundary layer at each blade root is reduced, and the flowing condition at each blade root is improved, so that the efficiency of the fan is increased; and moreover, a blade tip gap at each blade tip is avoided, so that detouring flow at each blade tip is avoided, a flow field structure is improved, energy conversion efficiency is increased, and a pneumatic noise is lowered.

Owner:NORTHWESTERN POLYTECHNICAL UNIV +1

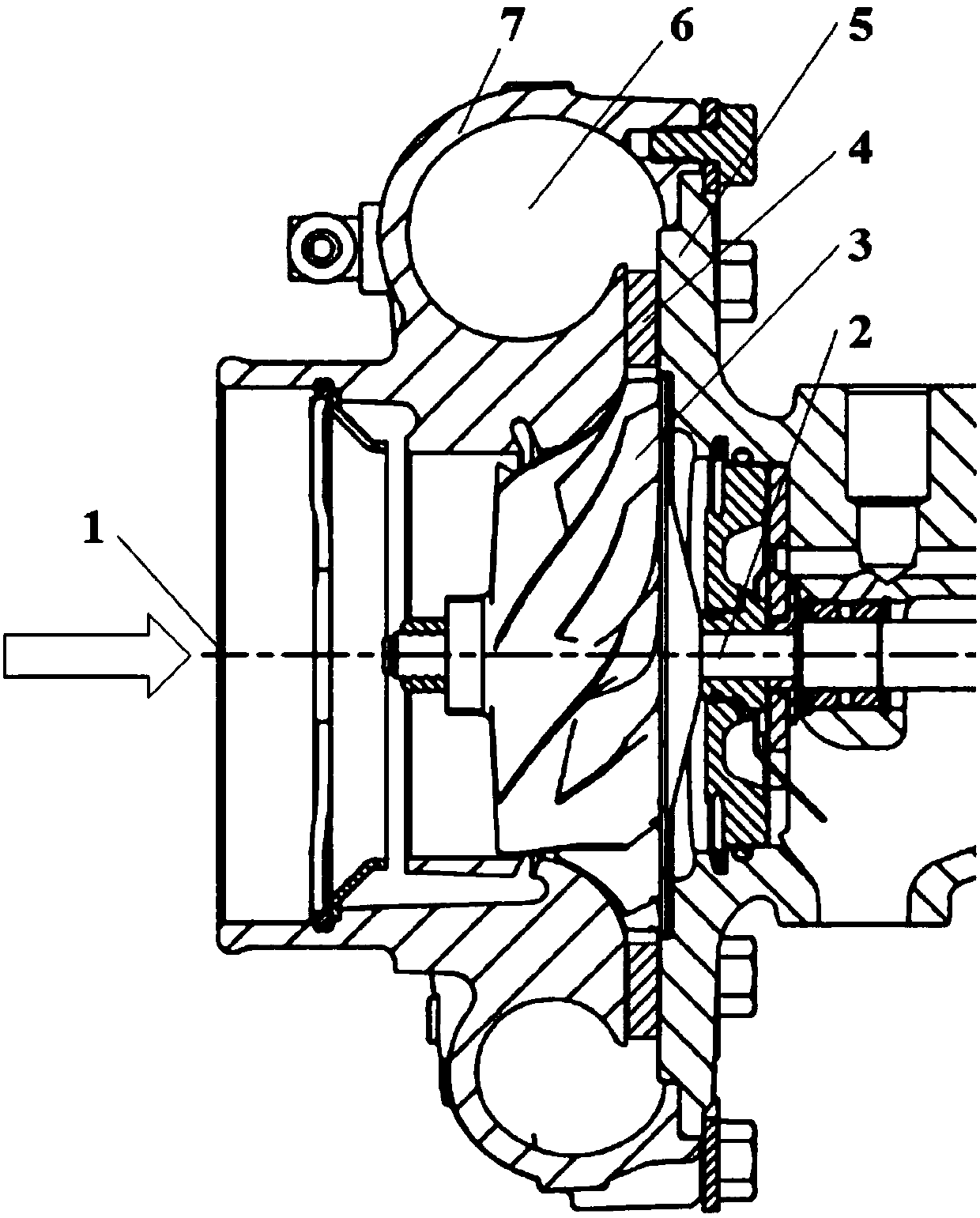

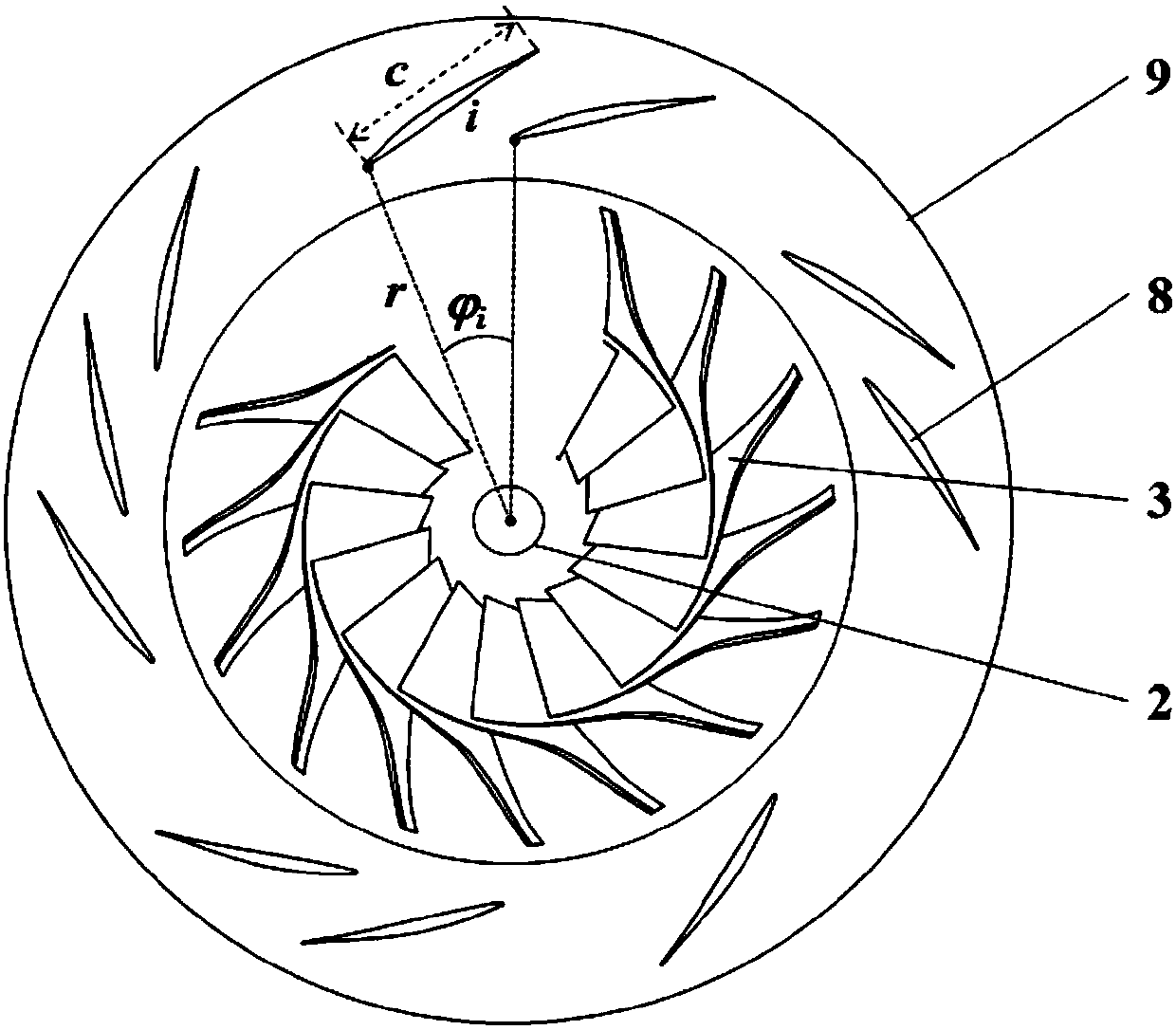

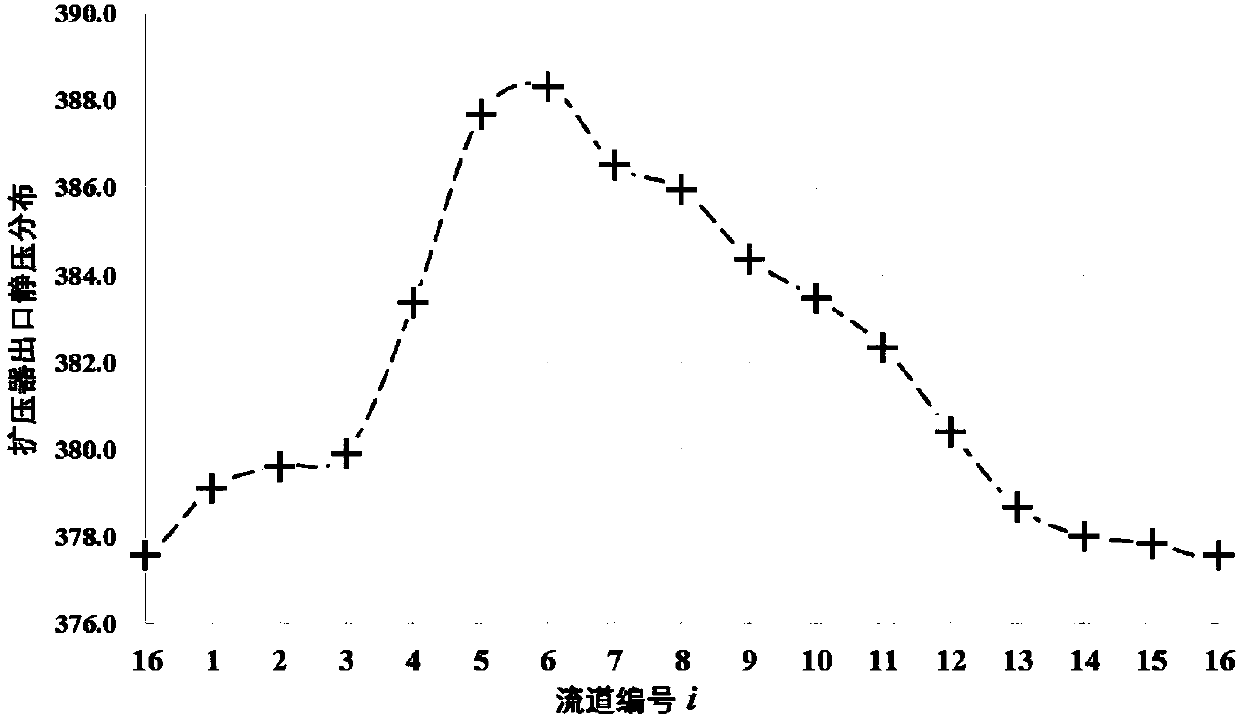

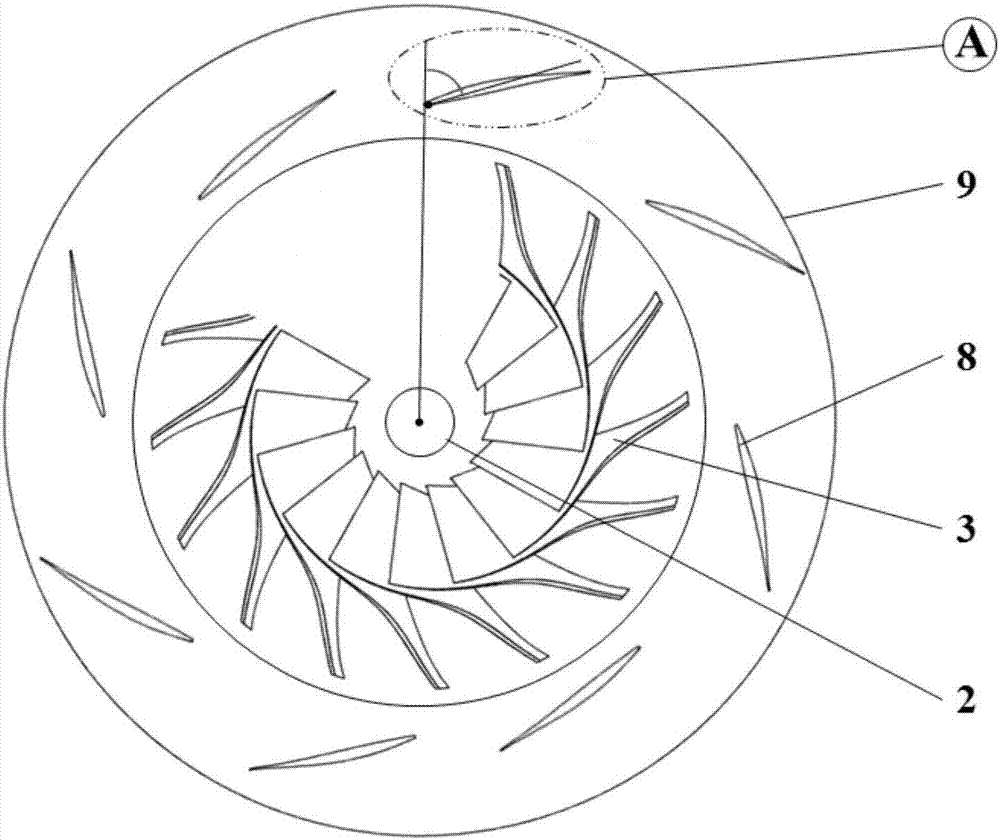

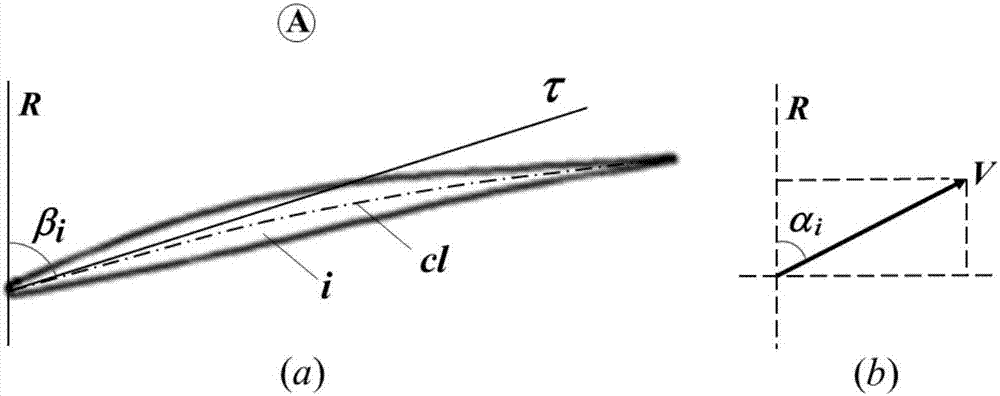

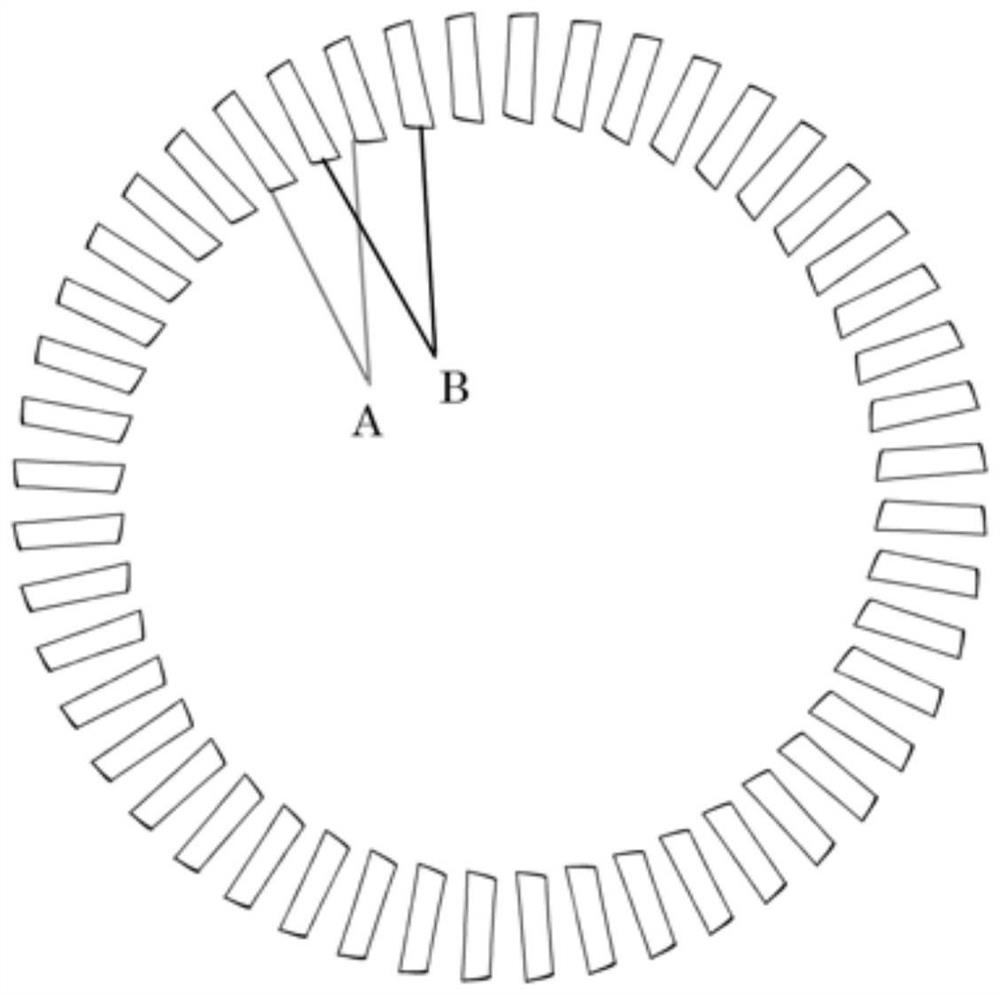

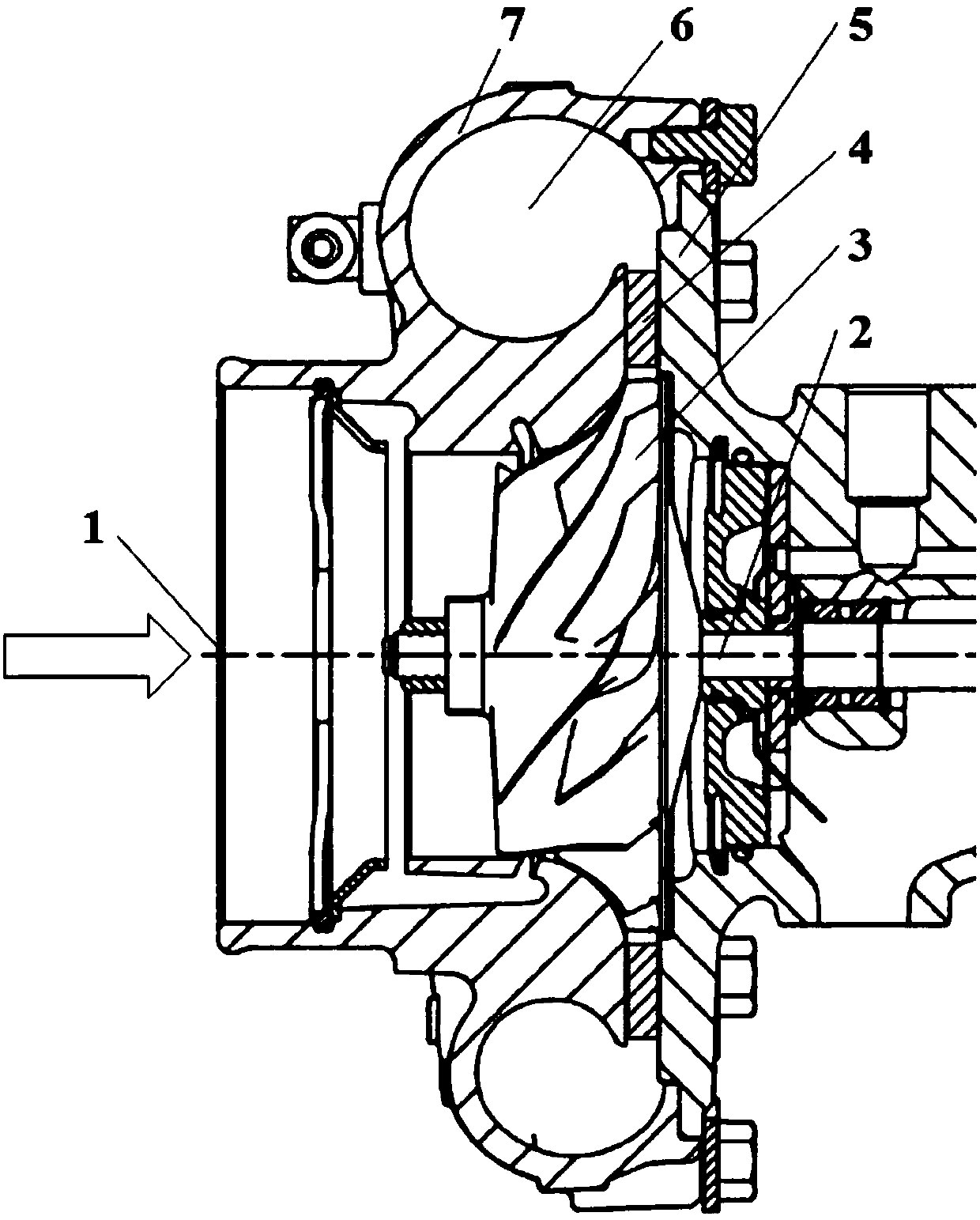

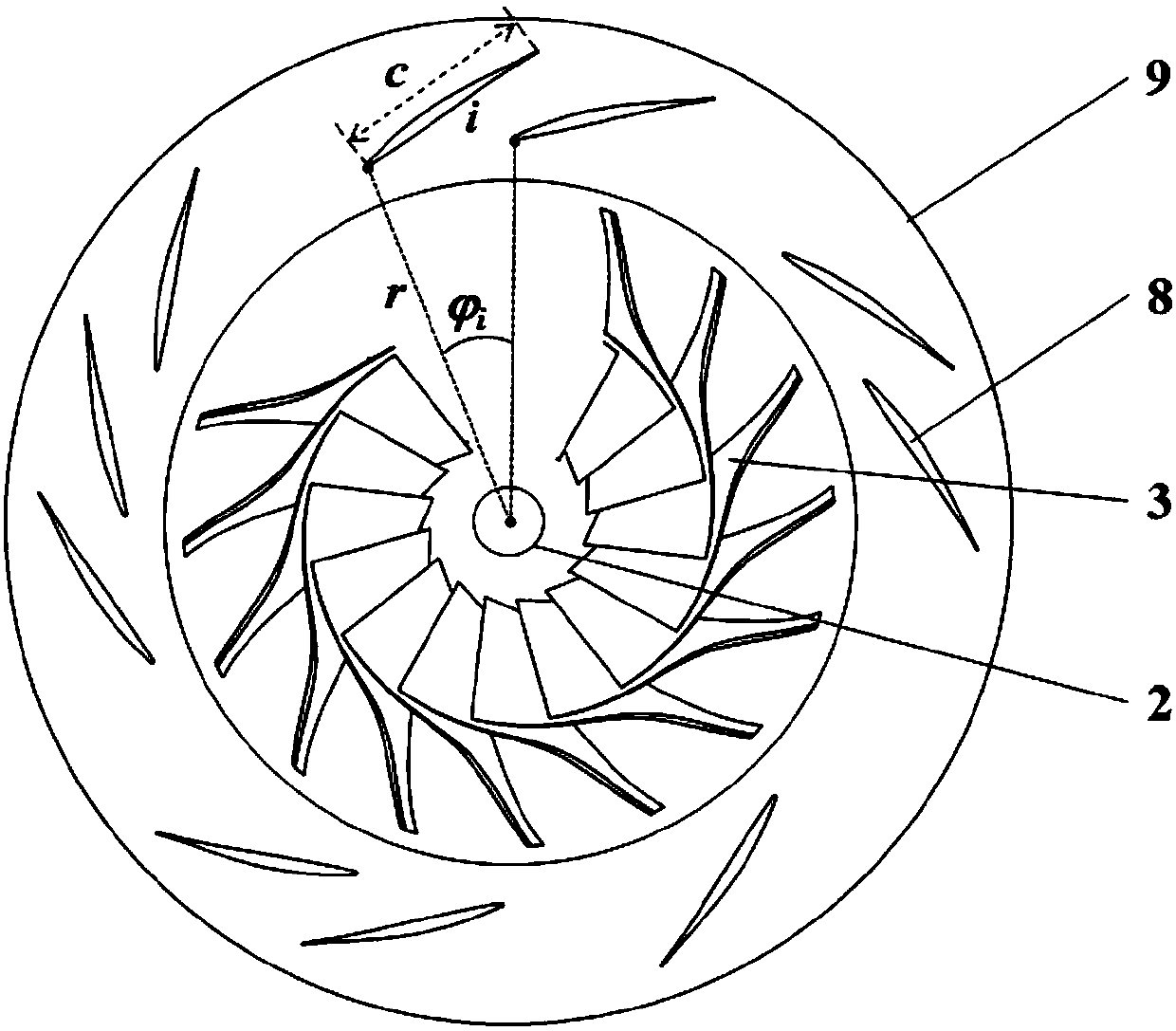

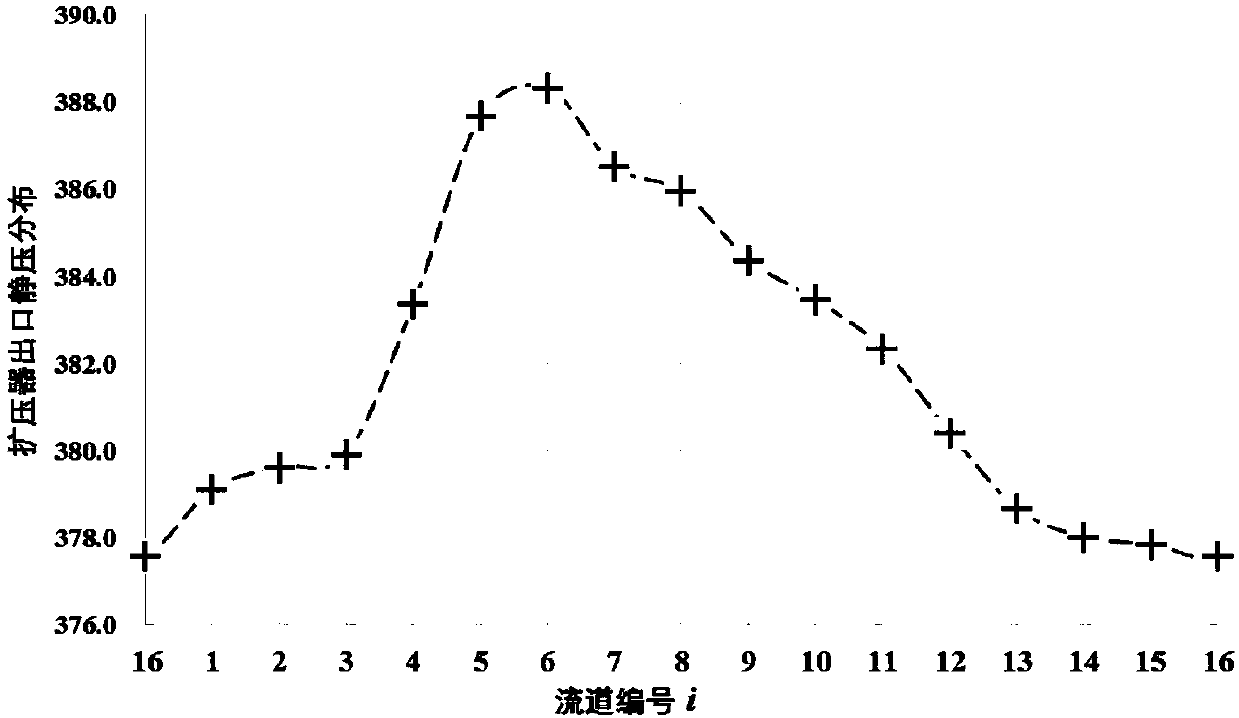

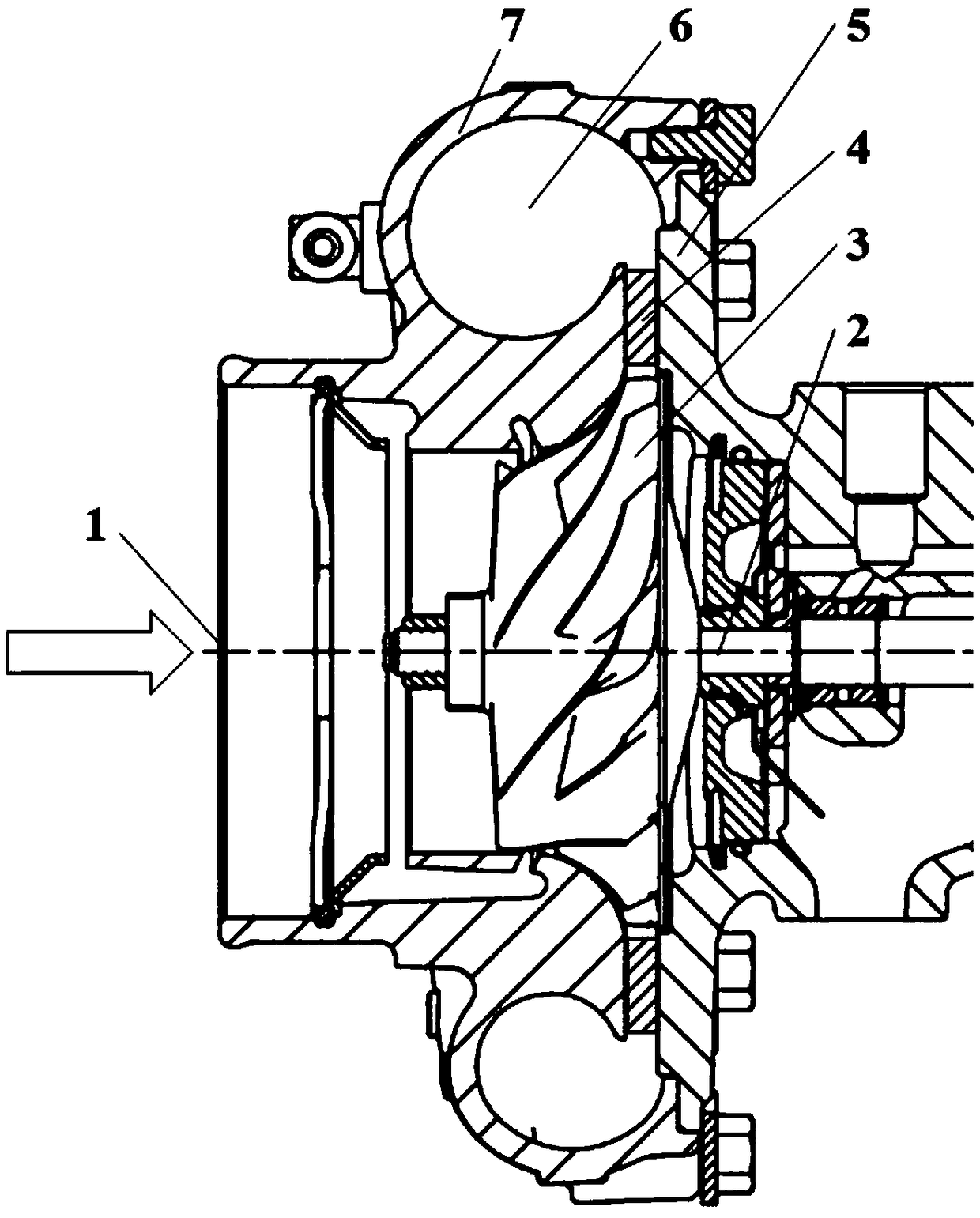

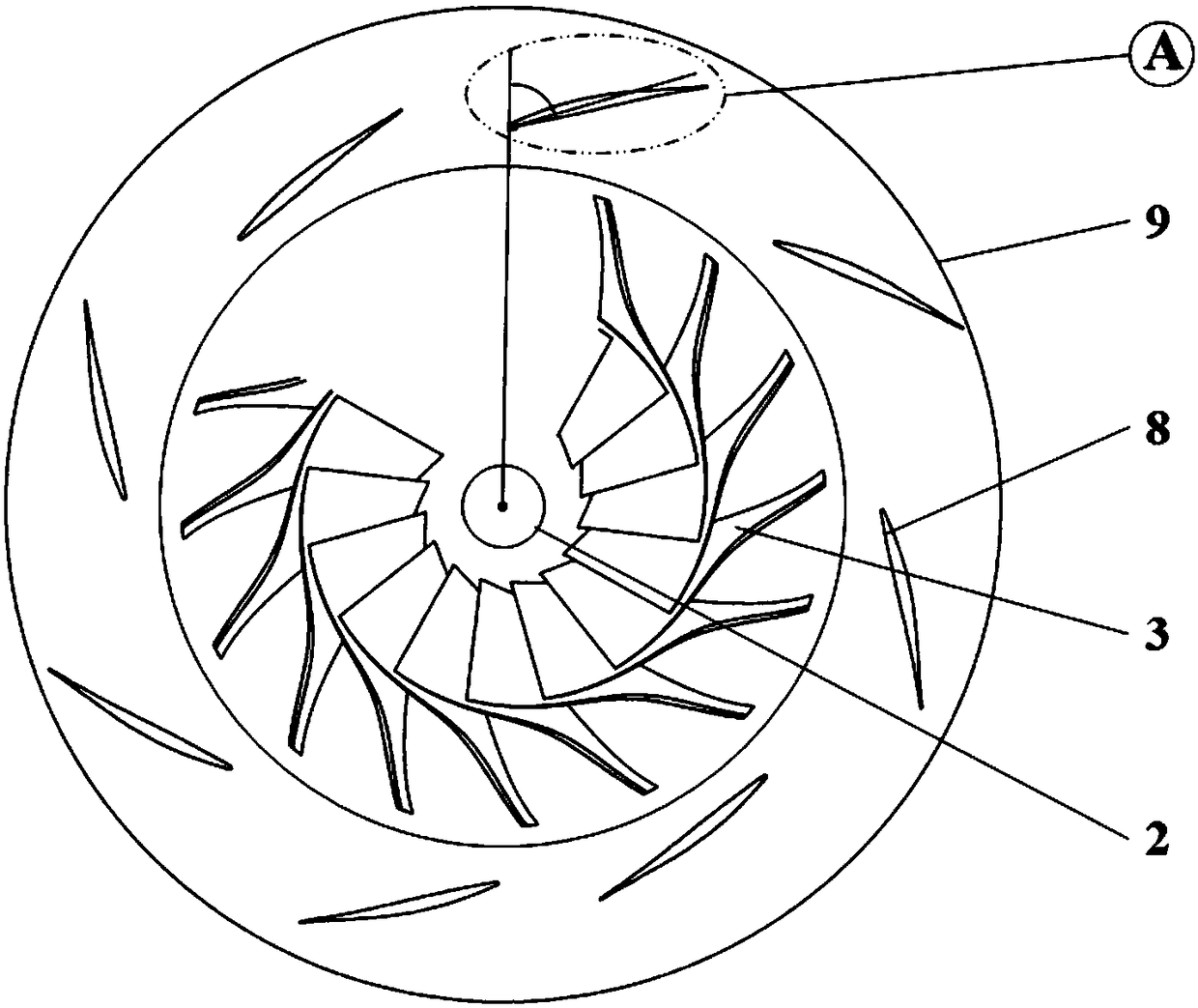

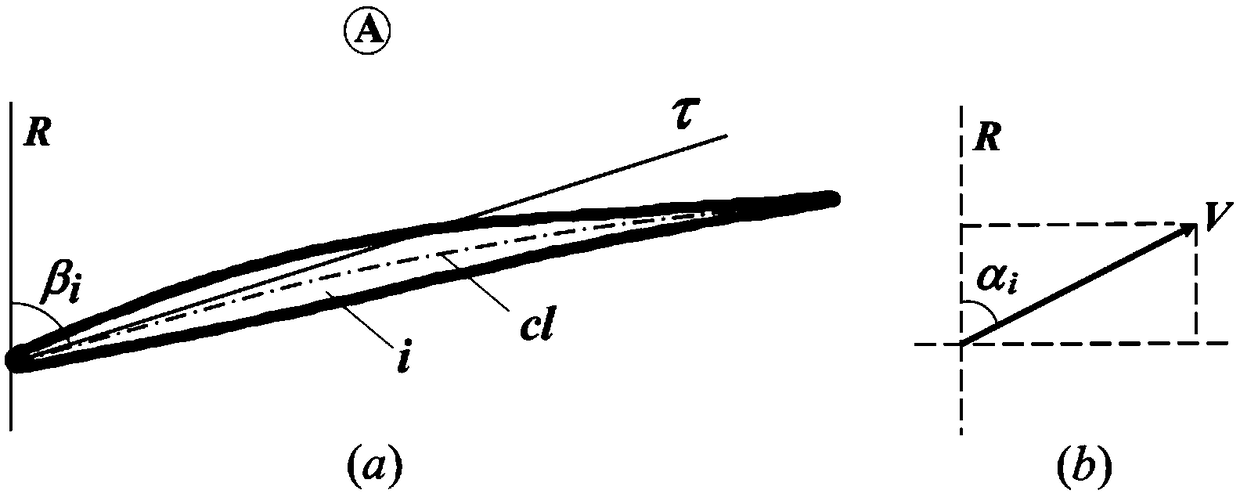

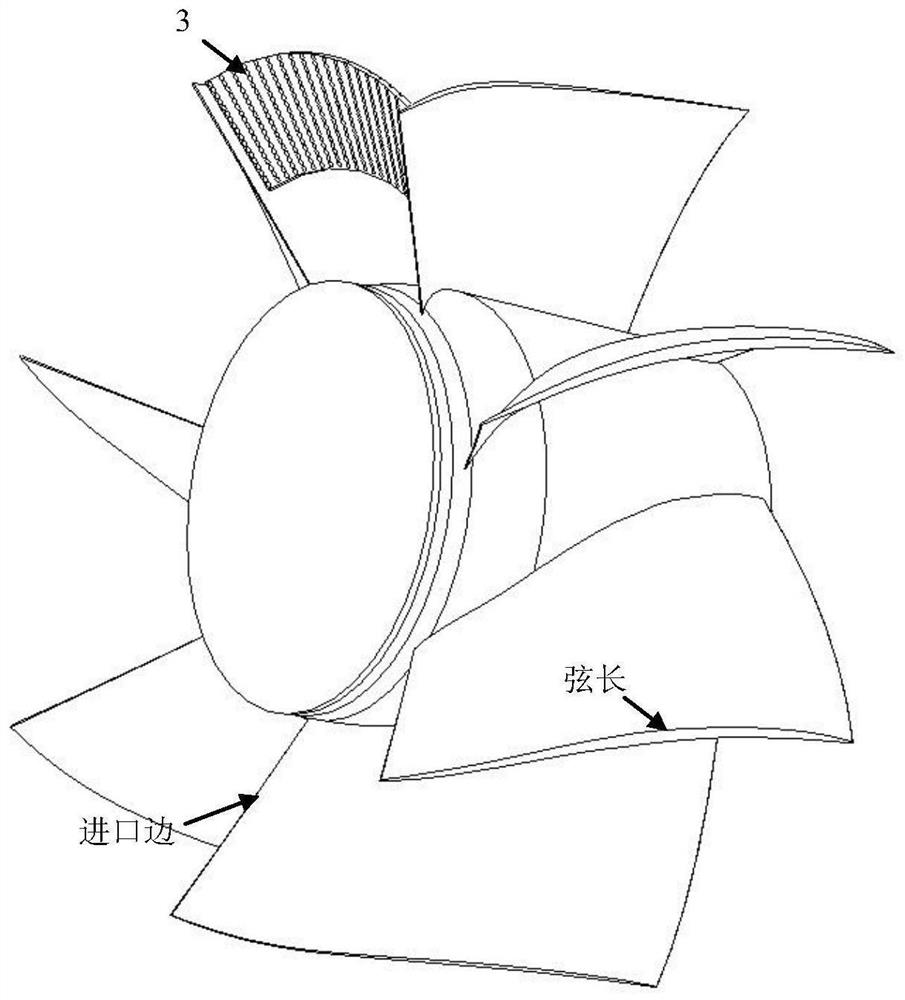

Centrifugal compressor using asymmetrical bladed diffuser with variable blade consistencies in circumferential direction

ActiveCN107061368AImprove flow field structureImprove performancePump componentsPumpsEngineeringFront edge

The invention relates to a centrifugal compressor using an asymmetrical bladed diffuser with variable blade consistencies in the circumferential direction, and belongs to the technical field of turbomachinery. The centrifugal compressor comprises a volute, a centrifugal impeller and the bladed diffuser. The inlet front edge positions and the bladed mounting angles are evenly distributed in the circumferential direction, the blade consistencies are asymmetrically distributed in the circumferential direction, and the consistencies are unequal in different circumferential positions. The blade consistencies are changed by changing the central angles (namely the front edge