A longitudinal vortex co-generation heat transfer element

A heat transfer element and longitudinal eddy current technology, which is applied in heat exchange equipment, heat exchanger shells, lighting and heating equipment, etc. Field structure, the effect of strengthening heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is further described below in conjunction with embodiment.

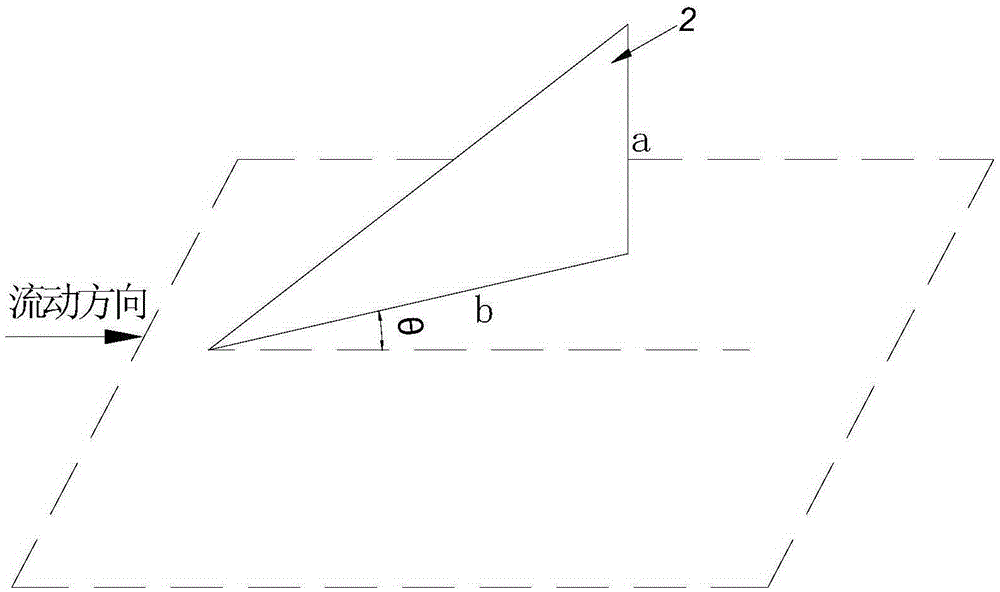

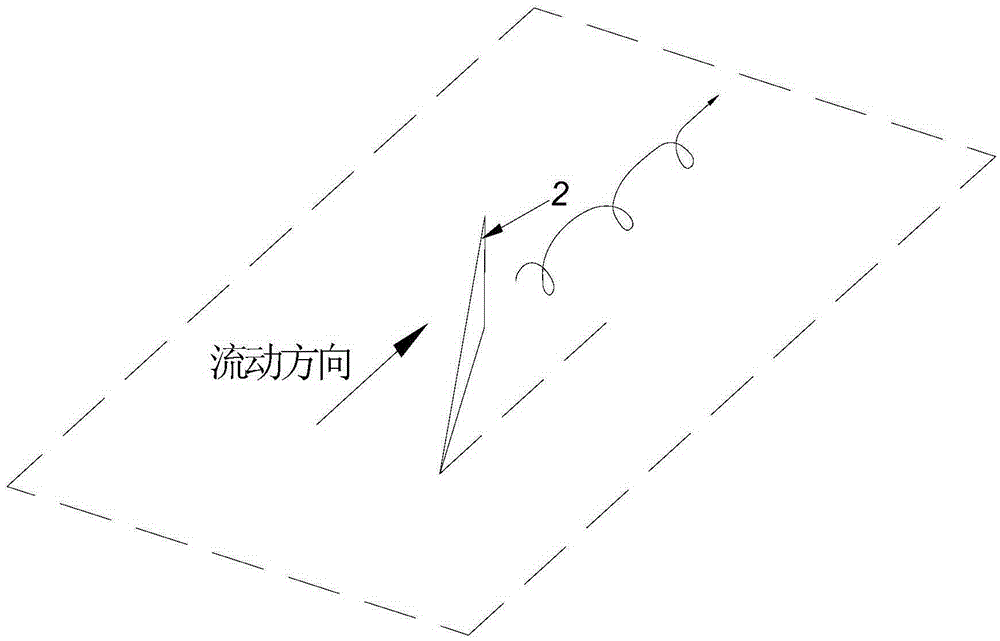

[0023] The structure of the spoiler is as figure 1 As shown, the right-angled side a of the spoiler is perpendicular to the central axis of the metal pipe, and a certain angle θ is formed between the right-angled side b and the central axis. After the fluid