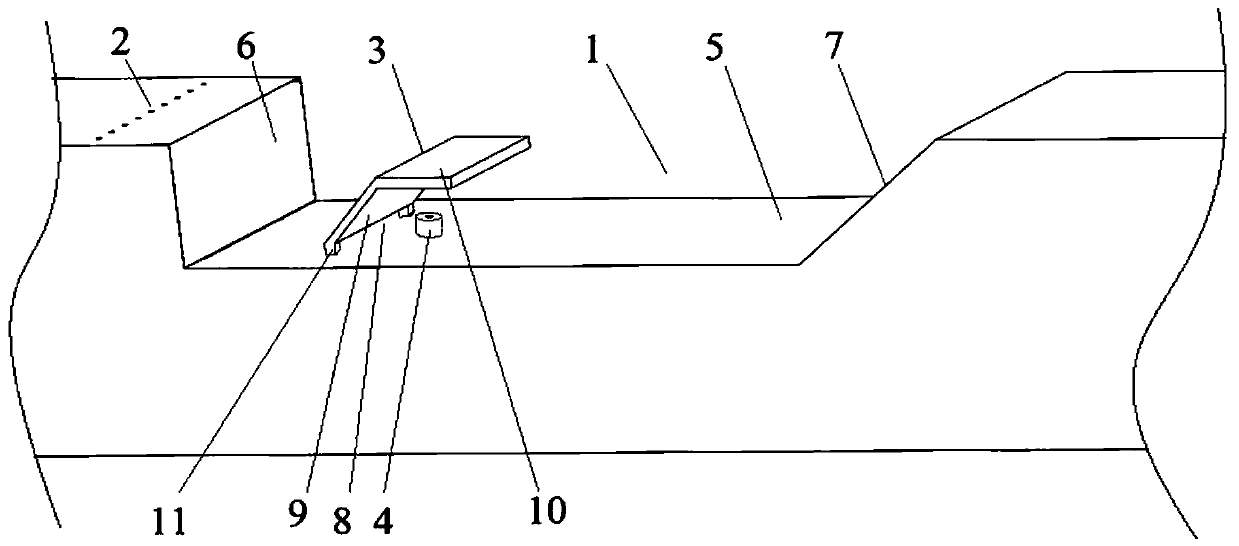

Ignition device in supersonic concave cavity combustion chamber and super-combustion stamping engine

A supersonic combustion chamber and ignition device technology, applied in the direction of combustion chambers, continuous combustion chambers, combustion methods, etc., can solve problems such as direct propagation, easy ignition failure, complex flow field structure, difficult local velocity and local equivalence ratio, etc., to achieve improved Fuel equivalence ratio, favorable effect on ignition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