interval between every two adjacent blades) corresponding to flow channels. The compressor can effectively adapt to the downstream circumferential pressure distortion of the bladed diffuser, the nonuniformity of a flow field in the bladed diffuser is reduced, the flowing stability of the centrifugal compressor is effectively improved, and the stable working range of the centrifugal compressor is enlarged.

Owner:TSINGHUA UNIV +1

Ignition device in supersonic concave cavity combustion chamber and super-combustion stamping engine

ActiveCN110822480APromote disseminationIncrease the equivalence ratioContinuous combustion chamberCombustion chamberEquivalence ratio

The invention provides an ignition device in a supersonic concave cavity combustion chamber and a super-combustion stamping engine. The supersonic combustion chamber is internally provided with a fuelinjection hole and a concave cavity, the fuel injection hole is arranged at the upper stream of the concave cavity, and the fuel injected through the fuel injection hole propagates in the direction of the supersonic airflow propagation in a main flow channel of the supersonic combustion chamber; and a flow guide plate is obliquely arranged on the bottom wall of the concave cavity in the directionof the supersonic airflow propagation in the main flow channel, the lower end of the flow guide plate is connected to the bottom wall of the concave cavity, a gap is formed in the lower end of the flow guide plate, and a spark plug used for ignition is arranged on the portion, below the inner side of the flow guide plate, of the bottom wall of the concave cavity. According to the ignition device,the flow guide plate is applied to the interior of the concave cavity so as to improve the local flow rate and the equivalence ratio in the concave cavity, so that the ignition enhancement effect isachieved.