passes through the spoiler, a longitudinal vortex is formed in a certain range at the tail of the spoiler, such as figure 2 shown. When the spoiler is deflected to the left of the flow direction, the velocity vector of the longitudinal vortex on the cross section is clockwise, otherwise it is counterclockwise. The strength of the longitudinal vortex is determined by the size of the right-angled side a and b of the spoiler and the deflection angle θ. According to the experimental results, when a / b=0.5 and θ=30°, the strength of the longitudinal vortex is better.

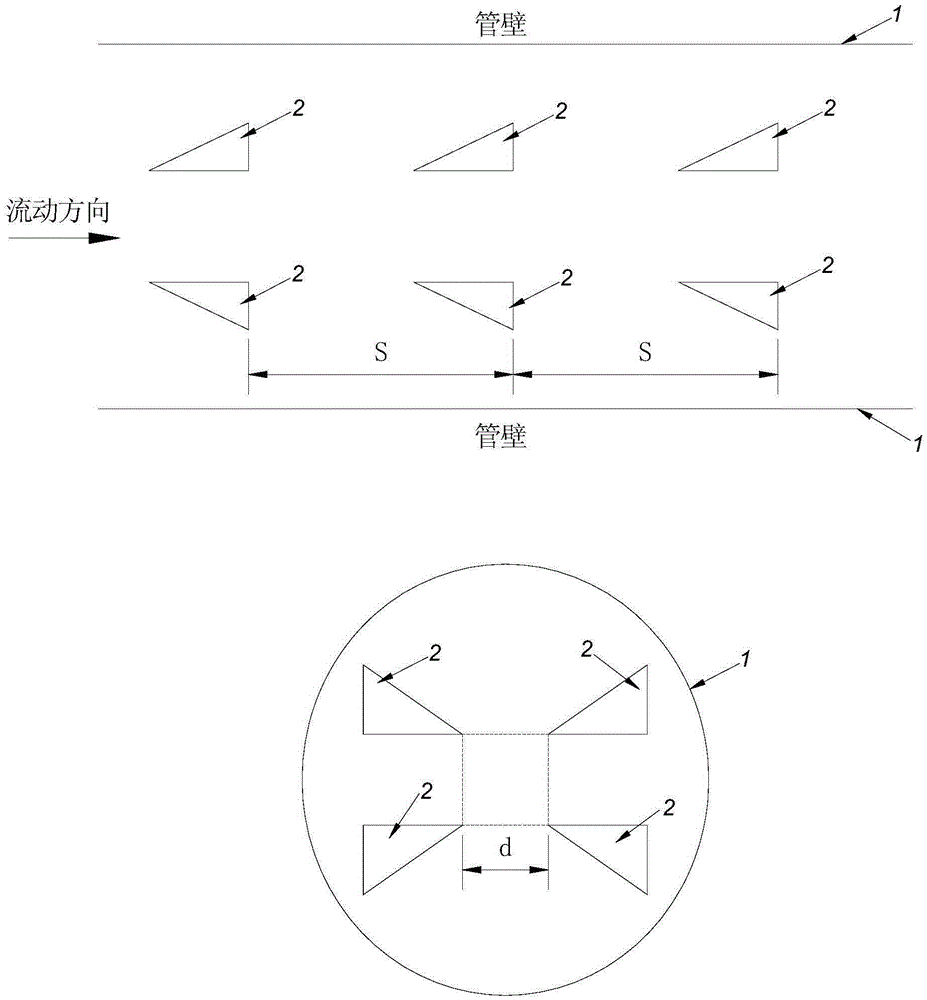

[0024] Put the spoiler set in accordance with image 3 As shown, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com