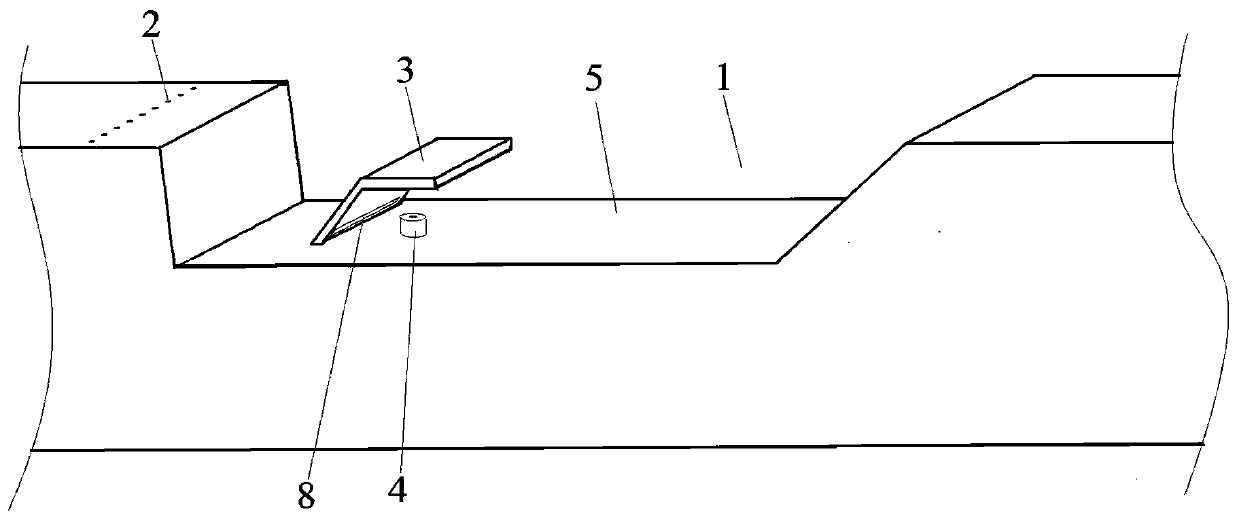

[0043] A scramjet engine includes a supersonic combustion chamber, and the ignition device in the supersonic concave cavity combustion chamber described in any one of the above technical solutions is arranged in the supersonic combustion chamber.

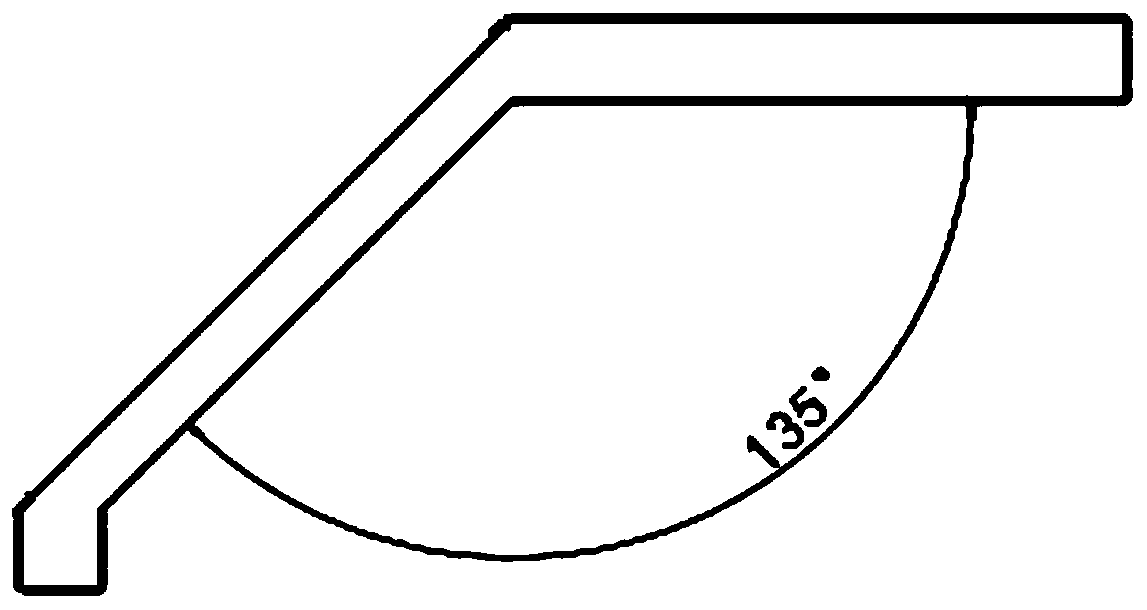

[0044] When the horizontal fuel injection scheme upstream of the concave cavity is adopted, the location of the bottom wall of the cavity with a local fast velocity occurs at the rear edge of the cavity, where the local fuel equivalence ratio is also high; while the position of the bottom wall of the cavity with a local slow velocity usually Occurs at the front and center of the cavity where the local fuel equivalent is relatively low. Therefore, when the fuel flows through the ignition position of the bottom wall of the concave cavity with the airflow, it is difficult to ensure that the local velocity and local equivalence ratio are both suitable, and the problems of difficult ignition and flameout are prone to occur. In the presen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com