Owner:NAT UNIV OF DEFENSE TECH

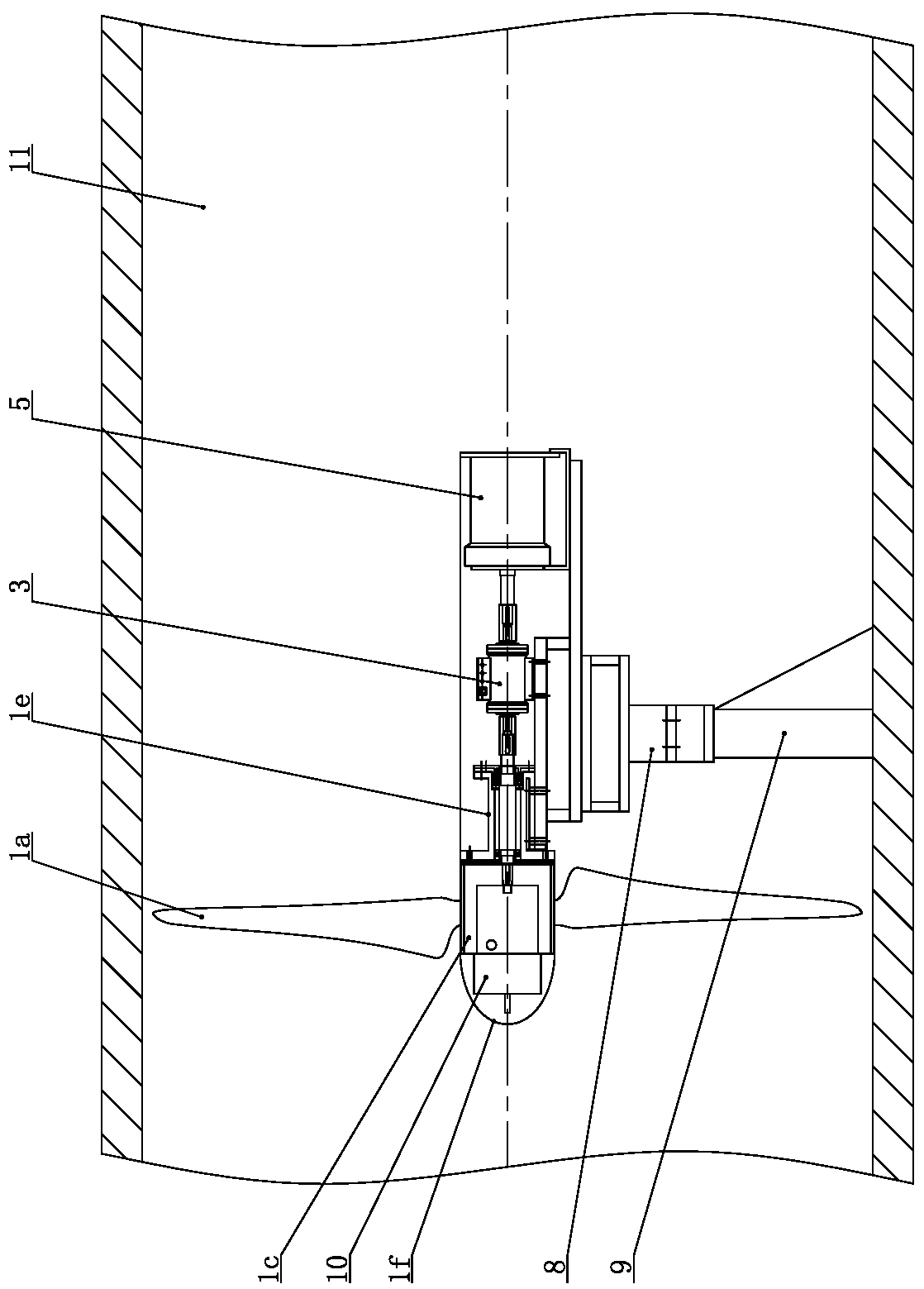

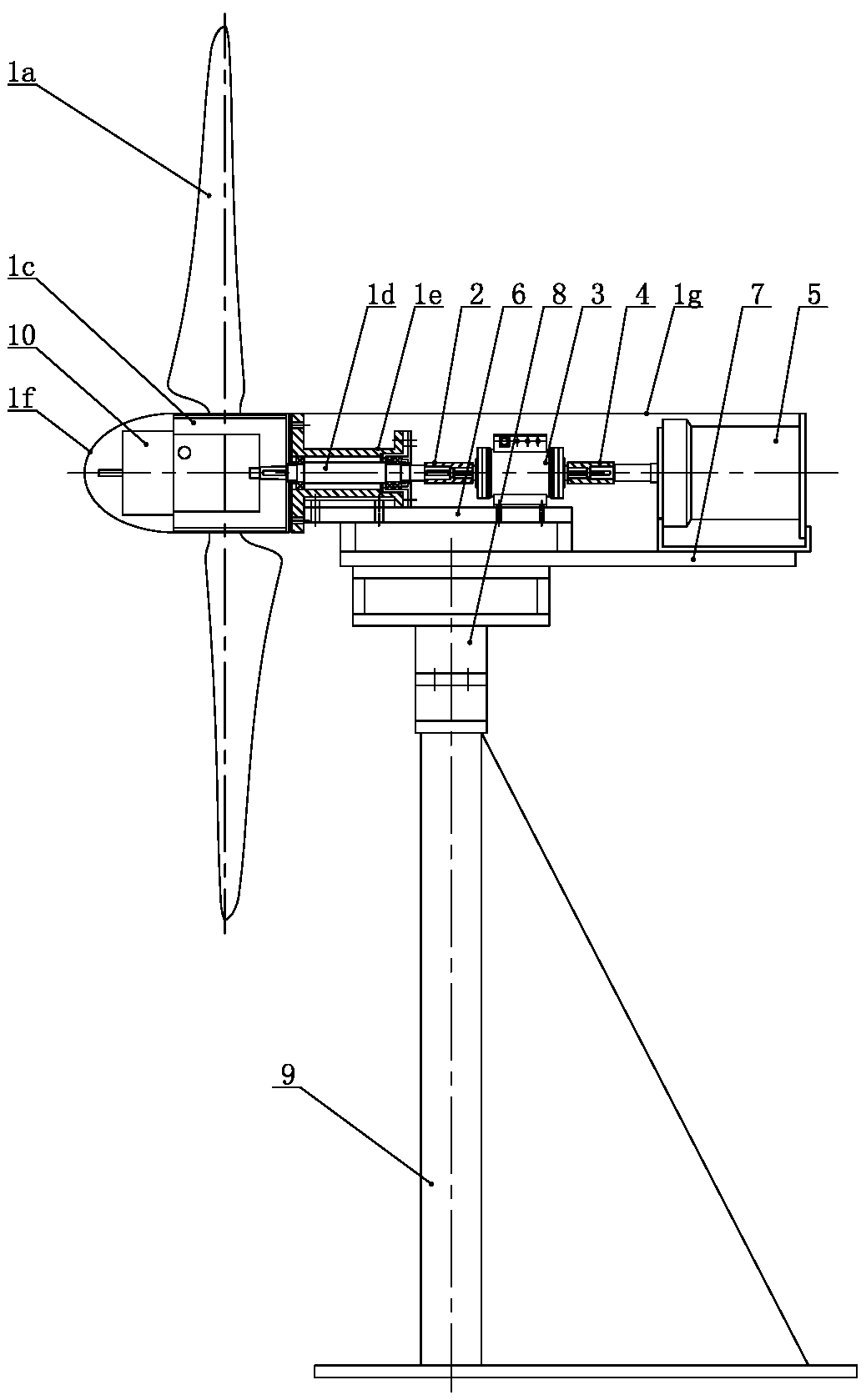

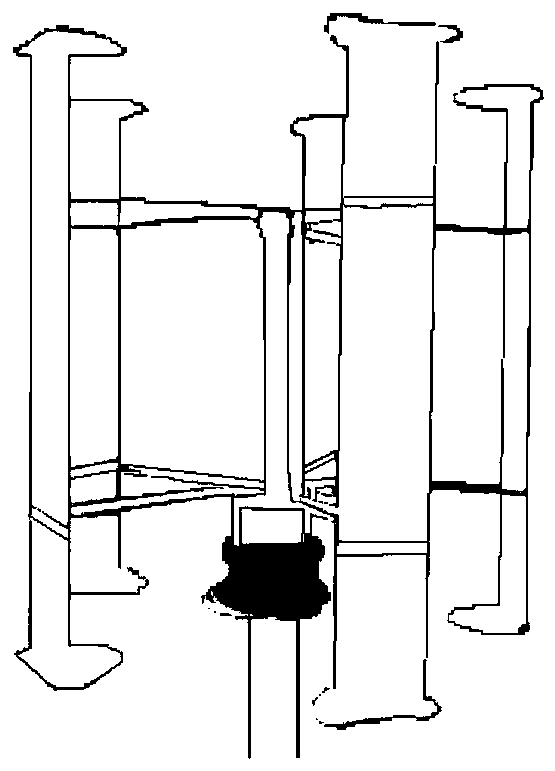

Small-power wind turbine aerodynamic characteristic measuring device suitable for wind tunnel test

ActiveCN110594105AStable and balanced operationExtended service lifeMachines/enginesWind motor monitoringCommon baseLoop filter

The invention relates to a small-power wind turbine aerodynamic characteristic measuring device suitable for a wind tunnel test. A wind turbine comprises a hub installed at the front end of a wind turbine shaft, blades are installed on the circumference of the hub, the wind turbine shaft is coaxial with a wind tunnel, a middle section of the wind turbine shaft is installed in a bearing seat, the rear end of the wind turbine shaft is connected with one end of a torque meter through a first coupling, and the other end of the torque meter is connected with a rotor shaft of a three-phase asynchronous generator through a second coupling; and the bearing seat and the torque meter are installed on a wind turbine base, the wind turbine base and the three-phase asynchronous generator are both fixedto a common base, the center of gravity of the common base is placed on a six-component balance, and the six-component balance is fixed to the top of a wind turbine support. The output end of the generator is connected with the input end of a three-phase full bridge rectifier through an air switch and a fuse, and the output end of the three-phase full bridge rectifier is connected with a main loop filter capacitor bank and connected with a load through a solid-state relay. The device can accurately measure aerodynamic performance parameters of the wind turbine when the rotating speed is stable.

Owner:YANGZHOU UNIV

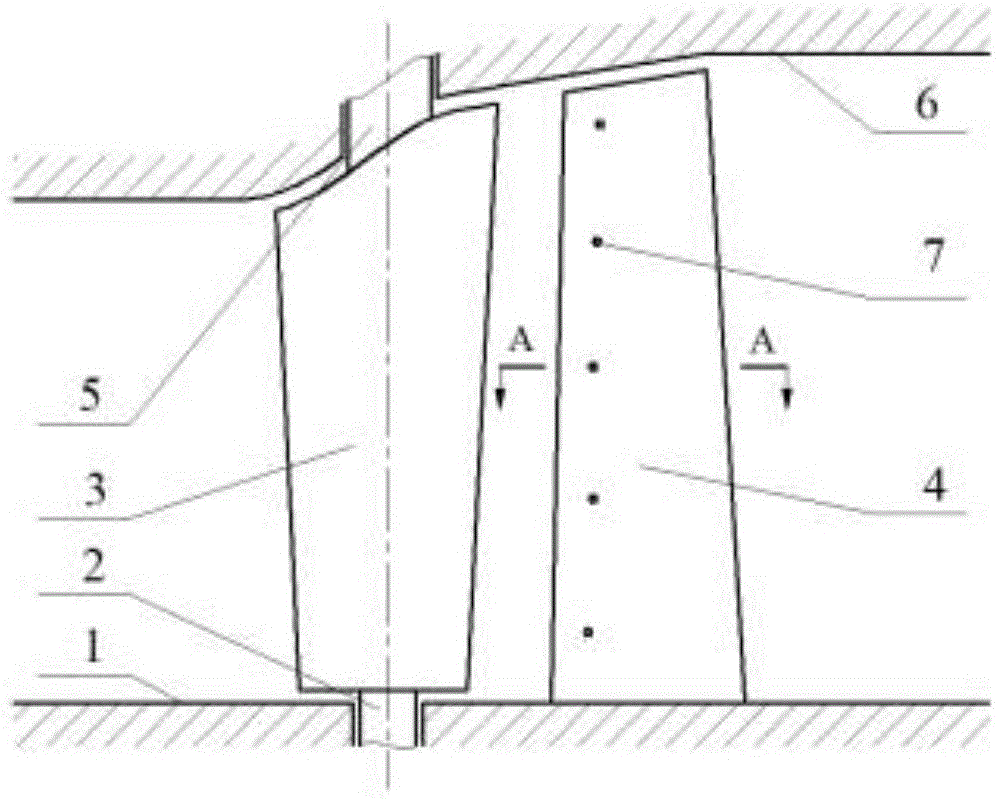

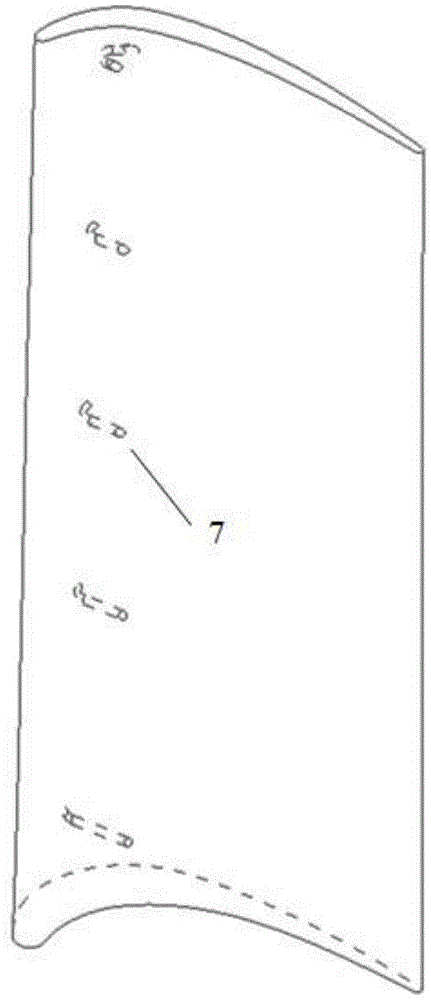

Variable geometry turbine with vortex elimination hole structures in front of movable blades

InactiveCN105626158AImprove flow field structureReduce aerodynamic lossesBlade accessoriesMachines/enginesAerospace engineeringOff design

The invention provides a variable geometry turbine with vortex elimination hole structures in the front of movable blades. The variable geometry turbine comprises a case and hubs, wherein adjustable static blades and the movable blades are uniformly installed between the case and the hubs in the circumferential direction, upper rotating shafts and lower rotating shafts are installed on the upper end faces and the lower end faces of the adjustable static blades respectively, the upper rotating shafts are embedded into the case, the lower rotating shafts are embedded into the correspondinghub, the movable blades are installed on the correspondinghub, the curved vortex elimination hole structures communicating with blade pressure surfaces and suction surfaces are formed in the front of the movable blades in the radial direction, and load distribution of blade profiles of the movable blades is of a rear-loading type. According to the variable geometry turbine, separation vortexes in the front of the blades can be reduced or even eliminated underthe off-design condition so that aerodynamic loss in channels of the movable blades can be obviously reduced, transverse differential pressure in front of the blades can be reduced underthe design condition, formation of secondary flow can be delayed, and then loss of the secondary flow can be reduced. The variable geometry turbine hasgood characteristic underall operating conditions on the whole.

Owner:HARBIN ENG UNIV

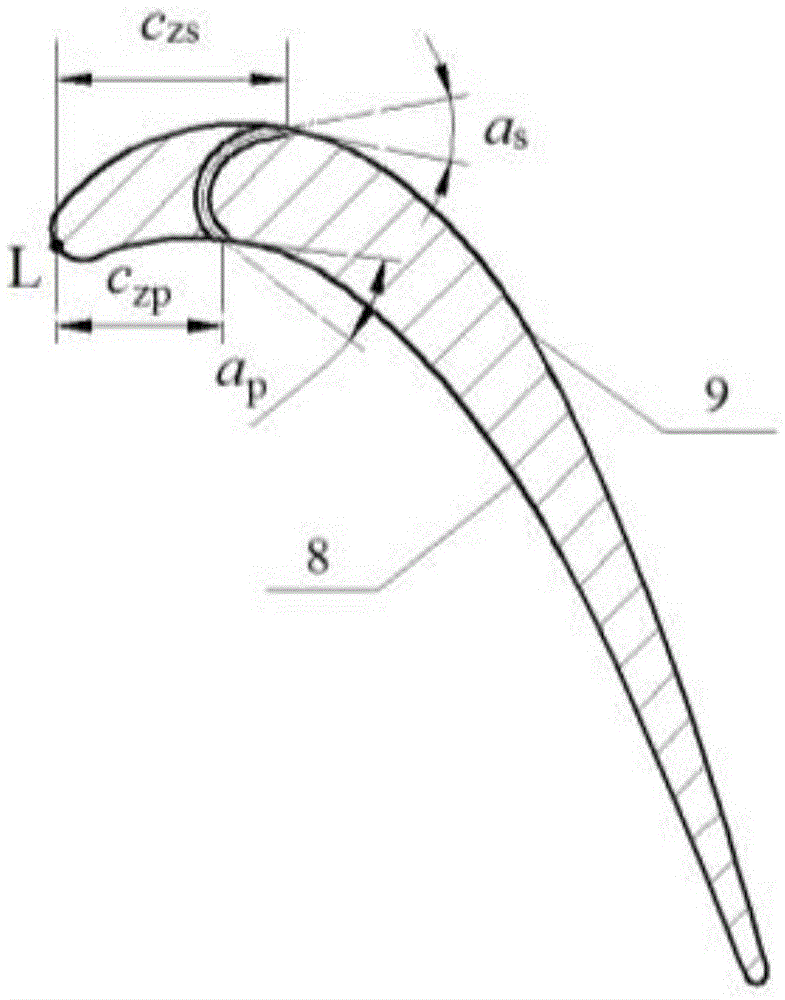

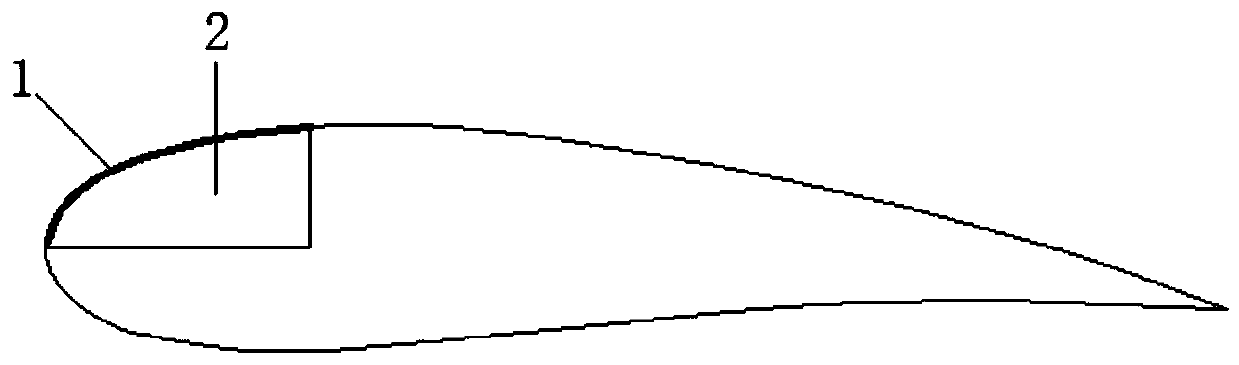

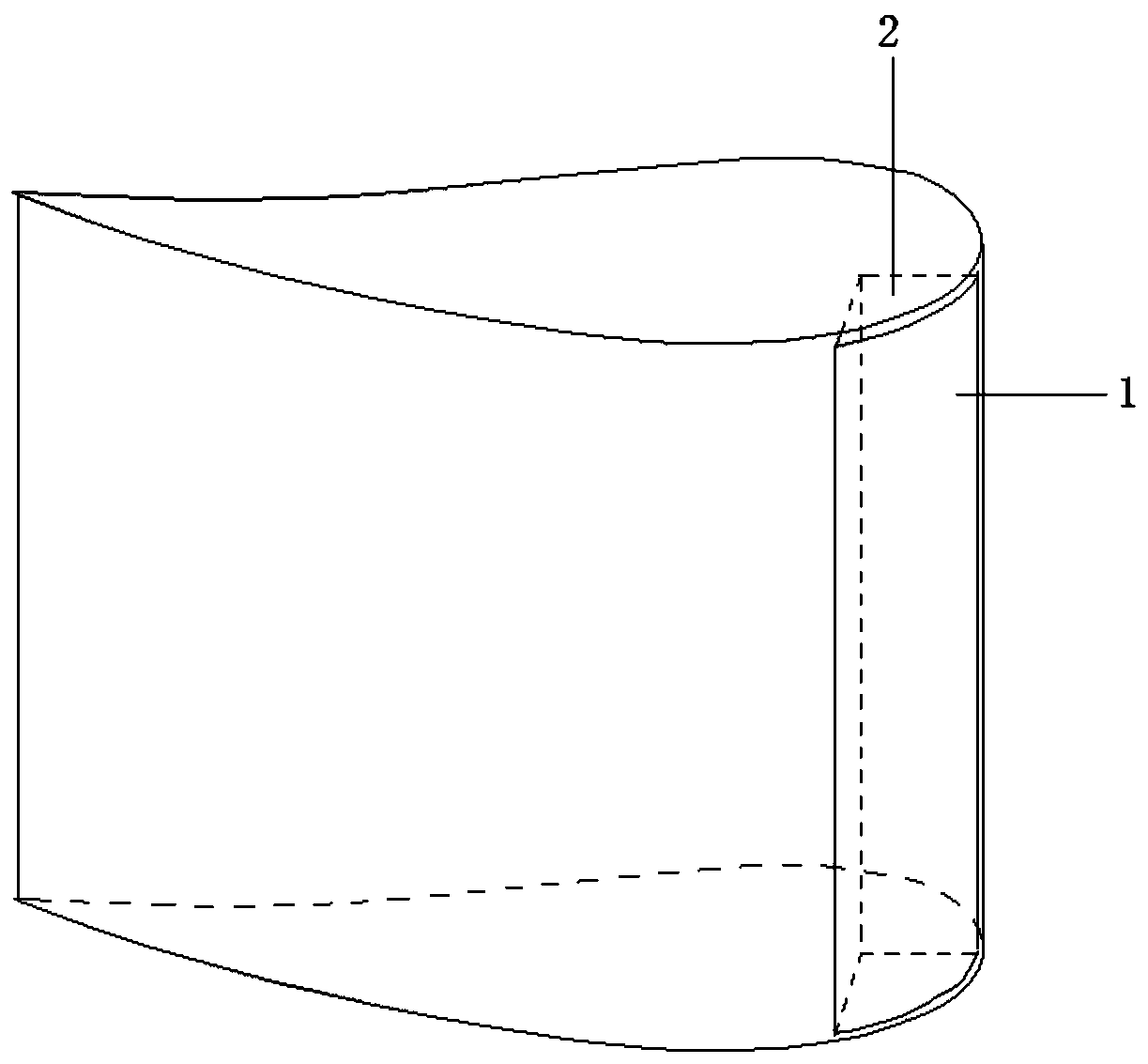

Rotatable ship rudder with bulge front edges

PendingCN111409812AIncrease the curvatureImprove hydrodynamic performanceSteering ruddersShip stabilityFront edge

The invention discloses a rotatable ship rudder with bulge front edges, which relates to the technical field of rudder structures. The rudder comprises a main rudder blade and a tail rudder blade, thetail rudder blade is arranged at the rear end of the main rudder blade, and the main rudder blade comprises a body and a plurality of bulge front edges which are arranged at the front end of the bodyand protrude forwards. The bulge front edge structure can improve the flow field structure, the main rudder blade and the tail rudder blade can increase the bending degree of the rudder blades, and the combination of the two can improve the hydrodynamic performance of the rudder and improve the stability of the ship; cavitation erosion can be reduced through the oval front edge or the curvature continuous front edge blade profile, and the service life of the rudder is effectively prolonged; the bulge front edge and the body curvature of the main rudder blade are in continuous transition combination, or the bulge front edge and the body ellipse of the main rudder blade are in transition combination, so that the rudder resistance during advancing can be reduced, and the oil consumption is reduced; the main rudder blade is connected with the ship body through the rudder stock, the tail rudder blade is connected with the ship body through the auxiliary rudder stock, bearing of the rudderstock can be reduced, and stability of the cantilever rudder is improved.

Owner:SHANGHAI MARITIME UNIVERSITY

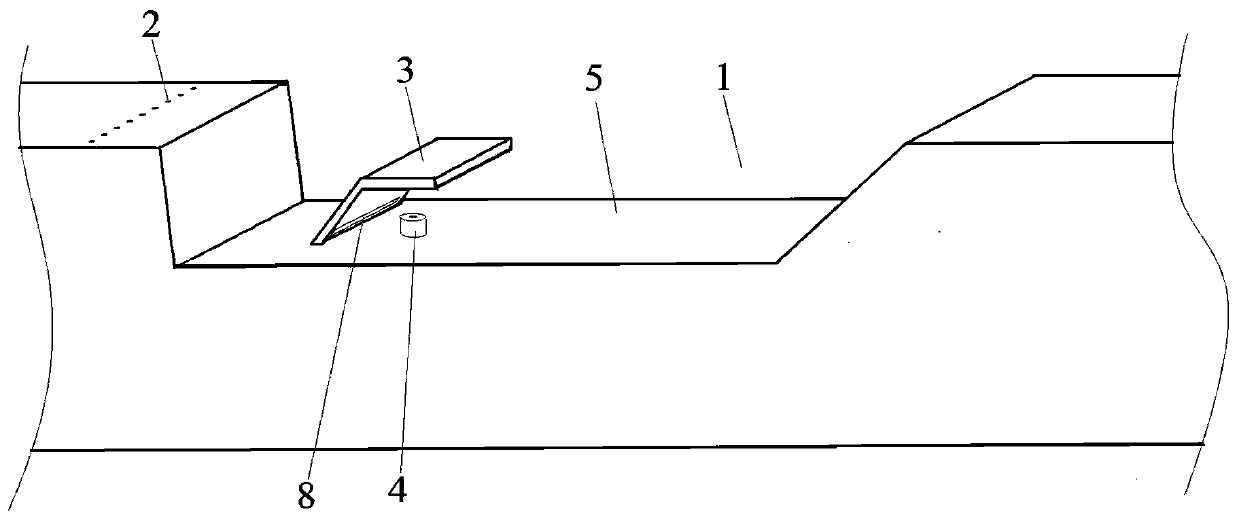

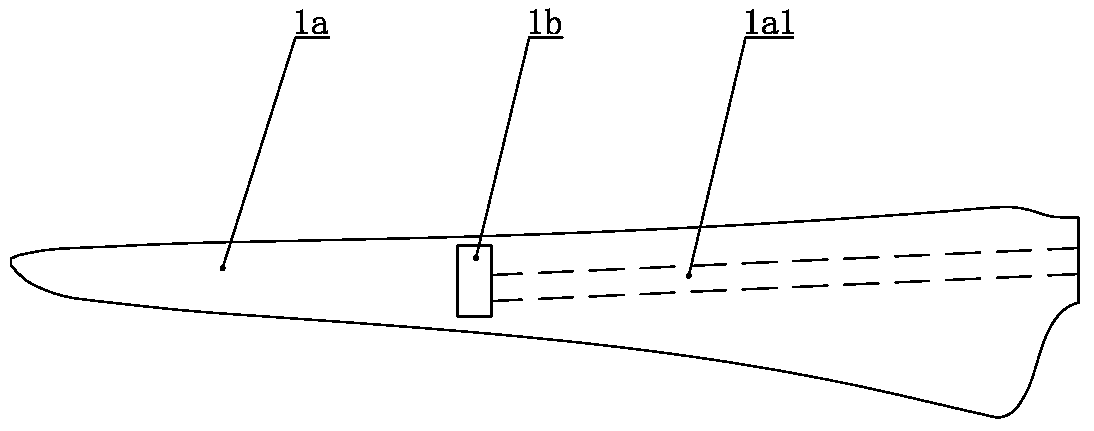

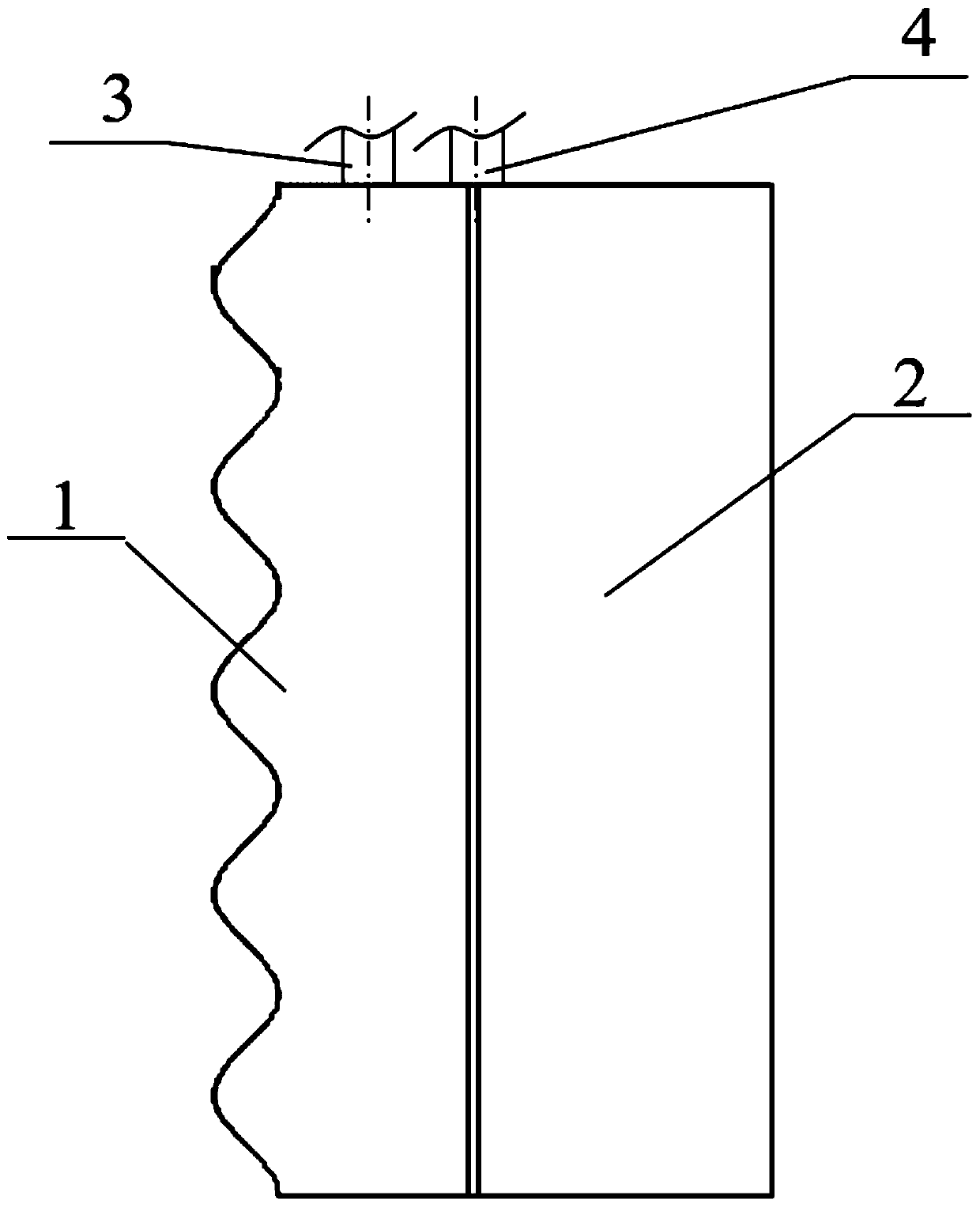

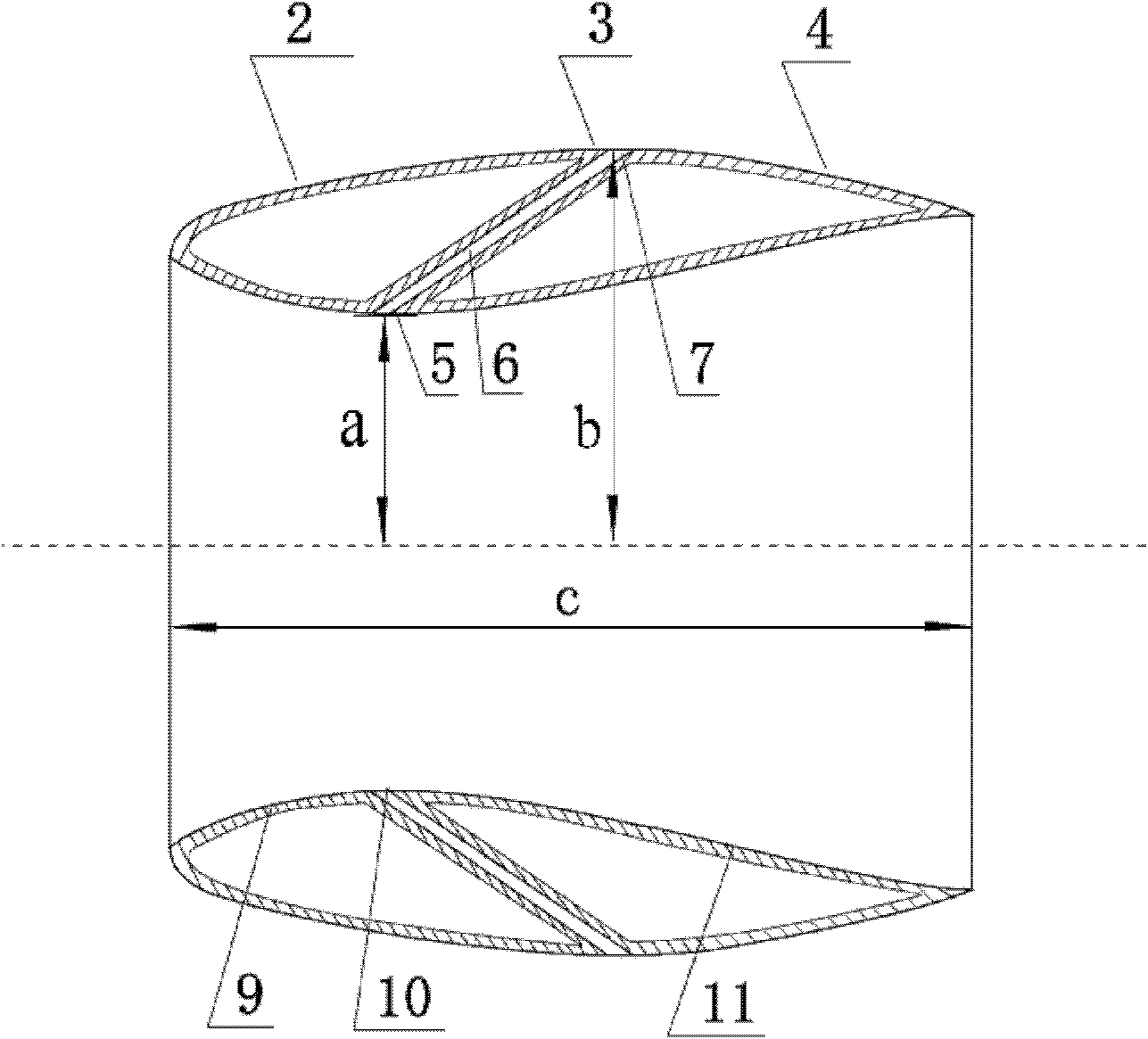

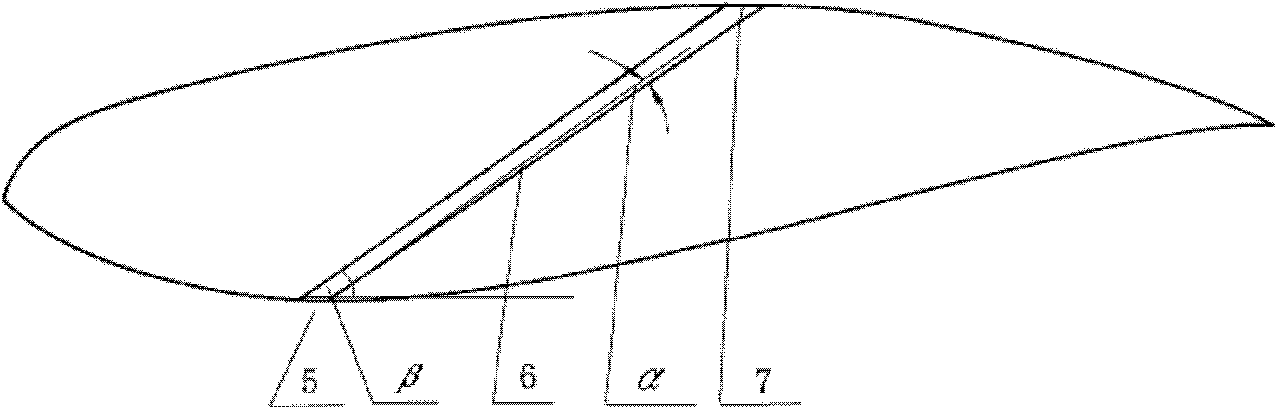

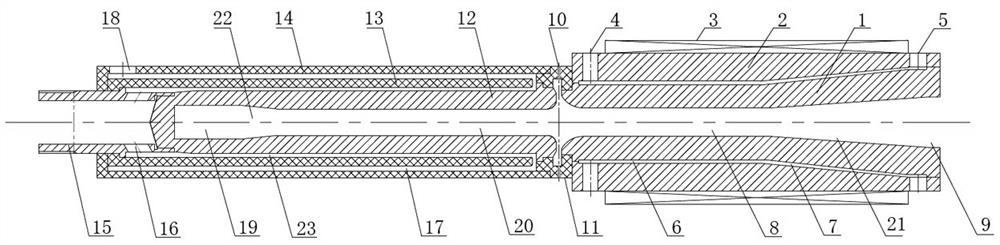

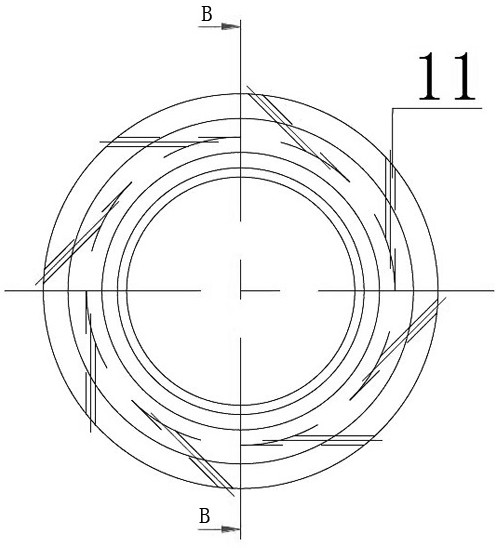

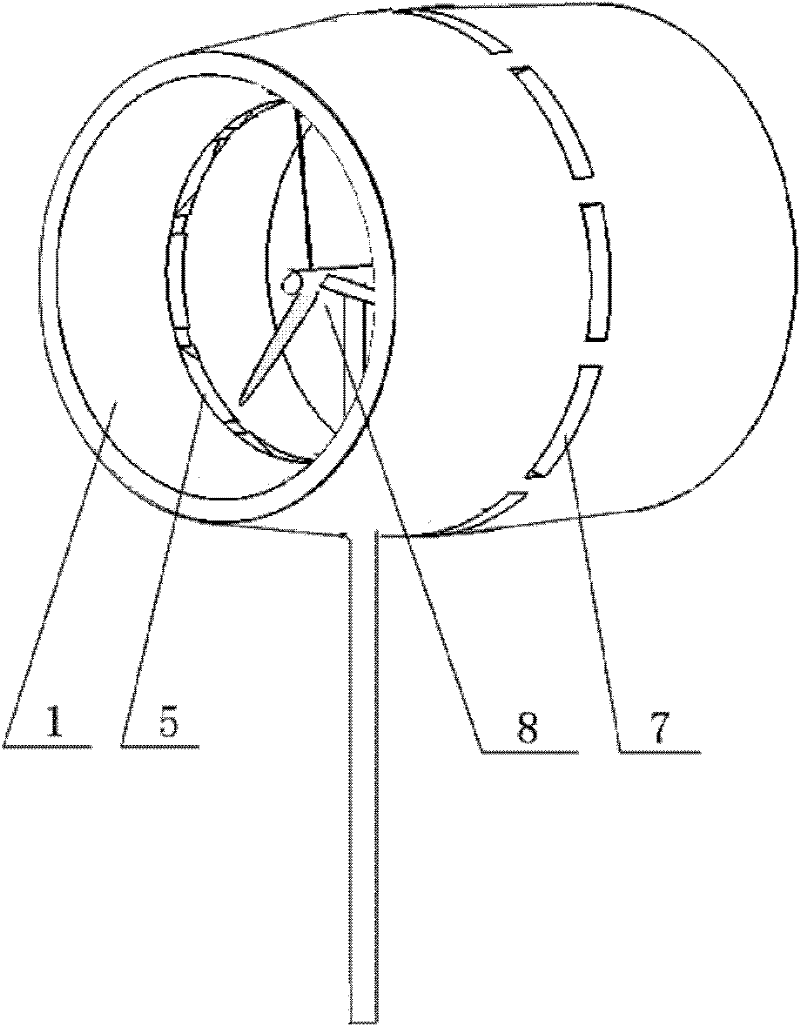

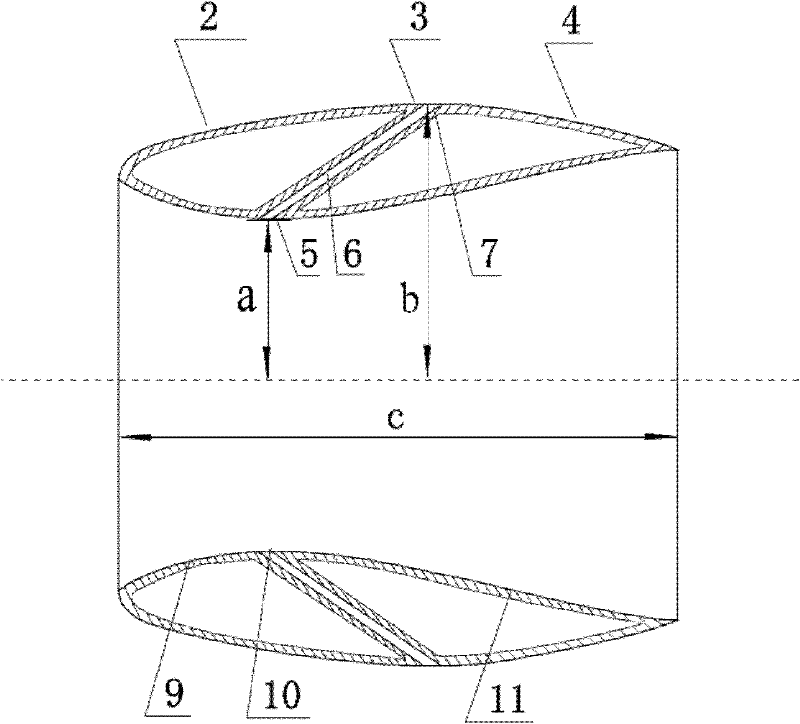

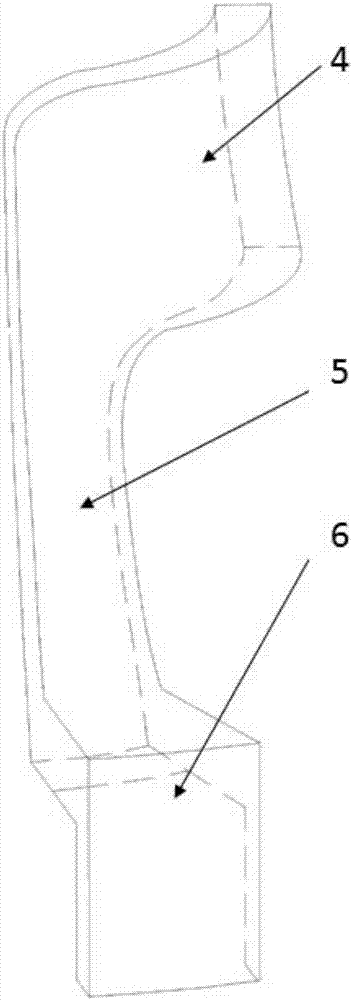

Culvert device of horizontal axis wind-driven generator

InactiveCN101865074AImprove mute effectIncrease profitMachines/enginesWind energy generationWind drivenHorizontal axis

The invention relates to a culvert device of a horizontal axis wind-driven generator. The culvert device is arranged on the horizontal axis wind-driven generator, and flow field structures around the horizontal axis wind-driven generator are reasonably arranged by using appearance design of inner and outer surfaces of a culvert. The device mainly comprises an inner flow passage formed inside the culvert and an outer flow passage formed outside the culvert; the outer flow passage comprises an external acceleration section (2), an external transition section (3) and an external deceleration section (4); the inner flow passage comprises an internal acceleration section (9), an internal transition section (10) and an internal deceleration section (11); suction passages (6) for connecting the inner and outer flow passages of the culvert are formed between the inner and outer flow passages; the opening size of the suction passages (6) is controlled through a baffle plate; and a plurality of suction passages (6) are uniformly distributed in the wall between the inner and outer flow passages. The device controls a suction device according to the working condition of the culvert wind-driven generator, and the working condition of a wind blade is improved by adjusting the opening size of the suction device.

Owner:JILIN UNIV

Hot-blast furnace combined grate suitable for stacking checker bricks with different structures

InactiveCN102321776AHigh porosityImprove accuracyBlast furnace detailsHeating stovesBrickEngineering

The invention relates to a hot-blast furnace combined grate suitable for stacking checker bricks with different structures, and can effectively solve the problem that the checker bricks are broken due to slippage between the checker bricks and the grate. A grate body is provided with round through holes; each positioning sleeve is a T-shaped cylinders formed by sleeving a big ring at one end of a small cylinder; small cylinders are arranged in the round through holes at equal intervals; the lower end faces of big rings are arranged on the hole walls of the grate body; positioning sleeves arranged on the grate body at intervals form positioning lug bosses; the positioning lug bosses are matched with grooves on checker brick transition blocks; and the checker brick transition blocks are arranged on the grate body and closely combined with the checker bricks. By the hot-blast furnace combined grate, the accuracy of stacking the checker bricks is improved, the through hole rate of the checker bricks is improved, the checker bricks are prevented from being damaged, and the effects of improving a flow field structure and enhancing heat transfer are achieved.

Owner:河南省豫兴热风炉工程技术有限公司

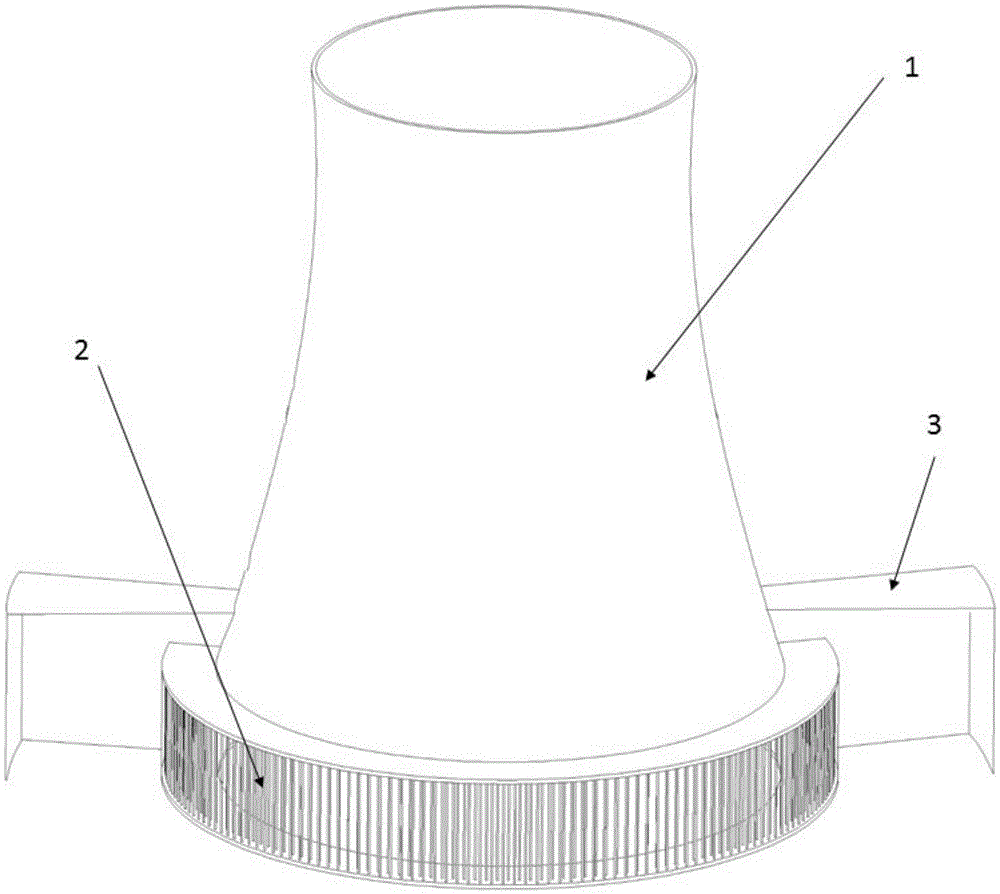

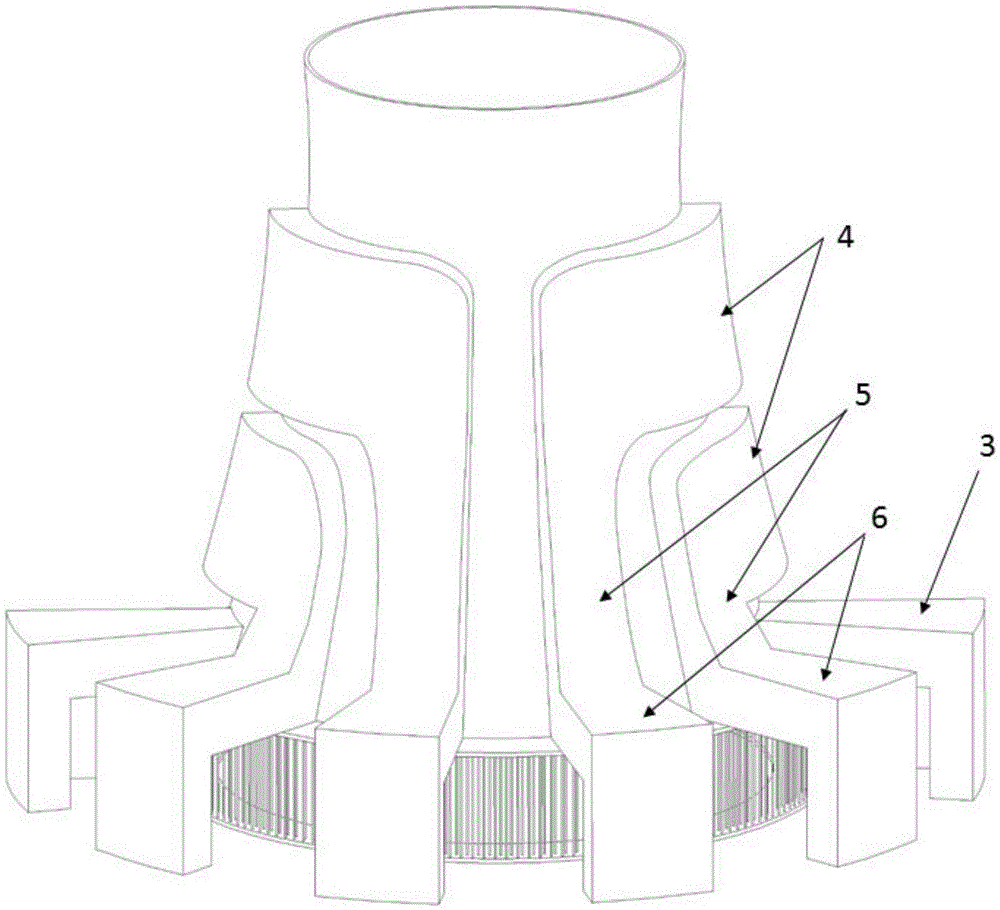

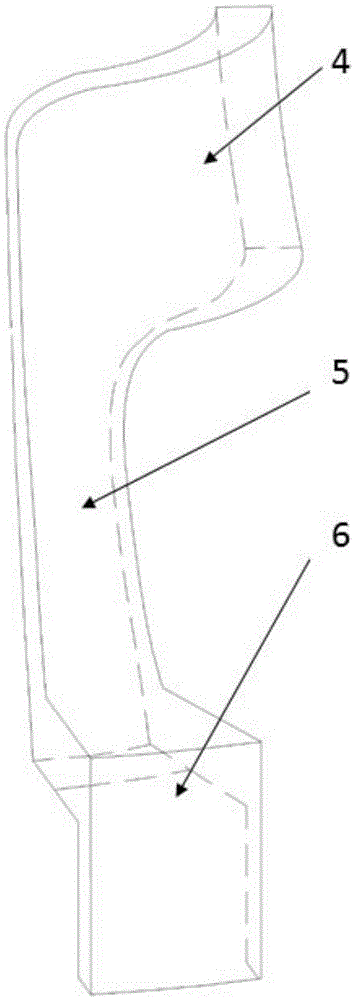

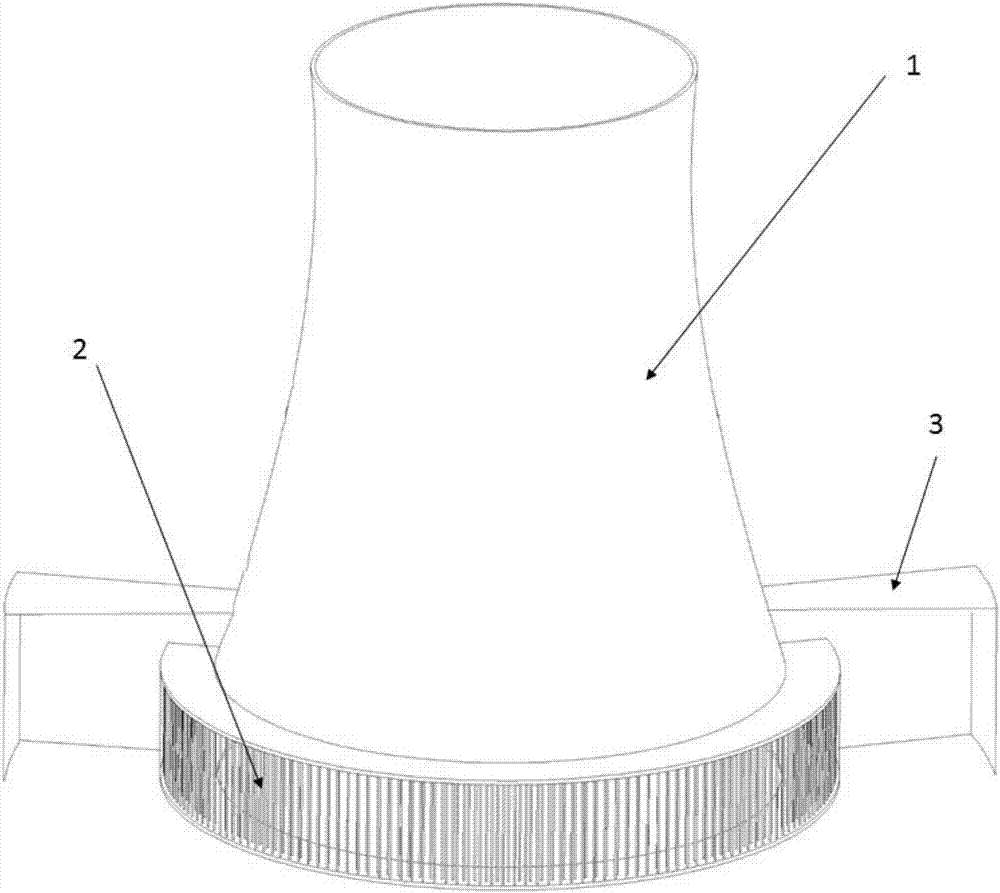

Cross wind recycling type wet cooling tower

InactiveCN105627782AImprove heat dissipationImprove circumferential uniformityHeat exchange apparatusTrickle coolersPower stationCooling Units

The invention discloses a cross wind recycling type wet cooling tower, in particular to a device for conducting flow guide utilization on environmental wind of a wet cooling unit of a power station. The wet cooling tower comprises a wet cooling tower shell, a bottom wind inlet and at least one wind collecting room arranged on the outer side of the bottom wind inlet. The wind collecting rooms are arranged in the circumferential direction of the wet cooling tower and are opened in the incoming flow direction of the environmental wind and are closed on the leeward side. At least one cross wind flow guide structure is arranged on the leeward side of the wet cooling tower. Each cross wind flow guide structure comprises an inlet wind flow guide section, a ventilation pipeline and a back outlet wind flow guide section, wherein the inlet wind flow guide section is opened in the incoming wind direction and is arranged on the upper side of the corresponding wind collecting room along the wet cooling tower shell. By means of the cross wind recycling tower wet cooling tower, due to the arrangement of the wind collecting rooms, the cross wind flow guide structures, wind blocking walls and the like, power sources of environmental cross wind are circumferentially arranged, the circumferential uniformity of inlet wind at the bottom of the wet cooling tower under the environmental wind condition is improved, a flow field structure in the wet cooling tower under the cross wind environment is improved, and therefore the ventilation characteristic and the cooling performance of the wet cooling tower are further enhanced.

Owner:TSINGHUA UNIV +2

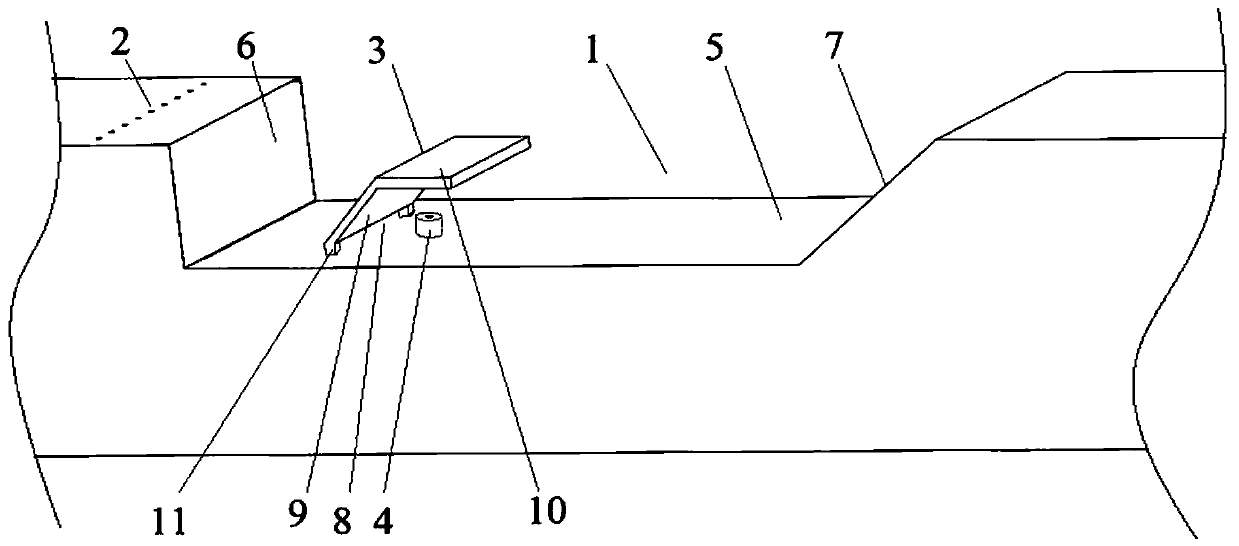

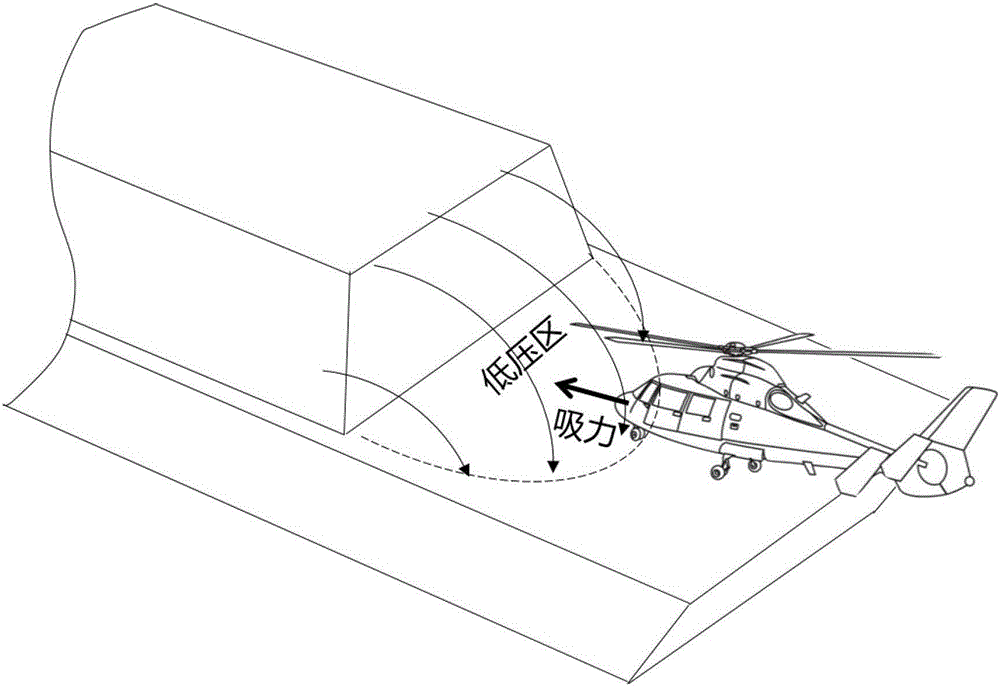

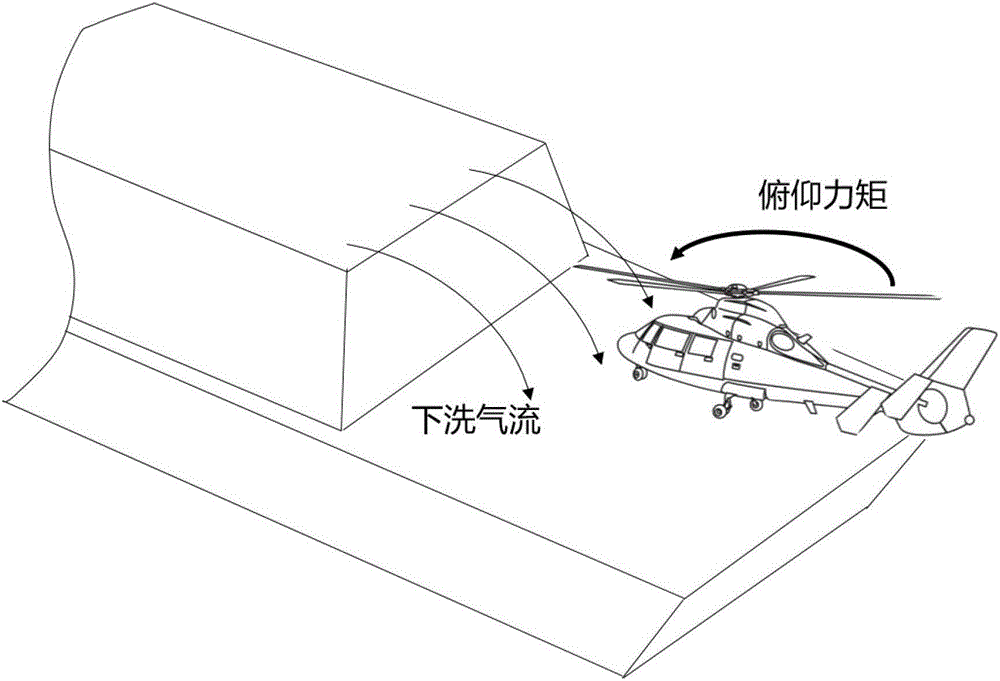

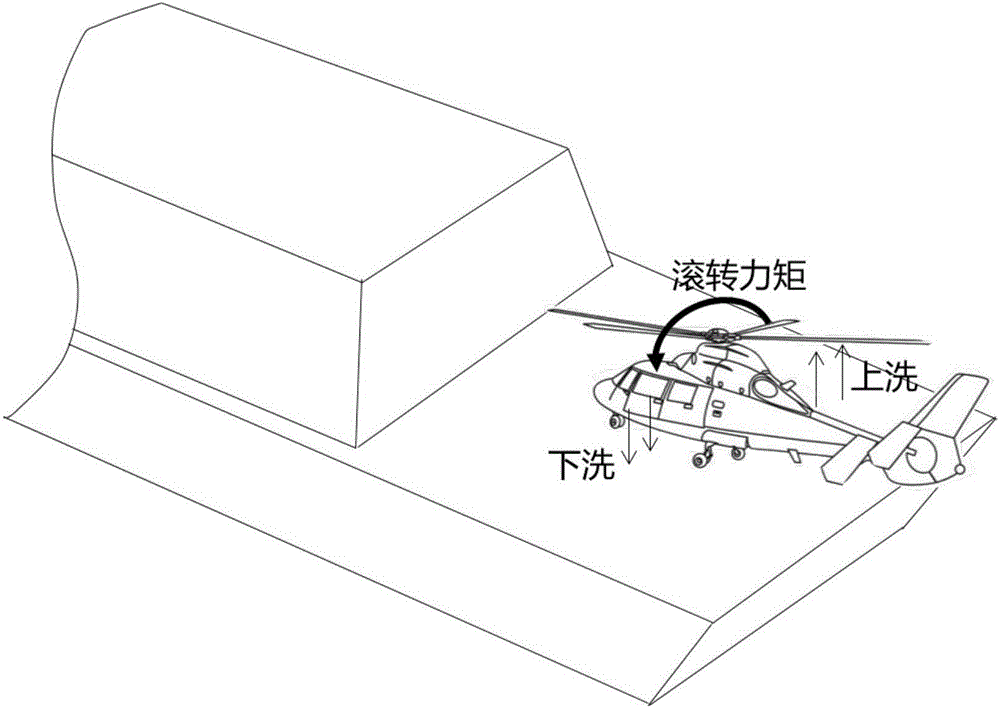

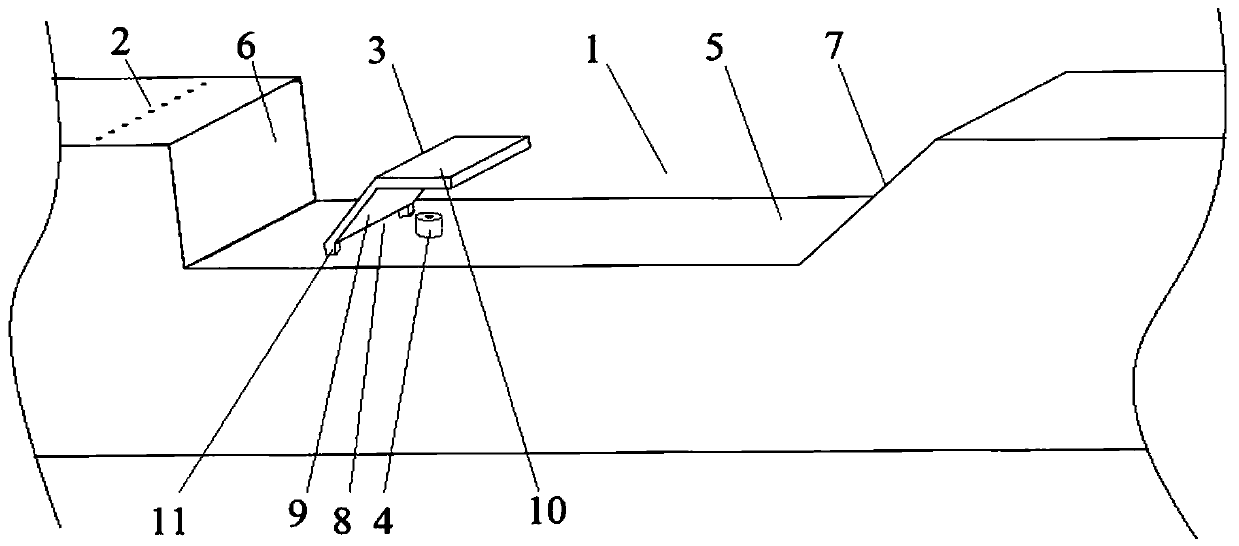

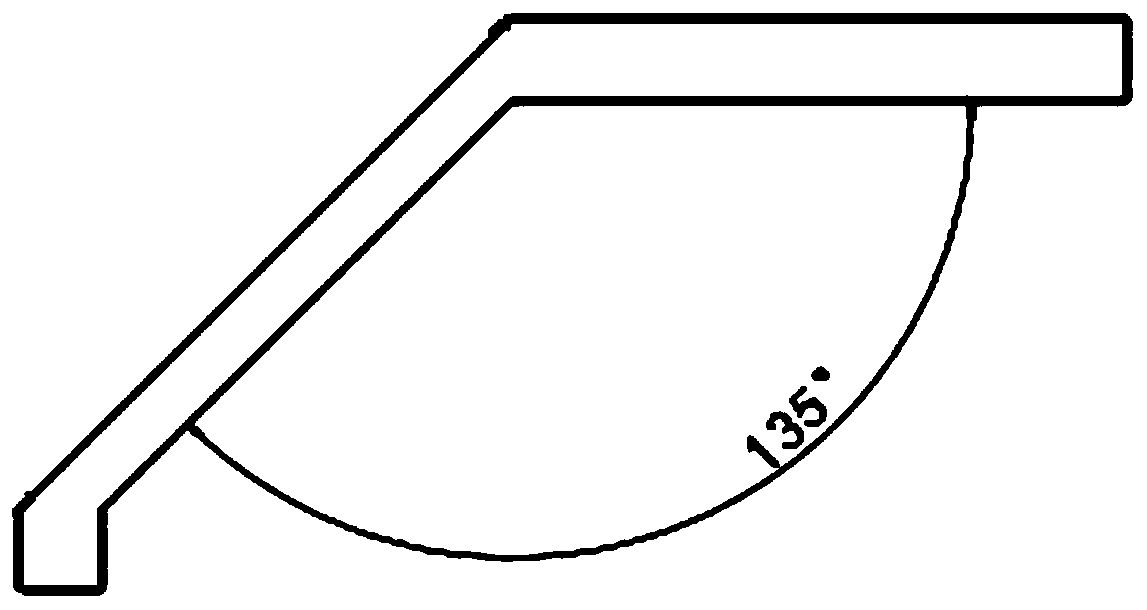

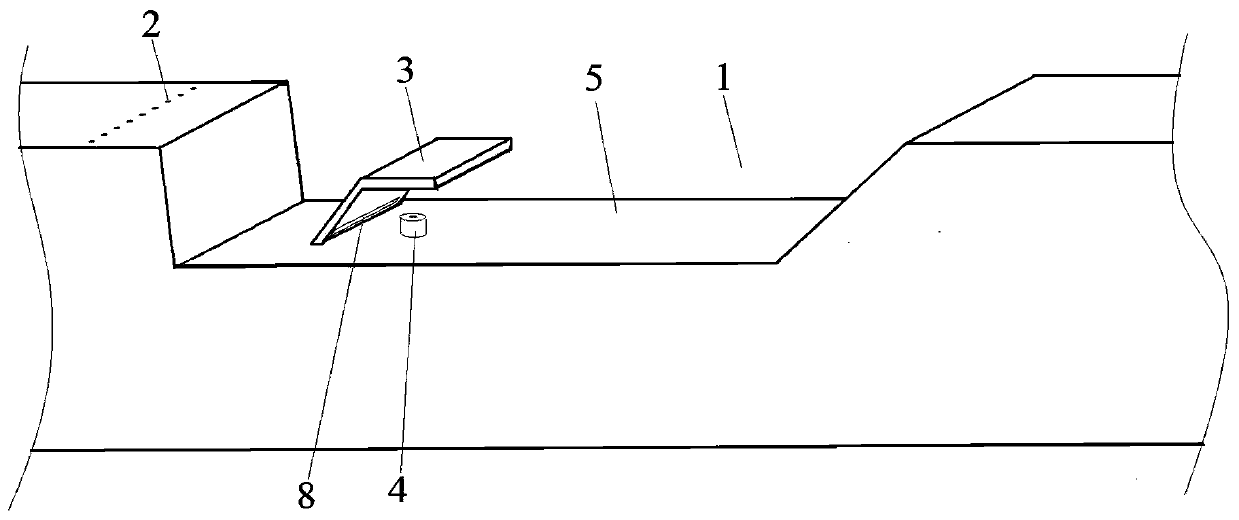

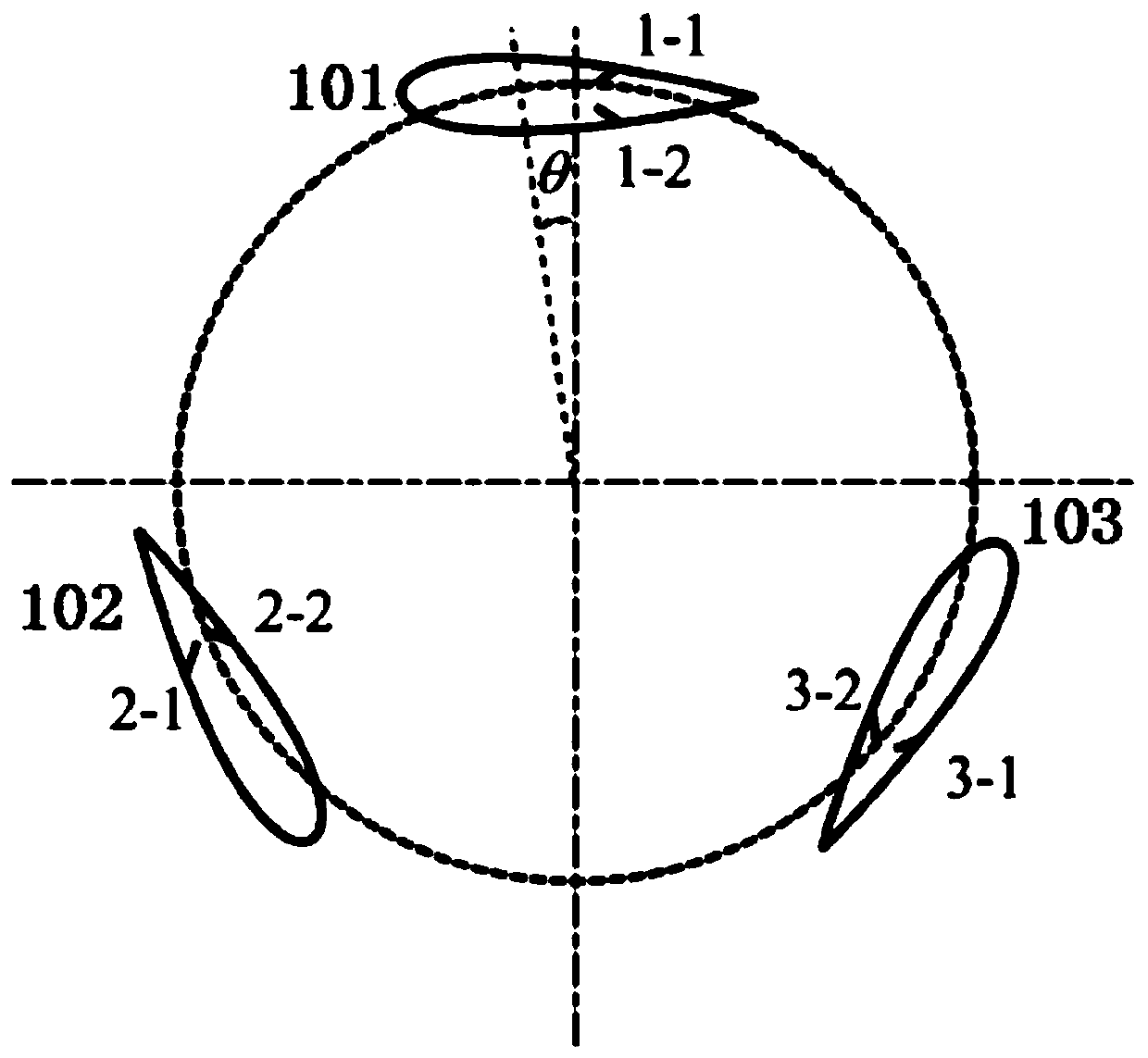

Driving flow control system and method of ship tail flight deck flow field

ActiveCN106828846AImprove flow field structureReduce instabilityAircraft carriersGround installationsMarine engineeringControl system

The invention discloses a driving flow control method of a ship tail flight deck flow field. The driving flow control method of the ship tail flight deck flow field is characterized in that the wind speed and the wind angle of a ship are detected by a wind speed and direction sensor; when a ship-based helicopter takes off or lands, a flow control actuating element is driven by a control unit to generate a control airflow according to the detected wind speed and wind angle, a flow state of a main flow is changed, the ranged of a vortex region is reduced, a high upwash airflow or a downwash airflow is restrained to form, a rolling moment and a yawing moment of the ship-based helicopter during ship landing are weakened, and a flow field structure above a ship tail flight deck is improved. The driving flow control method of the ship tail flight deck flow field is applied to ship types such as a marine surveillance ship with a hangar and a destroyer, a complex flow field above a deck can be controlled, and uniformity of the flow field is improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

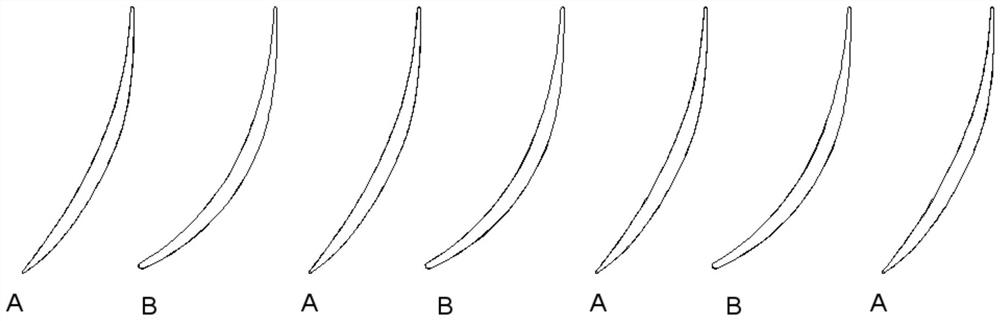

Centrifugal compressor using asymmetrical bladed diffuser with variable mounting angles in circumferential direction

ActiveCN107061322AImprove flow stabilityControl angle of attackPump componentsPump installationsFront edgeDistortion

The invention relates to a centrifugal compressor using an asymmetrical bladed diffuser with variable mounting angles in the circumferential direction, and belongs to the technical field of turbomachinery. The centrifugal compressor comprises a volute, a centrifugal impeller and the bladed diffuser. The inlet front edge positions and the consistency of the bladed diffuser are evenly distributed in the circumferential direction, the diffuser blade mounting angles are asymmetrically distributed in the circumferential direction, and the diffuser blade mounting angles are unequal in different circumferential positions. The compressor can effectively adapt to the circumferential distortion of front edge airflow angles of blades of the diffuser, the attack angle of local flowing airflow is prevented from being too large, the nonuniformity of a flow field in the diffuser is reduced, the flowing stability of the centrifugal compressor is effectively improved, and the stable working range of the centrifugal compressor is enlarged.

Owner:TSINGHUA UNIV +1

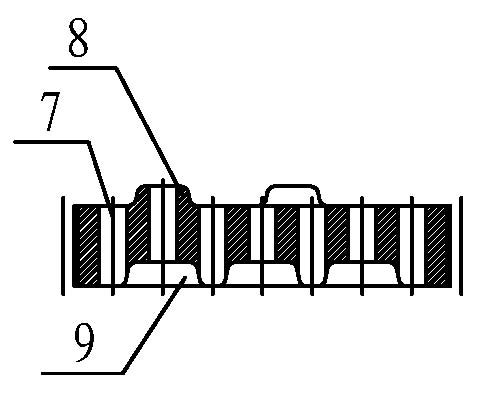

Novel direct-current plasma generator

InactiveCN112351570AImprove stabilityImprove flow field structurePlasma techniquePhysicsCooling coil

The invention discloses a novel direct-current plasma generator which is characterized by comprising a front electrode, a rear electrode, a rotary gas ring, a front electrode cooling mechanism, a rearelectrode cooling mechanism and a water-cooling coil, one end of the front electrode is fixedly connected with one end of the rotary gas ring, and the other end of the rotary gas ring is fixedly connected with one end of the rear electrode; the front electrode cooling mechanism is arranged on the outer side of the front electrode, the rear electrode cooling mechanism is arranged on the rear electrode, the water cooling coil is arranged on the front electrode cooling mechanism, a spray pipe arranged in the axis direction is arranged in the front electrode and comprises a spray pipe straight section, a spray pipe expansion section and a spray pipe outlet straight section, and a blind hole in the rear electrode is of a tail gradual expansion type well-shaped structure. The service life of the electrode is prolonged, and the hazardous waste disposal effect is greatly enhanced.

Owner:JIANGSU TIANYING PLASMA TECH CO LTD +1

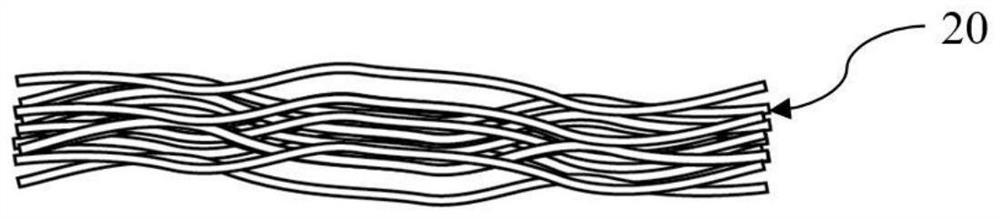

Efficient membrane humidifier for fuel cell

PendingCN112103534AReduce resistanceExtend membrane tube lifeFuel cellsHeat transfer efficiencyEngineering

The invention discloses a fuel cell efficient membrane humidifier which at least comprises a shell, opposite humidifying medium inlets and outlets are formed in the two sides of the shell, a flow guide cavity is formed in the shell, and the humidifying medium inlets and outlets are communicated with the flow guide cavity; a membrane humidifying assembly is arranged between the flow guide cavitiesin the two sides of the interior of the shell and is at least provided with humidifying membrane pipes arranged in a square matrix mode; connecting flow guide end covers are arranged on the two sides,adjacent to the inlet and outlet, of the shell, and the flow guide end covers on the two sides communicate with air guide openings. By means of the structure, the impact and separation effect betweenpipe bundles of the humidification film pipe can be effectively reduced, disturbance in a flow field is reduced, and the flow distribution uniformity of humidification media on the outer side of thehumidification film pipe is improved; the air flow in the humidifying membrane tube is smoother, the membrane tube is prevented from vibrating, the resistance in the membrane tube is reduced, and theservice life of the membrane tube is prolonged; in addition, the uniform gaps formed in the longitudinal direction of the humidifying film pipe increase the filling rate of the film pipe and meanwhiledo not increase resistance, and therefore the mass and heat transfer efficiency of the whole humidifier is improved.

Owner:天朤(江苏)氢能源科技有限公司

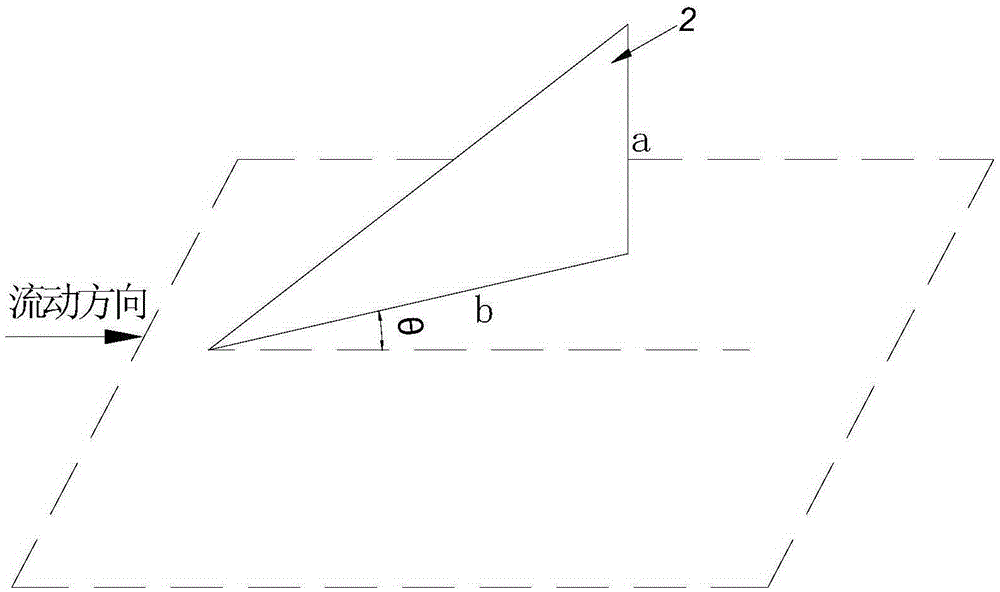

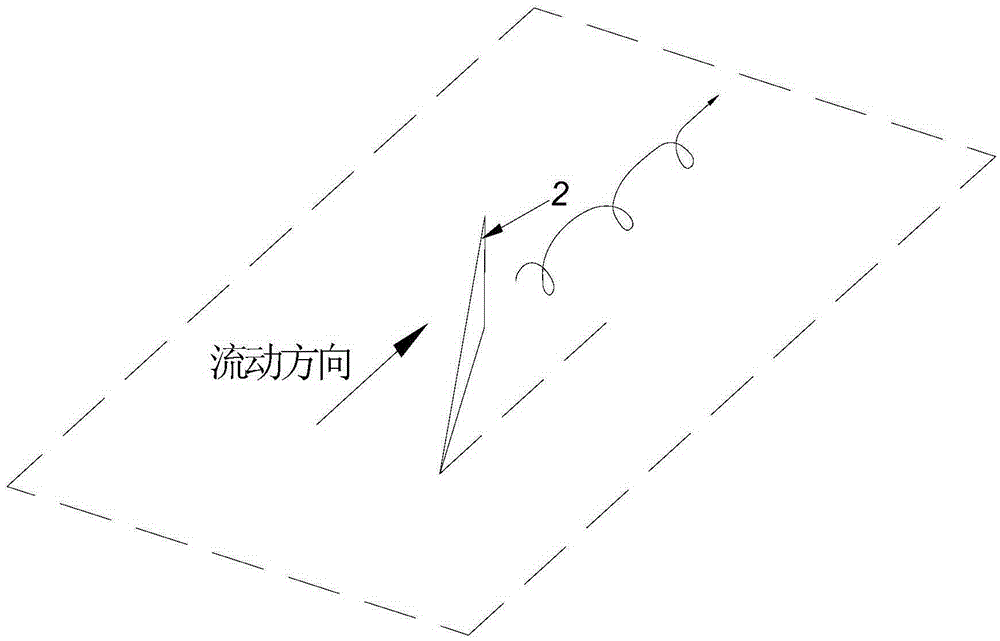

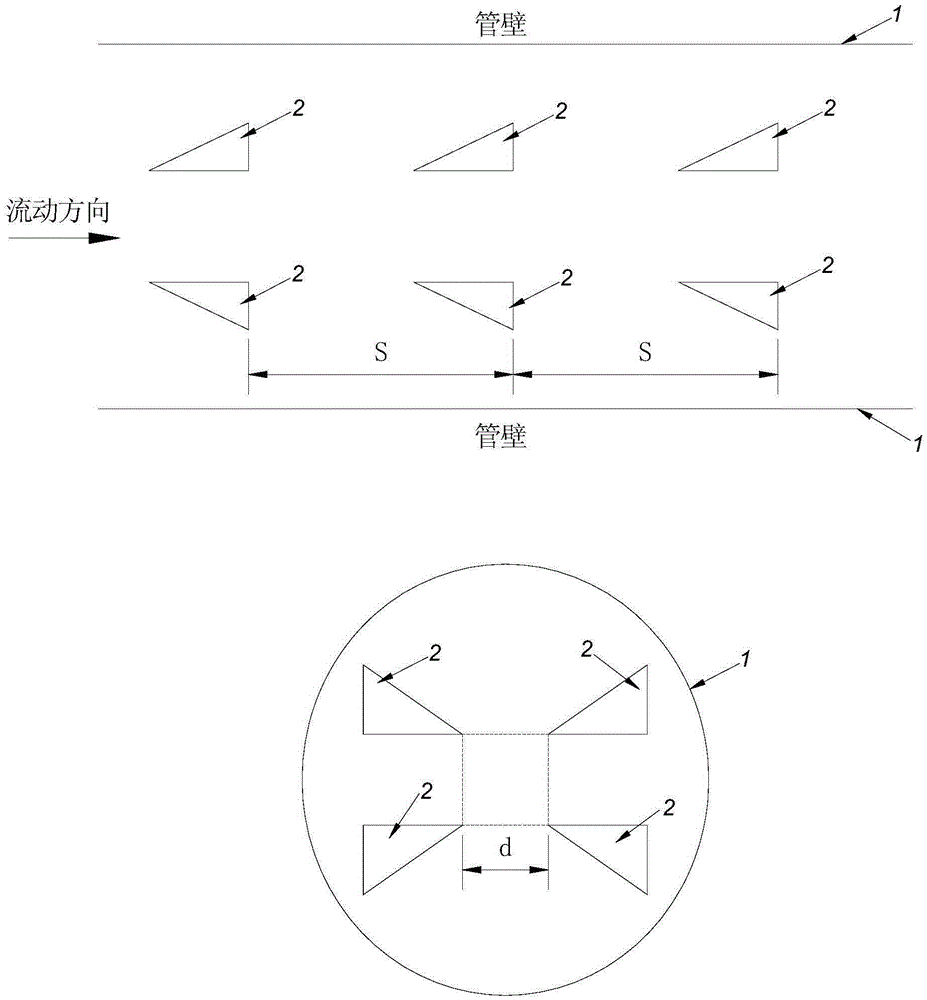

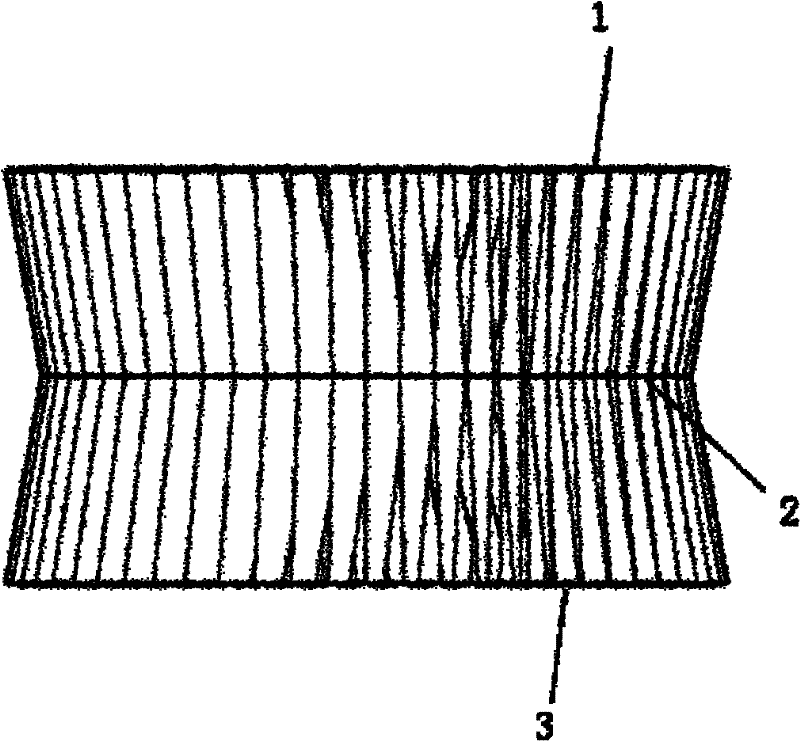

Longitudinal vortex synergistic-action heat transmission element

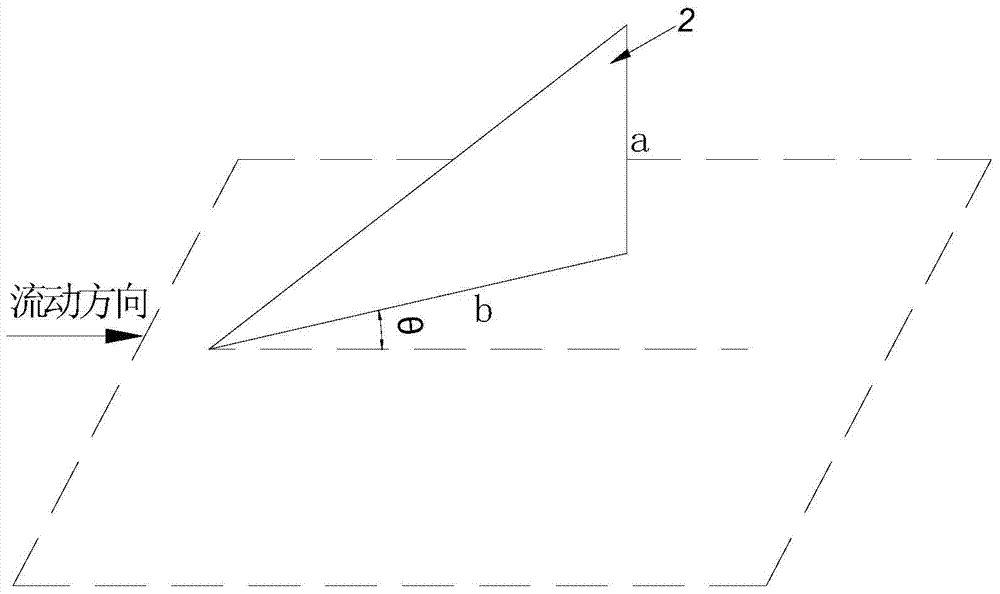

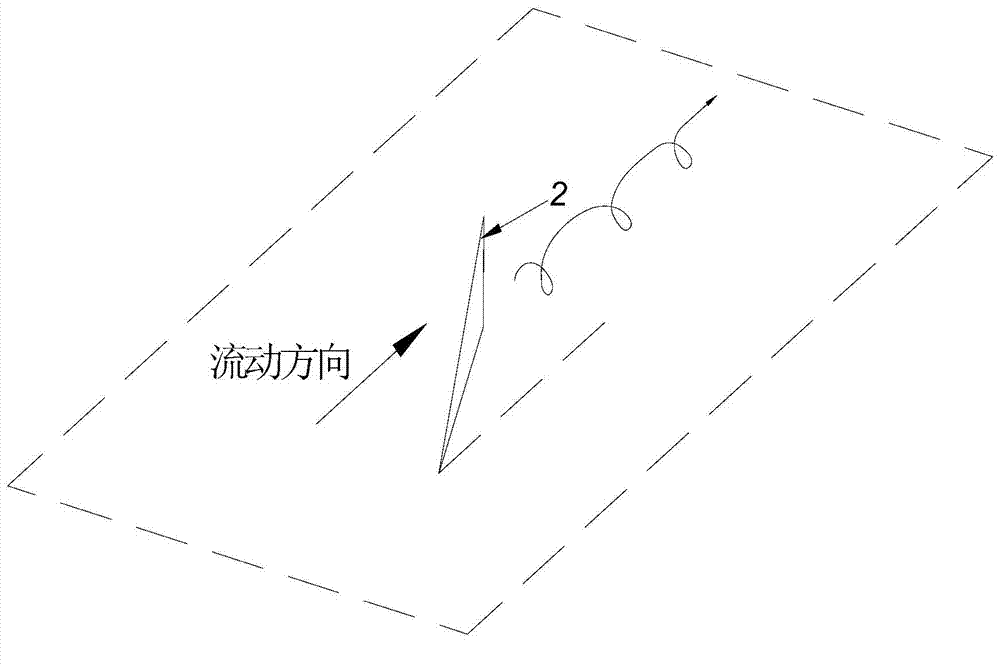

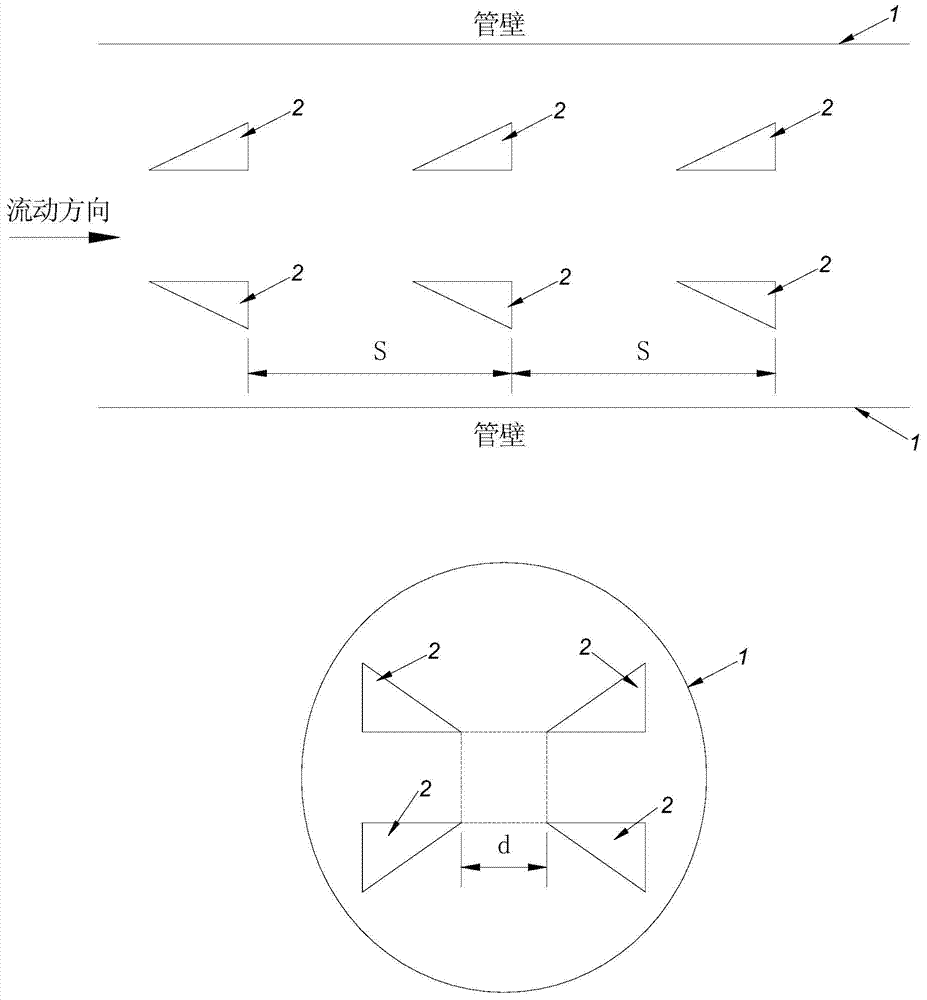

ActiveCN103940283AIncrease flow resistanceImprove flow field structureHeat exchanger casingsRight triangleVertical plane

The invention discloses a longitudinal vortex synergistic-action heat transmission element. The longitudinal vortex synergistic-action heat transmission element comprises a metal pipe and further comprises a plurality of spoiler sets, wherein each spoiler set comprises a plurality of spoilers which are even in number and of a right-triangle structure; the spoilers in the same spoiler set are distributed in a central symmetry and axial symmetry mode with respect to the central axis of the metal pipe; the top points of acute angles of the right-angle sides b of the spoilers in the same spoiler set are located on the same vertical plane, the right-angle sides a of the spoilers in the same spoiler set are perpendicular to the central axis of the metal pipe, and a certain deviation angle theta is formed between the right-angle side b of each spoiler and the central axis of the metal pipe; the spoiler sets are distributed in the metal pipe along the central axis of the metal pipe with a certain separation distance. According to the longitudinal vortex synergistic-action heat transmission element, by means of the spoiler sets in the metal pipe, speed vector synergistic match on the cross section of longitudinal vortexes generated in a heat transmission pipe can be achieved, a flow field structure is optimized, heat exchange is enhanced, and meanwhile increase of flow resistance in the metal pipe is effectively reduced.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

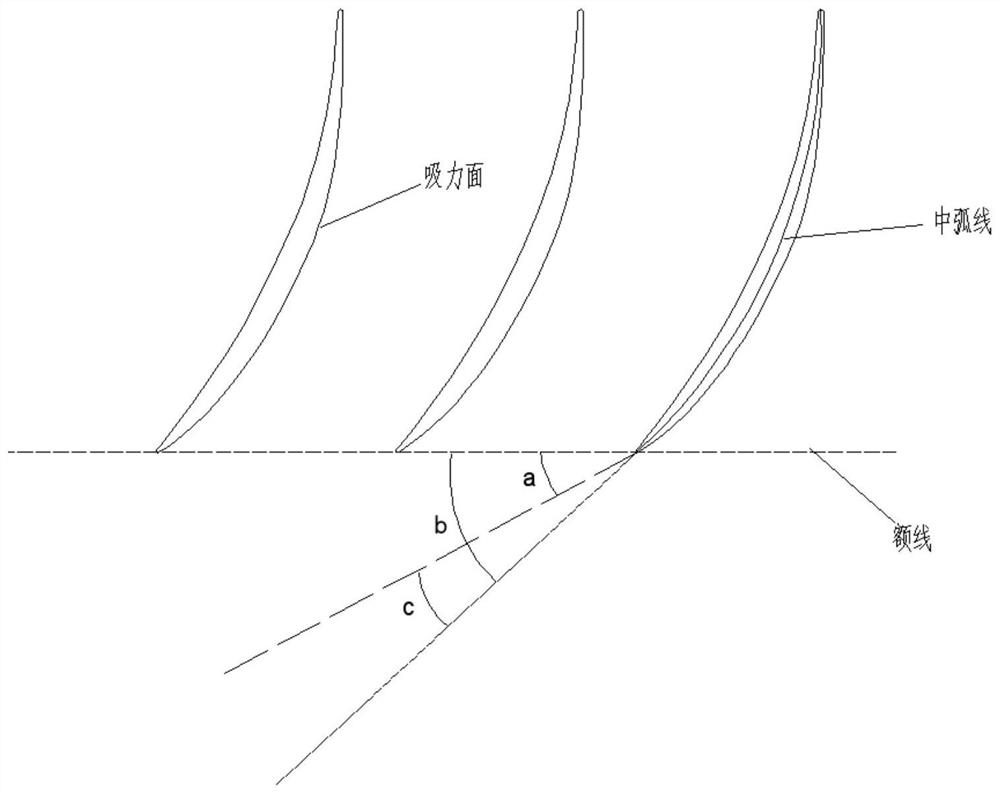

Axial flow compressor for improving full-cycle flow field

PendingCN113864243AReduce or even eliminate flow separation rangeEliminates flow separation rangePump componentsPumpsSuction forceMechanical engineering

The invention provides an axial flow compressor for improving a full-cycle flow field. In full-cycle stationary blades of a stator, large attack angle blades and small attack angle blades are alternately arranged, and the flow channel gaps among the blades are the same. In the full-cycle stationary blades of the stator, prototype blades and modified blades are alternately arranged, the gaps between the prototype blades and the two adjacent modified blades are the same, and the attack angle of the modified blades is smaller than that of the prototype blades. According to the axial flow compressor, the prototype blades in a prototype stator are partially or completely replaced by the modified blades capable of inhibiting the angular region separation of the suction surface, so that the structure of the full-cycle flow field is improved, and the through-flow capability is improved. According to the structure, stable operation under the working condition that an original stator blade profile can operate can be guaranteed, meanwhile, the flow field structure under the near-stall working condition can be greatly improved, and the flow separation range of an angular region of the suction surface is reduced or even eliminated.

Owner:CIVIL AVIATION UNIV OF CHINA

Culvert device of horizontal axis wind-driven generator

InactiveCN101865074BImprove mute effectLow start wind speedMachines/enginesWind energy generationWind drivenHorizontal axis

The invention relates to a culvert device of a horizontal axis wind-driven generator. The culvert device is arranged on the horizontal axis wind-driven generator, and flow field structures around the horizontal axis wind-driven generator are reasonably arranged by using appearance design of inner and outer surfaces of a culvert. The device mainly comprises an inner flow passage formed inside the culvert and an outer flow passage formed outside the culvert; the outer flow passage comprises an external acceleration section (2), an external transition section (3) and an external deceleration section (4); the inner flow passage comprises an internal acceleration section (9), an internal transition section (10) and an internal deceleration section (11); suction passages (6) for connecting the inner and outer flow passages of the culvert are formed between the inner and outer flow passages; the opening size of the suction passages (6) is controlled through a baffle plate; and a plurality ofsuction passages (6) are uniformly distributed in the wall between the inner and outer flow passages. The device controls a suction device according to the working condition of the culvert wind-driven generator, and the working condition of a wind blade is improved by adjusting the opening size of the suction device.

Owner:JILIN UNIV

Centrifugal Compressor Using Asymmetric Lobe Diffuser with Circumferentially Variable Blade Consistency

ActiveCN107061368BImprove flow field structureImprove performancePump componentsPumpsFront edgeDistortion

The invention relates to a centrifugal compressor using an asymmetrical bladed diffuser with variable blade consistencies in the circumferential direction, and belongs to the technical field of turbomachinery. The centrifugal compressor comprises a volute, a centrifugal impeller and the bladed diffuser. The inlet front edge positions and the bladed mounting angles are evenly distributed in the circumferential direction, the blade consistencies are asymmetrically distributed in the circumferential direction, and the consistencies are unequal in different circumferential positions. The blade consistencies are changed by changing the central angles (namely the front edge interval between every two adjacent blades) corresponding to flow channels. The compressor can effectively adapt to the downstream circumferential pressure distortion of the bladed diffuser, the nonuniformity of a flow field in the bladed diffuser is reduced, the flowing stability of the centrifugal compressor is effectively improved, and the stable working range of the centrifugal compressor is enlarged.

Owner:TSINGHUA UNIV +1

Ignition device and scramjet in supersonic cavity combustion chamber

ActiveCN110822480BStable and reliable combustionNo total pressure lossContinuous combustion chamberRamjetCombustion chamber

The invention provides an ignition device in a supersonic concave cavity combustion chamber and a super-combustion stamping engine. The supersonic combustion chamber is internally provided with a fuelinjection hole and a concave cavity, the fuel injection hole is arranged at the upper stream of the concave cavity, and the fuel injected through the fuel injection hole propagates in the direction of the supersonic airflow propagation in a main flow channel of the supersonic combustion chamber; and a flow guide plate is obliquely arranged on the bottom wall of the concave cavity in the directionof the supersonic airflow propagation in the main flow channel, the lower end of the flow guide plate is connected to the bottom wall of the concave cavity, a gap is formed in the lower end of the flow guide plate, and a spark plug used for ignition is arranged on the portion, below the inner side of the flow guide plate, of the bottom wall of the concave cavity. According to the ignition device,the flow guide plate is applied to the interior of the concave cavity so as to improve the local flow rate and the equivalence ratio in the concave cavity, so that the ignition enhancement effect isachieved.

Owner:NAT UNIV OF DEFENSE TECH

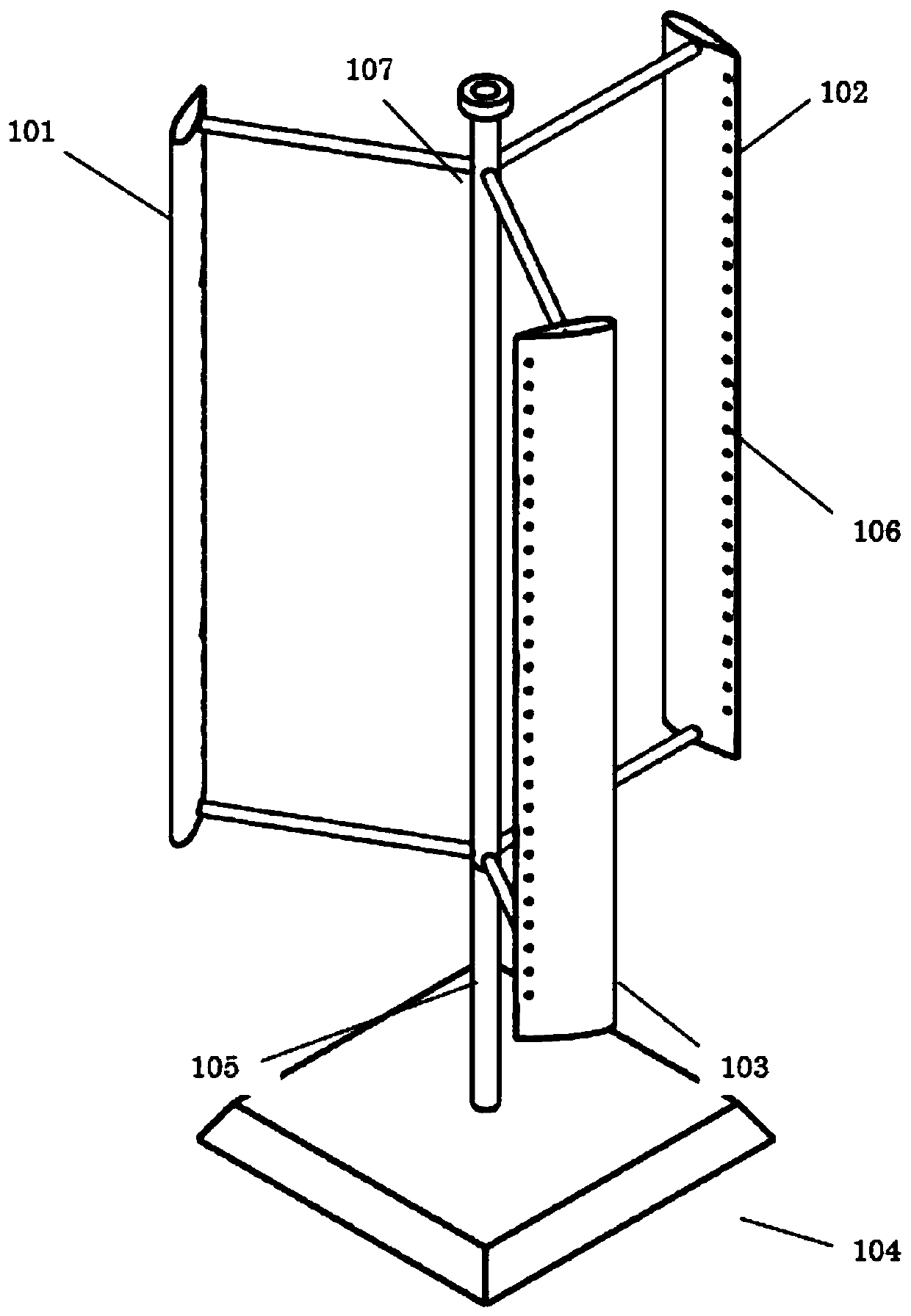

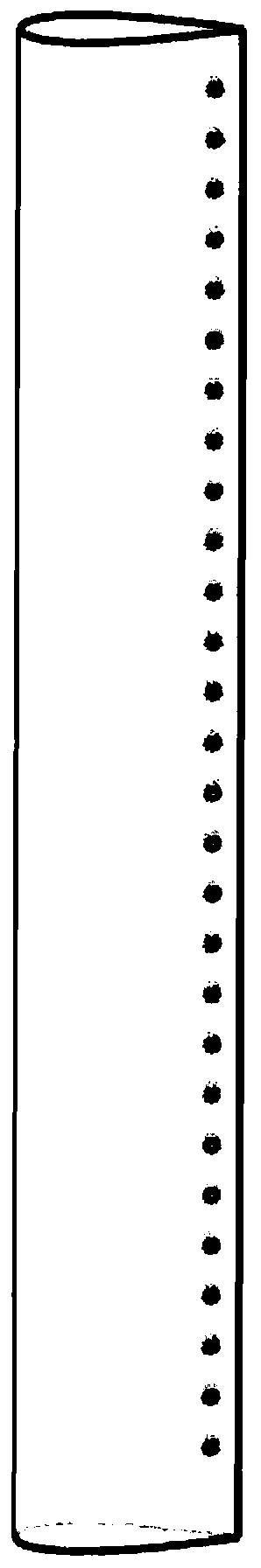

A vertical axis wind turbine blade assembly and synthetic jet control method thereof

ActiveCN108150348BReduce vibration amplitudeReduce vibration frequencyWind motor controlRenewable energy generationElectricityVertical axis wind turbine

The invention discloses a vertical axis wind turbine blade module and a synthesized jet control method thereof. The vertical axis wind turbine blade module is arranged on a base of a vertical axis wind turbine, and comprises multiple blade bodies, synthesized jet exciters and multiple jet holes, wherein the upper and lower ends of each blade body are fixed on a rotating shaft of the vertical axiswind turbine through fixed rod pieces; the synthesized jet exciters are uniformly and serially arranged in the blade bodies in the blade height directions of the blade bodies; the multiple jet holes are formed in the tail edges of the blade bodies; the synthesized jet exciters comprise shells, piezoelectric films, jet channels, piezoelectric drivers and control boxes, wherein the shells are squares, and are provided with upper openings and the lower openings; the piezoelectric films are squares, and cover the lower openings; the jet channels communicate with the upper openings; the piezoelectric drivers are arranged below the piezoelectric films, and are driven by rectangular pulse signals to generate a reverse piezoelectric effect so as to drive the square piezoelectric films to periodically vibrate up and down; and the control boxes are arranged above rotating shafts, are electrically connected with the piezoelectric drivers, and are used for inputting the rectangular pulse signals to the piezoelectric drivers.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

A side wind recovery type air cooling tower

The invention discloses a cross wind recycling type air cooling tower and relates to a device for conducting flow guide utilization on environmental wind of an air cooling unit of a power station. The air cooling tower comprises an air cooling tower shell, a bottom wind inlet and at least one wind collecting room arranged on the outer side of the bottom wind inlet. The wind collecting rooms are arranged in the circumferential direction of the air cooling tower and are opened in the incoming flow direction of the environmental wind and are closed on the leeward side. At least one cross wind flow guide structure is arranged on the leeward side of the air cooling tower. Each cross wind flow guide structure comprises an inlet wind flow guide section, a ventilation pipeline and a back outlet wind flow guide section, wherein the inlet wind flow guide section is opened in the incoming wind direction and is arranged on the upper side of the corresponding wind collecting room along the air cooling tower shell. By means of the cross wind recycling tower air cooling tower, due to the arrangement of the wind collecting rooms, the cross wind flow guide structures, wind blocking walls and the like, power sources of environmental cross wind are circumferentially arranged, the circumferential uniformity of inlet wind at the bottom of the air cooling tower under the environmental wind condition is improved, a flow field structure in the air cooling tower in the cross wind environment is improved, and therefore the ventilation characteristic and the cooling performance of the air cooling tower are further enhanced.

Owner:TSINGHUA UNIV +2

Centrifugal compressor with asymmetrical vaned diffuser with circumferentially variable vane installation angle

ActiveCN107061322BImprove flow stabilityControl angle of attackPump componentsPump installationsFront edgeDistortion

The invention relates to a centrifugal compressor using an asymmetrical bladed diffuser with variable mounting angles in the circumferential direction, and belongs to the technical field of turbomachinery. The centrifugal compressor comprises a volute, a centrifugal impeller and the bladed diffuser. The inlet front edge positions and the consistency of the bladed diffuser are evenly distributed in the circumferential direction, the diffuser blade mounting angles are asymmetrically distributed in the circumferential direction, and the diffuser blade mounting angles are unequal in different circumferential positions. The compressor can effectively adapt to the circumferential distortion of front edge airflow angles of blades of the diffuser, the attack angle of local flowing airflow is prevented from being too large, the nonuniformity of a flow field in the diffuser is reduced, the flowing stability of the centrifugal compressor is effectively improved, and the stable working range of the centrifugal compressor is enlarged.

Owner:TSINGHUA UNIV +1

A longitudinal vortex co-generation heat transfer element

ActiveCN103940283BIncrease flow resistanceImprove flow field structureHeat exchanger casingsRight triangleVertical plane

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

A vertical axis wind turbine

ActiveCN107035614BImprove the lift-to-drag ratioLarge output torqueWind motor controlRenewable energy generationAir velocityMarine engineering

The invention discloses a vertical axis wind power generator, which belongs to the field of wind power generation equipment and includes a wind power machine, a gearbox, and a generator. The wind power machine includes a vertical shaft and several blades. The two support plates are installed vertically on the vertical rotating shaft at equal intervals in the circumferential direction; the front edge of the blade is provided with a cavity, and the opening of the cavity is covered with a flexible film. The vertical axis wind power generator provided by the present invention adopts partial flexible blades, and has better aerodynamic performance compared with traditional rigid airfoils; at the same wind speed, it can effectively improve the lift-to-drag ratio of the wind turbine blades, increase the output torque of the wind turbine, and broaden the The range of effective working conditions of the blades of the wind turbine can realize the effective utilization of wind energy at low wind speeds, and the structure is simple and easy to control.

Owner:XI AN JIAOTONG UNIV

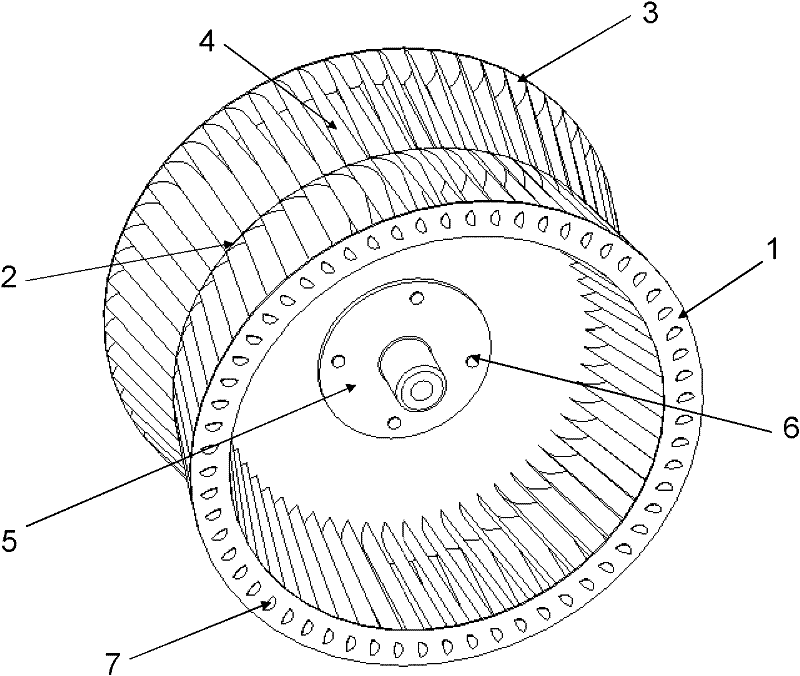

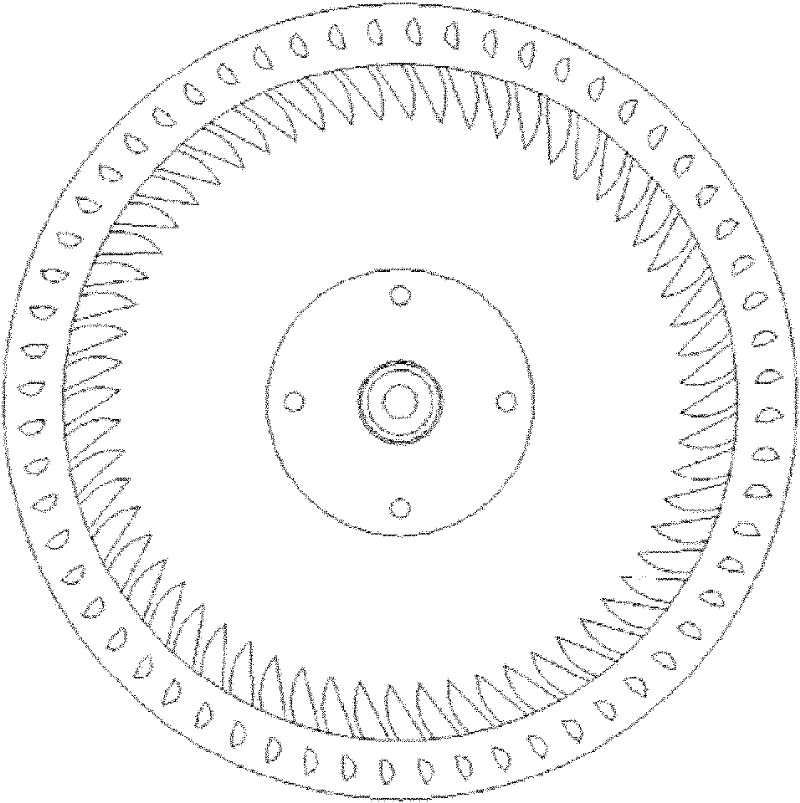

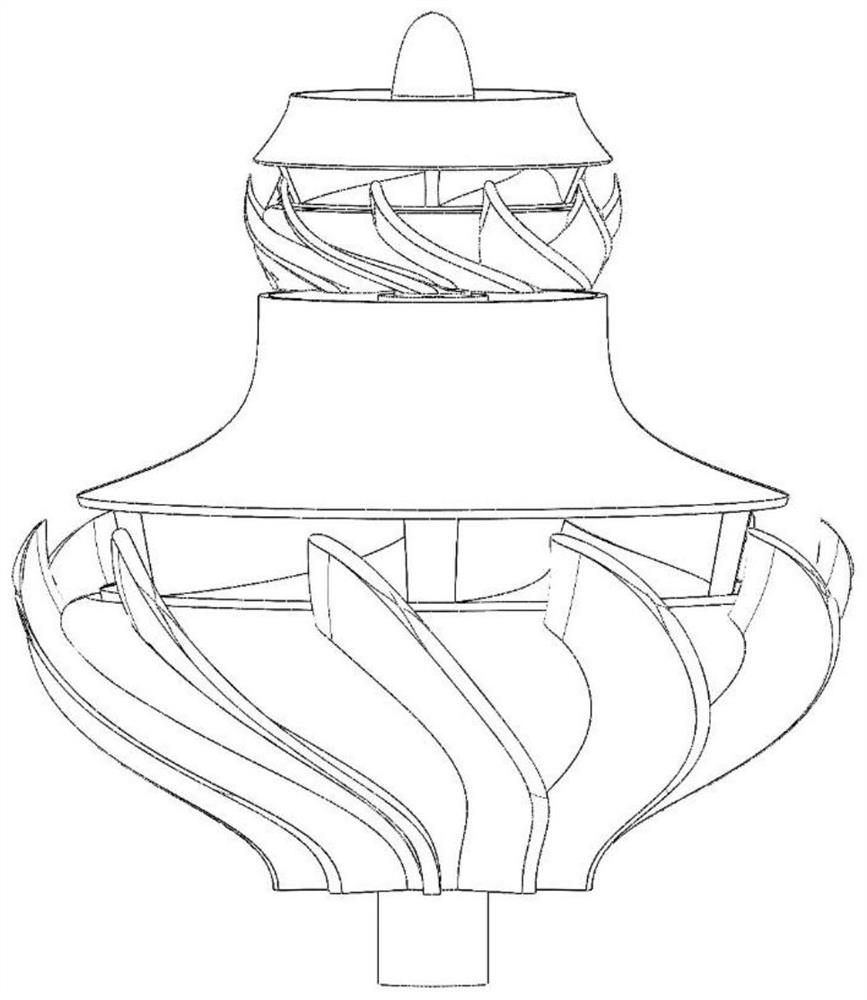

Biconical impeller for range hood

The invention provides a biconical impeller for a range hood. The biconical impeller is composed of an impeller front enclosed ring, an impeller central disk, an impeller rear enclosed ring and blades, wherein, the blades are vertically arranged between the impeller front enclosed ring and the impeller central disk and between the impeller rear enclosed ring and the impeller central disk, and thediameter of the impeller front enclosed ring and diameter of the impeller rear enclosed ring are respectively greater than that of the impeller central disk. By utilizing the biconical impeller provided by the invention, the air quantity of a fan is increased and simultaneously noise is effectively reduced.

Owner:XI AN JIAOTONG UNIV

A device for dissipating impeller wake vortex in stall condition of mixed flow pump

ActiveCN113153803BImprove efficiencyExpand the flow working rangePump componentsPumpsImpellerMixed flow

The invention discloses a wake vortex dissipating device for an impeller in a stall condition of a mixed-flow pump, which includes a guide vane and a wake vortex dissipating device; N uniformly distributed guide vanes divide the inside of the pump into N guide vane channels; A wake vortex dissipation device is installed in each guide vane flow channel, and one end of the wake vortex dissipation device is fixedly connected to the inner wall of the pump, so each wake vortex dissipation device is located in the middle and upper part of the guide vane flow channel, and does not occupy the guide vane below. The blade flow channel; the wake vortex dissipating device is provided with a pair of dissipation holes, and the energy of the wake vortex of the impeller is dissipated by using the pair of dissipation holes.

Owner:JIANGSU UNIV

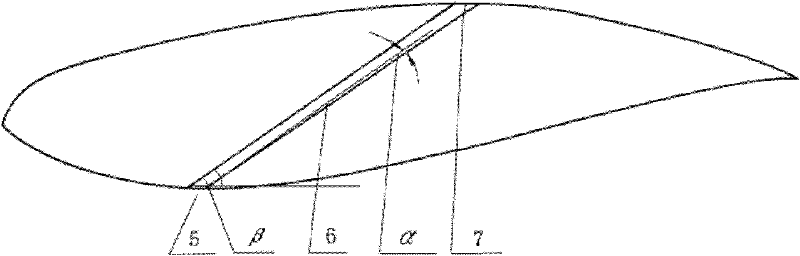

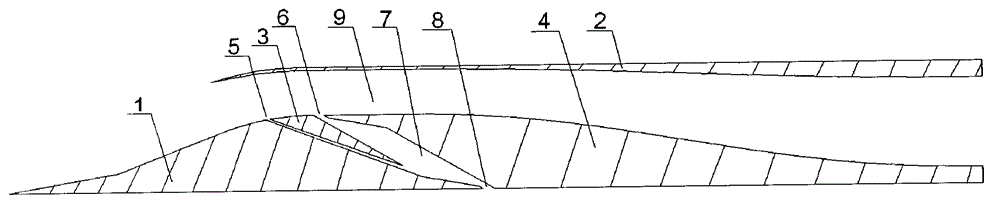

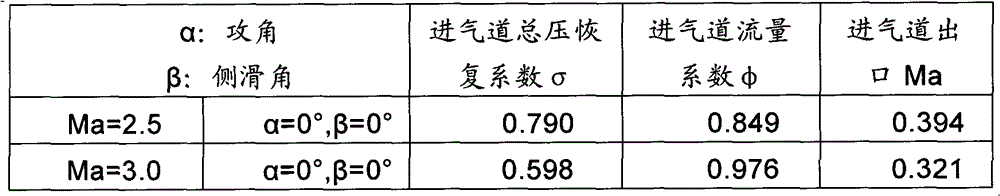

Binary mixed pressure intake duct applied to supersonic solid ramjet

InactiveCN102817716BSimple suction structureSuction structure without damageTurbine/propulsion air intakesRamjetLeading edge

A binary mixed pressure intake duct applied to supersonic solid ramjet comprises an upper part outer cover and a lower part containing a front body, a baffle plate and a back body. A ventilation channel is between the upper part and the lower part; and a section with equivalent height of the ventilation channel is a throat, which is arranged at the back of a leading edge of the outer cover; the baffle plate is clamped between the front body and the back body; a boundary layer auxiliary suction channel communicating with the ventilation channel of the binary mixed pressure intake duct is arranged between the front body and the baffle plate, and a communicating position is an inlet of the boundary layer auxiliary suction channel; a boundary layer suction cavity is between the baffle plate and the back body and communicates with the throat, and a communicating position is an inlet of the boundary layer suction cavity; the outlet of the boundary layer auxiliary suction channel enters into the boundary layer suction cavity; and the boundary layer suction cavity outlet is arranged between the front body and the back body. The invention has simple and convenient structure, does not occupy space in the intake duct, and can fully eliminate influences of the boundary layer on the intake duct and effectively improve the performance of the intake duct at a low suction flow.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

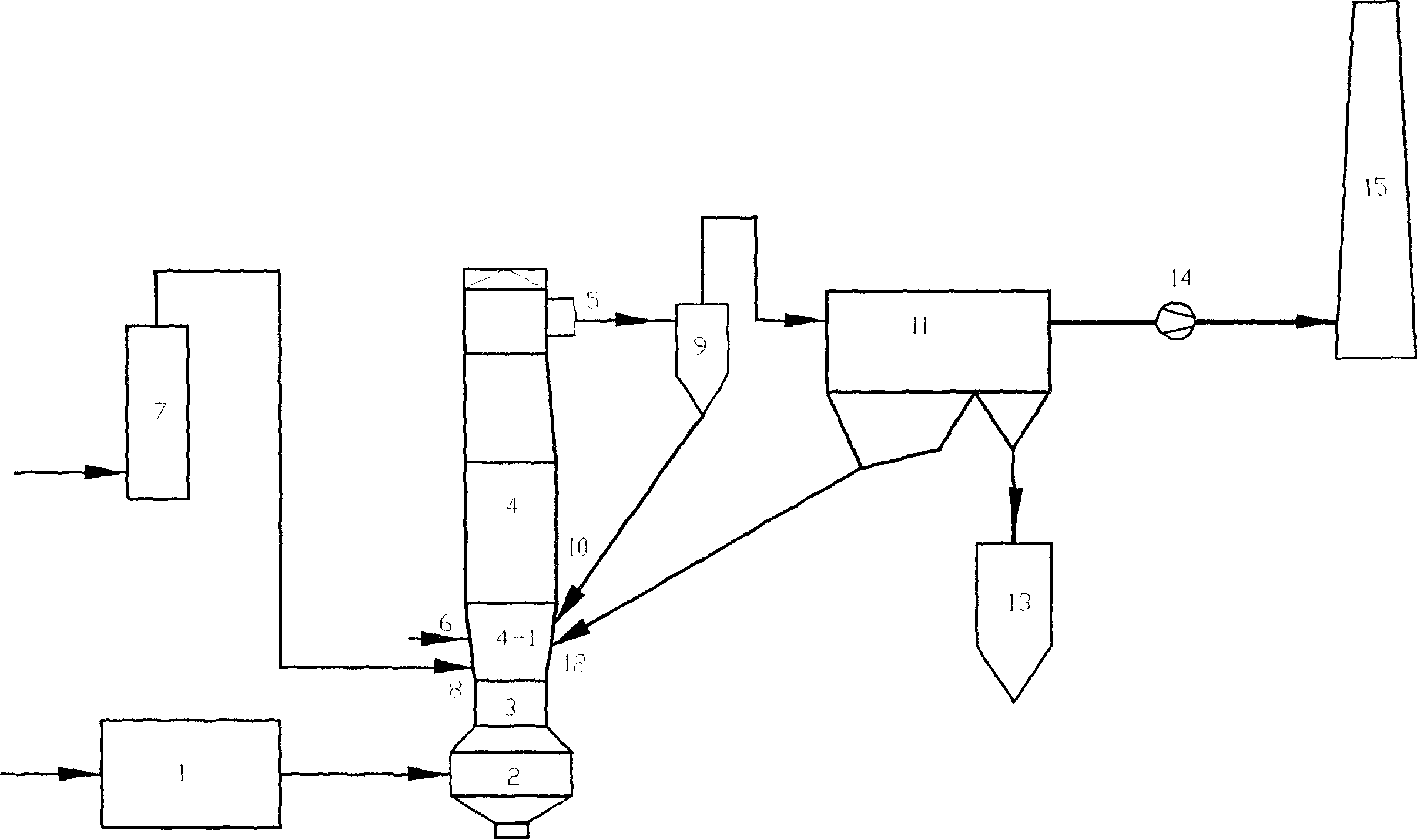

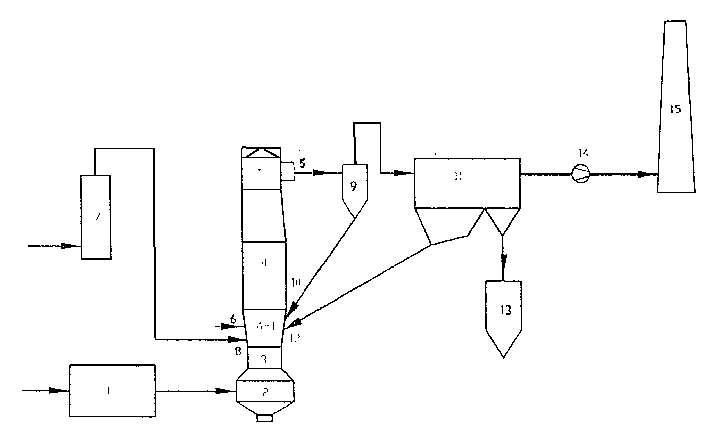

Smoke desulfurizing process by circulation fluid state dry method of layered feed back

The present invention relates to external grain re-circulating technology in large circular fluidizing dry fume desulfurizing system. The desulfurizing process includes preparing desulfurizing agent, desulfurizing reaction inside the desulfurizing reaction tower and external desulfurizing agent grain separation and re-circulation. In the external grain re-circulation, the returned material is two-stage separated and re-circulated, the grains separated by the first stage and the second stage desulfurizing agent grain separator are fed to the fluidizing region in the lower part of the desulfurizing reaction tower separately through different re-circulation inlets, resulting in raised desulfurizing agent grain utilization and desulfurizing reaction efficiency. Compared with available technology, the present invention has much higher fume dedusting efficiency, high desulfurizing efficiency up to 92 % at Ca / S of 1.1-1.3, less adhesion and blocking in the lower desulfurizing tower part and lowered load of the desulfurizing agent grain separator.

Owner:WUHAN KAIDI ELECTRIC POWER CO LTD

Impeller structure of artificial heart pump

PendingCN114712701AImprove pumping efficiencyHigh blood efficiencyBlood pumpsIntravenous devicesMechanical engineeringArtificial heart

The invention provides an impeller structure of an artificial heart pump, which comprises two groups of centrifugal pump blades, two centrifugal pump upper cover plates and two flow guide cones, and further comprises a corresponding shell which comprises an outer shell, one to two groups of guide blades and one to two flow guide cones, so that a special structure of the impeller structure is formed, and miniaturization and blood compatibility optimization of the artificial heart pump can be realized. The multi-stage centrifugal pump structure which is small in appearance and good in blood compatibility is adopted, the artificial heart pump structure which is simple and compact is constructed, the multiple centrifugal pump blades are connected in series in the structure, higher-efficiency blood pumping can be achieved in a more compact space, meanwhile, the flow guide cone structure is added, and the structure is more compact. The flow field structure of the heart pump can be effectively improved, good transition of flow fields of all centrifugal pumps is achieved, and blood compatibility is improved.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com